Patents

Literature

1193 results about "Cashew nut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

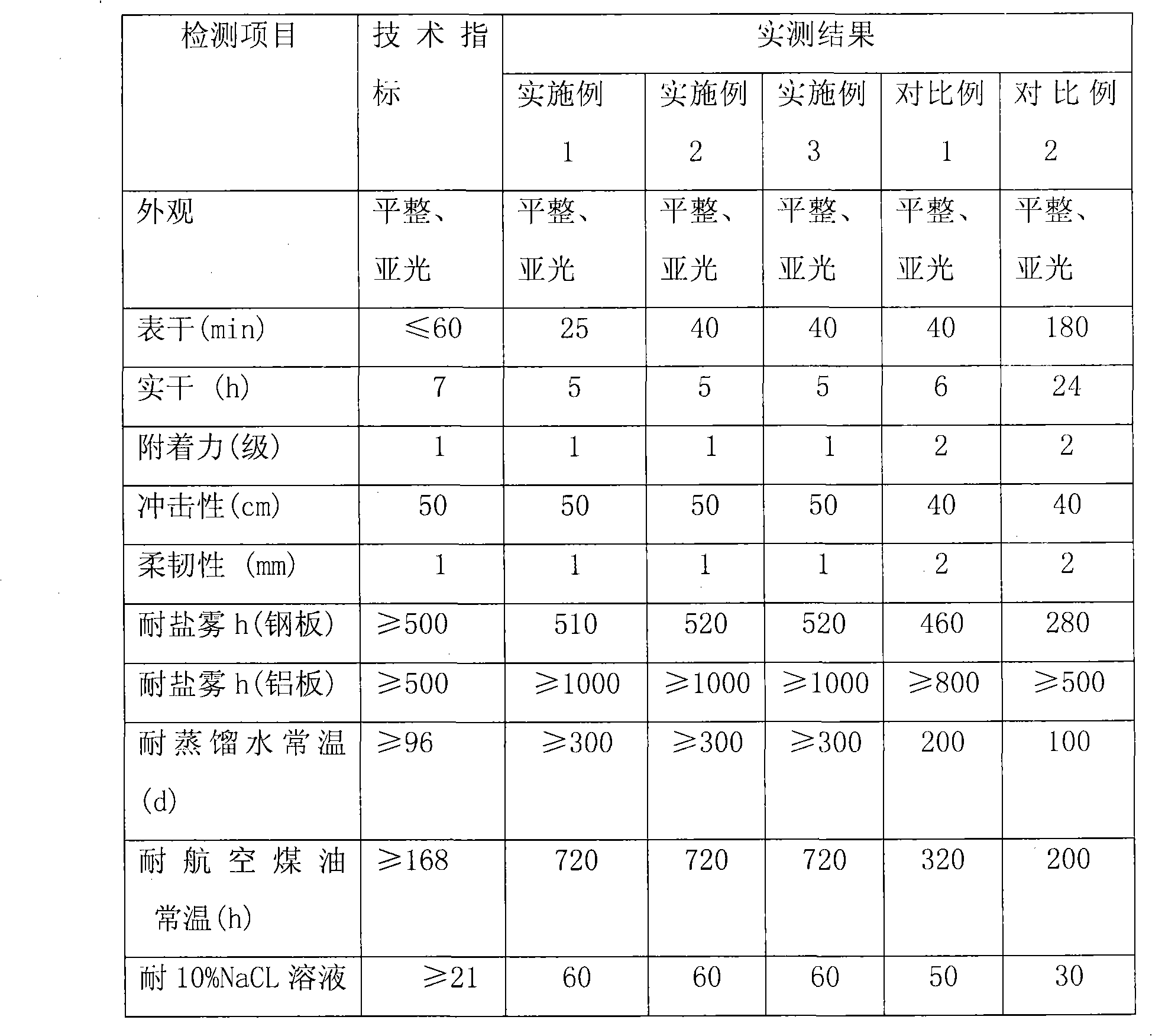

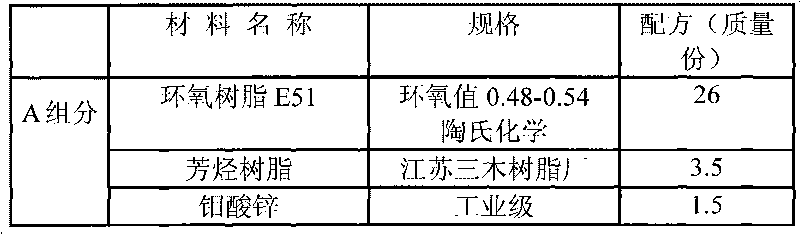

Chromium-free environment-friendly epoxy anticorrosion primer

Owner:DE LAITTERN ENVIRONMENTAL COATING BEIJING

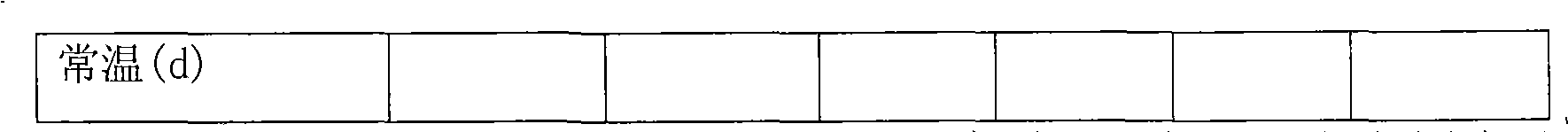

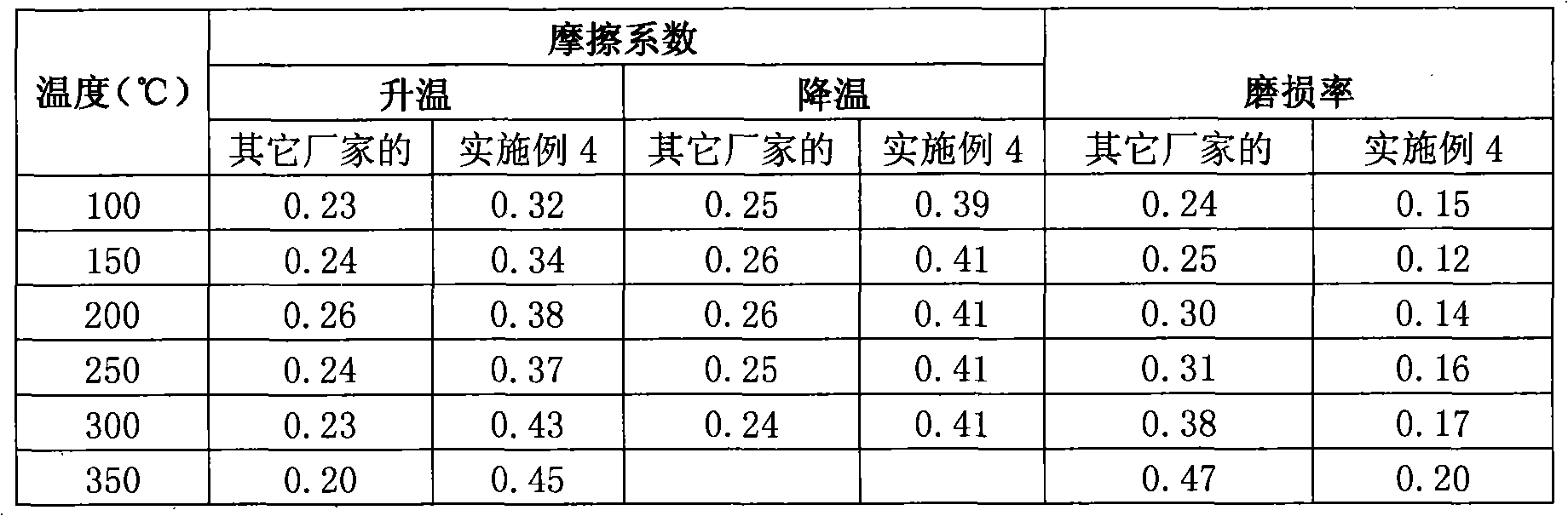

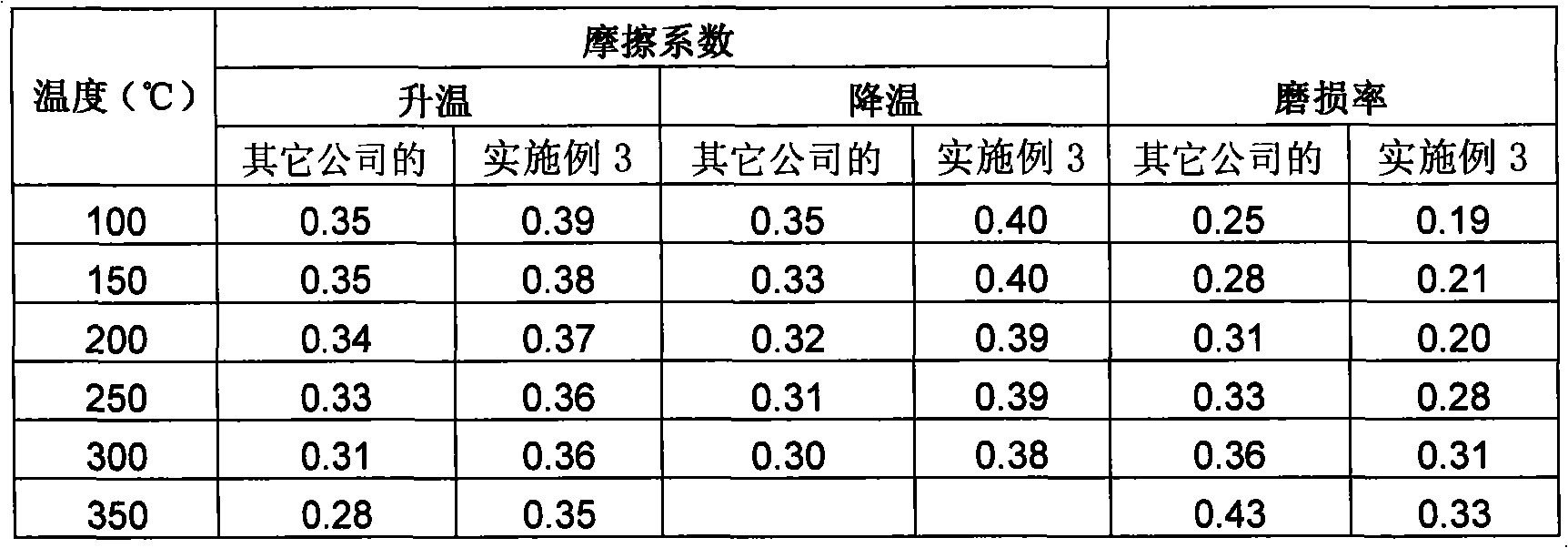

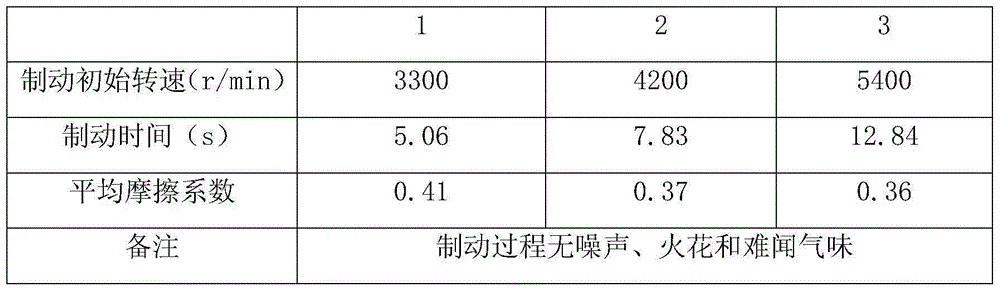

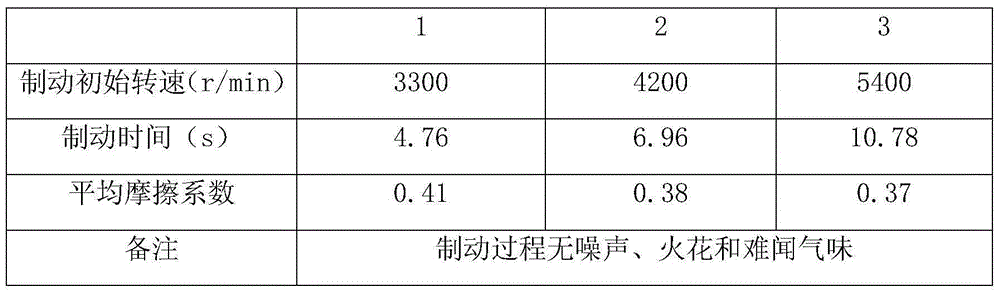

Friction material composition and friction material for preparing brake pad

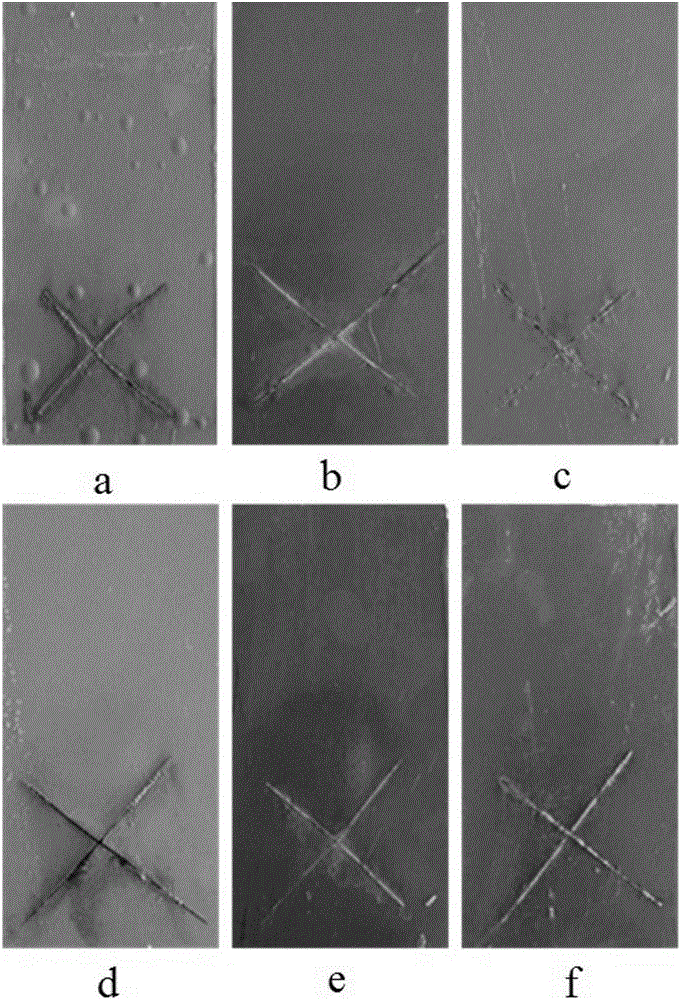

The invention provides a friction material composition for preparing a brake pad. The composition contains binding agent, reinforced materials, friction increase agent, lubricating agent and filler, wherein the binding agent contains the binary modified phenolic resin of cashew nut shell oil and chemigum. The invention also provides a friction material for preparing the brake pad. The friction material is obtained in such a way that the friction material composition carries out heat treatment after being molded by hot press, wherein the friction material composition is provided by the invention. The friction material composition for preparing the brake pad can obviously improve the stability of the friction coefficient of the friction material.

Owner:BYD CO LTD

Acidophilus milk and preparation method thereof

InactiveCN101715821ANutritional diversityComprehensive health functionMilk preparationPolygonum fagopyrumCereal grain

The invention relates to an acidophilus milk which comprises the following raw materials in parts by weight relative to total 1000 parts: 50-200 parts of nut, 0-200 parts of pulp, 0-200 parts of grain, 0-15 parts of albumen powder, 70-85 parts of white granulated sugar, 0.5-13.5 parts of stabilizing agent, 0-5 parts of edible essence and the balance of fresh milk. 0.02-0.08 activity unit / kilogram lactobacillus is used for fermenting. The nut is selected from filbert, a pine nut, almond, a Chinese chestnut, a pistachio nut, a sunflower seed, a walnut, anacardium occidentale, a lotus seed, peanut and / or armeniaca. The pulp is selected from coconut, strawberry, a yellow peach, blueberry, mulberry, tangerine, raisin, a grape, cherry, a mango, rubus corchorifolius and / or aloe vera gel. The grain is selected from barley, oat, wheat, rye, buckwheat, rice, wheat seed, broomcorn and maize. A preparation method of the acidophilus milk comprises the steps of inspecting raw milk, mixing, metering volume, homogenizing, sterilizing, cooling, vaccinally fermenting, adding, inspecting and refrigerating. The invention is convenient for the transport and storage of products and ensures the uniformity and completion of added substances.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

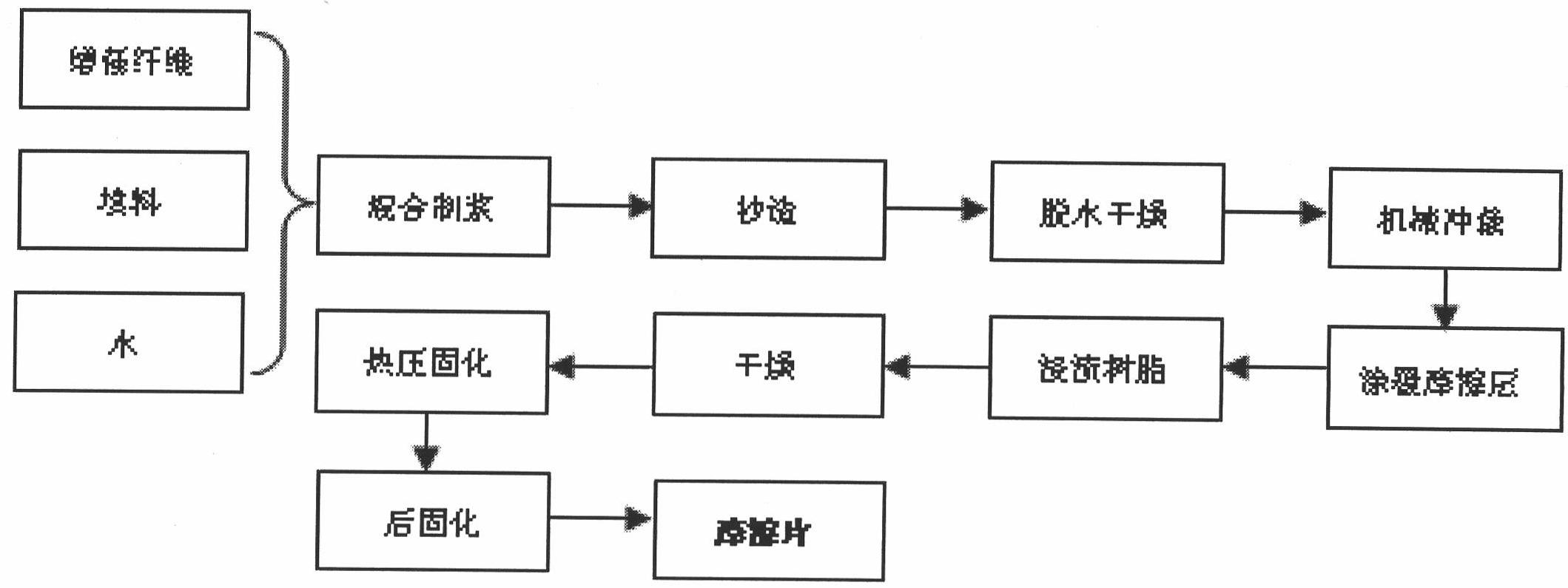

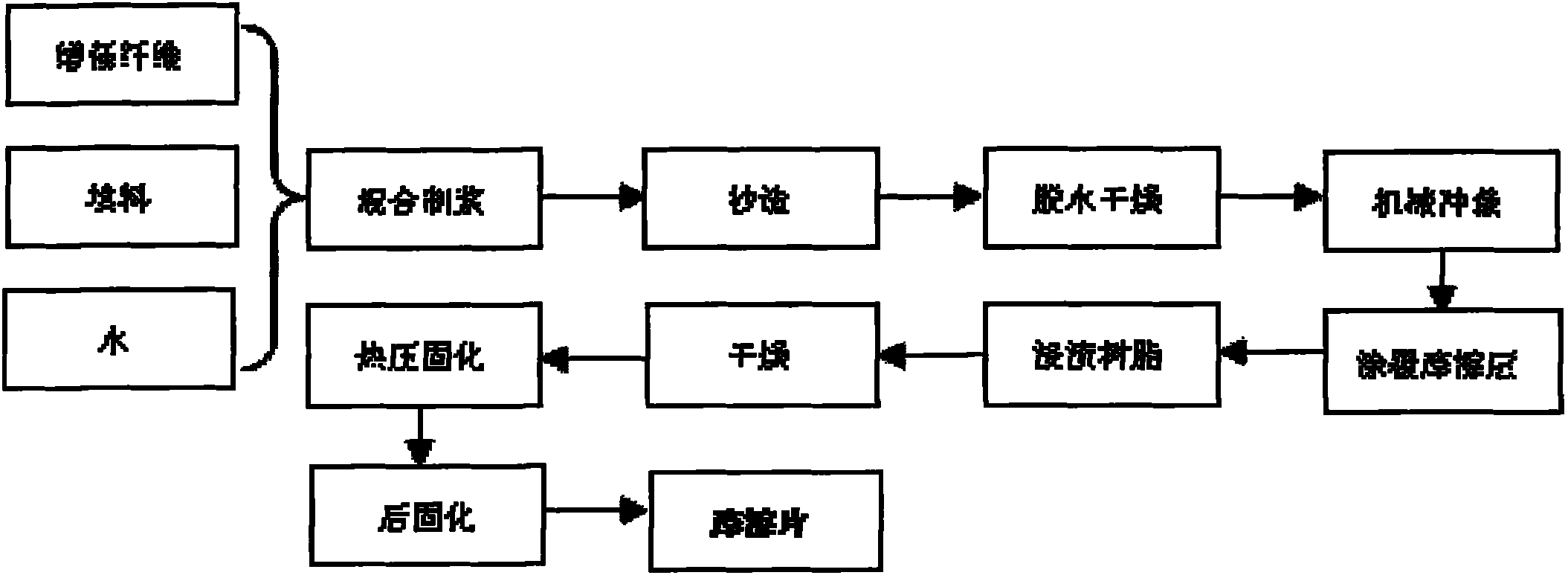

Raw paper of high-performance environment-friendly paper based friction material and manufacturing method of friction plate

ActiveCN101805589AGood physical and mechanical propertiesIncrease coefficient of frictionOther chemical processesNon-macromolecular organic additionAdhesiveStatic friction

The invention discloses raw paper of a high-performance environment-friendly paper based friction material and a manufacturing method of a friction plate. The high-performance environment-friendly paper based friction material is characterized by comprising the following components in percentage by weight: a substrate comprises 7-15% of carbon fiber, 5-10% of chopped aramid fiber, 5-10% of aramidpulp and 9-30% of bamboo fiber pulp; a friction agent comprises 10-20% of kieselguhr and 8-12% of cashew nut shell powder; a frictional property regulator adopts 2-4% of rubber particles, 5-10% of calcium carbonate and 10-15% of flake graphite; and a forming adhesive comprises 1-2% of fluororubber, 3-15% of silicone resin and 3-15% of phenolic resin. The invention fully forms the materials of thefriction material into a whole by changing the traditional impregnation process, effectively improves the physical and mechanical properties of the friction plate, improves the friction factors, regulates the dynamic and static friction ratio factors, and reduces the abrasion ratio of the friction plate.

Owner:陕西帕若德新材料科技有限公司

High-performance semi-metallic brake pad

ActiveCN101555915ASensitive brakesReduce brake noiseFriction liningGraphite particleAluminium silicate

A high-performance semi-metallic brake pad comprises the following components according to weight percentages: 4-6% of nitrile rubber powder, 2-4% of tyre powder, 3-5% of crystalline flake graphite, 6-9% of foam iron powder, 9-13% of boron containing phenolic resin, 8-12% of chopped steel fibre, 2-4% of alumina fibre, 8-11% of red copper fibre, 2-5% of cashew nut oil friction powder, 2-3% of graphite particle, 2-3% of calcined petroleum coke, 7-13% of barite, 3-4% of chromite, 2-3% of magnetite, 2-4% of diatomite, 7-10% of glued aluminium silicate fibre, 3-5% of flake aluminium powder, 2-4% of molybdenum disulfide, 0.2-0.5% of zinc stearate, 0.7-1% of antimony sulphide, 0.5-1% of copper sulphide, and 0.3-0.5% of tungsten carbide. After the brake pad is used, the car brake is sensitive, brake noise is low and comfort performance is good. The brake drum or brake disc has no damage in long-term use.

Owner:摩擦一号制动科技(仙桃)有限公司

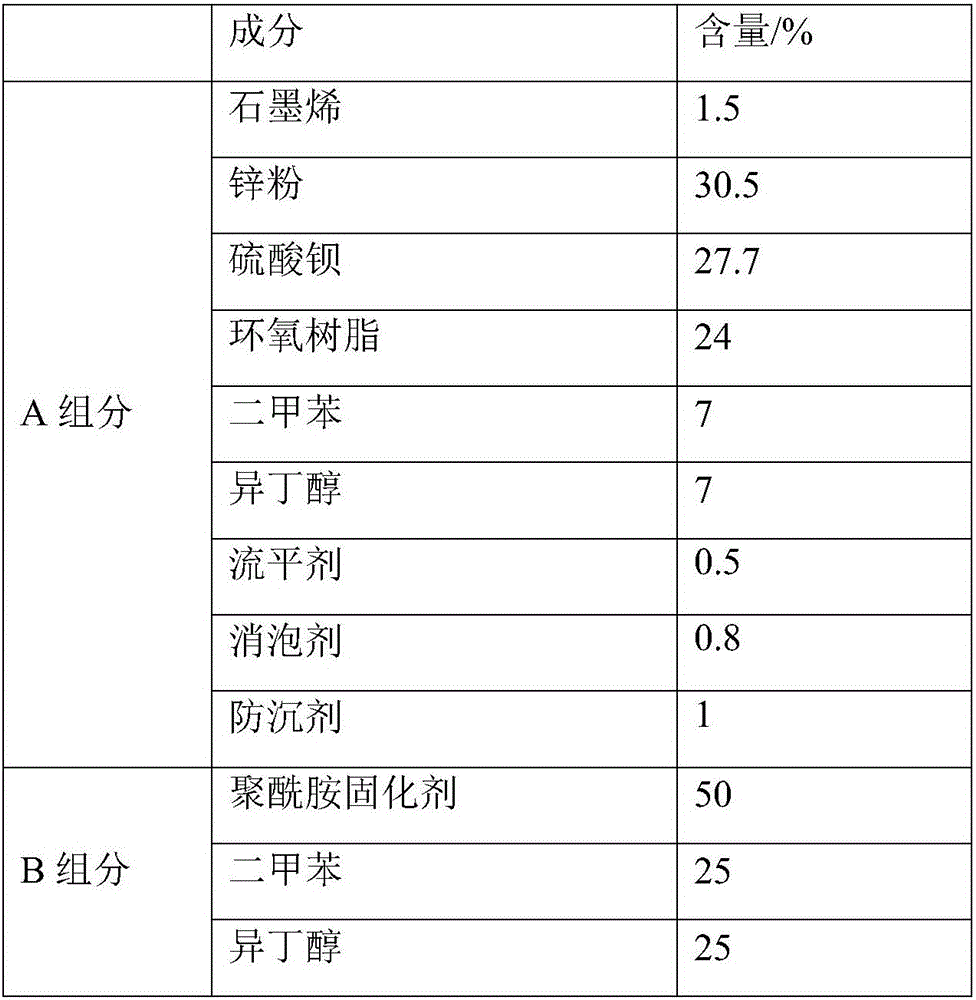

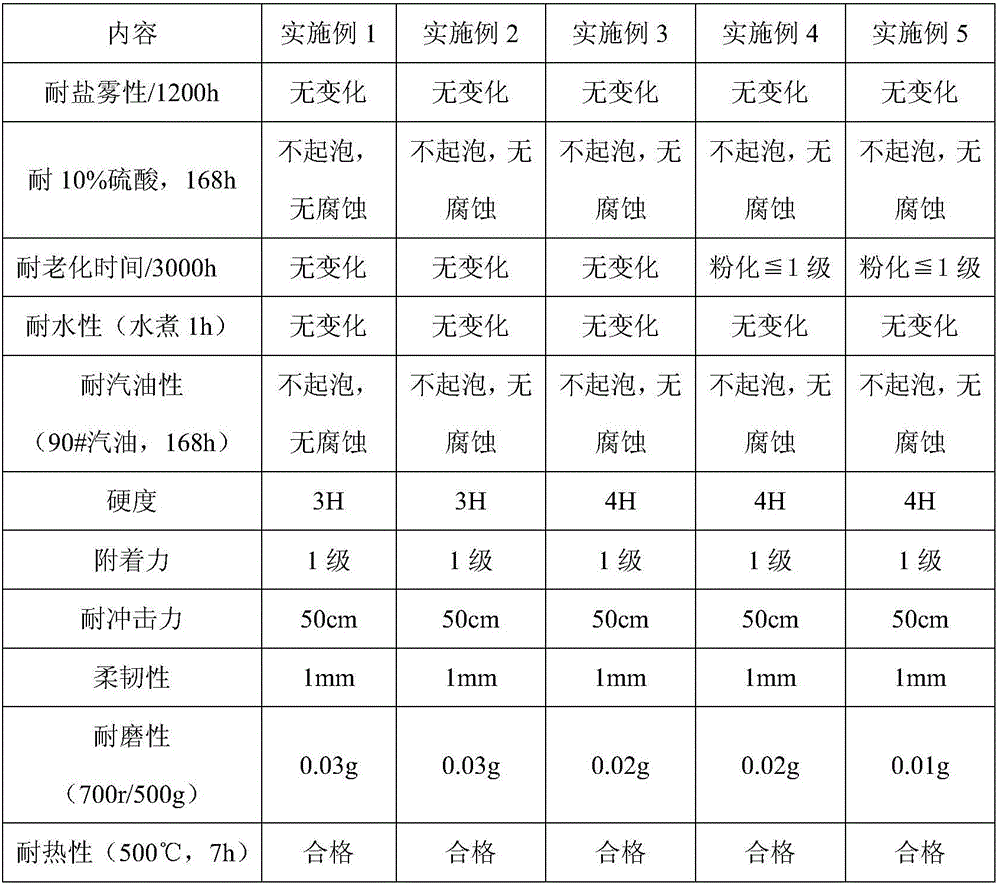

Graphene anticorrosive coating and preparation method thereof

ActiveCN106189719AEasy reunionSolving Dispersion ProblemsAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

The invention provides a graphene anticorrosive coating and a preparation method thereof. The graphene anticorrosive coating is prepared from a component A and a component B, wherein in percentage by weight, the component A comprises 20%-30% of epoxy resin, 1%-3% of graphene, 0.5%-2% of a dispersing agent, 15%-25% of talcum powder, 10%-20% of zinc powder and 1%-5% of aluminum paste, and the component B comprises 30%-50% of cashew nut shell oil phenolic amide and 10%-30% of polyamide. The graphene anticorrosive coating provided by the invention is safe and environment-friendly, is moderate in cost, simple and convenient in process, stable in storage, excellent in adhesive force on base materials such as steel, iron and the like, excellent in mechanical performance such as flexibility, wear resistance performance and the like, and prominent in protective effects in chemical media such as an acid, an alkali, a salt and the like, shows excellent protective performance such as high and low temperature resistance, high salinity resistance and the like in a condition of a simulation marine environment experiment, and can be applied as primer for an anticorrosive coating in ocean engineering with various steel and iron materials.

Owner:HUNAN AEROSPACE SANFENG SCI & TECH CO LTD

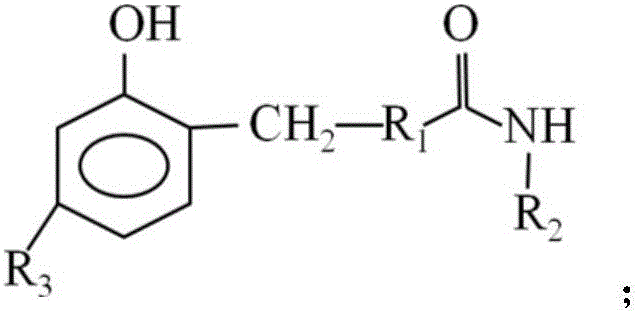

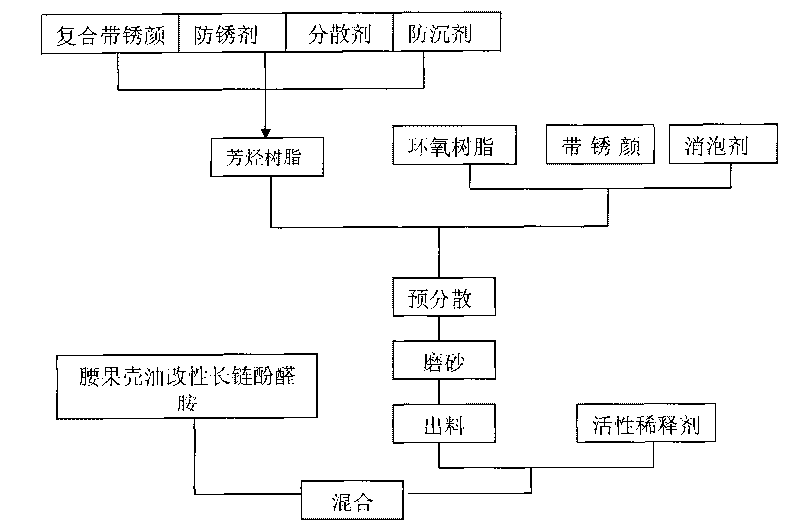

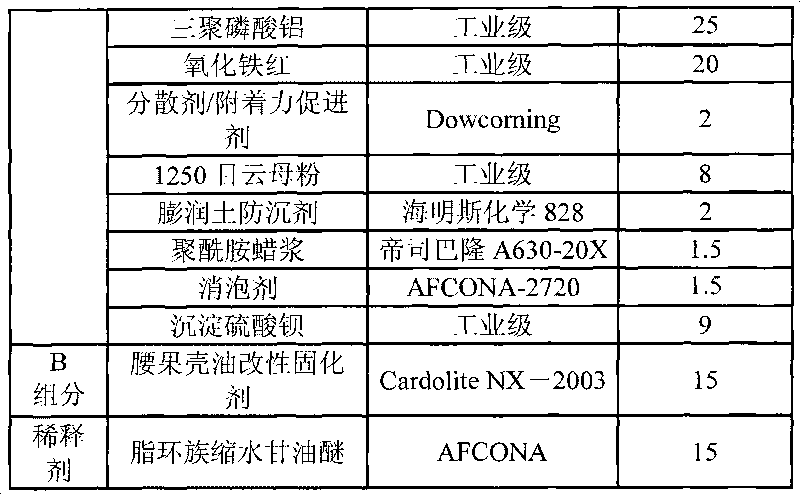

Environment-friendly solvent-free humidified and rusted anticorrosive paint

InactiveCN101747825AEasy pretreatmentConvenient anti-corrosion solutionAnti-corrosive paintsEpoxy resin coatingsOrganic filmSolvent free

The invention relates to a paint material with formed organic film, in particular to an epoxy solvent-free anticorrosive paint applied to low surface treatment steel structure. The anticorrosive paint is prepared by efficiently compounding rusted coating pigments such as zinc molybdate, zinc phosphate, aluminium trippolyhosphate, iron oxide red and the like, using cashew nut oil modified long-chain amine phenolic aldehyde as, alicyclic glycidyl ether as active diluent, thus overcoming the problems that surface treatment technique in coating construction costs high and heavy anticorrosive paint with high solvent content pollutes the environment, having easy preparation and construction, low cost, fast solidification at high temperature, good mechanical and anticorrosive performance, solvent-free and environment-friendly properties, and being applicable to heavy anticorrosive projects of steel structures such as ship, train, bridge and the like.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

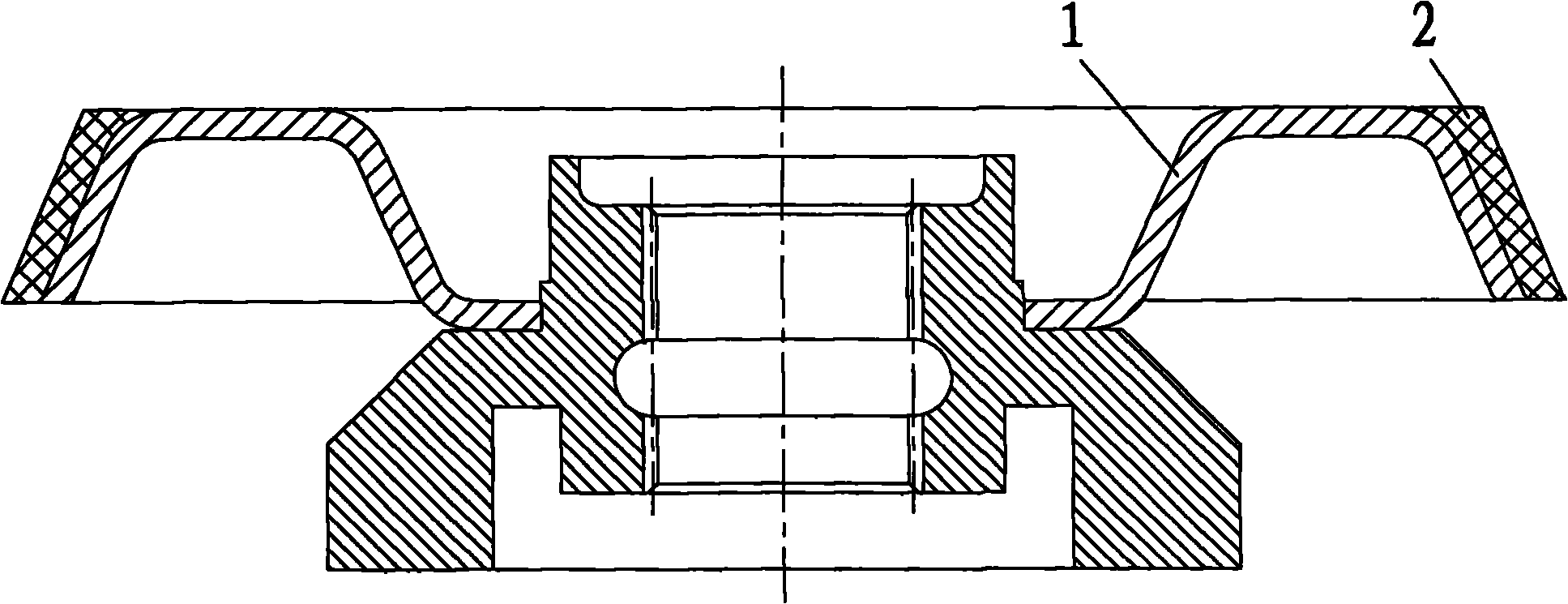

Friction material of disc brake pad, disc brake pad and preparation technology of disc brake pad

ActiveCN102965078AOvercoming performance deficienciesImprove performanceOther chemical processesFriction liningFiberPotassium

The invention discloses a friction material of a disc brake pad. The friction material comprises the following raw materials in parts by weight: 13-18% of cashew nut shell oil-modified phenolic resin, 9-16% of butyronitrile rubber powder, 3-7% of steel wool fiber, 6-11% of calcium sulfate whisker, 2-5% of potassium feldspar powder, 3-6% of graphite, 2-6% of brown fused alumina, 3-5% of antimony sulfide, 11-16% of baryta powder, 5-9% of chromite powder, 6-11% of heavy calcium carbonate, 2-4% of zircon sand and 3-6% of brass powder. Visibly, in the preparation raw materials, the cashew nut shell oil-modified phenolic resin is adopted for replacing ordinary phenolic resin as an organic carrier of a brake pad material, so that the shortcomings of poor resistance to thermal ablation, high abrasiveness, low anti-impact strength and the like of the ordinary phenolic resin are eliminated, the performance defects of the friction material of the disc brake pad caused by the ordinary phenolic resin can be avoided, and the overall performance of the friction material of the disc brake pad can be further improved.

Owner:SHANDONG GOLD PHOENIX

Heavy corrosion resistant, heat insulating and static conductive coating

InactiveCN101899257AStrong adhesionGood static conductivityAnti-corrosive paintsEpoxy resin coatingsNon toxicityPetrochemical

The invention discloses a heavy corrosion resistant, heat insulating and static conductive coating, which is prepared by the following steps of: dissolving acrylic acid modified epoxy resin which is taken as a substrate into active and inactive diluents in a way of taking liquid polysulfide rubber as a toughening agent in the presence of a functional pigment and an aid to prepare a first component; preparing a second component in a way of taking cashew nut shell liquid-synthesized modified amine as a curing agent under the cooperation of an accelerator and a hydrophilic agent; and mixing the first and second components in the weight ratio of 2:1. The heavy corrosion resistant, heat insulating and static conductive coating has the characteristics of no solvent, high adhesive power, high static conductivity, heavy corrosion resistance, high heat-insulating property, environmental friendliness, non-toxicity, wet rusty thick coating capability, great coating cost reduction, and applicability to the corrosion-resistant coating of inner and outer walls of large oil tanks, ballast tanks of ships, offshore drilling platforms, bridges, open petrochemical equipment, ships, high-speed trains and the like.

Owner:北京虹霞正升装饰装修工程有限责任公司

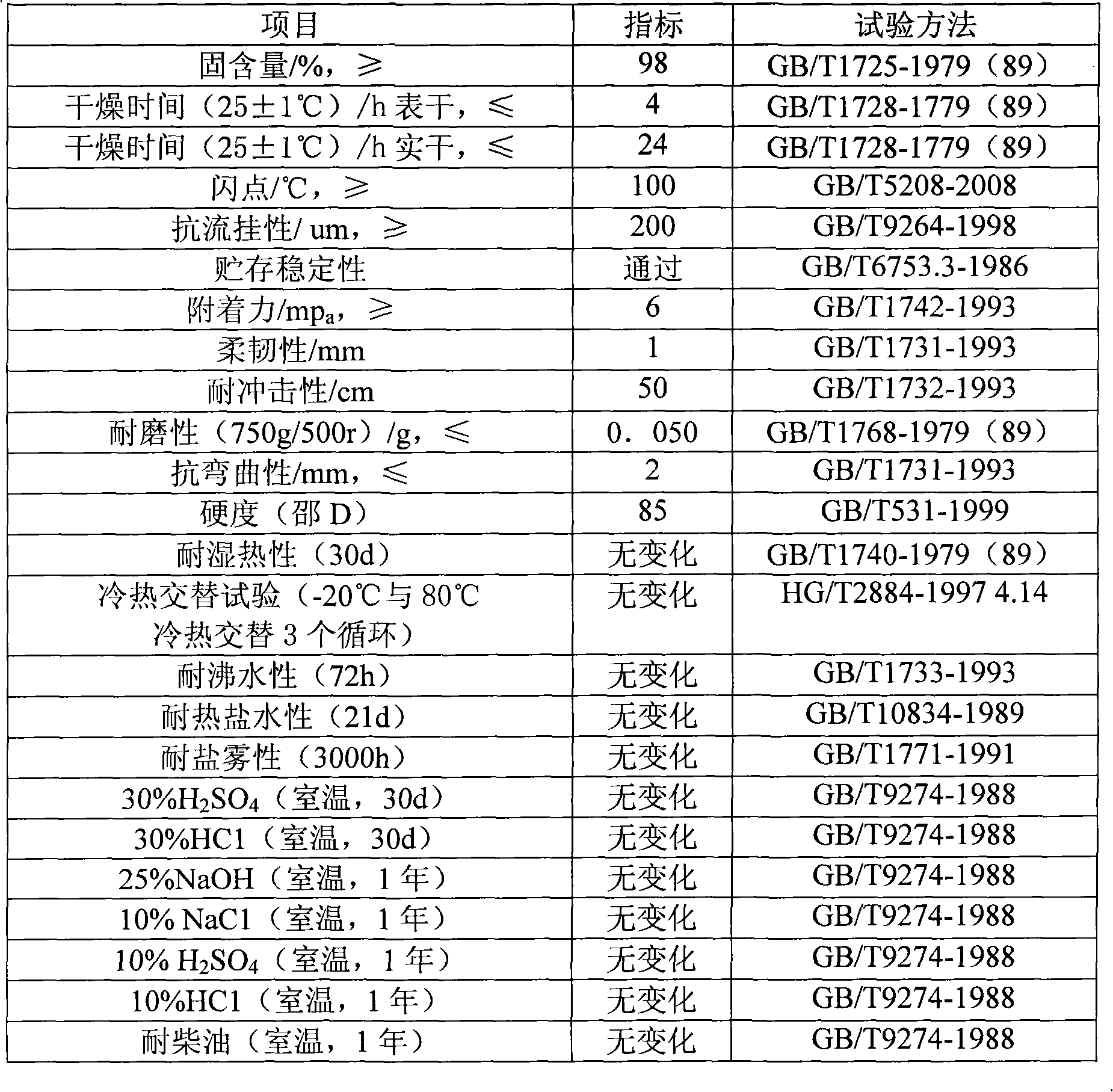

Non aqueous gel technology

A method of treating an earth formation that includes injecting at least one lipophilic monomer into the earthen formation; wherein the at least one lipophilic monomer is selected from epoxide-functionalized derivative of soybean oil linseed oil, rapeseed oil, cashew nut shell oil; perilla oil, tung oil, oiticia oil, safflower oil, poppy oil, hemp oil, cottonseed oil, sunflower oil, high-oleic triglycerides, triglycerides of euphorbia plants, peanut oil, olive oil, olive kernel oil, almond oil, kapok oil, hazelnut oil, apricot kernel oil, beechnut oil, lupine oil, maize oil, sesame oil, grapeseed oil, lallemantia oil, castor oil, herring oil, sardine oil, menhaden oil, whale oil, and tall oil, injecting at least one crosslinking agent into the earthen formation; wherein the at least one crosslinking agent comprises at least one primary amine; and allowing the lipophilic monomer and the crosslinking agent to react in the earth formation is disclosed.

Owner:MI

Bi-component corrosion-proof dope

InactiveCN101100578AGood oil resistanceImprove water resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

A titanium-nickel nanometer alloy powder contains A and B components; A components consist of epoxy-resin, titanium-nickel nanometer alloy powder, antirust pigment, filler corrosion stabilizer and anti-sagging accessory; B components consist of composite curing agent with cashew nut shell modified phenolic amine curing agent and polyamide epoxy curing agent; the proportion of A and B is 10:1. It has excellent adhesion and physical performance and better oil, water, acid-alkali and salt fog resistances and mating ability. It can be used as universal base coat and used for various substrate materials such as steel, aluminum and stainless steel etc.

Owner:中国人民解放军海军装备技术研究所

Feed for breeding porcupines and preparation method thereof

The invention relates to feed for breeding porcupines. The feed contains corn flour, tapioca flour, sweet potato flour, kudzu root powder, peanut powder, silkworm chrysalis powder, cod liver oil, dry yeast, angelica powder, pistachio nut powder and chicken cashew nut powder. According to the formula, the feed provides complete and a plenty of nutrients for porcupine breeding, and the growth feed contains fat, carbohydrates, crude fibers and minerals, so that the growth of the porcupines can be promoted, and the resistance of the porcupines can be improved. Furthermore, the feed is suitable for the mouth feel of the porcupines, has certain elasticity and chewiness and is suitable for the tooth grinding of the porcupines. The phenomenon that the porcupines disorderly nibble and chew is prevented.

Owner:徐玉文

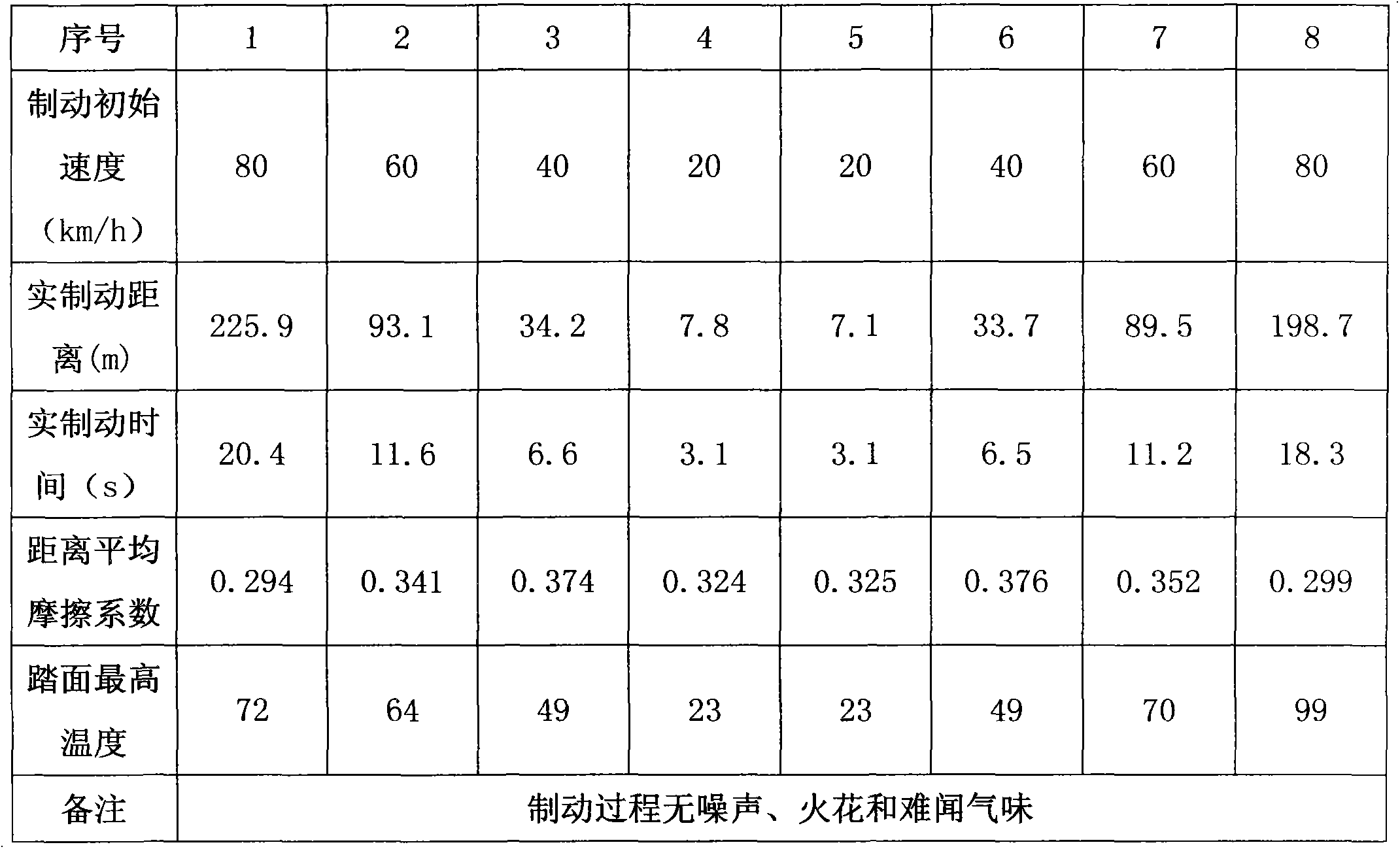

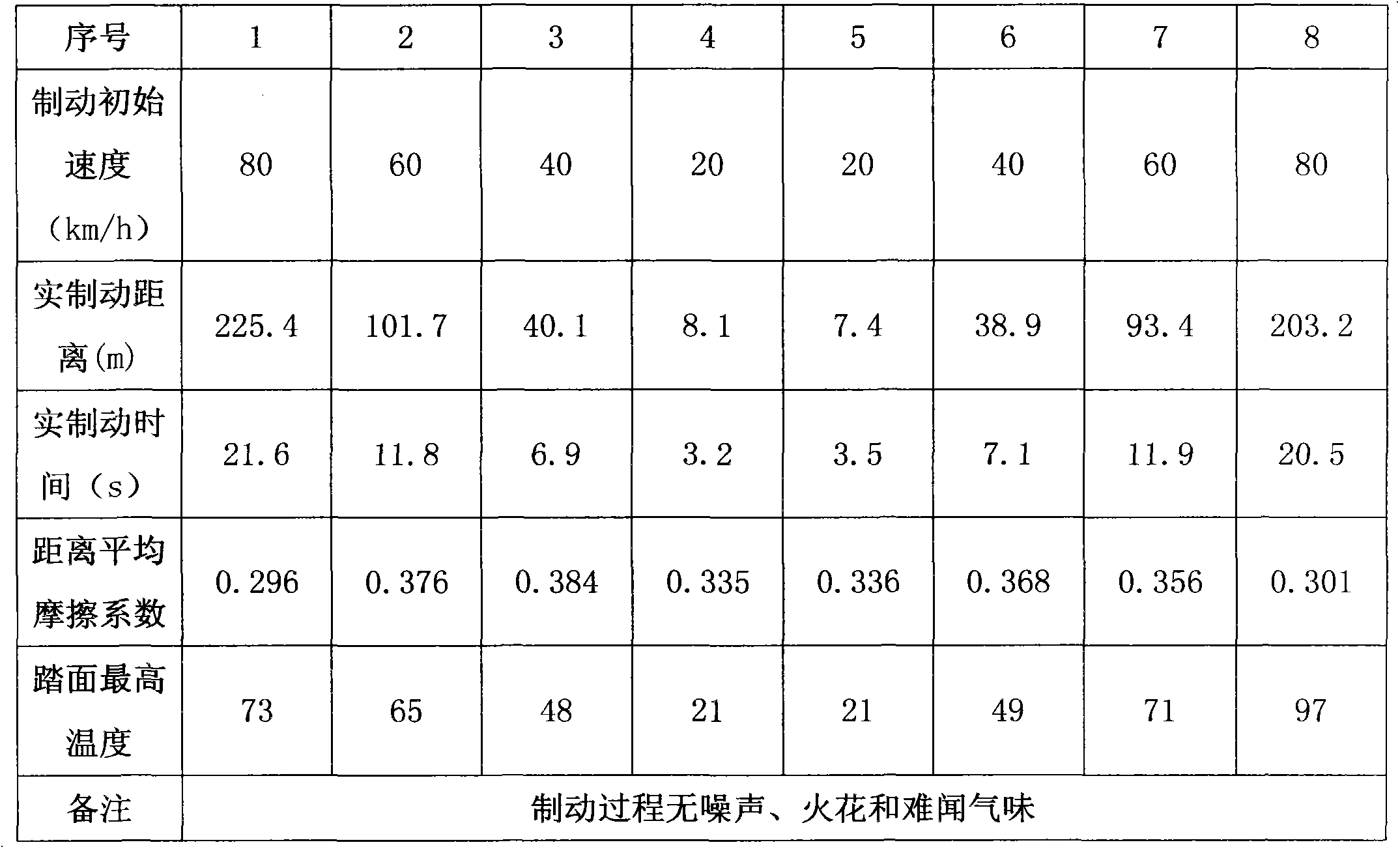

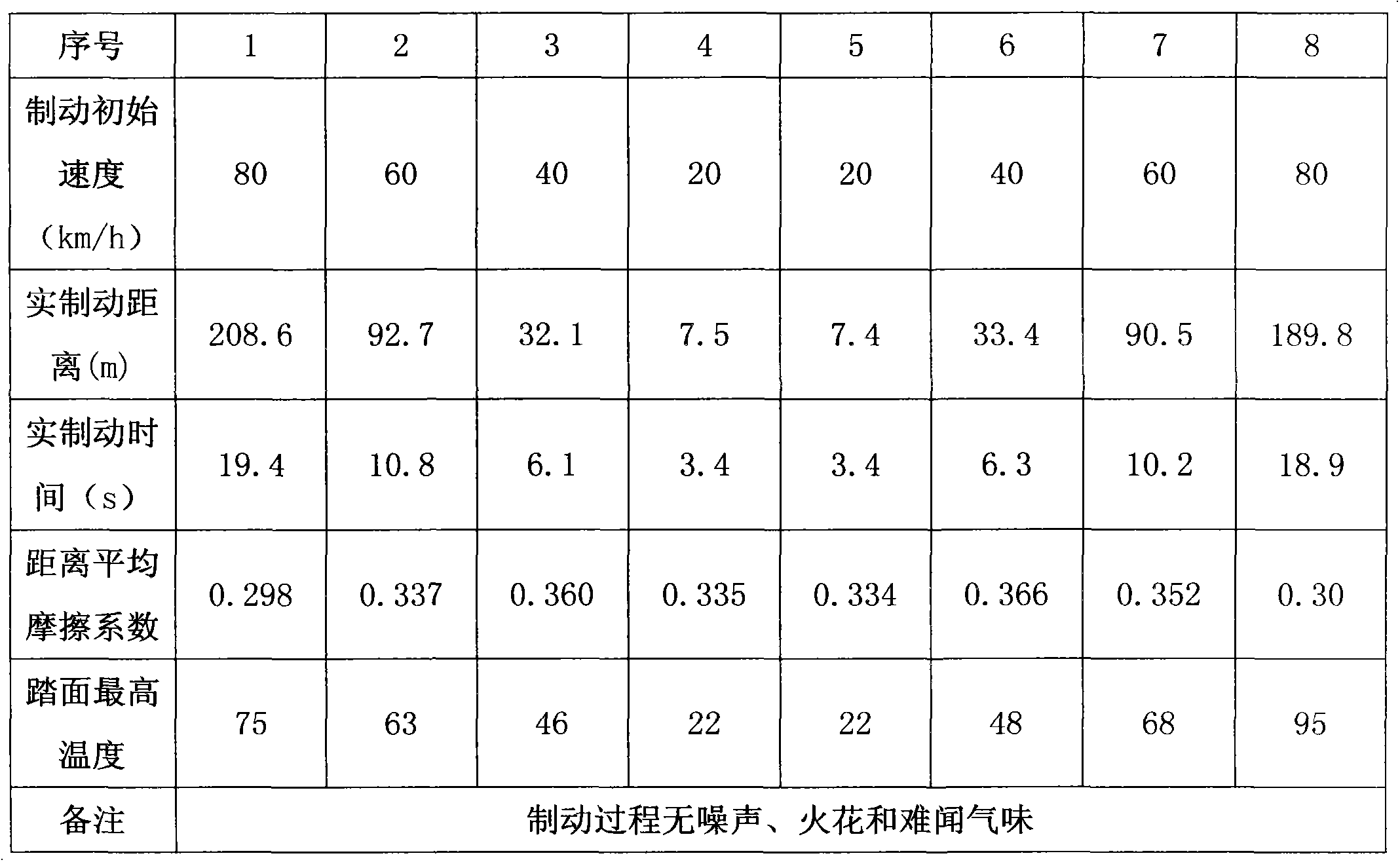

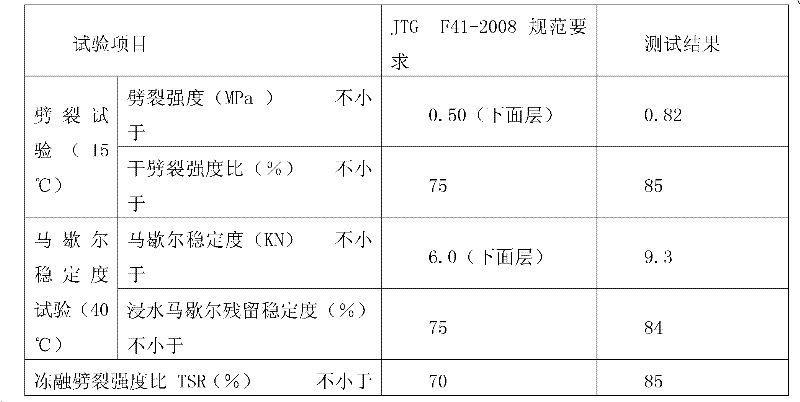

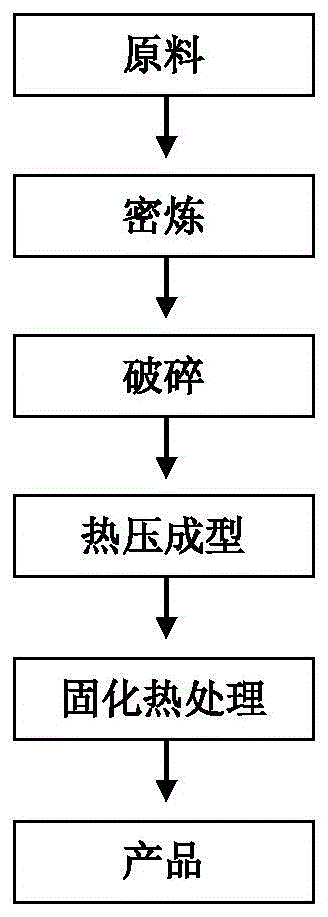

Composition brake shoe for urban rail vehicle and manufacturing method thereof

ActiveCN103410893AImprove brittlenessImprove heat resistanceFriction liningCarbon fibersHexamethylenetetramine

The invention relates to a composition brake shoe for an urban rail vehicle and a manufacturing method of the composition brake shoe for the urban rail vehicle. The composition brake shoe comprises the following components of, by weight, 10-15 parts of butadiene-acrylonitrile rubber, 10-20 parts of cashew nut shell oil modified phenolic resin, 6-10 parts of basalt fibers, 4-8 parts of carbon fibers, 8-15 parts of steel fibers, 5-8 parts of sepiolite fibers, 2-6 parts of hexamethylenetetramine, 5-8 parts of iron oxide powder, 5-7 parts of crystalline flake graphite, 5-7 parts of chromite, 6-9 parts of barium sulfate, 3-6 parts of potassium feldspar and 5-8 parts of frictional powder. The manufacturing method of the composition brake shoe is a dry method production technology, and comprises the steps of steel back production, abrasive blasting processing, shaping, burdening, mixing, hot compacting, heat processing, subsequent processing, finished product forming and inspection. The manufactured composition brake shoe is inspected through the 1:1 rack test, is excellent in friction and abrasion resisting performance, stable in brake performance, safe and environmentally friendly, and solves the problem that the friction coefficient drops too fast under the conditions of damascene of the composition brake shoe for the urban rail vehicle, hot cracks, hot spots and rain and snow weather.

Owner:GUANGXI UNIV FOR NATITIES

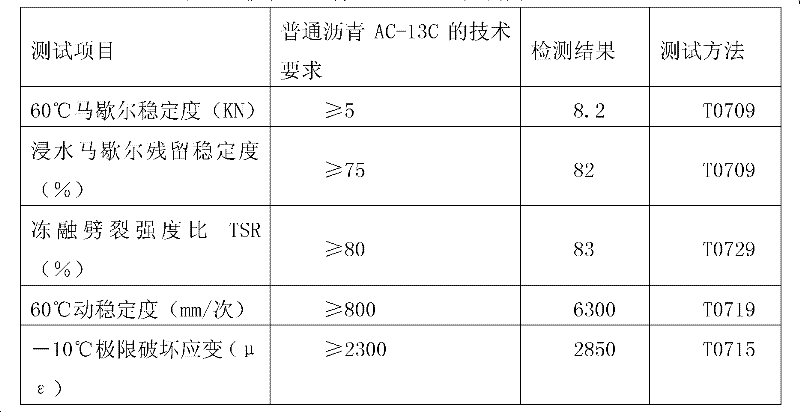

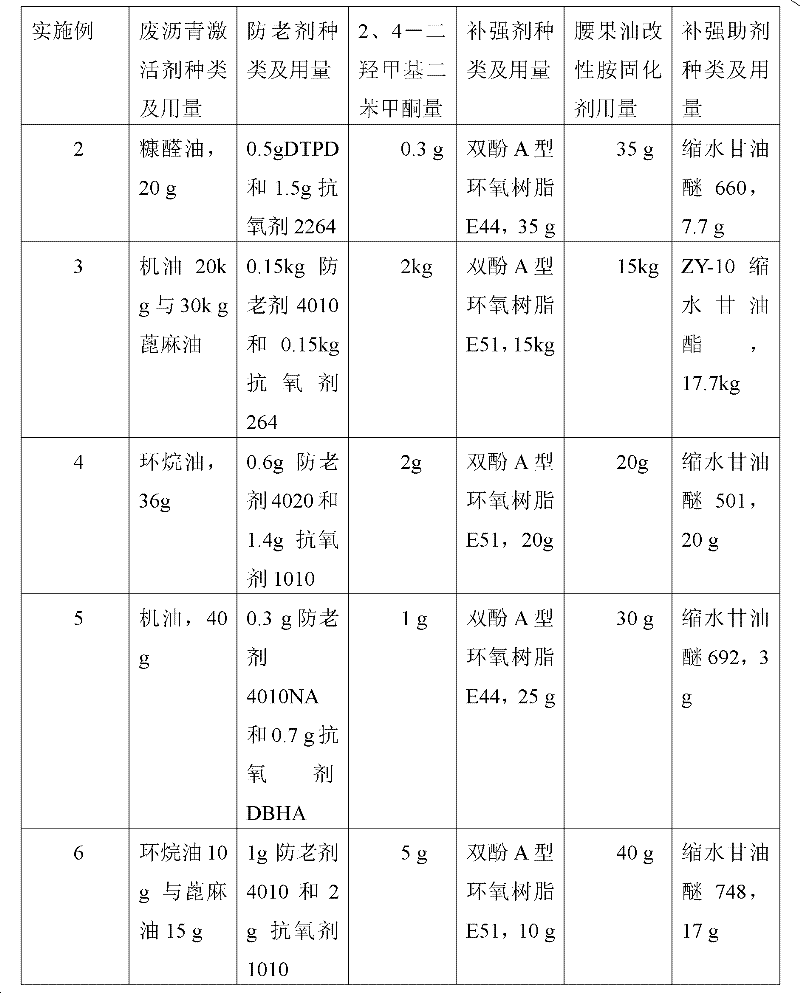

Asphalt cold recycling agent and preparation method thereof

ActiveCN102174267ANo pollution in the processImprove recycling ratesSolid waste managementBuilding insulationsCrack resistanceAntioxidant

The invention relates to an asphalt cold recycling agent, which is characterized by being prepared from a waste asphalt activator, an anti-aging agent, an ultraviolet absorbent, a reinforcing agent, a reinforcing curing agent and a reinforcing auxiliary agent serving as raw materials, wherein the waste asphalt activator consists of any one or more of engine oil, castor oil, naphthenic oil, aromatic hydrocarbon oil and furfural oil; the anti-aging agent is a mixture of an antioxidant and a p-phenylenediamine anti-aging agent; the ultraviolet absorbent is 2,4-dihydroxymethyl benzophenone; the reinforcing agent is bisphenol A epoxy resin E44 or E51; the reinforcing curing agent is a cashew nut oil modified amine curing agent; and the reinforcing auxiliary agent is a glycidyl ester epoxy active diluent. An asphalt recycled mixture prepared by adding the asphalt cold recycling agent into waste asphalt has high comprehensive performance, namely high bonding strength, high-temperature performance, low-temperature crack resistance and rheological performance, the actual service life of 8 years, and high aging resistance and weather resistance.

Owner:重庆市智翔铺道技术工程有限公司

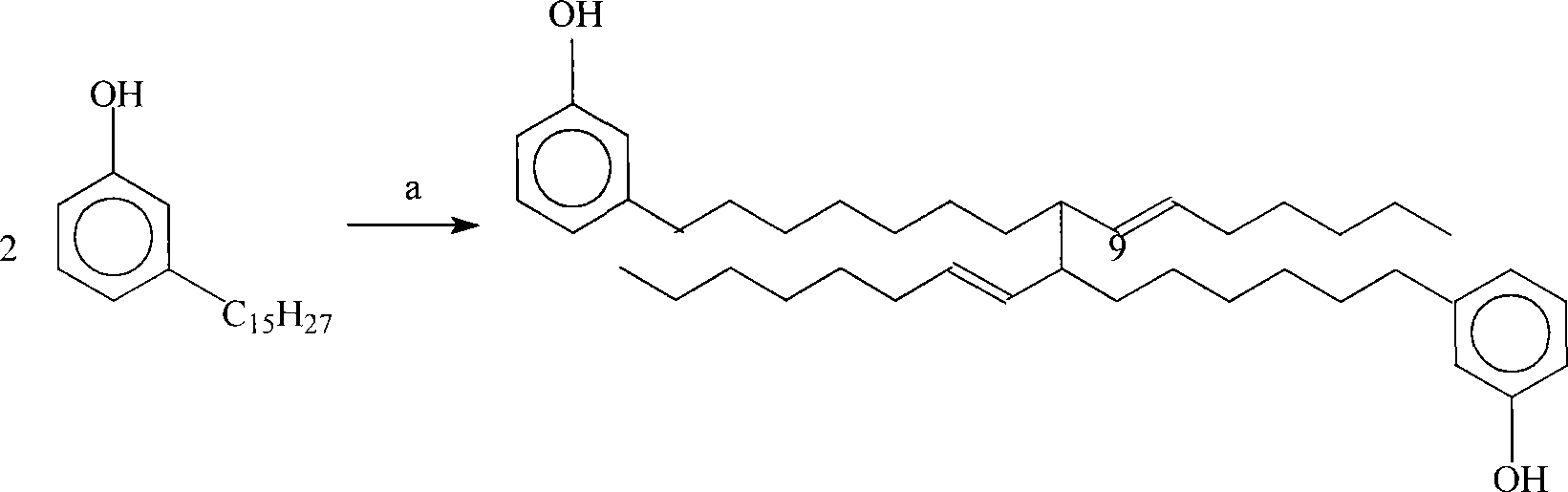

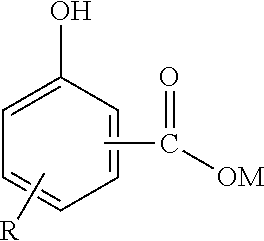

Cashew shell modified alkyd resin and preparation method thereof

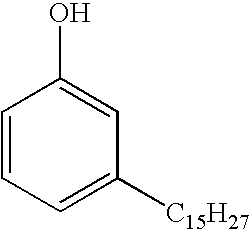

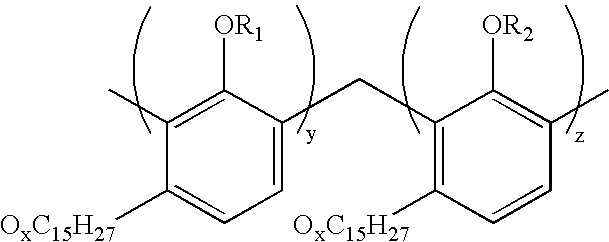

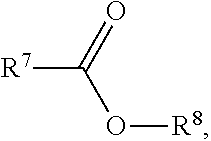

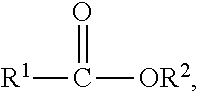

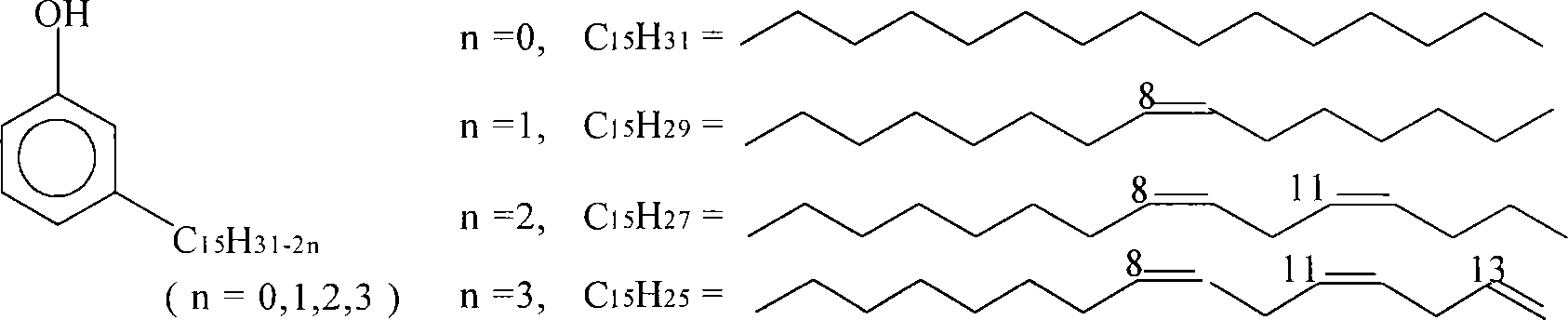

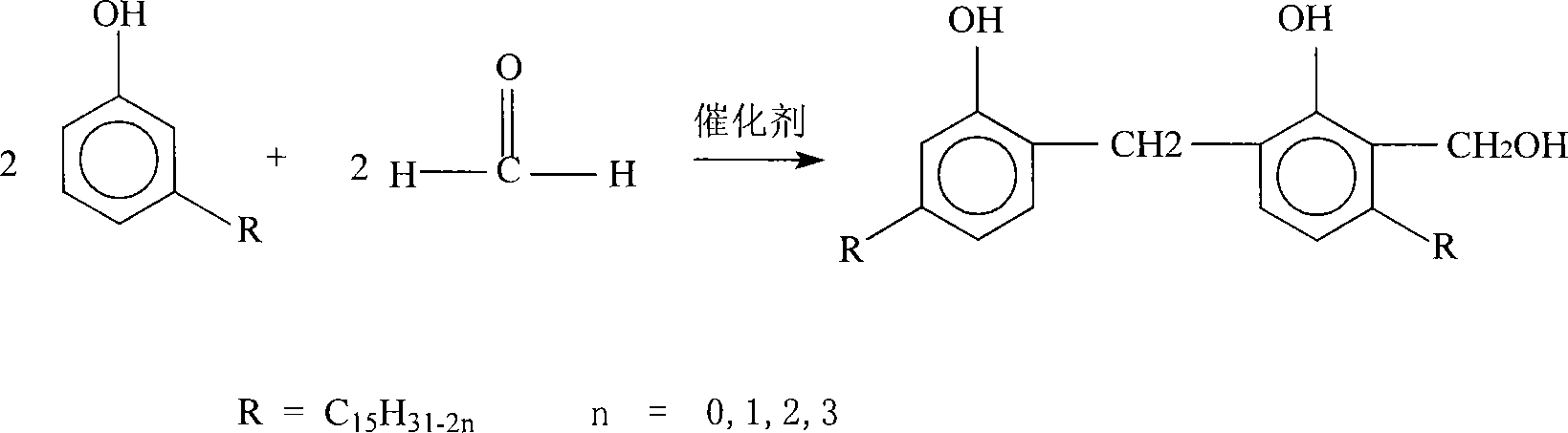

The invention relates to a production method of cashew nut oil modified phenolic resin. Phenol and cashew nut oil are sufficiently mixed under the acidic or alkaline environment, wherein, the main ingredient of the cashew nut oil is the polyhydric phenol of C8-C27, the weight of the cashew nut oil accounts for twenty to thirty percent (weight percentage) of the total weight of the cashew nut oil and the phenol, and the acidic environment is obtained by using catalyst, the addition amount of which is one to three percent (one to two percent for the alkaline environment); the mixture is mixed with formaldehyde, temperature is raised, reaction lasts until the synthesis of the phenolic resin is finished, and wherein, the molar ratio of the formaldehyde is 1:0.72 to 0.78 (1:1.2 to 1.4 for the alkaline environment. the catalyst must be ammonia). The thermoplastic phenolic resin prepared by the invention is characterized in low free phenol and high molecular weight and can be applied to not only molding materials but also friction materials; meanwhile, the production process of the modified phenolic moulding materials is simple, the use amount of phenol and formaldehyde is reduced, the concentration of wastewater is lowered, and therefore environment is protected; moreover, the plant oil applied by the preparation method of the invention is a regenerative resource.

Owner:浙江南方塑胶制造有限公司

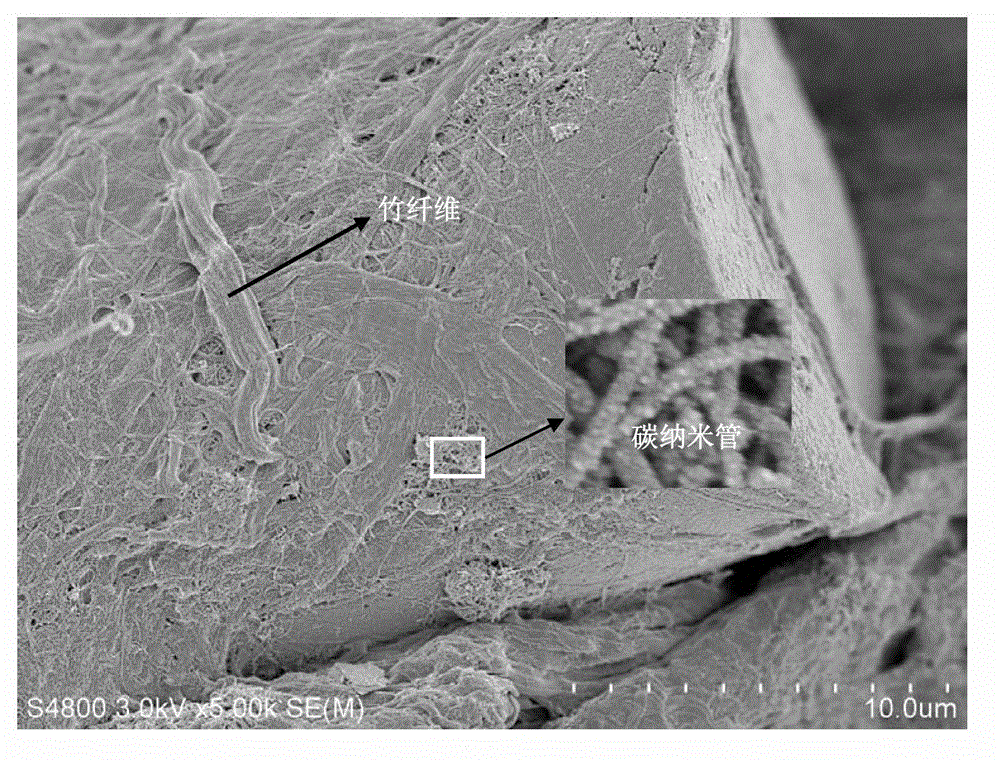

Method for preparing MWNT (Multi-Walled Carbon Nanotube) modified paper-based friction material

ActiveCN102943410AOvercoming the problem of unstable friction performanceIncrease frictionOther chemical processesPaper/cardboardFiberCarbon fibers

The invention relates to a method for preparing an MWNT (Multi-Walled Carbon Nanotube) modified paper-based friction material, which comprises the following steps of: dissolving cashew nut shell modified phenolic resin into absolute ethyl alcohol to obtain solution A; dispersing MWNTs into aqueous solution of sodium dodecyl sulfate to obtain suspension B; dispersing chopped carbon fibers, bamboo fibers and kieselguhr into water and then adding the suspension B to obtain solution C; after pouring the solution C into a fluffer to disperse, carrying out sheet making on a sheet making machine and drying to obtain a sample wafer D; and after impregnating the sample wafer D in the solution A, taking out the sample wafer D, naturally air-drying the sample wafer D and carrying out hot-press forming on a vulcanizing machine so as to obtain the MWNT modified paper-based friction material with a stable friction performance. According to the invention, the carbon nanotubes are used as the raw materials to be added into a carbon fiber reinforced reins-based wet friction material so as to prepare the single-layer paper-based friction material. The problems of delamination and unstable friction performance in the long-term application process, which are caused by the case that the carbon nanotubes are used as an enhancement layer to be added into the friction material in a conventional process, are solved; the friction performance of the paper-based friction material is greatly improved; and the wear rate is effectively reduced.

Owner:杨洁如

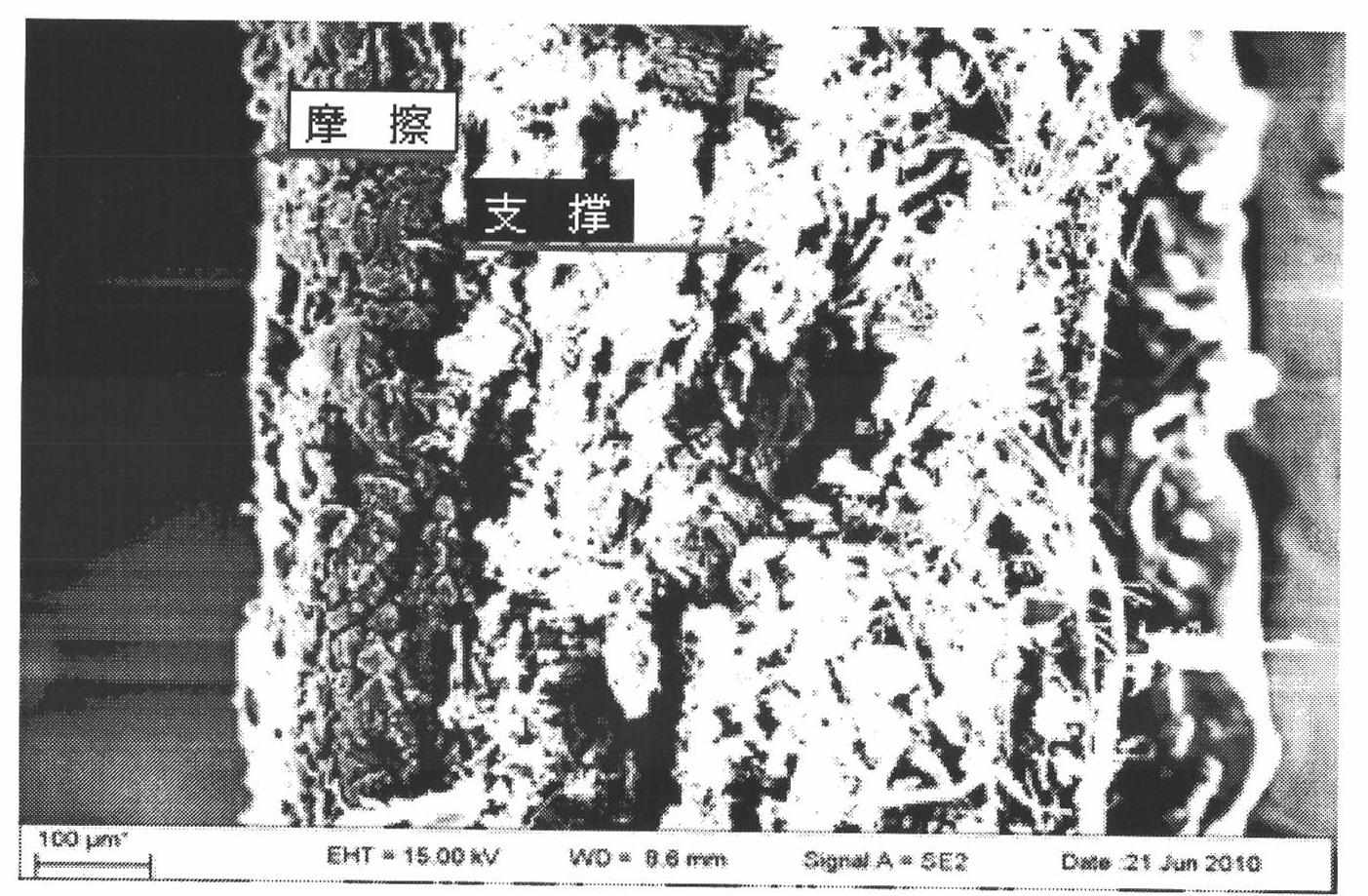

Carbonaceous double-layer paper-based friction material and preparation method thereof

InactiveCN102093842AIncrease coefficient of frictionCopy molding process is simpleOther chemical processesFiberStatic friction coefficient

The invention discloses a carbonaceous double-layer paper-based friction material and a preparation method thereof, aiming at solving the technical problem of low friction coefficient of the traditional double-layer paper-based friction material. According to the technical scheme, the carbonaceous double-layer paper-based friction material is prepared from 15-30% of reinforced fibre, 20-35% of filler, 5-15% of carbonaceous material, 5-10% of alumina and graphite and 25-35% of cashew nut shell oil modified phenolic resin. The preparation method comprises the following steps of: manufacturing and shaping a support layer in one time; and coating a friction layer on the surface of the support layer to obtain the carbonaceous double-layer paper-based friction material. Compared with the two-time manufacturing and shaping process in the background art, the preparation method is simpler. The coefficient of dynamic friction of the carbonaceous double-layer paper-based friction material is improved to 0.145-0.168 from 0.112-0.140 in the background art, and the coefficient of static friction is improved to 0.194-0.232 from 0.155-0.191 in the background art.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Compositions comprising aromatic compounds for use in oil and/or gas wells and related methods

InactiveUS20190055459A1Enhances flowbackEasy to oilDrilling compositionLiquid separationEmulsionRoom temperature

Compositions comprising aromatic compounds for use in various aspects of a life cycle of an oil and / or gas well, and related methods, are generally provided. In some embodiments, the composition is an emulsion or a microemulsion comprising a cashew nut shell liquid, a derivatized cashew nut shell liquid, an aromatic compound having a melting point above room temperature, and / or a non-aromatic compound having a melting point above room temperature. In some embodiments, the emulsion or the microemulsion comprises an aqueous phase, a non-aqueous phase, and at least one surfactant, and an additive which is an aromatic compound or mixture of aromatic compounds having a melting point above room temperature.

Owner:FLOTEK CHEM LLC

Vegetarian diet set meal, and preparation method thereof

InactiveCN106165883APrevent agingIncrease vitalityVegan ingredientsVegetarian ingredientsBiotechnologyBottle gourd

The invention discloses a vegetarian diet set meal. The vegetarian diet set meal comprises following raw materials, sticky rice, coix seed, black rice, corn, buckwheat grain, oat, milled glutinous broomcorn millet, millet, unpolished rice, sorghum rice, wheat, barley, lucid ganoderma, hazelnut kernel, pine nut kernel, pistachio nut kernel, apricot kernel, sunflower seed kernel, peanut kernel, ginkgo kernel, soybean, black soya bean, black kidney bean, circassian bean, mung bean, pea, broad bean, chickpea, hyacinth bean, sword bean, petits pois, kidney bean, snow bean, green soy bean, dwarf bean, winged bean, hickory kernel, cowpea, pumpkin seed, cashew nut, grape seed, cucumber seed, purple perilla seed, lettuce seed, brassica juncea var seed, Chinese waxgourd seed, bitter gourd seed, chayote seed, gold towel gourd seed, towel gourd seed, winter squash seed, cucurbita pepo seed, bottle gourd seed, and celery seed. According to a preparation method, 159 raw materials which are used contain the comprehensive nutrients needed by human body, nutrient balance and sufficiency are achieved, requirements of people on nutrients are satisfied effectively, effect is excellent, and only natural food materials are used.

Owner:韩丹

Preparation method of cashew nut oil modified alkyd resin

InactiveCN101081890AGood flexibilityPlay the role of internal plasticizationMetal layered productsPolymer scienceSolvent

The present invention is process of preparing cashew nut oil modified phenolic resin. The process includes the following steps: preparing the resin A; mixing the resin A 100 weight portions, formaldehyde solution 80-280 weight portions and alkaline catalyst 0.1-5 weight portions; reaction at 70-100 deg.c for 1-5 hr; vacuum distilling in a vacuum distilling kettle at temperature of 40-80 deg.c and vacuum degree of -0.03 MPa to -0.1 MPa to dewater to water content of 0.5-20 %, cooling to room temperature, and adding solvent while stirring to regulate the solid resin content to 30-70 % and viscosity at 25 deg.c to 40-400 cp to obtain the cashew nut oil modified phenolic resin. The cashew nut oil modified phenolic resin has high heat resistance, flame resistance and high toughness, and may be applied as the base material for copper clad panel.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

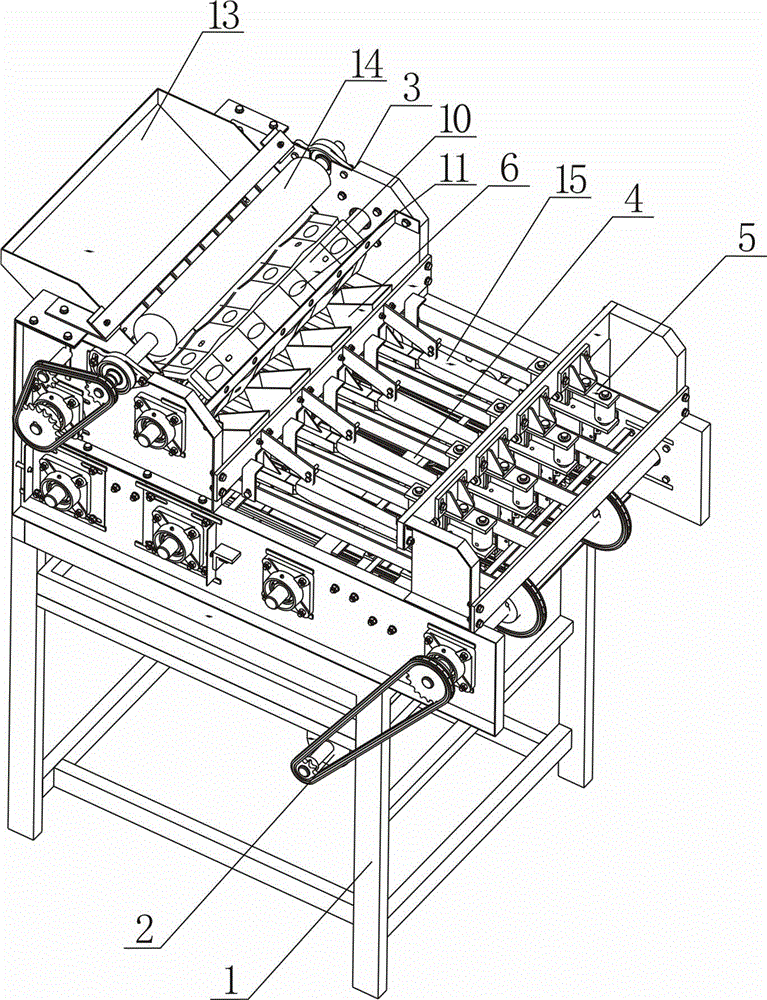

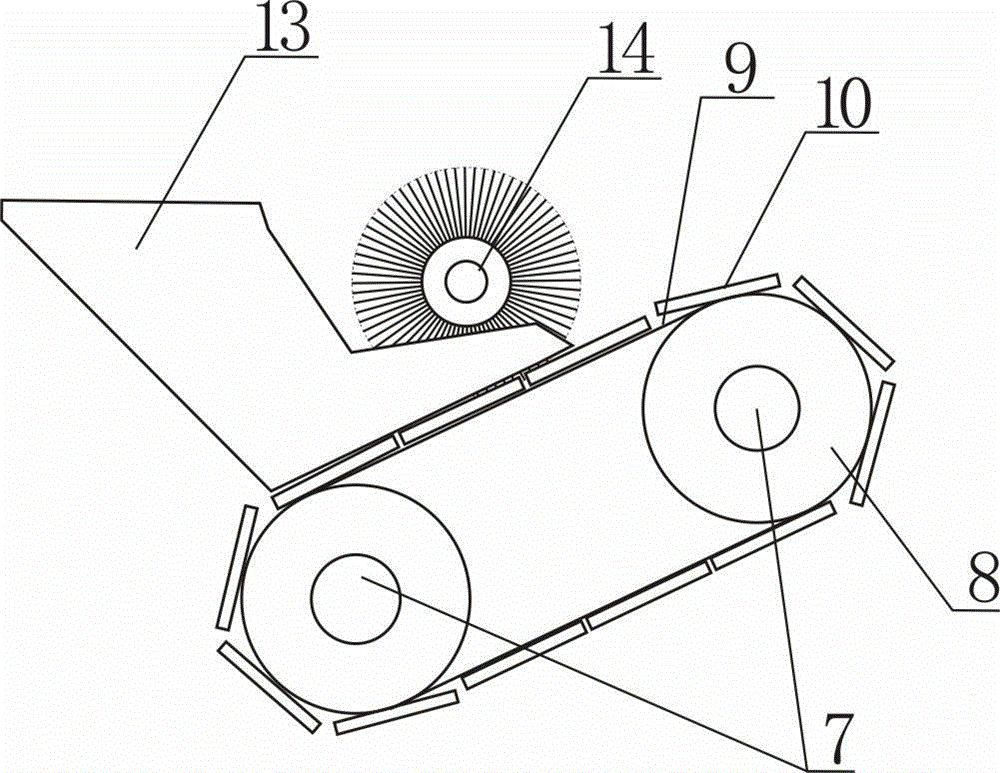

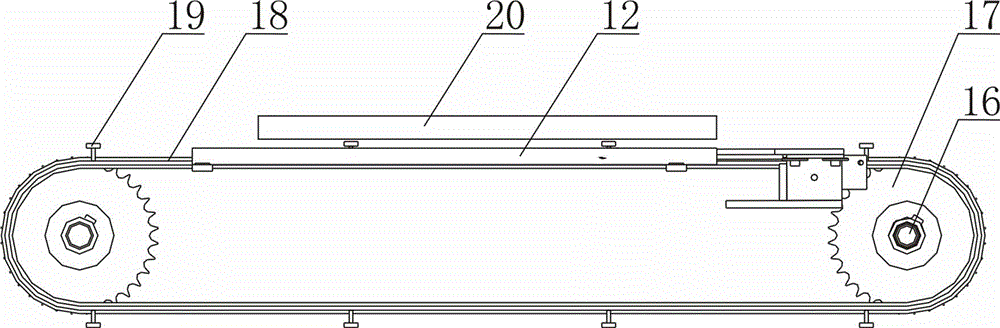

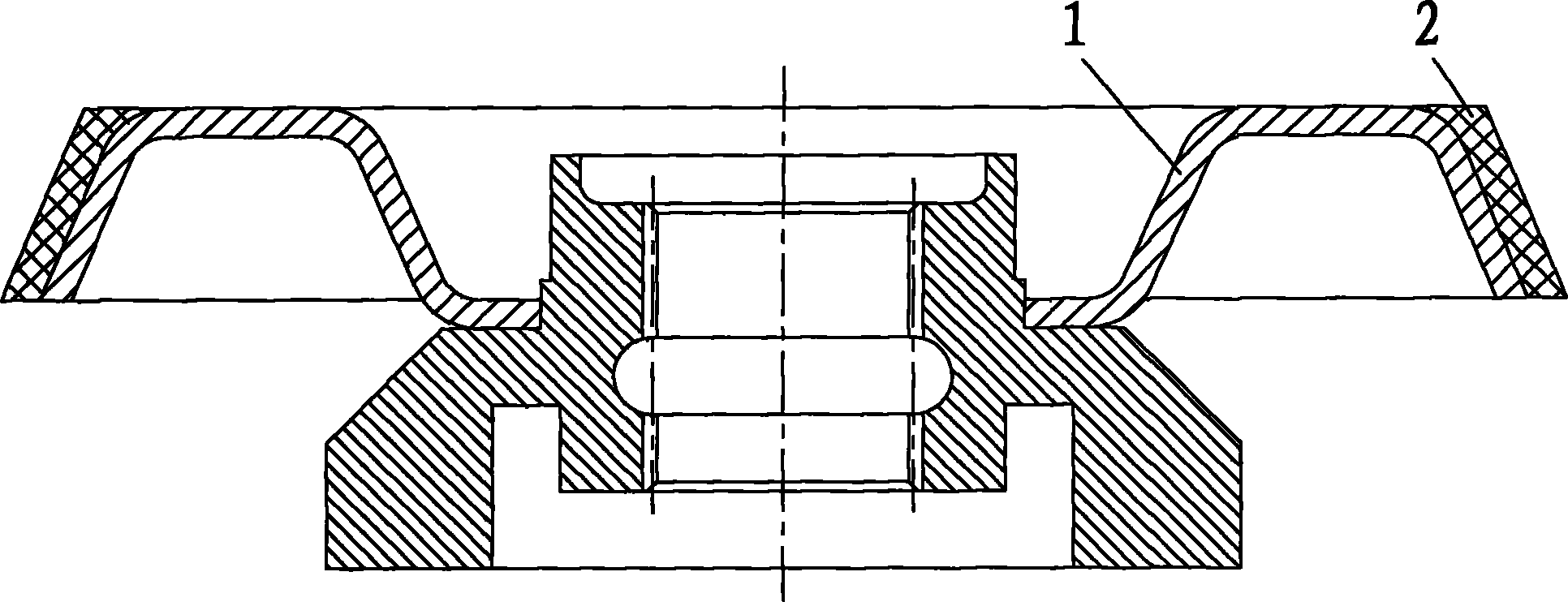

Full automatic cashew nut hull breaking machine

The invention discloses a full automatic cashew nut hull breaking machine which is mainly composed of a machine frame, a motor, a feeding mechanism, a conveying mechanism, a fruit picking mechanism and a cutting mechanism. The conveying mechanism is mainly formed by guide rails, a transmission shaft, a transmission chain wheel, a transmission chain and a fruit pushing plate. The guide rails are formed by an upper guide rail and a lower guide rail, the transmission chain drives the fruit pushing plate to penetrate a gap between the upper guide rail and the lower guide rail, the feeding mechanism is located at one end of the guide rail, and the cutting mechanism is located at the other end of the guide rail. The lower guide rail is formed by a left half portion and a right half portion. The fruit picking mechanism is mainly formed by two transmission shafts, a transmission chain wheel, two transmission chains and more than two fruit poking plates, and the transmission chains drive the fruit poking plates to enable poking pieces on the fruit poking plates to penetrate a gap between the left half portion and the right half portion. The full automatic cashew nut hull breaking machine is capable of achieving automatic feeding, conveying and centralizing, can improve the production efficiency, reduce labor intensity and reduce production cost, and is high in safety. The rate of perfect kernel can reach 50%-70%.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

High-performance organic fibre brake pad

ActiveCN101555918AStable coefficient of frictionSmall thermal expansionFriction liningLow noiseCellulose

A high-performance organic fibre brake pad comprises the following components according to weight percentages: 5-9% of cashew nut oil friction powder, 4-8% of chromite, 7-10% of barite, 4-7% of calcined petroleum coke, 3-7% of crystalline flake graphite, 3-6% of sepiolite fibre, 4-7% of ceramic fibre, 1.5-3% of antimony sulphide, 4-7% of red copper fibre, 3-5% of glued aluminium silicate fibre, 1-2% of alumina fibre, 8-11% of vermiculite powder, 9-13% of organosilicone phenol-formaldehyde resin, 1-2% of carbon fibre, 5-7% of bastose, 1-2.5% of wood pulp cellulose, 3-6% of viscose fibre, 6-9% of bamboo carbon fibre, 3-5% of nitrile rubber and 0.3-0.5% of zinc oxide. The invention has the advantages of light weight, strong wear resistance, good flexibility, low noise and long service life, and the like, and the friction performance is stable at operating temperature between 100 DEG C and 450 DEG C.

Owner:摩擦一号制动科技(仙桃)有限公司

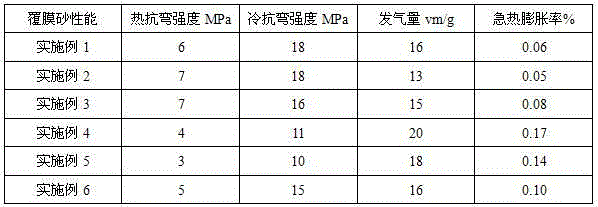

3D printing precoated sand and preparation method thereof

ActiveCN104923712AStrong adhesionImprove smoothnessFoundry mouldsFoundry coresMelamine formaldehydeMelamine formaldehyde resin

The invention relates to a precoated sand for a casting field, in particular to a 3D printing precoated sand. The 3D printing precoated sand comprises the following components: 5-8 wt% of cashew nut shells, 1-2 wt% of melamino-formaldehyde resins, 1-5 wt% of cashew nut shell liquid modified phenolic resins, 0.6-0.8 wt% of urotropin, 0.1-0.4 wt% of lubricant, 0.1-0.8 wt% of binding agents, 0.1-0.4 wt% of coupling agents, 0.5-1 wt% of dispersing agents, and the balance of crude sands. The prepared 3D printing precoated sand has high strength, high-temperature resistance, low gas generating amount and low expansion rate.

Owner:SHIYAN CHANGJIANG RIVER MOLDING MATERIAL

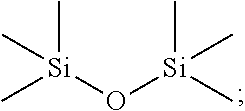

Epoxy polysiloxane graphene heavy-duty anticorrosion coating and preparation method

ActiveCN105860761AImprove aging resistanceImprove water resistanceAnti-corrosive paintsEpoxy resin coatingsNitrogen gasSolvent

The invention discloses epoxy polysiloxane graphene heavy-duty anticorrosion coating, comprising component A and component B according to a weight ratio of 100:17-24; the component A includes: epoxy resin, epoxy polysiloxane and graphene; the component B includes: cashew nut shell oil-modified amine curing agent. A preparation method of this coating includes: (1), hydrogenated bisphenol A epoxy resin and epoxy polysiloxane into a reactor introduced with nitrogen, heating to 60-80 DEG C, and adding dibutyltin dilaurate; heating slowly to 125-135 DEG C, and reacting for 5-6 h; cooling to 55-60 DEG C, adding silane coupling agent, and continuing to react for 2 h; extracting with petroleum ether, and removing a solvent at 40 DEG C at low vacuum pressure of 0.08 MPa; (2), mixing the epoxy resin, the epoxy polysiloxane of step (1) and graphene, heating for dissolving, adding other materials, and mixing; the coating prepared herein has excellent properties such as aging resistance, water resistance, hardness, flexibility, and salt water resistance.

Owner:WUHAN HOSTS COATING MATERIAL CO LTD

Nutritious food and production process thereof

InactiveCN102008041AProportional balanceImprove osteoporosisFood preparationBiotechnologyPumpkin seed

The invention discloses a nutritious food and a production process thereof. The nutritious food mainly comprises the following raw materials: brown rice, corns, wheat, oat, millet, soy beans, red beans, black-eyed beans, peanuts, lotus seeds, Chinese chestnuts, sunflower seeds, cashews and pumpkins, wherein the brown rice can be replaced by black rice; the soy beans can be soybeans or black soya beans, and also can be replaced by green beans or azuki beans; the Chinese chestnut can be replaced by walnuts; the sunflower seeds can be replaced by pumpkin seeds or sesames; the cashews can be replaced by pistachio nuts; and the pumpkins can be replaced by green vegetables, carrots, taros, scammony roots or yams. The raw materials are prepared, cooked, ground, sterilized, cooled and packaged to obtain a pasty food. By taking the grains and beans as raw materials and combining with nuts, vegetables or potatoes, the nutritious food has the advantages of rich nutrition, balanced nutritious components, good taste and reasonable price, has the efficacies of nourishing brain and strengthening bones, and can prevent and improve the heart cerebrovascular disease.

Owner:余凤云

Soybean sauce mutton shashlik and preparation method thereof

The invention provides soybean sauce mutton shashlik and a preparation method thereof. The mutton shashlik is characterized by being prepared from the following raw materials in parts by weight: 260-280 parts of mutton, 1-1.5 parts of liquorice, 2-2.2 parts of platycladi seed, 1.2-1.4 parts of semen plantaginis, 2.2-2.4 parts of white poria, 2.5-2.7 parts of thunbergia fragrans root, 3-3.3 parts of carrot leaf, 1.5-1.8 parts of morusaustralis poir, 8-10 parts of cashew nut, 10-11 parts of panicum miliaceum, 3-4 parts of cheese powder, 4-5 parts of water-soaked bamboo slice, 1-2 parts of grape seed powder, 4-5 parts of hawthorn kernel powder, 22-24 parts of soybean sauce, 50-55 parts of rock candy, 10-11 parts of grape juice, and 3-4 parts of nutrition additive. The mutton flavor is rich because beneficial components in traditional Chinese medicines can be sufficiently absorbed by the mutton through cooking, the mutton shashlik tastes sweet and refresh due to the syrup cooked by the rock candy and the grape juice, and the prepared mutton shashlik is bright in color, unique in flavor and nice in smelling, and can meet the requirement of consumers to color, flavor and taste. Furthermore, the soybean sauce mutton shashlik has the effects of invigorating spleen and replenishing qi, clearing heat and removing toxicity, tranquilizing by nourishing the heart, and resisting tumors.

Owner:HUAIYUAN DAYU FOOD TECH

Calcium carbonate whisker reinforced rubber base friction material and preparation method therefor

InactiveCN105111532AImprove brittlenessImprove heat resistanceOther chemical processesFriction liningButadiene-styrene rubberPetroleum coke

The present invention discloses a calcium carbonate whisker reinforced rubber base friction material, and a preparation method therefor. The material comprises: 8-15 parts of nitrile rubber, 10-15 parts of styrene-butadiene rubber, 5-10 parts of phenolic resin, 5-25 parts of calcium carbonate whisker, 10-20 parts of steel fiber, 2-8 parts of sepiolite fiber, 0-8 parts of mineral fiber, 0-3 parts of aramid fiber, 5-8 parts of barium sulfate, 5-10 parts of magnesium oxide, 2-3 parts of aluminum oxide, 5-10 parts of flake graphite, 1-5 parts of carbon black, 5-10 parts of petroleum coke, 3-6 parts of Cardolite cashew nut shell oil friction powder, 0.5-1 parts of sulfur, and 0.5-1 parts of accelerator. The preparation method comprises process steps of such as material collocation, mixing, pressing molding and the like. Brake pads synthesized by the method provided by the invention have the advantages including excellent friction and wear performance, stable braking performance, high heat-resistant property, safe, environmentally-friendly, and low in cost; and is suitable for braking devices for automobiles and motive power machines, thereby achieving a very wide application prospect and applying to industrial production.

Owner:GUANGXI UNIV +2

Friction brake disk of double-speed electric-block and preparation method thereof

ActiveCN101870438AIncrease coefficient of frictionIncreased shear strengthOther chemical processesFriction liningMetal fiberLow noise

The invention relates to a friction brake disk of a carbon-base double-speed electric-block and a preparation method thereof, aiming to provide the brake disk which has large brake moment, high shear strength, high temperature resistance, wear resistance, environmental protection and low noise. The preparation method has the advantages of simple technology, convenient manufacture and low cost. The invention has the technical scheme that the friction brake disk of the double-speed electric-block comprises an iron-base frame and a friction material layer which is attached to the brake surface of the iron-base frame, wherein the friction material layer comprises modified phenol-formaldehyde resin, aramid fiber, short carbon fiber, SACF mineral fiber, precipitated baryte, modified bauxite, metal sulfides, hydrogenated nitrile-butadiene rubber, metal fiber, nano calcium carbonate, stearic acid, vulcanization accelerator, medium-carbon frictional property modifier and melamine-cashew nut shell oil. The preparation method comprises the following steps: (1) weighing raw materials; (2) synthetically kneading the raw materials; (3) compression molding; (4) thermocuring; and (5) machining.

Owner:杭州汉乐科新材料科技有限公司

Purple rice cake and preparation method thereof

ActiveCN103393002AHigh in nutrientsBalanced and reasonable nutritionFood preparationHuman healthMillet flour

The invention relates to a purple rice cake and a preparation method thereof, and belongs to the technical field of food. The purple rice cake is composed of the following raw materials by weight: 150-200 parts of purple rice, 30-50 parts of millet flour, 20-40 parts of chestnut flour, 15-30 parts of pumpkin, 10-15 parts of chrysanthemum, 6-12 parts of sweet scented osmanthus, 5-9 parts of cassia seed, 3-8 parts of tangerine peel, 4-6 parts of lemon slice, 10-18 parts of honey, 10-20 parts of milk, 10-12 parts of wine, 5-8 parts of yogurt, 2-4 parts of salt roasted cashew nut, 5-8 parts of red dates and 3-6 parts of niblet. The purple rice cake provided by the invention is added with a tea soup prepared from a plurality of teas with different efficacies as traditional Chinese medicines, so that a finished product contains tea fragrance and has health care effect; in addition, other substances containing abundant nutrition elements are added to improve the preparation method and enrich nutrients in the traditional purple rice cake. The purple rice cake has more equalized and reasonable nutrition matching and is beneficial for human health.

Owner:佛山市顺德区百辉食品有限公司

Marine engine lubrication

ActiveUS20120103303A1Not effectiveEasy to handleCombustion enginesEngine controllersEngineeringFuel oil

Trunk piston marine engine lubrication, when the engine is fueled by heavy fuel oil, is effected by a composition comprising a major amount of an oil of lubricating viscosity and a minor amount of one or more phenolic compounds comprising distilled cashew nut shell liquid or hydrogenated distilled cashew nut shell liquid. Asphaltene precipitation in the lubricant, caused by the presence of contaminant heavy fuel oil, is prevented or inhibited.

Owner:INFINEUM INT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com