Concrete anticorrosive rust inhibitor for cast-in-place piles

A concrete and rust inhibitor technology, applied in the field of concrete anticorrosion and rust inhibitors, can solve problems such as construction quality accidents and inconvenient measurement operations, and achieve the effects of prolonging service life, optimizing pore structure, and increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

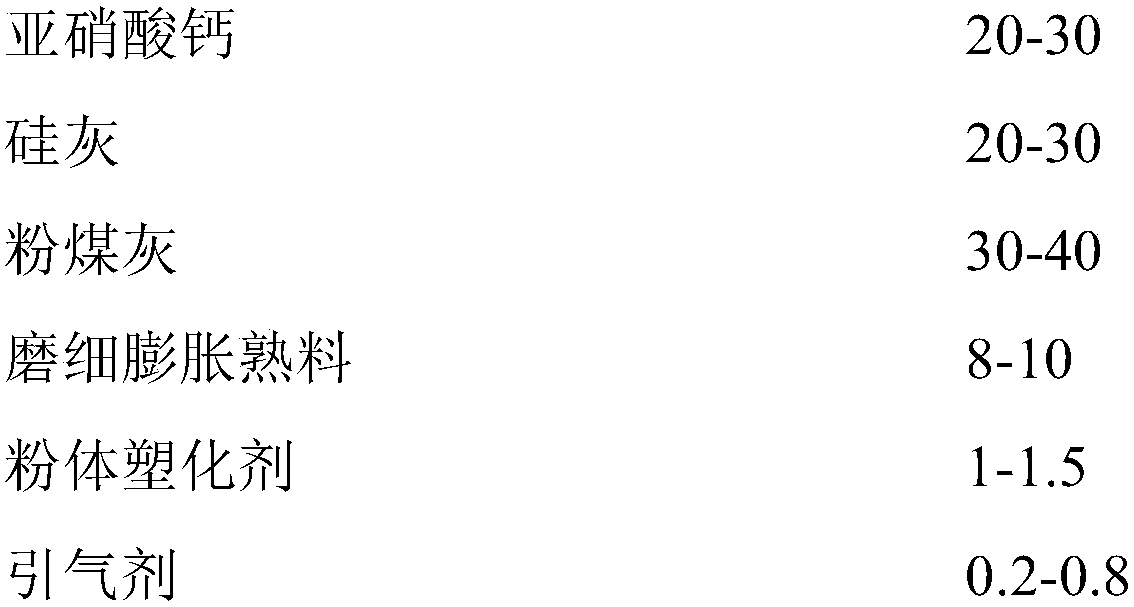

[0020] Prepare concrete anticorrosion and rust inhibitor according to the following ratio, accurately weigh it, put it into a mixer and stir evenly, and control the mixing time for 20 minutes.

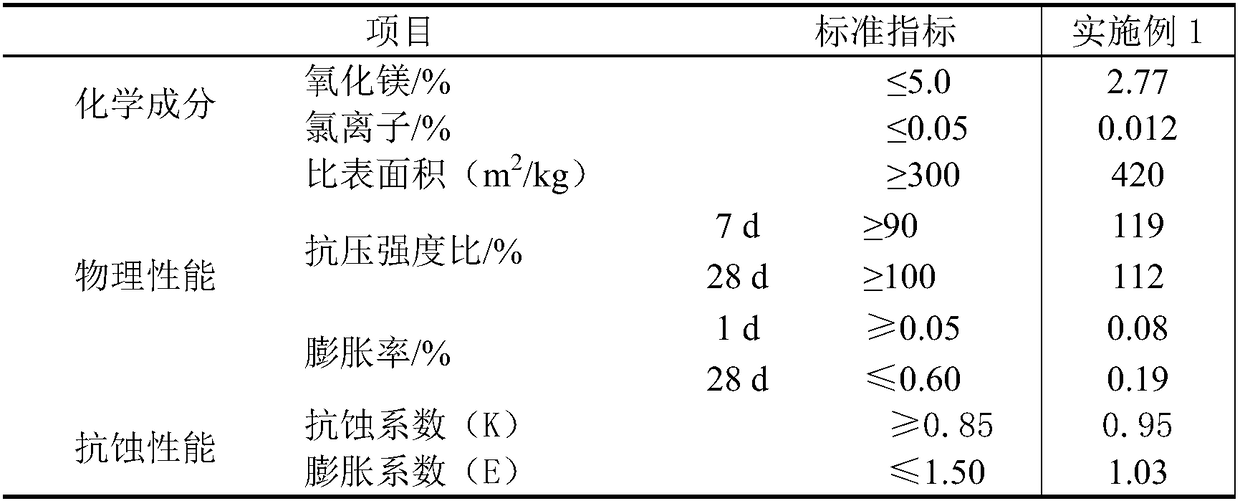

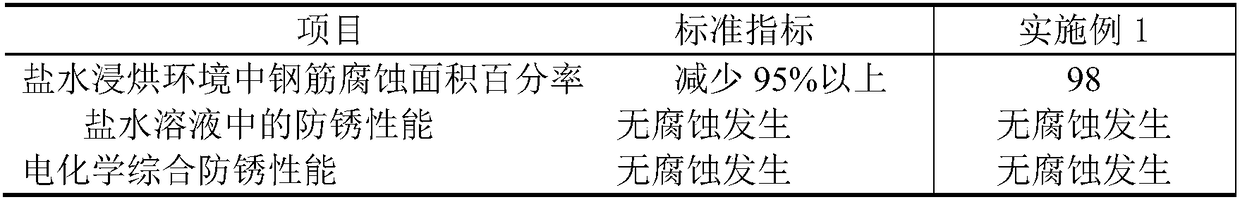

[0021] Its composition is: 20% of calcium nitrite, 30% of silica fume, 40% of Class I fly ash of F class, 8% of ground and expanded clinker (the main component is calcium oxide, calcined at high temperature, cooled to room temperature, and ground to Specified fineness, its specific surface area is greater than 300m 2 / kg, less than 400m 2 / kg), powder plasticizer (solid polycarboxylic acid) 1.5%, rosin air-entraining agent (triterpene saponin) 0.5%. Among them, the specific surface area of silica fume is 650m 2 / kg, the specific surface area of the particles after mixing all the materials is 420m 2 / kg. According to the provisions of JC / T1011-2006 "Concrete Sulfate Corrosion Resistance Anticorrosion Agent", the dosage is 10% by mass of cement (internal mixing method). Its physi...

Embodiment 2

[0028] Prepare the concrete anticorrosion and rust inhibitor according to the following proportions. After the components are accurately weighed, put them into the mixer and mix them evenly. The mixing time is controlled to be 20 minutes.

[0029] Composition: 30% calcium nitrite, 30% silica fume, 30% primary fly ash, 9% ground expanded clinker, 0.5% powder plasticizer, and 0.5% air-entraining agent. Among them, the specific surface area of silica fume is 650m 2 / kg, the type of each component chemical material in the composition is the same as that of Example 1. After mixing all the materials, the specific surface area of the particles is 430m 2 / kg.

[0030] According to the provisions of JC / T 1011-2006 "Concrete Sulfate Corrosion Resistance Anticorrosion Agent", the dosage is 10% by mass of cement (internal mixing method). Its physical and chemical properties are shown in Table 3, and all indicators meet the requirements. .

[0031] Table 3 Requirements for physical...

Embodiment 3

[0037] Prepare the concrete anti-corrosion and rust inhibitor according to the following ratio, accurately weigh it, put it into the mixer and mix it evenly, and control the mixing time for 20 minutes.

[0038] Calcium nitrite 25%, silica fume 25%, primary fly ash 40%, ground expanded clinker 9%, powder plasticizer 0.2%, air-entraining agent 0.8%. Among them, the specific surface area of silica fume is 650m 2 / kg, the type of each component chemical material in the composition is the same as that of Example 1. The specific surface area of the mixture particles is 410m 2 / kg.

[0039] According to the provisions of JC / T 1011-2006 "Concrete Sulfate Corrosion Resistance Anticorrosion Agent", the dosage is 10% by mass of cement (internal mixing method). Its physical and chemical properties are shown in Table 5, and all indicators meet the requirements .

[0040] Table 5 Requirements for physical and chemical properties of anti-sulfate corrosion inhibitors

[0041]

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com