Patents

Literature

104results about How to "Overcoming performance deficiencies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formation method for lithium ion secondary battery

InactiveCN101315994AOvercoming performance deficienciesImprove cycle performanceFinal product manufactureElectrolyte accumulators manufactureLithiumPhysical chemistry

The invention provides a formation method used for a lithium ion secondary battery. The method comprises the following steps that: electrolyte is injected into the lithium ion secondary battery and then aged; subsequently, the lithium ion secondary battery is charged; the charging method comprises a first charging process and a second charging process; after the first charging process is completed, the electrolyte is injected into the lithium ion secondary battery again; the injected electrolyte before the first charging process and the electrolyte which is injected into the lithium ion secondary battery after the first charging process respectively and independently are mixed solution which contains the electrolyte lithium salt and the chain-shaped acid ester; wherein, the electrolyte injected into the lithium ion secondary battery before the first charging process also contains film-forming additive; the electrolyte which is injected into the lithium ion secondary battery again after the first charging process also contains overcharging additive. The formation method of the lithium ion secondary battery of the invention can effectively improve the comprehensive electrochemical performance of the battery.

Owner:SHANGHAI BYD

Friction material of disc brake pad, disc brake pad and preparation technology of disc brake pad

ActiveCN102965078AOvercoming performance deficienciesImprove performanceOther chemical processesFriction liningFiberPotassium

The invention discloses a friction material of a disc brake pad. The friction material comprises the following raw materials in parts by weight: 13-18% of cashew nut shell oil-modified phenolic resin, 9-16% of butyronitrile rubber powder, 3-7% of steel wool fiber, 6-11% of calcium sulfate whisker, 2-5% of potassium feldspar powder, 3-6% of graphite, 2-6% of brown fused alumina, 3-5% of antimony sulfide, 11-16% of baryta powder, 5-9% of chromite powder, 6-11% of heavy calcium carbonate, 2-4% of zircon sand and 3-6% of brass powder. Visibly, in the preparation raw materials, the cashew nut shell oil-modified phenolic resin is adopted for replacing ordinary phenolic resin as an organic carrier of a brake pad material, so that the shortcomings of poor resistance to thermal ablation, high abrasiveness, low anti-impact strength and the like of the ordinary phenolic resin are eliminated, the performance defects of the friction material of the disc brake pad caused by the ordinary phenolic resin can be avoided, and the overall performance of the friction material of the disc brake pad can be further improved.

Owner:SHANDONG GOLD PHOENIX

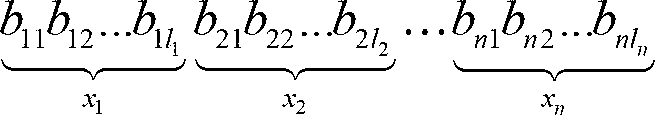

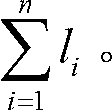

Method for generating MIMO (multiple-input and multiple-output) radar orthogonal polyphase code signals on the basis of genetic-tabu hybrid algorithm

ActiveCN102999783AImprove climbing abilityImprove transmit waveform performanceGenetic modelsMulti inputSignal on

The invention provides a method for generating MIMO (multiple-input and multiple-output) radar orthogonal polyphase code signals on the basis of genetic-tabu hybrid algorithm. The method includes: firstly, randomly generating an initial population; secondly, judging whether a stop criterion of genetic algorithm is satisfied or not; thirdly, calculating a fitness function; fourthly, selecting by proportional selection; fifthly, intersecting; sixthly, mutating by tabu search algorithm; seventhly, updating the population, and returning to the step 3 for continuing genetic algorithm with the new population. Transmission signals with fine self-correlation and cross-correlation can be designed, and polyphase code waveform designed by the method has fixed phase and is easy to generate and more suitable for practical application.

Owner:HARBIN ENG UNIV

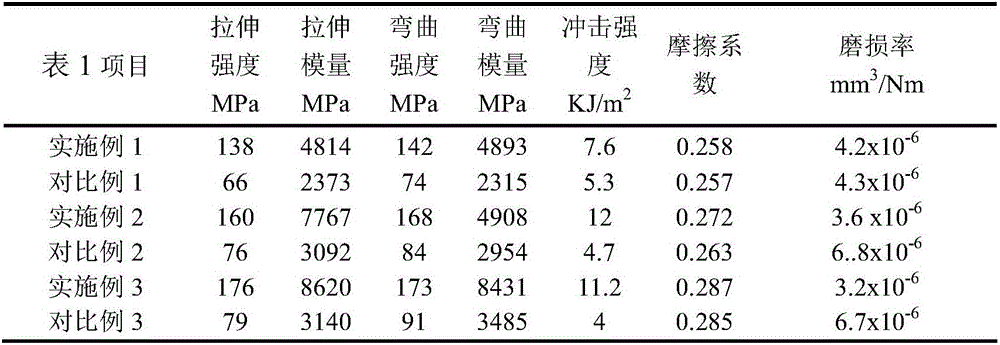

Low-odor, low-emission, high abrasion-resistant and high-temperature-resistant nylon and preparing method thereof

The invention relates to low-odor, low-emission, high abrasion-resistant and high-temperature-resistant nylon and a preparing method thereof. The material is prepared by the steps of stirring and mixing 90-98 parts of high-temperature-resistant nylon, 1-5 parts of a hydrophobic high-temperature-resistant odor-adsorption masterbatch, 1-5 parts of surface treated nano silicon carbide, 0.1-0.5 part of a solid lubricant, 0.2-1.0 part of a lubricant and 0.1-1 part of an antioxidant and then carrying out melting extrusion granulation through a twin-screw extruder. Tetraethoxysilane and a coupling agent are used for composite surface treatment of the nano silicon carbide, the dispersity of the nano silicon carbide as a wear-resisting agent in matrix resin is increased, and thus the cohesive property of the wear-resisting agent and the high-temperature-resistant nylon matrix is improved, the prepared high-temperature-resistant nylon has significant improvement in wear resistance; at the same time, with use of the hydrophobic high-temperature-resistant odor-adsorption masterbatch, the product is kept a low-odor characteristic in processing and application processes.

Owner:HEFEI GENIUS NEW MATERIALS

Phase-change energy-storage dual-limit temperature adjustment mortar and preparation method thereof

The invention discloses phase-change energy-storage dual-limit temperature adjustment mortar and a preparation method thereof. The phase-change energy-storage dual-limit temperature adjustment mortar comprises the following raw materials in parts by weight: 25 parts of cement, 20-55 parts of medium sand, 10-30 parts of phase-change microcapsules, 10-40 parts of expanded perlite shape-stabilized phase-change particles, 0.25-1 part of fibers, 0.2-0.5 parts of cellulose ether, 1.5-3 parts of redispersible latex powder and 25-30 parts of water, wherein the phase-change temperature of the phase-change microcapsules is 18-20 DEG C and the phase-change temperature of the expanded perlite shape-stabilized phase-change particles is 26-28 DEG C. The phase-change energy-storage dual-limit temperature adjustment mortar prepared by the method has a dual-limit temperature adjustment function, not only can remarkably adjust a room temperature to be within upper and lower limit ranges of a comfortable temperature of a human body and improve thermal comfort of a human settlement environment but also improves energy-storage and temperature-adjustment capabilities of a phase-change mortar product and overcomes performance deficiencies existent during addition of a single phase-change medium through compound addition of two phase-change mediums, that is to say, the phase-change microcapsules and the expanded perlite shape-stabilized phase-change particles.

Owner:建筑材料工业技术监督研究中心

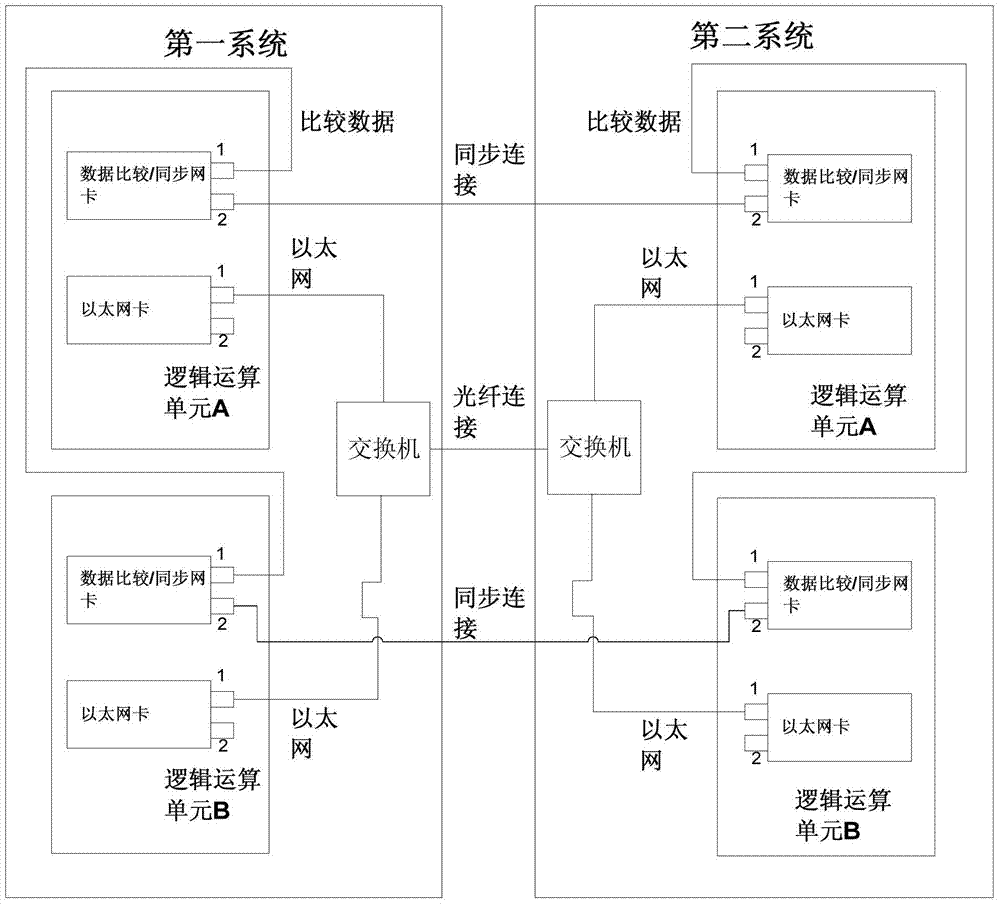

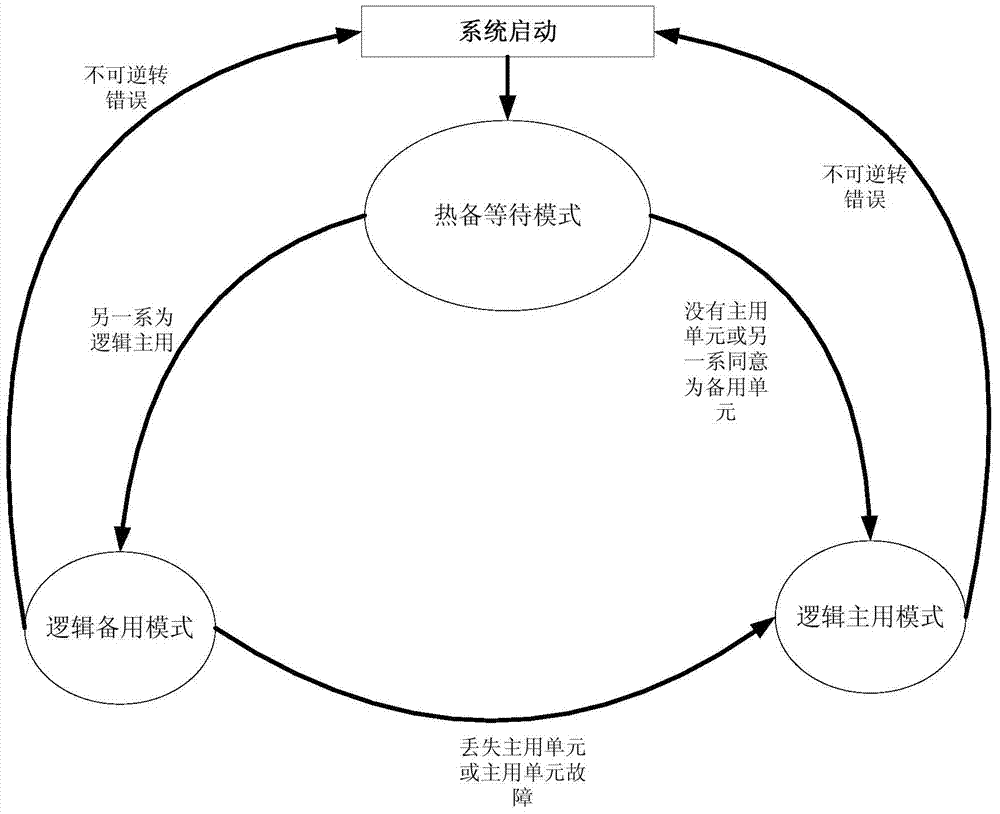

Hot redundancy interlocking subsystem and main and standby switching method thereof

InactiveCN104268037AEliminate common mode faultsAvoid performance pitfalls of clock-level synchronizationRedundant hardware error correctionComputer scienceTask level

The invention discloses a hot redundancy interlocking subsystem. The hot redundancy interlocking subsystem comprises a first system and a second system which are identical and are connected, wherein each of the first system and the second system comprises two heterogeneous hardware and two CPUs synchronizing at task level. The two sets of different software run on two CPUs respectively. The first system and the second system obtain inputs from track sides and synchronize preset time for one time, and operations of the two systems are compared and then output simultaneously. The hot redundancy interlocking subsystem achieves a hot redundancy double 2-vote-2 hot standby switching mechanism.

Owner:SHANGHAI ELECTRIC THALES TRANSPORTATION AUTOMATION SYST CO LTD

Method for preparing road concrete from admixtures steel slag micro-powder, superfine slag powder and fly ash

InactiveCN104961413AReduce manufacturing costTake advantage ofSolid waste managementBreaking strengthSocial benefits

The invention discloses a method for preparing road concrete from admixtures steel slag micro-powder, superfine slag powder and fly ash. The road concrete mainly consists of a cementing material, mixing water, coarse and fine aggregates and additives, wherein the cementing material is obtained by compounding the following components in percentage by mass: 40 to 80 percent of cement, 5 to 20 percent of steel slag micro-powder, 5 to 20 percent of superfine slag powder and 5 to 20 percent of fly ash; the water-cement ratio is controlled to be 0.35 to 0.45; the coarse and fine aggregates are continuously graded; the sand ratio is controlled to be 31 to 41 percent; the additives comprise a polycarboxylic superplasticizer and a plant protein air-entraining agent, and the doping amounts of the polycarboxylic superplasticizer and the plant protein air-entraining agent are 1.5 to 2.5 percent and 0.5 to 1.5 percent based on the mass of the cementing material respectively. The method is simple, and has remarkable economic benefits and social benefits, the prepared road concrete has breaking strength of 4.7 to 7.6MPa, and is higher in working performance, mechanical performance and durability, and the utilization rates of steel slag micro-powder, superfine slag powder and fly ash can be remarkably increased.

Owner:UNIV OF JINAN

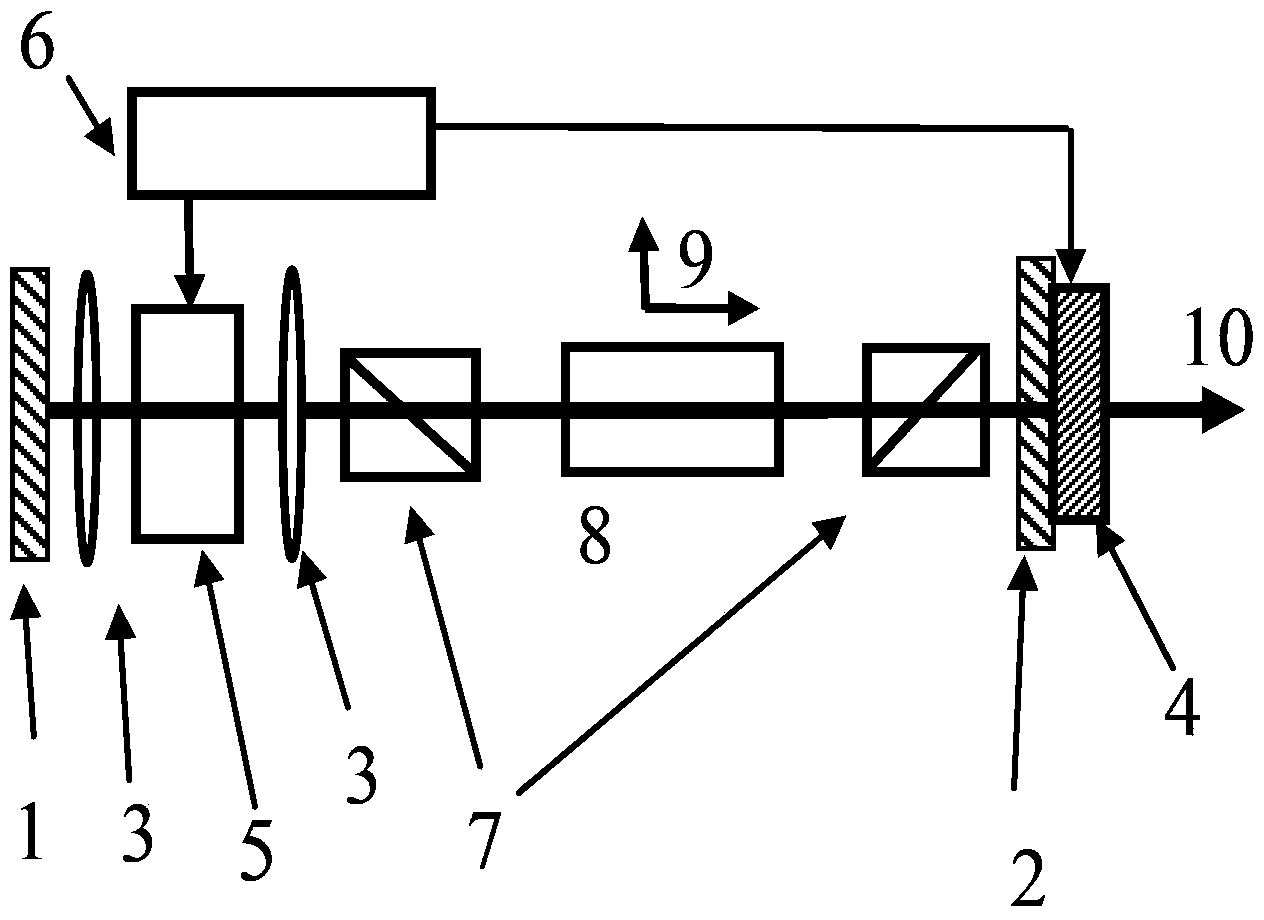

Method and device for producing active light clock with gain medium and quantum reference medium separated

ActiveCN103414470AMeet the needs of high output powerIncrease output powerPulse automatic controlFrequency stabilizationLine width

The invention relates to a method and device for producing an active light clock with a gain medium and a quantum reference medium separated. The device comprises an optical resonant cavity, the quantum reference medium and the population-inversion gain medium, wherein the quantum reference medium and the population-inversion gain medium are located inside the optical resonant cavity and separated from each other in space, and the quantum reference medium is located in a magnetic field. A laser light field produces the Faraday magneto-optical rotation effect on an atomic clock transition spectral line of the quantum reference medium in the outer magnetic field, under the back feeding effect of the optical Fabry-Perot resonant cavity and under the condition that a collimating lens conducts collimation on light beams, the gain medium products stimulated radiation and reaches a laser oscillation threshold, and laser light of the active light clock is formed and output from the output end of the optical resonant cavity. According to the method and the device, the two mediums which are completely independent and separated in space are used for meeting the requirements that the output power of the active light clock is high and the narrow line of the active light clock is wide, and the output laser light has very good frequency stability and accuracy.

Owner:浙江法拉第激光科技有限公司

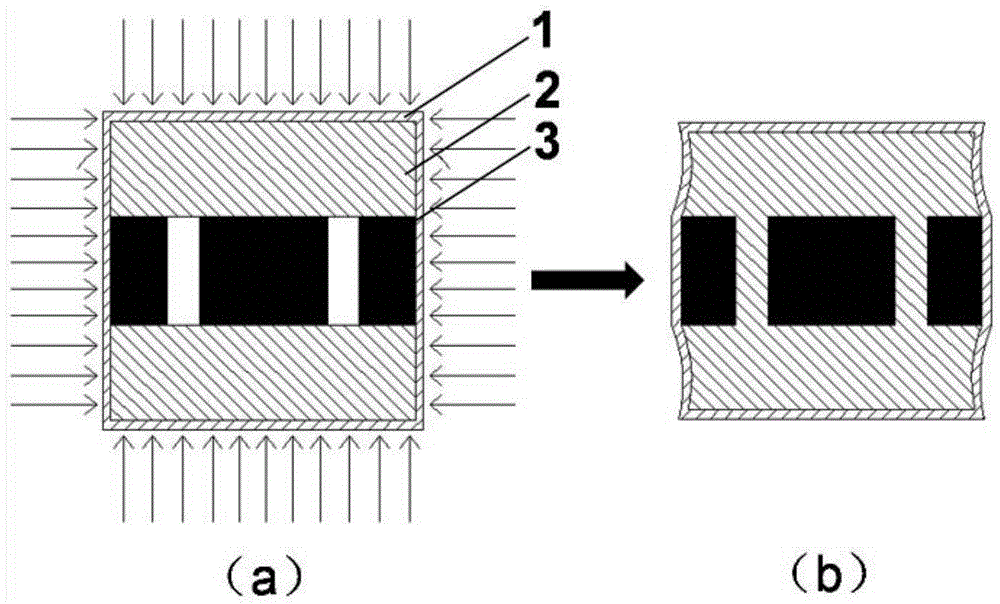

Hot isostatic pressure near-net forming method for semi-solid complex difficult-machining compact piece

InactiveCN105772726ASmall and uniform tissueGuaranteed forming accuracyHigh pressureTemperature and pressure

The invention discloses a hot isostatic pressure near-net forming method for a semi-solid complex difficult-machining compact piece. The hot isostatic pressure near-net forming method comprises the steps that a semi-solid material is used as a forming material, graphite is used as an internal form control core, the hot isostatic pressure temperature is selected as the solid-liquid two-phase interval temperature, and the compact piece in a complex shape is directly formed under coupling of temperature and pressure. According to the hot isostatic pressure near-net forming method for the semi-solid complex difficult-machining compact piece, performance defects caused by powder surface pollutants in traditional methods can be effectively overcome, and the part forming precision can be effectively ensured through high pressure at the high temperature; in addition, the temperature close to the melting point of an alloy material is adopted, and a solid-liquid coexisting phase occurs in a ladle sleeve at the temperature; due to the fact that liquid phase components exist among crystal grains or solid phase particles, the solid phase particles almost have no binding force and are very low in flow deformation resistance, and a complex runner in the form control core is filled with parent metal advantageously; and moreover, the solid phase particles are easy to separate on specification portions, and while, due to the fact that the liquid phase components exist, the separated portions are very easy to connect integrally.

Owner:HUAZHONG UNIV OF SCI & TECH

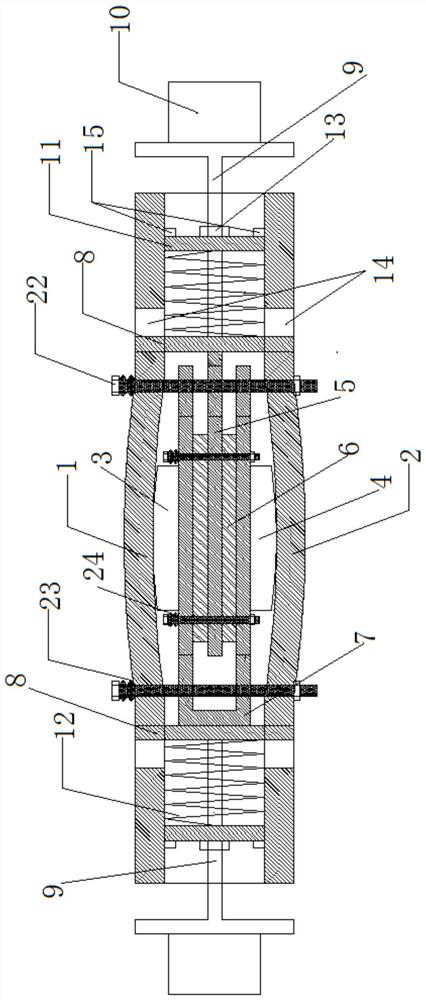

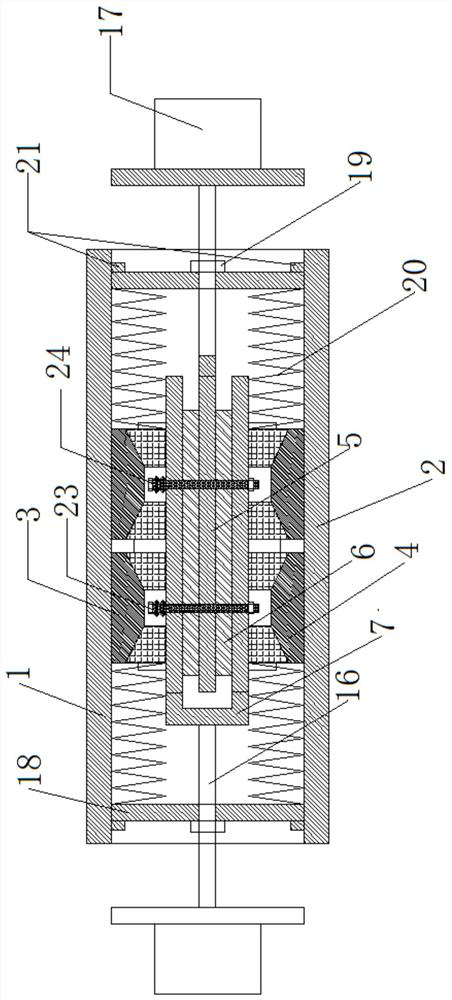

Self-resetting variable-damping variable-rigidity viscoelasticity and friction composite damper

ActiveCN112922182AImprove energy consumptionRealize the function of energy dissipation and shock absorption protectionProtective buildings/sheltersShock proofingViscoelastic dampingEarthquake resistance

The invention belongs to the field of earthquake resistance and shock absorption of buildings, particularly relates to a self-resetting variable-damping variable-rigidity viscoelasticity and friction composite damper, and is suitable for the field of building new construction, reinforcement and repair. The damper comprises a first friction base plate and a second friction base plate which are oppositely and fixedly arranged and a viscoelastic damper arranged between the first friction base plate and the second friction base plate in the length direction; a first friction plate and a second friction plate are arranged on the two corresponding sides of the fixed end of the viscoelastic damper respectively; and the first friction plate and the second friction plate are correspondingly connected with the first friction base plate and the second friction base plate in a pressed mode. According to the self-resetting variable-damping variable-rigidity viscoelasticity and friction composite damper, an internal viscoelastic damper unit can perform energy dissipation and shock absorption on high-frequency-band and small-displacement seismic oscillation, and an external self-resetting variable-friction damper unit can perform energy dissipation and shock absorption on low-frequency-band and large-displacement seismic oscillation, so that the energy dissipation and shock absorption capacity of a single damper is improved, and the performance defect of a single energy dissipation mode can be overcome.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

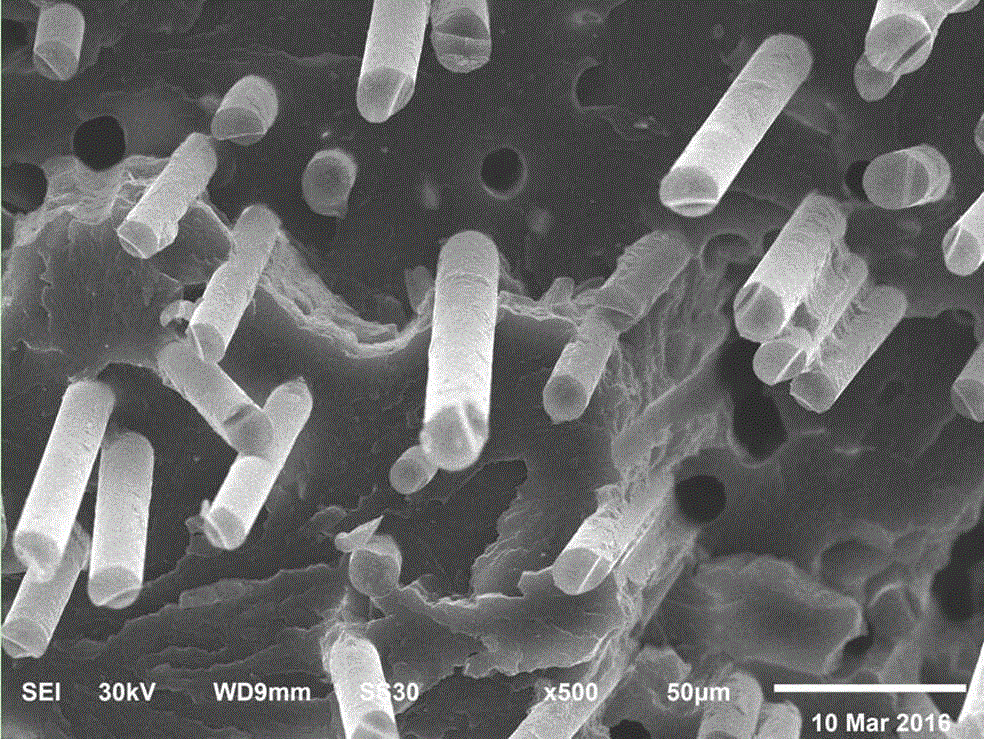

Bamboo fiber reinforcement composite material

The invention provides a fiber strengthening complex material which is produced by adopting bamboo blasting pulp fiber as strengthening material, employing nylon, ABS and polypropylene as matrix, combining unqiue impingine and drying technology and adding wax type carboxylation polyether interface modifier synthesized through a thermal catalysis method in matrix resin. The invention processes various bamboo main stems into bamboo stripe (sheet) fiber and bamboo shoot tail materials into powder materials, which are used for strengthening thermosetting and thermoplastic plastics such as nylon, ABS, polypropylene, etc., thereby light, high and strong, energy saving and cheap strengthening complex material with high performance is produced and various boards, tubes, boxes, barrels, tanks, containers, profiles, bars and moulding products can be made of the strengthening complex materials. The invention is characterized by light weight and low price and has the advantages of relative small shrinkage and torsion of materials, high stabile dimension, good processing property, low abrasion to production equipment, etc.; besides, the invention can be used in industries such as automobiles, appliances, construction materials, interior decoration, etc. and is used for replacing the complex materials in early age such as similar glass fiber reinforced plastics, etc. Compared with the existing complex materials, the invention has remarkable advantages of wide sources of raw materials, low cost, easy processing and excellent performance. The bamboo fiber used in the invention can employ a large quantity of overstock bamboo materials in China, thus relieving the present shortage of timber, steel and plastic raw materials.

Owner:SHENGHONG GRP CO LTD

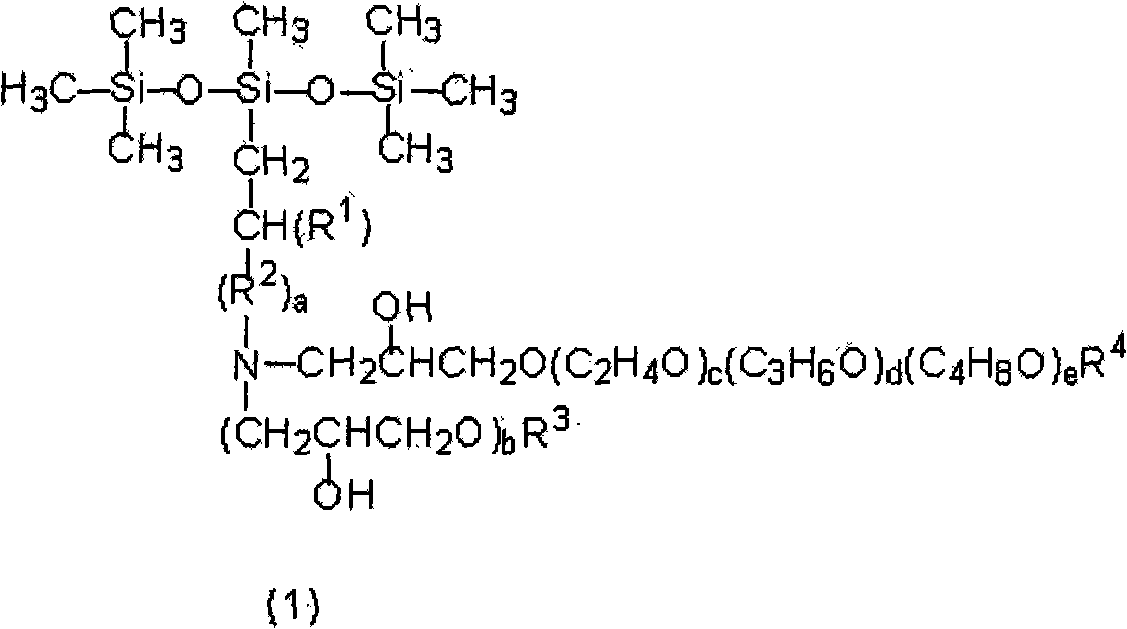

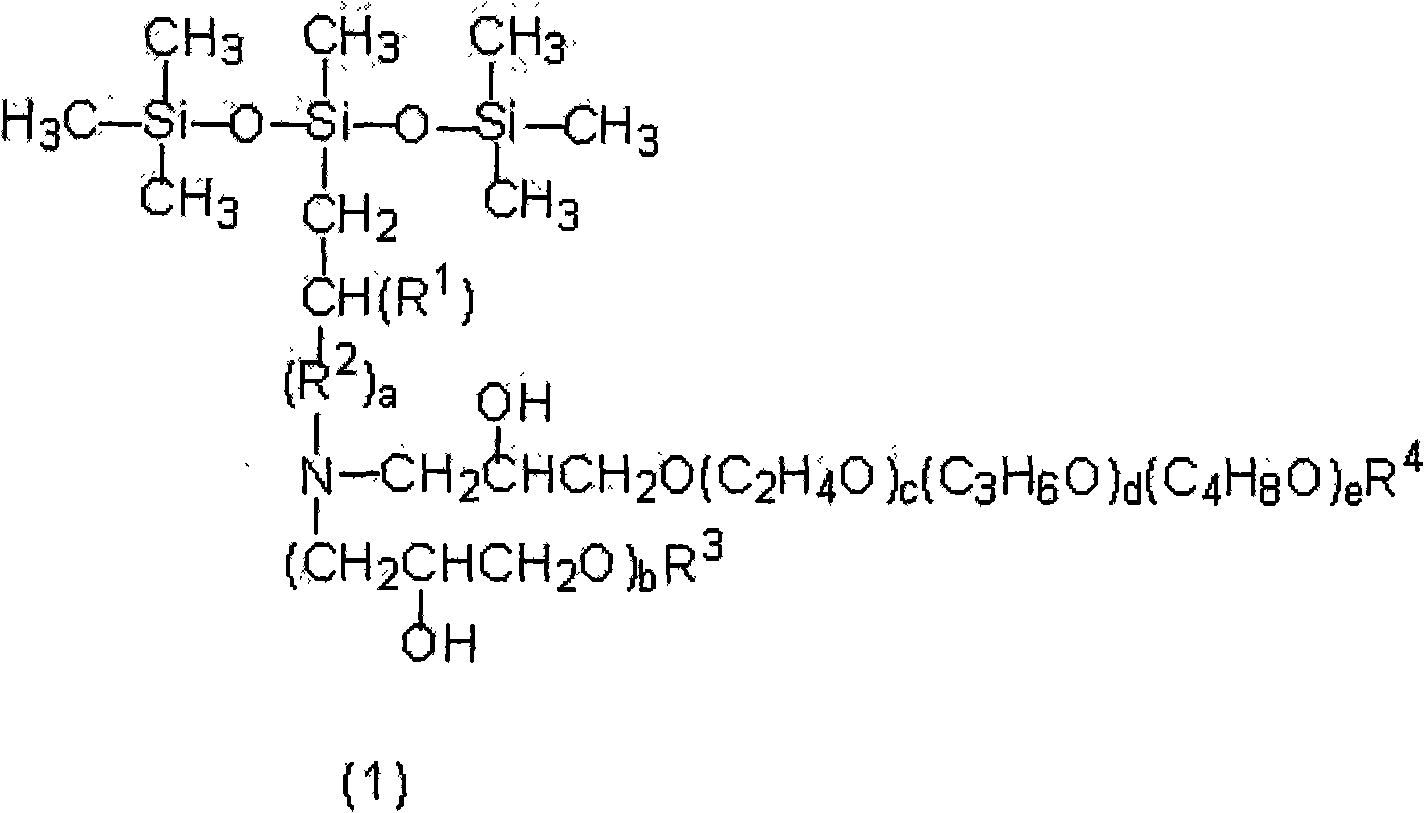

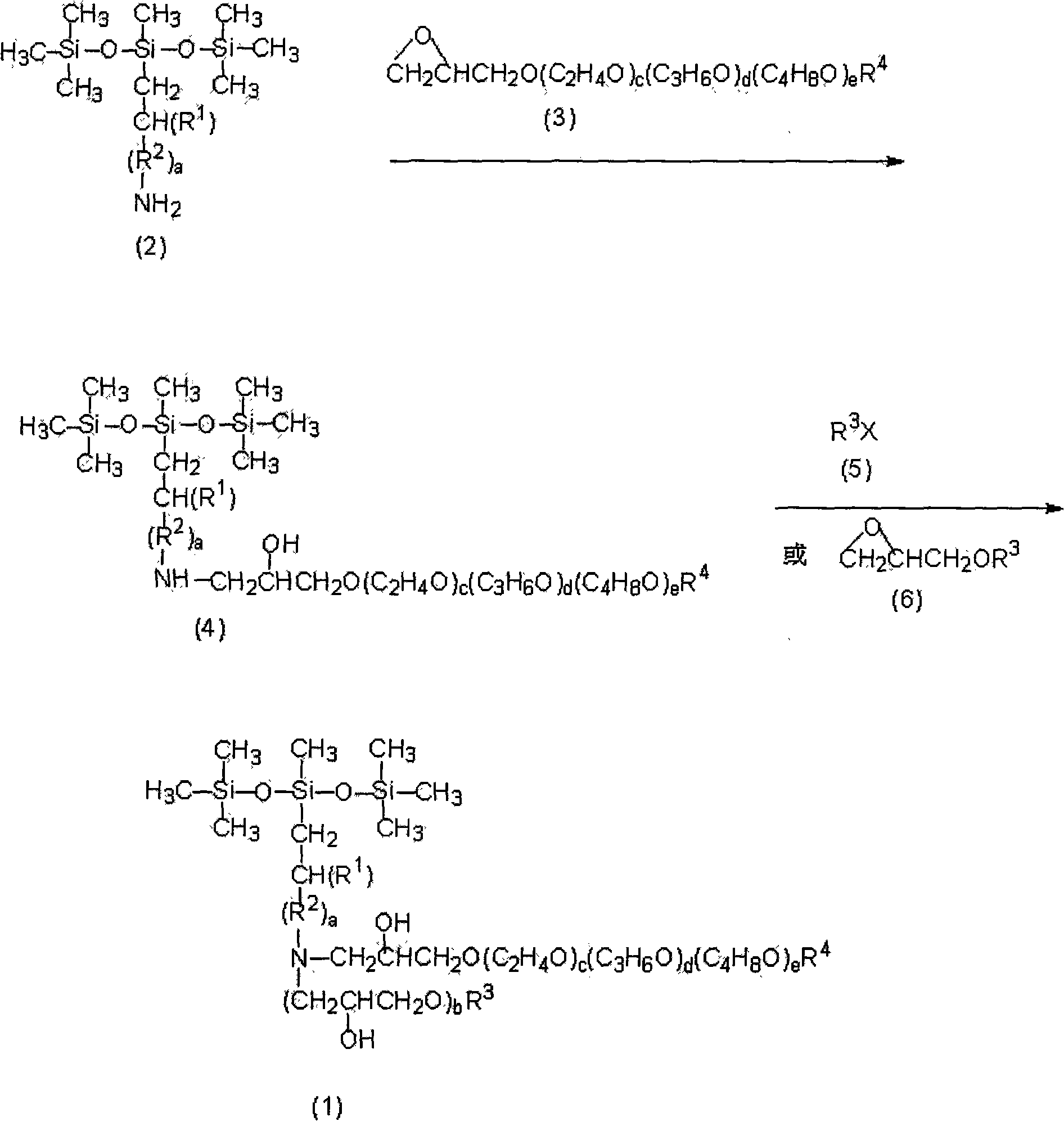

Hydrolyzation resistant double-tail trisiloxane surfactant

InactiveCN101318115AFacilitate spreadingOvercoming performance deficienciesBiocideTransportation and packagingSiloxanePESTICIDE ADJUVANTS

The invention discloses a double-tail tri-siloxane surfactant as shown in the formula (1); wherein, the R<1> is hydrogen or methyl; R<2> is the alkylene with 1-6 carbon atoms; a and b are 0 or 1; R<3> is the alkyl with 1-20 carbon atoms; R<4> is hydrogen, the alkyl with 1-6 carbon atoms, or acetyl; c, d and e are 0 or positive numbers meeting the conditions that c+d+e is not less than 3 and not more than 30 and c is not less than 3. The double-tail tri-siloxane surfactant of the invention has the advantages of remarkably reducing the surface tension of aqueous solution and having stronger hydrolysis resistant performance and spreading performance on low-energy hydrophobic surface, which is suitable for pesticide adjuvant.

Owner:HUIZHOU UNIV

Long basalt fiber reinforced PA6 composite material and melt impregnation preparation method thereof

ActiveCN105694444AOvercoming performance deficienciesImprove mechanical propertiesTemperature controlPolymer science

The invention belongs to the field of composite materials, and in particular relates to a long basalt fiber reinforced PA6 composite material and a melt impregnation preparation method thereof. The composite material is prepared from the following raw materials by weight percent: 15 to 50 percent of long basalt fibers, 48 to 80 percent of PA6 master batch and 2 to 5 percent of processing additive; and the processing additive is a silane coupling agent. Compared with the prior art, the melt impregnation preparation method of the long basalt fiber reinforced PA6 composite material realizes sufficient impregnation of the resin to the fibers by virtue of a concave-convex wheel structure of an impregnation roll and can realize the precise control to the melt temperature by combining a temperature control device of an impregnation mold. According to the long basalt fiber reinforced PA6 composite material prepared by the method, the fibers and a resin matrix are closely combined, and the mechanical performance and the friction abrasion performance are excellent, so that the performance deficiency of the PA6 matrix can be solved, the reinforcing effect and the cost performance advantages of the basalt fibers can be sufficiently realized, the processing method is simple, and the industrialized application prospect is wide.

Owner:ZHONGBEI UNIV

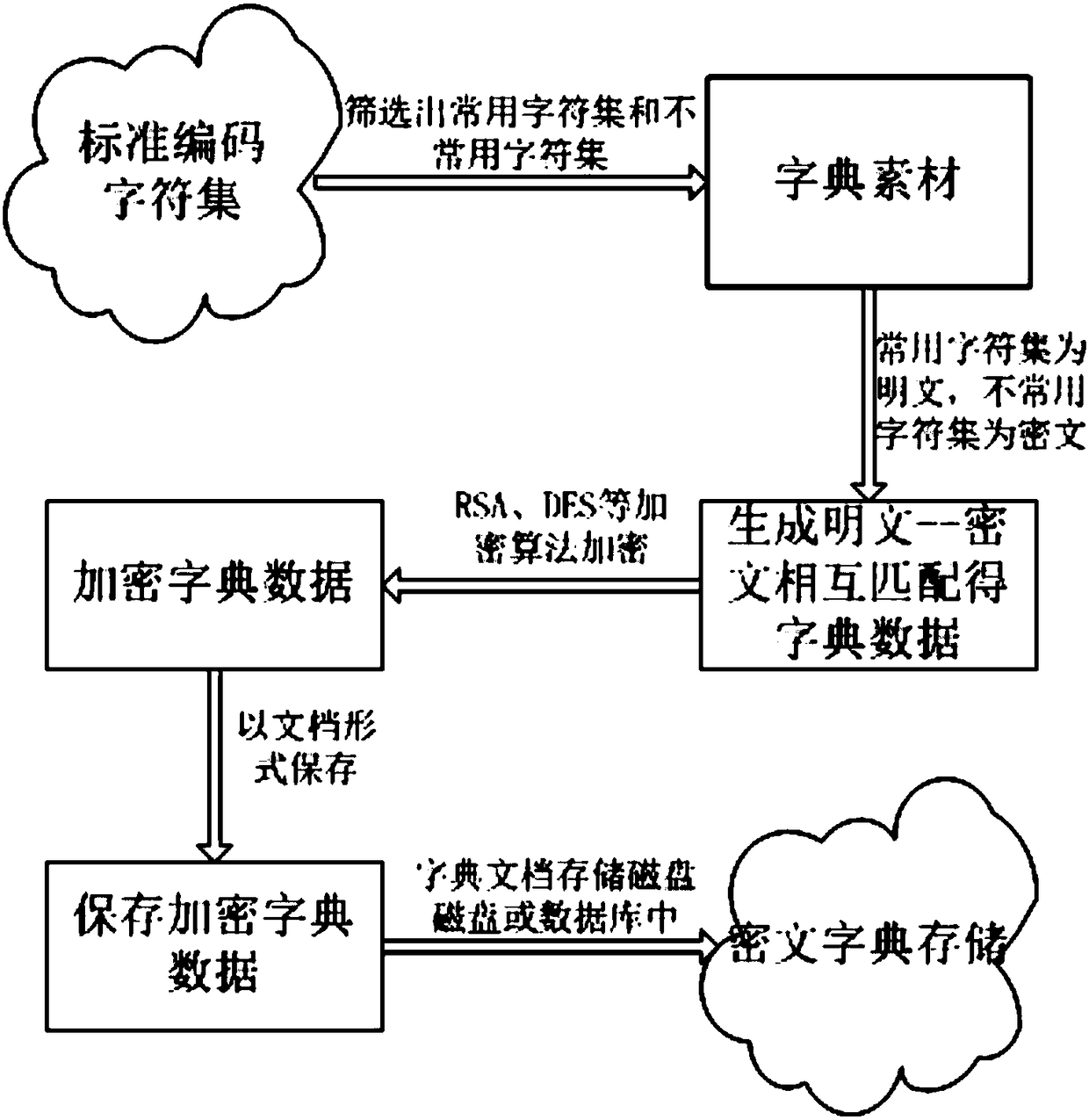

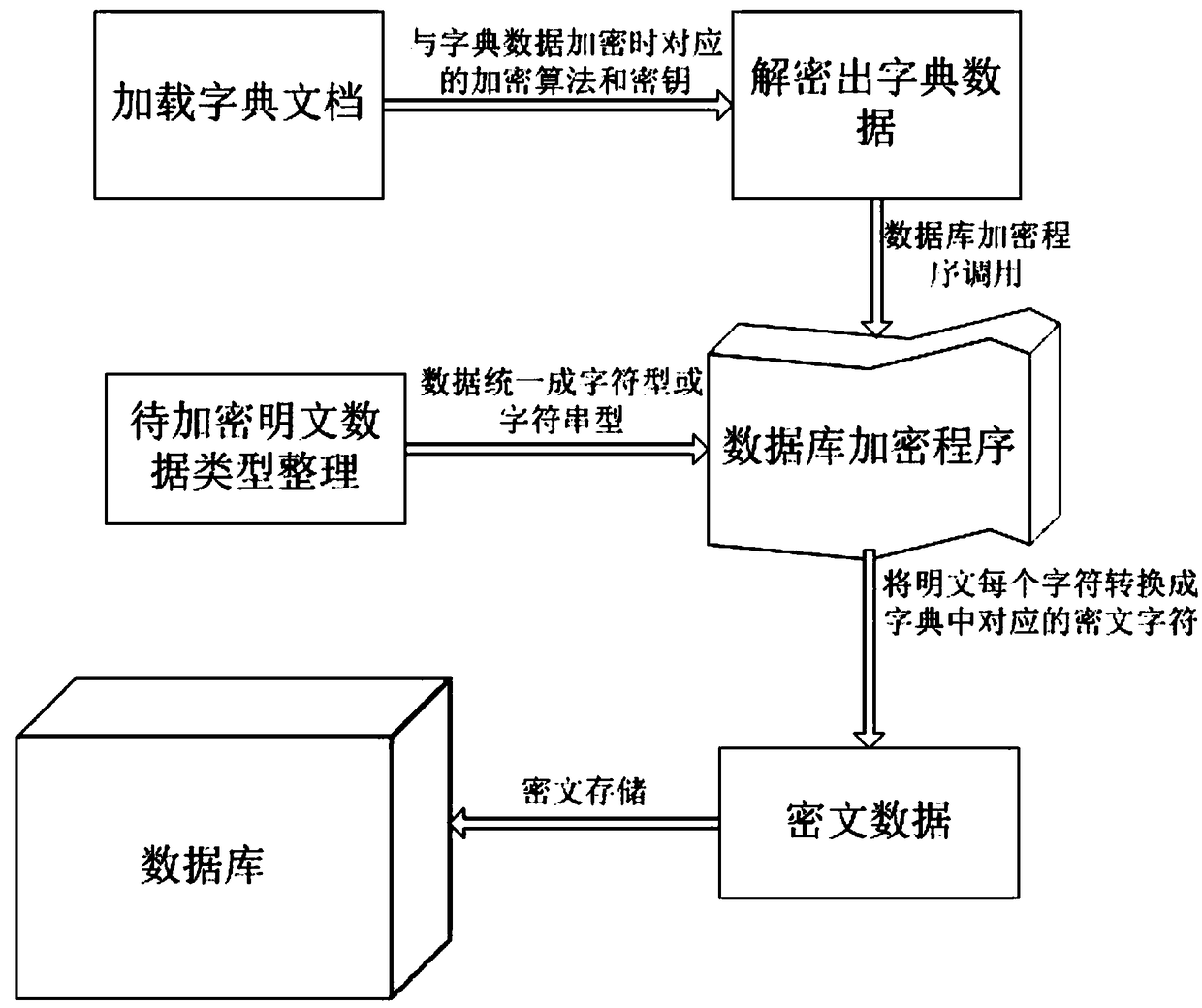

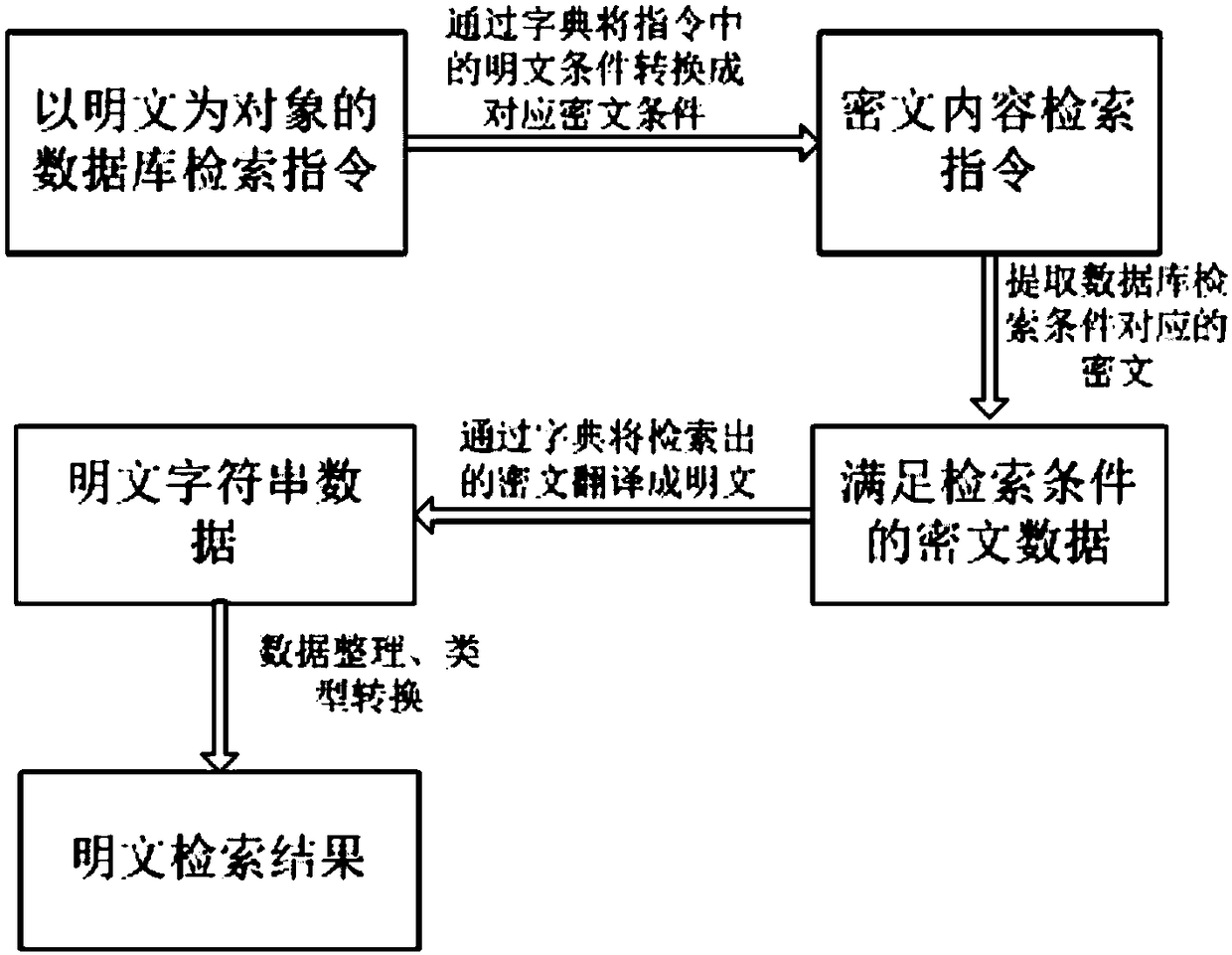

Efficient database encryption method based on dictionary mapping

ActiveCN108734024AIncrease the difficultyImprove securityEncryption apparatus with shift registers/memoriesPublic key for secure communicationGeneration processCiphertext

The invention discloses an efficient database encryption method based on dictionary mapping. The method comprises at least a dictionary generation process, a dictionary encryption and storage process,a dictionary calling and decryption process, a ciphertext data generation and storage process, a ciphertext search process, a dictionary update process, and a double-dictionary running process. The efficient database encryption method based on dictionary mapping effectively prevents data information from disclosing after a database is invaded, and makes data break and breach much harder at the cost of small system performance.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Water-based wooden toy paint

InactiveCN102093795AEasy to dryGood weather resistancePolyurea/polyurethane coatingsWater basedToxic material

The invention relates to a water-based wooden toy paint, which is prepared by mixing and stirring the following raw materials in percentage by mass: 30 to 40 percent of waterborne acrylic emulsion, 15 to 25 percent of waterborne polyurethane dispersion, 3 to 5 percent of functional resin, 1 to 2 percent of film forming aid, 0.2 to 0.4 percent of wetting agent, 0 to 0.2 percent of leveling agent, 0.01 to 0.02 percent of preservative, 10 to 45 percent of pigment, 0 to 15 percent of water-based color paste, 0.5 to 1 percent of thickening agent and the balance of deionized water. The invention has the advantages that: the water-based wooden toy paint does not contain heavy metals and other toxic substances, meets the toy safety standard, cannot harm the health of children, and also has the characteristics of high drying speed, high film hardness, fullness, wear resistance, water resistance, after tackiness resistance and the like.

Owner:FUZHOU DEXIAN CHEM CO LTD

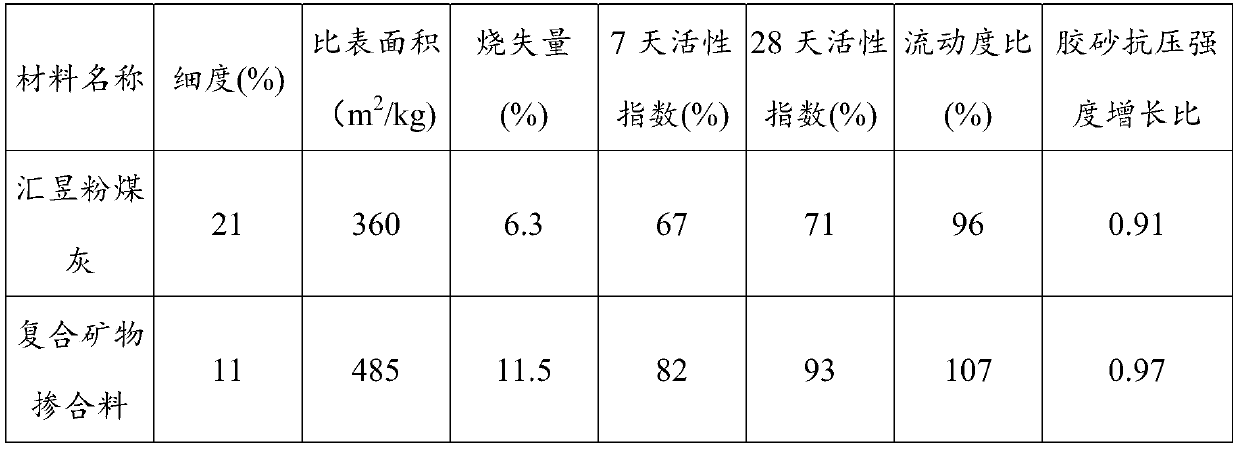

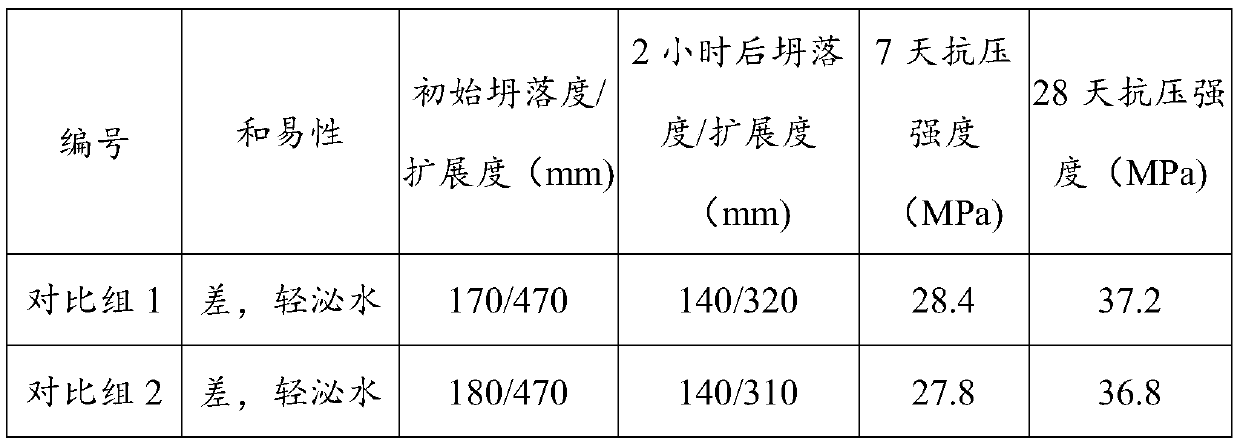

Composite mineral admixture, preparation method thereof and artificial sand concrete material containing composite mineral admixture

The invention relates to a composite mineral admixture, a preparation method thereof and an artificial sand concrete material containing the composite mineral admixture. Grinding raw materials: limestone powder, volcanic ash and granulated blast furnace slag are conveyed into a ball mill in proportion; a composite grinding aid accounting for 0.1-0.2% of the total mass of the grinding raw materialsis added at the same time; the mixture is grinded until the screen residue of a 0.045 mm sieve is less than or equal to 12%, and the specific surface area is controlled to be 450-500 m<2> / kg, therebyobtaining the composite mineral admixture. Limestone powder, natural volcanic ash and blast furnace slag are used as raw materials, a proper composite grinding aid is doped, the performance of the artificial sand concrete can be effectively improved, and the production cost is reduced.

Owner:广州市圣丰混凝土有限公司

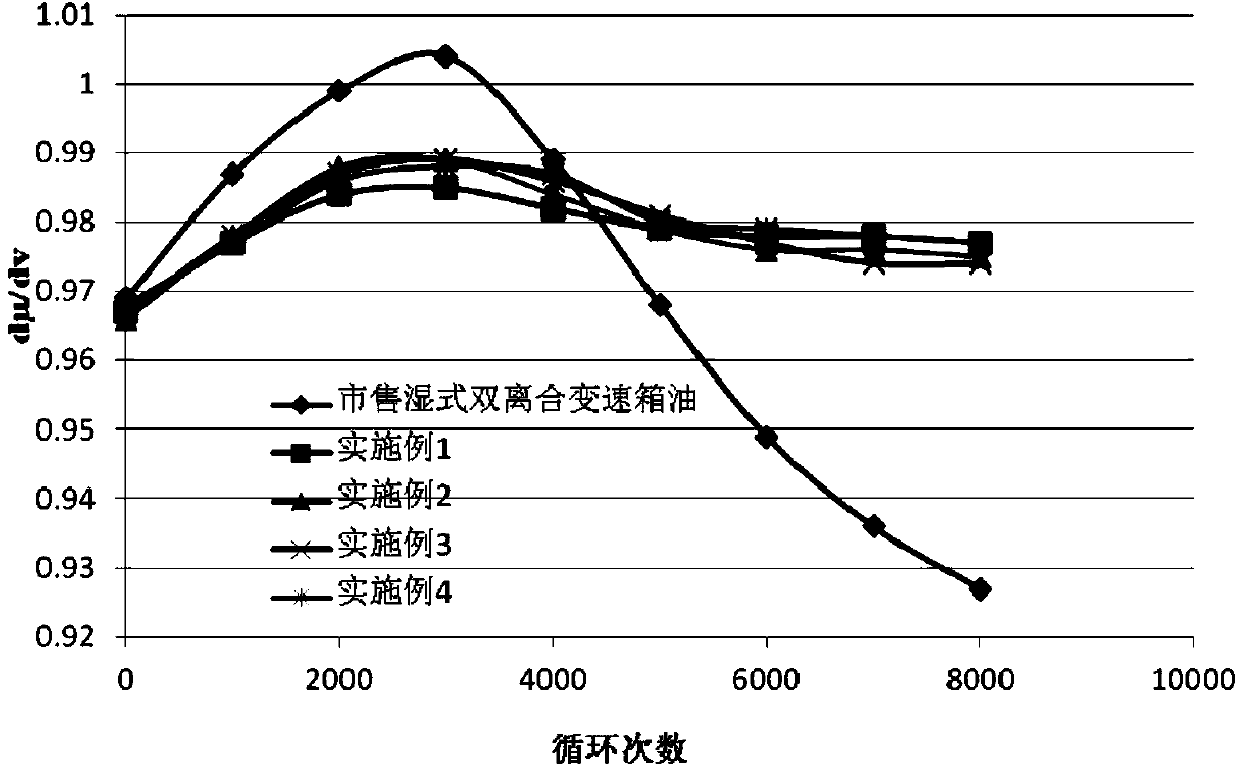

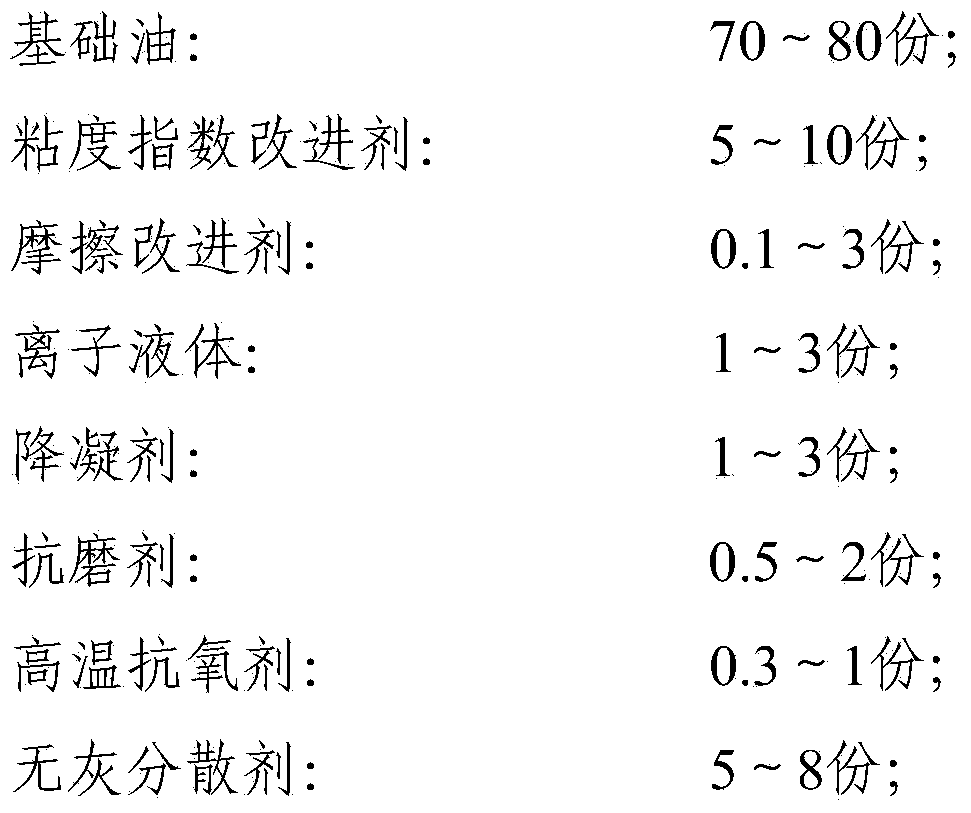

Composition for double clutch gearbox oil, use of composition and lubricating oil comprising composition

InactiveCN104194881AGood low temperatureImprove friction characteristicsAdditivesMarketed productsViscosity index

The invention relates to a composition for double clutch gearbox oil. The composition comprises the following components in parts by mass: 0.5-15 parts of viscosity index improver, 0.05-10 parts of friction improver and 0.1-10 parts of ionic liquid. The invention further relates to use of the composition and wet type double clutch gearbox lubricating oil comprising the composition. The composition provided by the invention can satisfy the lubricating requirements of clutches, a synchronizer, a gear and a bearing in a wet type double clutch gearbox, and thus can be used for the wet type double clutch gearbox lubricating oil. The lubricating oil has excellent low temperature performance, frictional characteristic, performance of the synchronizer and rust and corrosion resistance. Compared with similar marketed products, the lubricating oil added with the composition has a remarkable advantage in wearing endurance and is simple in ingredients and simple and convenient in manufacturing process.

Owner:CHINA PETROLEUM & CHEM CORP

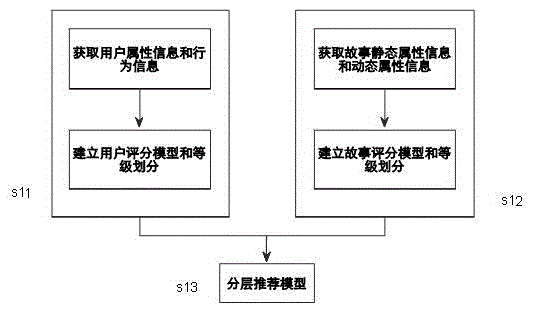

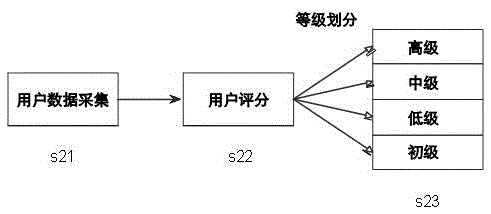

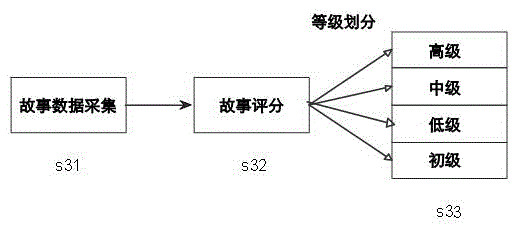

Method and device for story screening and accurate presentation

InactiveCN106815216AMaintain stabilityMaintenance activitySpecial data processing applicationsRecommendation modelComputer science

The invention provides a method and a device for story screening and accurate presentation. The method for story screening and presentation comprises: establishing a user scoring model and a grading mechanism, according to user attribute and behavior information, grading the users and dividing corresponding user classes; establishing a story scoring model and a grading mechanism, according to story attribute and user operation information, scoring stories and dividing corresponding story classes; and establishing a hierarchical recommendation model, establishing different recommendation system models for users and stories in different hierarchies, used to realize high-quality story screening and accurate presentation.

Owner:北京云莱坞文化传媒有限公司

Compound type epoxy curing agent applied to heavy anti-corrosion coating and preparation method

ActiveCN106995527AImprove performanceOvercoming performance deficienciesAnti-corrosive paintsEpoxy resin coatingsChemistryPhenolic amine

The invention discloses a compound type epoxy curing agent applied to heavy anti-corrosion coating. The compound type epoxy curing agent is prepared from modified aromatic amine and modified phenolic amine, and the weight ratio of the modified aromatic amine to the modified phenolic amine is 1 to (1 to 3). According to the compound type epoxy curing agent disclosed by the invention, the modified aromatic amine and the modified phenolic amine are prepared through preferred schemes, and then the compound type curing agent with excellent comprehensive performance can be compounded and obtained through preferred proportion. Experiment results show that the modified aromatic amine and the modified phenolic amine can be mixed and dissolved with each other, can be matched with each other and have stable character. The compound type epoxy curing agent disclosed by the invention overcomes the performance defect of single curing agent and can meet an application requirement of the epoxy heavy anti-corrosion coating. The compound type epoxy curing agent disclosed by the invention can be applied to curing varieties of types of epoxy resin to prepare and obtain coating films, has low viscosity, excellent hardness, impact resistance, adhesion and softness, further has quick surface drying time and further has good chemical corrosion resistance. Compared with the single curing agent and epoxy resin film formation, the compound type epoxy curing agent has more excellent performance and achieves a very good technological effect.

Owner:江苏三木化工股份有限公司 +1

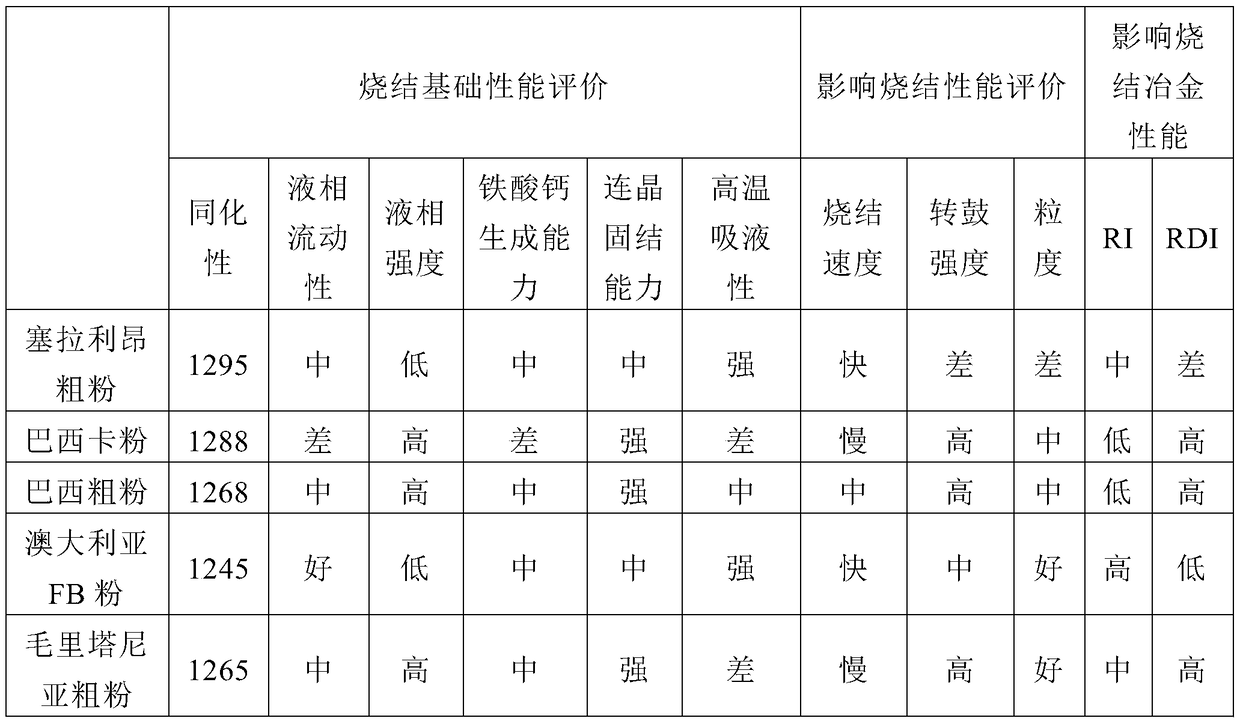

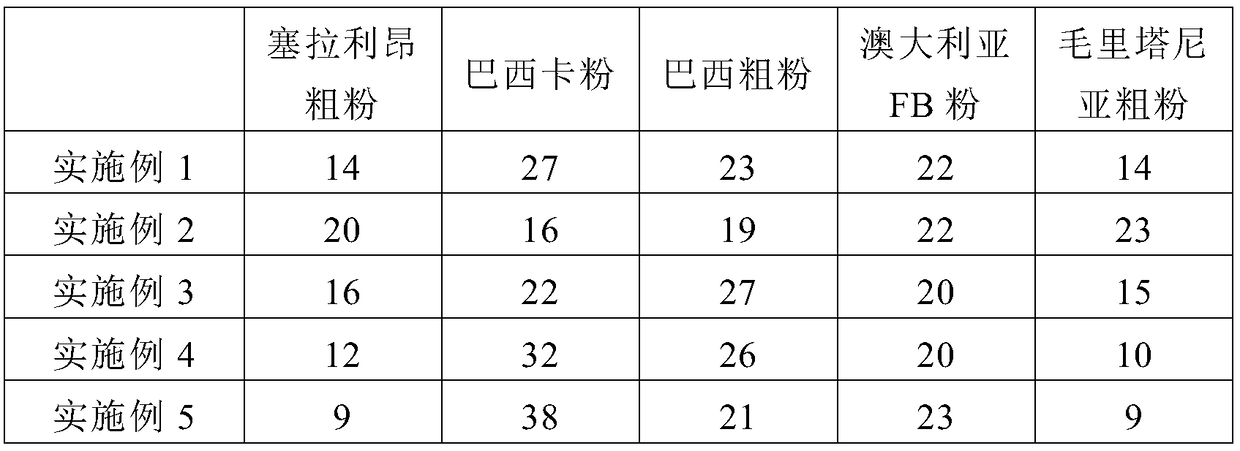

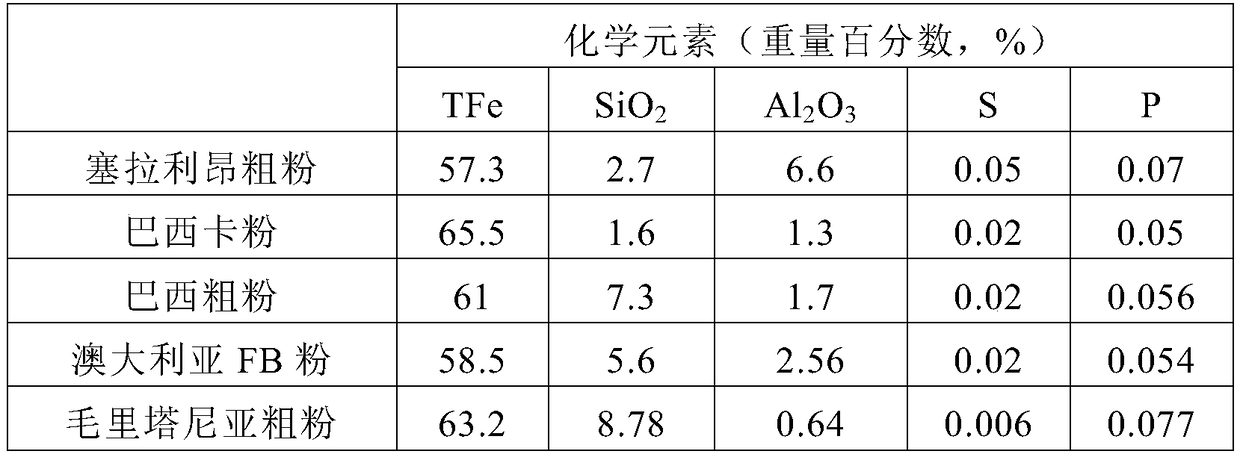

Iron ore well-blended powder with Sierra Leone coarse powder for reducing cost and improving efficiency

The invention discloses an iron ore well-blended powder with Sierra Leone coarse powder for reducing cost and improving efficiency. The iron ore well-blended powder includes, by weight, 8-25% of the Sierra Leone coarse powder, 15-40% of Brazilian Carajas sinter feed, 15-30% of Brazilian coarse iron ore powder, 15-25% of Australian FB powder, and 8-25% of Mauritania coarse powder. In the invention,the Sierra Leone coarse powder is successfully applied to sinter the well-blended ore; by matching proper iron ore, adverse factors, such as high content of Al2O3, high assimilation temperature and low liquid phase strength, of the Sierra Leone coarse powder, are overcome, thus guaranteeing the application effect of the Sierra Leone coarse powder.

Owner:上海慧安科技股份有限公司

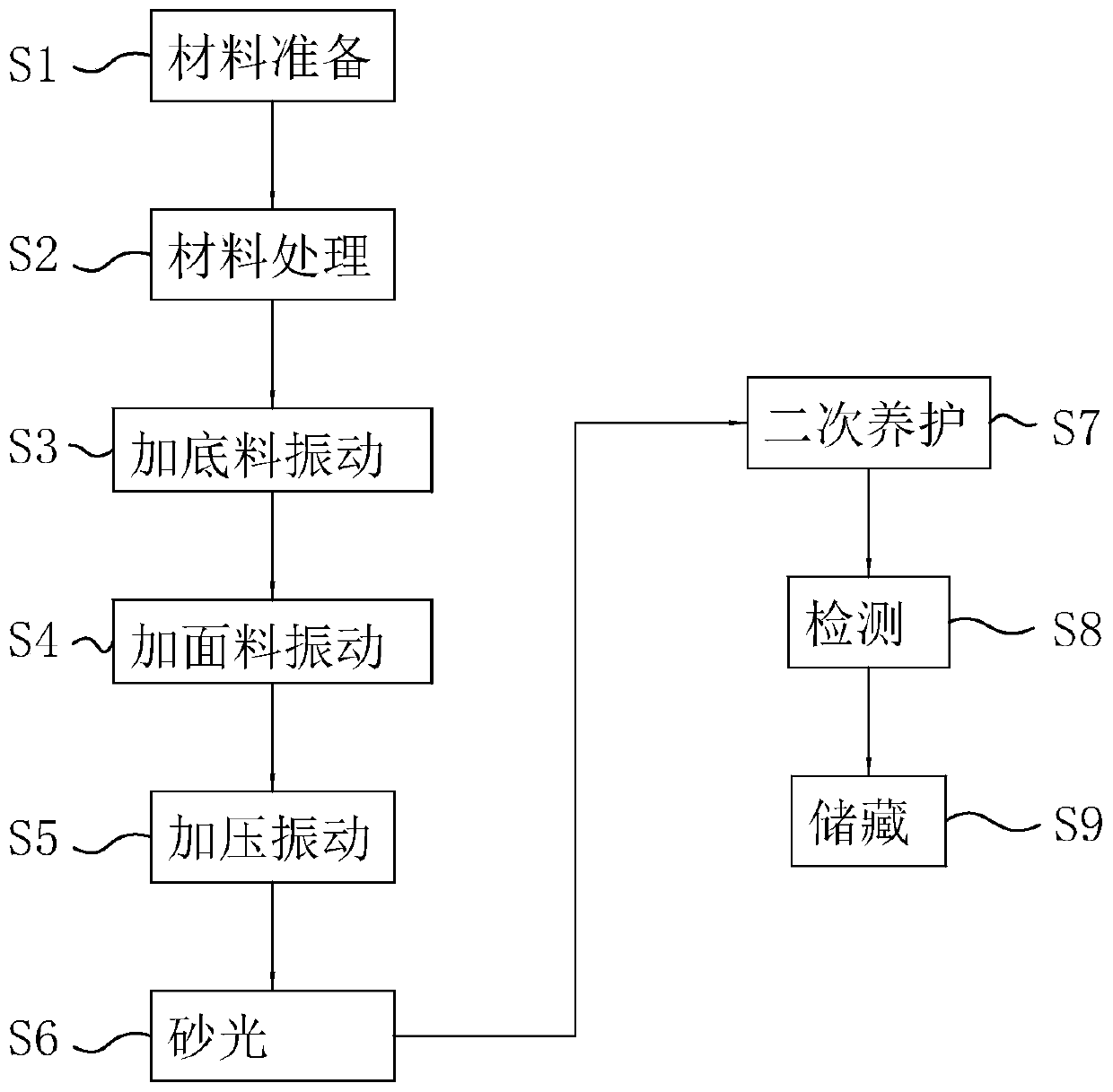

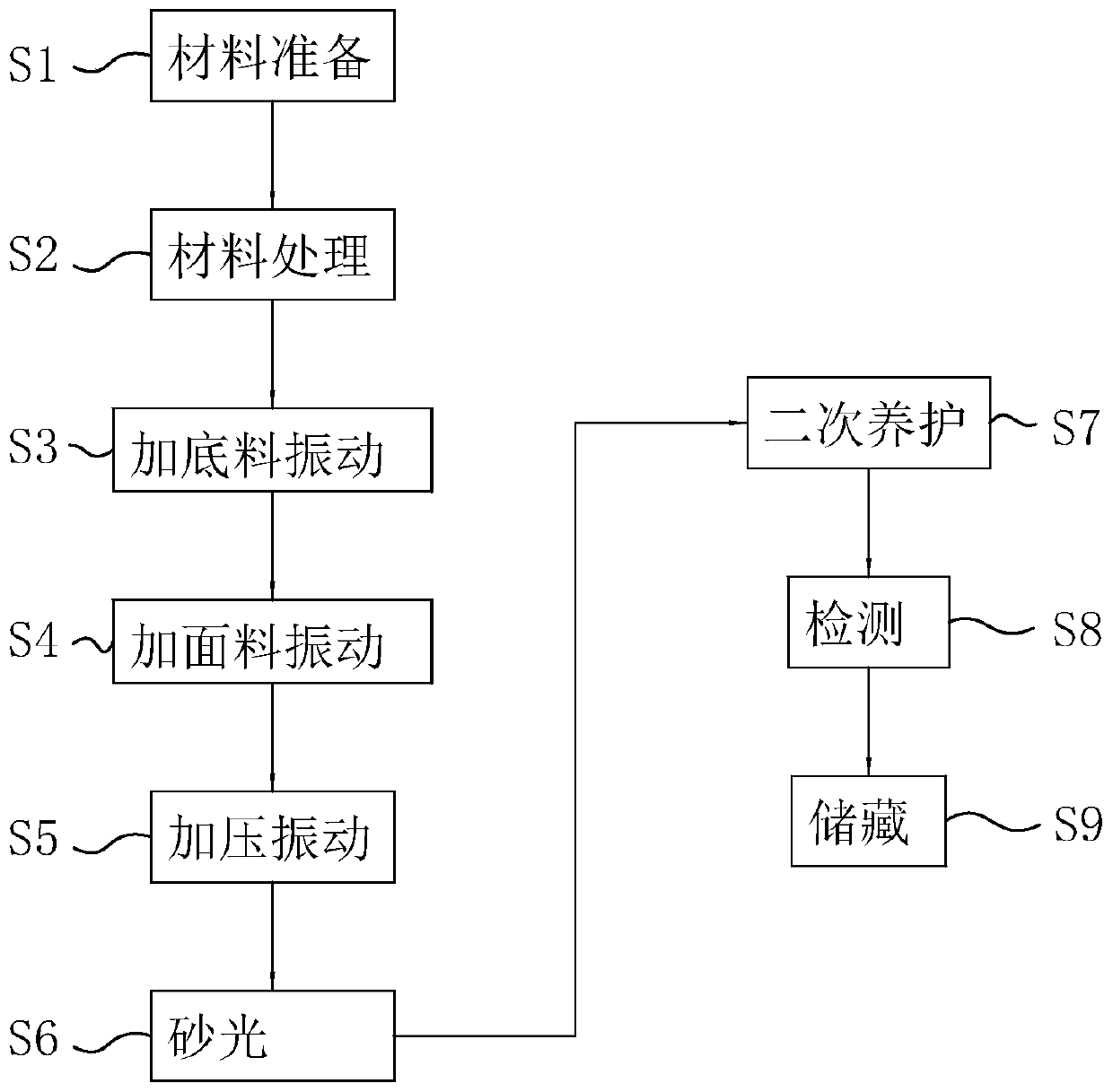

Process for preparing reclaimed concrete pavement bricks

The invention relates to a process for preparing reclaimed concrete pavement bricks. The reclaimed concrete pavement bricks comprise bedding materials and facings and are characterized in that the bedding materials are prepared from the following raw materials in parts by weight: 42-55 parts of construction waste recycled aggregates, 10-15 parts of gravels of 0 to 5mm, 14-20 parts of mixed water granulated slag, 10-15 parts of cement P.C 32.5, 5-8 parts of fly ash, 3-5 parts of gelling agent, 1.5-4.5 parts of water-absorption-swollen inorganics, 0.6%-1.5% of polycarboxylic acid water reducer powder, 0.3% to 0.6% of aminosulfate water reducer powder and 0.2-0.4 part of dispersant. Performance defects of recycled aggregates are effectively eliminated through synergism of the materials and control on humidity, vibration, pressure and the like in a production process; the strength is improved through remolding a crystal structure; and thus, construction wastes are effectively recycled, thecost is reduced, defects of recycled materials are overcome through processes and interaction among the materials, and the pavement bricks with high strength and excellent various properties are prepared.

Owner:深圳绿景环保再生资源有限公司

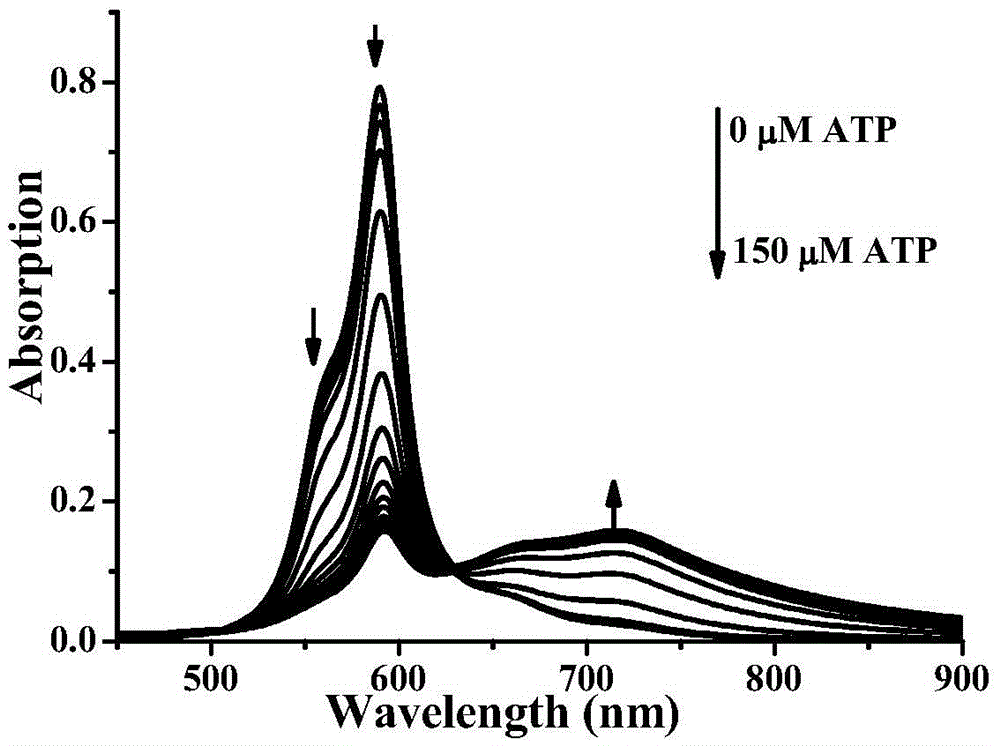

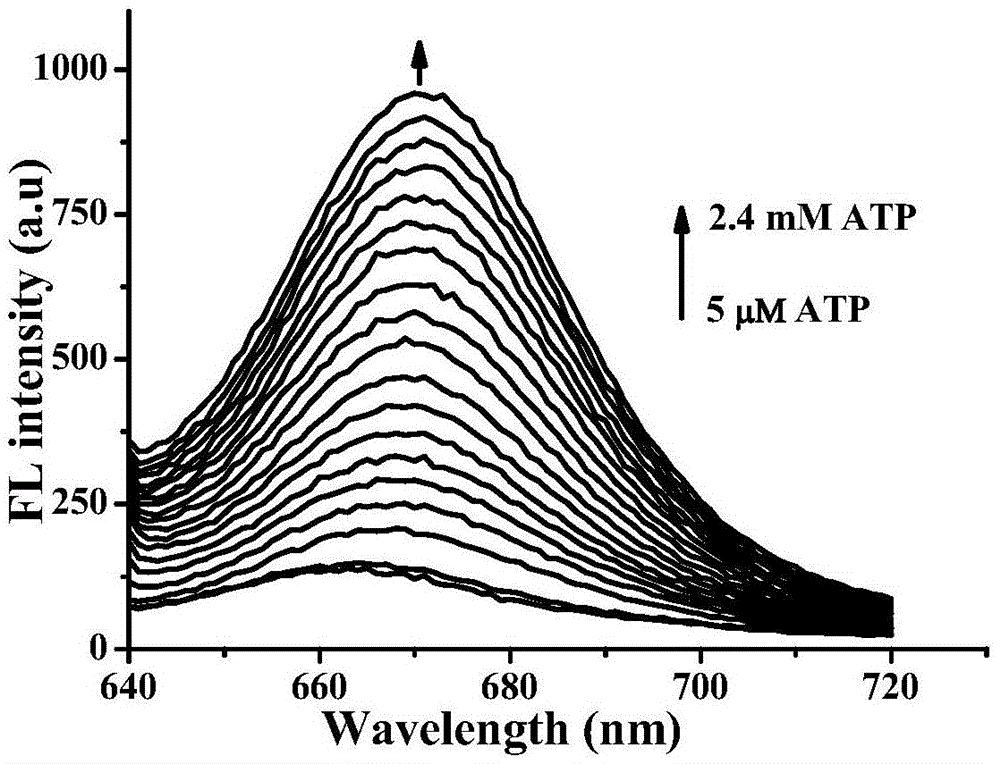

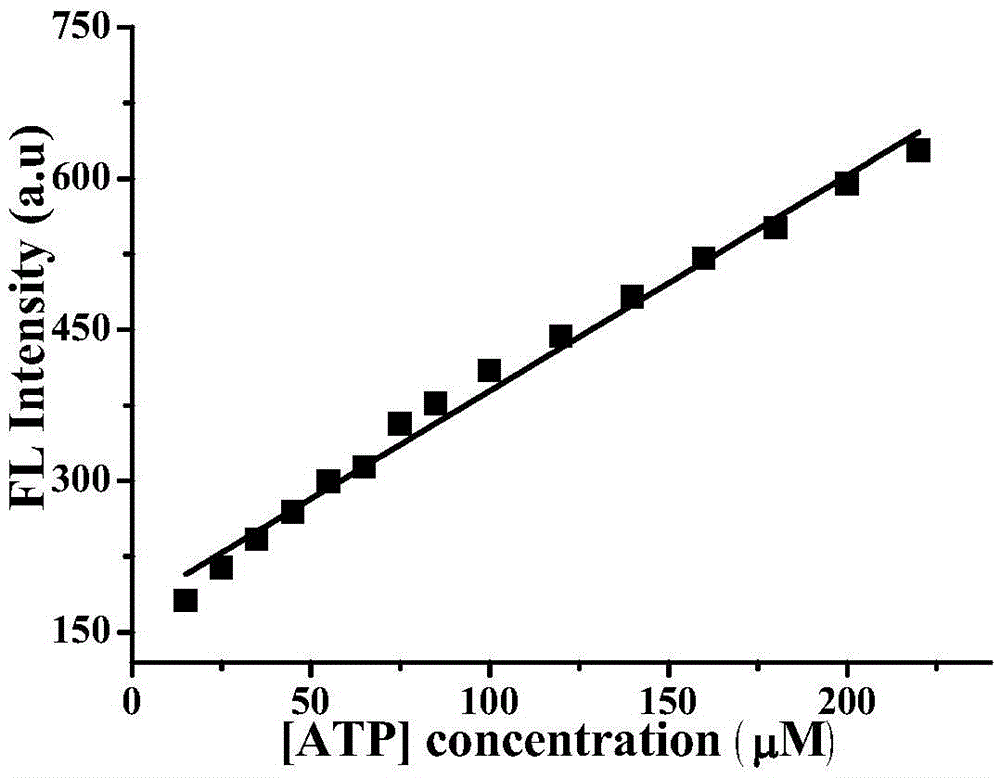

Preparation method of ATP (adenosine triphosphate) near infrared fluorescent probe

ActiveCN105541754AReduce outside distractionsThe synthesis steps are simpleOrganic chemistryFluorescence/phosphorescenceCyanineColumn chromatography

The invention provides a preparation method of an ATP (adenosine triphosphate) near infrared fluorescent probe. The method comprises the following steps of dissolving squarylium cyanine dyestuff into an organic solution to obtain a squarylium cyanine organic solution; dissolving N, N-di(2-aminoethyl)-1,2-quadrol into the organic solution to obtain an N, N-di(2-aminoethyl)-1,2-quadrol organic solution; dripping the squarylium cyanine organic solution into the N, N-di(2-aminoethyl)-1,2-quadrol organic solution; stirring the mixture in room temperature environment; removing the organic solution; performing column chromatography separation and purification to obtain the ATP near infrared fluorescent probe. The near infrared fluorescent probe prepared by the method provided by the invention has the characteristics that the ATP can be fast and sensitively analyzed; the defects of the existing fluorescent probe can be overcome; the ATP is efficiently detected; the synthesis steps are simple; the fluorescent method is used, so that the analysis is fast and convenient; interference is small.

Owner:NORTHWEST A & F UNIV

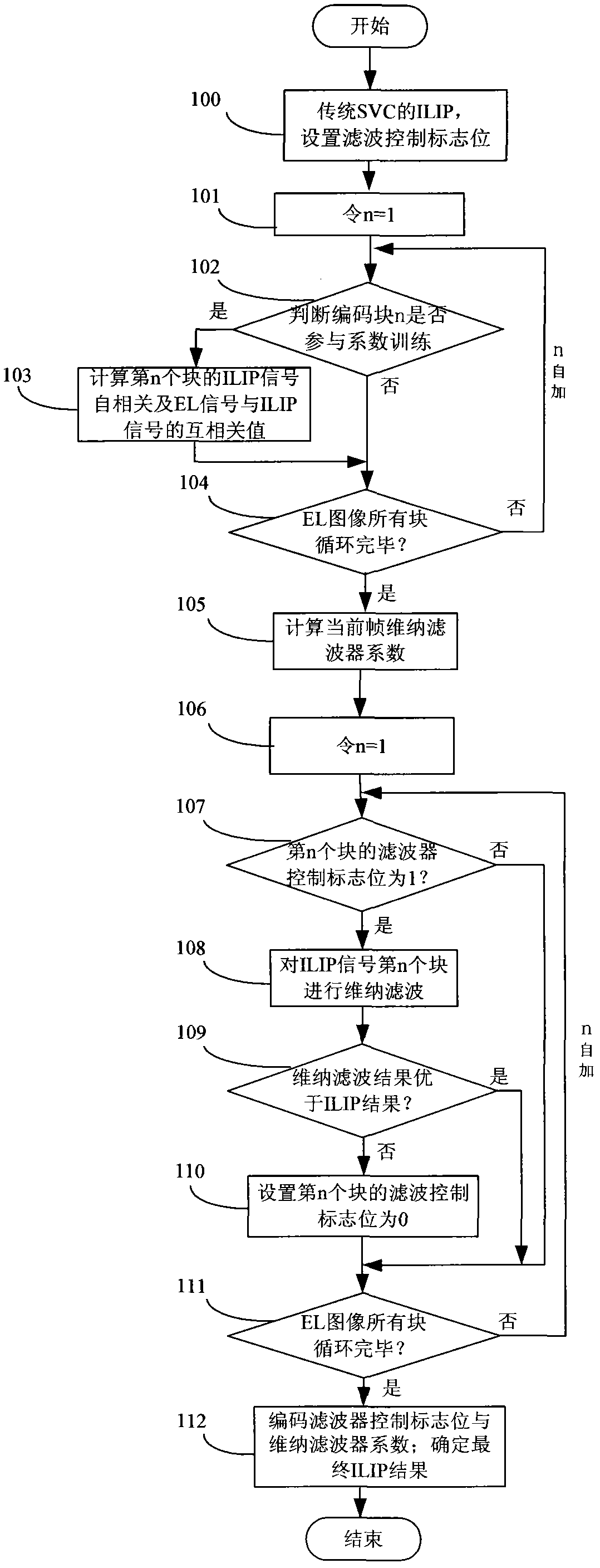

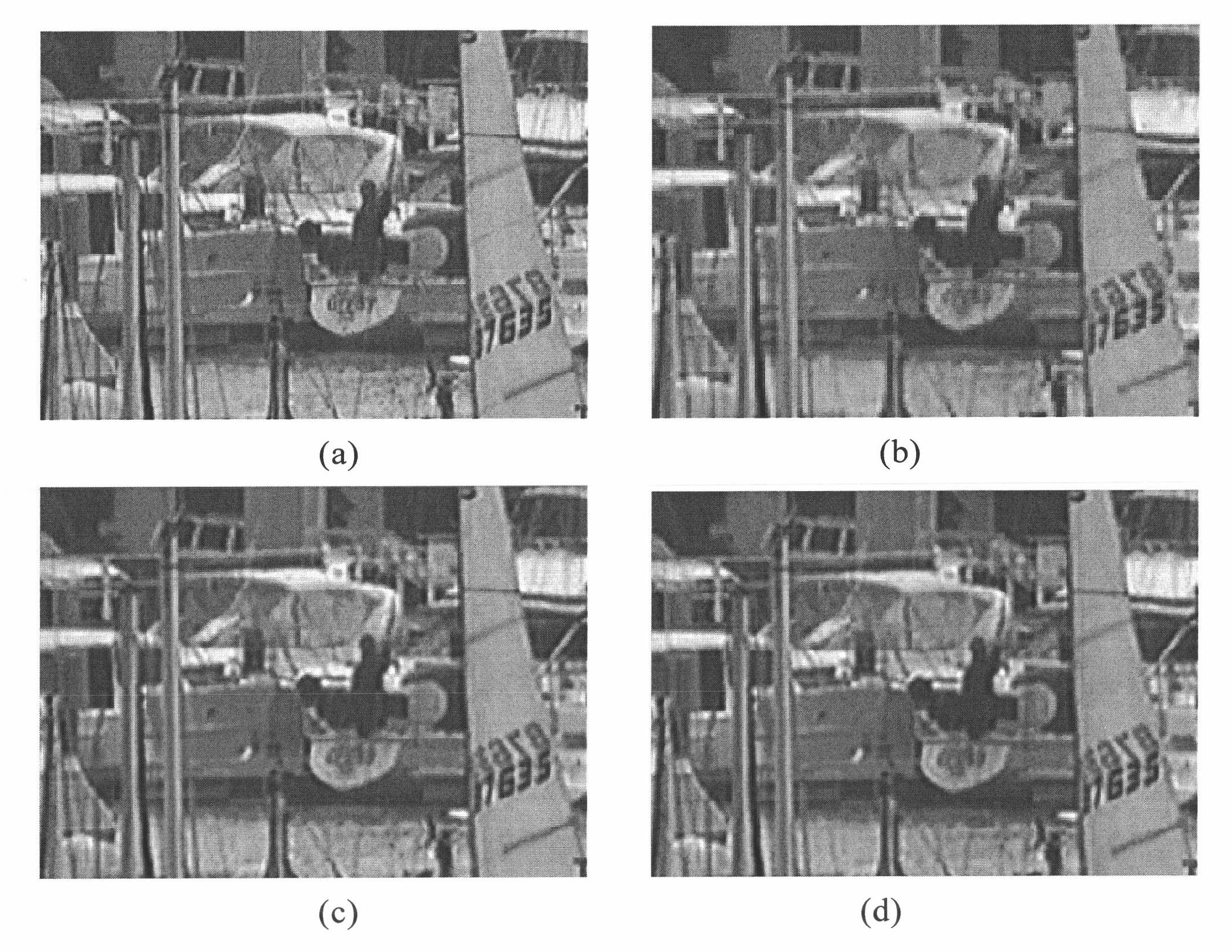

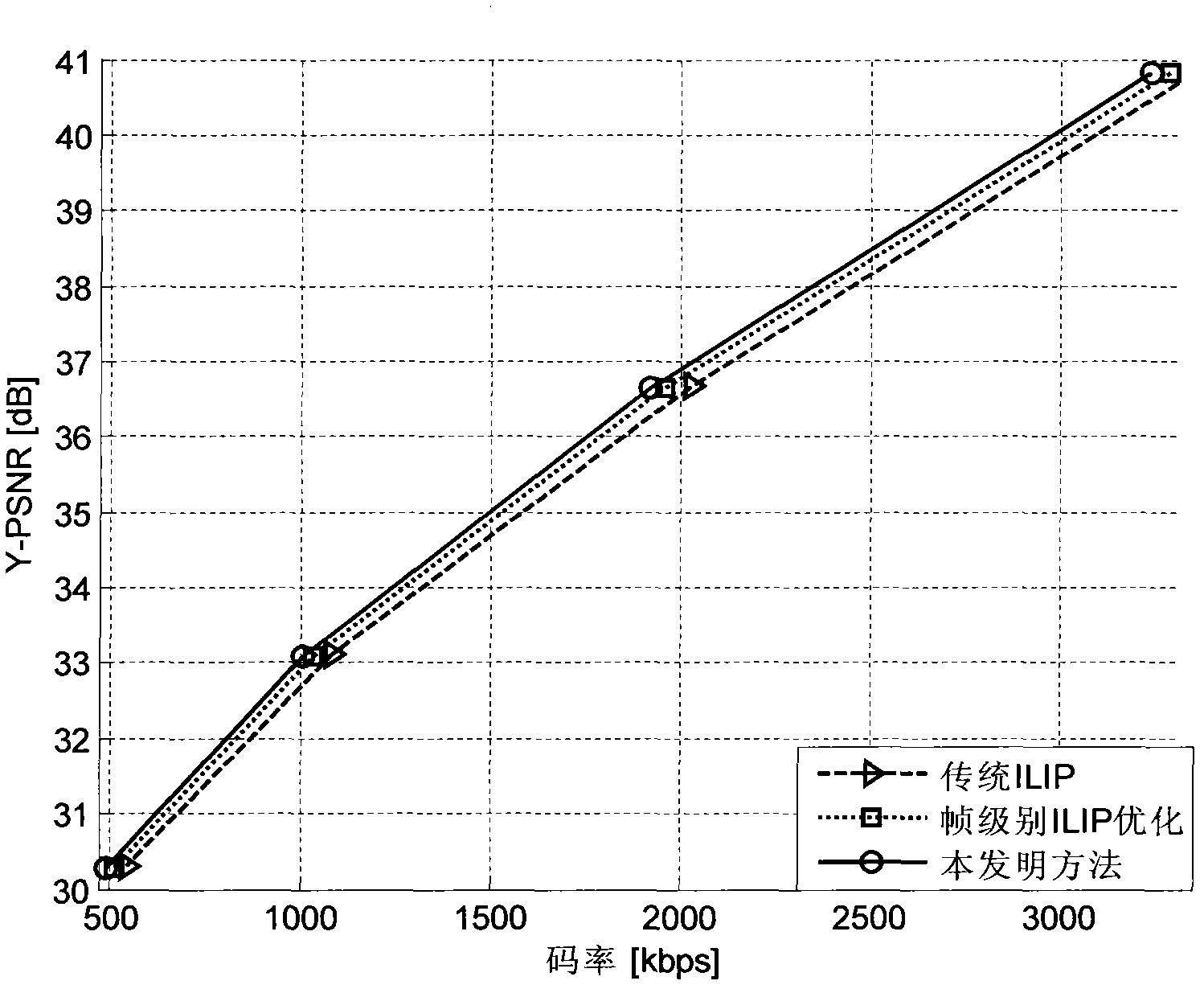

Scalable video encoding (SVC) block-level interlayer intra prediction (ILIP) method

ActiveCN102355583AOvercoming performance deficienciesImprove coding efficiencyTelevision systemsDigital video signal modificationBlock levelVideo encoding

The invention discloses a scalable video encoding (SVC) block-level interlayer intra prediction (ILIP) method, which comprises the following steps of: at a coding end, sequentially calculating the variance of each block in a current coding frame of an enhancement layer (EL), and setting a filter control flag bit according to the variance values; if the flag bit is 1, calculating a self-correlation value among ILIP signals and a cross-correlation value between original EL signals and the ILIP signals; if all blocks in the frame are finished circulating, calculating a Wiener filter coefficient corresponding to the current frame; carrying out filtering operation on an ILIP result of the block, of which the filter control flag bit is 1 in the current coding frame of the EL by using the calculated Wiener filter coefficient, and further, judging whether the filtering should be carried out on the ILIP result of the block or not according to a filter result; and coding the filter control flagbit and the Wiener filter coefficient, then, writing in a header message, and transmitting the header message to a decoding end. With the adoption of the method disclosed by the invention, the accuracy of the ILIP technology can be effectively enhanced, and the coding efficiency of a coder is increased.

Owner:RUNJIAN COMM

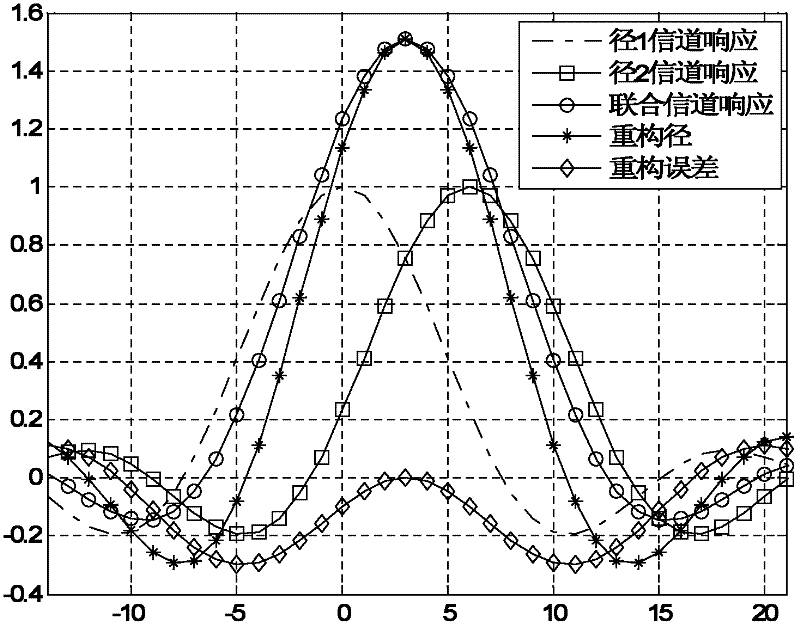

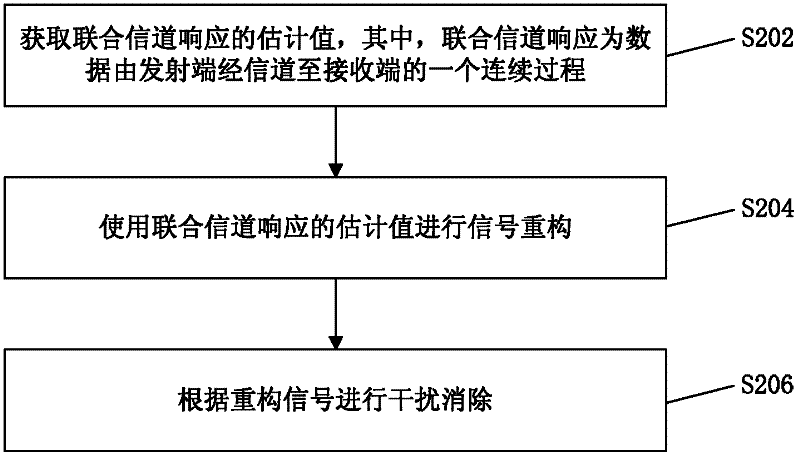

Interference elimination method and device

ActiveCN102340327AOvercoming performance deficienciesReduced search precision requirementsTransmissionElimination methodInterference elimination

The invention discloses an interference elimination method and an interference elimination device. The method comprises the following steps of: acquiring an estimated value of a joint channel response, wherein the joint channel response is a continuous process of transmitting data to a receiver through a channel by a transmitter; performing signal reconstruction by using the estimated value of the joint channel response; and performing interference elimination according to a reconstructed signal. By the technical scheme provided by the invention, the performance shortcomings of a parametrization interference elimination method in the prior art are overcome, the problem of complexity of a required searcher in the prior art is solved, and the requirements of a system on searching accuracy are reduced.

Owner:如东县东广物流有限公司

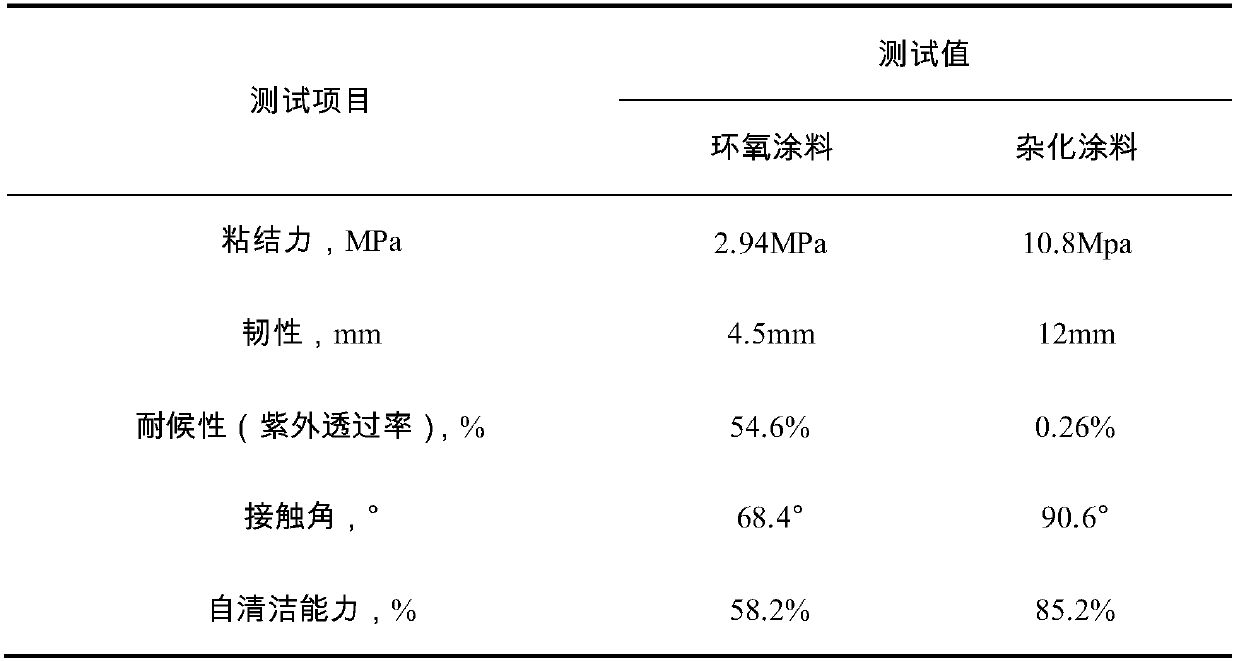

Method for producing hybrid material on the basis of Si/Ti composite sol modified epoxy resin

InactiveCN109535652AImprove featuresImprove stabilityAnti-corrosive paintsEpoxy resin coatingsEpoxyNanoscopic scale

A method for producing a hybrid material on the basis of Si / Ti composite sol modified epoxy resin includes: 1) performing co-hydrolysis on a silane coupling agent with a functional group, tetraethoxysilane and tetrabutyl titanate to prepare Si / Ti composite sol; 2) performing a reaction on the Si / Ti composite sol and epoxy resin with a curing agent to prepare the epoxy / Si / Ti organic-inorganic hybrid material. Herein, the sol and the epoxy group are bonded through chemical bonds, thus forming the epoxy / Si / Ti organic-inorganic hybrid material having great performance. The hybrid material, as a composite coating, has the advantages of both organic resin and inorganic materials, so that combination between the organic high-polymer and the inorganic phase on nano-scale is achieved and strong interfacial interaction between the two phases is achieved, which manifest as by adding a less amount of the composite sol, the toughness and anti-aging effect of epoxy resin and binding strength with metal are all improved greatly.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of organic-inorganic lithium ion battery diaphragm

InactiveCN110379982AImprove temperature resistanceImprove securitySecondary cellsCell component detailsClay mineralsCeramic coating

The invention discloses a preparation method of an organic-inorganic lithium ion battery diaphragm, and belongs to the technical field of lithium batteries. The method comprises the following steps: polymer raw material preparation, high-temperature melting, extrusion casting, longitudinal and transverse stretching extraction pore-forming, heat setting, ceramic slurry coating, heat setting, cutting, rolling and inspection. Organic clay minerals and inorganic ceramic oxide are combined to form the organic-inorganic lithium ion battery diaphragm. The performance defects of commercial polyolefindiaphragms or conventional ceramic coating diaphragms are effectively overcome; on one hand, the temperature resistance of the lithium battery is improved; on the other hand, the electrochemical performance of the lithium ion power battery is improved in the aspects of resisting large-current charging and discharging, and an interface between an electrode and an electrolyte and the like are reduced, so that the safety performance and the rate capability of the lithium ion power battery are improved.

Owner:高芳

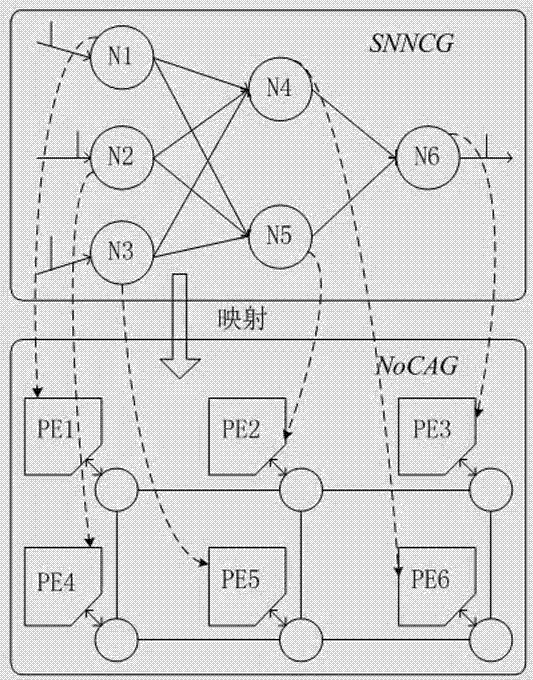

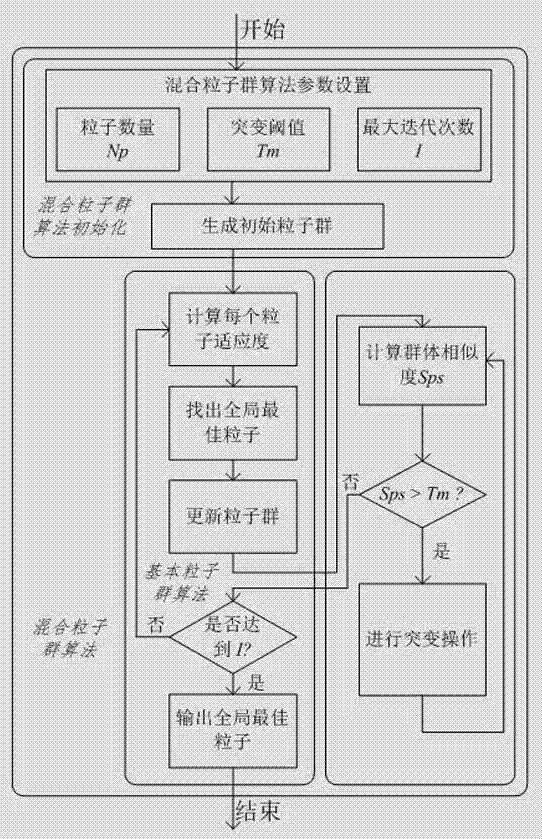

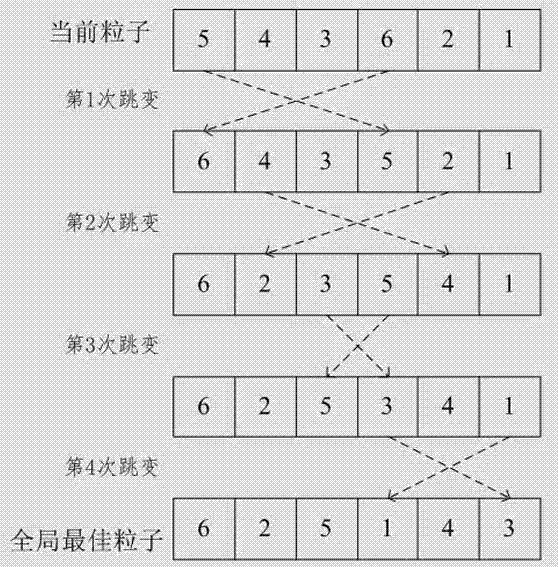

Hybrid particle swarm pulse neural network mapping method for power consumption

InactiveCN107169561AOvercoming performance deficienciesUse search capabilitiesNeural architecturesGenetic algorithmsLocal optimumNODAL

The invention discloses a hybrid particle swarm pulse neural network mapping method for power consumption. On the basis of a neuron node mapping way with combination of a particle swarm algorithm and a genetic algorithm, an optimal mapping result of mapping of a neuron node to a hardware system is obtained. The mapping method employs the particle swarm algorithm; the mutation operation of the genetic algorithm is combined during the particle swarm algorithm operation process and thus the basic particle swarm algorithm is improved; and the algorithm is circulated until a terminal condition is met. Therefore, defects of performances of the basic particle swarm algorithm can be overcome and the original searching capability of the particle swarm algorithm is utilized completely; a defect that the basic particle swarm algorithm is convergent too early and thus is easy to fall into local optimal node can be overcome; and thus the algorithm can search a global optimal solution. And thus the power consumption of the system can be reduced and the applicability of the mapping plan can be enhanced.

Owner:GUANGXI NORMAL UNIV

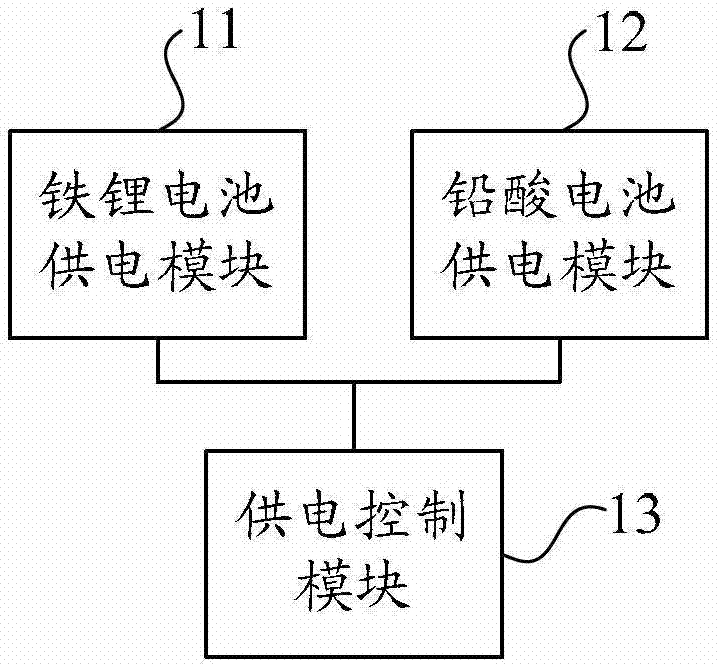

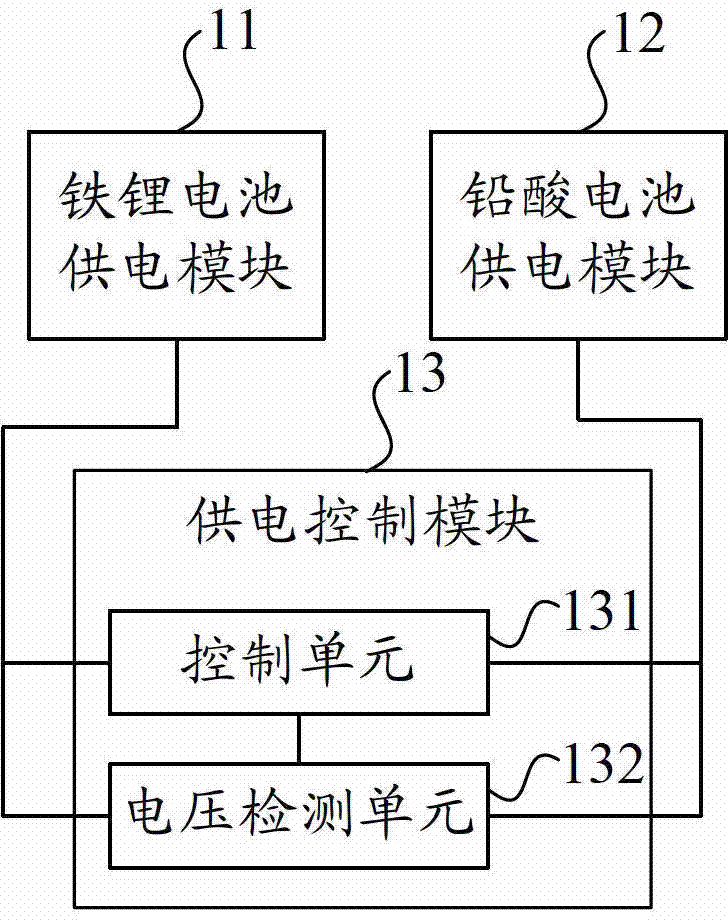

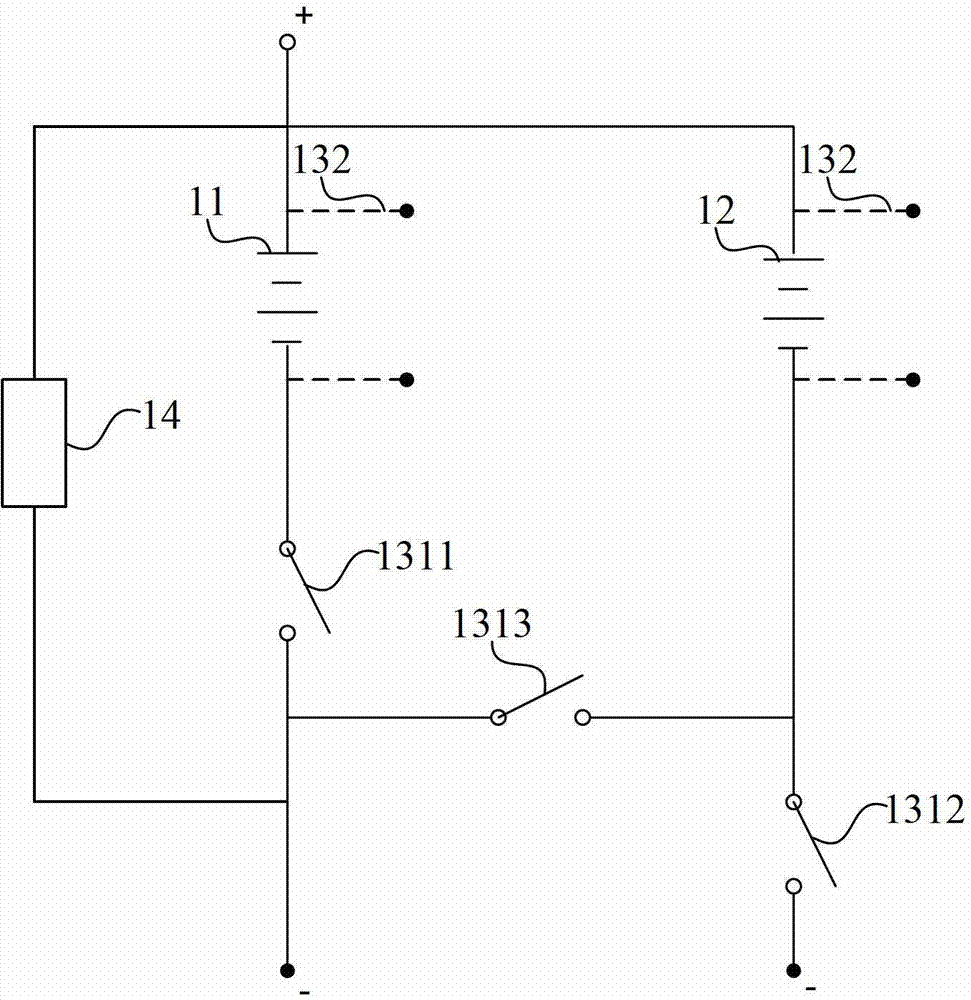

Composite power supply method and device

ActiveCN103036299AOvercoming performance deficienciesImprove power supply efficiencyEnd cell switching arrangementsEngineeringPower unit

The embodiment of the invention provides a composite power supply method and a device. The composite power supply device comprises an iron lithium cell power supply module, a lead-acid cell power supply module and a power supply control module. The iron lithium cell power supply module is used for providing power for a load under the control of the power supply control module. The lead-acid cell power supply module is used for providing power for the load under the control of the power supply control module. The power supply control module is used for controlling the iron lithium cell power supply module to provide power for the load or controlling the iron lithium cell power supply module and the lead-acid cell power supply module to be connected in parallel to provide power for the load according to a power supply scene. According to the technical scheme, excellent properties of the iron lithium cell power supply module and the lead-acid cell power supply module can be fully used according to the power supply scene, performance deficiencies of the iron lithium cell power supply module and the lead-acid cell power supply module can be avoided, and therefore power supply efficiency of a power unit is improved, and cost is reduced.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

Bone tissue repairing material and its preparation method

InactiveCN100998891AHigh hardnessImprove brittlenessCoatingsProsthesisEpoxyEthylene Oxide Sterilization

A porous bone tissue repairing material with high biocompatibility, degradability, mechanical strength and toughness is prepared from collagen A, strontium polyphosphate (SRPP) and calcium polyphosphate (CPP) through mixing, freeze-drying and sterilizing by epoxy ethane.

Owner:于海鹰

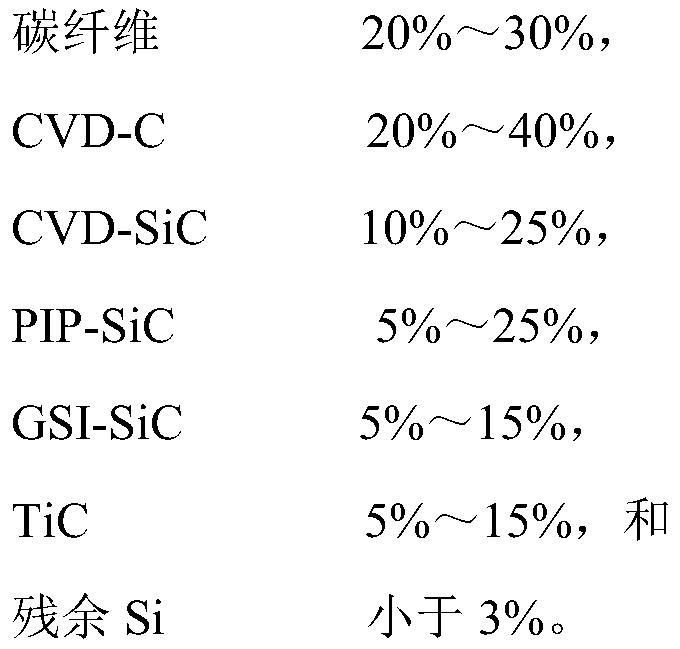

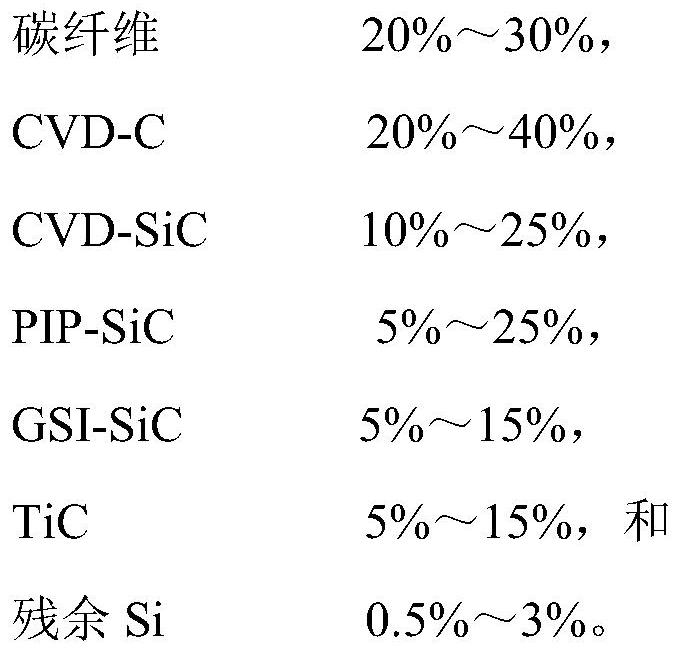

Ceramic-based composite material as well as preparation method and application thereof

ActiveCN112266259AImprove protectionReduce the degree of siliconization damageCarbon fibersWear resistance

The invention discloses a ceramic-based composite material as well as a preparation method and application thereof. The ceramic-based composite material comprises the following components in percentage by mass: 20%-30% of carbon fibers, 20%-40% of C-VDC, 10%-25% of CVD-SiC, 5%-25% of PIP-SiC, 5%-15% of GSI-SiC, 5%-15% of TiC and less than 3% of residual Si. The preparation method sequentially comprises the following steps: deposition of a C layer on a carbon fiber preform; deposition of a SiC layer; impregnation and cracking of a precursor for preparation of SiC; impregnation of asphalt and carbonization; preparation of TiC; and gas-phase siliconizing. The ceramic-based composite material disclosed by the invention has the advantages of excellent friction and wear resistance, mechanical properties and thermal properties, the content of each component can be flexibly designed and adjusted according to actual requirements, and the requirements of the field of high-performance braking andaerospace structural parts on material properties are met.

Owner:中京吉泰(北京)科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com