Friction material composition and friction material for preparing brake pad

A friction material and composition technology, applied in the field of friction material composition and friction material, can solve problems such as unstable friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

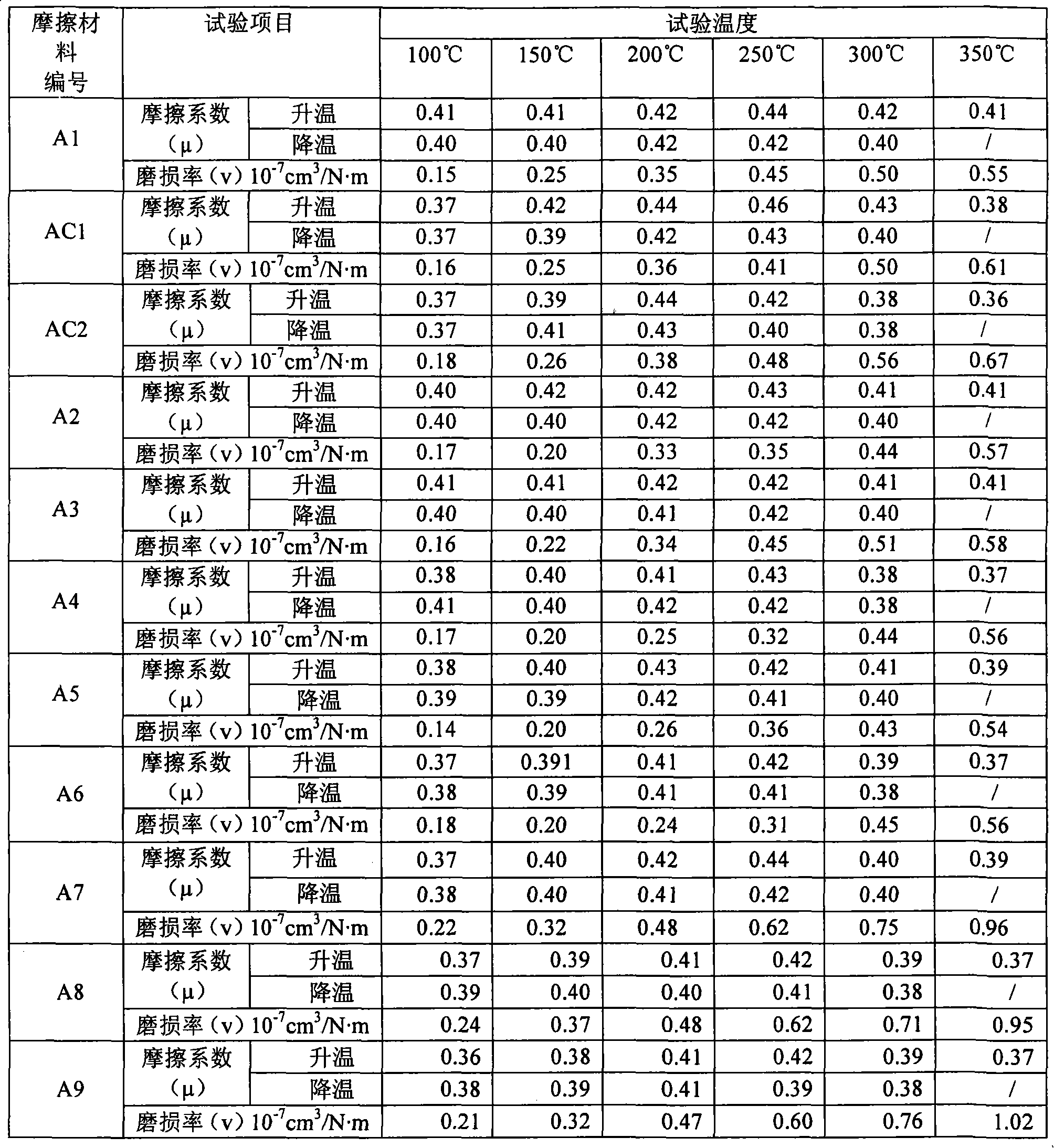

Image

Examples

preparation example Construction

[0028] The present invention has no particular limitation on the preparation method of the composition, as long as the binder, reinforcing material, friction enhancer, lubricant and filler are mixed uniformly. The types of the components added during mixing are the same as the corresponding components above, and will not be described here. The mixing conditions and equipment are well known to those skilled in the art, for example, the JF810SJ model pear rake mixer produced by Jilin University Electromechanical Equipment Research Institute can be used for mixing, and the mixing conditions include that the mixing temperature can be At 0-30°C, the mixing time can be 10-30 minutes, preferably 10-20 minutes.

[0029] The present invention also provides a friction material for preparing a brake pad, the friction material is obtained by heat treatment after hot pressing of a friction material composition, wherein the composition is the friction material composition provided by the pr...

Embodiment 1

[0034] This example is used to illustrate the friction material composition and friction material for preparing the brake pad provided by the present invention.

[0035] (1) Preparation of friction material composition for preparing brake pads

[0036] 14 parts by weight of cashew nut shell oil and nitrile-butadiene rubber double-modified phenolic resin (KT-3640CRA model of Kunyi resin material company, the average particle diameter is 60 microns, wherein, cashew nut shell oil and nitrile-butadiene rubber double-modified phenolic resin are prepared. At the time, the weight ratio of the consumption of cashew nut shell oil and nitrile rubber and phenolic resin is 0.04: 0.04: 1), 10 parts by weight of steel fibers (Dazheng Metal Fiber Co., Ltd., D1-80, the average diameter is 150 microns, the average length 0.3 cm), 5 parts by weight of copper fiber (Dazheng Metal Fiber Co., Ltd., DT1-99, average diameter of 150 microns, average length of 0.3 cm), 10 parts by weight of composite ...

Embodiment 2

[0046] This example is used to illustrate the friction material composition and friction material for preparing the brake pad provided by the present invention.

[0047] 7 parts by weight of cashew nut shell oil and nitrile-butadiene rubber double-modified phenolic resin (KT-3640CRB model of Kunyi resin material company, the average particle diameter is 40 microns, wherein, prepare cashew nut shell oil and nitrile-butadiene rubber double-modified phenolic resin. When the weight ratio of the consumption of cashew nut shell oil and nitrile rubber and phenolic resin is 0.05: 0.08: 1), 3 parts by weight of epoxy resin (Shengquan Chemical Co., Ltd., PF6400-A, the average particle diameter is 40 microns) , 10 parts by weight of iron fibers (Dazheng Metal Fiber Co., Ltd., with an average diameter of 100 microns and an average length of 0.1 cm), 8 parts by weight of aluminum fibers (Dazheng Metal Fiber Co., Ltd., DA-#000, with an average diameter of 100 microns) , the average length i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com