Composite mineral admixture, preparation method thereof and artificial sand concrete material containing composite mineral admixture

A technology of composite minerals and admixtures, applied in the field of artificial sand concrete materials, can solve the problems of high cost and complex composition, and achieve the effects of improving poor fluidity, large specific surface area, and preventing segregation and bleeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1. Dry the grinding raw materials according to the proportion, that is, limestone powder 40%, volcanic ash 30%, granulated blast furnace slag 30%, and dry them separately, and control the moisture content of the grinding materials below 2%.

[0051] If the moisture content of the grinding material is too high, static electricity will be generated when the steel balls rub against each other, resulting in the phenomenon of "ball wrapping" (commonly known as full grinding), resulting in low output, high power consumption, and abnormal quality of the finished product ( If it is used in concrete, it is prone to rapid setting phenomenon). Generally, the moisture content of limestone powder before drying is 2% to 3%, the moisture content of slag is 8% to 15%, and the moisture content of pozzolan ash is 15% to 20%. Controlling the water content in the mill to ≤2% can improve the grinding efficiency and obtain stable composite mineral admixtures.

[0052] 2, diethanol monoisopr...

Embodiment 2

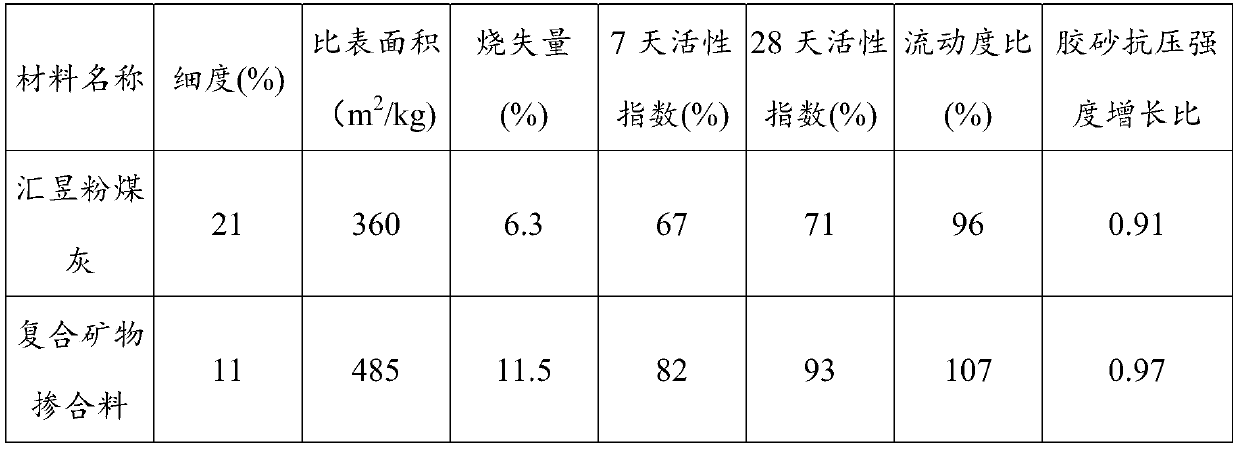

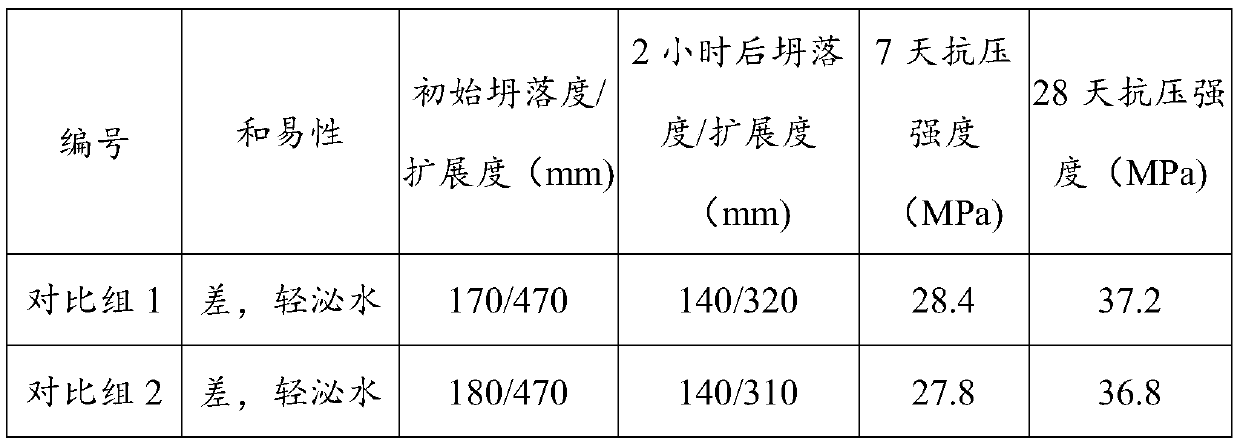

[0059] The composite mineral admixture prepared in Example 1 was used to replace the fly ash in an equivalent amount for concrete trial mix (strength grade C30). The admixture used in comparative groups 1-3 is fly ash, and the admixture used in experimental groups 1-3 is the composite mineral admixture prepared in Example 1. The content of each component of the concrete in this embodiment is shown in Table 2.

[0060] Table 2. Contents of each component of concrete (unit: kg / m 3 )

[0061] Numbering Taiwan Cement Conch Cement Hongfeng Cement artificial sand gravel Admixture water Admixture Comparison group 1 290 / / 702 1052 96 170 8.88 Comparison group 2 / 290 / 702 1052 96 170 8.88 Comparison group 3 / / 290 702 1052 96 170 8.88 Implementation group 1 290 / / 702 1052 96 170 8.88 Implementation group 2 / 290 / 702 1052 96 170 8.88 Implementation group 3 / / 290 702 1052 96 ...

Embodiment 3

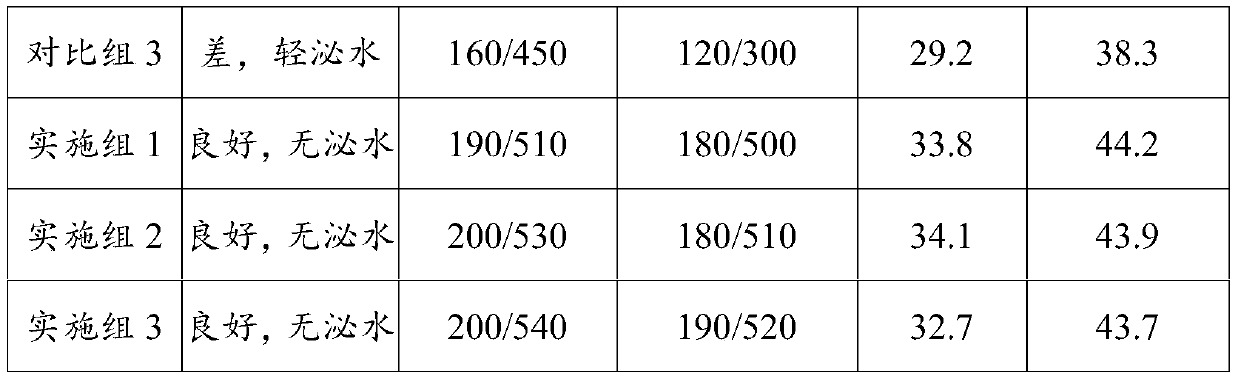

[0067] In this example, the composite mineral admixture of the present invention is used to completely replace fly ash, and replace 5%, 10%, and 15% of cement to prepare concrete with C30 strength grade, and investigate its performance. The cement used in this implementation is P·Ⅱ42.5R cement produced by Taiwan Cement Co., Ltd.

[0068] Table 4. Contents of each component of concrete (unit: kg / m 3 )

[0069]

[0070] The result is as shown in table 5, when only completely replacing fly ash with composite mineral admixture of the present invention, the concrete strength of making can be higher than the concrete strength of using fly ash, along with the increase of replacing cement ratio, concrete strength Reduced, when fly ash and 15% cement are completely replaced, the concrete strength is still close to that of concrete using only fly ash as an admixture. Therefore, the composite mineral admixture of the present invention can completely replace single mineral admixtures...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com