High-strength active powder concrete and preparation method

A technology of active powder and concrete, applied in the field of concrete materials, to achieve the effect of improving bearing capacity, high fire performance and reducing cross-sectional size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The components of the present invention are (parts by weight): quartz sand 40-55, cement 25-30, fly ash 0-10, silica fume 0-7, steel fiber 1-4, water reducing agent 1-2, water 2- 7.

[0031] Further can be: quartz sand 45-50, cement 27-30, fly ash 1-9, silica fume 1-6, steel fiber 1-3, water reducer 1-2, water 2-6.

[0032] It can also be: quartz sand 47-49, cement 27-29, fly ash 3-8, silica fume 3-5, steel fiber 2-3, water reducing agent 1-1.5, water 3-5.

[0033] The content of the present invention is further described below in conjunction with the examples, but the content of the present invention is not limited only to the following examples.

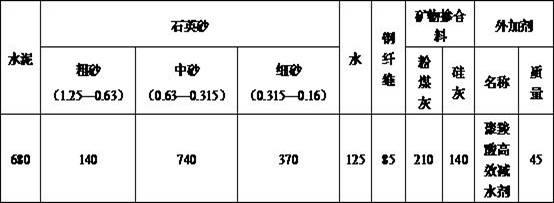

[0034] The amount of material used per cubic meter in the design mix ratio is (kg):

[0035]

[0036] Performance requirements for RPC materials maintained under the same conditions:

[0037] project Compressive strength Flexural strength Elastic Modulus Chloride penetration Antifreeze label Ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com