Patents

Literature

43results about How to "Inhibit the electrochemical reaction process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

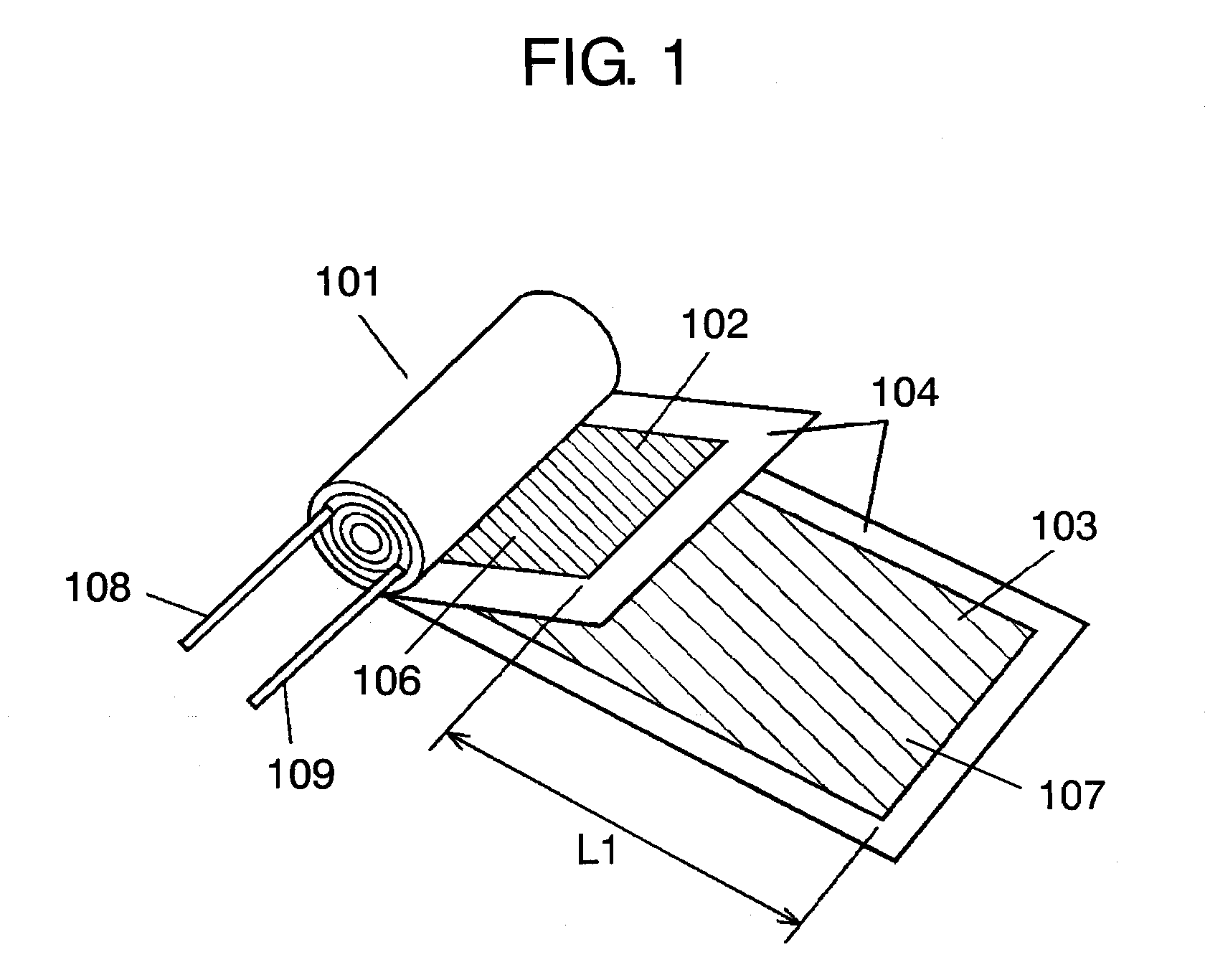

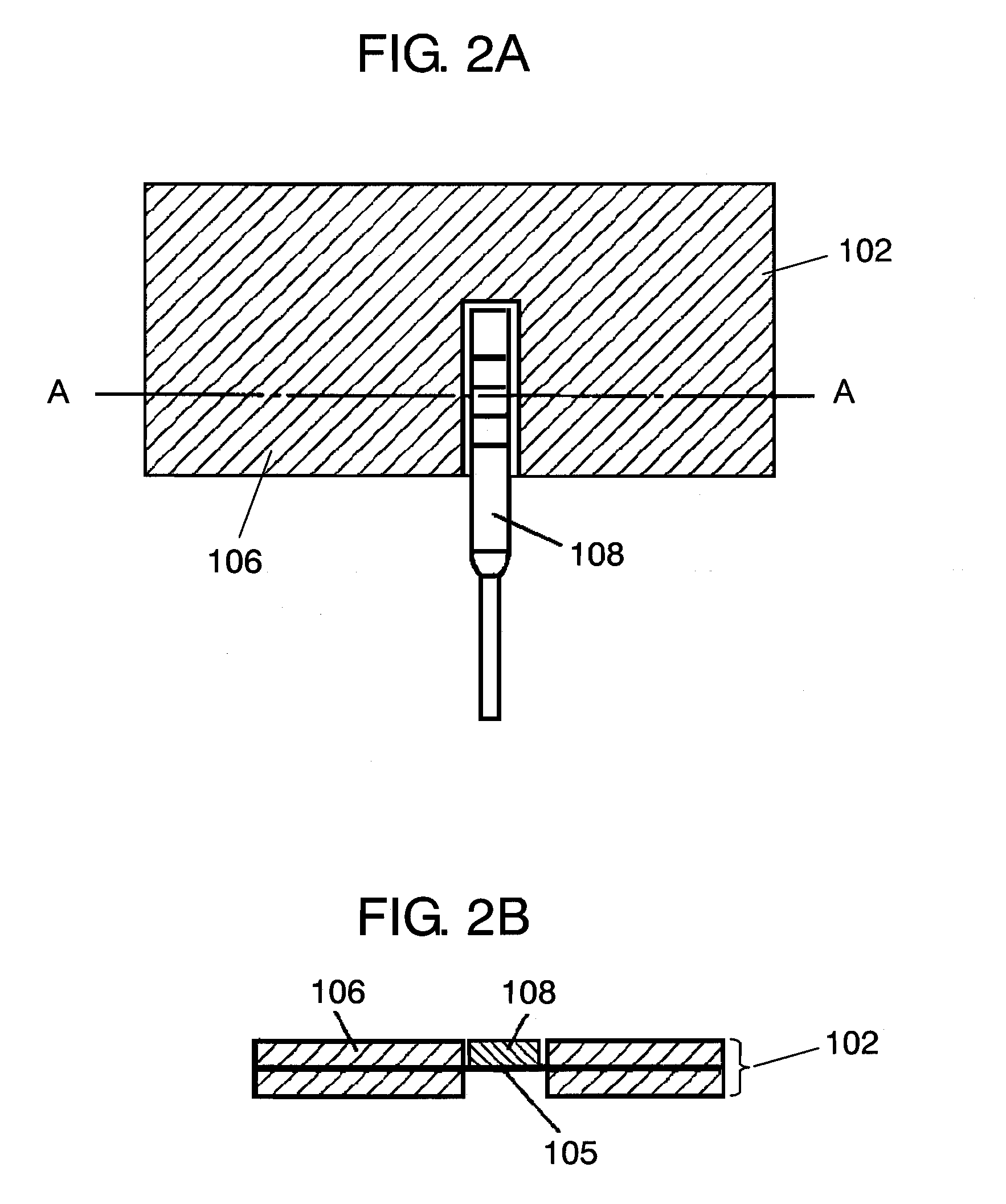

Wound electric double-layer capacitor

ActiveUS7881043B2Inhibit the electrochemical reaction processReduce degradationHybrid capacitor separatorsProtecting/adjusting hybrid/EDL capacitorElectrochemical responsePolymer capacitor

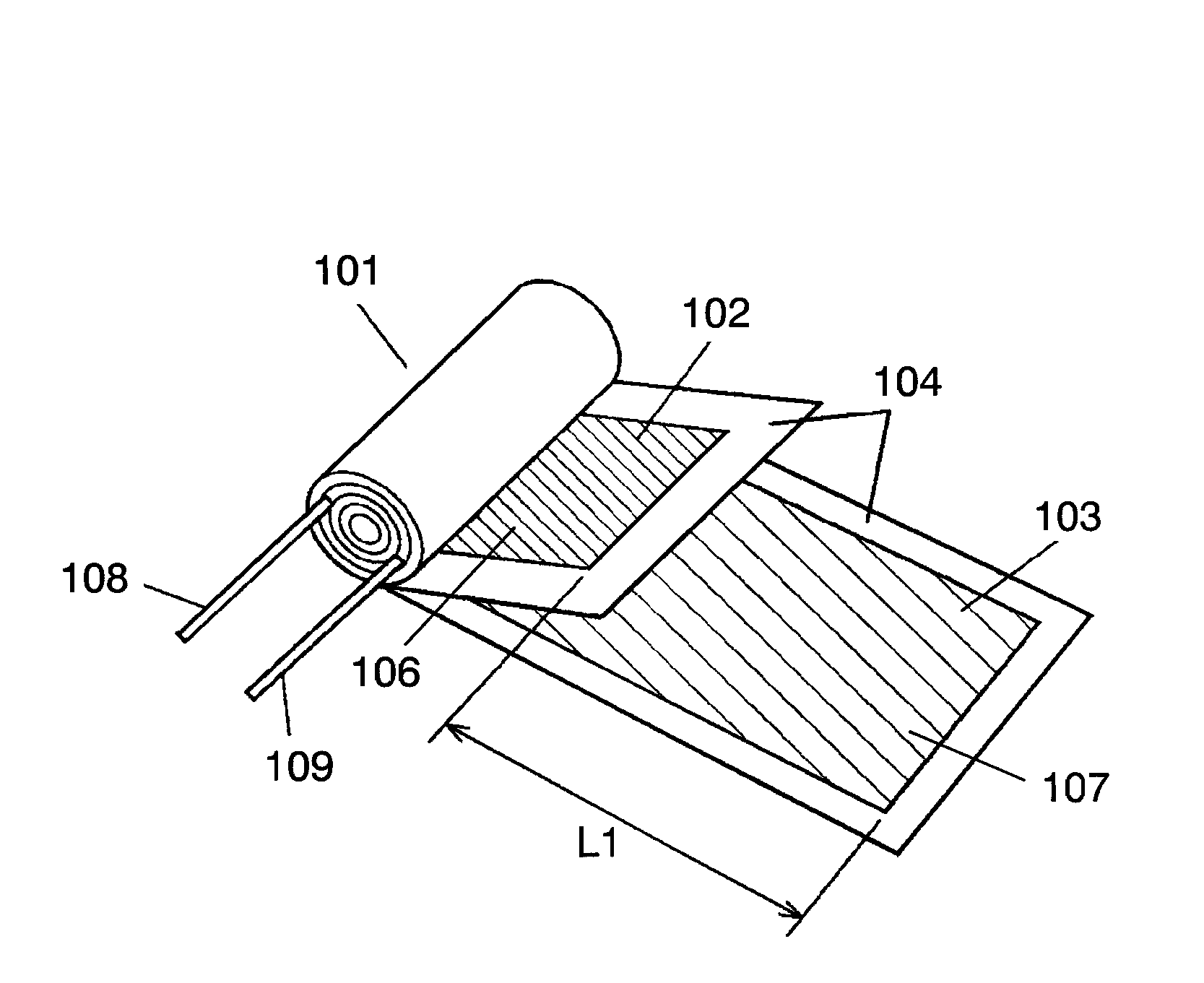

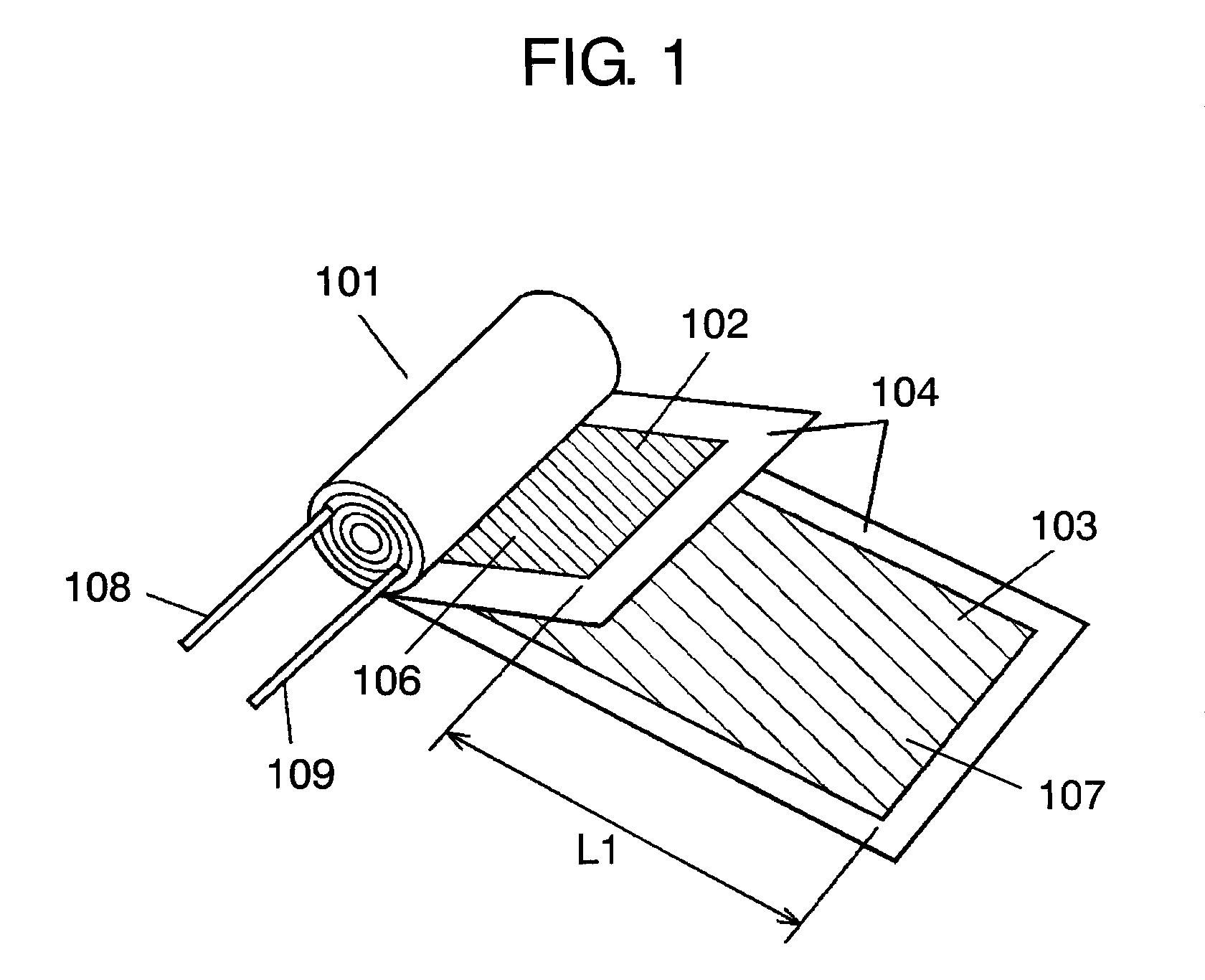

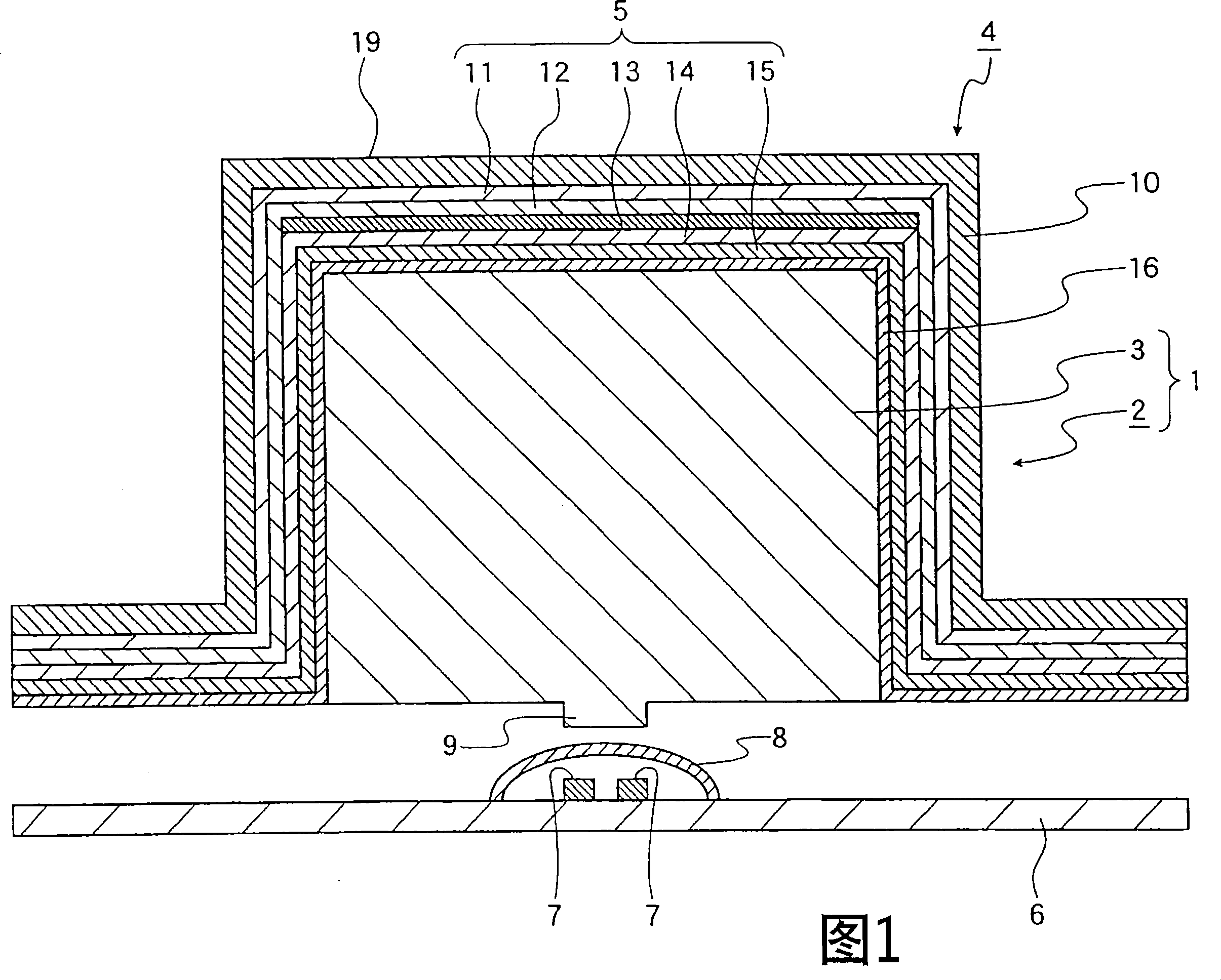

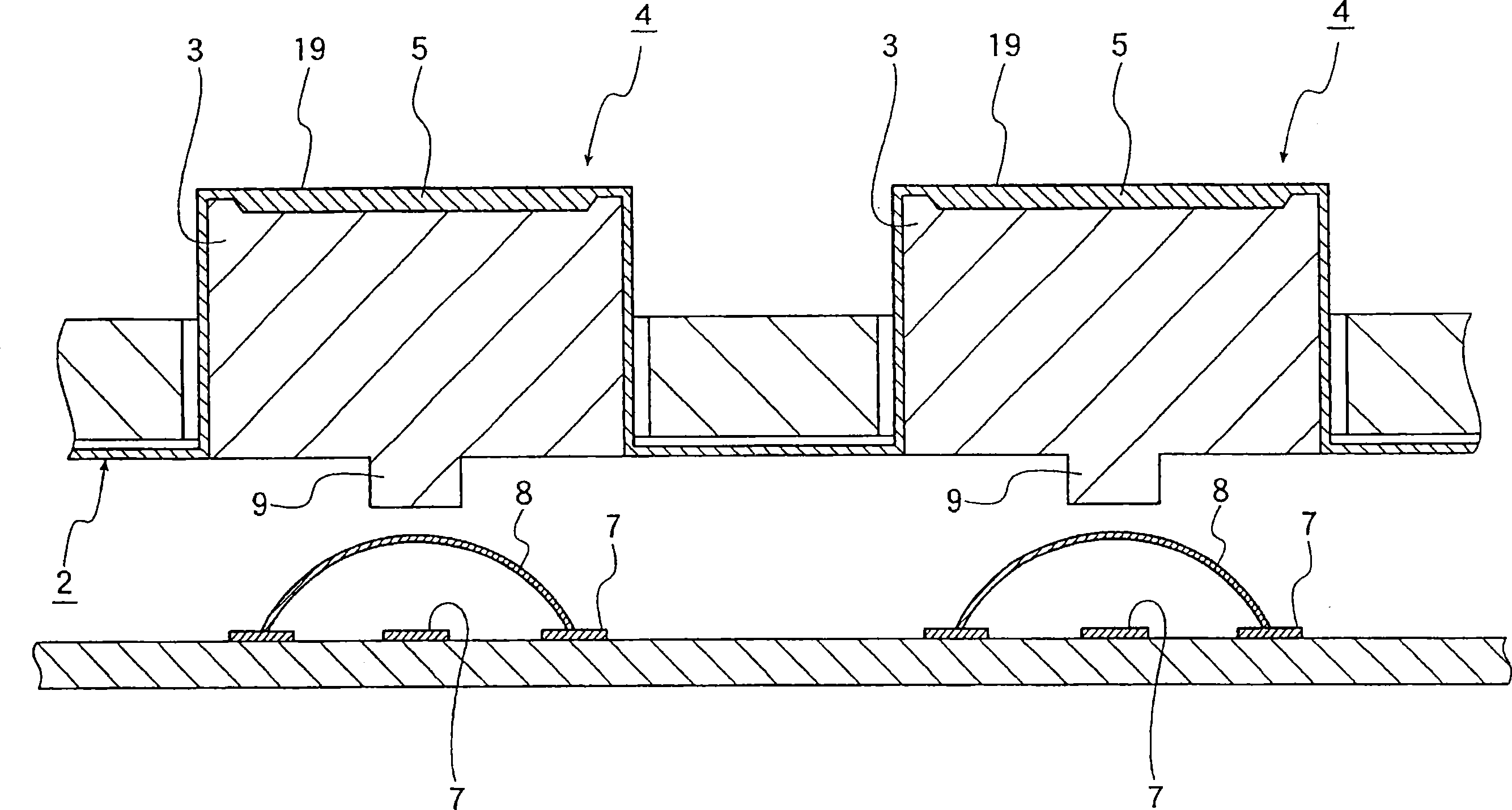

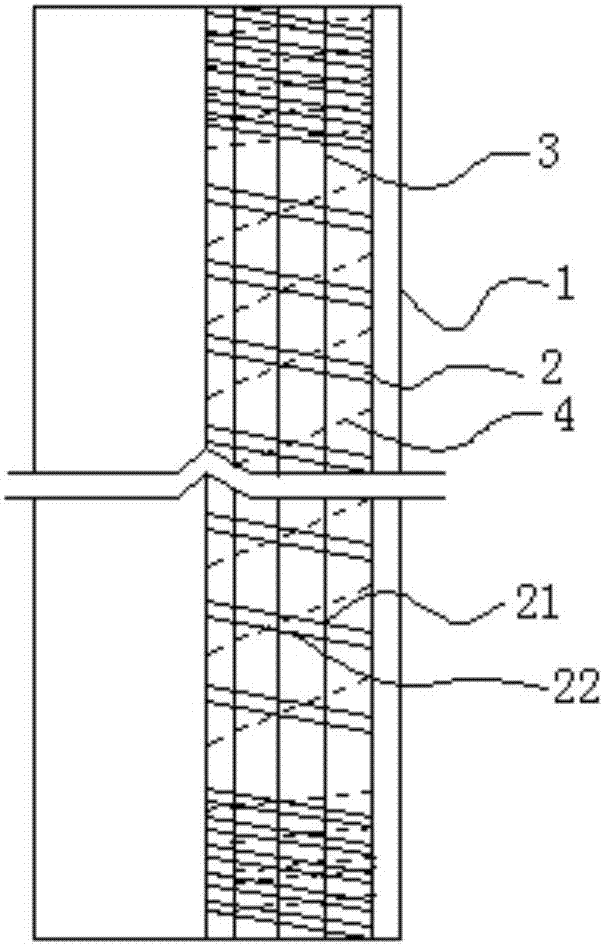

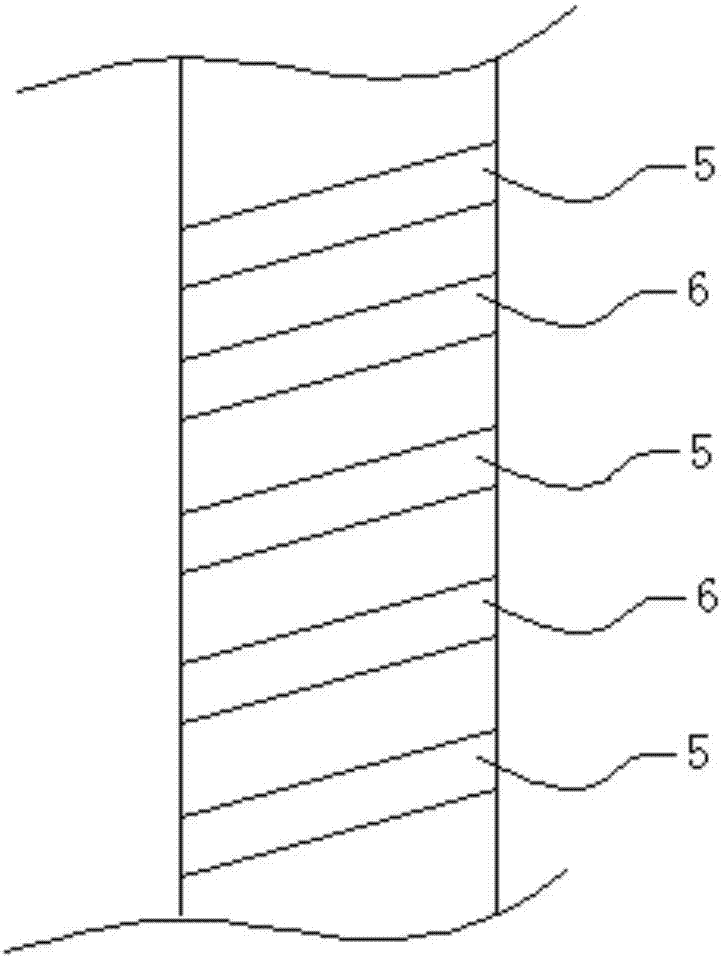

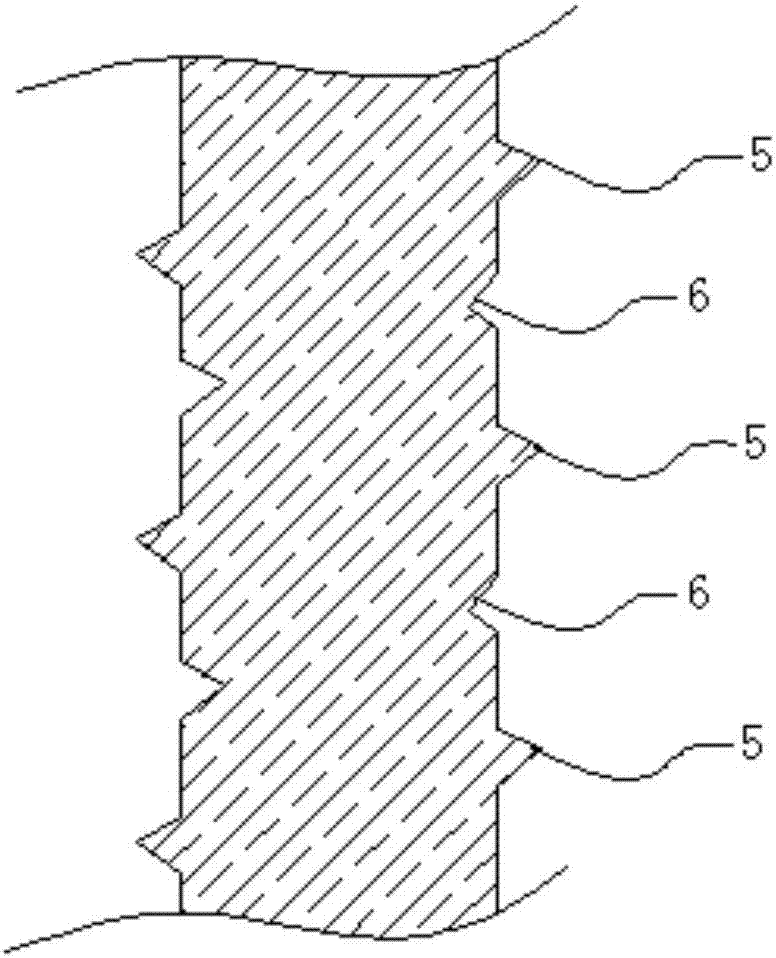

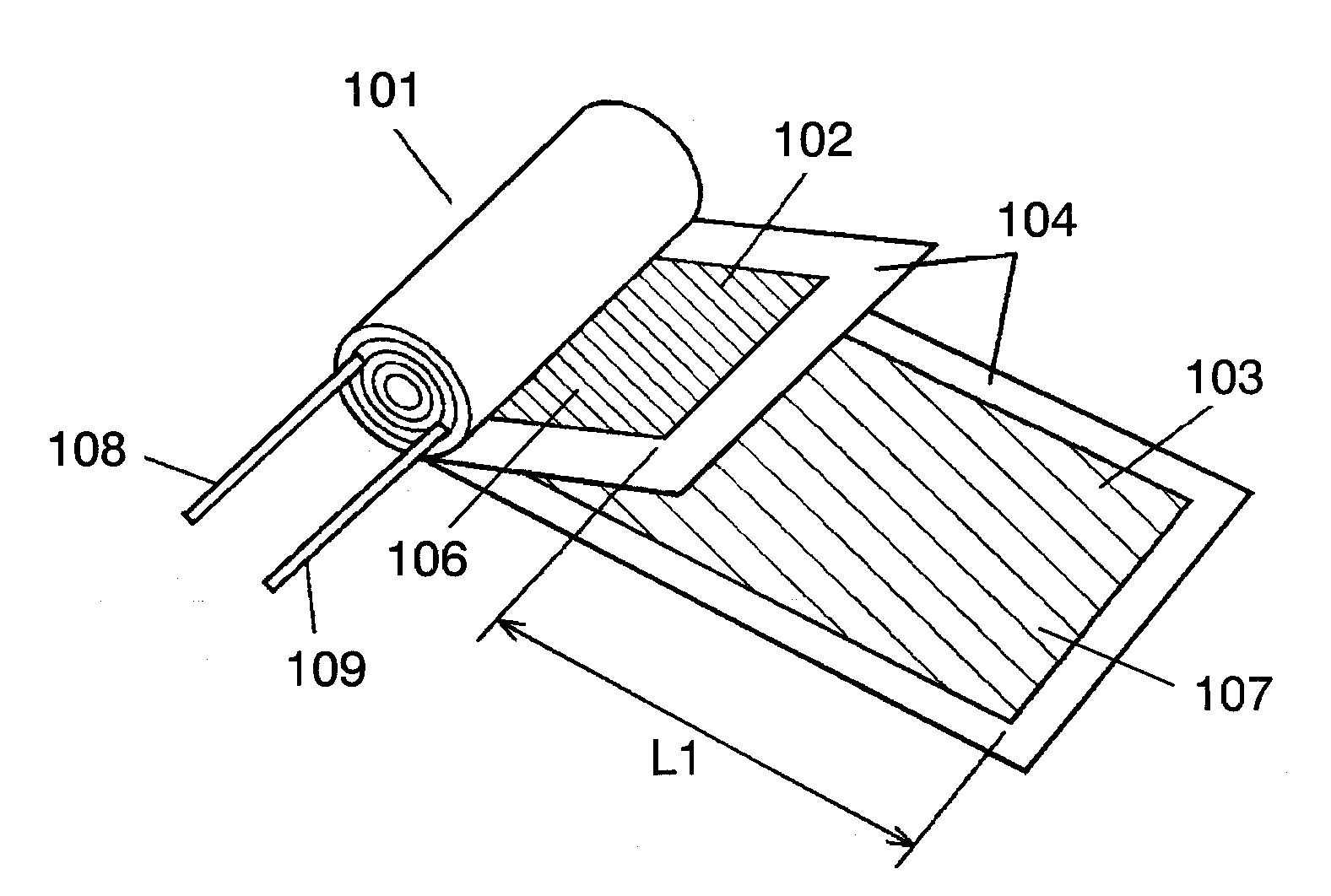

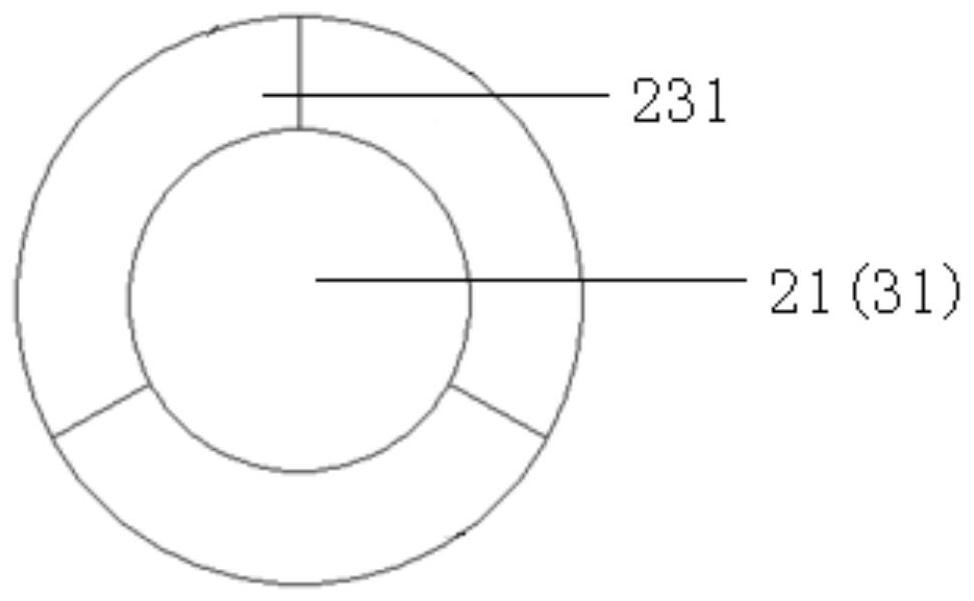

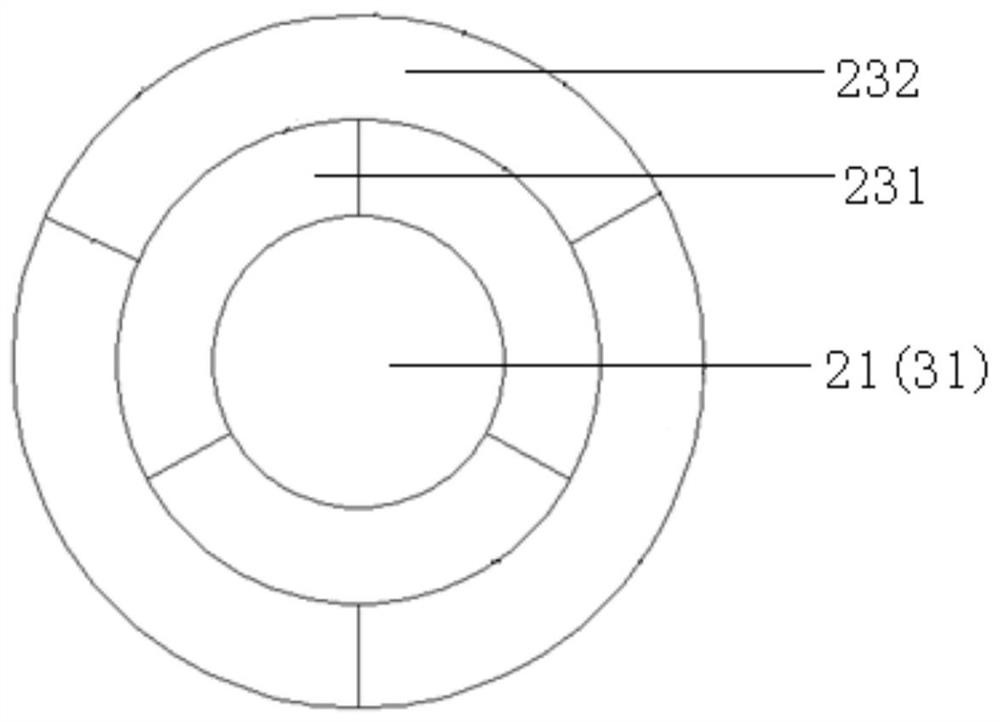

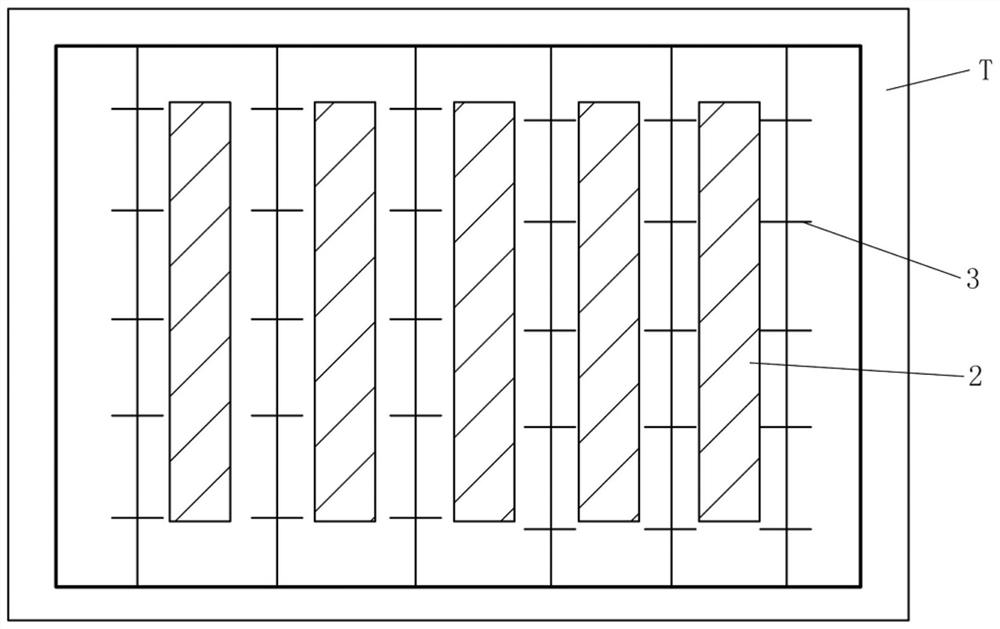

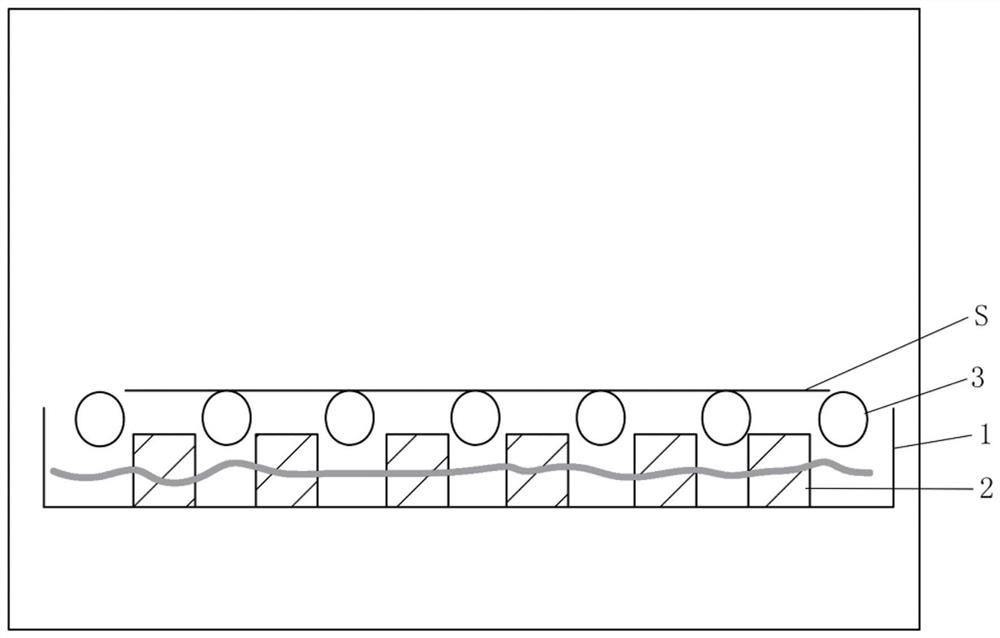

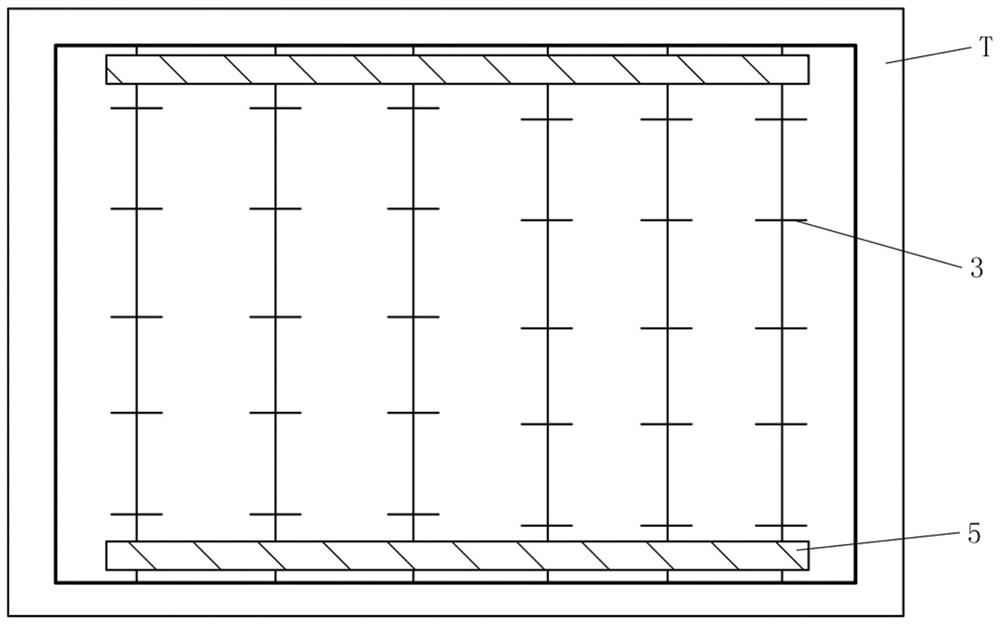

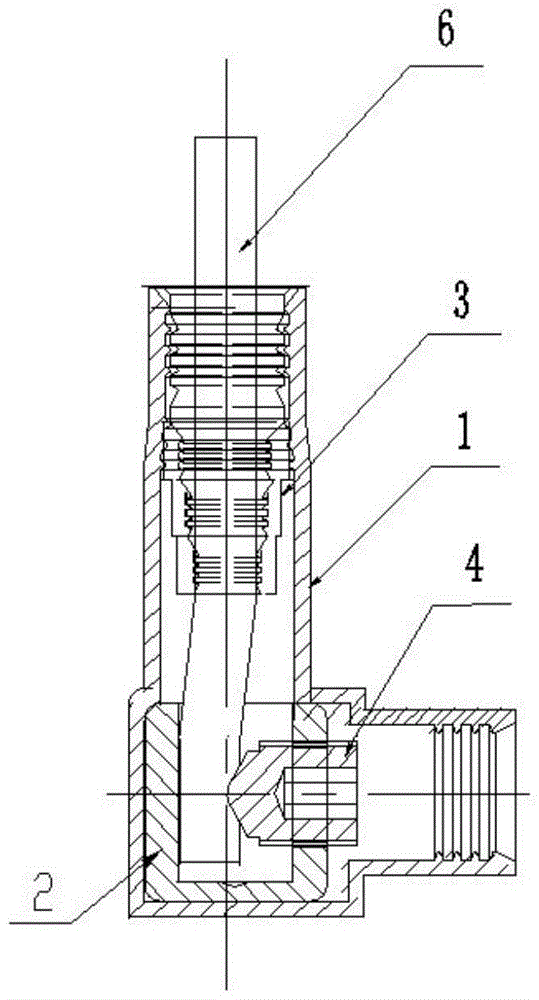

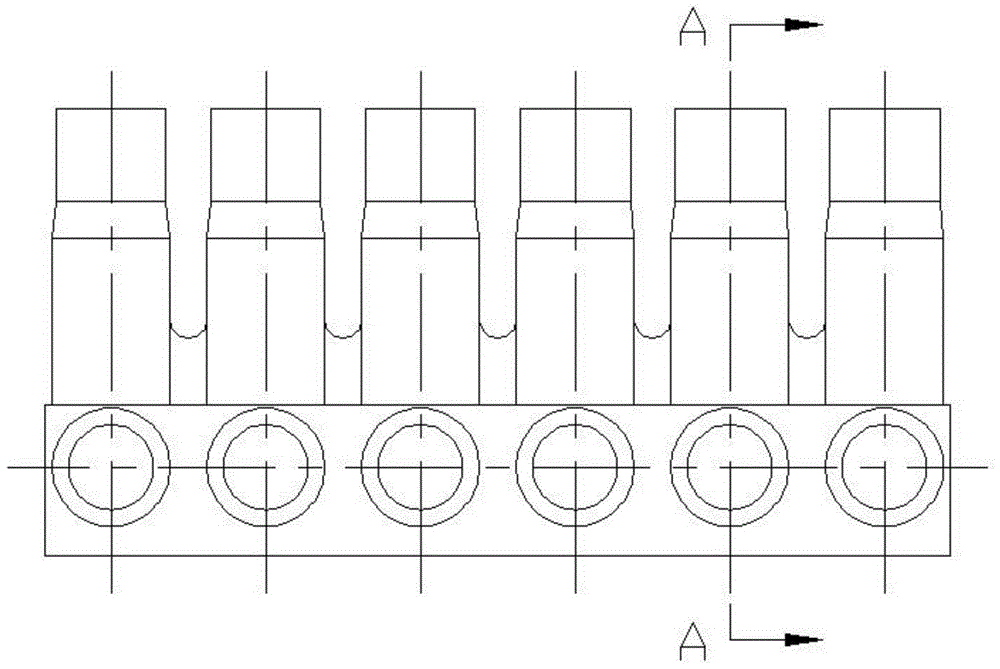

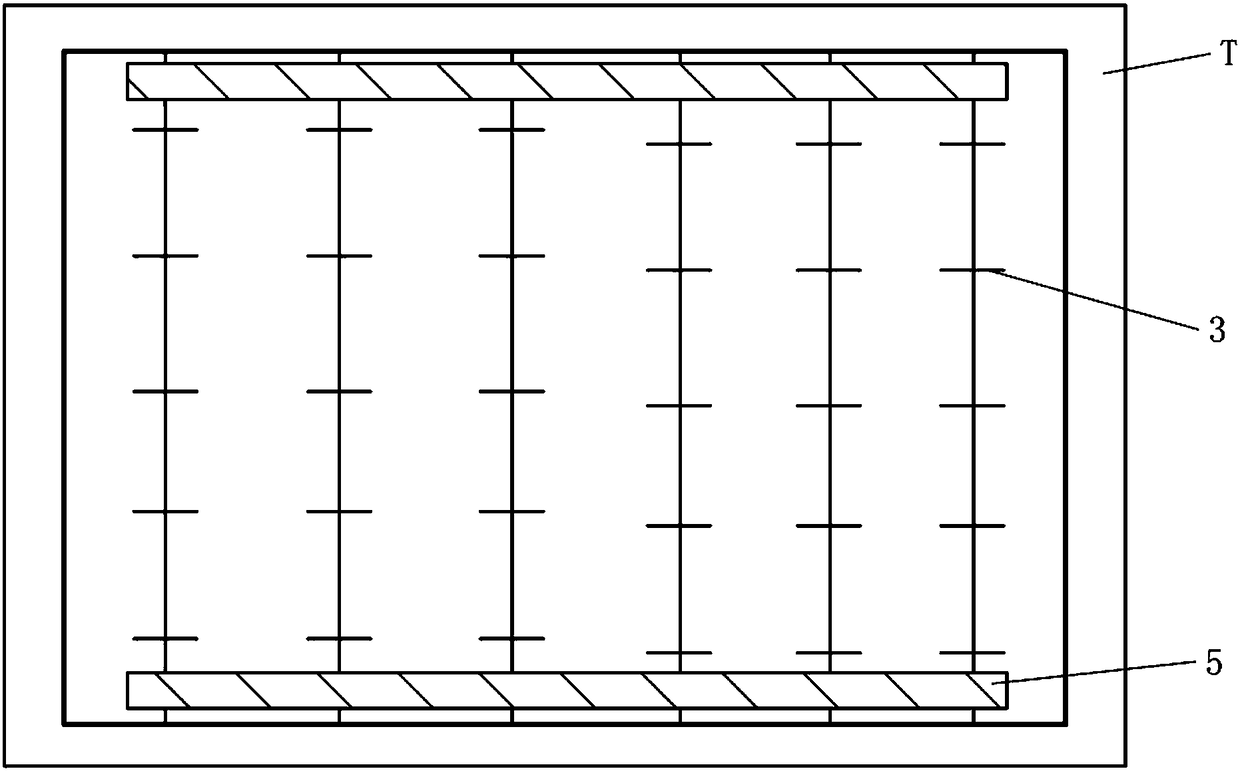

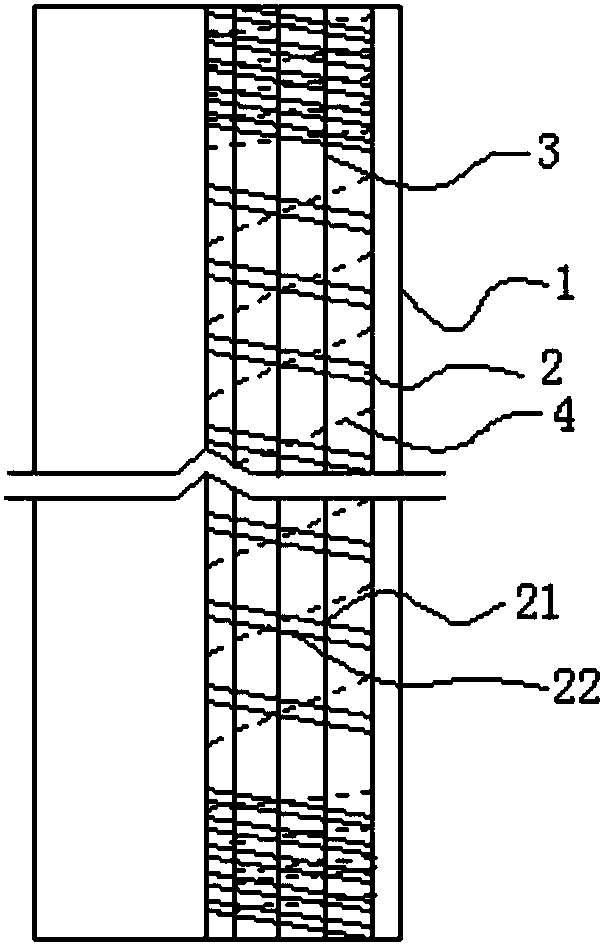

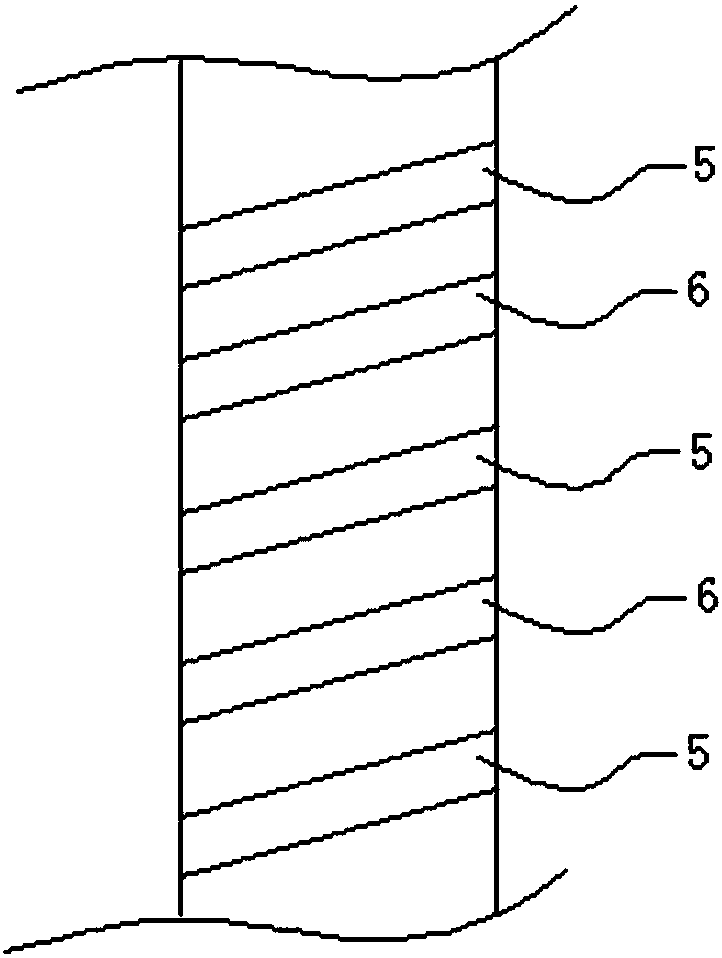

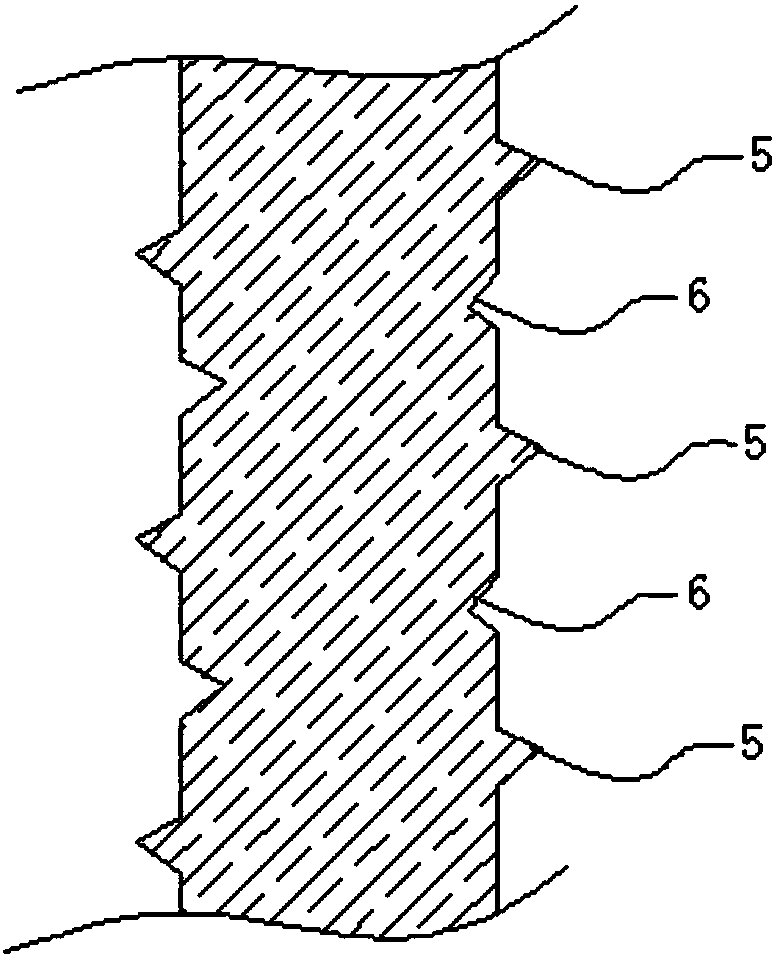

A wound electric double-layer capacitor suppresses electrochemical reaction on polarized electrode layers, reduces characteristic degradation, and has high reliability. The capacitor has a capacitor element formed by winding positive and negative electrodes with a separator interposed between them, a metal case for storing the capacitor element and an electrolyte for driving, and a sealing member for sealing an opening of the metal case. In the positive and negative electrodes, positive and negative electrode lead wires are coupled to exposed parts of current collectors having polarized electrode layers on their both surfaces, respectively. The negative electrode is wound at least one extra turn from the winding end of the positive electrode of the capacitor element, and hence a part where the polarized electrode layers formed in the negative electrode face each other through the separator is formed on the outermost periphery of the capacitor element.

Owner:PANASONIC CORP

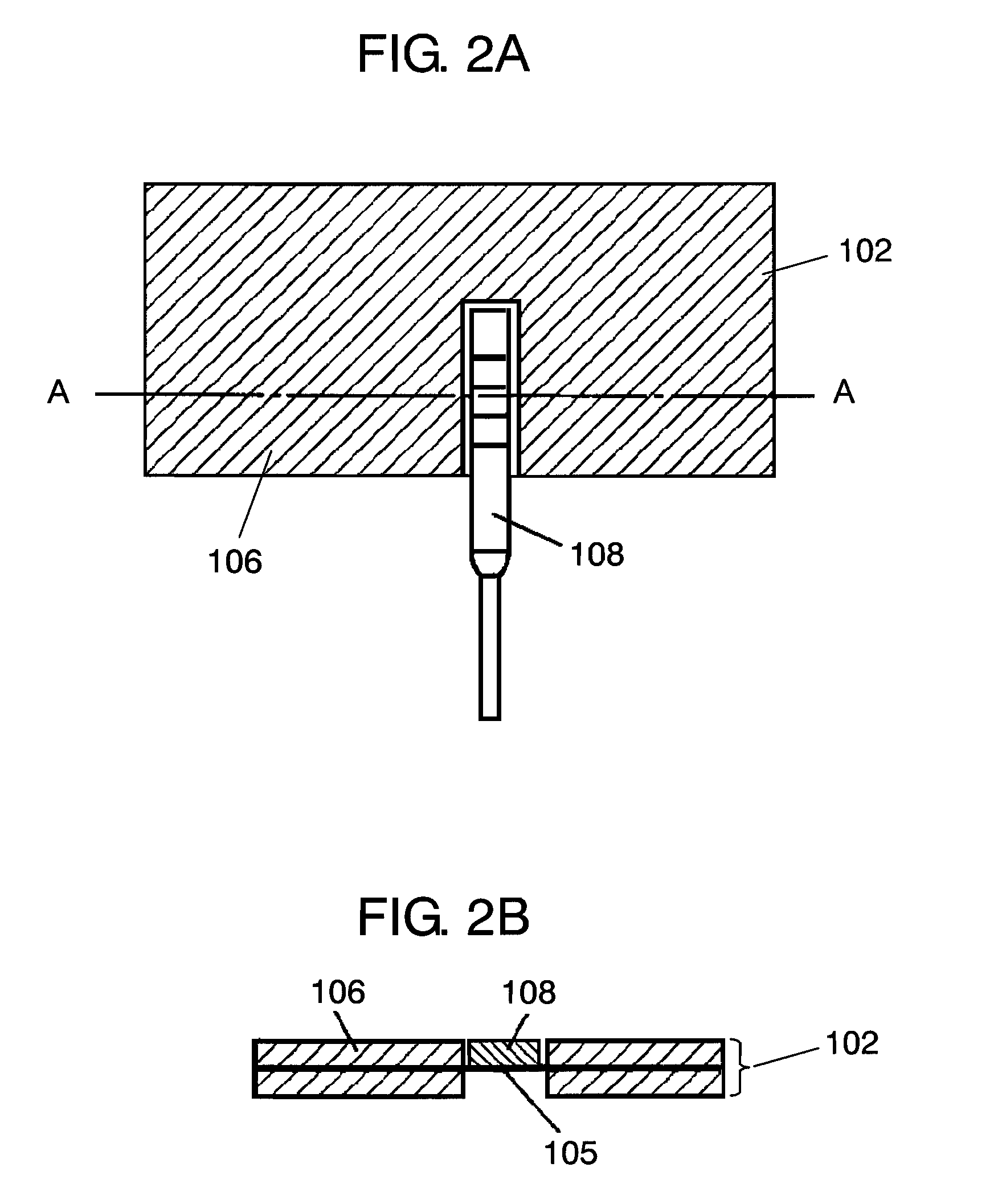

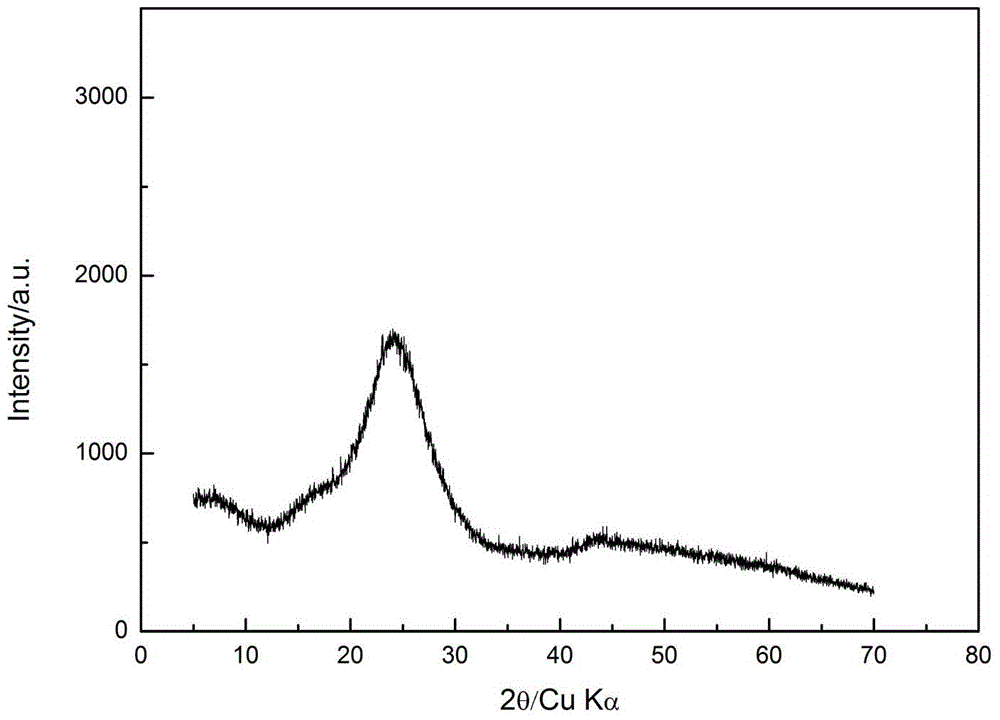

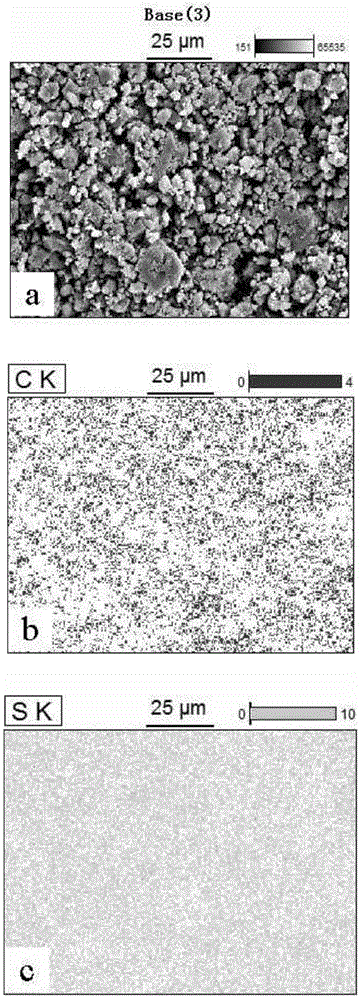

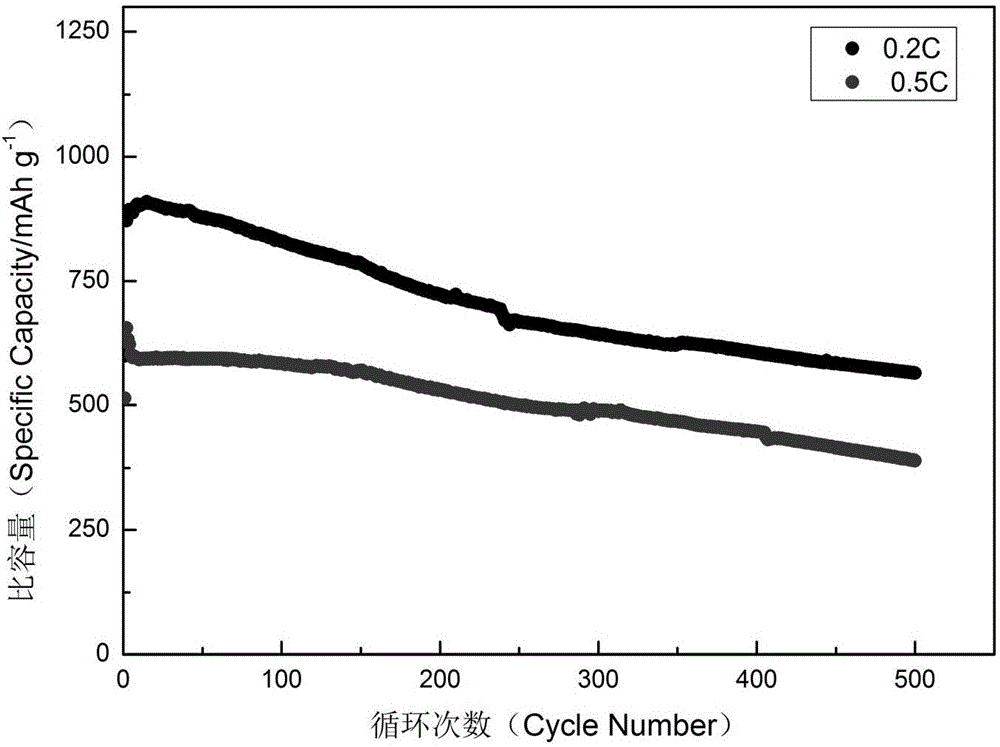

Preparation method of S-C positive pole composite material of high cycle performance lithium sulfur battery

InactiveCN103560232AGood electron transport propertiesImprove uniformityCell electrodesMicrowave ovenOrganic solvent

The invention relates to a preparation method of an S-C positive pole microwave composite material of a high cycle performance lithium sulfur battery. Firstly, sulfur, carbon materials are put into a ball mill for ball-milling mixing, and then put into a microwave oven for microwave heating and compositing to prepare the S-C positive pole microwave composite material with high dispersion uniformity. The S-C positive pole microwave composite material and a conductive agent are ground and mixed uniformly, the S-C positive pole microwave composite material and a binder are dispersed in an organic solvent in a certain proportion, and stirred to prepare paste, and then the paste is evenly coated onto a current collector sheet, and dried to prepare a positive pole. The preparation method adopts an advanced microwave heating method, has the advantages of fast heating speed, mild conditions and high efficiency, the prepared positive pole composite material is stable in structure, the battery has good cycle stability, at the same time, the commercial carbon material with low price is used, the material cost is greatly reduced, and the preparation method is suitable for popularization.

Owner:NANJING UNIV OF TECH

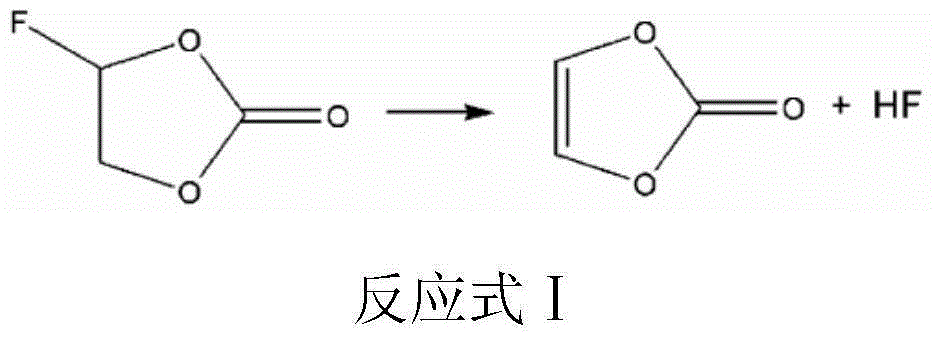

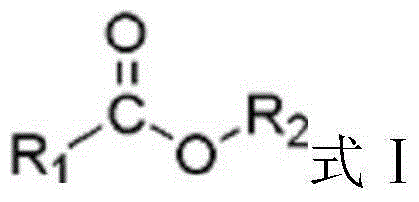

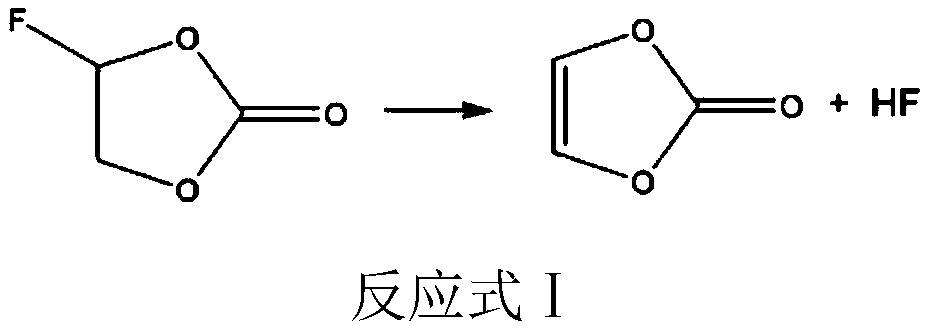

Lithium ion battery

InactiveCN106602131AReduce interface impedanceReduce consumptionSecondary cellsNon-aqueous electrolyte accumulator electrodesCurrent collectorLithium electrode

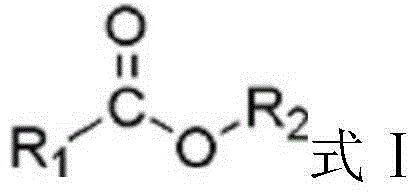

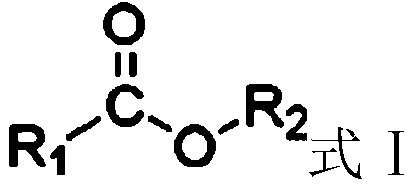

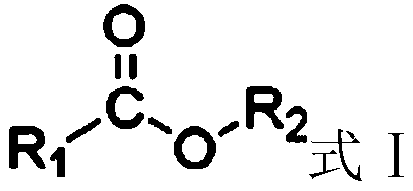

The present invention provides a lithium ion battery, which comprises: a positive electrode sheet, wherein the positive electrode sheet comprises a positive electrode current collector and a positive electrode membrane sheet arranged on the positive electrode current collector; a negative electrode sheet, wherein the negative electrode sheet comprises a negative electrode current collector and a negative electrode membrane sheet arranged on the negative electrode current collector; a separation membrane arranged between the positive electrode sheet and the negative electrode sheet in a spacer manner; and a non-aqueous electrolyte, wherein the non-aqueous electrolyte comprises a lithium salt, a non-aqueous organic solvent and an additive, both surface coating weights of the positive electrode membrane sheet are not less than 28 mg / cm<2> and the compaction density is not less than 3.5 g / cm<3>, both surface coating weights of the negative electrode membrane sheet is not less than 14 mg / cm<2> and the compaction density is not less than 1.4 g / cm<3>, the non-aqueous organic solvent comprises a linear carboxylic acid ester having a structure represented by a formula I, R1 and R2 in the formula I are respectively and independently selected from C2-C4 alkyl, and the additive comprises 1,3-propanesultone and fluoroethylene carbonate. The lithium ion battery of the present invention has advantages of high energy density, high first Kurun efficiency, excellent fast charging performance, and excellent low-temperature charging performance. The formula I is defined in the specification.

Owner:NINGDE AMPEREX TECH

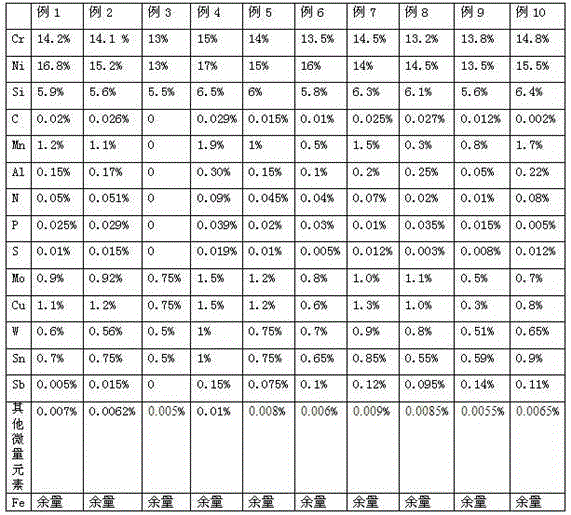

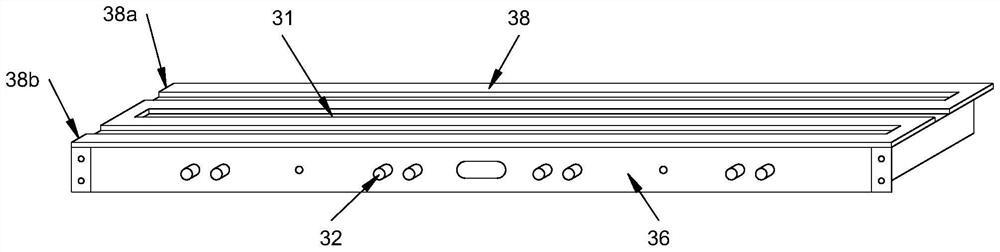

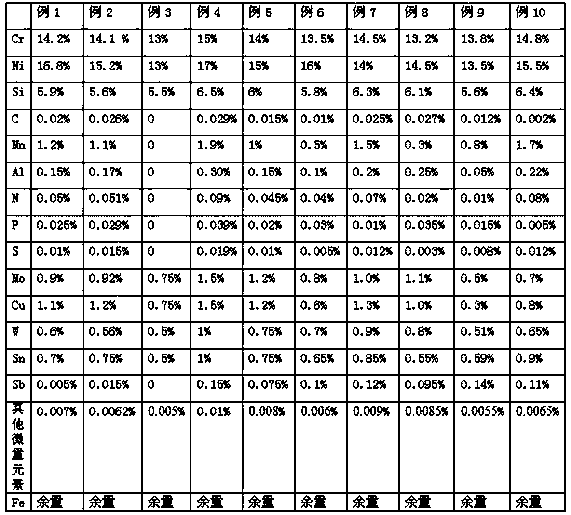

High-silicon austenitic stainless steel resistant to concentrated sulfuric acid corrosion and preparing method of high-silicon austenitic stainless steel

ActiveCN106756559AImprove erosion abilityImprove the corrosion resistance of high temperature concentrated sulfuric acidSS - Stainless steelAustenite

The invention provides high-silicon austenitic stainless steel resistant to concentrated sulfuric acid corrosion and a preparing method of the high-silicon austenitic stainless steel, the high-silicon austenitic stainless steel can resist concentrated sulfuric acid corrosion, has good mechanical performance and welding performance, and can be used for producing a device and a pipeline used for producing concentrated sulfuric acid. The stainless steel comprises, by weight percent, 13%-15% of Cr, 13%-17% of Ni, 5.5%-6.5% of Si, smaller than 0.03% of C, smaller than 2% of Mn, smaller than or equal to 0.30% of Al, smaller than 0.1% of N, smaller than 0.04% of P, smaller than 0.02% of S, 0.75%-1.5% of Mo, 0.75%-1.5% of Cu, 0.5%-1% of W, 0.5%-1% of Sn, smaller than or equal to 0.15% of Sb, 0.005%-0.01% of other microelements, and the balance Fe. According to the preparing method, the production technology of mother liquor smelting through a Consteel electric furnace and an intermediate frequency furnace, AOD, LF, casting and electroslag remelting is adopted.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

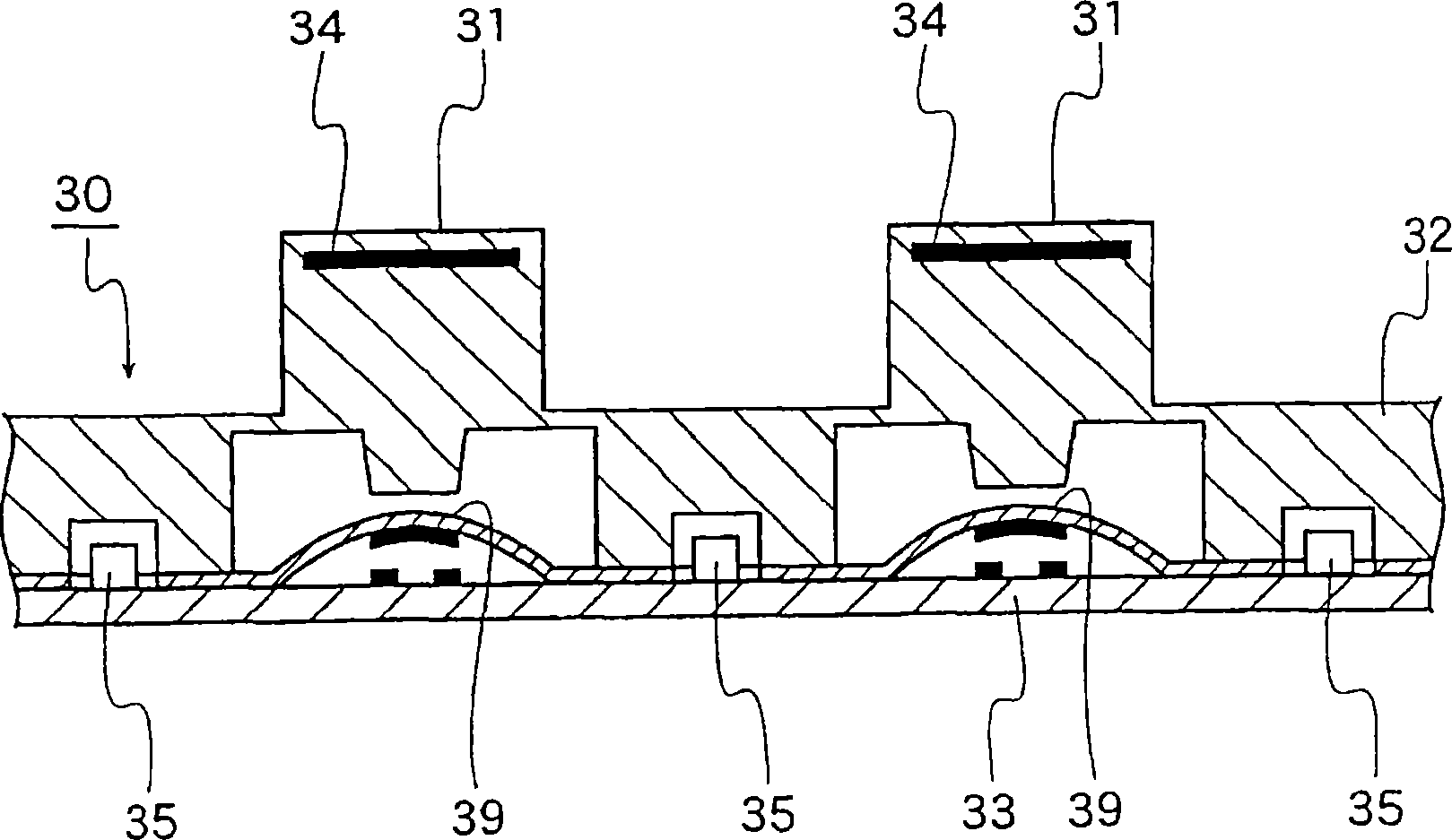

EL sheet and component for lighting type push-button switch

InactiveCN1906977ALuminous stabilityImprove bindingElectroluminescent light sourcesElectric switchesPolyesterPolyolefin

It is to provide an EL sheet and a member for lighting a push-button switch capable of emitting light stably and sufficiently for a long period of time without problems such as non-light emission phenomena and generation of black dot, even if the EL element is subjected to, for example, a drawing process to form into a three-dimensional shape. A laminated EL sheet is formed that comprises a counter electrode layer 15, a dielectric layer 14, a light-emitting layer 13, and a transparent electrode layer 11. An adhesive layer 12 made of adhesive having excellent adhesiveness to the electroconductive polymer is disposed between the transparent electrode layer 11 made of an electroconductive polymer and the light-emitting layer 13. In order that the adhesives have excellent adhesiveness, polyester, acrylic, cyanoacrylate, polyolefin, ethylene-vinyl acetate or ethylene ethyl acrylate type adhesive is used. The dielectric layer is made of fluoro type, polyester type or acrylic type resin binder. Furthermore, to improve durability in a hot and high-humidity environment, a second counter electrode layer 17 and / or a second dielectric layer 17, both having an ion diffusion-preventing function is / are disposed.

Owner:SHIN-ETSU POLYMER CO LTD

Method for preparing corrosion-resistant antibacterial polyurea composite coating

InactiveCN103436149AHigh hardnessImprove wear resistanceBiocideAntifouling/underwater paintsAnti bacterialAntibacterial agent

The invention relates to a method for preparing a corrosion-resistant antibacterial polyurea composite coating, relating to a preparation method of a polymer nanometer composite coating. The method comprises the following steps of preparing a component A of the coating; preparing a component B mixed with a nanometer antibacterial agent; respectively adding the component A and the component B mixed with the nanometer antibacterial agent to spraying equipment for spraying so as to prepare the corrosion-resistant antibacterial polyurea composite coating. Compared with the prior art, the corrosion-resistant antibacterial composite coating with a metal or concrete surface, which is provided by the invention, enhances the antibacterial capacity of the polyurea coating by adding the nanometer antibacterial agent to the component B, reduces the microdefects of the coating and enhances the corrosion resistance and abrasion resistance of the coating.

Owner:扬州龙华环境工程有限公司

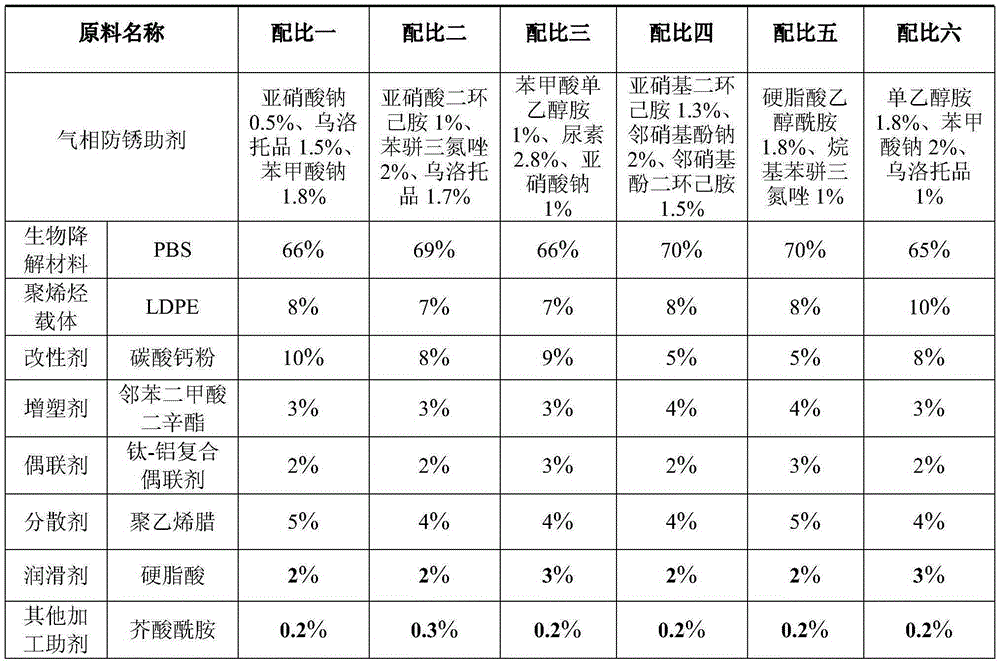

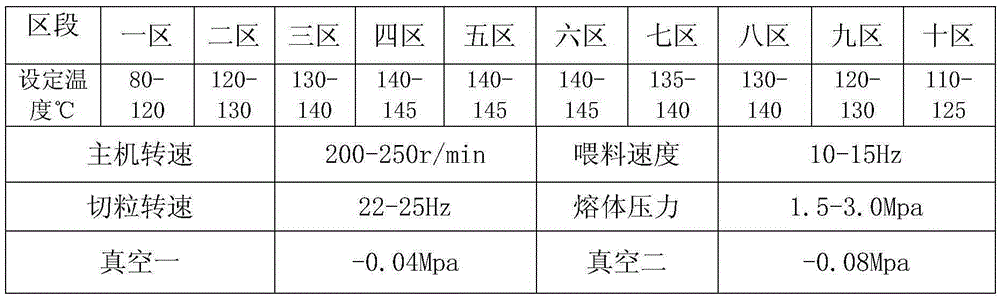

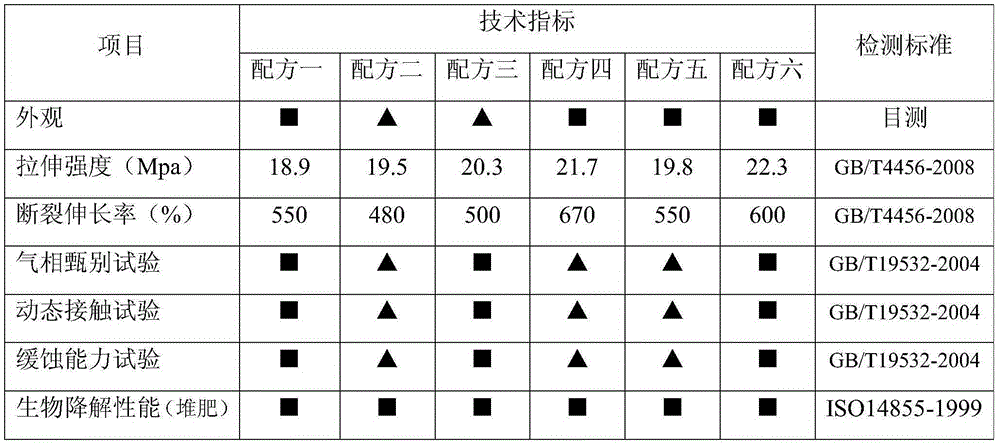

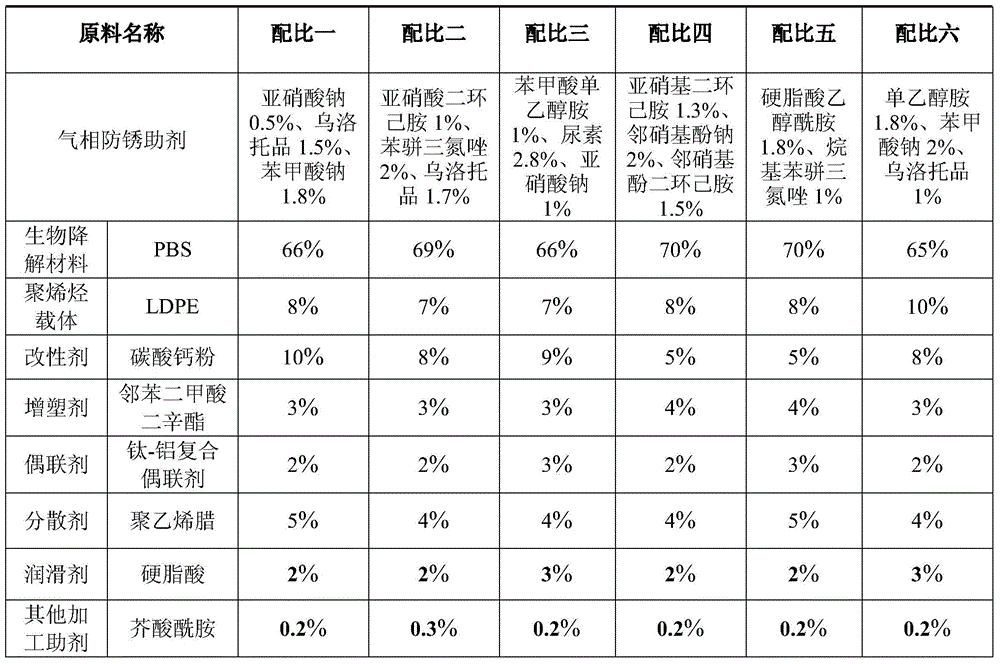

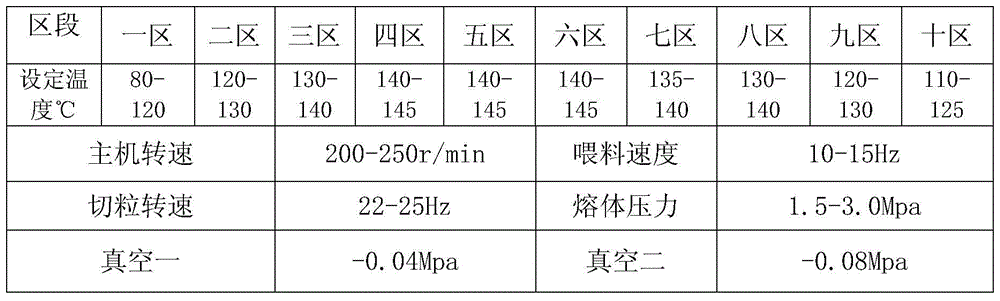

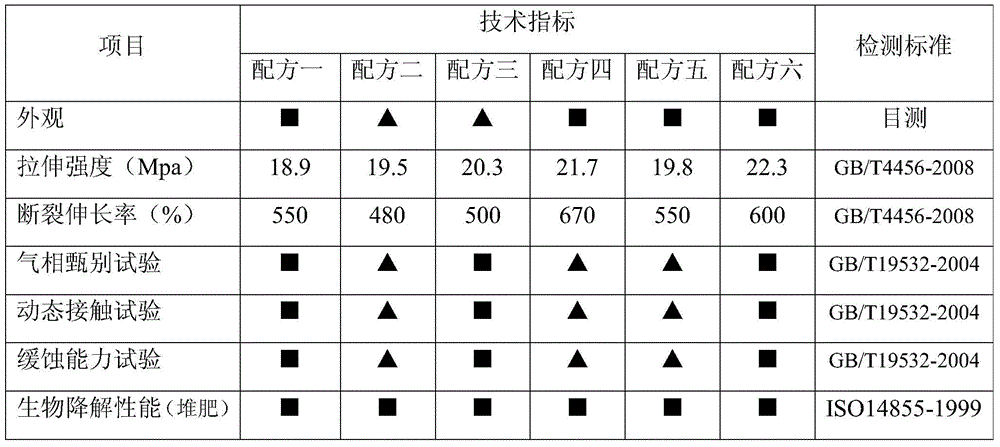

Composite biodegradation gas-phase anti-rusting membrane and preparation process thereof

The invention belongs to the technical field of multi-functional high polymer materials, in particular relates to a composite biodegradation gas-phase anti-rusting membrane and a preparation process thereof, and aims to provide a composite biodegradation gas-phase anti-rusting membrane which is rapid in preparation method, simple to prepare, low in cost and free of environment pollution, and a preparation process thereof. The composite biodegradation gas-phase anti-rusting membrane is prepared from the following raw materials in percentage by mass: 2-5% of a gas-phase anti-rusting additive, 60-75% of a biodegradation material, 5-10% of a polyolefin carrier, 5-10% of a modifier, 2-5% of a plasticizer, 2-3% of a coupling agent, 4-6% of a dispersing agent, 1-3% of a lubricant and 0.1-0.3% of other processing additives. The composite biodegradation gas-phase anti-rusting membrane provided by the invention has the characteristics of good barrier property, conductivity, flame retardancy and ultraviolet ray prevention, and gas-phase anti-rusting gases generated from the composite biodegradation gas-phase anti-rusting membrane can be volatilized and permeated into corners which cannot be covered by anti-rusting oil in package parts, and can be biologically degraded.

Owner:重庆博浪塑胶股份有限公司

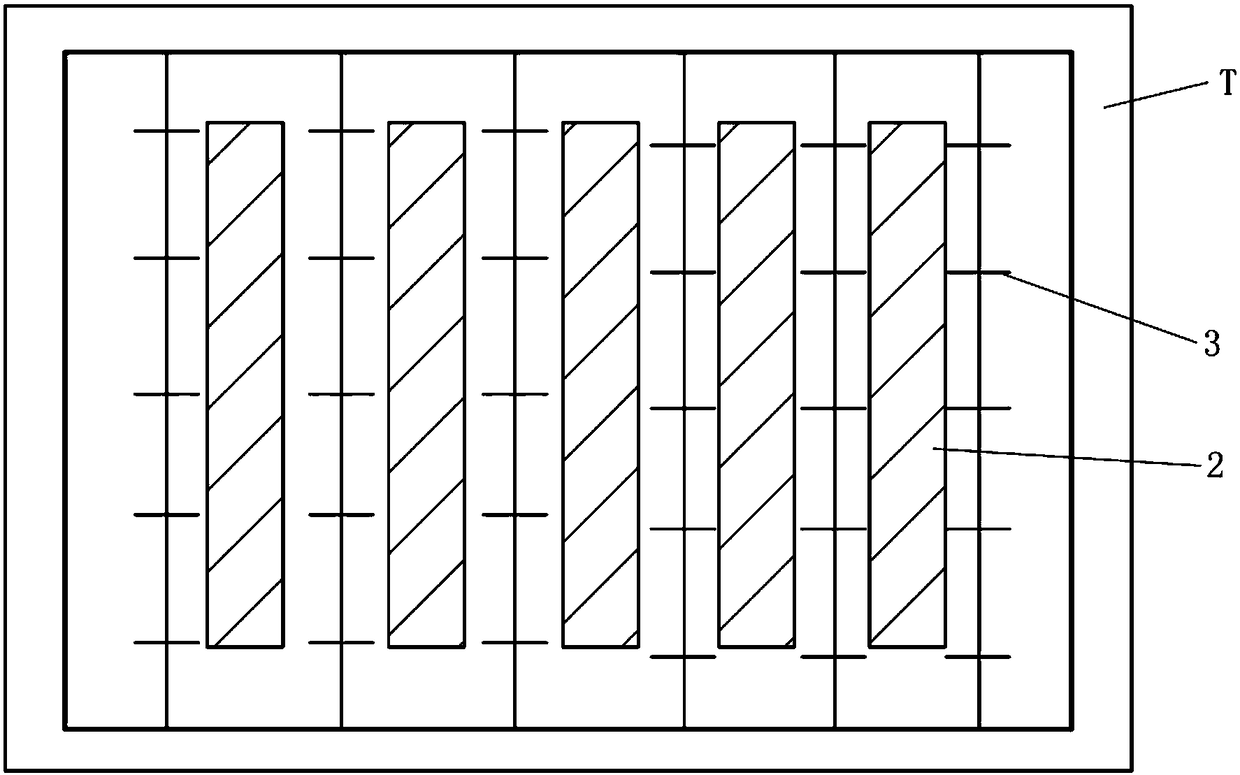

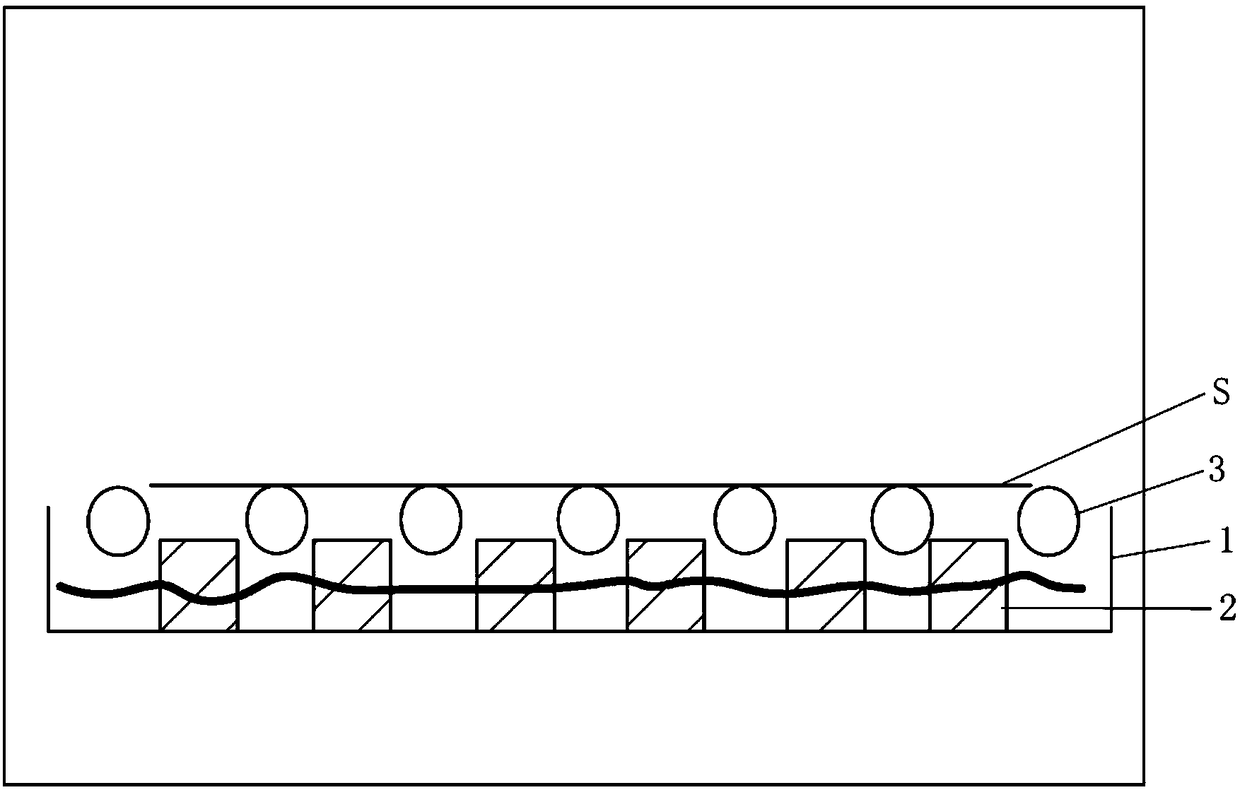

Anti-seismic anti-corrosive prestress pipe pile and manufacturing method thereof

ActiveCN106917400AImprove vertical pull-out resistanceStrong shear resistanceShaping reinforcementsProtective foundationEpoxyPre stress

The invention discloses an anti-seismic anti-corrosive prestress pipe pile which comprises a pile body, and steel bars, namely, longitudinal main ribs, a double helix stirrup and an annular stirrup that are embedded into the pile body; the double helix stirrup is wound on the outer sides of the longitudinal main ribs; the annular stirrup is welded on the inner sides of the longitudinal main ribs; the helix direction of the double helix stirrup is intersected with the oblique direction of the annular stirrup; double helix structures formed by distributing helix ribs and helix grooves in a spaced manner are arranged on the surfaces of the steel bars; the steel bars are coated with first anti-corrosive layers which are epoxy resin antirust layers; the pile body is a concrete pile body; and an organosilicon anti-corrosive layer is arranged on the surface of the pile body. The anti-seismic anti-corrosive prestress pipe pile has the advantages of good erosion resistance and high acid and alkali resistance, is high in shearing resistance, good in bending resistance and bearing capacity, excellent in anti-seismic property and long in service life, and is particularly suitable for coastal soft soil. More preferably, the anti-seismic anti-corrosive prestress pipe pile is short in manufacturing cycle, high in safety and low in cost.

Owner:SINOMA SUZHOU CONSTR

Wound electric double-layer capacitor

ActiveUS20090310281A1Inhibit the electrochemical reaction processReduce degradationHybrid capacitor separatorsProtecting/adjusting hybrid/EDL capacitorPolymer capacitorElectrochemical response

A wound electric double-layer capacitor suppresses electrochemical reaction on polarized electrode layers, reduces characteristic degradation, and has high reliability. The capacitor has a capacitor element formed by winding positive and negative electrodes with a separator interposed between them, a metal case for storing the capacitor element and an electrolyte for driving, and a sealing member for sealing an opening of the metal case. In the positive and negative electrodes, positive and negative electrode lead wires are coupled to exposed parts of current collectors having polarized electrode layers on their both surfaces, respectively. The negative electrode is wound at least one extra turn from the winding end of the positive electrode of the capacitor element, and hence a part where the polarized electrode layers formed in the negative electrode face each other through the separator is formed on the outermost periphery of the capacitor element.

Owner:PANASONIC CORP

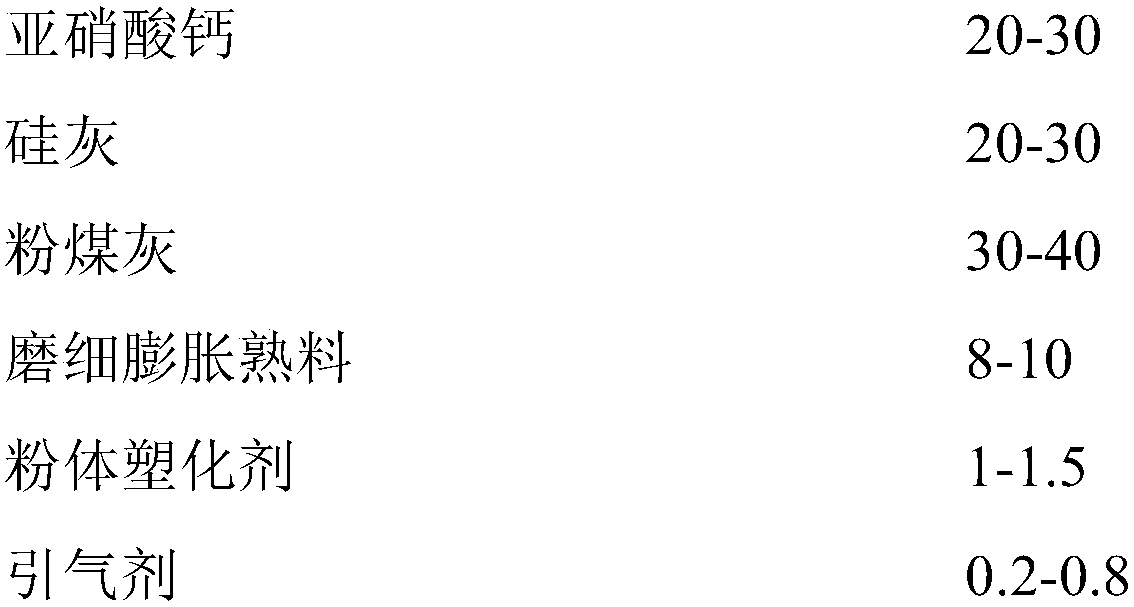

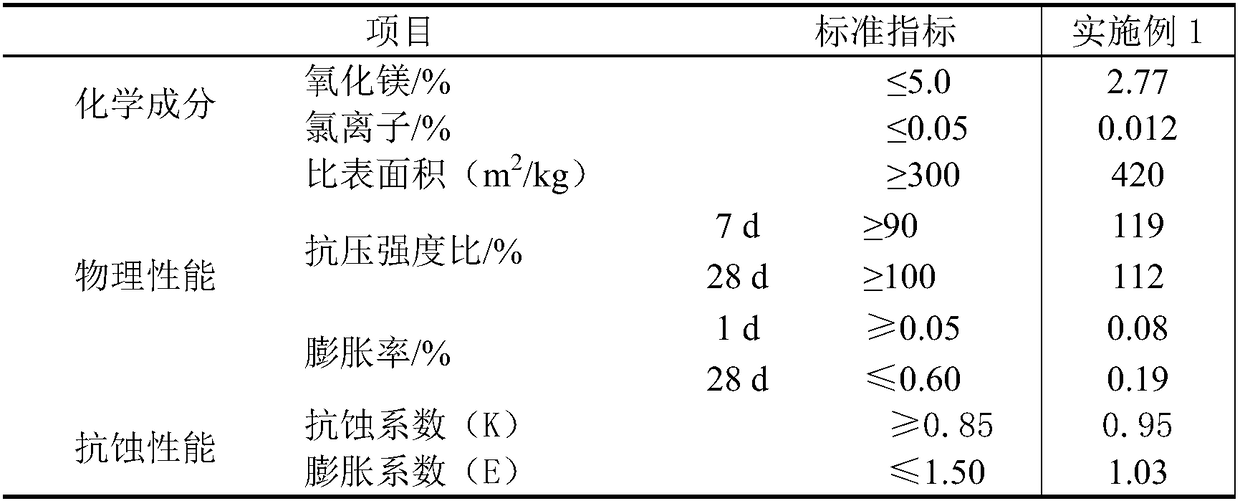

Concrete anticorrosive rust inhibitor for cast-in-place piles

The invention discloses a concrete anticorrosive rust inhibitor for cast-in-place piles. The concrete anticorrosive rust inhibitor is formed by mixing and stirring the following components by mass: 20-30% of calcium nitrite, 20-30% of silica fume, 30-40% of fly ash, 8-10% of finely ground expansive clinker, 1-1.5% of a powder plasticizer and 0.2-0.8% of an air entraining agent. The concrete anticorrosive rust inhibitor has no significant effect on working performance of concrete under appropriate dosage, improves age strength of the concrete, increases compactness of the concrete by certain self-expansion, forms a dense protective layer on a surface of a reinforcing bar, and effectively improves sulfate corrosion resistance of the concrete and erosion resistance of the reinforcing bar.

Owner:HEBEI CONSTR & INVESTIGATION RES INST

Antirust attapulgite drier

InactiveCN107583611AHygroscopicAvoid corrosionOther chemical processesDispersed particle separationIron powderDesiccant

The invention discloses an antirust attapulgite drier which is characterized by comprising an antirust agent and an attapulgite drier, wherein the weight percentage of the antirust agent is 5-30%; theattapulgite drier is composed of silicon dioxide, calcium oxide, magnesium oxide, aluminum oxide and iron oxide; the formula of the attapulgite drier comprises the following components by mass percent: 50-70% of silicon dioxide, 5-25% of calcium oxide, 3-15% of magnesium oxide, 5-11% of aluminum oxide and 0.2-0.5% of iron oxide; and the formula of the antirust agent comprises the following components by mass percent: 13-55% of magnesium oxide, 9-24% of attapulgite, 12-35% of iron powder and 0.3-12% of carbon powder. The antirust attapulgite drier is prepared in the manner of mixing and refining the antirust agent and the attapulgite drier, has gasifying antirust property and moisture absorption of the drier and can overcome the defect of only a drying function of the ordinary drier.

Owner:MINGGUANG CITY HAIGANGAONI MINING CO LTD

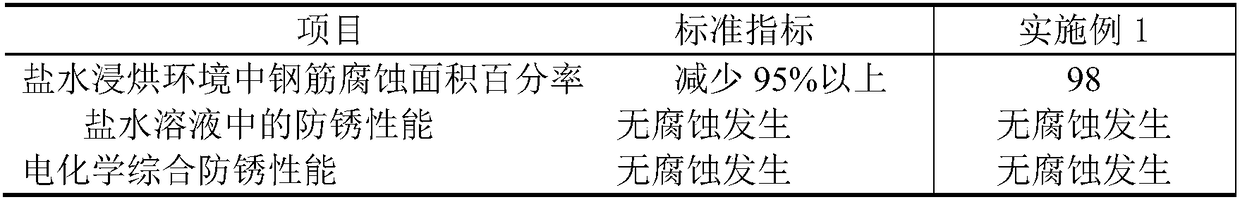

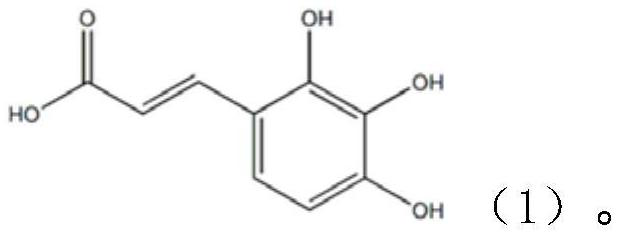

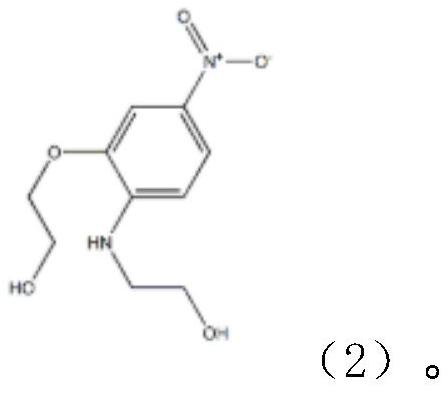

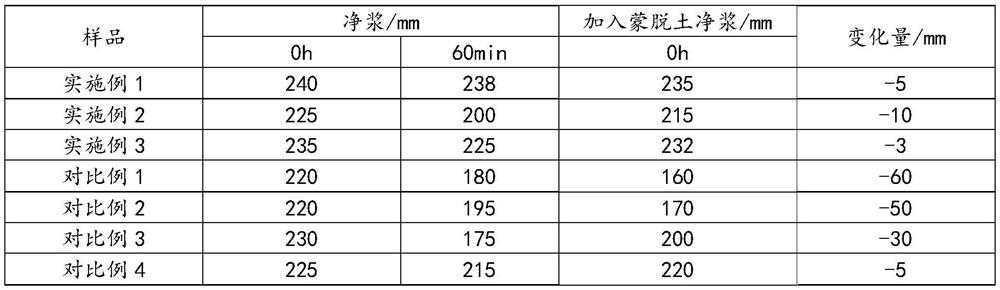

Ether polycarboxylate superplasticizer with rust inhibition function and preparation method thereof

ActiveCN112708070AInhibit the electrochemical reaction processReduce the cathodic reaction rateFunctional monomerComposite material

The invention relates to the technical field of concrete admixtures, in particular to an ether polycarboxylate superplasticizer with a rust inhibition function and a preparation method thereof. The ether polycarboxylate superplasticizer with a rust inhibition function is prepared from an esterification product, unsaturated polyoxyethylene ether, acrylic acid, an unsaturated polyhydroxy monomer and a rust inhibition functional monomer B with double bonds, amino groups and sulfur bonds through copolymerization. The esterification product is prepared from a rust inhibition functional monomer A with benzene rings and hydroxyl groups and unsaturated acid through esterification reaction. The rust inhibition functional monomer A containing benzene rings and hydroxyl groups and unsaturated acid are esterified to prepare an esterification product which participate in copolymerization, so that molecules of the polycarboxylate superplasticizer contain groups such as benzene rings, amino groups and hydroxyl groups, nitrogen atoms in the amino groups and the hydroxyl groups can improve the adsorption capacity with the surface of a steel bar, the electrochemical reaction process of the surface of the steel bar is inhibited, and meanwhile, the amino groups can be combined with H<+> on the cathode surface, the cathode reaction rate is reduced, and the rust inhibition effect of the steel bar is enhanced.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

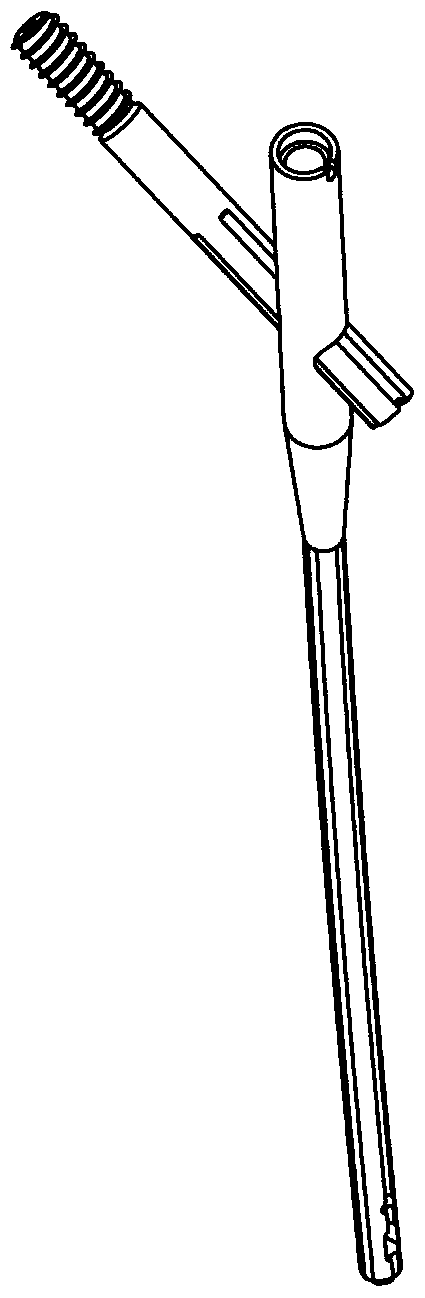

Heterogeneous conductor of submarine cable, processing method of heteroconductor, submarine cable and preparation method of submarine cable

ActiveCN114005577AImprove welding qualityInhibit the electrochemical reaction processClimate change adaptationSubmarine cablesElectrical conductorMarine engineering

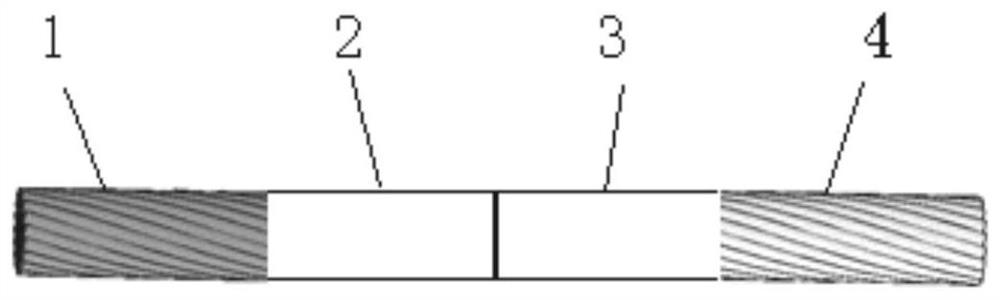

The invention provides a heterogeneous conductor of a submarine cable, a processing method of the heterogeneous conductor, the submarine cable and a preparation method of the submarine cable. The heterogeneous conductor of the submarine cable comprises a first conductor, a second conductor, a third conductor and a fourth conductor which are sequentially connected, wherein the second conductor comprises a second conductor core, the third conductor comprises a third conductor core, the second conductor and the third conductor are made of different materials, the first conductor and the second conductor are made of the same material, the third conductor and the fourth conductor are made of the same material, the first conductor is formed by twisting and pressing first conductor metal wires, and the fourth conductor is formed by twisting and pressing second conductor metal wires. The second conductor and the third conductor which are made of different materials are in friction welding, and an alloy structure made of two materials is formed at a joint, so electrochemical reaction between the second conductor and the third conductor can be restrained, and the strength of the copper-aluminum welding joint can be effectively controlled; and therefore, the welding quality of the heterogeneous conductor of the submarine cable is improved on the whole.

Owner:ZHONGTIAN TECH SUBMARINE CABLE CO LTD

Lithium ion battery

ActiveCN111416145AInhibit the electrochemical reaction processAvoid chemical reactionsSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrolytic agentHigh energy

The invention provides a lithium ion battery. The lithium ion battery comprises a positive plate which comprises a positive diaphragm; a negative plate which comprises a negative diaphragm; and an electrolyte including an organic solvent and an additive. The double-sided coating weight of the positive diaphragm is 28-56mg / cm <2>, and the compaction density is not less than 3.5 g / cm <3>; the double-sided coating weight of the negative electrode diaphragm is 14-28mg / cm <2>, and the compaction density is not less than 1.4 g / cm <3>; the organic solvent comprises linear carboxylic ester with a structure as shown in a formula I; in the formula I, R1 and R2 are independently selected from alkyl with 2-4 carbon atoms respectively; the mass fraction of the linear carboxylic ester with the structureas shown in the formula I in the organic solvent is 5-60%; the additive is prepared from 1, 3-propane sultone and fluoroethylene carbonate; the mass fraction of the 1, 3-propane sultone in the electrolyte is 0.1%-5%; the mass fraction of the fluoroethylene carbonate in the electrolyte is 0.1%-7%. The lithium ion battery provided by the invention has high energy density, high initial coulombic efficiency, excellent rapid charging performance and low-temperature charging performance at the same time.

Owner:NINGDE AMPEREX TECH

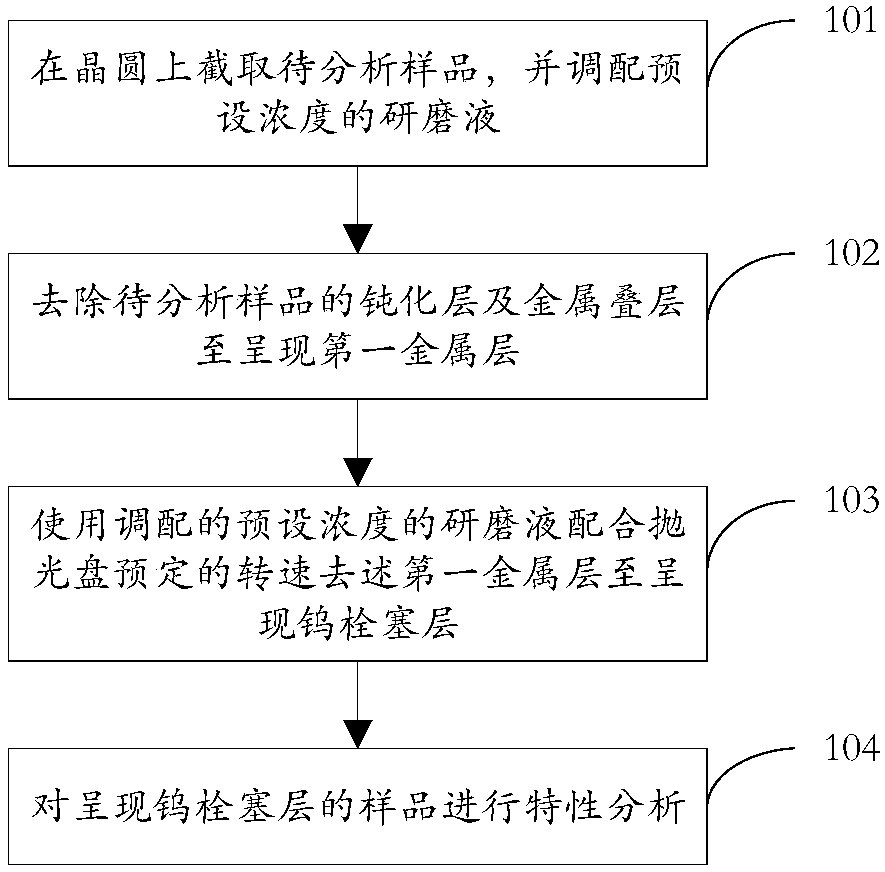

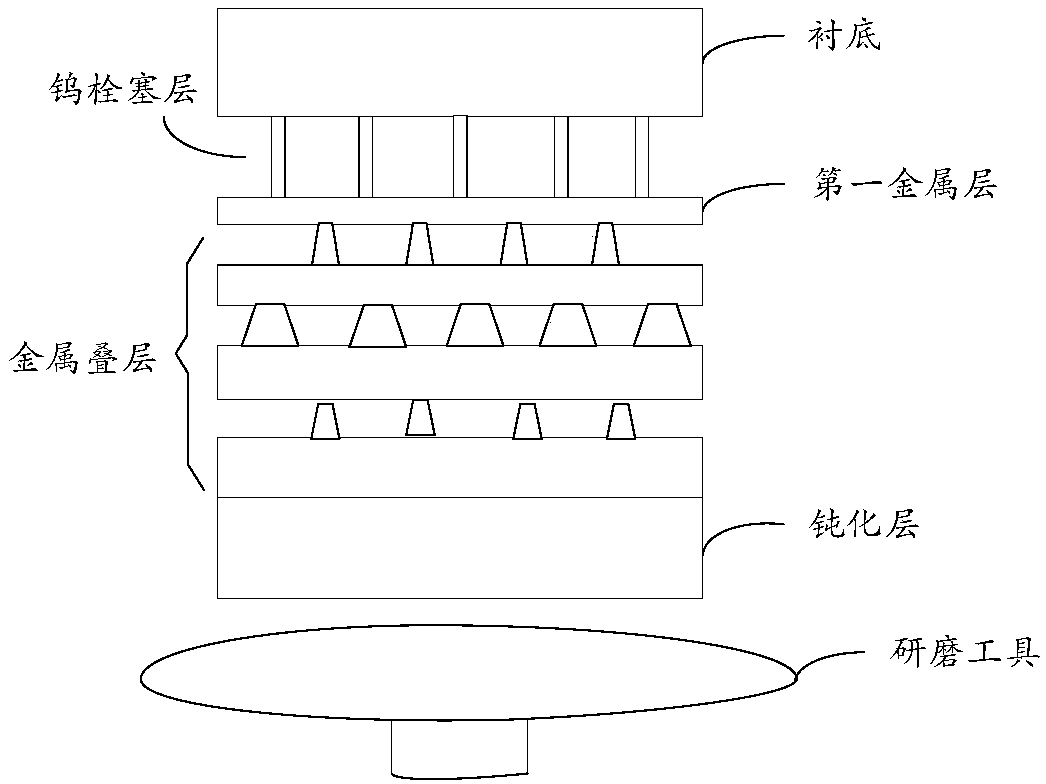

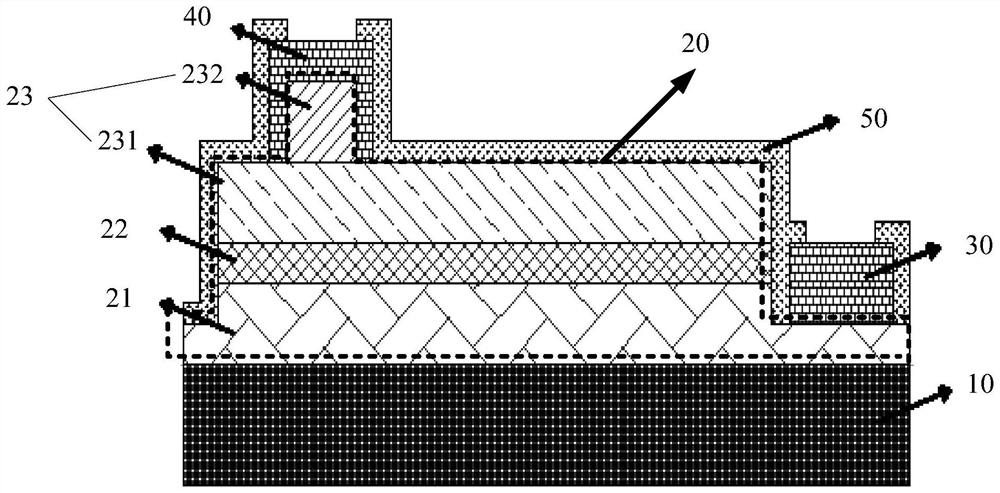

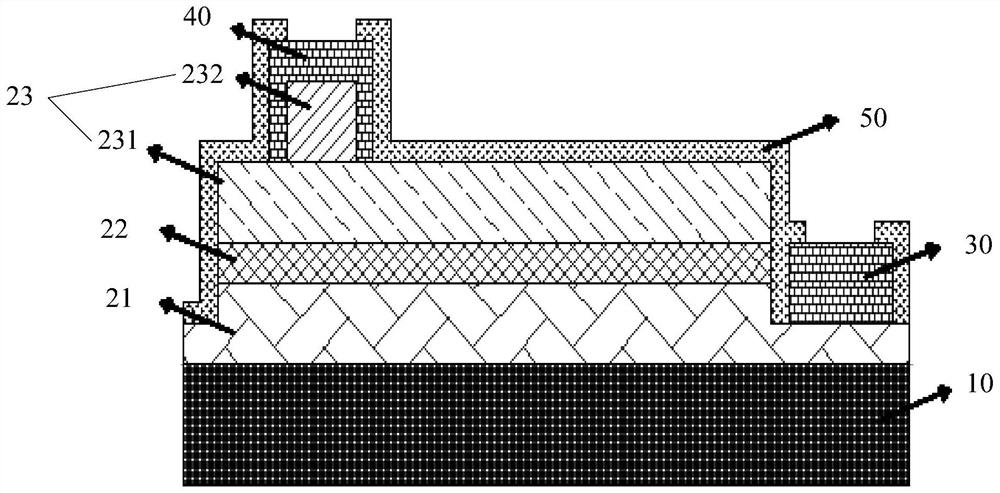

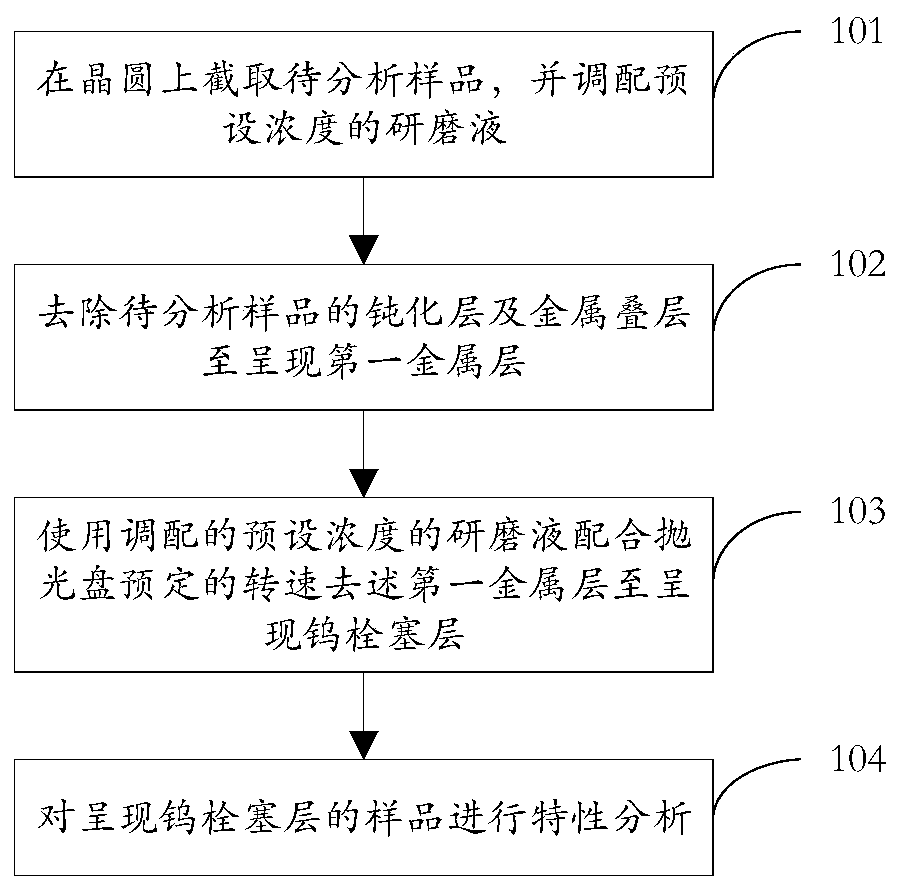

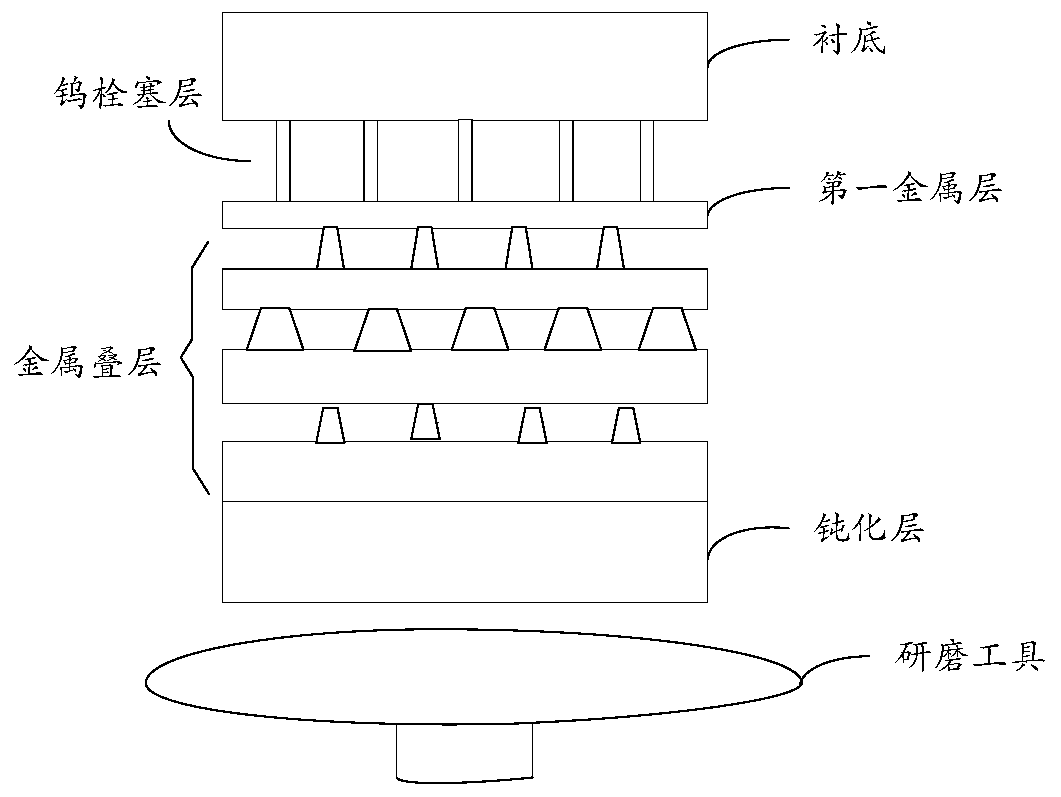

Semiconductor characteristic analysis method for preventing corrosion of tungsten plug

ActiveCN107731746AInhibition of electrochemical reactionsGuaranteed to be intactSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingSemiconductor propertiesElectrochemical response

The invention discloses a semiconductor characteristic analysis method for preventing corrosion of a tungsten plug and belongs to the technical field of semiconductors. The method comprises the stepsthat a sample to be analyzed is cut in a wafer, and grinding liquid with the preset concentration is prepared; a passivation layer and a metal lamination layer of the sample to be analyzed are removeduntil a first metal layer is presented; the prepared grinding liquid with the preset concentration is used and matched with the preset rotation speed of a polishing disk to remove the first metal layer until a tungsten plug layer is presented; the sample which presents the tungsten plug layer is subjected to characteristic analysis. According to the semiconductor characteristic analysis method, the safe and environment friendly grinding liquid with the preset concentration is prepared, by matching with the certain rotation speed of the polishing disk, the first metal layer of the sample to beanalyzed is removed, the electrochemical reaction of the tungsten plug is effectively inhibited, then the completeness of the tungsten plug is guaranteed so that complete device standardization can be conducted on the tungsten plug layer, and the mistaken judgement of characteristic analysis due to sample processing problems is avoided.

Owner:YANGTZE MEMORY TECH CO LTD

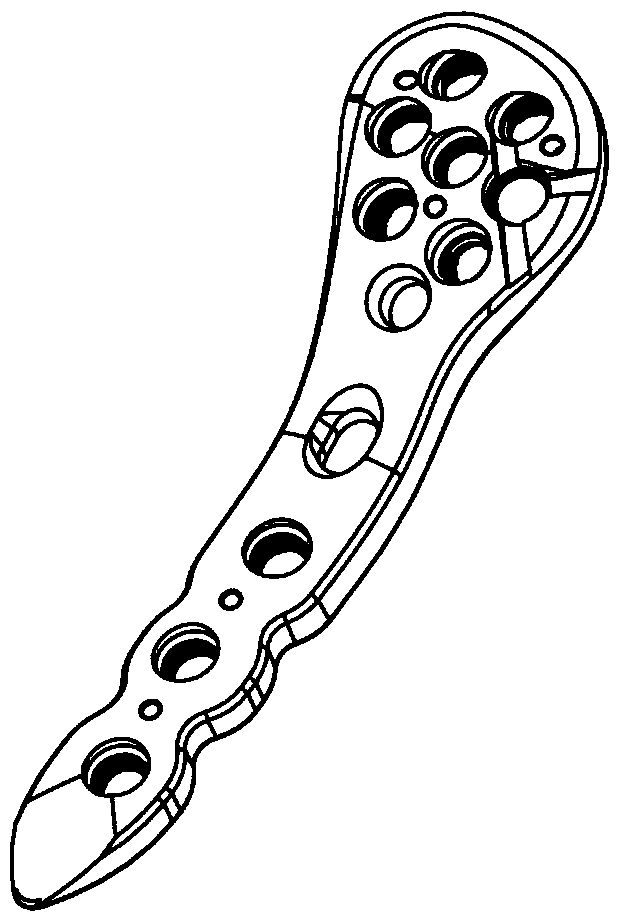

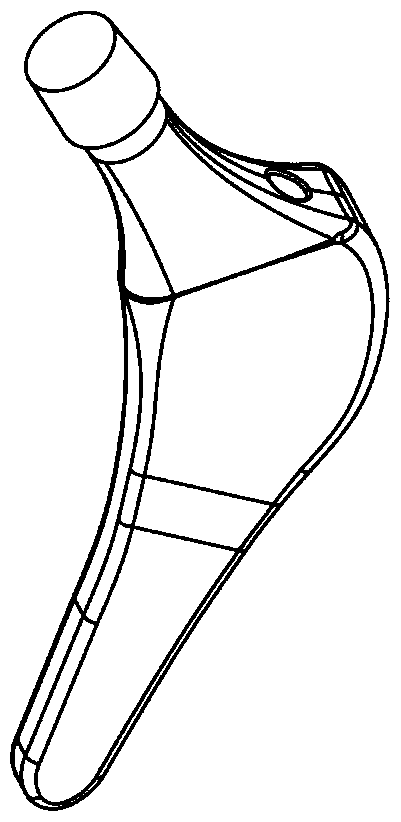

An orthopedic implant with a polymer-wrapped metal prosthesis

ActiveCN105031745BInhibit the electrochemical reaction processReduce adverse reactionsInternal osteosythesisJoint implantsElectrochemical responseDissolution

An orthopedic implant with a polymer-wrapped metal prosthesis, comprising a metal implant body and a high-molecular layer wrapping the surface of the implant. The orthopedic implant is formed by wrapping the surface of a metal implant body material with an anti-corrosion organic high-molecular material, such that a metal implant is prevented from being corroded by human body liquid. An organic high-molecular material wraps between two metal implants in contact with each other, so that contact between metal and metal is prevented, thereby inhibiting electrochemical reactions caused by the contact between metal and metal, and further reducing adverse reactions on a human body caused by dissolution of metal ions. Meanwhile, the existence of a high-molecular interface aids in enhancement of locking between metal implants, prevents and reduces slight movement, and accelerates operation healing.

Owner:SUZHOU SINOMED BIOMATERIALS CO LTD

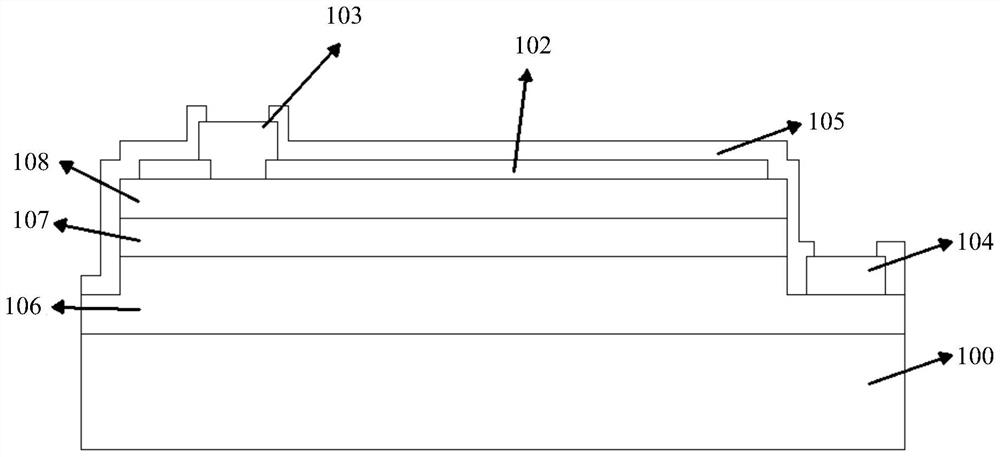

A method for wet process of thin film transistor array substrate

ActiveCN108281431BHigh electrical deepening activityInhibit the electrochemical reaction processSolid-state devicesNon-linear opticsChemical reactionElectrochemical corrosion

The invention provides a method for a wet process of a thin film transistor array substrate. The method comprises the step of placing a substrate in a processing room so that a metal layer and a blocking layer both are in contact with a medium liquid in the processing room for wet processing, wherein the metal layer and the blocking layer are formed on the substrate, the blocking layer is arrangedon the metal layer, a metal piece of which electrochemical activity is larger than that of the metal layer and which is not in chemical reaction with the medium liquid is arranged in the processing room, and the metal layer does not generate electrochemical reaction with the medium liquid. By the method, an electrochemical corrosion phenomenon occurring in the fabrication process of the thin filmtransistor array substrate can be prevented, and the quality of the thin film transistor array substrate is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Low-voltage cable distribution joints and low-voltage cable distribution boxes

ActiveCN104332938BGuaranteed insulation recoveryGuaranteed insulation performanceCable junctionsLow voltageEngineering

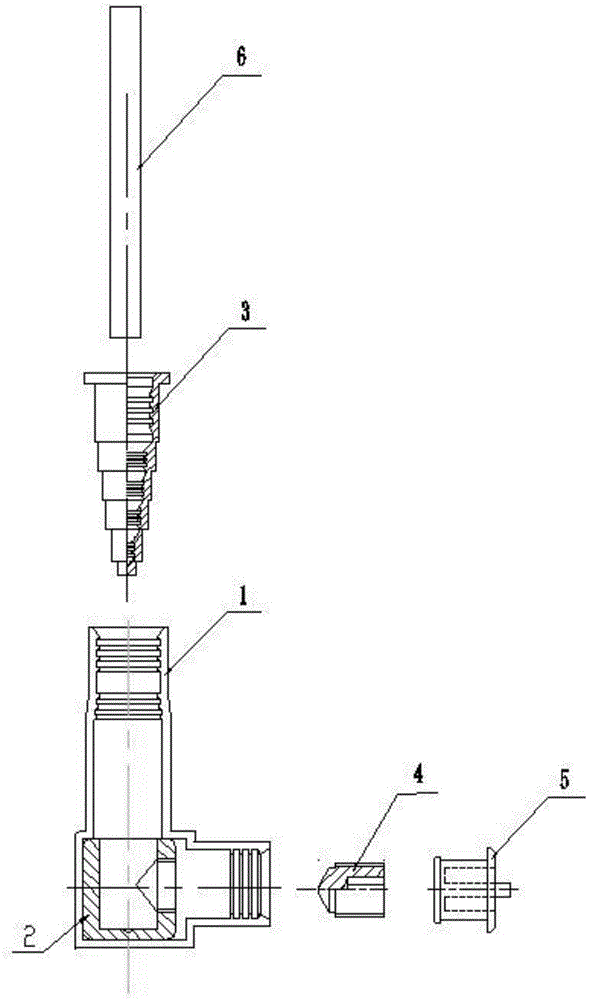

The invention discloses a low-voltage cable branching connector and a low-voltage cable distribution box. The low-voltage cable branching connector is characterized in that annular tooth grooves are machined inside vertical side pipeline openings and horizontal side pipeline openings of right-angle pipelines inside a connector body cover; right-angle portions of the right-angle pipelines are communicated through a connector body; two adjacent surface positions of the connector body, which are opposite to vertical side pipelines and horizontal side pipelines, are provided with circular holes; every two circular holes are communicated; internal threads are machined on the circular holes which are corresponding to horizontal pipelines; middle sleeves are arranged inside the vertical side pipeline openings of the connector body cover; the annular tooth grooves are formed inside the middle sleeves and cables are inserted inside the annular tooth grooves; ends of the cables are inserted into the connector body circular holes which are corresponding to the vertical side pipelines and are compressed through cable pressing nuts. The low-voltage cable distribution box is characterized in that the above four rows of low-voltage cable branching connectors are installed on trapezoid folding plates of a box body base plate. The low-voltage cable branching connector and the low-voltage cable distribution box can safely and efficiently achieve load distribution.

Owner:HUNAN HAOSHENG ELECTROMECHANICAL EQUIP

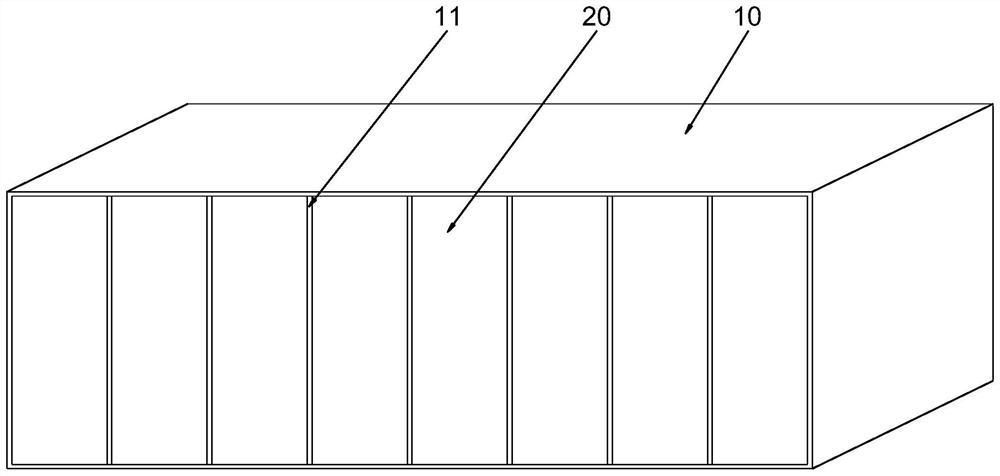

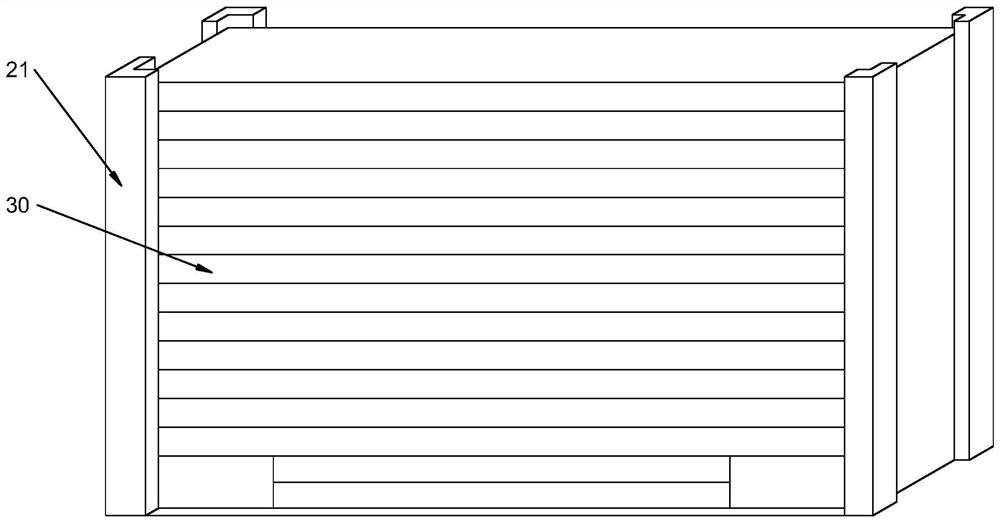

Energy storage monomer, energy storage cluster and energy storage device

PendingCN113991227AImprove operating temperatureImprove operational safety performanceBattery isolationSecondary cellsExhaust valveOperation safety

The invention discloses an energy storage monomer which comprises a monomer shell. An energy storage battery cell is arranged in the monomer shell, and a monomer temperature control system and a monomer explosion-proof system are arranged on the monomer shell; the monomer temperature control system comprises a temperature control channel for temperature control medium circulation, and two ends of the temperature control channel are respectively provided with a first medium inlet and a first medium outlet; the monomer explosion-proof system comprises an exhaust valve used for exhausting when the air pressure in the monomer shell exceeds a set threshold value. The invention further discloses an energy storage cluster which comprises a cluster support, and a plurality of energy storage monomers are installed on the cluster support. The invention further provides an energy storage device which comprises a box body. A plurality of energy storage clusters are installed in the box body. According to the energy storage monomer, the energy storage cluster and the energy storage device, the temperature control effect can be improved, and the operation safety of the energy storage device is improved.

Owner:九环储能科技有限公司

A kind of high-silicon austenitic stainless steel resistant to concentrated sulfuric acid corrosion and its preparation method

ActiveCN106756559BImprove erosion abilityImprove the corrosion resistance of high temperature concentrated sulfuric acidSiliconAustenitic stainless steel

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

Backboard material for photovoltaic cell module

InactiveCN109817740AImproves metal ductilityReduce pinholesPhotovoltaic energy generationSemiconductor devicesDuctilityChromium

The invention belongs to the technical field of photovoltaic power generation, and relates to a backboard material for a photovoltaic cell module. The backboard material comprises the following components in parts by mass: 5-10 parts of iron, 10-15 parts of chromium, 1-10 parts of vanadium, 50-70 parts of aluminum and 10-30 parts of magnesium. Preferably, the backboard material for the photovoltaic cell module comprises the following components in parts by mass: 6-8 parts of iron, 11-13 parts of chromium, 4-8 parts of vanadium, 55-65 parts of aluminum and 15-25 parts of magnesium. Preferably,the backboard material for the photovoltaic cell module comprises the following components in parts by mass: 7 parts of iron, 12 parts of chromium, 6 parts of vanadium, 60 parts of aluminum and 20 parts of magnesium. Preferably, the thickness of the backboard material of the photovoltaic cell module is 15-20 [mu] m. According to the invention, while the metal ductility of the backboard material for the photovoltaic cell module is improved, pinholes are reduced, and the cost can be effectively reduced. The backboard material prepared according to the ratio of the technical scheme of the invention can prevent electrochemical reaction of the photoelectric conversion unit.

Owner:山东天拓电子科技有限公司

Method for wet process of thin film transistor array substrate

ActiveCN108281431AHigh electrical deepening activityInhibit the electrochemical reaction processSolid-state devicesNon-linear opticsElectrochemical responseBlock layer

The invention provides a method for a wet process of a thin film transistor array substrate. The method comprises the step of placing a substrate in a processing room so that a metal layer and a blocking layer both are in contact with a medium liquid in the processing room for wet processing, wherein the metal layer and the blocking layer are formed on the substrate, the blocking layer is arrangedon the metal layer, a metal piece of which electrochemical activity is larger than that of the metal layer and which is not in chemical reaction with the medium liquid is arranged in the processing room, and the metal layer does not generate electrochemical reaction with the medium liquid. By the method, an electrochemical corrosion phenomenon occurring in the fabrication process of the thin filmtransistor array substrate can be prevented, and the quality of the thin film transistor array substrate is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

An anti-seismic and corrosion-resistant prestressed pipe pile and its manufacturing method

ActiveCN106917400BImprove vertical pull-out resistanceStrong shear resistanceProtective foundationShaping reinforcementsEpoxyPre stress

Owner:SINOMA SUZHOU CONSTR

LED chip and manufacturing method thereof

PendingCN114242867AAvoid nudityInhibit the electrochemical reaction processSemiconductor devicesEngineeringActive layer

The embodiment of the invention discloses an LED chip and a manufacturing method thereof, the LED chip comprises a chip substrate, an epitaxial structure, a P-type electrode, an N-type electrode and an insulating layer, the epitaxial structure comprises a first P-type layer, a first active layer and a first N-type layer, the first N-type layer comprises a first N-type sub-layer and a second N-type sub-layer, the active layer and the first N-type sub-layer expose part of the surface of the P-type layer, and the first N-type sub-layer and the second N-type sub-layer expose part of the surface of the P-type layer. The second N-type sub-layer is located on the surface of the first N-type sub-layer, the N-type electrode is located on the side, away from the surface of the chip substrate, of the second N-type sub-layer and covers the second N-type sub-layer, and the insulating layer covers the part, except the surface of the P-type electrode and the surface of the N-type electrode, of the surface of the LED chip. Therefore, the N-type electrode covers the second sub-N-type layer, the second sub-N-type layer can be prevented from being exposed, and the insulating layer wraps the uncovered parts of the first sub-N-type layer and the second sub-N-type layer, so that electrochemical reaction between the N-type layer and water vapor in the environment can be inhibited.

Owner:XIAMEN CHANGELIGHT CO LTD

Analysis method of semiconductor characteristics for preventing tungsten plug corrosion

ActiveCN107731746BInhibit the electrochemical reaction processGuaranteed integritySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingElectrochemical responseWafer

The invention discloses a semiconductor characteristic analysis method for preventing corrosion of a tungsten plug and belongs to the technical field of semiconductors. The method comprises the stepsthat a sample to be analyzed is cut in a wafer, and grinding liquid with the preset concentration is prepared; a passivation layer and a metal lamination layer of the sample to be analyzed are removeduntil a first metal layer is presented; the prepared grinding liquid with the preset concentration is used and matched with the preset rotation speed of a polishing disk to remove the first metal layer until a tungsten plug layer is presented; the sample which presents the tungsten plug layer is subjected to characteristic analysis. According to the semiconductor characteristic analysis method, the safe and environment friendly grinding liquid with the preset concentration is prepared, by matching with the certain rotation speed of the polishing disk, the first metal layer of the sample to beanalyzed is removed, the electrochemical reaction of the tungsten plug is effectively inhibited, then the completeness of the tungsten plug is guaranteed so that complete device standardization can be conducted on the tungsten plug layer, and the mistaken judgement of characteristic analysis due to sample processing problems is avoided.

Owner:YANGTZE MEMORY TECH CO LTD

A composite biodegradable vapor phase antirust film and its preparation process

The invention belongs to the technical field of multi-functional high polymer materials, in particular relates to a composite biodegradation gas-phase anti-rusting membrane and a preparation process thereof, and aims to provide a composite biodegradation gas-phase anti-rusting membrane which is rapid in preparation method, simple to prepare, low in cost and free of environment pollution, and a preparation process thereof. The composite biodegradation gas-phase anti-rusting membrane is prepared from the following raw materials in percentage by mass: 2-5% of a gas-phase anti-rusting additive, 60-75% of a biodegradation material, 5-10% of a polyolefin carrier, 5-10% of a modifier, 2-5% of a plasticizer, 2-3% of a coupling agent, 4-6% of a dispersing agent, 1-3% of a lubricant and 0.1-0.3% of other processing additives. The composite biodegradation gas-phase anti-rusting membrane provided by the invention has the characteristics of good barrier property, conductivity, flame retardancy and ultraviolet ray prevention, and gas-phase anti-rusting gases generated from the composite biodegradation gas-phase anti-rusting membrane can be volatilized and permeated into corners which cannot be covered by anti-rusting oil in package parts, and can be biologically degraded.

Owner:重庆博浪塑胶股份有限公司

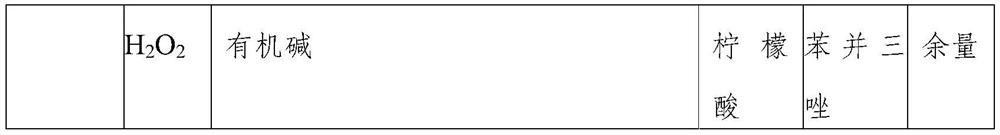

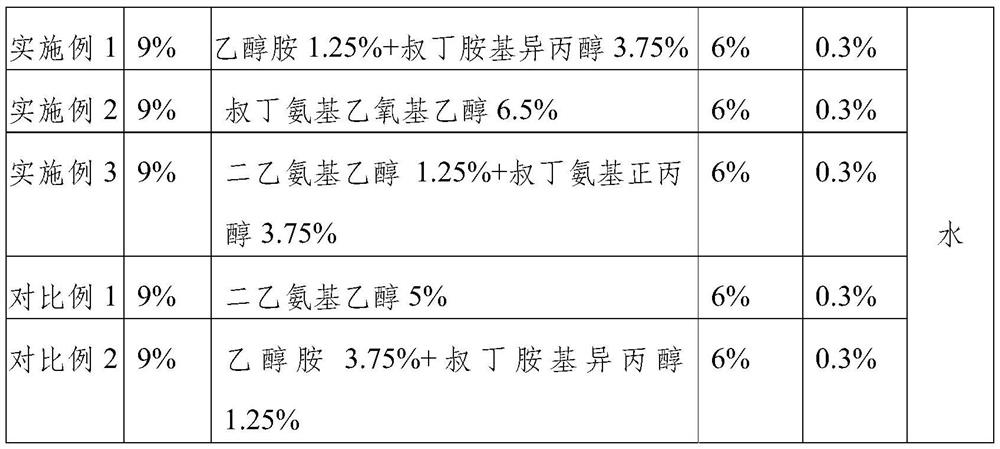

Etching solution composition and etching method for copper-molybdenum alloy

ActiveCN113026018AImprove undercut problemInhibit the electrochemical reaction processFluorine freeOrganic acid

The invention discloses a copper-molybdenum alloy etching liquid composition. The copper-molybdenum alloy etching liquid composition mainly comprises, by weight, 5%-12% of hydrogen peroxide, 5%-10% of organic acid, 5%-10% of organic alkali and 0%-0.5% of etching inhibitor. The organic alkali is steric hindrance amine or the main composition of the organic alkali comprises the steric hindrance amine, and the pKa of the steric hindrance amine is 10.3-11.1 at the temperature being 25 DEG C. The steric hindrance amine is adopted for etching liquid composition of the copper-molybdenum alloy as the organic alkali, or the organic alkali mainly comprises the steric hindrance amine, and by utilizing the steric hindrance of a molecular structure of the organic alkali, in an etching system without fluorine ions and phosphorus components, the problem of molybdenum or molybdenum alloy undercutting caused by organic acid consumption and alkalinity enhancement fluctuation in the later reaction stage is solved. The invention further discloses an etching method of the etching solution composition based on the copper-molybdenum alloy.

Owner:四川江化微电子材料有限公司

Paint for pipelines

InactiveCN104559779AGood antibacterial effectExtended service lifeAntifouling/underwater paintsPaints with biocidesEpoxyElectrochemical response

The invention discloses a paint for pipelines, and belongs to the technical field of chemical industry paints. The paint comprises the following components in parts by weight: 15-25 parts of modified asphalt liquid, 2-5 parts of molybdenum disulfide, 0.5-1.3 parts of sodium pyrophosphate, 0.2-1.4 parts of N,N-dimethyl pyrrolidinone, 0.2-1.5 parts of anhydride maleique, 1-3 parts of polybutadiene epoxy resin, 0.3-1.5 parts of a dual-imidazoline quaternary ammonium salt corrosion inhibitor, 0.5-1.8 parts of ammonium persulfate, 2-3 parts of calcium metaaluminate and 2-6 parts of maleic acid. The paint has a good bacterial inhibition property, besides, a coating uniformly and effectively prevents the electrochemical reaction, and further the service life of the paint is prolonged.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

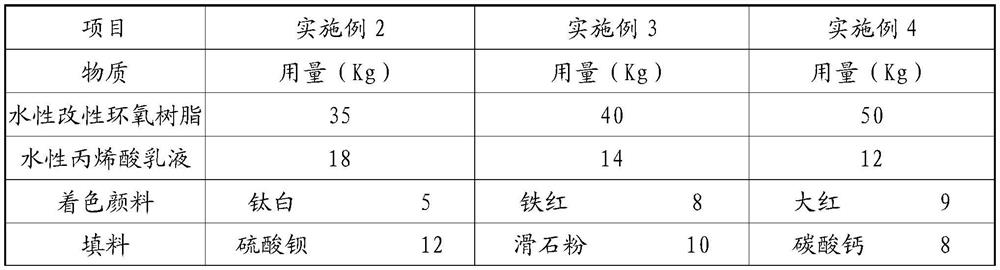

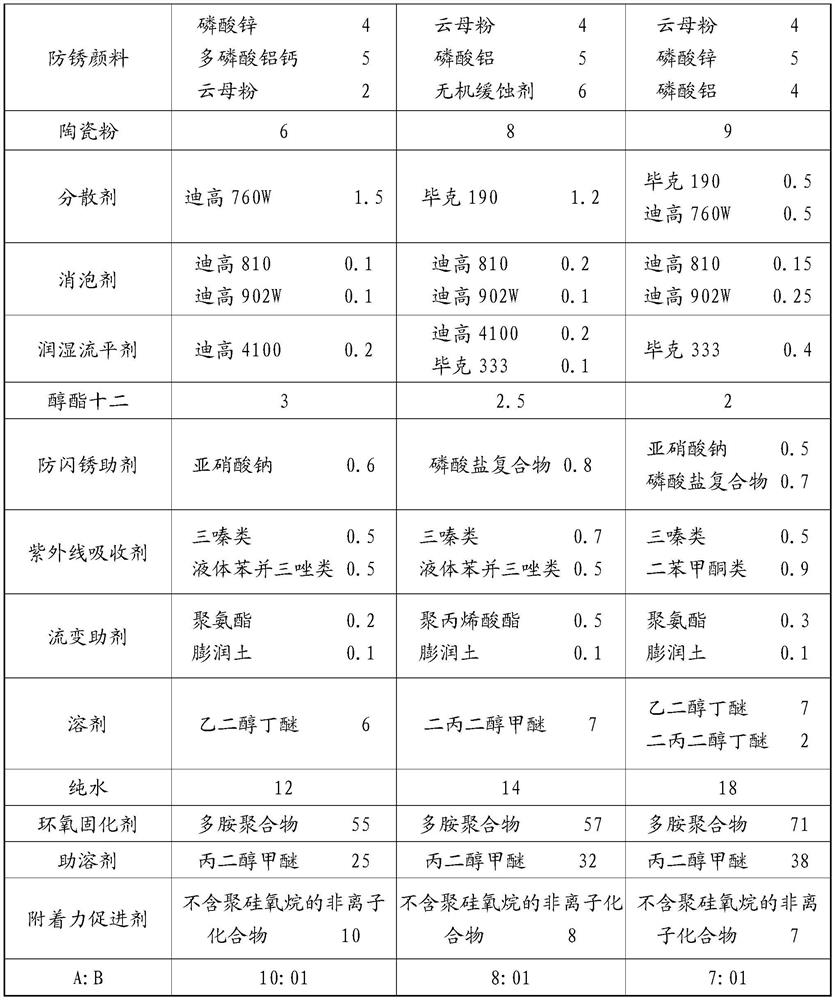

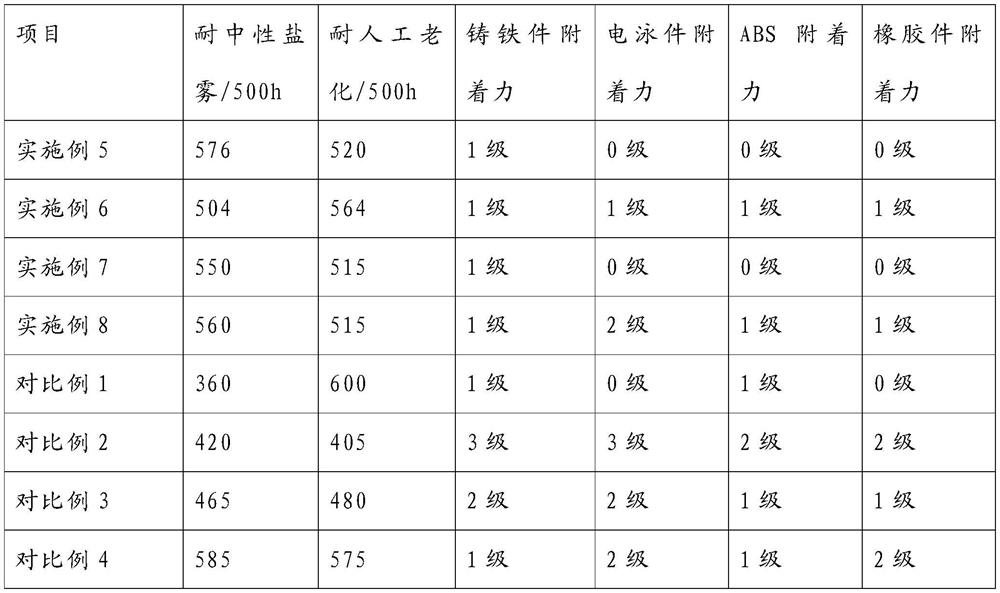

High-salt-spray-resistance and high-weather-resistance two-component water-based primer-topcoat coating and preparation method thereof

PendingCN114806330AGood weather resistanceStrong adhesionAnti-corrosive paintsEpoxy resin coatingsWeather resistanceUltraviolet lights

The invention discloses a two-component water-based primer-topcoat coating with high salt mist resistance and high weather resistance and a preparation method of the two-component water-based primer-topcoat coating. The coating consists of a component A and a component B, the component A is prepared from 30 to 60 parts of water-based modified epoxy resin, 10 to 20 parts of water-based acrylic emulsion, 2 to 10 parts of coloring pigment, 8 to 15 parts of filler, 10 to 20 parts of anti-rust pigment, 5 to 10 parts of ceramic powder, 1 to 2 parts of dispersing agent, 0.1 to 0.5 part of defoaming agent, 0.2 to 0.5 part of wetting flatting agent, 1 to 4 parts of coalescing agent, 0.5 to 2 parts of anti-flash-rust additive, 1 to 2 parts of ultraviolet light absorber, 10 to 20 parts of pure water, 0 to 1 part of rheological additive and 5 to 10 parts of solvent; and the component B comprises the following components in parts by weight: 50-80 parts of an epoxy curing agent, 20-40 parts of a cosolvent and 5-10 parts of an adhesion promoter. According to the invention, a single coating has good adhesive force, higher salt spray resistance and higher weather resistance to a complex substrate at the same time.

Owner:山东七维新材料有限公司

A Repairing Method for Reinforced Concrete of Damaged Bridge Pier

A method for repairing reinforced concrete of damaged bridge piers. First, the surface of the damaged bridge pier is cleaned until the surface is free of debris and water, and the surface of the exposed steel bars is coated with a steel bar rust inhibitor. The steel bar rust inhibitor is composed of sodium tetraborate 10‑12g / L, sodium silicate 8‑10g / L, tetradecyl dimethyl benzyl ammonium chloride 3‑6g / L, tetrahydrofuran 3‑6g / L, chromium nitrate 3‑4g / L, threonine Acid 1-4g / L, the balance is water, bake the rust-proof layer after coating, the baking temperature is controlled at 60-70°C, and the baking time is 10-15 minutes, the steel bar rust inhibitor of the present invention makes the whole The steel bar is wrapped by a layer of passivation film, dense and stable, which can prevent the penetration of chloride ions, reduce the free speed of iron ions, effectively inhibit, prevent and delay the electrochemical reaction process of steel bar corrosion, thereby prolonging the life of reinforced concrete structures service life.

Owner:江西赣粤高速公路工程有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com