High-salt-spray-resistance and high-weather-resistance two-component water-based primer-topcoat coating and preparation method thereof

A technology of salt spray resistance and weather resistance, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problem that it is difficult to meet the engine corrosion resistance, salt spray resistance and weather resistance at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

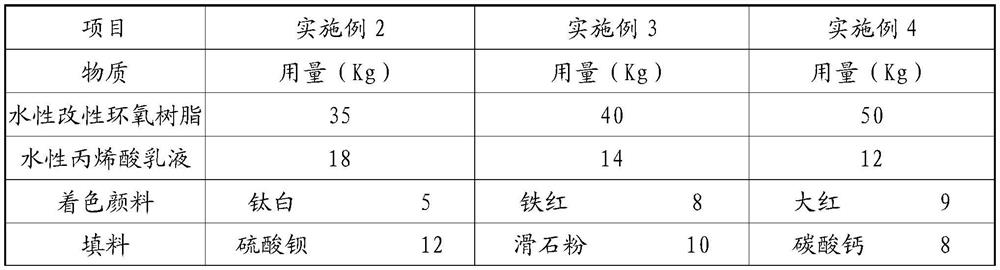

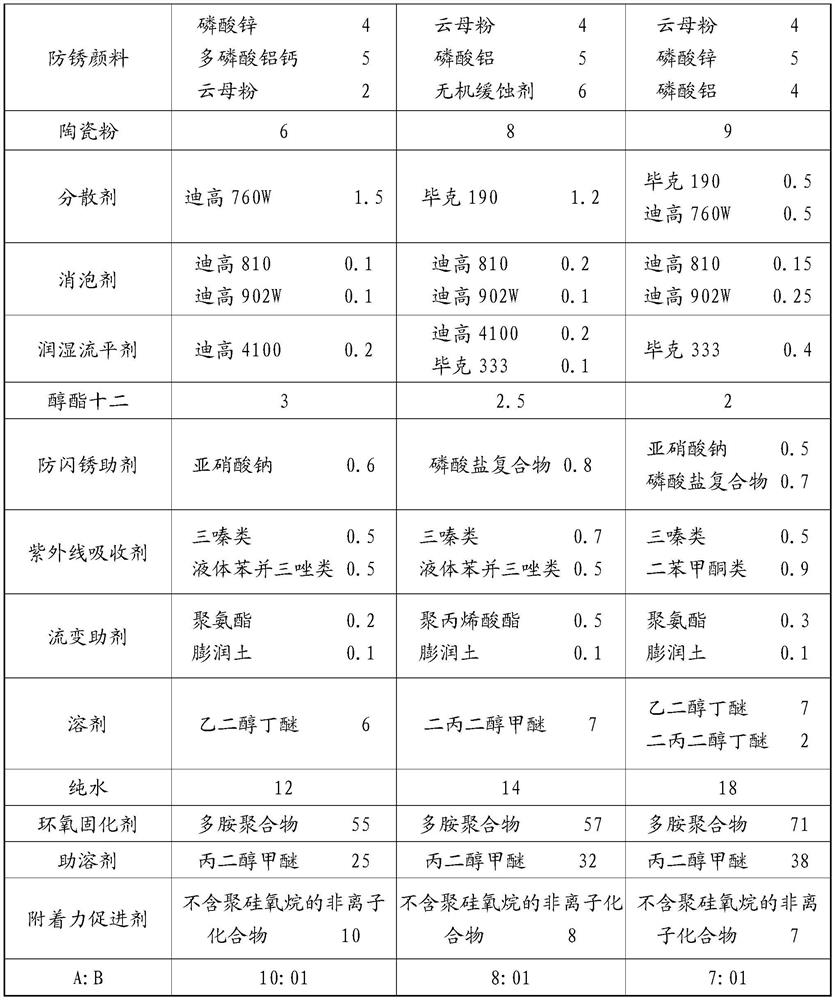

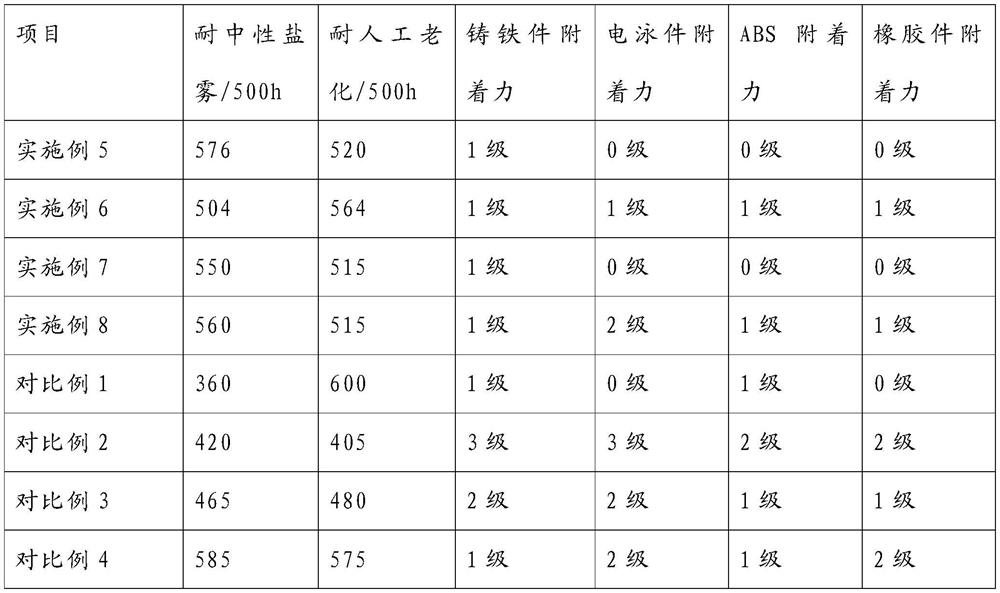

Examples

Embodiment 1

[0040] A two-component water-based bottom surface-in-one paint with high salt spray resistance and high weather resistance, the paint is composed of component A and component B with a weight ratio of 9:1;

[0041]Component A includes: non-ionic water-based modified epoxy resin (epoxy equivalent 1200~1400g / mol, density 1.0~1.1g / mL, solid content 50~55wt%, viscosity 300~800cp) 45Kg, water-based acrylic emulsion ( Acrylic acid pH8.0~9.0, density 1.0~1.1g / mL, active substance content 50~55wt%, viscosity <500cp) 12Kg, coloring pigment carbon black 3Kg, filler barium sulfate 9Kg, anti-rust pigment mica powder 4Kg, zinc phosphate 2Kg, calcium aluminum polyphosphate 5Kg, ceramic powder 7Kg, dispersant TEGO760W 1.5Kg, defoamer TEGO 810 0.15Kg, wetting and leveling agent TEGO 4100 0.3Kg, film-forming aid alcohol ester 1.5Kg, anti-flash rust Auxiliary phosphate compound 0.9Kg, UV absorber triazine 0.5, liquid benzotriazole 1.0Kg, pure water 13Kg, rheology assistant polyurethane 0.4Kg, so...

Embodiment 5

[0048] According to the weight proportioning of embodiment 1, first prepare A component:

[0049] (1) Add the water-based modified epoxy resin, solvent and pure water into the grinding cylinder, start stirring, keep the rotating speed at 850r / min and stir for 15min, add dispersant, defoamer, coloring pigment, filler, antirust in turn Pigment and ceramic powder, keep rotating speed 1350r / min and disperse for 18min;

[0050] (2) grinding the dispersion slurry obtained in step (2), controlling the grinding temperature not to be higher than 40°C, and grinding to a fineness of 25-26 μm;

[0051] (3) adding the water-based acrylic emulsion into another grinding cylinder, keeping the stirring speed at 850 r / min, adding the film-forming aid, the wetting and leveling agent, the grinding slurry obtained in step (2), the anti-flash rust aid in turn agent, ultraviolet absorber and rheological aid, and stir for 25 minutes to obtain the A component;

[0052] Next prepare component B:

[...

Embodiment 6

[0056] According to the weight proportioning of embodiment 2, first prepare A component:

[0057] (1) Add the water-based modified epoxy resin, solvent and pure water into the grinding cylinder, start stirring, keep the rotating speed at 900r / min and stir for 15min, and add dispersant, defoamer, coloring pigment, filler, antirust in turn Pigment and ceramic powder, keep rotating speed 1400r / min and disperse for 16min;

[0058] (2) grinding the dispersion slurry obtained in step (2), controlling the grinding temperature not to be higher than 40°C, and grinding to a fineness of 26-27 μm;

[0059] (3) adding the water-based acrylic emulsion into another grinding cylinder, keeping the stirring speed at 900 r / min, adding the film-forming aid, the wetting and leveling agent, the grinding slurry obtained in step (2), the anti-flash rust aid in turn agent, ultraviolet absorber and rheological aid, and stir for 20 minutes to obtain the A component;

[0060] Next prepare component B: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com