Patents

Literature

107results about How to "Reduce the water-binder ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-early strength antifreezing polycarboxylate high performance water reducing agent and preparation

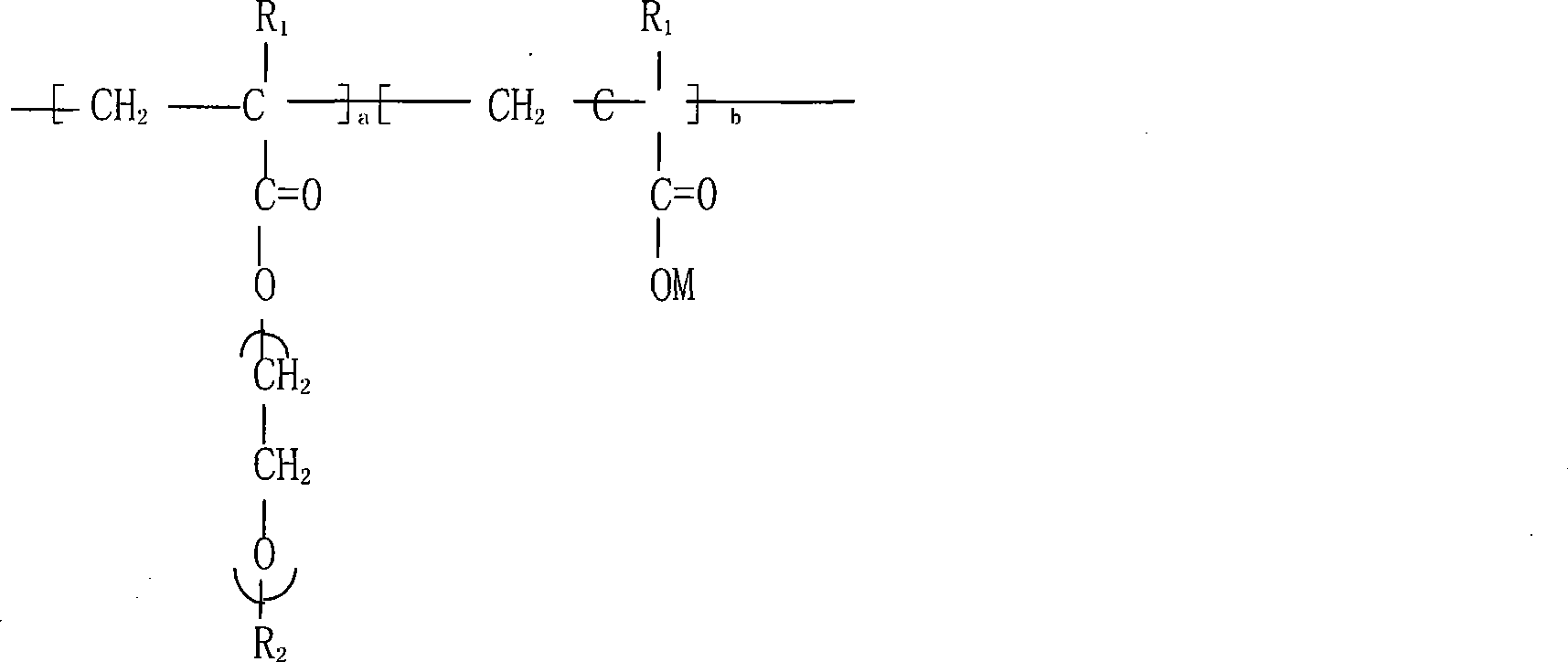

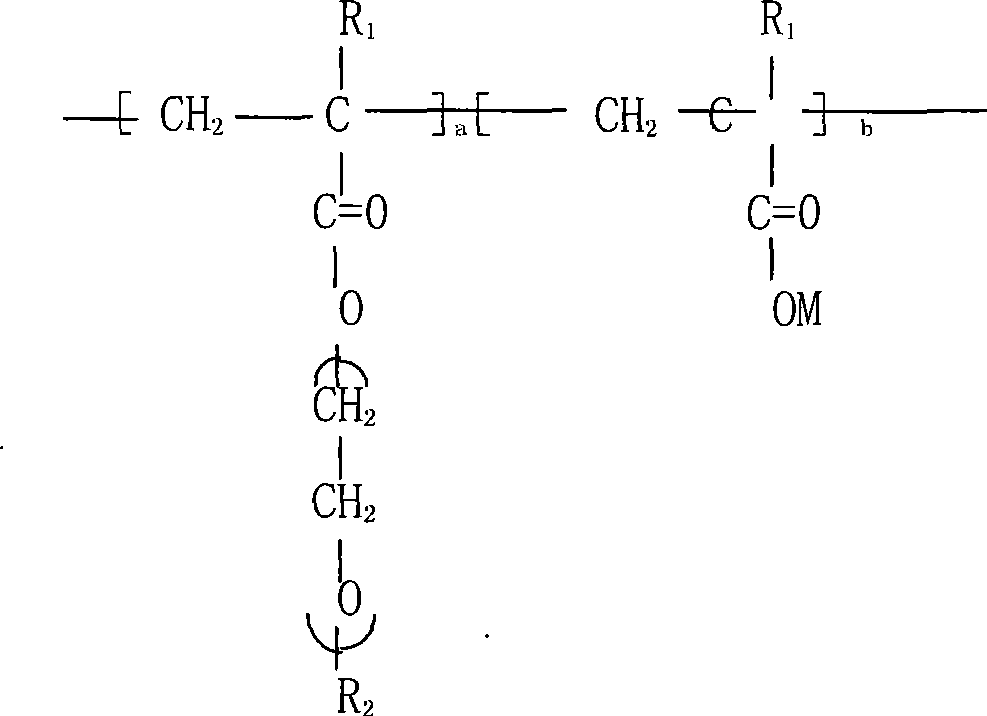

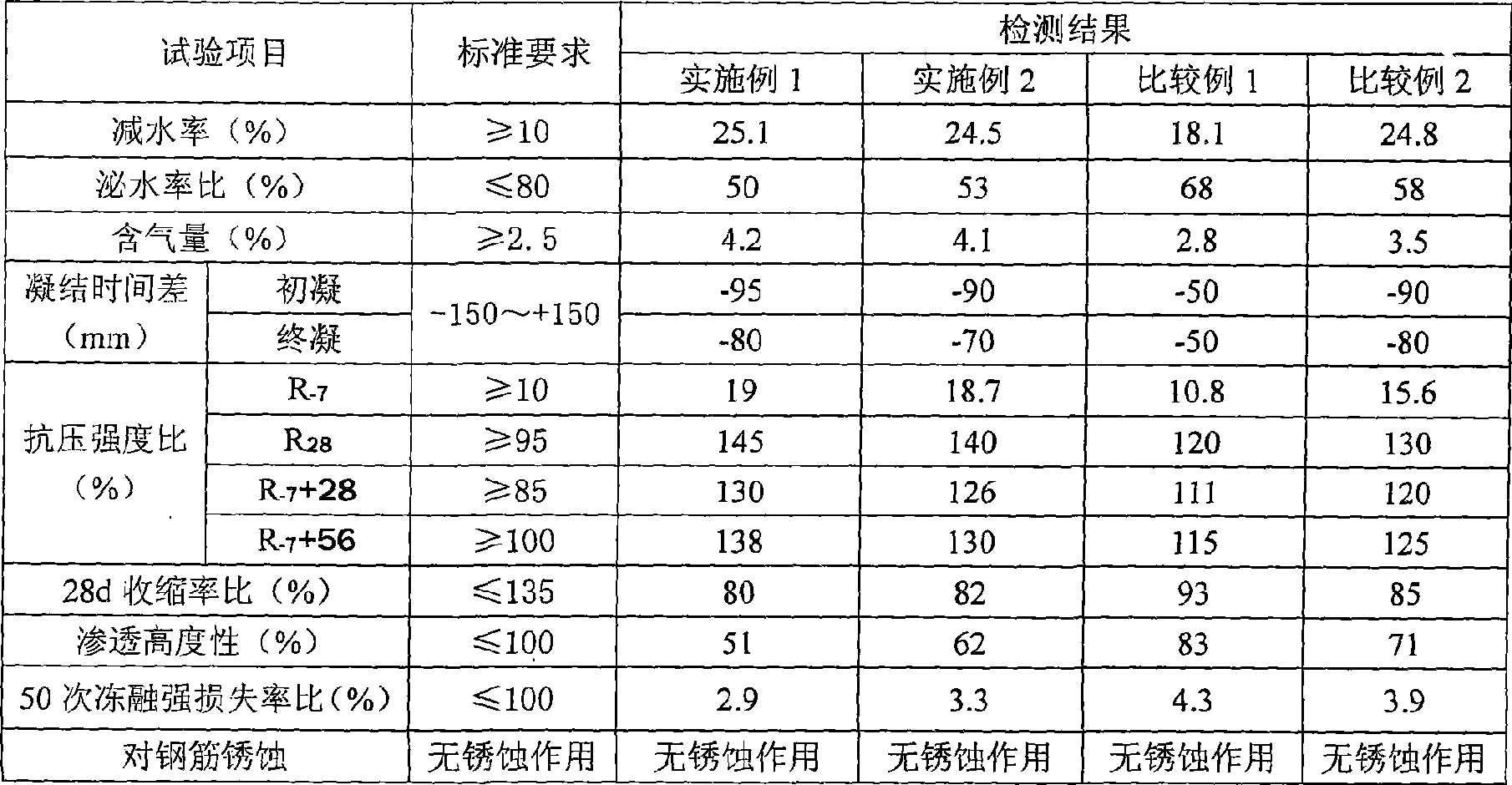

The invention discloses an early-strength antifreezing polycarboxylate high-performance water reducing agent and a method for preparing the same. The early-strength antifreezing water reducing agent is prepared from a polycarboxylate water reducing agent, an early-strength antifreezing agent, an air entraining agent and water. The method comprises the following steps: A, the synthesis of the polycarboxylate high-performance water reducing agent: (1) esterification reaction; adding methacrylic acid, and the like to a reaction kettle, and (2) polymerization reaction; heating big monomer methoxy polyethyleneglycol methacrylic ester; B, the preparation for the solution of an early-strength antifreezing agent: a, weighing water and adding the same to the reaction kettle, and adding calcium formate to the reaction kettle, and b, adding triethanolamine, and the like to the reaction kettle to prepare the early-strength antifreezing agent solution; C, the preparation of the air entraining agent: weighing water and adding the same to the reaction kettle, and adding powdered three-level colophony to the reaction kettle to obtain the air entraining agent; and D, the preparation of the finished product: weighing the polycarboxylate water reducing agent and adding the same to the reaction kettle, and adding the air entraining agent and the early-strength antifreezing agent solution to the reaction kettle. The early-strength antifreezing polycarboxylate high-performance water reducing agent has higher water reducing rate and remarkable enhancing effect, and is suitable to prepare various common concrete and high-performance concrete at a negative temperature range of between 20 DEG C below zero and 0 DEG C.

Owner:武汉市联合石油化工有限责任公司

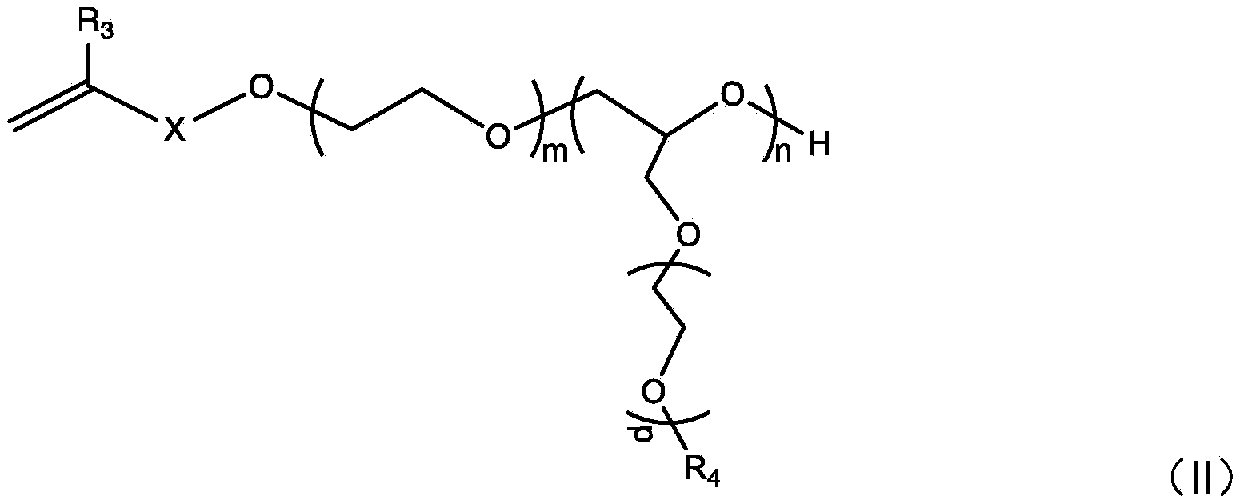

Method for preparing viscosity-reduction-type polycarboxylic acid superplasticizer and application of viscosity-reduction-type polycarboxylic acid superplasticizer

The invention provides a method for preparing a viscosity-reduction-type polycarboxylic acid superplasticizer and application of the viscosity-reduction-type polycarboxylic acid superplasticizer. The method is simple in operating process, and the prepared polycarboxylic acid superplasticizer is applied to high- and ultrahigh-strength concrete, can be used for effectively lowering the viscosity of concrete and improving the placeability and flow velocity of the concrete and is beneficial to pumping construction. According to the method, the viscosity-reduction-type polycarboxylic acid superplasticizer is prepared through carrying out free-radical copolymerization on a carboxylic monomer a, a branched side chain containing monomer b and a rigid cyclic group containing monomer c which are in the mole ratio of (4-15): 1: (0.5-2). The polycarboxylic acid superplasticizer prepared by the method provided by the invention can serve as a cement dispersant so as to greatly lower the water-cement ratio of concrete; and the polycarboxylic acid superplasticizer can be used for effectively lowering the viscosity of the high- and ultrahigh-strength concrete and improving the placeability and flow velocity of the concrete, so that the pumpability is excellent.

Owner:JIANGSU SOBUTE NEW MATERIALS +2

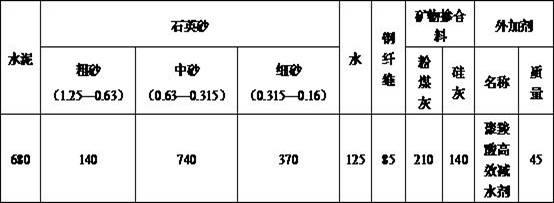

High-strength active powder concrete and preparation method

InactiveCN102320789AImprove performanceImprove uniformityCeramic shaping apparatusDry mixingWater reducer

The invention discloses a cement-based composite material - high-strength active powder concrete which comprises the following raw materials by weight: 40-55 parts of quartz sand, 25-30 parts of cement, 0-10 parts of fly ash, 0-7 parts of silica fume, 1-4 parts of steel fibers, 1-2 parts of water reducers, and 2-7 parts of water; in the components, the particle size of quartz sand is less than 1.25 mm, wherein the weight content of SiO2 is 97%. The mixing preparation comprises the following steps: weighing quartz sand and steel fibers according to the mixing ratios, adding into a stirring pot, performing dry mixing for 2 min; weighing cement and a special composite admixture according to the mixing ratios, adding into the stirring pot, performing dry mixing with quartz sand and steel fibers for 2 min; finally adding the high-efficient water reducer and water together, stirring for 6 min; after the stirring of the concrete, blanking and molding. The concrete of the invention has ultrahigh strength, low brittleness, high durability, and high compactness, brings into better play of the excellent performance of the active powder concrete, and reaches the purposes of less maintenance or free of maintenance, and prolongation of structure service life.

Owner:SICHUAN SOUTHWEST JIAOTONG UNIV RAILWAY DEV

Ultrahigh-strength concrete and preparation method thereof

The invention discloses ultrahigh-strength concrete which comprises the following components in parts by weight: 300-350 parts of cement, 270-315 parts of composite mineral admixture, 30-35 parts of composite expanding agent, 96-112 parts of water, 680-720 parts of river sand, 1012-1080 parts of gravel, 13.2-14.0 parts of polycarboxylic acid high-efficiency water reducing agent, 4.4-4.7 parts of plastic retaining agent and 0.18-0.21 part of defoaming agent, wherein the composite mineral admixture is prepared from 42-49 parts of ore powder, 150-175 parts of fly ash, 30-35 parts of silica fume, 18-21 parts of zeolite powder and 30-35 parts of wollastonite powder. The invention is characterized in that the 60d concrete compression strength is 140-160 MPa, the 60d splitting tensile strength is 9.2-10.2 MPa, extruded concrete can achieve self-compaction effect within 3 hours, and the 14d self-shrinkage value is less than 0.05%.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

Active powder concrete for railroad bridge cover plate

The invention discloses an active powder concrete for a railroad bridge cover plate, which is prepared by evenly mixing cement, silica powder, quartz sand, admixture, steel fiber, additive and water according to the weight ratio of 650-700:170-200:1,150-1,200:160-250:140-150:30-40:135-160, wherein the admixture is fly ash or slag, and the additive is a non-air-entraining type high-efficiency water reducing agent. The active powder concrete has the advantages of superior lasting quality, high-grade compression strength and rupture strength and simple preparation process, and a footway cover plate processed from the active powder concrete can completely satisfy the design requirement on special lines for passenger trains in China and has small workloads of later-period maintenance.

Owner:CHINA RAILWAY FIRST GRP CO LTD

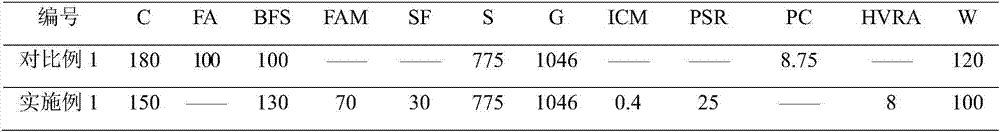

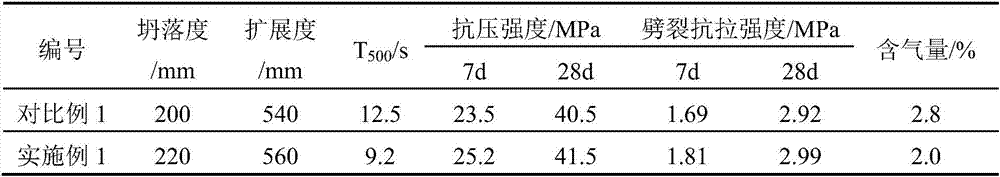

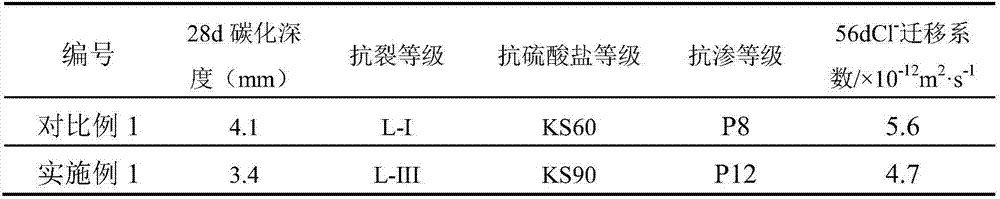

Sea sand anti-corrosion marine concrete and preparation method thereof

The invention discloses sea sand anti-corrosion marine concrete. By adjusting the proportion of binding materials, cement, mineral powder, silicon ash and fly ash micro-spheres are uniformly distributed, and adsorption of corrosive ions is increased by hydration reaction of high-aluminum minerals and chemical curing of Cl- ions in sea sand. Transmission paths of the Cl- ions in the sea sand and the corrosive ions in a marine environment can be effectively inhibited by pore structure adjustment and corrosive ion transmission inhibitors, and reinforcing steel corrosion is decreased. Micro-expansion and water retention components in internal maintenance materials can effectively avoid cracking of the inside of the concrete due to excessive shrinkage under the moisture coupling action of a marine environment, and the working performance and the compactness of the concrete can be improved by special ball effects of ultra-dispersed shrinkage additives and the fly ash micro-spheres. The sea sand anti-corrosion marine concrete can effectively solve the problem of river sand resource shortage, resource application of the sea sand is realized, and the sea sand anti-corrosion marine concrete more effectively serves a severe marine environment and has an important engineering application value.

Owner:HAINAN RUIZE NEW BUILDING MATERIAL +2

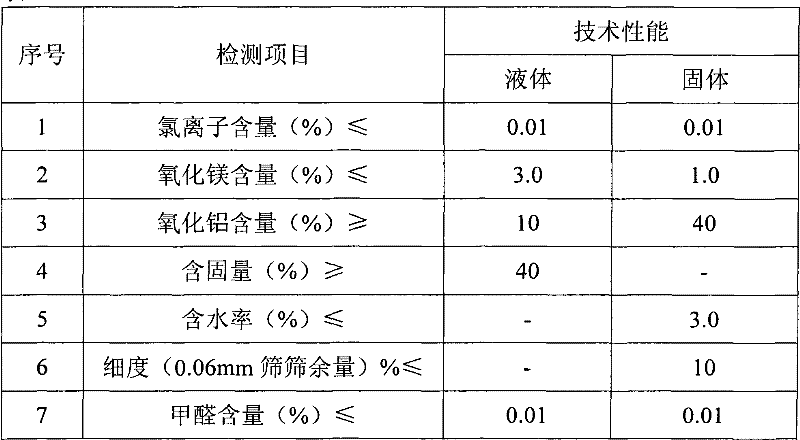

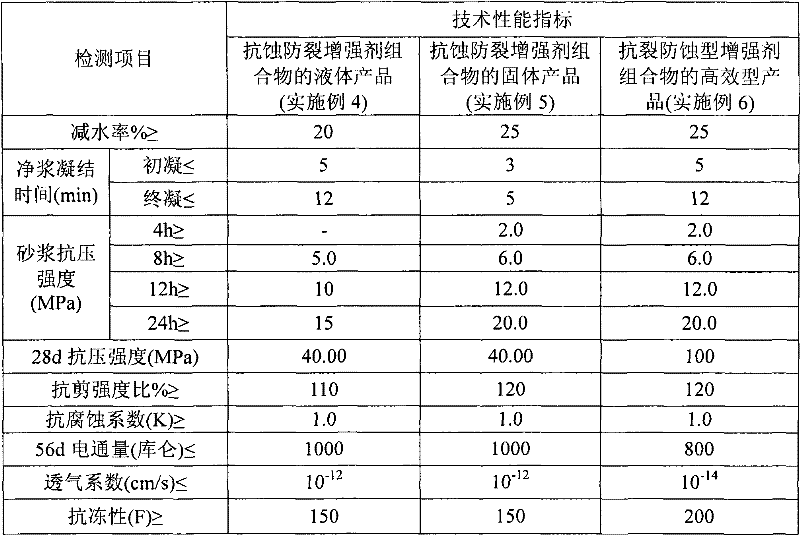

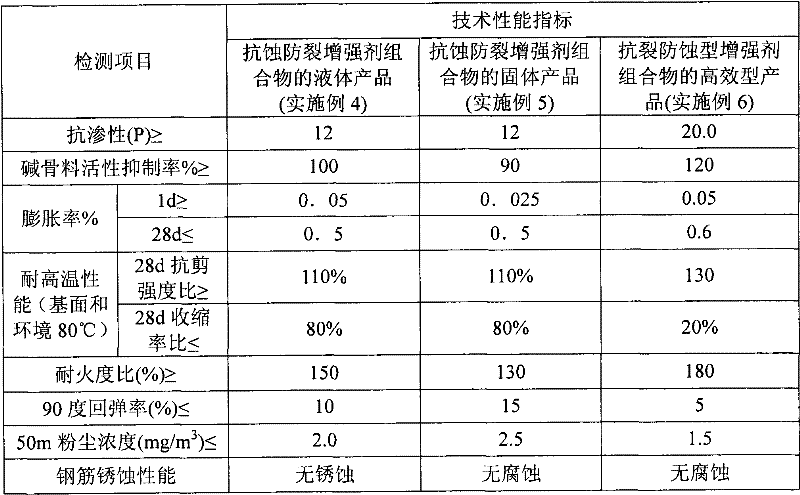

Anti-corrosion anti-cracking reinforcing agent composition and preparation method thereof

The invention relates to an anti-corrosion anti-cracking reinforcing agent composition for concrete, mortar, and net slurry used in injection (first-aid repair) engineering, and a preparation method thereof. The composition comprises the following components on a percentage basis: 2-50% of micro-expansive powder, 5-30% of reinforcing powder, 5-20% of anti-corrosion compacting agents, 10-20% of plasticizers, 1-6% of catalysts, and 10-60% of carriers. The composition of the invention prepares solid and liquid products by processes of melting refinement, polymerization, ball milling, jet milling, complex formulation, and the like, and thus meets construction process requirements of different first-aid repair endurance engineering.

Owner:四川巨星新型材料有限公司

Non-autoclave-curing dry-mix active powder concrete and preparation method thereof

The invention relates to a non-autoclave-curing dry-mix active powder concrete and a preparation method thereof. The active powder concrete is prepared by proportionally mixing a dry material and water. The dry material is prepared by homogenizing the following components in parts by mass: 1 part of cementing material, 0.8-1.3 parts of powder additive, 0.01-0.2 part of aggregate and 0.01-0.25 part of steel fiber. The proportion of the dry material to the water is 1:(0.1-0.3). Under normal-temperature curing conditions, the compression strength of the active powder concrete material can reach 130 MPa above, the folding strength can reach 19 MPa above, and the elastic modulus can reach 48 GPa above. Field casting, controllable quality and environmental protection of the powder concrete are successfully implemented on the basis of the concept on dry-mix material preparation; and the prepared non-autoclave-curing active powder concrete can be used in the fields of high-speed railway cable trough cover plates, sidewalk plates, bridge floor, municipal well covers, repair and reinforcement, and the like.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

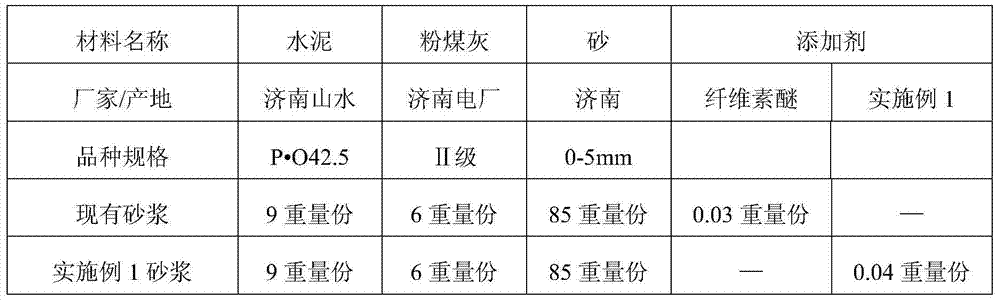

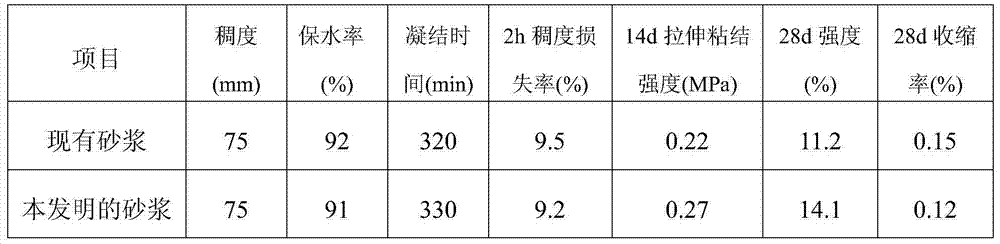

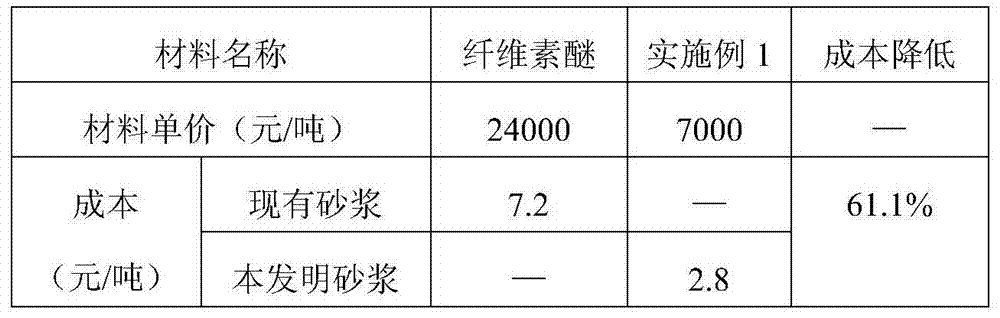

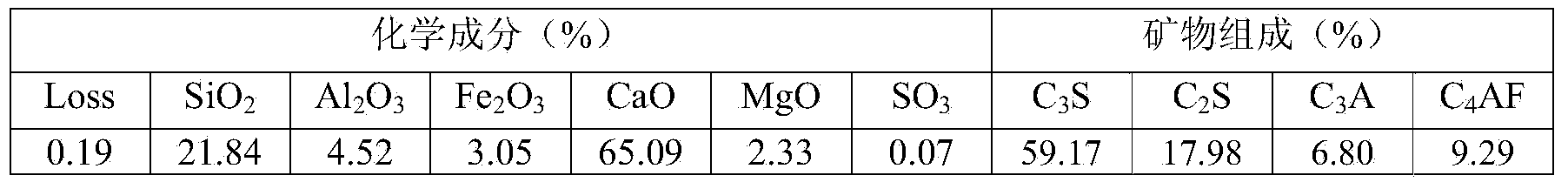

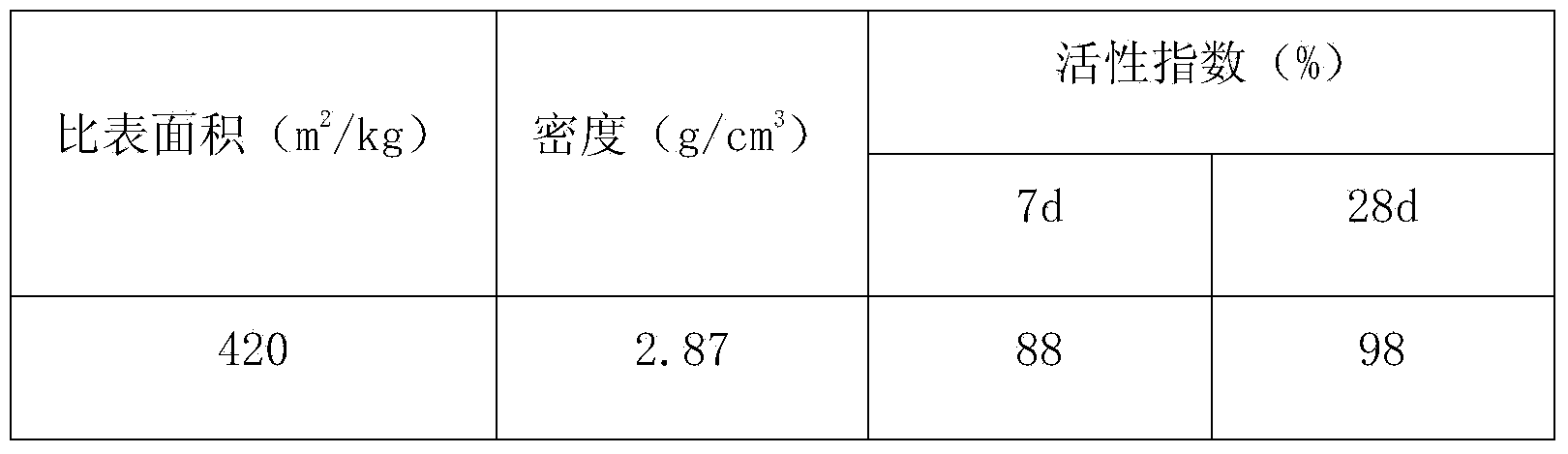

Water-retaining, thickening and reinforcing additive for cement mortar and cement mortar containing additive

The invention discloses a water-retaining, thickening and reinforcing additive for cement mortar and cement mortar containing the additive, wherein the additive is corn straw cellulose or / and modified corn straw cellulose. The water-retaining, thickening and reinforcing additive for cement mortar and the cement mortar containing the additive, disclosed by the invention, have the beneficial effects that the water-retaining, thickening and reinforcing additive for cement mortar is a green environment-friendly product which is free from toxicity, peculiar smell, pollution and corrosivity; if the water-retaining, thickening and reinforcing additive for cement mortar, disclosed by the invention, is doped into cement mortar, the water-retaining property of mortar can be effectively improved; the water-retaining property of freshly mixed mortar is more than 90% and meets standard requirements; simultaneously, the intensity of mortar is obviously increased; the use amount of cement is effectively reduced; the intensity of mortar is increased by above 25%; the 14d tensile adhesive intensity is increased by above 13%; the cost of the water-retaining and thickening material is reduced by above 16%; a utilization way of the industrial by-product, namely cellulose, separated from corn straws, is effectively provided; furthermore, the utilization value is higher. The cost of the water-retaining, thickening and reinforcing additive for cement mortar, disclosed by the invention, is 4000-8000 yuan / ton, and the water-retaining, thickening and reinforcing additive for cement mortar, disclosed by the invention, is wide in source of used raw materials, proper in cost, convenient to use, high in operability and beneficial to popularization.

Owner:SHANDONG HUASEN CONCRETE

High-performance corrosion-resistant dry-mixed waterproof mortar

The invention discloses high-performance corrosion-resistant dry-mixed waterproof mortar. The high-performance corrosion-resistant dry-mixed waterproof mortar is prepared from the following raw materials in parts by weight: 60-70 parts of cement, 35-45 parts of mineral powder, 10-30 parts of coal ash, 300-500 parts of regenerated fine aggregates and 5-10 parts of a compounded additive, wherein the compounded additive is prepared from the following raw materials in parts by weight: 40-60 parts of coal ash, 5-7 parts of a water repellent, 40-50 parts of an expanding agent, 2-5 parts of an air-entraining and water-reducing agent, 2-4 parts of anti-crack short fiber and 2-10 parts of a water-retaining thickening agent. By virtue of a dry-mixing form, the high-performance corrosion-resistant dry-mixed waterproof mortar is convenient to use, and the sulfate corrosion can be effectively prevented.

Owner:潍坊德霖建材科技有限公司

Addition for concrete of road for enhacing anti-bending strength

InactiveCN1559966AReduce dosageReduce the water-binder ratioSolid waste managementRebarPrecast concrete

The invention relates to a road concrete additive of improving folding strength, prepared of benzene solfonic acid formaldehyde condensation compound, lignin calcium sulfonate, sugar calcium, sodium calcium sulphate, ferrous sulphate, calcium nitrite and powder coal ashes. It can reduce the water dosage of concrete by above 18%, enhances the early strength of concrete by a large margin and increase the 28 d pressive strength, obviously enhance the folding strength of concrete, thus on condition of less dosage of cement, able to make the folding strength of concrete up to the requirements for above secondary roads (folding strength above 4.5 MPa), and simultaneously able to improve the durability of concrete. It can be widely applied to road concrete and simultaneously applied to the constructions (structures) of reinforced concrete, precast concrete, steam cured concrete, etc.

Owner:TONGJI UNIV

C70 mass concrete and preparation process thereof

The invention discloses C70 mass concrete. The C70 mass concrete is prepared from the following components by mass: 140 to 170 parts of water, 400 to 450 parts of cement, 1,000 to 1,200 parts of crushed stone, 550 to 650 parts of gravel, 70 to 110 parts of coal ash, 60 to 90 parts of mineral powder, 30 to 70 parts of silica fume, 8 to 10 parts of a pumping agent, 35 to 45 parts of an anti-crackingagent, and 0.3 to 0.4 part of an internal curing agent. The invention also discloses a preparation method for the C70 mass concrete. The method comprises a first step of uniformly mixing sand, graveland water and a second step of adding other components and carrying out uniform mixing under stirring. According to the composition of the mass concrete in the invention, mineral powder, silica fumeand fly ash are used as mineral admixtures and can delay the release rate of cement hydration heat and reduce the shrinkage and deformation of the concrete, and the mineral admixtures acts synergistically with the other components to inhibit the generation of cracks at the same time; and the preparation method of the invention is simple in process and easy to implement.

Owner:陕西秦汉恒盛新型建材科技股份有限公司

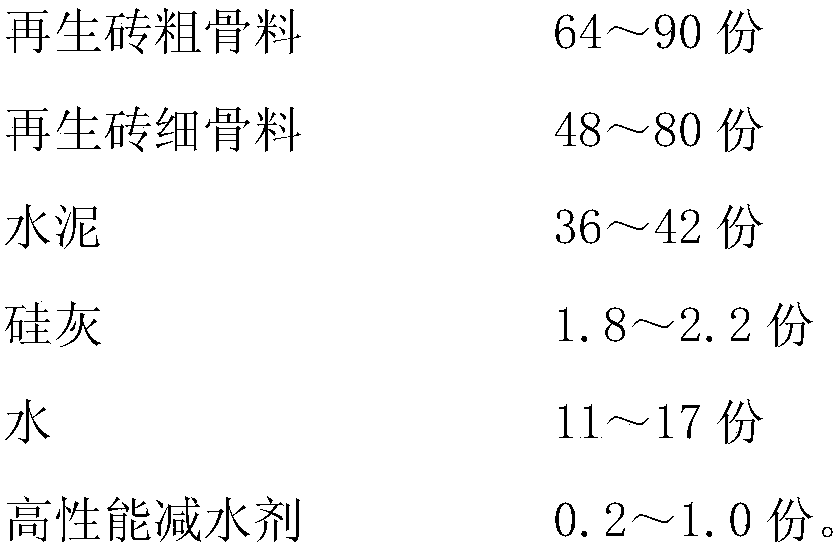

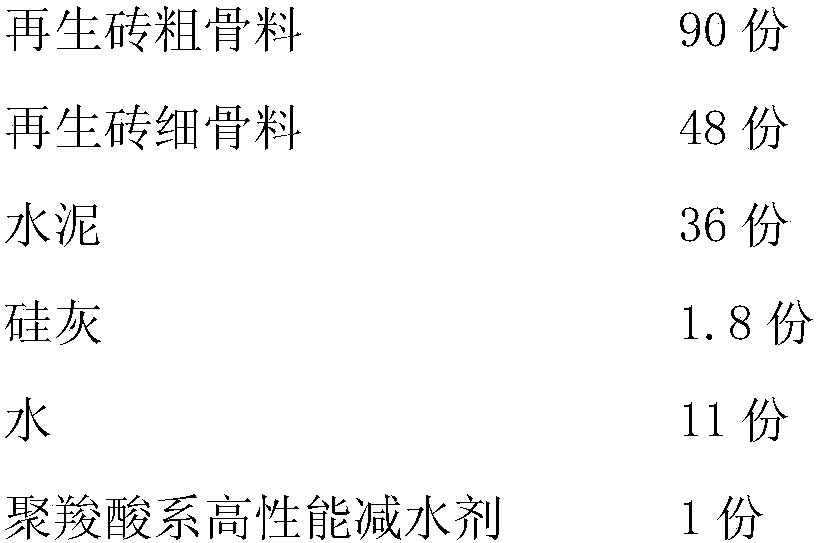

Recycled brick aggregate concrete and preparation method thereof

The present invention discloses recycled brick aggregate concrete and a preparation method thereof. The concrete comprises the following components by mass: 64 to 90 portions of a recycled brick coarse aggregate, 48 to 80 portions of a recycled brick fine aggregate, 36 to 42 portions of cement, 1.8 to 2.2 parts of silica fume, 11 to 17 parts of water and 0.2 to 1.0 part of a high-performance waterreducer. The preparation method is as follows: 1) the recycled brick coarse aggregate and the recycled brick fine aggregate are weighed according to proportion, and evenly mixed to obtain a recycledbrick aggregate; 2) the cement and the silica fume are proportionally evenly mixed, and added into the recycled brick aggregate to obtain a mixture through even stirring and mixing; and 3) the water and the high performance water reducer are proportionally weighed and added to the mixture to obtain the recycled brick aggregate concrete through even stirring and mixing. The recycled brick aggregateconcrete has good workability and good cohesiveness, and compared with ordinary concrete, the recycled brick aggregate concrete has better thermal insulation effect, and the seismic performance and fire resistance are improved.

Owner:SOUTHEAST UNIV

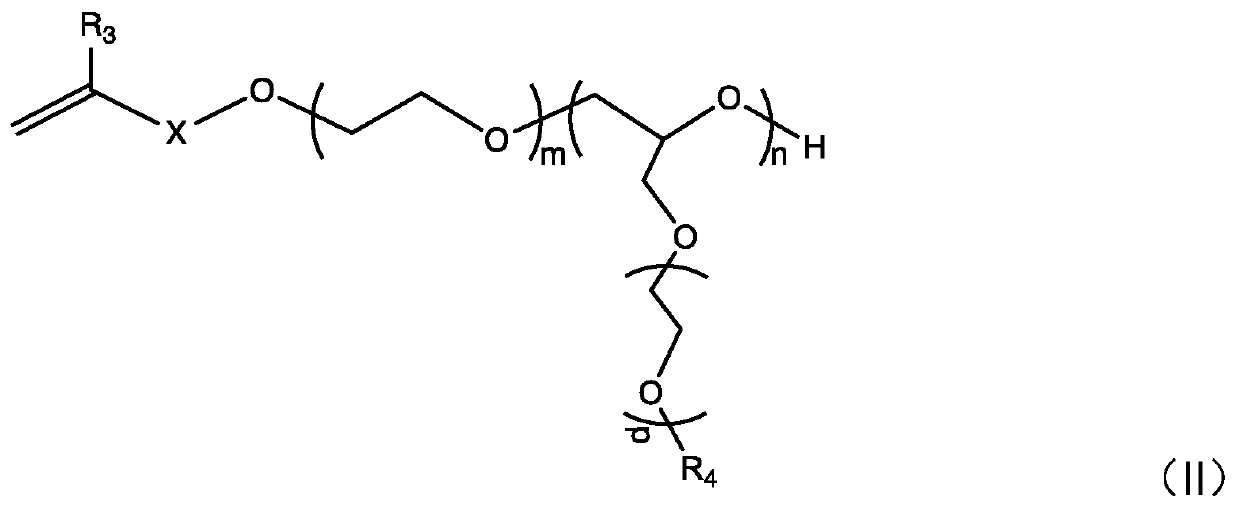

Preparation method and application of viscosity-reducing polycarboxylate superplasticizer

The invention provides a preparation method and application of a viscosity-reducing polycarboxylate superplasticizer. The method is simple in operation, and the prepared polycarboxylate superplasticizer is used in high and ultra-high-strength concrete, which can effectively reduce the Increase the viscosity of concrete, improve the workability and flow speed of concrete, and facilitate pumping construction. The method is as follows: Carboxyl group-containing monomer a, branched side chain-containing monomer b and rigid ring group-containing monomer c are carried out in a molar ratio (4-15):1:(0.5-2) Viscosity-reducing polycarboxylate superplasticizer obtained by free radical copolymerization. The polycarboxylate superplasticizer obtained by the method of the present invention can be used as a cement dispersant, greatly reducing the water-binder ratio of concrete, and can effectively reduce the viscosity of high and ultra-high strength concrete, improve its workability and flow rate, Excellent pumpability.

Owner:JIANGSU SOBUTE NEW MATERIALS +2

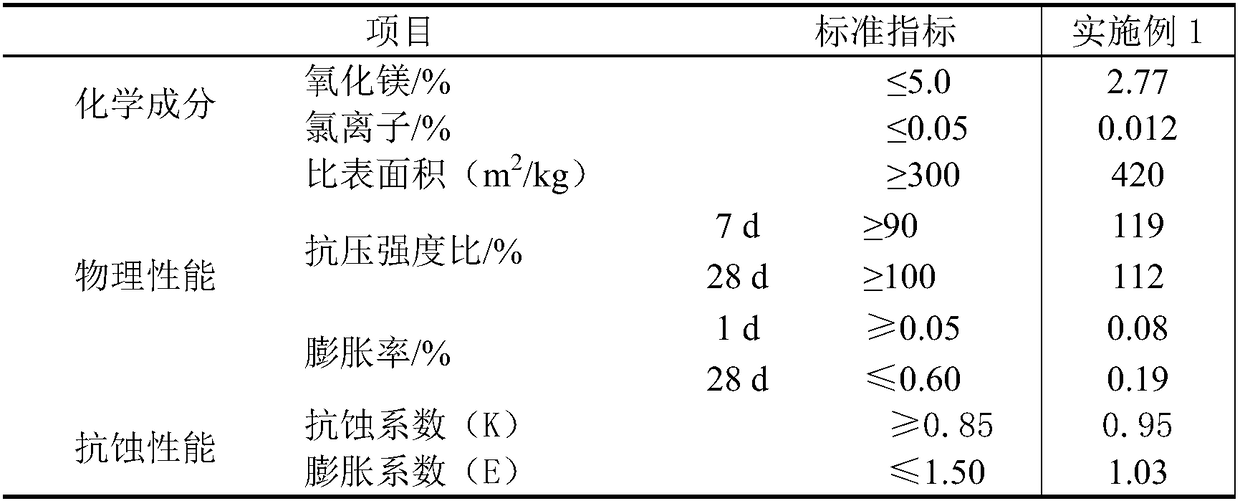

Ecological dustproof type seawater sea-sand anti-corrosion marine concrete and preparation method thereof

The invention discloses an ecological dustproof type seawater sea-sand anti-corrosion marine concrete and a preparation method thereof. The concrete comprises the following raw materials: cement, silica fume, coal ash beads, blast furnace slag powder, corroding ion inhibitors, sea sand, steel fibers, a water reducing agent and seawater. The preparation method comprises the following steps: mixingcement, silica fume, coal ash beads, blast furnace slag powder, corroding ion inhibitors and steel fibers and then uniformly stirring with a stirrer; adding sea sand and continuing to uniformly stir;adding seawater and the water reducing agent; mechanically stirring till uniformly stirring, thereby acquiring a concrete slurry; pouring and then removing a mold and maintaining for 48h at 80 DEG C under the condition of humidity of 95%, thereby acquiring the marine concrete. The concrete disclosed by the invention has the advantages of high curing rate of chloride ions, excellent working performances, high durability, lower cost, locally acquired raw materials, short construction period and suitability for popularization and application.

Owner:HOHAI UNIV

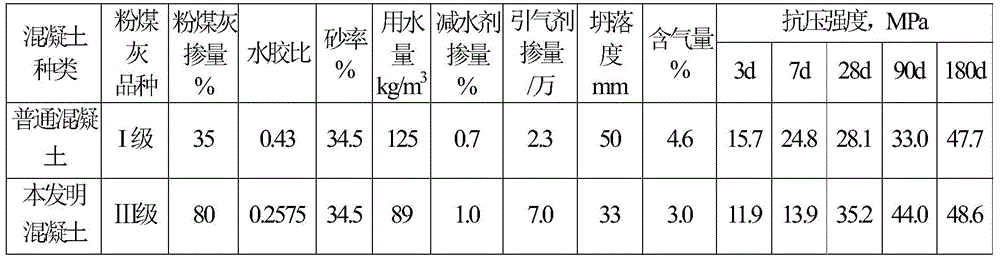

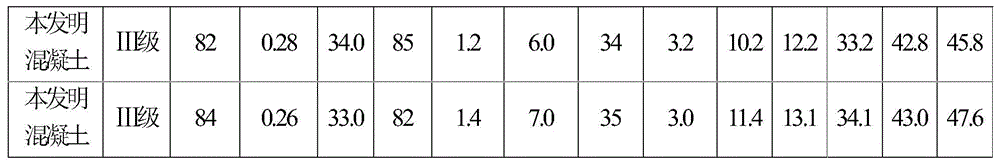

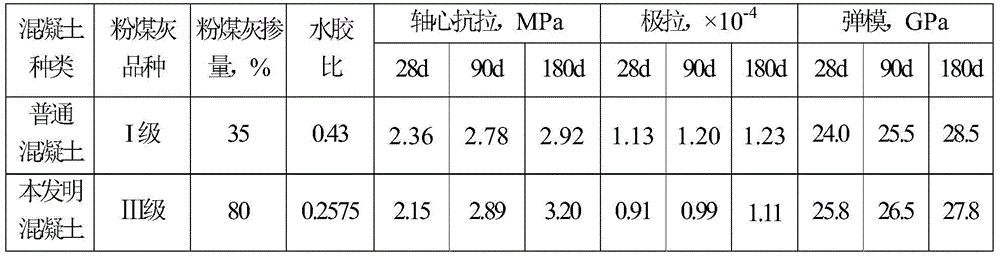

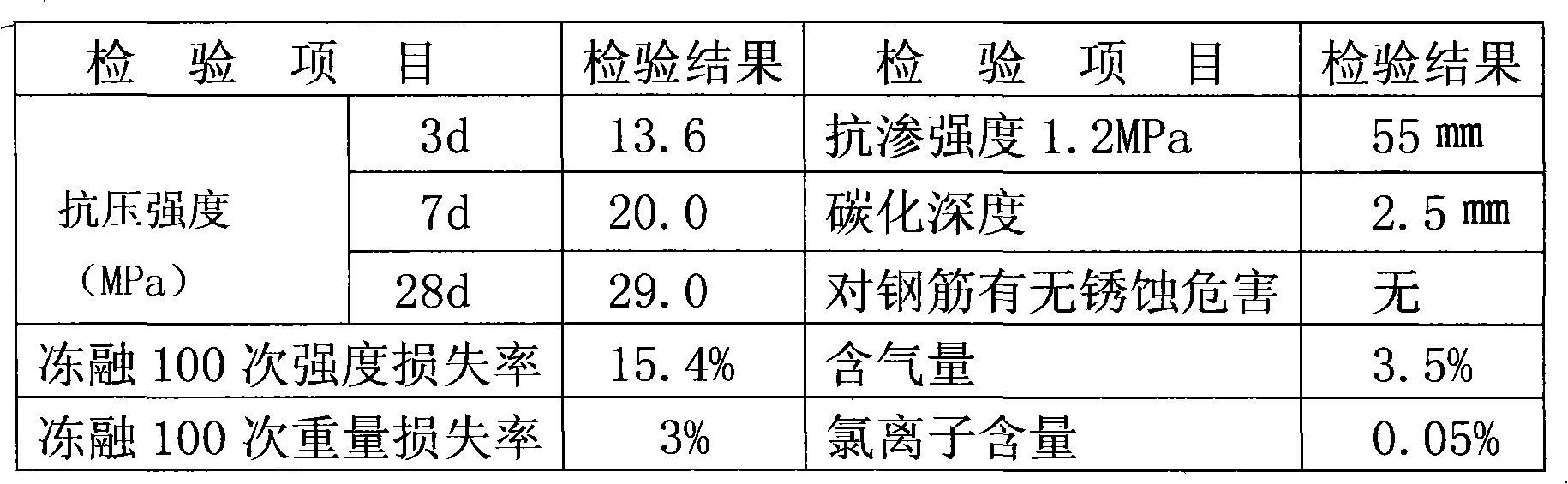

Concrete with ultrahigh content of mixed fly ash

ActiveCN105731919AReduce water consumptionGuaranteed StrengthSolid waste managementTemperature controlWater resources

The invention discloses a concrete with an ultrahigh content of mixed fly ash, and relates to the field of construction materials. The concrete comprises the following components in parts by weight: 48 to 60 parts of cement, 240 to 272 parts of fly ash, 656 to 696 parts of sand, 1293 to 1333 parts of broken stone, 3.0 to 4.8 parts of water reducer, 0.18 to 0.26 part of air-entrainer, and 80 to 90 parts of water. The mechanical performance and deformation performance of the concrete meet the requirements of water resources and hydropower engineering C18040 concrete and lower grades; moreover, the hydration temperature rise is lower, the anti-cracking performance is stronger, thus the happening rate of cracks in concrete is reduced, and the cost of temperature control is reduced.

Owner:HUBEI GEZHOUBA TESTING +1

Premixed concrete produced by tailings

InactiveCN101306935AReduce the water-binder ratioImprove frost resistanceSolid waste managementRiver sandAir drying

The invention relates to premixed concrete made by tailings, and is characterized in that: tailings concrete with the strength grade under C35 is made by waste tailings of mine mineral processing; the waste tailings is used as one component of the premixed concrete, and comprises the raw materials of PS32.5 cement, III-grade fly ash, river sand, crushed stone, tailings powder, water and tailings modifier. A method for making the premixed concrete is as follows: waste tailings undergoes natural air drying to take leave of water; the feeding order during tailings concrete stirring is as follows: river sand, tailings powder, PS32.5 cement and III-grade fly ash; after 20-second stirring, crushed stone is added and stirred for 20 seconds; then, water and tailings modifier are added and stirred for 60 seconds and then are discharged out of a stirring machine. The premixed concrete is a high performance premixed concrete of low water-binder ratio and high compactness, and completely meets the GB / T14902-2003 standards of premixed concrete according to detection; moreover, the premixed concrete can be adapted to concrete placement of various types of structures.

Owner:周志华 +1

Cement-based composite material with high strength, toughness, impact resistance and abrasion resistance and casting method thereof

The invention relates to a cement-based composite material with high strength, toughness, impact resistance and abrasion resistance. The cement-based composite material comprises the following materials in percentage by mass: 22.1-26.5% of cement, 15.2-23.1% of a multi-element composite mineral admixture, 44.5-55.1% of corundum, 0.72-0.78% of a water reducing agent, 1.1-2.5% of steel fibers and 7.5-10.2% of water. A building member cast by adopting the cement-based composite material provided by the invention has the characteristics of high strength, toughness, impact resistance and abrasion resistance, and is suitable for severe engineering environments with high pressure and impact abrasion such as release structures in hydraulic engineering. The raw materials used by the invention are conventional building materials for preparing common concrete, so the raw materials are readily available and low in cost. The preparation method disclosed by the invention is simple and feasible, and has the characteristic of environment friendliness by comprehensively utilizing massive industrial waste slag.

Owner:NANJING FORESTRY UNIV

Method for preparing high-strength semi-regenerative coarse aggregate concretes

The invention discloses a method for preparing high-strength semi-regenerative coarse aggregate concretes, and belongs to the technical field of regenerative coarse aggregate concretes. The preparation method comprises the step of preparing the high-performance semi-regenerative coarse aggregate concretes with good working performance, high early strength and good development in long-term strength by regulating the mixing amount of additives, mineral powder and coal ash in reference to the using amount of rubber materials of the common concretes.

Owner:BEIJING UNIV OF TECH

Construction method for densifying surface layer of middle/low-strength concrete

InactiveCN101886474AStrengthen early maintenanceImprove compactnessBuilding material handlingSurface layerUltimate tensile strength

The invention discloses a construction method for densifying the surface layer of middle / low-strength concrete, which relates to the technical field of concrete construction. The middle / low-strength concrete is poured by a concrete temperature and humidity preservation maintenance template which is disclosed in a patent with the patent number of 2009200384330. The mixing proportion of the middle / low-strength concrete is optimized, the using amount of a gelatinization material and the using amount of water are controlled, the ratio of the water to the gelatinization material is also controlled, and the early-stage maintenance of the concrete is enhanced, so the ratio of the water to the gelatinization material of the concrete of the surface layer can be maximally reduced, the compactness and durability of the concrete can be improved, the surface layer densifying degree of the middle / low-strength concrete can be improved, the generation of temperature shrinkage cracks of the concrete can be prevented and the full development of the strength of the concrete is ensured.

Owner:JIANGSU WATER CONSERVANCY SCI RES INST

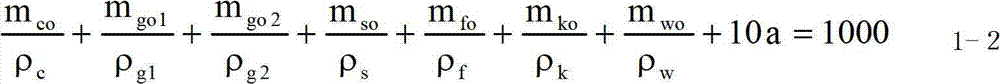

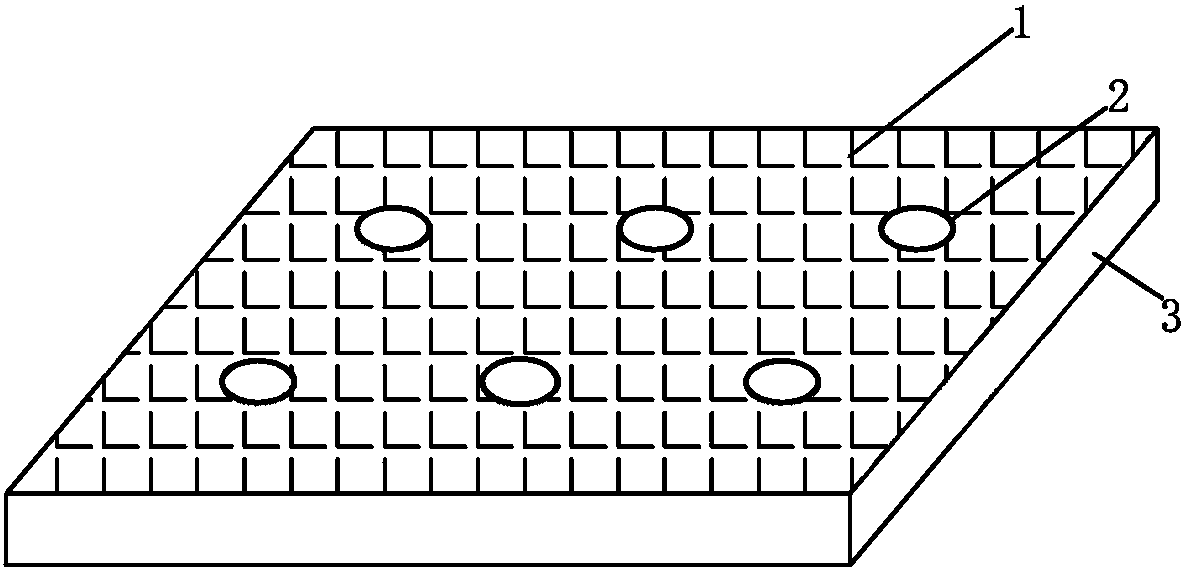

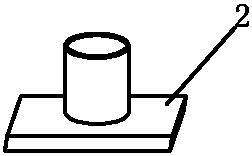

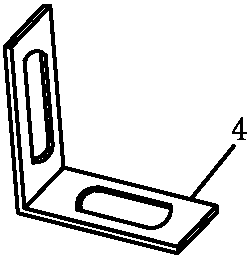

Production and mounting method of nano cement-based composite ultrahigh-strength artificial stone board

InactiveCN108409261AHigh strengthImprove compactnessCovering/liningsShaping press ramWeather resistanceSlag

The invention provides a production and mounting method of a nano cement-based composite ultrahigh-strength artificial stone board. The nano cement-based composite ultrahigh-strength artificial stoneboard comprises a board body material, reinforcing meshes and fibers and T-shaped nuts. The preparation of the board body material uses ultrahigh-strength mortar reaching above C100, and the ultrahigh-strength mortar adopts high-grade cement, silica fume, slag powder, sandstone aggregate with particle size being below 6mm, polycarboxylate superplasticizer and water-binder ratio below 25. Board production equipment has functions of high-frequency vibration, strong compression and vacuumizing and can discharge bubbles in the board, compress and suck moisture in the board and extract gas in the board to increase the density of the board so as to reach the ultralow water-binder ratio needed by ultrahigh-strength concrete. Various defects such as proneness to fading, proneness to breaking, poorfreeze-thaw resistance and short service life caused by the fact that a common-strength cement-based artificial stone board is poor in weather resistance, low in strength and low in density.

Owner:钟兵

High-speed railway active powder concrete prefabricated component and preparation method thereof

The invention belongs to the technical field of concrete construction, and particularly relates to a high-speed railway active powder concrete prefabricated component and a preparation method thereof.The high-speed railway active powder concrete prefabricated component is prepared from the following raw materials: cement, silicon powder, coal ash, quartz sand, water, a water reduction agent and steel fibers. By utilizing the high strength, high durability, high toughness and high stability of RPC for producing relevant concrete component products in the field of high-speed railway, the service life of the component can be effectively prolonged, the maintenance expense can be greatly reduced, and the comprehensive expense of the engineering construction and application can be reduced.

Owner:RUZHOU ZHENGTIE SANJIA CEMENT PROD

Deicing salt-resisting cement-based channel repairing agent

The invention relates to the field of a repairing agents, and discloses a deicing salt-resisting cement-based channel repairing agent. The repairing agent is prepared fromconsists of the following components: potassium dihydrogen phosphate, magnesium oxide, borax, calcium carbonate, coal ash, silica fume, polyacrylamide, air entraining agent, awater reducing agent, fine aggregates, coarse aggregates and water. The invention also discloses a preparation method of the deicing salt-resisting cement-based channel repairing agent. The deicing salt-resisting cement-based channel repairing agent is short in time of coagulation, high in adhesive strength, excellent in anti-permeability and deicing salt corrosion resistance, and suitable for repairing road side channels, drainage channels and the like damaged by the stripping erosion of the deicing salt.

Owner:沈阳建大博成科技有限公司

A steel bridge deck pavement layer and a preparation method thereof

PendingCN109098084AImprove skid resistanceExtended service lifeBridge structural detailsBridge erection/assemblyRough surfaceEmulsion

The invention belongs to the technical field of pavement, and discloses a steel bridge deck pavement layer and a preparation method thereof. The steel bridge deck pavement layer comprises an adhesivelayer, a composite layer and an anti-sliding and wear-resisting layer. The thickness ratio of the composite layer and the anti-sliding and wear-resisting layer is 0.4: As that anti-skid and wear-resistant lay of the invention is formed by mix and solidifying emulsion and aggregate, The aggregate part is embedded in the emulsion, and part of the aggregate is exposed on the emulsion surface. After the aggregate is cured, the bare aggregate forms a rough surface, increases the friction with the contact surface of the vehicle tire, improves the skid resistance performance of the pavement layer, makes up for the defect that the skid resistance performance of the composite material layer is low, and improves the safety of driving; In addition, the contact surface between fine-grained aggregate particles is larger, the coupling force is stronger, the strength is higher, the abrasion resistance force is stronger, and the service life of the pavement is prolonged.

Owner:NANJING COMM INST OF TECH

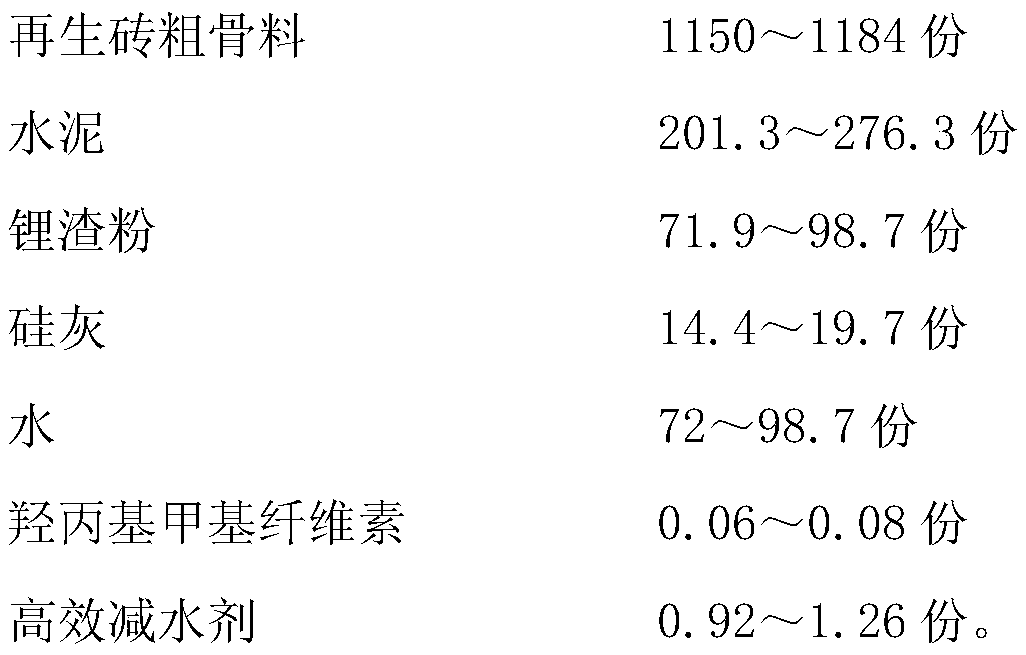

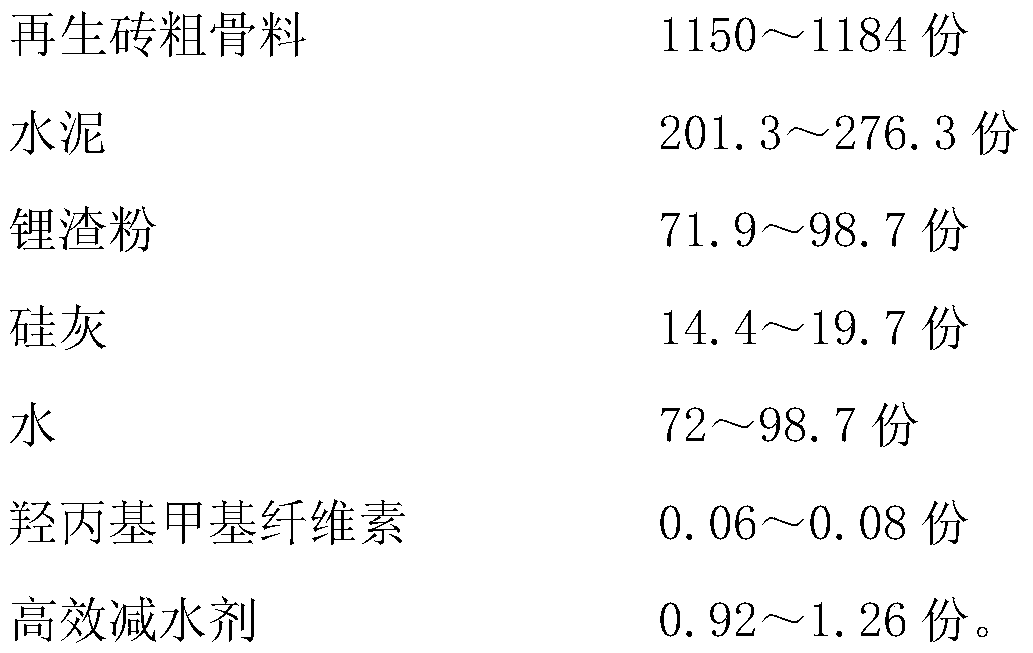

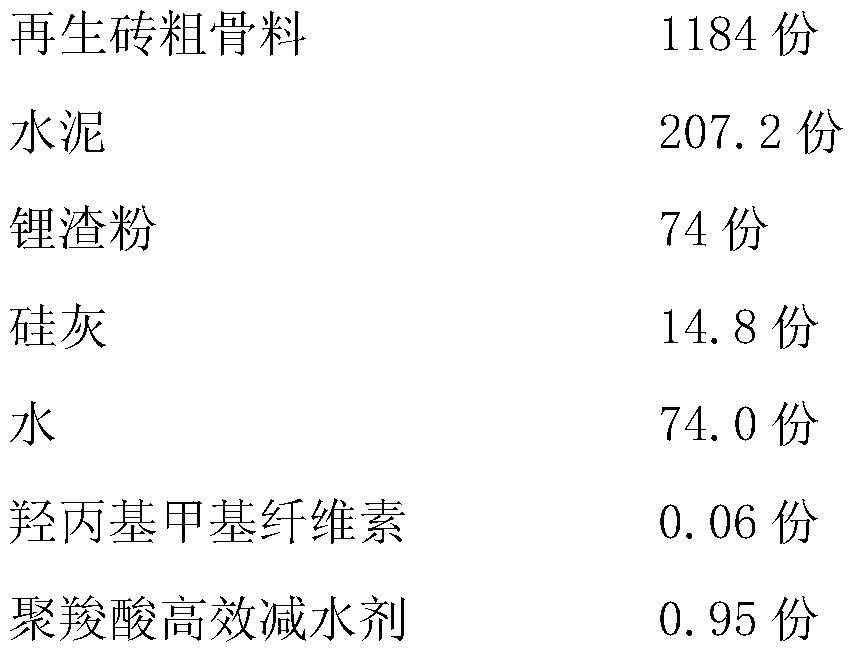

Recycled brick aggregate permeable concrete and preparation method thereof

The invention relates to recycled brick aggregate permeable concrete and a preparation method thereof. The recycled brick aggregate permeable concrete comprises the following components in parts by mass: 1150-1184 parts of a recycled brick aggregate, 201.3-276.3 parts of cement, 71.9-98.7 parts of lithium slag powder, 14.4-19.7 parts of silica fume, 72-98.7 parts of water, 0.06-0.08 part of hydroxypropyl methylcellulose and 0.92-1.26 parts of a polycarboxylate superplasticizer. The preparation method is as follows: 1) weighing the cement, the silica fume and the lithium slag powder according to proportion and mixed evenly; 2) weighing the recycled brick aggregate in proportion, adding the mixture obtained in the step 1), and stirring and mixing uniformly; (3) weighing the water, the hydroxypropyl methylcellulose and the polycarboxylate superplasticizer in proportion and adding into the mixture obtained in the step (2), and stirring and mixing evenly to obtain the recycled brick aggregate permeable concrete. The recycled brick aggregate permeable concrete has good adhesiveness, low dead weight, high water absorption, good water retention, good water purification effect, capability of adsorbing heavy metal ions and low cost, and can be widely applied to places such as river banks, slope protection, road base pavement and the like.

Owner:SOUTHEAST UNIV

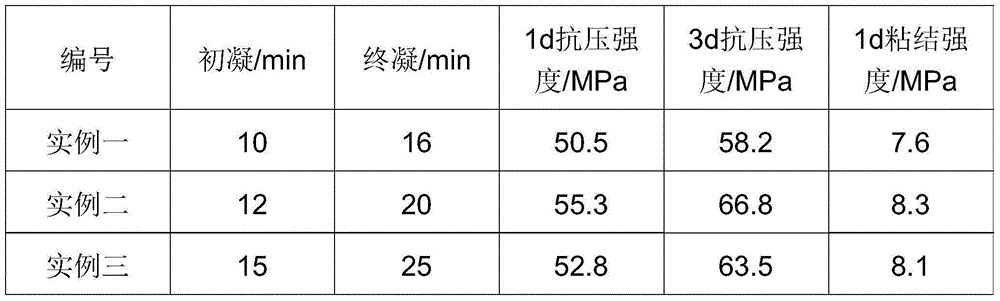

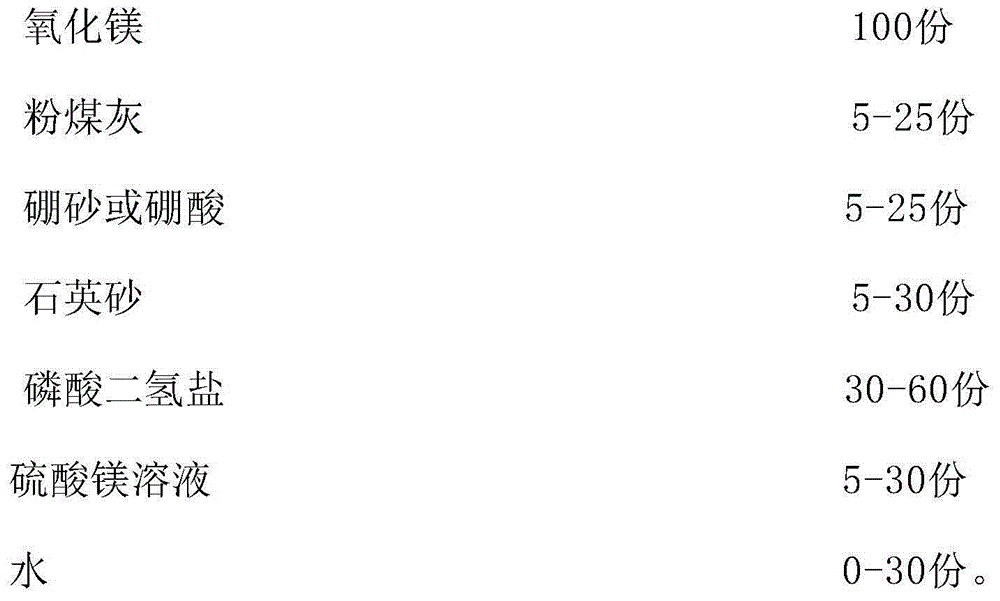

Indoor high-intensity rapid-setting repairing material and preparation method therefor

The invention discloses an indoor high-intensity rapid-setting repairing material and a preparation method therefor. The repairing material is prepared from magnesium oxide, fly ash, borax, quartz sands, dihydric phosphate, a magnesium sulfate solution and water through uniform stirring. Compared with the prior art, the repairing material has excellent performances of short setting time, high early stage intensity, good bonding performance, high wear resistance, low dry shrinkage and the like.

Owner:ZHUO DA NEW MATERIAL TECH GRP

Underwater anti-dispersion mortar for large area cavity grouting, and preparation method thereof

ActiveCN103922659AHigh resistance to dispersion under waterHigh compressive strengthUnderwaterUltimate tensile strength

The present invention discloses an underwater anti-dispersion mortar for large area cavity grouting. The underwater anti-dispersion mortar is prepared from a cementing material, an aggregate, water, a water reducing agent and a thickening agent, wherein the amount of the cementing material is 700-1200 kg / m<3>, the amount of the aggregate is 700-1500 kg / m<3>, the amount of the water reducing agent is 0.5-6.0% of the total mass of the cementing material, the amount of the thickening agent is 0.01-0.2% of the total mass of the cementing material, and a water-cement ratio is 0.25-0.50. According to the present invention, the underwater anti-dispersion mortar has characteristics of high fluidity and high underwater anti-dispersion property, and can meet continuous and stable casting in the case of small grouting pipe diameter and not large construction scene; the water-cement ratio is reduced to increase the compressive strength of the mortar, such that the mortar has high affluence strength; and the prepared mortar has advantages of simple construction process, convenient and rapid construction, and easily available raw materials.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

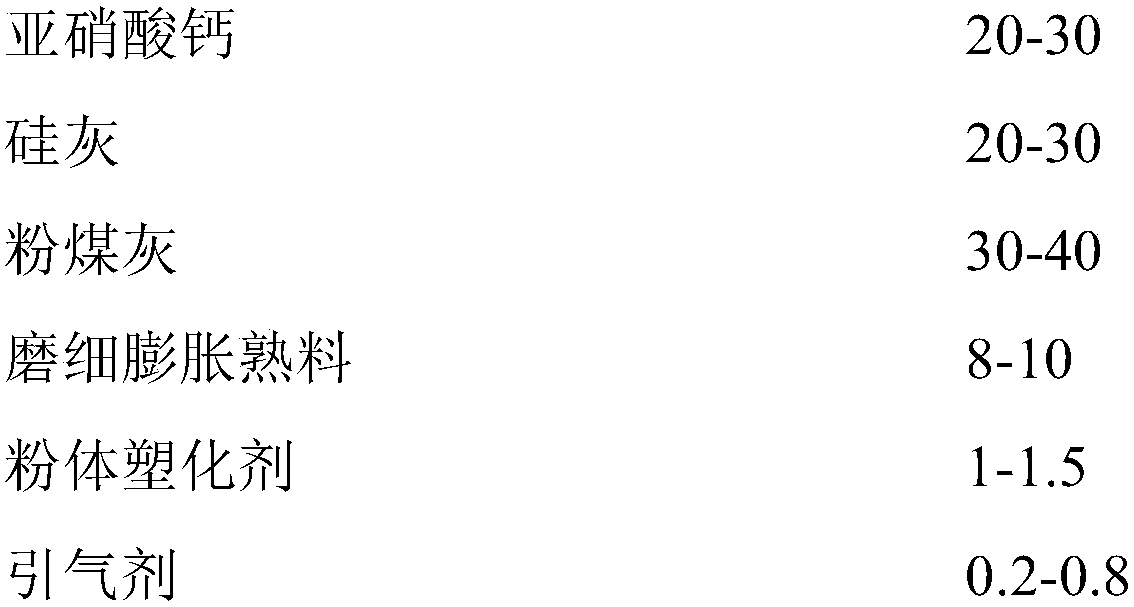

Concrete anticorrosive rust inhibitor for cast-in-place piles

The invention discloses a concrete anticorrosive rust inhibitor for cast-in-place piles. The concrete anticorrosive rust inhibitor is formed by mixing and stirring the following components by mass: 20-30% of calcium nitrite, 20-30% of silica fume, 30-40% of fly ash, 8-10% of finely ground expansive clinker, 1-1.5% of a powder plasticizer and 0.2-0.8% of an air entraining agent. The concrete anticorrosive rust inhibitor has no significant effect on working performance of concrete under appropriate dosage, improves age strength of the concrete, increases compactness of the concrete by certain self-expansion, forms a dense protective layer on a surface of a reinforcing bar, and effectively improves sulfate corrosion resistance of the concrete and erosion resistance of the reinforcing bar.

Owner:HEBEI CONSTR & INVESTIGATION RES INST

Cement-based environmentally-friendly inorganic high-strength artificial stone and preparation method thereof

InactiveCN110342877AHigh strengthDisperses and enhances interfacial bondingSolid waste managementGlass fiberHigh intensity

The invention relates to cement-based environment-friendly inorganic high-strength artificial stone and a preparation method thereof. The artificial stone is characterized by comprising the followingcomponents in parts by mass: 800-1500 parts of broken sand, 800-2000 parts of mine waste rock broken powder, 800-1900 parts of cement, 315-740 parts of water, 20-85 parts of a water reducing agent, 0.001-0.1 part of toner, 0.01-0.5 part of a dispersing agent, 0.03-0.15 part of silica fume and 0.01-0.1 part of glass fibers. The method provided by the invention has the advantages that waste is turned into wealth, and the obtained artificial stone is high in strength.

Owner:福建省筑达石业有限公司

Ultra-high performance concrete for expansion joint transition area and preparation method thereof

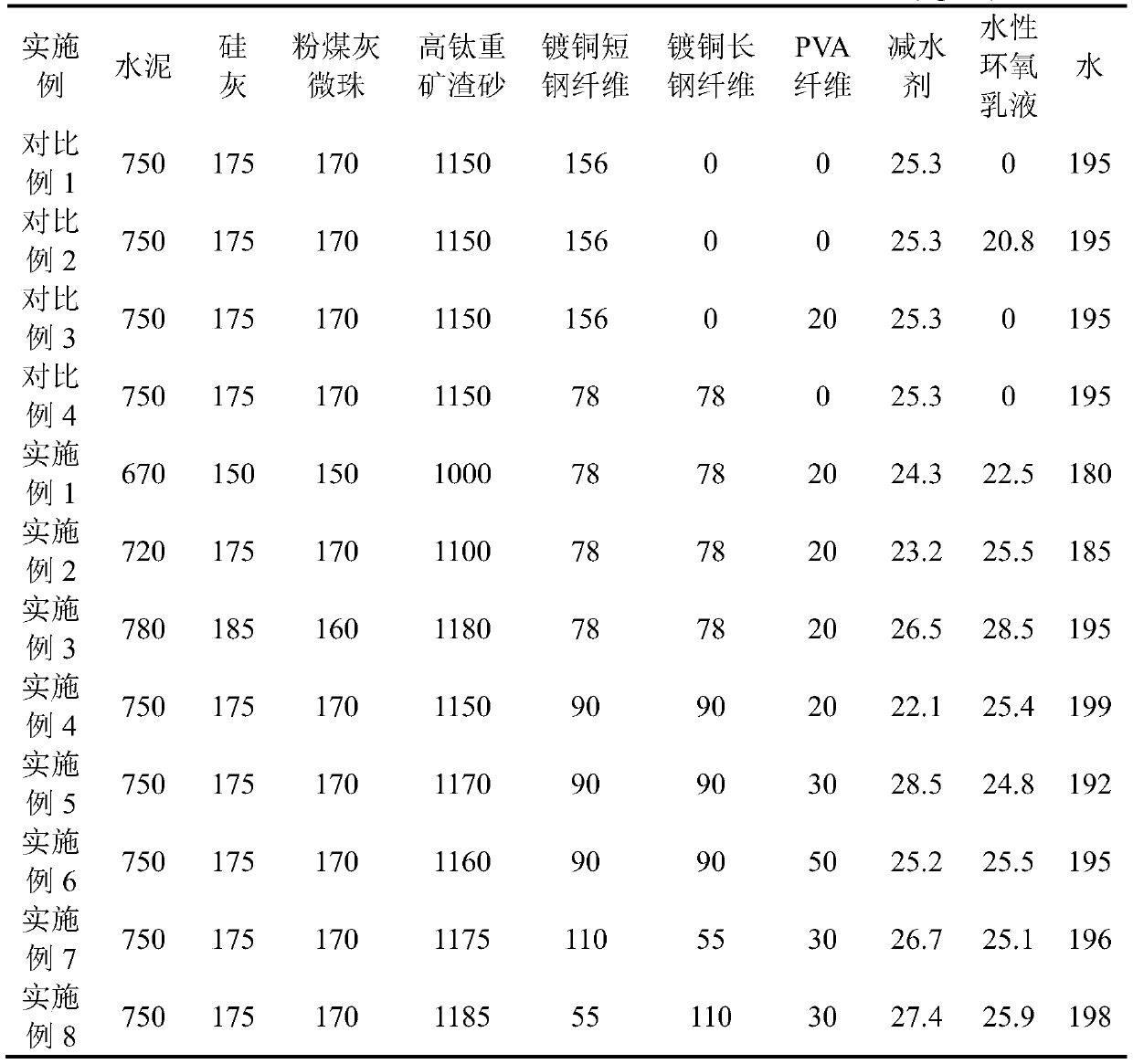

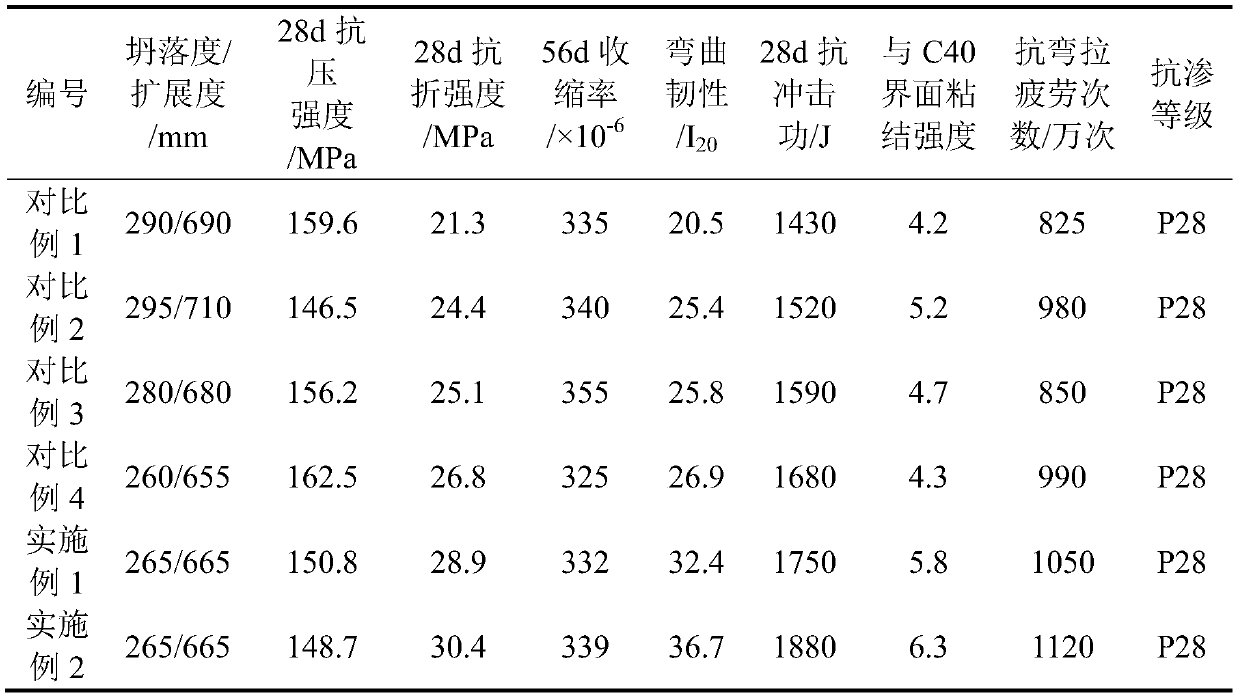

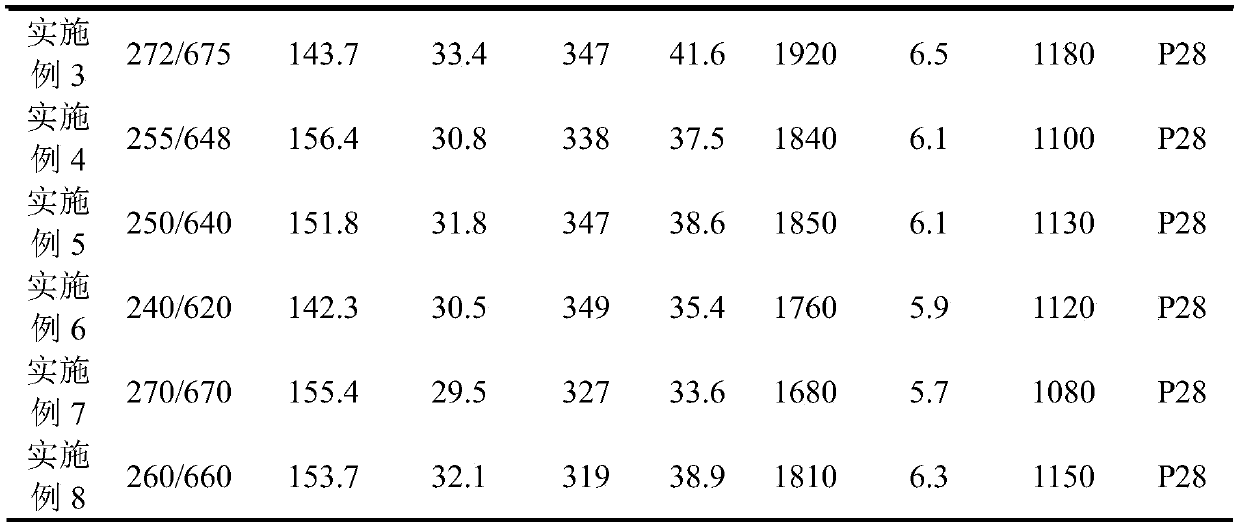

The invention discloses an ultra-high performance concrete for an expansion joint transition area. The ultra-high performance concrete is prepared from the following main raw materials: cement, fly ash microbeads, silica fume, high-titanium heavy slag sand, organic-inorganic hybrid fiber, a waterborne epoxy emulsion, a water reducing agent and water. According to the invention, the high-titanium heavy slag sand is used as aggregate, the internal curing and pin effects of the aggregate are utilized to improve the volume stability, anti-permeability and cracking resistance, and mechanical properties of the concrete; an organic-inorganic fiber composite toughening technology is adopted to enhance the bending toughness and impact resistance; the water reducing agent and fly ash microbeads areadded to improve the working performance and compactness; and the obtained ultra-high performance concrete has the advantages of high flow state, low shrinkage, high toughness, high adhesion, high impact performance, fatigue resistance and the like, can fundamentally solve the problems of repeated repairing, repeated damage and the like of concrete in expansion joint transition areas, and has important practical application value.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com