Patents

Literature

226 results about "Rebar corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rebar corrosion occurs when chloride ions migrate to concrete material like steel bars. It is a type of corrosion that occurs in most highway bridges. These structures are usually constructed with rebar that is reinforced by steel throughout the support structures.

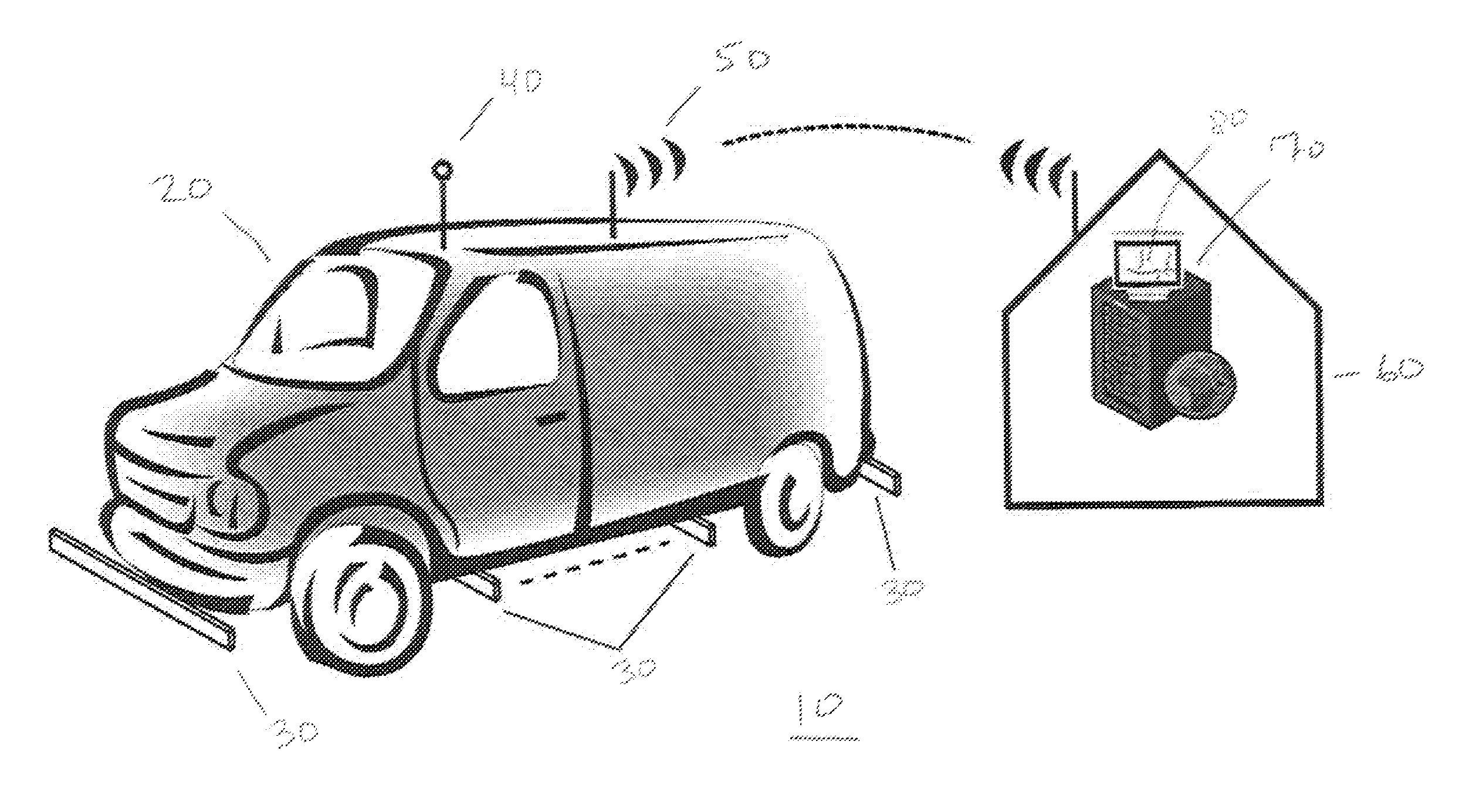

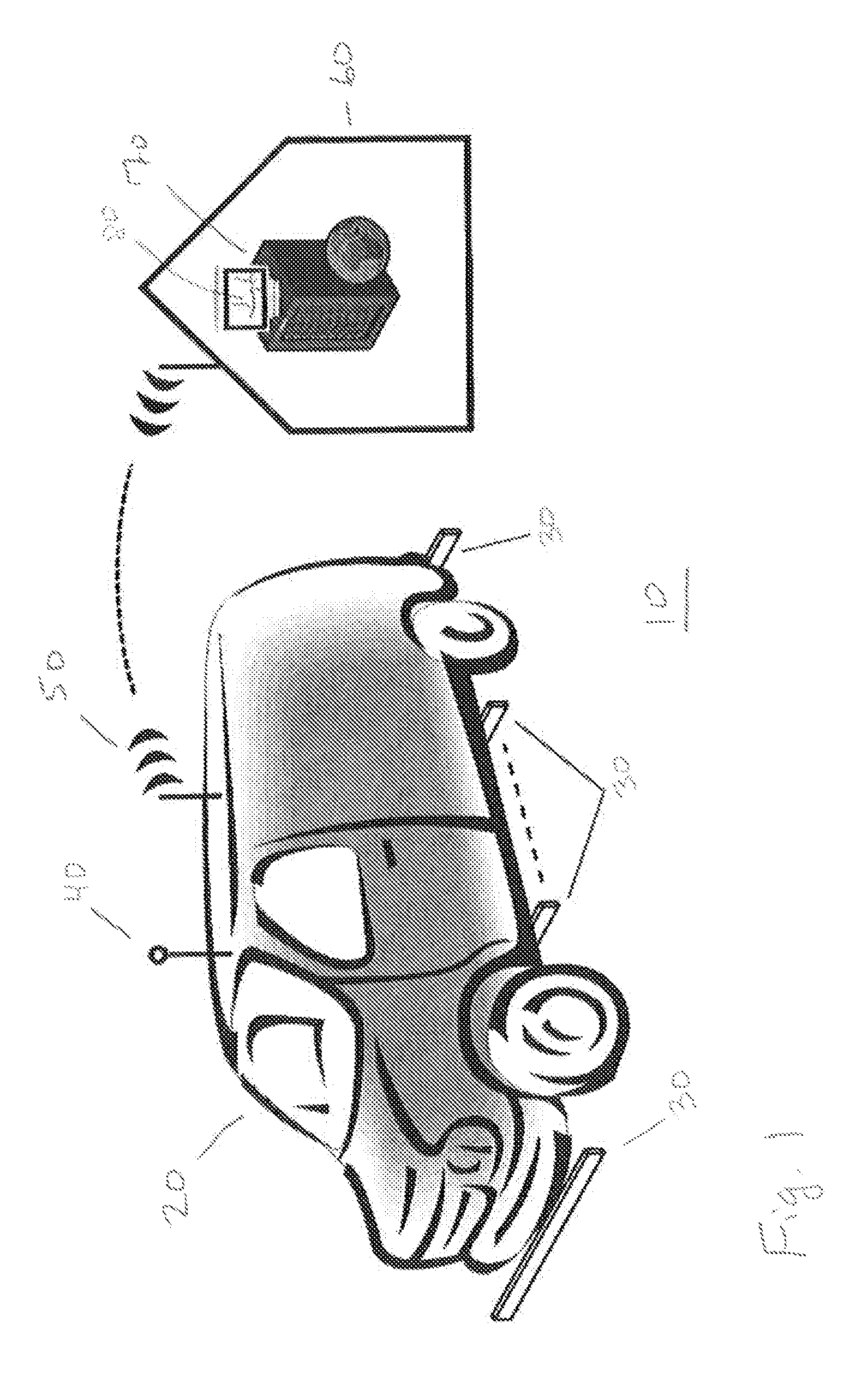

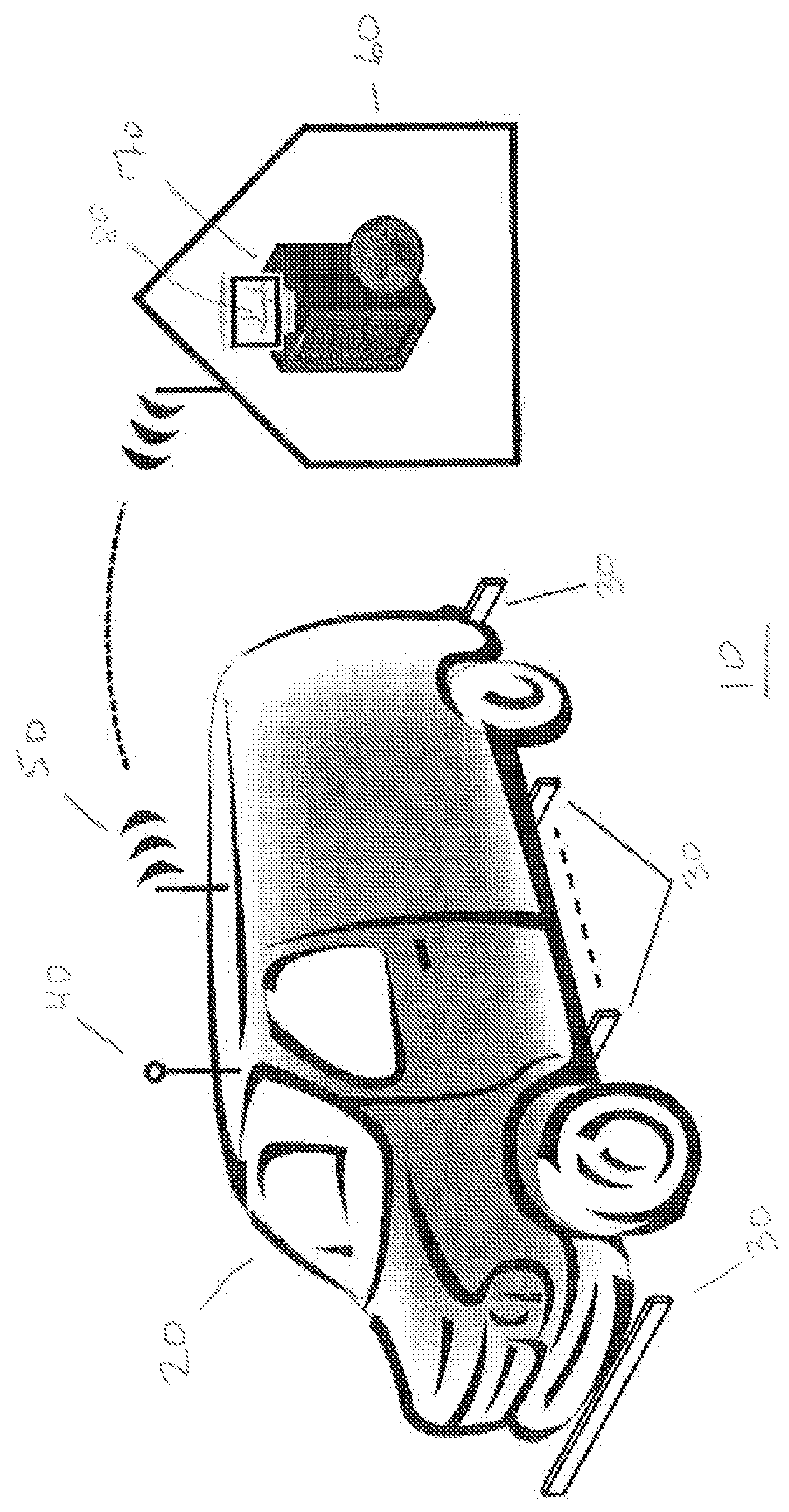

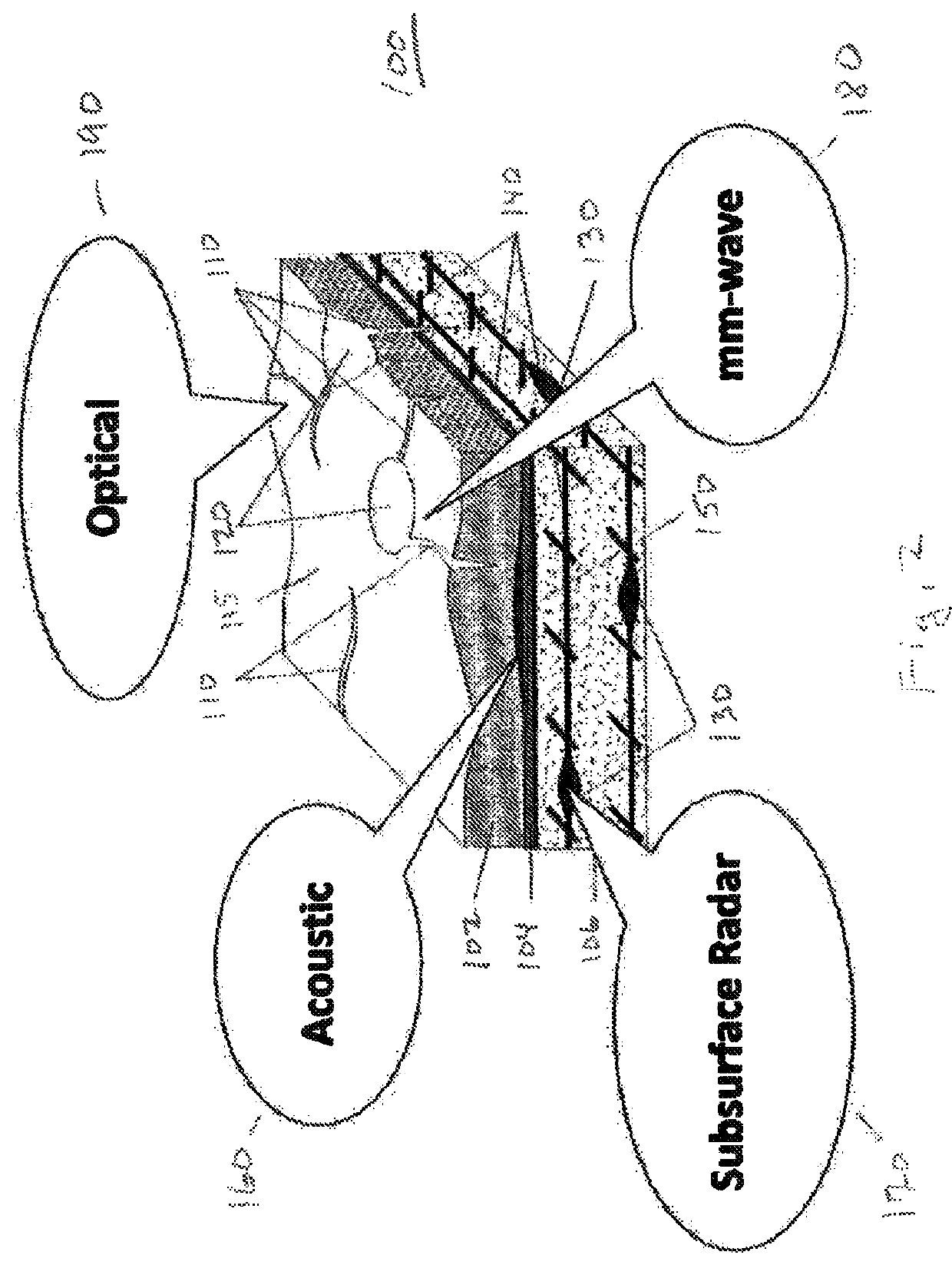

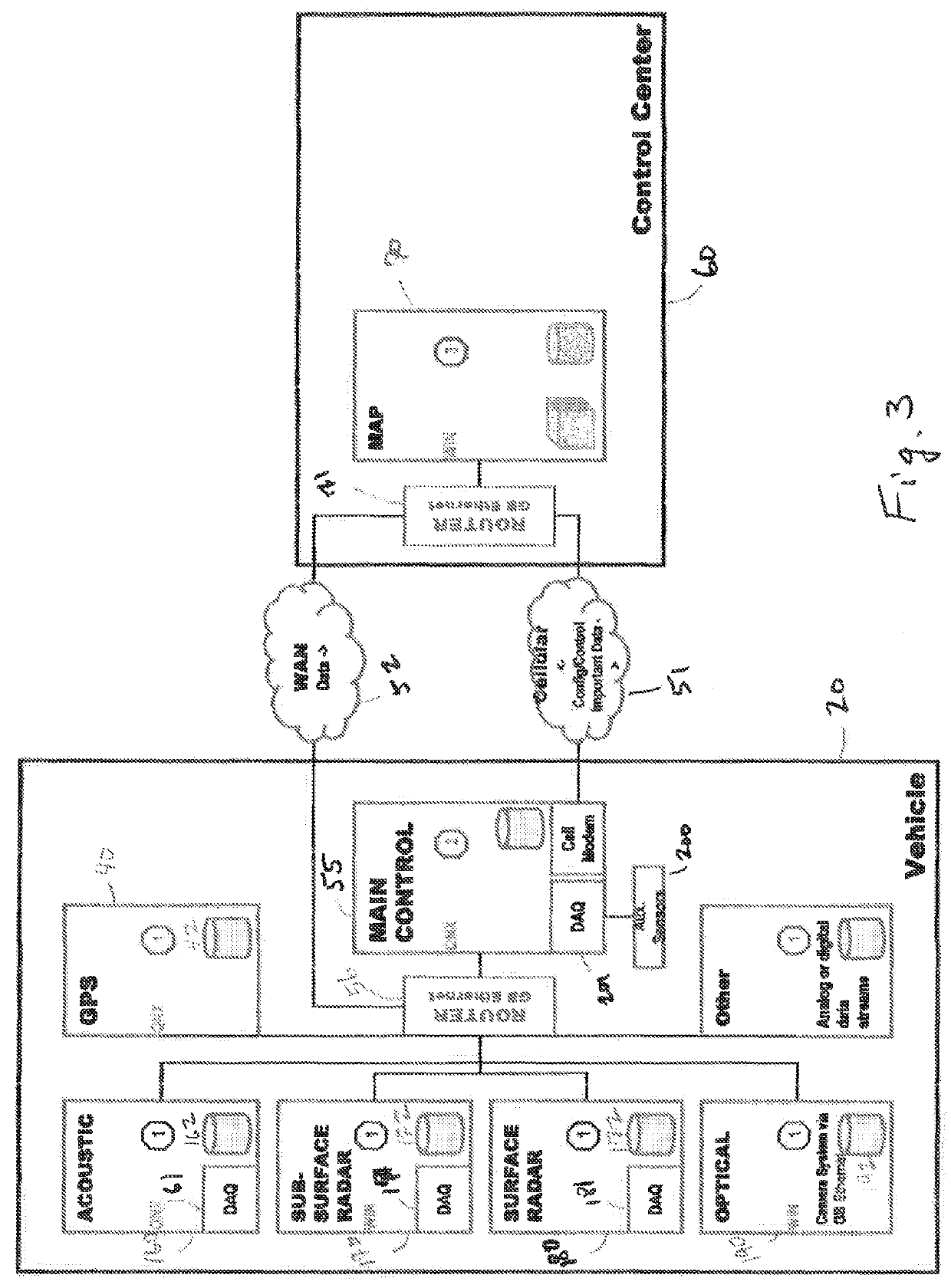

Roaming Mobile Sensor Platform For Collecting Geo-Referenced Data and Creating Thematic Maps

ActiveUS20130018575A1Improve securityTraffic can be stoppedInstruments for road network navigationRoad vehicles traffic controlRebar corrosionBridge deck

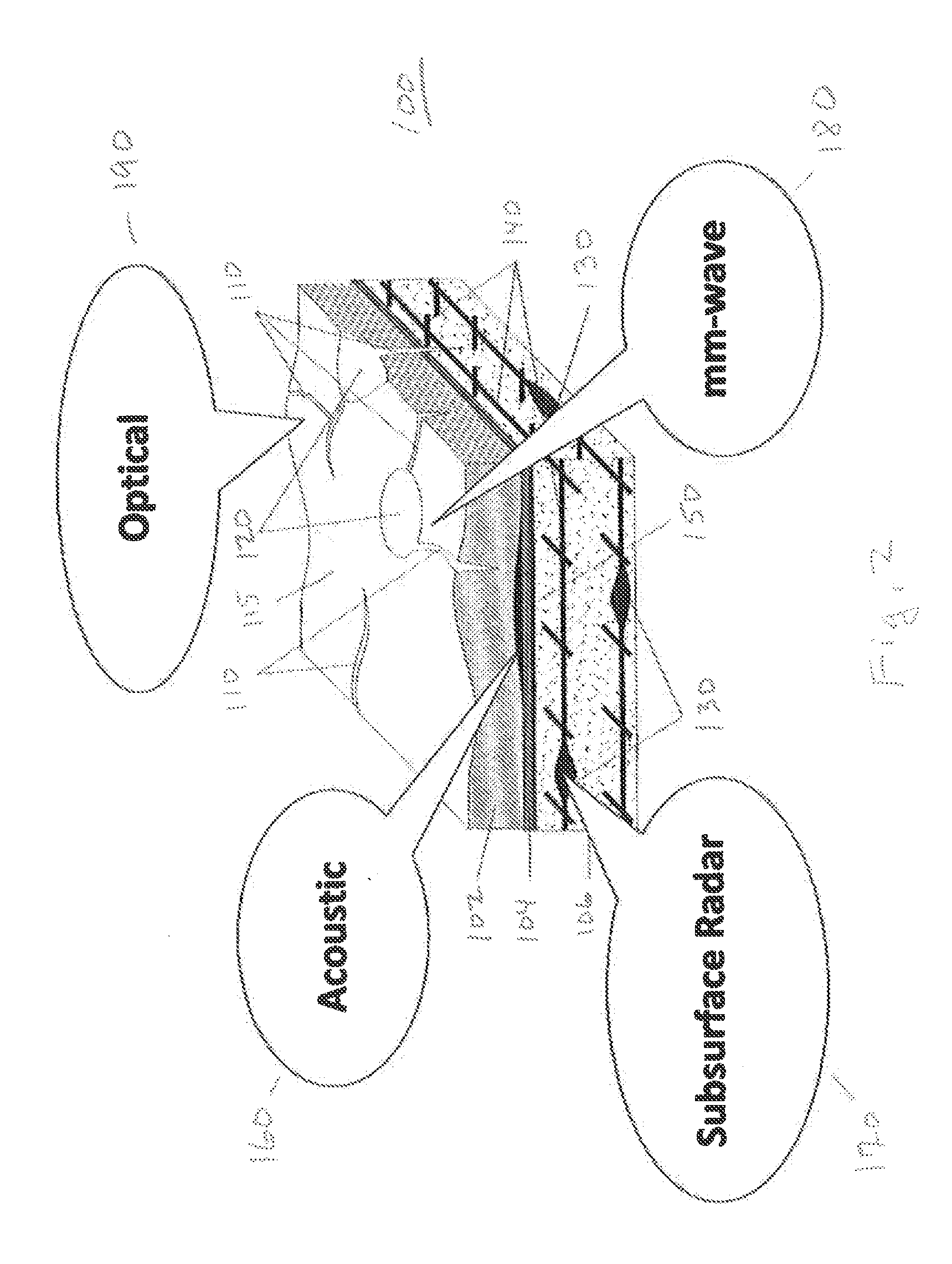

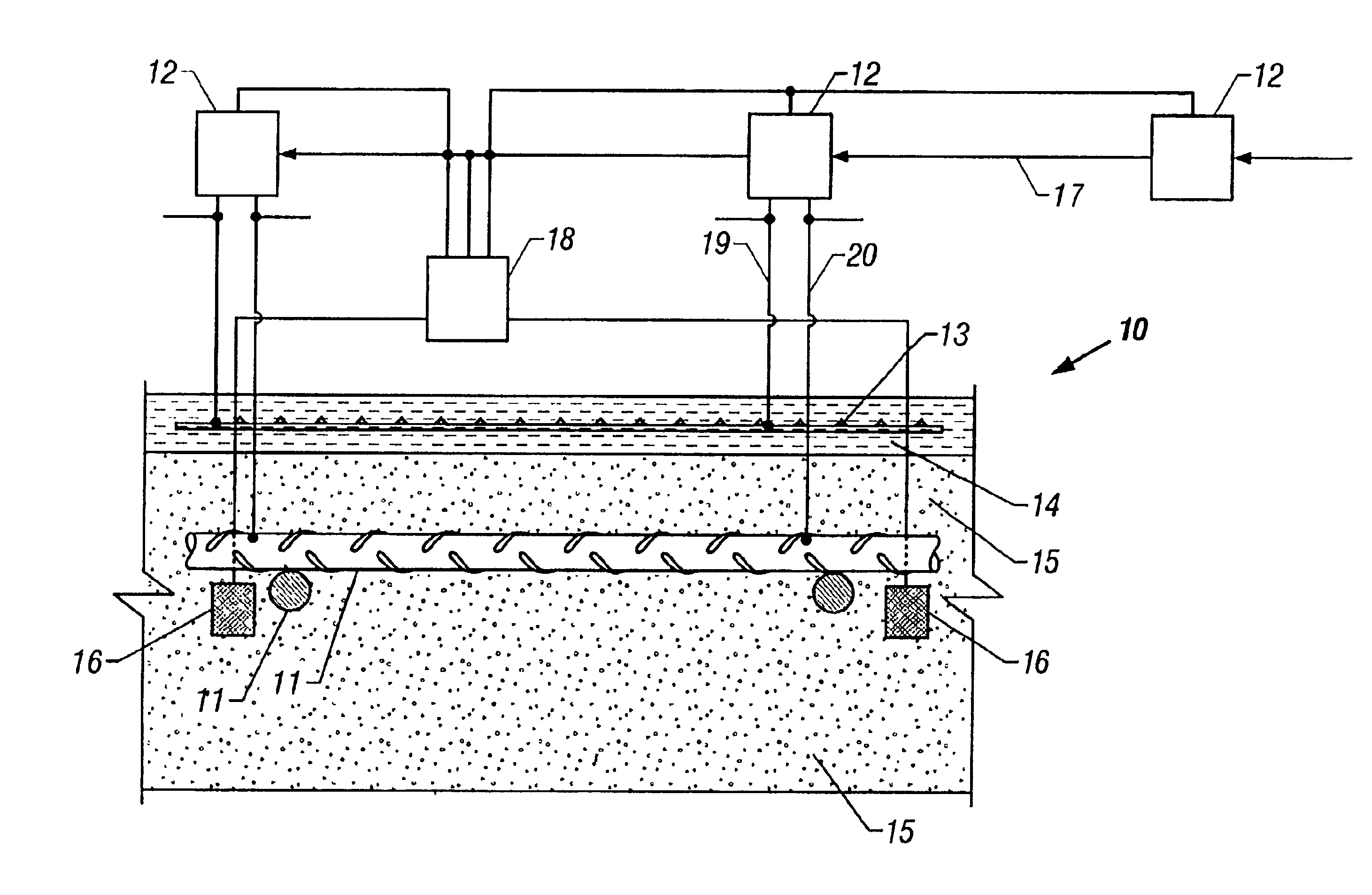

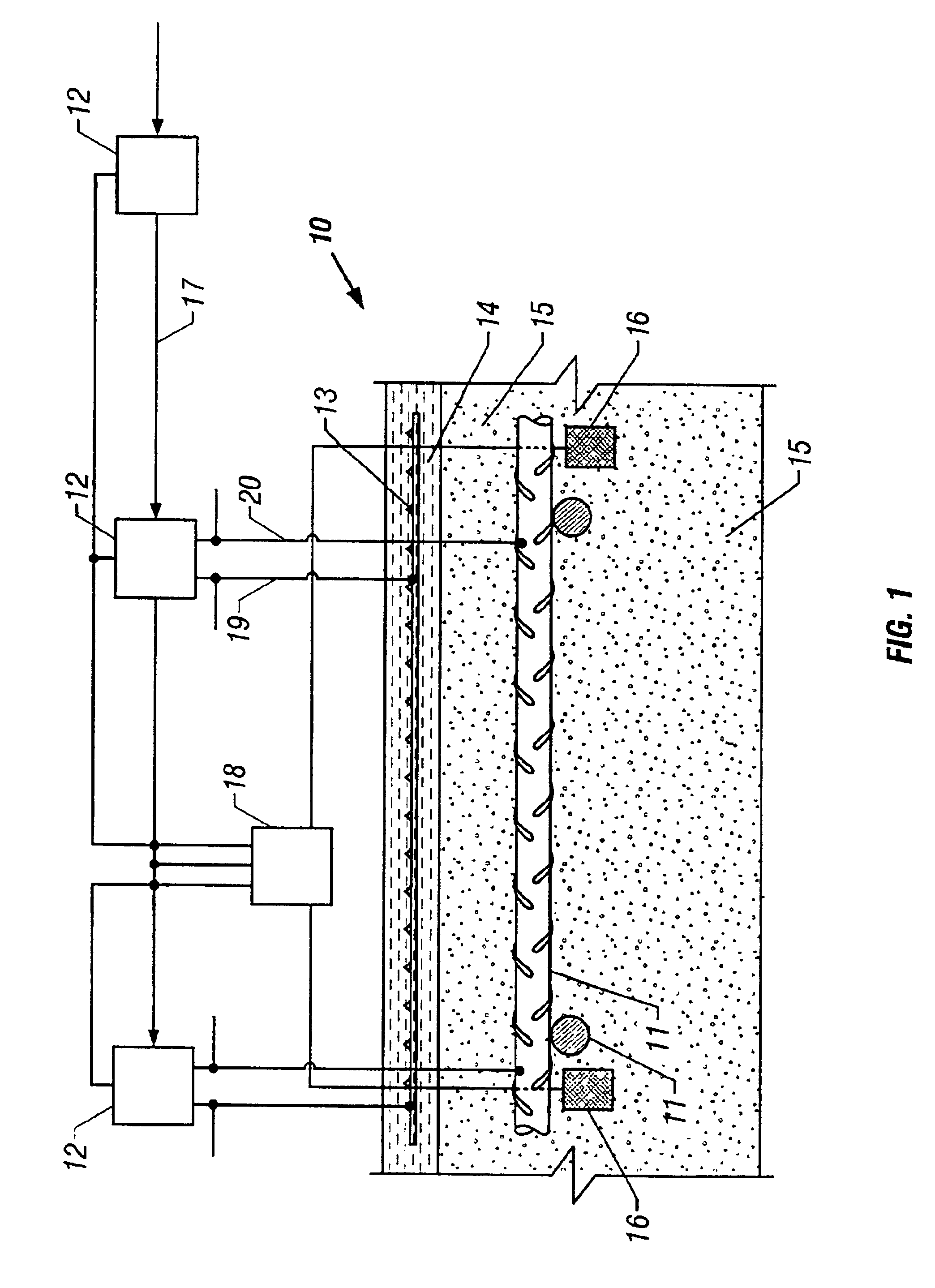

A roaming sensor system collects data on the condition of roads and bridge decks and identifies and maps defects, including cracks, potholes, debonding, tracking, delamination, surface ice, surface water, and rebar corrosion. Data are collected by a vehicle or a fleet of vehicles driven at normal traffic speeds. The vehicle is outfitted with sensors that collect data using acoustic surface waves, ground penetrating radar, mm wave surface radar, and / or video images. The data are transmitted to a control center for analysis and distribution.

Owner:NORTHEASTERN UNIV

Method for detecting corrosion of concrete bar in reinforced concrete

InactiveCN1438478AAccurately determineAccurately determine the depthWeather/light/corrosion resistanceMaterial electrochemical variablesRebar corrosionMaterials science

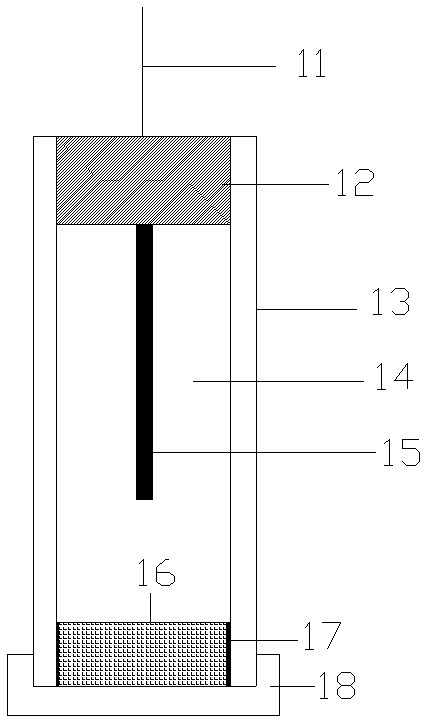

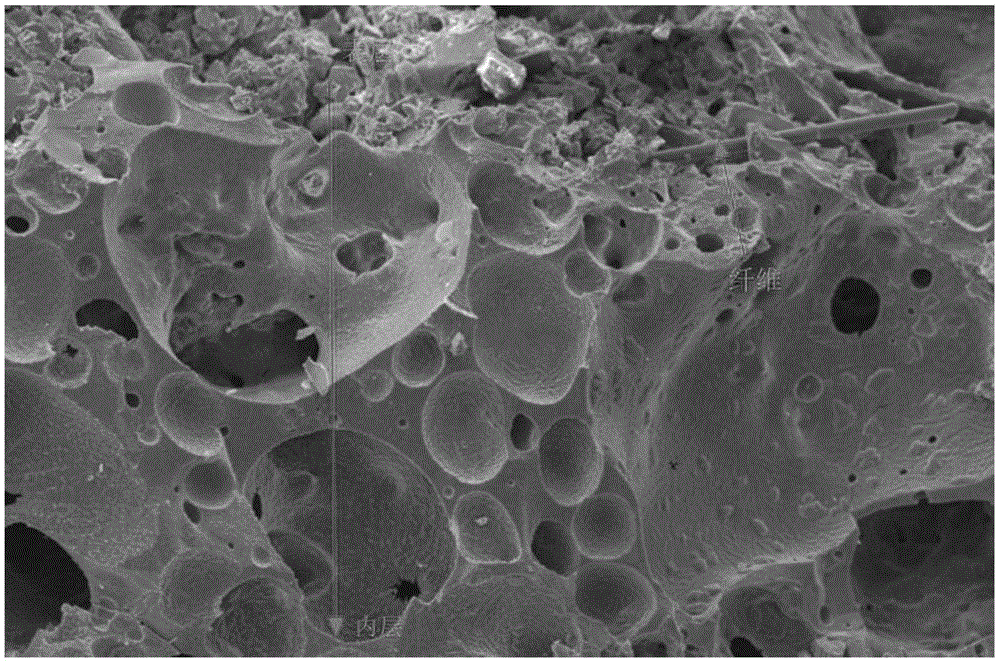

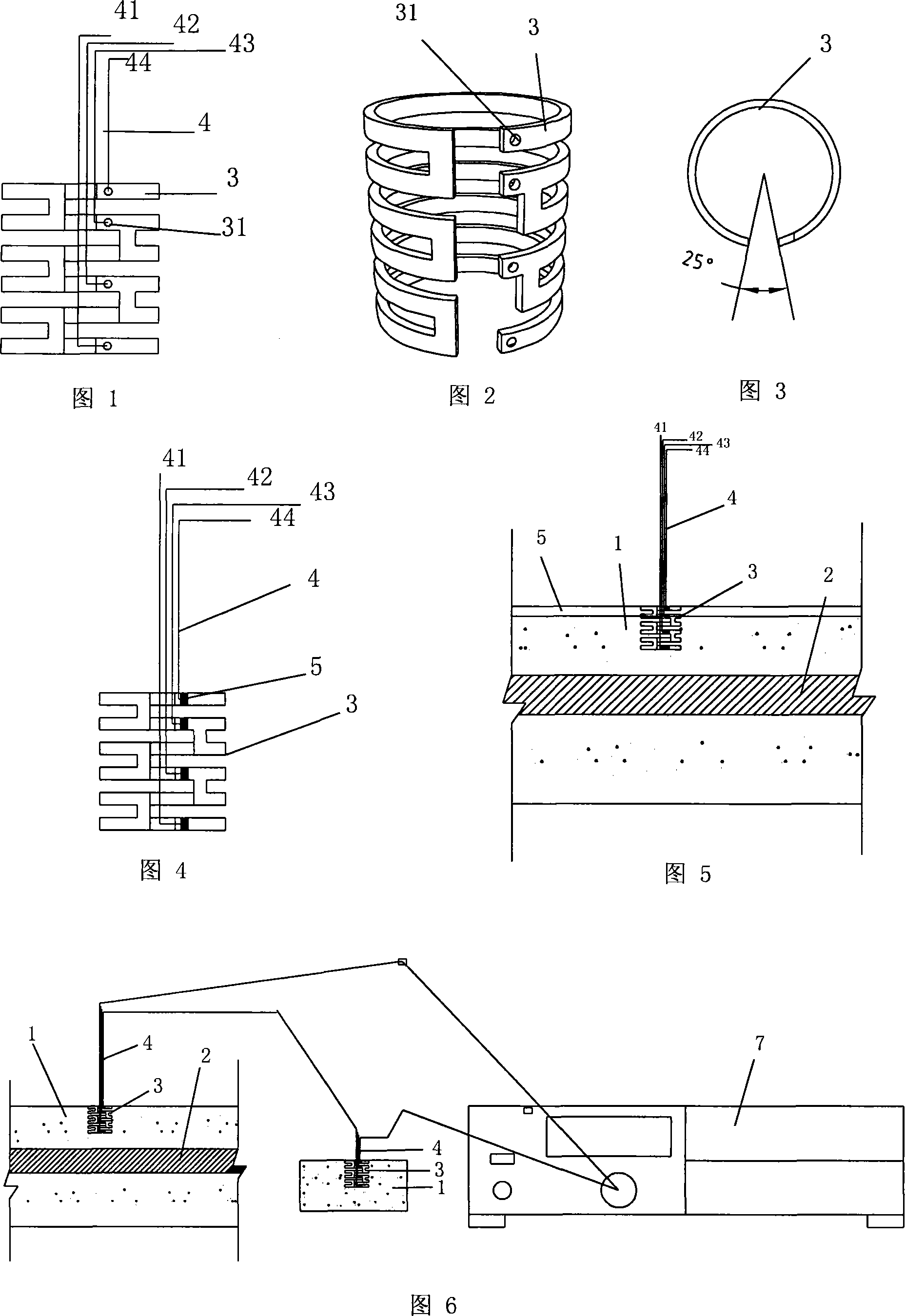

The method directly measures the corrosion happened on reinforcing steel bars in real time. The sensor comprises several reinforcing steel bars with non equal lengths, the stainless steel bars having same quantities and lengths as of the reinforcing steel bars, the base seat and the conducting wires. The reinforcing steel bars and the stainless steel bars in stepped appearance are fixed in the fixed slot in the base seat of the sensor side by said. The conducting wires are leaded out and numbered from the threading hole in the middle of the fixed slot. In the time of construction, the said sensors are embedded into concretes. While in the period of the constructions being used, the data from the sensors are collected regularly.

Owner:SHANGHAI JIAO TONG UNIV

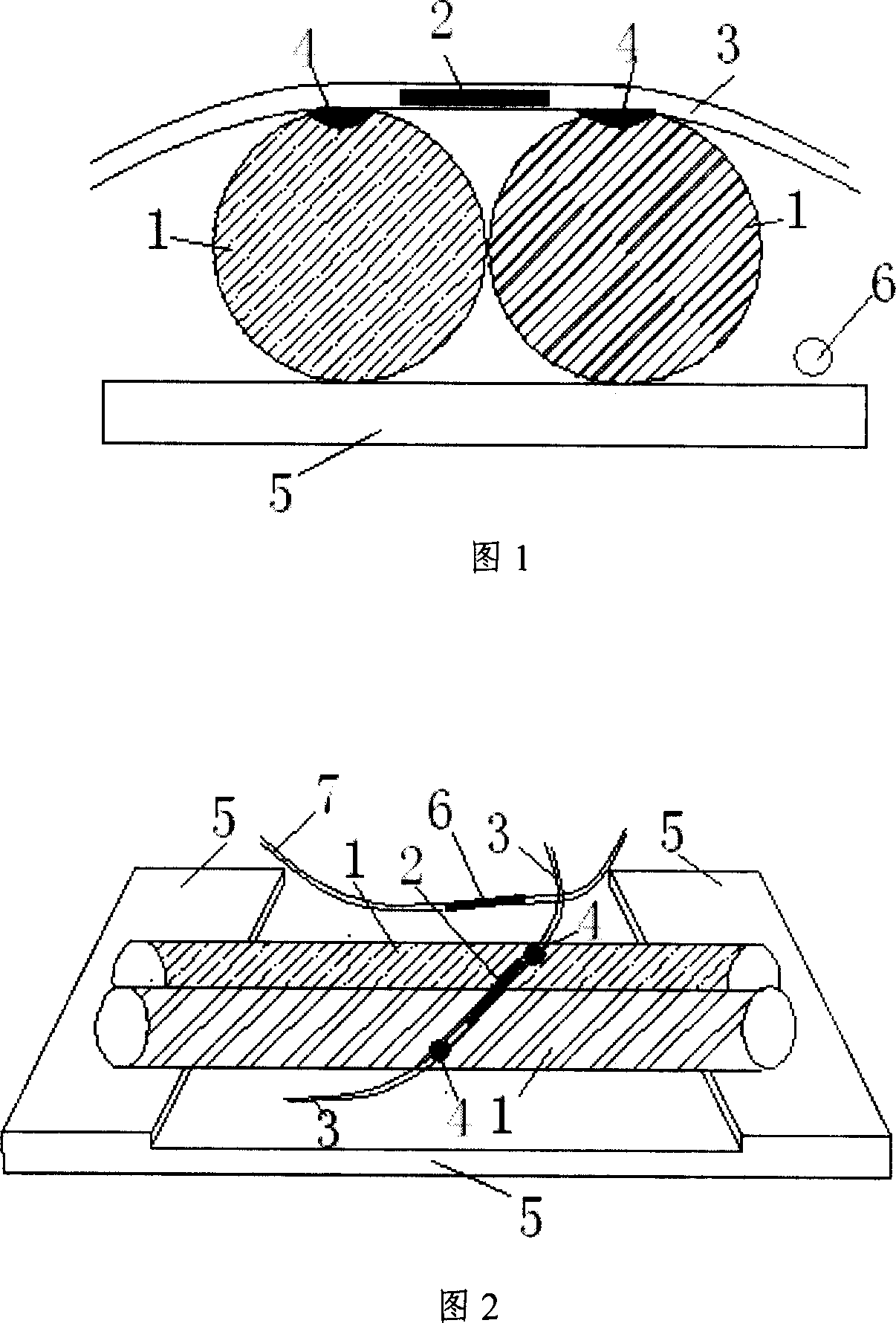

Method for testing steel corrosion of reinforced concrete members

InactiveCN101008620ASimple structureAccurately determineFoundation testingOptically investigating flaws/contaminationFiberRebar corrosion

This invention relates to one steel concrete structure anti-erosion test method in structure engineer field, which comprises the following steps: a, sensor processing to parallel two steel bars in same materials for fixing and sticking the stress fiber grating to top end and putting one free temperature compensation fiber grating connected by the compensation fiber and sealing on shell; b, positioning the sensor and drilling it into concrete with stress fiber and temperature compensation connected to spectrum; c, monitoring by periods to test grating wave length volume and speed to infer anti-erosion degree and speed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

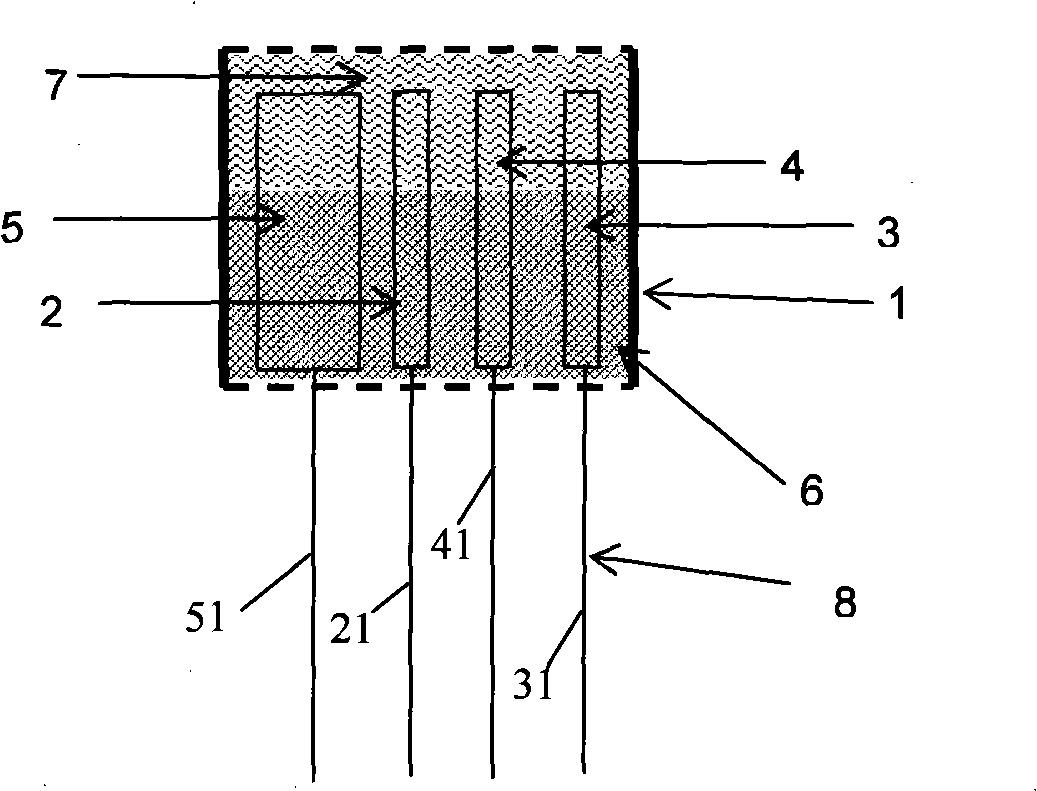

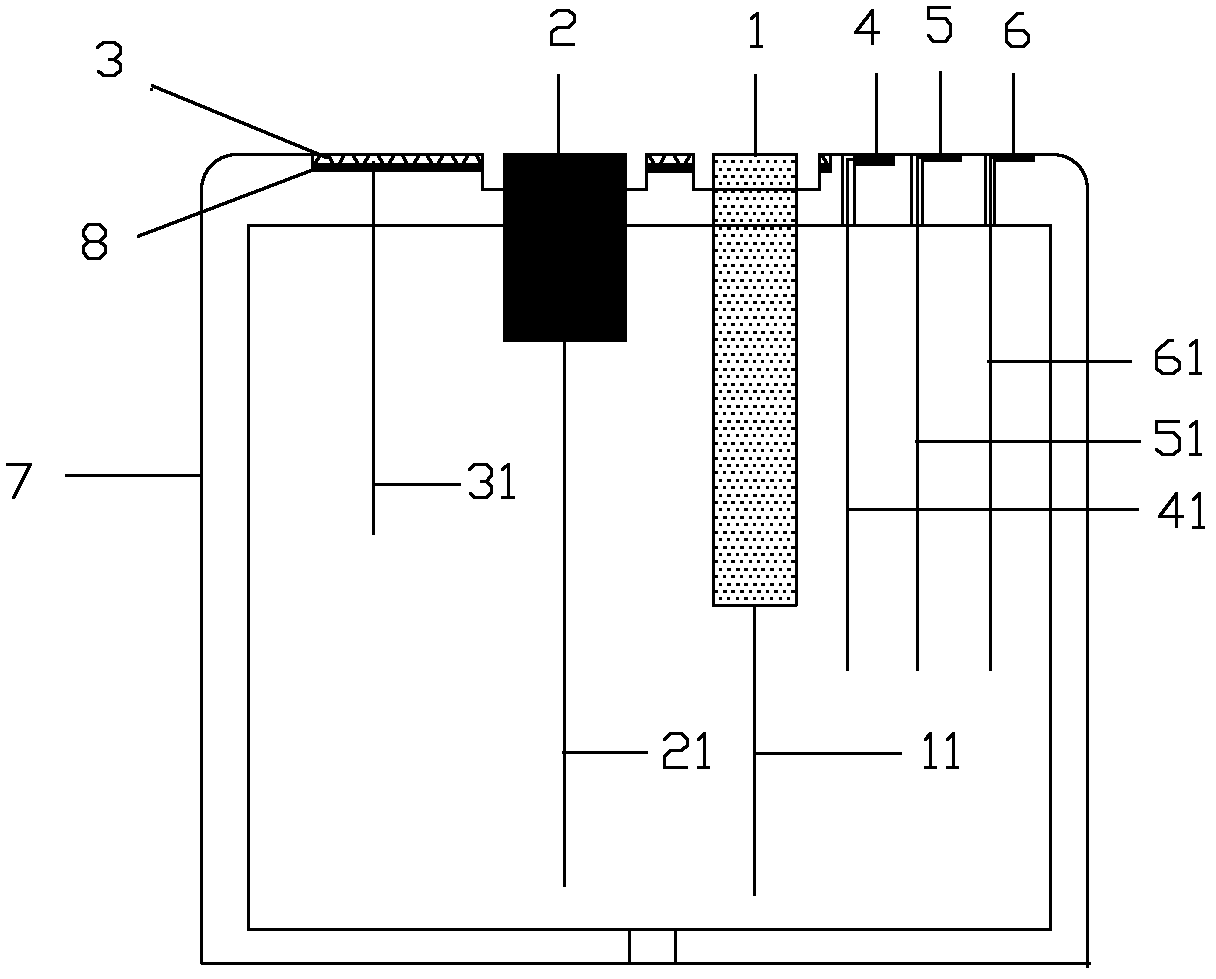

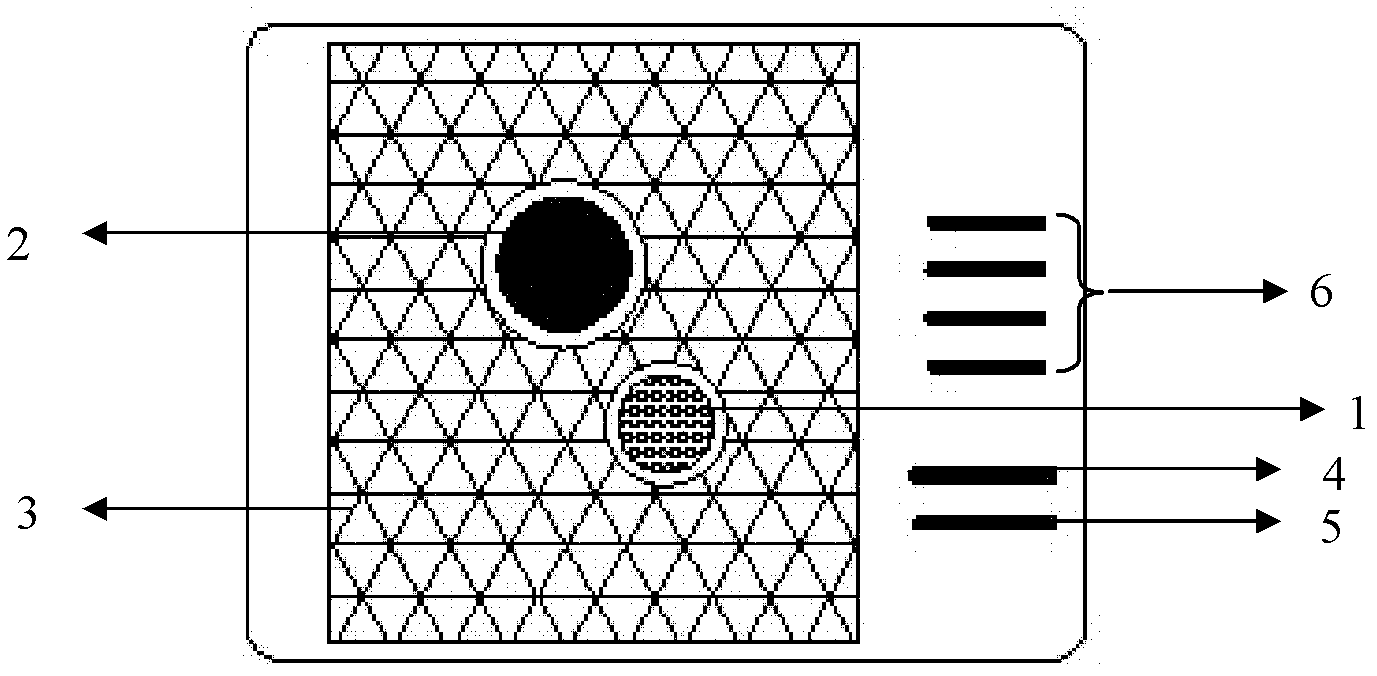

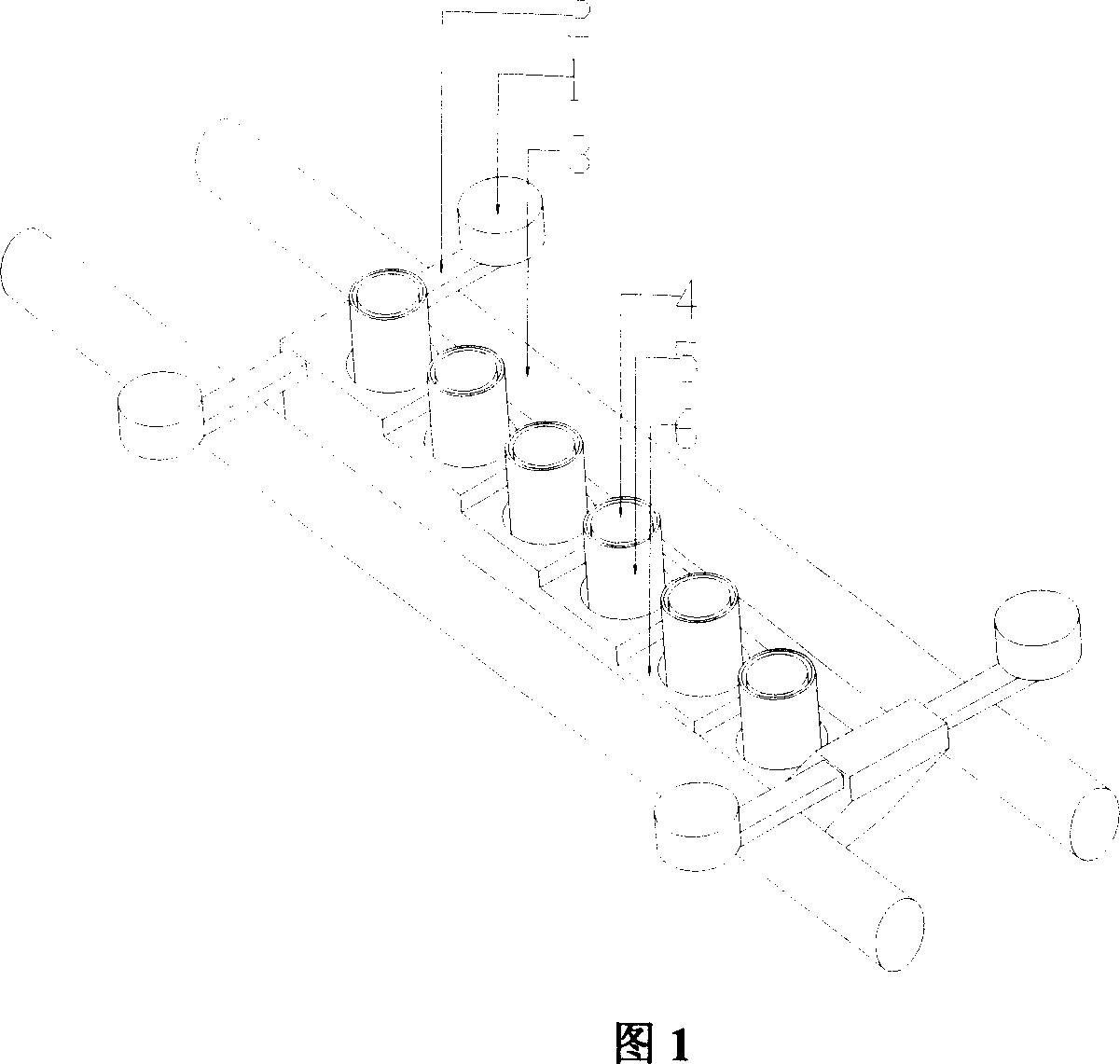

Multifunctional sensor for monitoring reinforced concrete structure erosion

InactiveCN101334353AImprove responsivenessImprove reliabilityWeather/light/corrosion resistanceMaterial electrochemical variablesRebar corrosionCarbonization

The invention discloses a multifunctional sensor that is used for monitoring the corrosion of a reinforced concrete structure, relating to a sensor, and provides a multifunctional sensor that is used for monitoring the corrosion of a reinforced concrete structure and can simultaneously monitor electrochemical corrosion parameters of carbonization of concretes, Cl<-> concentration, corrosion status and corrosion speed of reinforcement metals and the like on the spot, as well as a preparation method of the multifunctional sensor. The multifunctional sensor is provided with a metal shell, a Cl<-> probe, a pH probe, a reinforcement metal electrode, a MnO2 reference electrode and external guide lines. The Cl<-> probe, the pH probe, the reinforcement metal electrode and the MnO2 reference electrode are prepared separately, and then arranged in the shell. The external guide lines of each probe and each electrode are connected with and extend from the metal shell, each probe and each electrode are sealed and fixed with the metal shell, and insulating materials are exposed at the upper ends of each probe and each electrode and the ends exposing outside are covered by pervious materials; connecting parts between the external guide lines and the metal shell are sealed.

Owner:XIAMEN UNIV

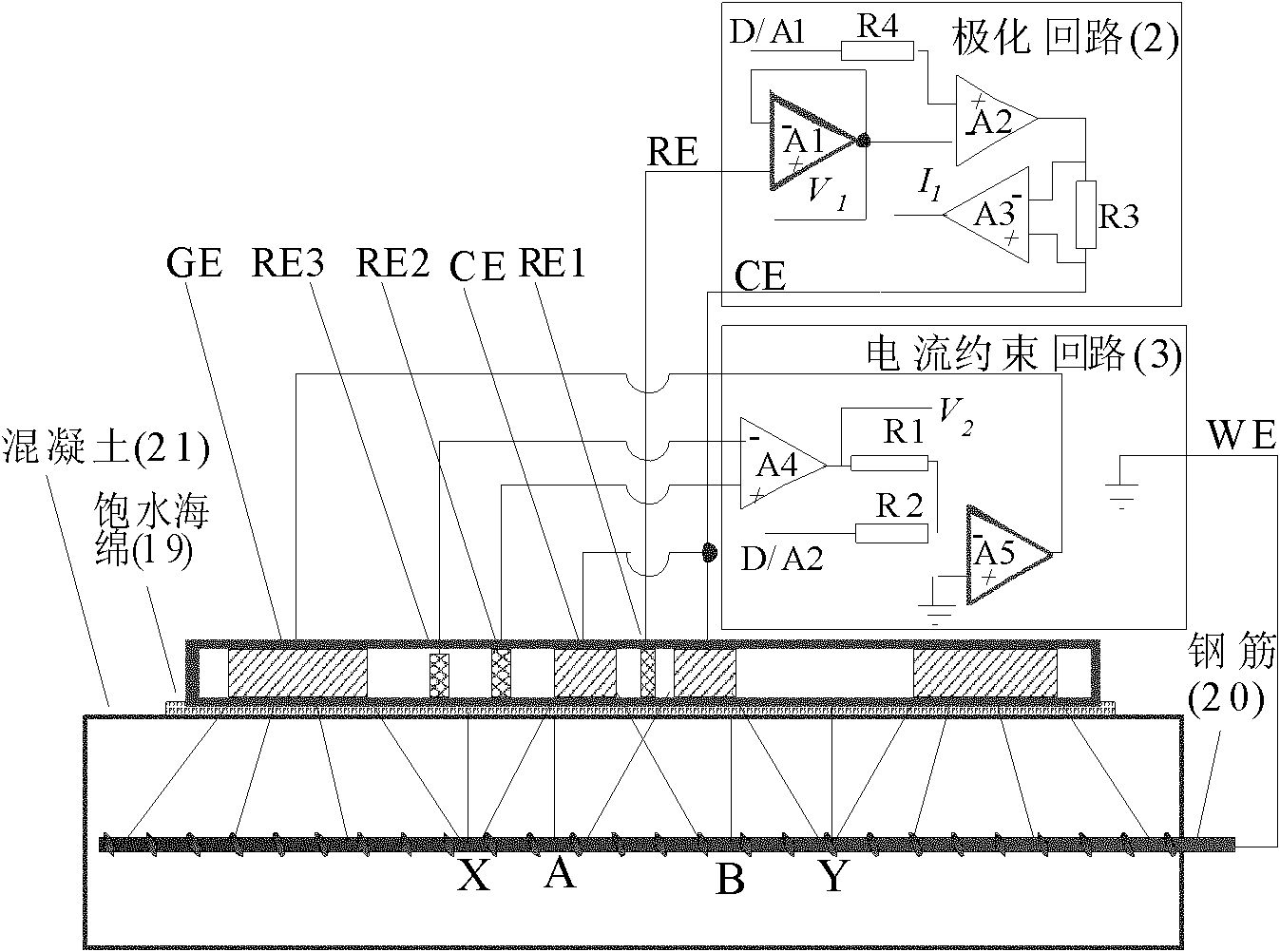

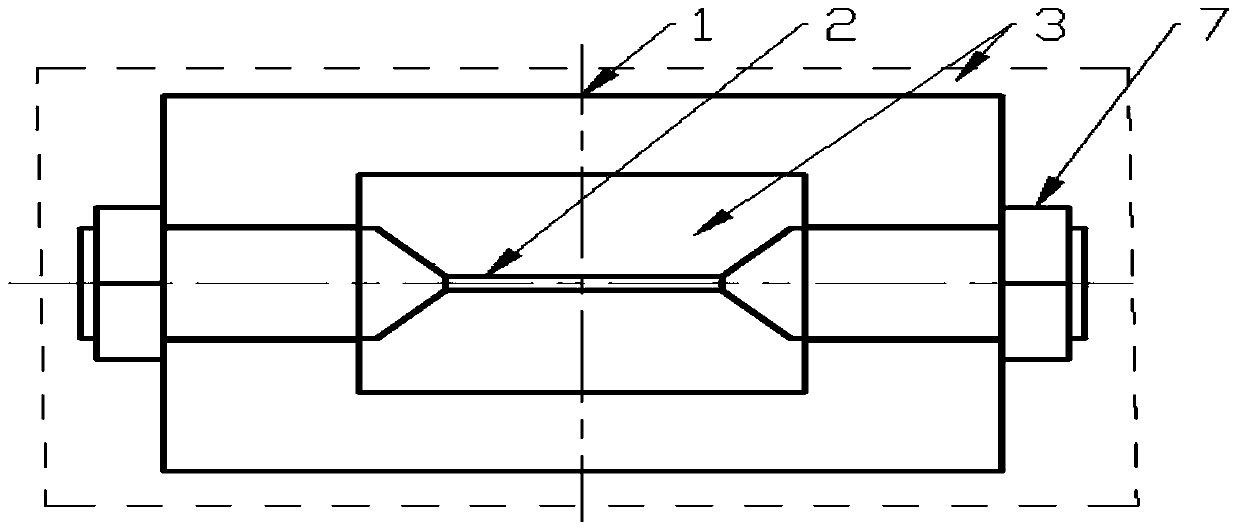

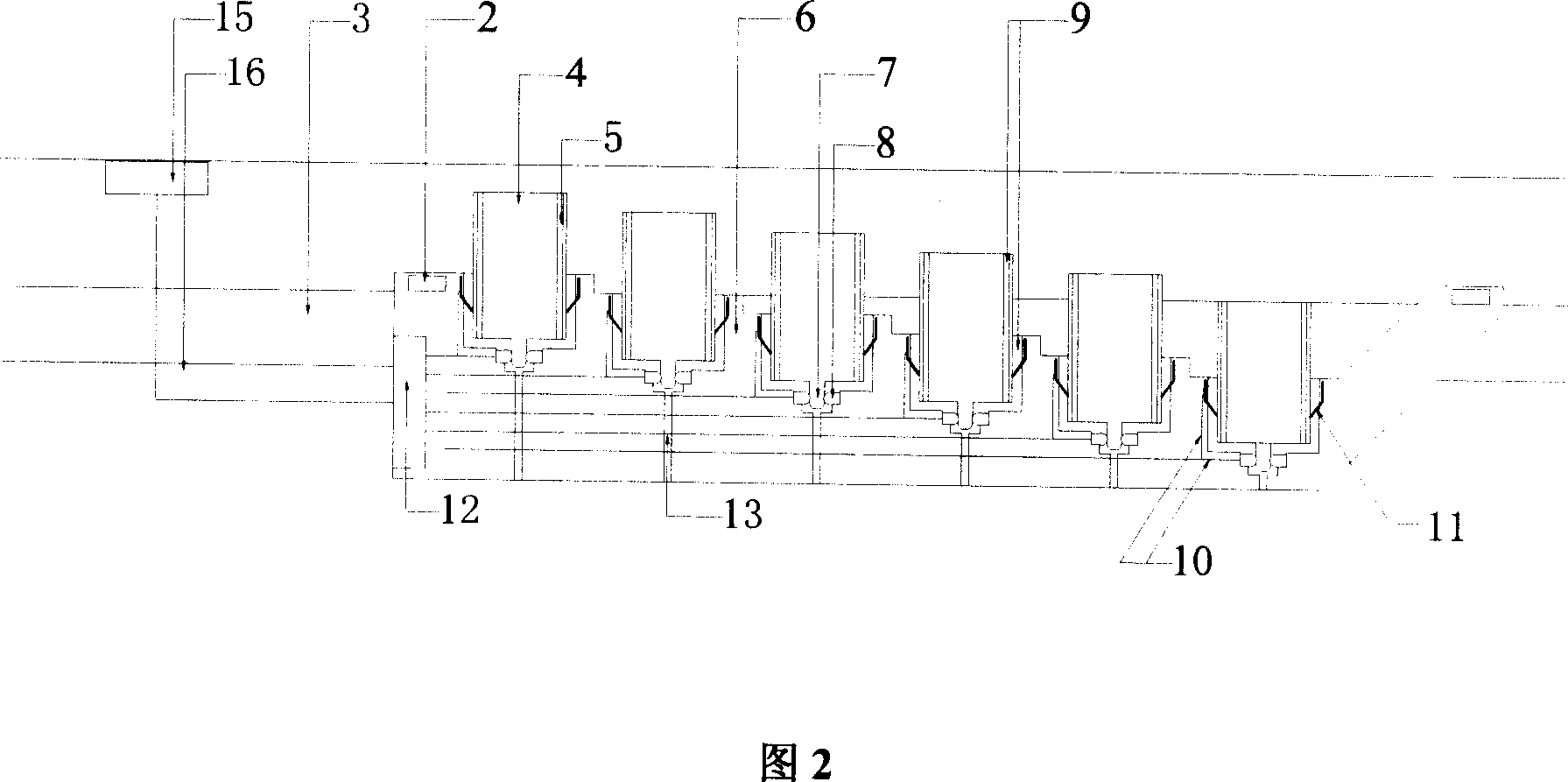

On-line corrosion detector for reinforced concrete and method thereof

InactiveCN101943655AAccurate measurementQuick measurementWeather/light/corrosion resistanceRebar corrosionPotential difference

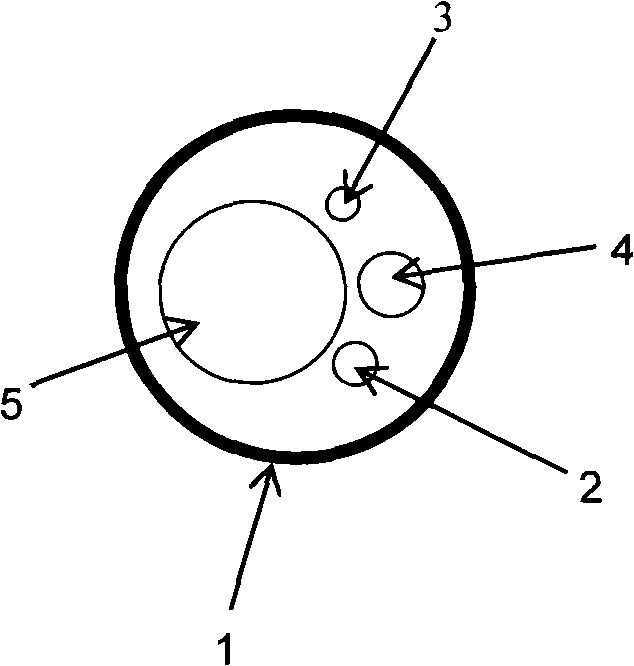

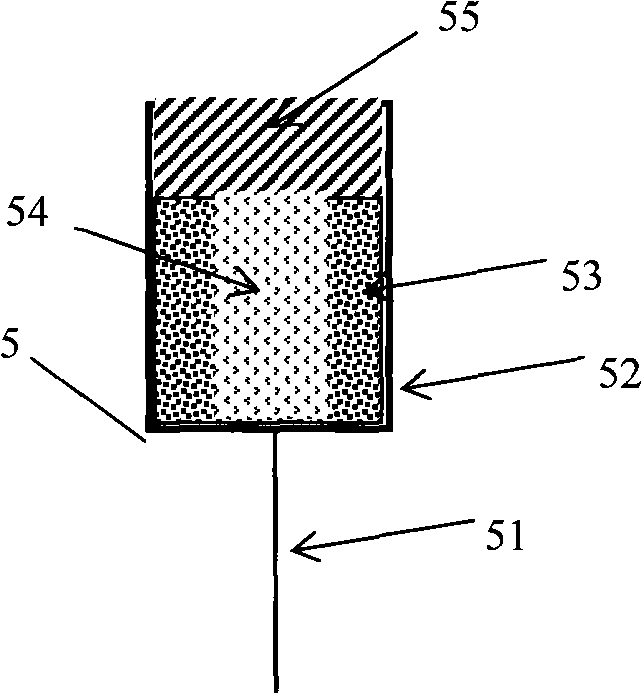

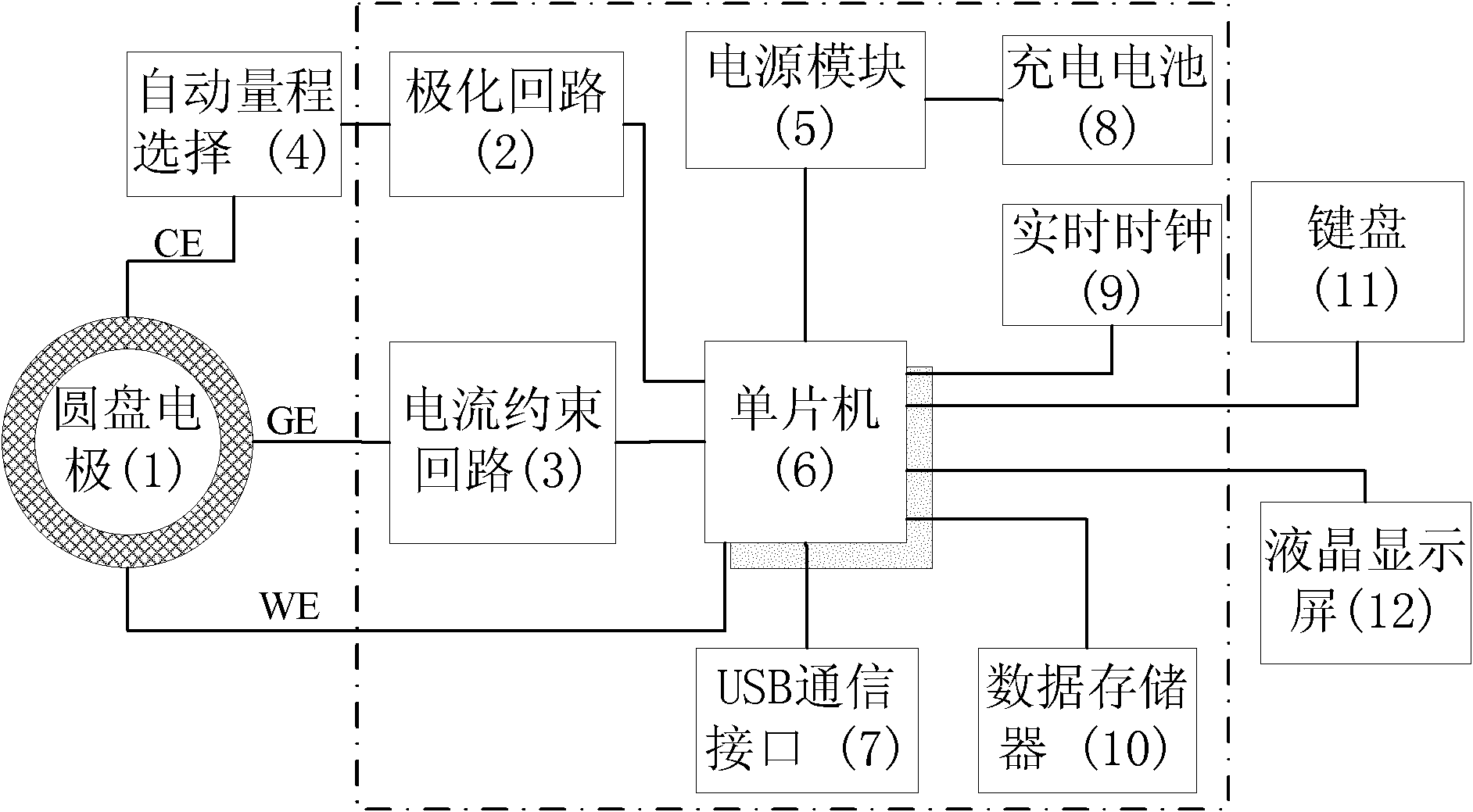

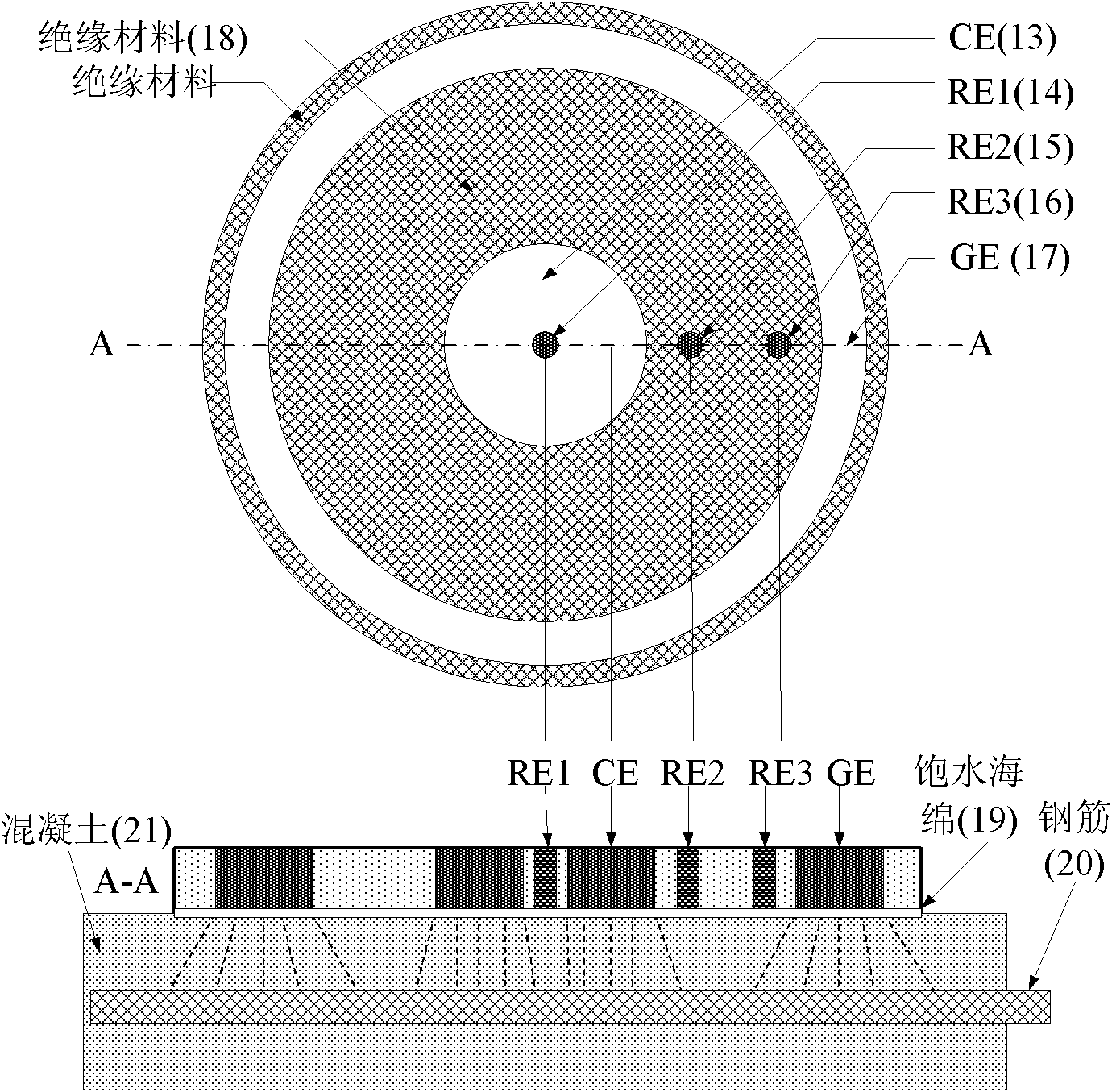

The invention provides an on-line corrosion detector for reinforced concrete based on a disk electrode. The on-line detector comprises a polarization circuit (2) and a current constraint circuit (3), wherein the disk electrode (1) comprises reference electrodes RE1, RE2 and RE3, an auxiliary electrode CE (13) and a circular ring electrode GE (17); the polarization circuit (2) polarizes the reinforcing steel bars in concrete through the auxiliary electrode CE (13) and the reference electrode RE1 in the disk electrode (1); and meanwhile the current constraint circuit (3) restrains polarization current through the circular ring electrode GE (17) and potential difference between the reference electrodes RE2 and the reference electrodes RE3 so as to limit the polarization current in a projection zone of the auxiliary electrode CE (13). The invention further provides a method for measuring corrosion rate of the reinforcing steel bar in a concrete structure by using the detector. The invention improves measurement accuracy of the corrosion rate of the reinforcing steel bars in the concrete structure and avoids measurement errors caused by current over-constraint and under-constraint.

Owner:HUAZHONG UNIV OF SCI & TECH

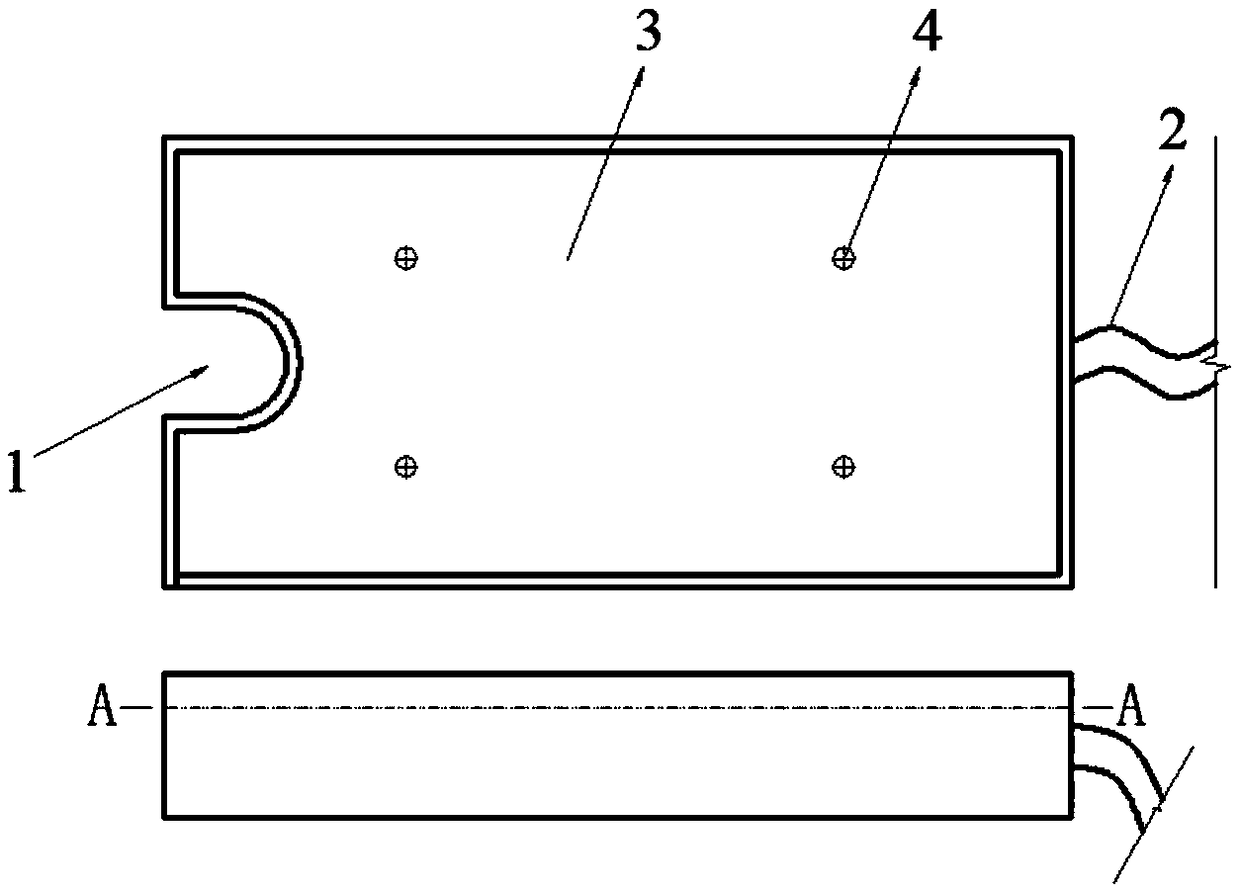

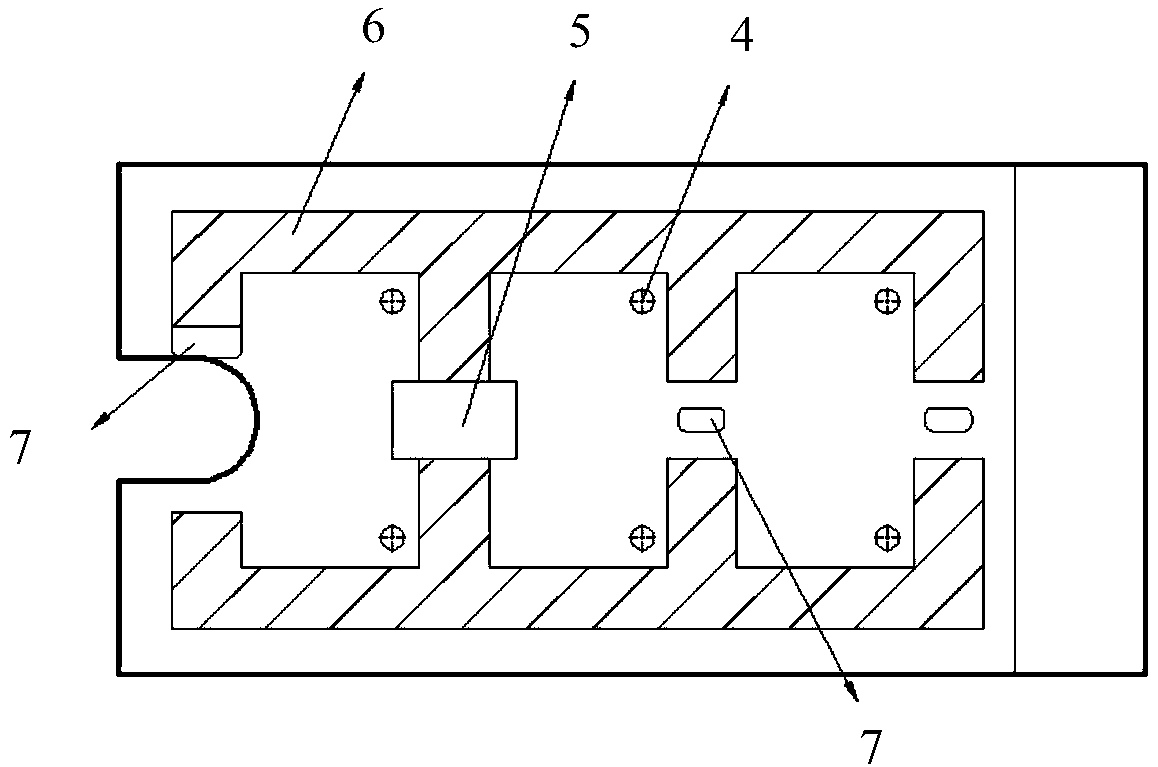

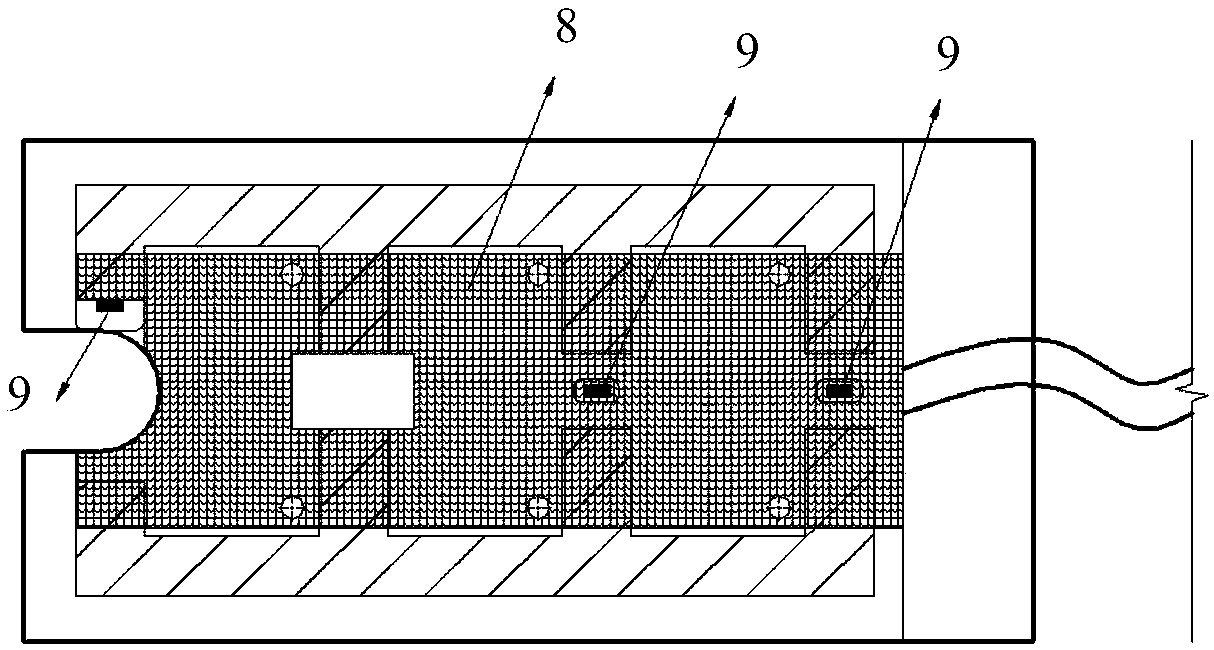

Non-destructive dynamic monitoring sensor for corrosion of reinforcing steel bar in concrete based on magnetic field and system

InactiveCN109374726AHigh precisionImprove stabilityMaterial magnetic variablesNon destructiveDynamic monitoring

The invention relates to the monitoring technique of corrosion of reinforcing steel bars in construction engineering, and aims to provide a non-destructive dynamic monitoring sensor for corrosion of areinforcing steel bar in concrete based on a magnetic field and a system. A slot for clamping a to-be-detected reinforcing steel bar is formed in one end of a shell of the sensor; two epsilon-type protruding teeth and oppositely arranged stainless steel frames are arranged in the shell, and mounting positions of Hall sensors are retained among other opposite teeth beside a permanent magnet arranged between one opposite teeth; end opposite teeth of the stainless steel frame and a mounting position of a Hall sensor are arranged on two sides of the slot, the Hall sensors are fixed to a data collection plate and the main body parts are located in the mounting positions. The corrosion rate of the reinforcing steel bar is monitored by mean of a magnetic field principle, so that the precision and the stability are relatively high; non-destructive and dynamic monitoring of the corrosion rate of the reinforcing steel bar in concrete can be achieved. The corrosion rate of the reinforcing steelbar in concrete can be given directly quantitively. The instrument device is small in size, convenient to carry and convenient to operate in an engineering site.

Owner:ZHEJIANG UNIV +1

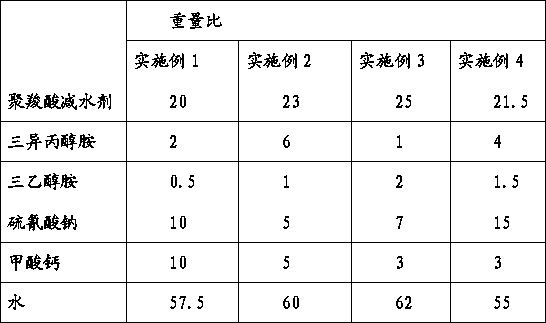

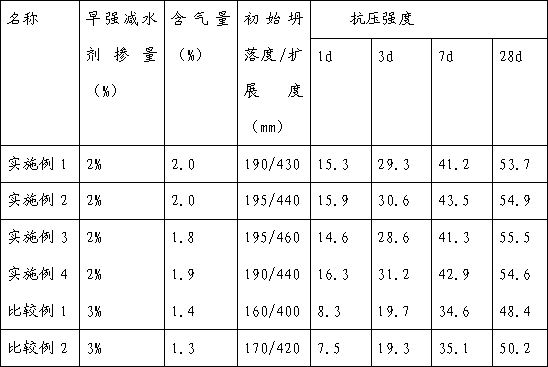

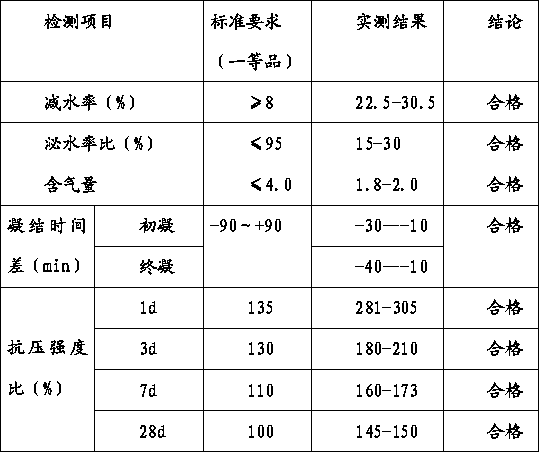

Early-strength water reducer for recycled aggregate concrete

The invention provides an early-strength water reducer for recycled aggregate concrete, which is suitable for the field of building materials. The the early-strength water reducer comprises the following raw materials by weight percent: 20-25% of a polycarboxylic acid water reducer, 1-6% of tri-isopropanolamine, 0.5-2% of triethanolamine, 5-15% of sodium sulfocyanate, 3-10% of calcium formate, and 42-70.5% of water. The early-strength water reducer provided by the invention is low in dosage, good in early-strength effect, free from chloride ions, resistant to the corrosion of steel bars, suitable for recycled concrete, and capable of enhancing the early strength of a recycled concrete product and improving the peaceability of a recycled concrete mixture.

Owner:北京新奥混凝土集团有限公司

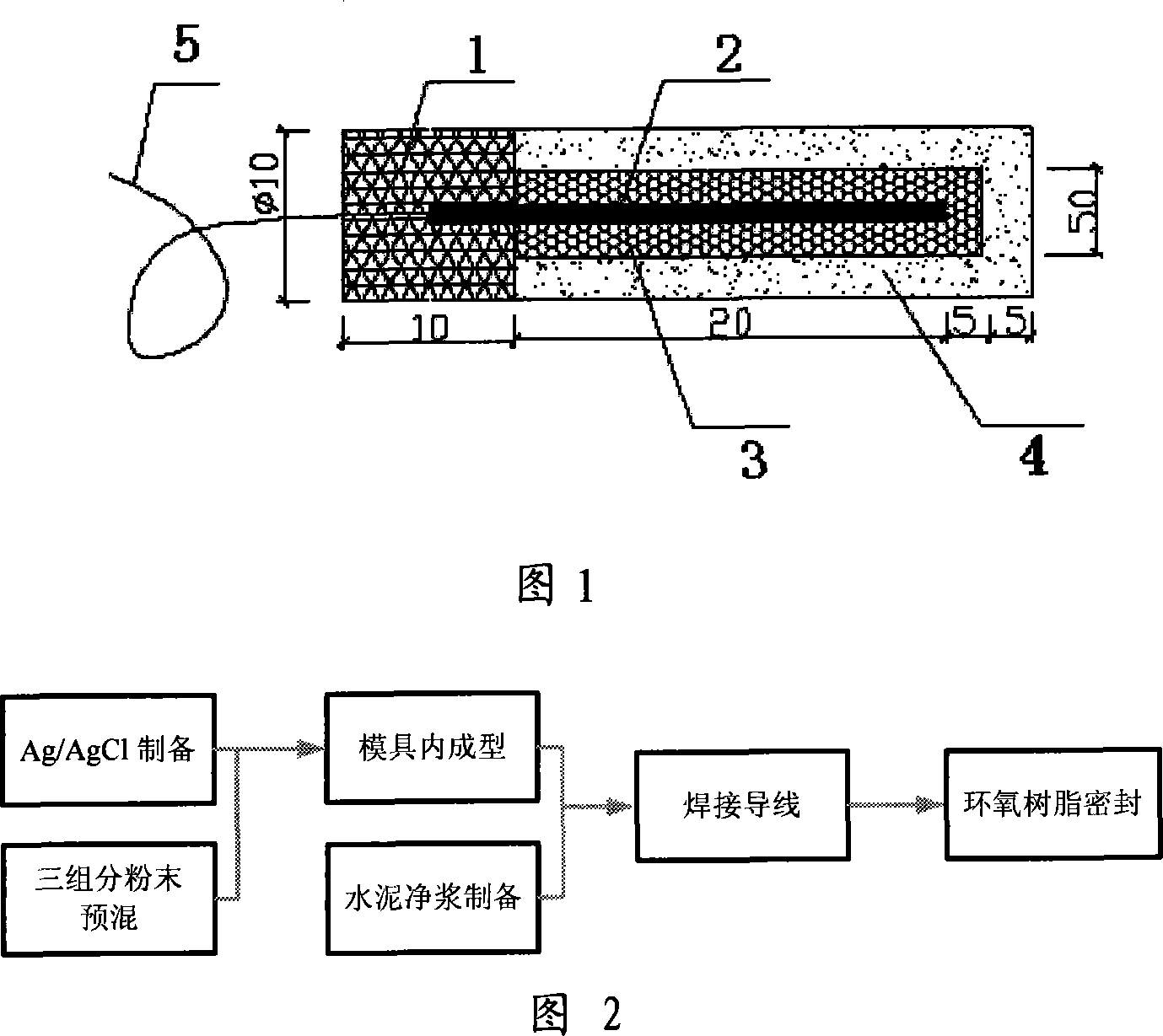

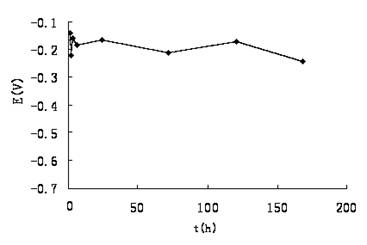

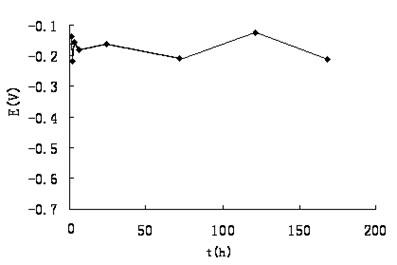

All-solid reference electrode for monitoring steel bar corrosion of concrete and its preparation method

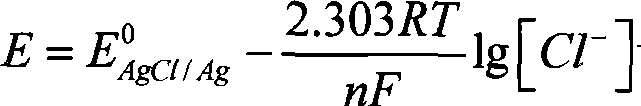

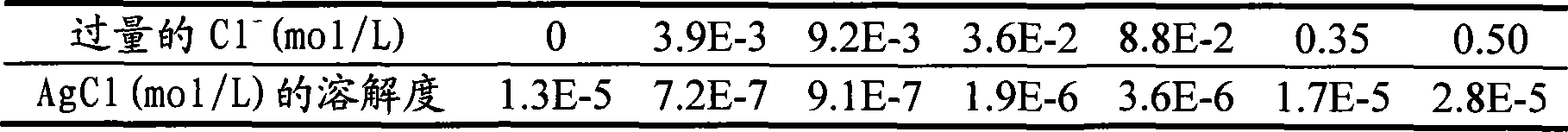

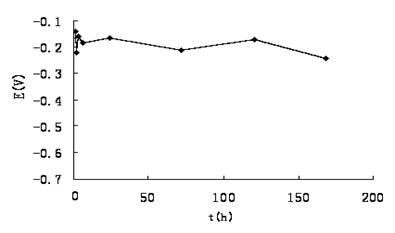

InactiveCN101144790AEliminate liquid junction potentialGuaranteed accuracyWeather/light/corrosion resistanceMaterial electrochemical variablesRebar corrosionPorous layer

The invention provides a full-solid-state reference electrode used for reinforcing steel rust monitoring in concrete and the preparation method. The reference electrode adopts an Ag / AgCl / KClsat system, and consists of an Ag and AgCl layer with 99.99 percent purity, a ter-component porous layer and a cement slurry layer in sequence from the axle center of the reference electrode to the outside. The invention makes a full consideration to the particularity that the rebar corrosion monitoring in concrete requires a reference electrode with a long life and a stable electric potential, and adopts the inexpensive Ag / AgCl / KClsat system to prepare a novel full-solid-state long life reference electrode (ASSRE), and the disadvantages that the service life of the common liquid state reference electrode is short, and the intensity is low are overcome by adopting the ter-component porous structure; simultaneously because the cement slurry with a similar characteristic with the concrete is adopted to be as the outermost layer, the liquid-junction potential between the liquid state reference electrode used commonly and the concrete medium is eliminated, and the accuracy of the electrochemistry measurement is ensured.

Owner:HARBIN INST OF TECH

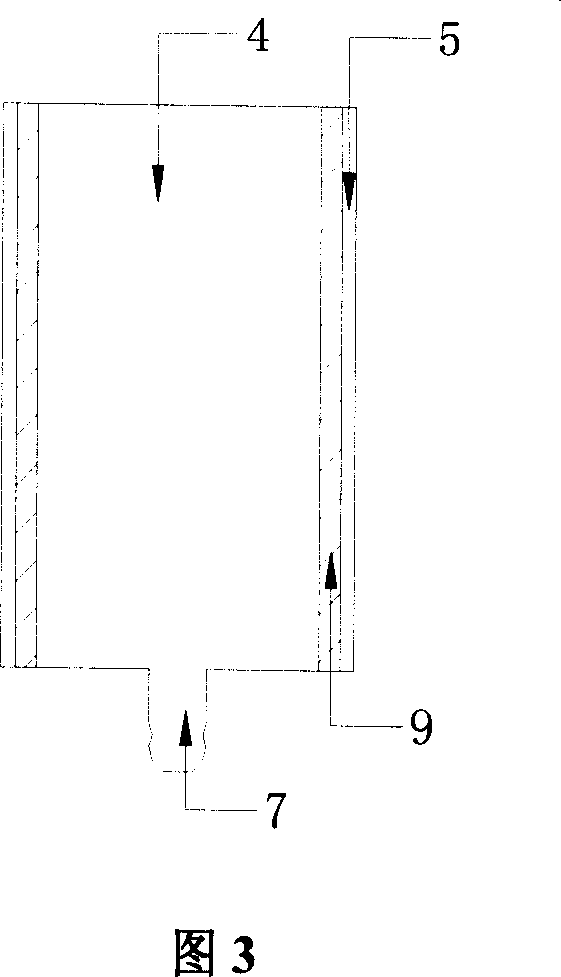

Real-time monitoring sensor for durability of concrete structures and fabricating method thereof

ActiveCN102680387ACorrosion rate real-time monitoringAccurate monitoring of corrosion rateWeather/light/corrosion resistanceMaterial electrochemical variablesElectrical resistance and conductanceRebar corrosion

The invention discloses a real-time monitoring sensor for durability of concrete structures. The real-time monitoring sensor comprises a sensor shell, and further comprises a reference electrode, a rebar electrode, an auxiliary electrode, a chlorion probe, a pH probe and a concrete resistivity probe. The auxiliary electrode is laid on the upper surface of the shell, at least parts of the reference electrode, the rebar electrode, the chlorion probe, the pH probe and the concrete resistivity monitoring probe are exposed out of the upper surface of the sensor shell to serve as detecting ends, and the other ends are connected with copper cables which penetrate through the sensor shell from top to bottom and stretch out of the shell. According to the real-time monitoring sensor, not only corrosion rate, chlorion concentration and pH of rebar, but also concrete resistivity can be monitored in real time; further, system resistance can be compensated during the monitoring of rebar corrosion current density, and corrosion rate of rebar can be monitored more accurately by the monitoring of concrete resistance.

Owner:CCCC FOURTH HARBOR ENG INST +3

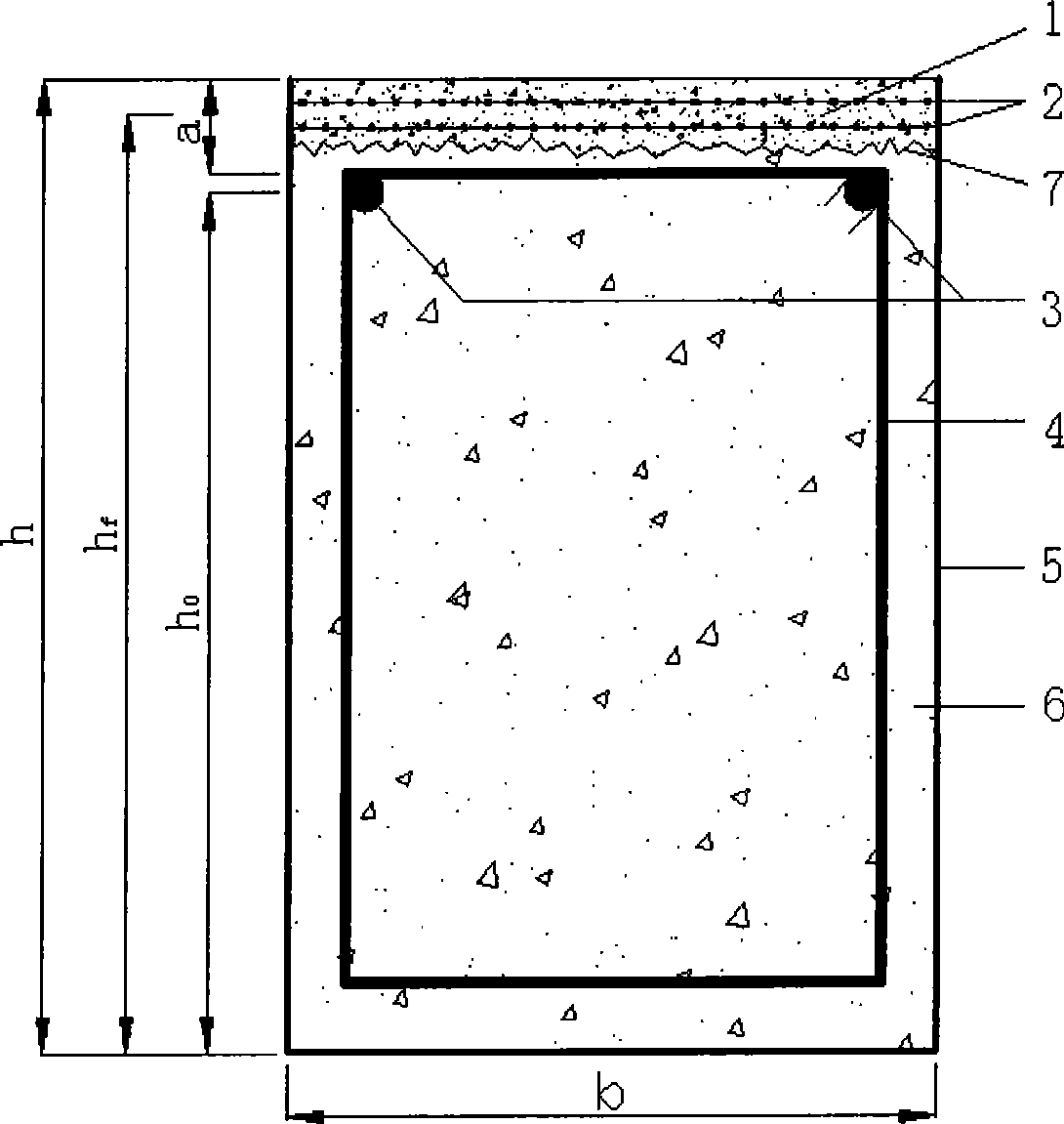

Construction structure for textile reinforced composite reinforced bar concrete and manufacturing method thereof

InactiveCN101481930AHigh strengthLimit or improve cracksSolid waste managementBuilding reinforcementsFiberRebar corrosion

The invention belongs to the technical field of concrete reinforcement, relating to utilizing fiber mesh grids to enhance the concrete strength. The arrangement of structural reinforcing steel, the thickness of concrete protective layers of main stress ribs and the grade of the concrete strength of the invention are designed according to the design criterion of a reinforced concrete structure. The invention is characterized in that before the initial setting of the concrete, fine concrete and the fiber mesh grids are cast on the outer side of the stretched and drawn area of the structure or the external surface of a large-scale integral structure, the total thickness of the fiber mesh grids and the fine concrete ranges from 10mm to 20mm, concrete with equal thickness of external surfaces are replaced, and the fiber mesh grids are evenly distributed in the fine concrete. The grid type or the plate type structure of the invention can adopt the structure of replacing partial reinforcing steel with the fiber mesh grids. The invention can effectively control cracks and solve the problems of concrete cracking and reinforcing steel corrosion, and has the advantages of firm bonding of the boundary surfaces of the fine concrete and the concrete, light self weight, low production cost, corrosion resistance, safe and durable usage, etc.

Owner:DALIAN UNIV OF TECH

In-situ monitoring method for rusting and stress state of reinforcing steel bar in concrete

ActiveCN104215569ASolving Corrosion Monitoring ProblemsAvoid destructionWeather/light/corrosion resistanceForce measurement by measuring optical property variationStress concentrationRebar corrosion

The invention relates to an in-situ monitoring method for rusting and a stress state of a reinforcing steel bar in concrete. The method comprises the following steps of establishing an automatic prestress balance system, applying initial prestress to a reinforcing steel bar sheet which is made of a same material with that of the reinforcing steel bar in the concrete, and embedding the reinforcing steel bar sheet into a concrete structure; arranging continuous strain measuring points on different heights of the reinforcing steel bar sheet, and monitoring the stress state of the area in which the strain measuring points are arranged; and forming a plane stress state on the reinforcing steel bar sheet, generating stress concentration after the reinforcing steel bar sheet is locally corroded, and reflecting the initial rusting time, rusting rate and rusting degree of the reinforcing steel bar according to the strain variation of the continuous measuring points on the different heights of the cross section. The reinforcing steel bar sheet can be embedded in different depths from the surface of the concrete, and the monitoring and rusting risk evaluation on the rusting degree of the reinforcing steel bar and the stress state of the embedded area in the different depths can be realized. The method is not subjected to the influence of ambient factors such as different ions, temperature and humidity in the concrete and is particularly suitable for evaluating the rusting risk and the rusting degree of the reinforcing steel bar in the reinforced concrete structure in a wave erosion environment wave splashing area and a tidal range zone.

Owner:UNIV OF SCI & TECH BEIJING +1

Rust-resistant agent for concrete reinforcing bar and preparation method thereof

InactiveCN101948264AExcellent chelating antirust abilityGood migration and diffusion propertiesRebar corrosionAlkali soil

The invention discloses a rust-resistant agent for a concrete reinforcing bar and a preparation method thereof. The rust-resistant agent for the concrete reinforcing bar is prepared based on a gas-phase corrosion inhibitor prepared by reacting a dicarboxylic acid with organic amine. The rust-resistant agent for the concrete reinforcing bar comprises the following raw materials in percentage by mass: 5 to 10 percent of sodium monofluorophosphate, 2 to 5 percent of calcium gluconate, 20 to 40 percent of the gas-phase corrosion inhibitor and the balance of water. The rust-resistant agent for theconcrete reinforcing bar of the invention does not comprise nitrite, comprises the gas-phase corrosion inhibitor and has a function of migrating and diffusing in the concrete. Compared with the traditional rust-resistant agent for the reinforcing bar, the rust-resistant agent for the concrete reinforcing bar has the advantages of excellent corrosion inhibition and rust-resistant properties, high environmentally-friendly property and the like, can be widely applied to fresh reinforced concrete construction of harbour engineering, coastal buildings, buildings in saline and alkaline lands and other buildings with the requirements of preventing the concrete reinforcing bar from rust and corrosion, and can also be applied to the repair of the reinforced concrete structures in major construction projects and routine maintenance.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Hydrated calcium silicate as well as preparation method thereof and concrete anti-freeze agent containing the same

InactiveCN101182000ASimple production processSave raw materialsSilicon compoundsDamage effectsCorrosion

The invention relates to a calcium silicate hydrate and a preparation method thereof and concrete antifreezing agent containing the calcium silicate hydrate, which pertains to the field of construction materials and manufacturing method thereof. The invention solves the problems of antifreezing agent in existing market of poor durability of concrete, steel-bar corrosion, alkaline aggregate reaction, etc., caused by large quantity of salt content in the concrete antifreezing agent. The calcium silicate hydrate is made from calcareous material, siliceous material and water. The preparation method comprises the steps that: the calcareous material and the siliceous material are evenly mixed and grinded and added with water to prepare pasty material, which goes through heat reaction at 1 to 3atm for 2 to 5h. The concrete antifreezing agent containing the calcium silicate hydrate is made of the calcium silicate hydrate, antifreezing components, water reducing components, air entraining components and fly ash. The calcium silicate hydrate uses seed crystal hydration to improve the hydration of the concrete, which leads set cement to be more impact and the long-term property of the concrete not to be reduced. The antifreezing agent of the invention does not contain chloride salts, reduces the damage effect of the steel-bar corrosion caused by mixing the chloride salts with the concrete when in construction during winter period and greatly reduces the salt content in the concrete.

Owner:HARBIN INST OF TECH

Method for monitoring of steel bar corrosion in real time

InactiveCN102445452AAvoid damageSolve monitoring problemsOptically investigating flaws/contaminationFiberRebar corrosion

The invention discloses a method for real-time monitoring of steel bar corrosion. The method comprises the following steps: (a) coating a layer of rust conversing paint on a surface of a steel pipe packaged fiber grating strain sensor and controlling a temperature in a coating environment at 0-40 DEG C and an air relative humidity at no more than 80%; (b) polishing a surface of a selected steel bar by a grinder to realize a flattening and smooth surface and keeping for usage; (c) pasting the steel pipe packaged fiber grating strain sensor obtained from the step (a) on a polished position of the steel bar to be used in the step (b); and (d) carrying out real-time monitoring on a wavelength drift amount by a fiber grating demodulator, meanwhile laying a steel pipe packaged fiber grating temperature sensor for monitoring change of temperature and completing temperature compensation. The invention can not only monitor early stage steel bar corrosion in a structure but also have good protection effect on the fiber grating sensor during a monitoring process and have strong realizability.

Owner:SHENYANG JIANZHU UNIVERSITY

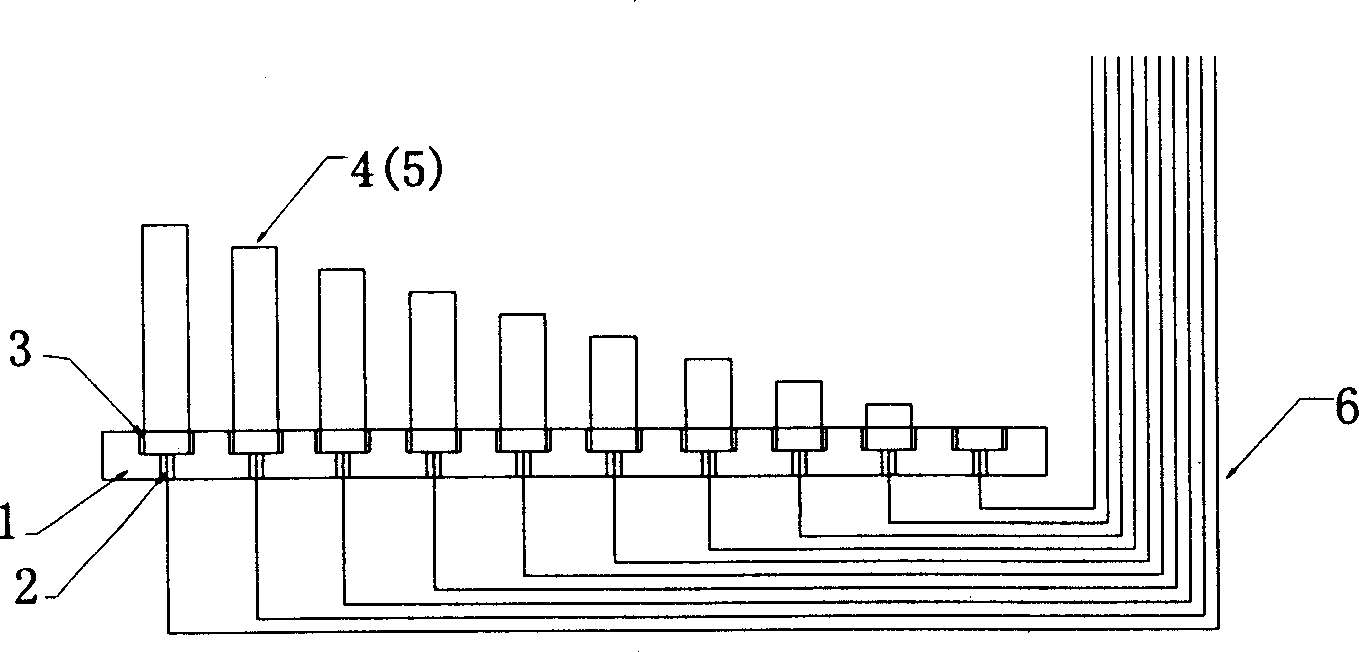

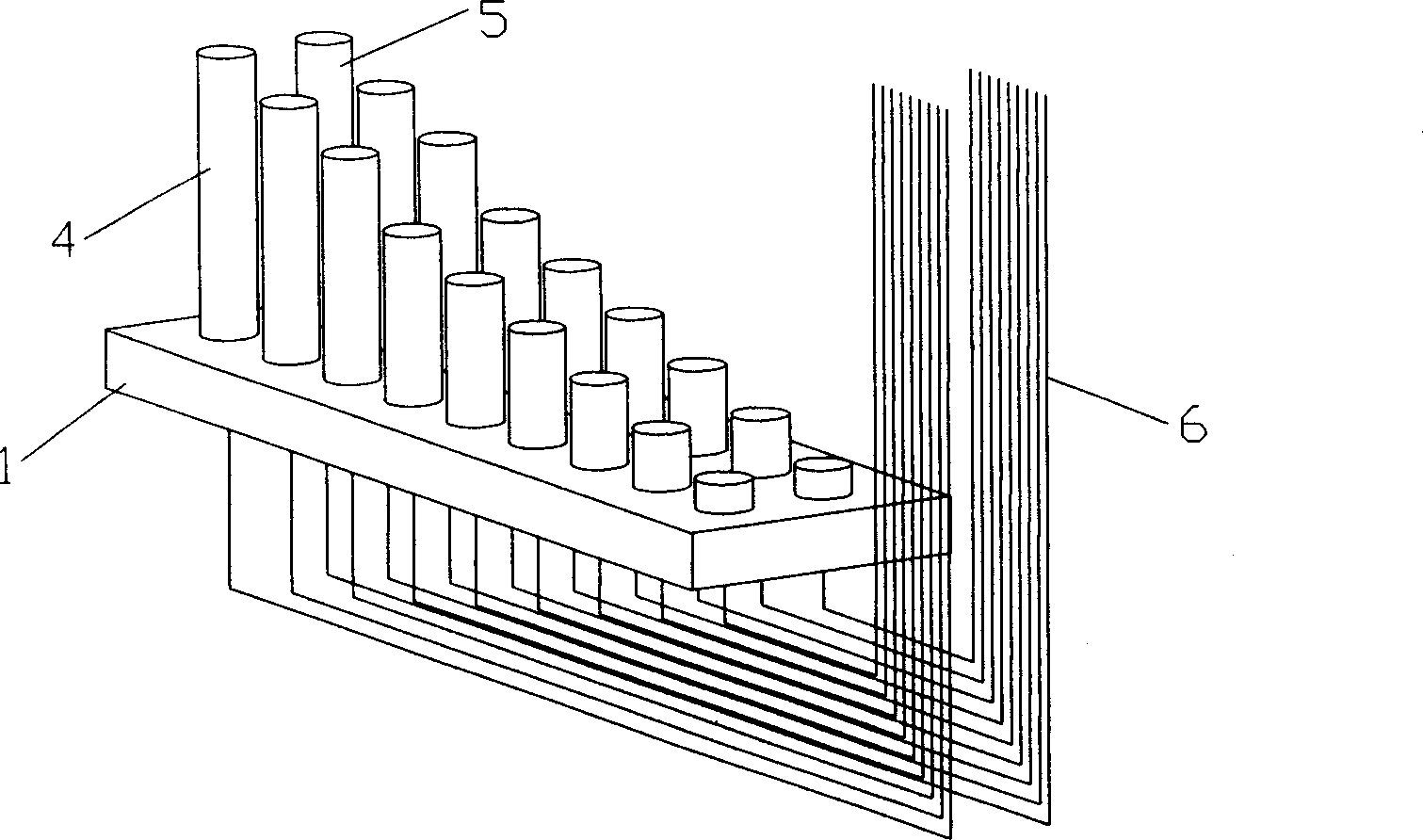

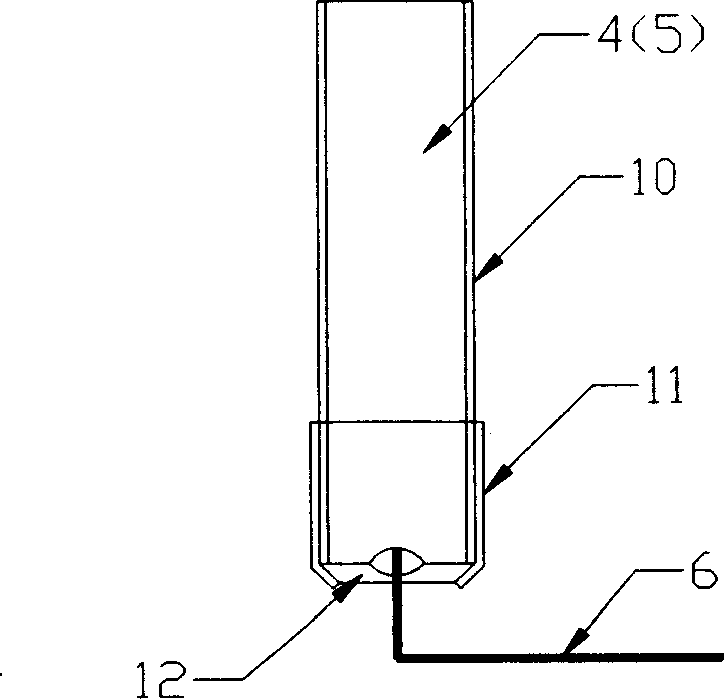

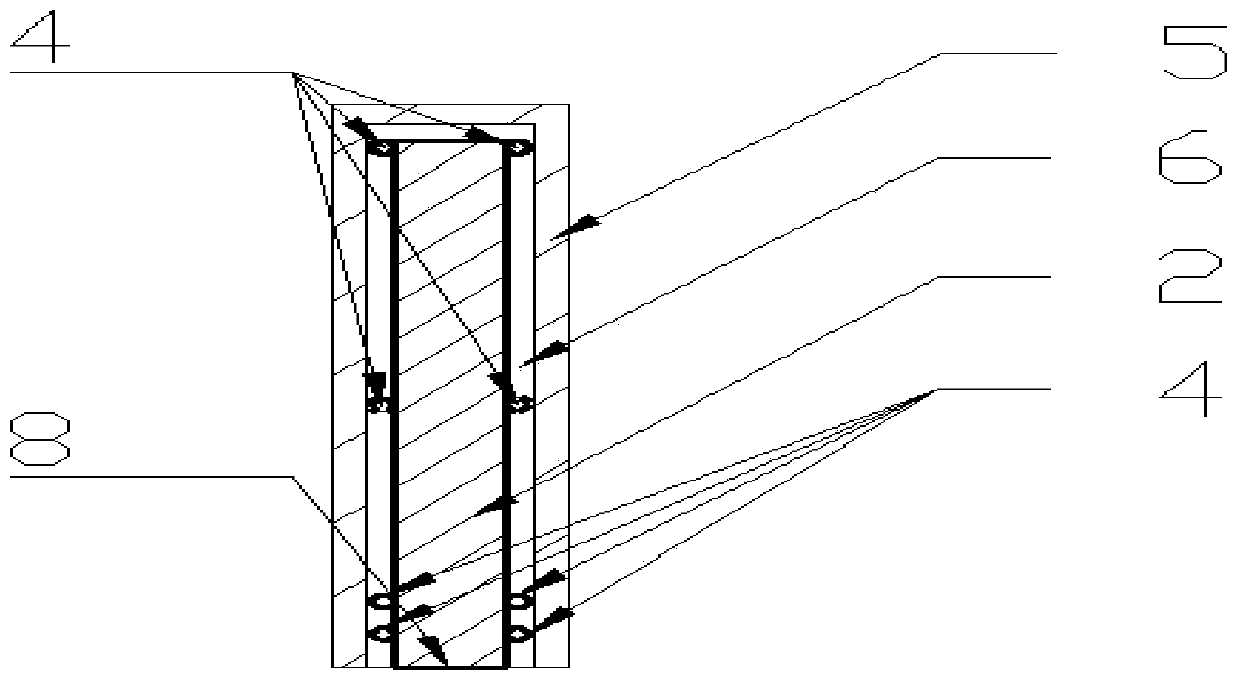

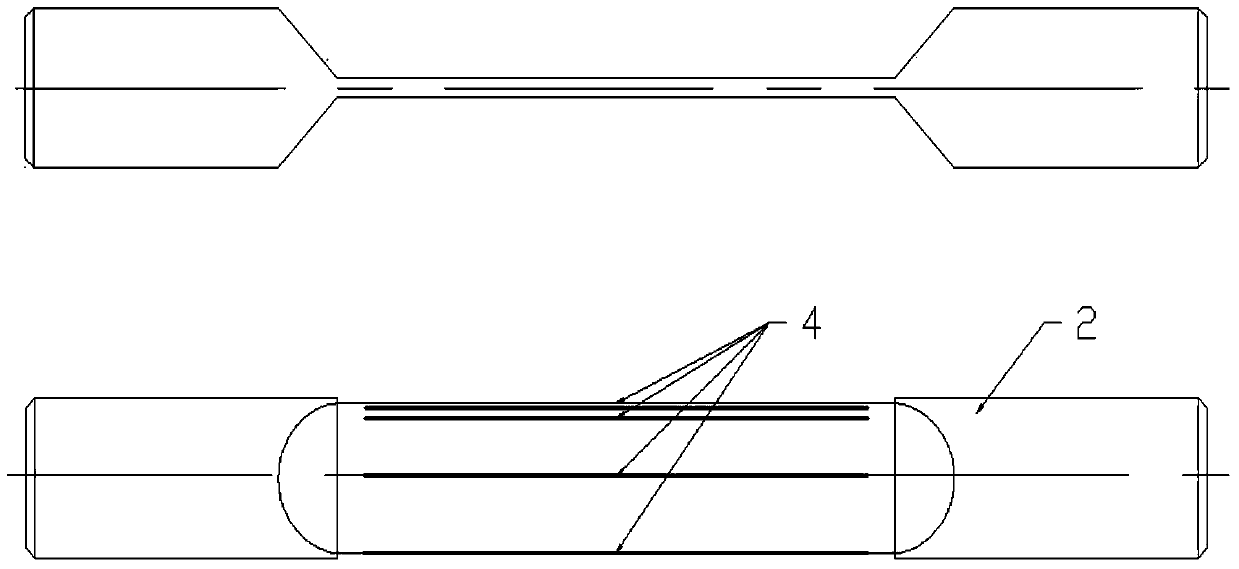

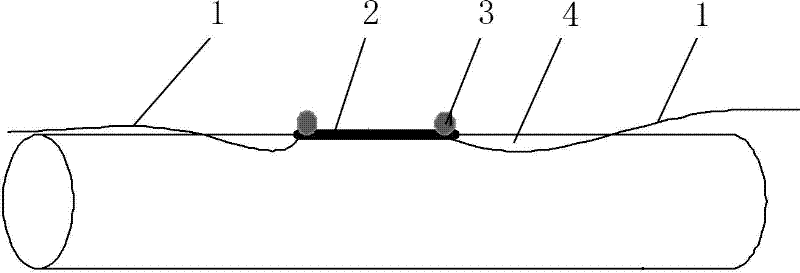

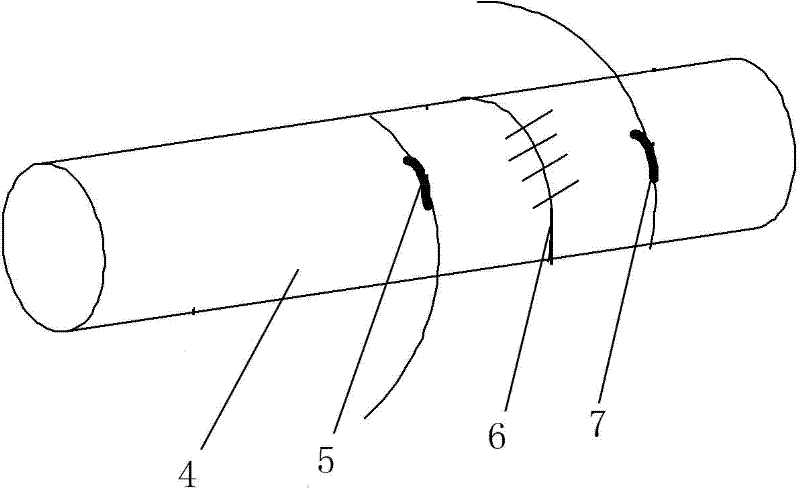

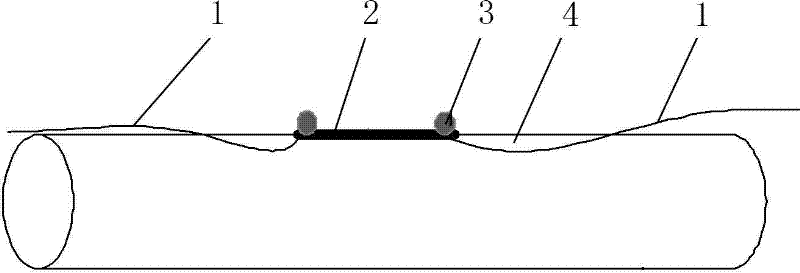

Long term monitoring sensor for steel bar corrosion in steel concrete member

InactiveCN1945278AEffective guardianshipReduce distanceWeather/light/corrosion resistanceMaterial electrochemical variablesRebar corrosionData acquisition

The long term monitoring sensor for corrosion of steel bar in steel concrete member consists of electrode rods in the same length, pedestal, wires and sacrificed anode. The electrode rods are fixed in the sensor pedestal in stepped form, and the wires are connected through leaf springs to the anode and cathode of the electrode rods. During construction, the monitoring sensor is embedded into the concrete for subsequent regular data acquisition. In the case of finding out corroded steel bar in some electrode rod, the steel bar is protected via the cathode protector. The present invention can perform non-destroying detection of the steel bars in different depth and determine the frontal surface distance of the invading corrosive medium.

Owner:SHANGHAI JIAO TONG UNIV

Rebar corrosion resistant coating and coating method therefor

ActiveCN105131660AImprove adhesionIncreased strain valuePretreated surfacesAnti-corrosive paintsRebar corrosionAbsorbed energy

The invention discloses a rebar corrosion resistant coating, and raw material comprises the following components: 45-70 parts of glass powder, 2-8 parts of clay, 26-50 parts of borax, 0.5-3 parts of fiber, 5-15 parts of opacifier, 1-10 parts of adherence agent and 0.25-2.8 parts of electrolyte. The invention further discloses a rebar corrosion resistant coating coating method, comprising the following step of: 1) dry mixing; 2) wet mixing; 3) pre-treating; 4) coating; 5) drying; 6) sintering; and 7) cooling at room temperature. The rebar corrosion resistant coating is high in ductility, high in adhesion performance, high in compactness and excellent in corrosion resistance, the fiber is introduced into the coating so that the corrosion resistant coating, during the breaking process, absorbs energy through mechanisms such as crack deflection, fiber breakage and fiber and removal, so that the coating toughness is improved, the cracking formation is delayed, and the mechanical property of the rebar can be maintained at the same time.

Owner:ZHEJIANG UNIV

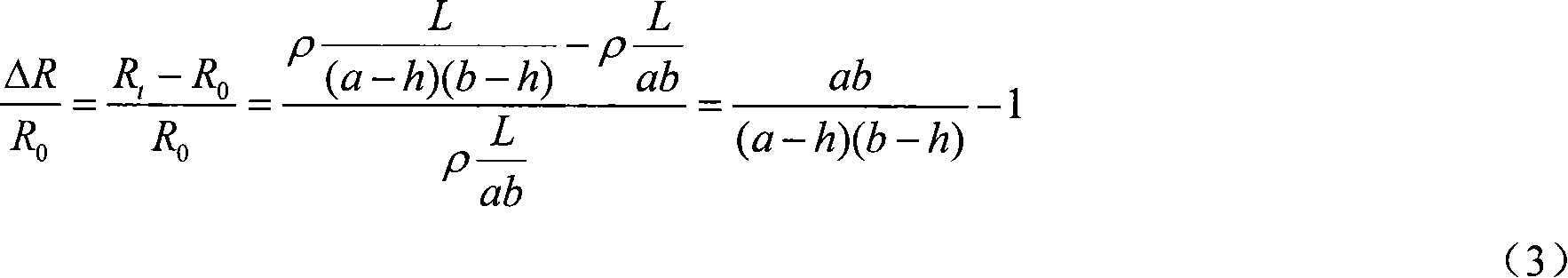

Steel reinforcement corrosion sensor and preparation method and its detection method for reinforcement corrosion

InactiveCN101216412ASimple structureLow costWeather/light/corrosion resistanceMaterial analysis by electric/magnetic meansRebar corrosionElectrical resistance and conductance

The invention provides a steel bar corrosion sensor with simple structure and lower cost, a preparation method thereof, and a steel bar corrosion detection method capable of accurately and nondestructively detecting the distance between a hazardous frontal surface and the steel bar in specific corrosion environment on the premise of not damaging concrete surface. The steel bar corrosion sensor comprises a base body and an extraction wire, wherein the base body has a spiral layered distribution in the vertical direction and is provided with longitudinal openings. The preparation method comprises removing screw thread of a steel bar, and cutting to obtain the base body; drilling holes at different heights on the base body; and connecting the extraction wire with the holes and sealing to obtain the steel bar corrosion sensor. The detection method comprises the following steps of: respectively arranging the sensors at different sections of a concrete component, periodically collecting data of the steel bar corrosion sensors at the different positions by a low-resistance tester within the service period of the concrete component, periodically measuring and recording, and determining the corrosion state of the steel bar to be detected to obtain the environmental corrosion condition of concrete.

Owner:XIAMEN UNIV

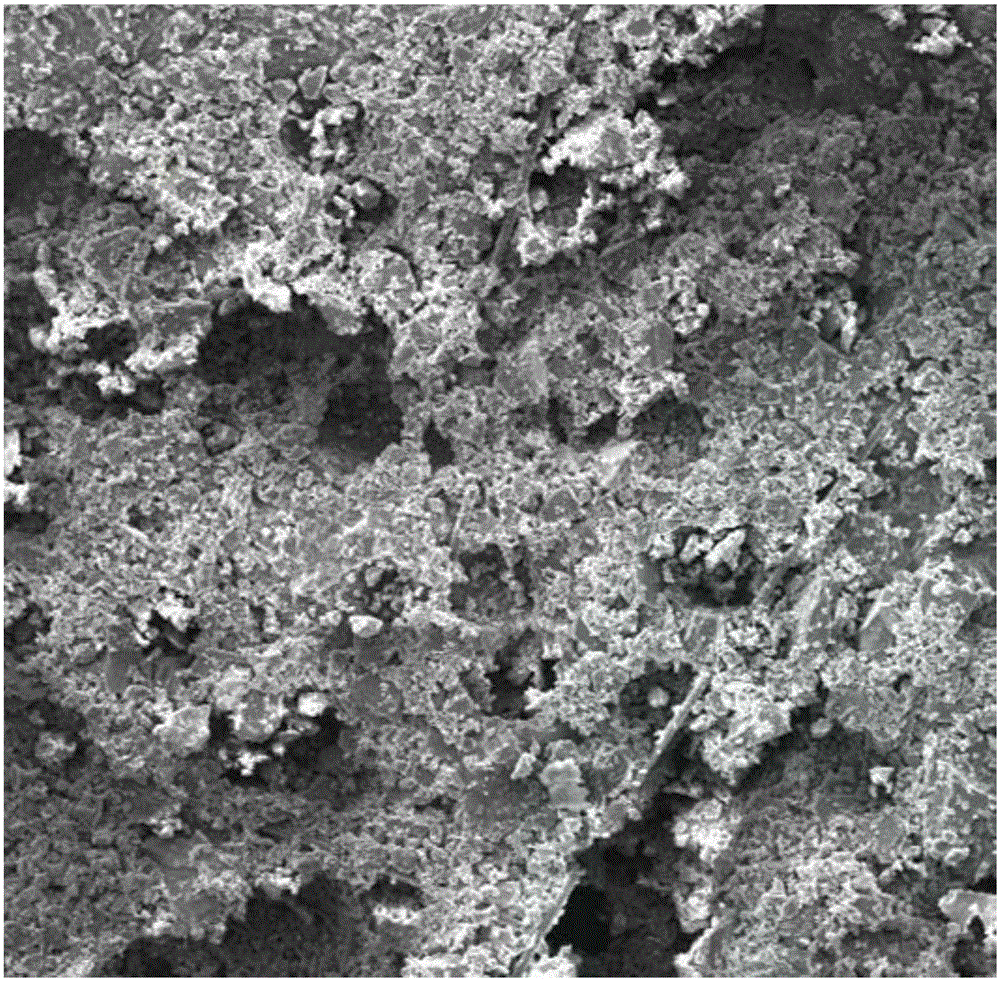

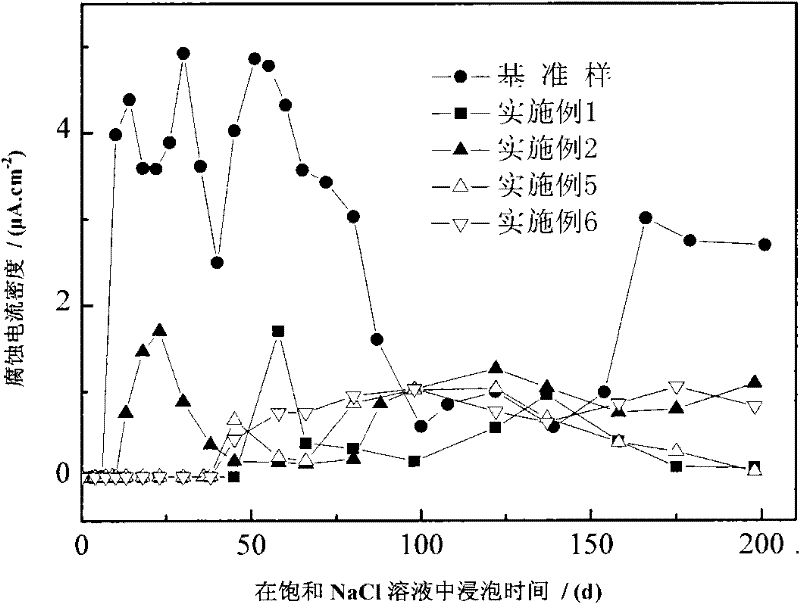

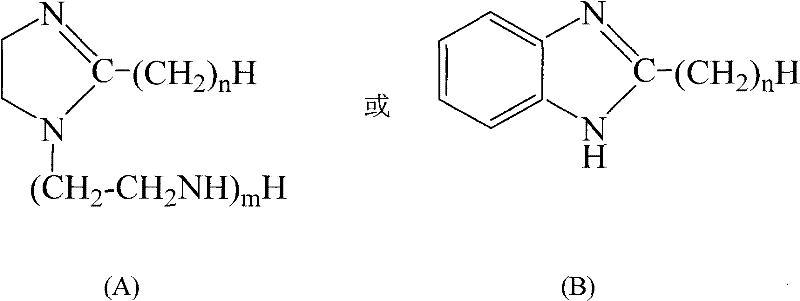

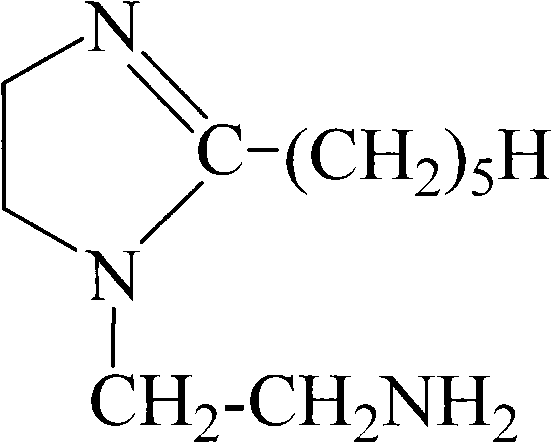

Doped all organic corrosion inhibitor for steel bar in concrete

The invention relates to the field of building materials, in particular to a doped all organic corrosion inhibitor for a steel bar in concrete. The corrosion inhibitor comprises the following components in percentage by weight: 5 to 30 percent of imidazoline derivative, 5 to 15 percent of organic alcohol, 0.3 to 1.5 percent of organic metal salt and 60 to 85 percent of water. During use, the corrosion inhibitor in recommended using amount is directly added into water to be dissolved and mixed, and the corresponding using amount of water when the concrete is poured is subtracted according to the proportion of the water in the components simultaneously; and the addition amount of the corrosion inhibitor is calculated in the amount of cement required by each cubic meter of concrete structure. The corrosion inhibitor can effectively reduce and slow down the corrosion of the steel bar in the concrete, reduces the damage of chloride ions to the surface passivation property of the steel bar so as to slow down the corrosion of the chloride ions to the steel bar, and can be widely applied to industrial and civil reinforced concrete buildings in offshore areas, harbors, wharfs and coastal areas.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Methods of preventing corrosion

ActiveUS20090020186A1Avoid corrosionInhibiting corrosion in the cooling systemFireproof paintsAntifouling/underwater paintsRebar corrosionPre treatment

The invention provides a method for pre-treating a metal surface with a corrosion inhibitor prior to painting, a method for inhibiting corrosion in a cooling system, wherein the cooling system includes a metal surface and a coolant; and a method for inhibiting corrosion of a reinforcement steel in concrete wherein the method comprising the step of adding to a concrete mixture an anti-corrosive mixture.

Owner:PIGMENTAN

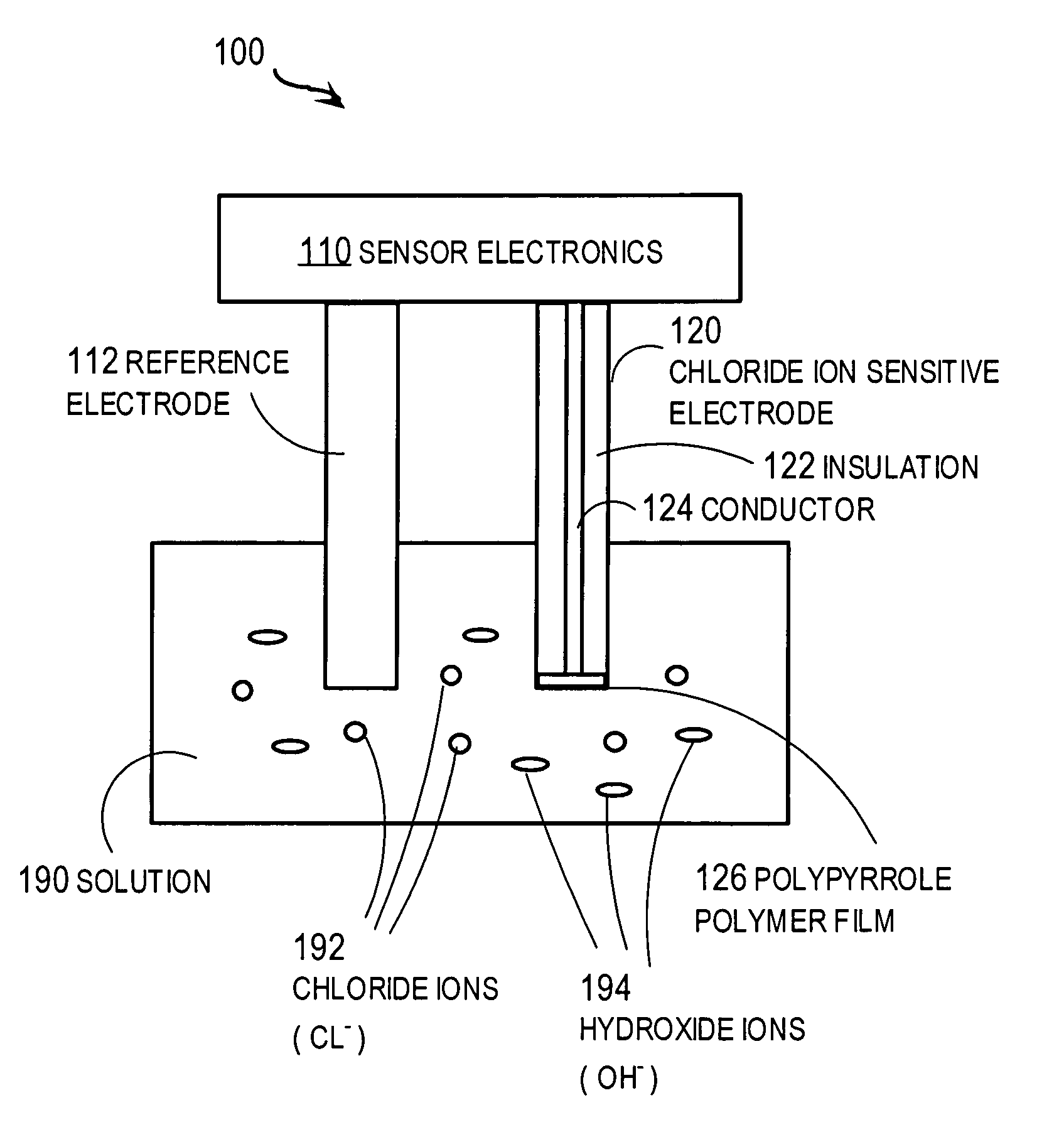

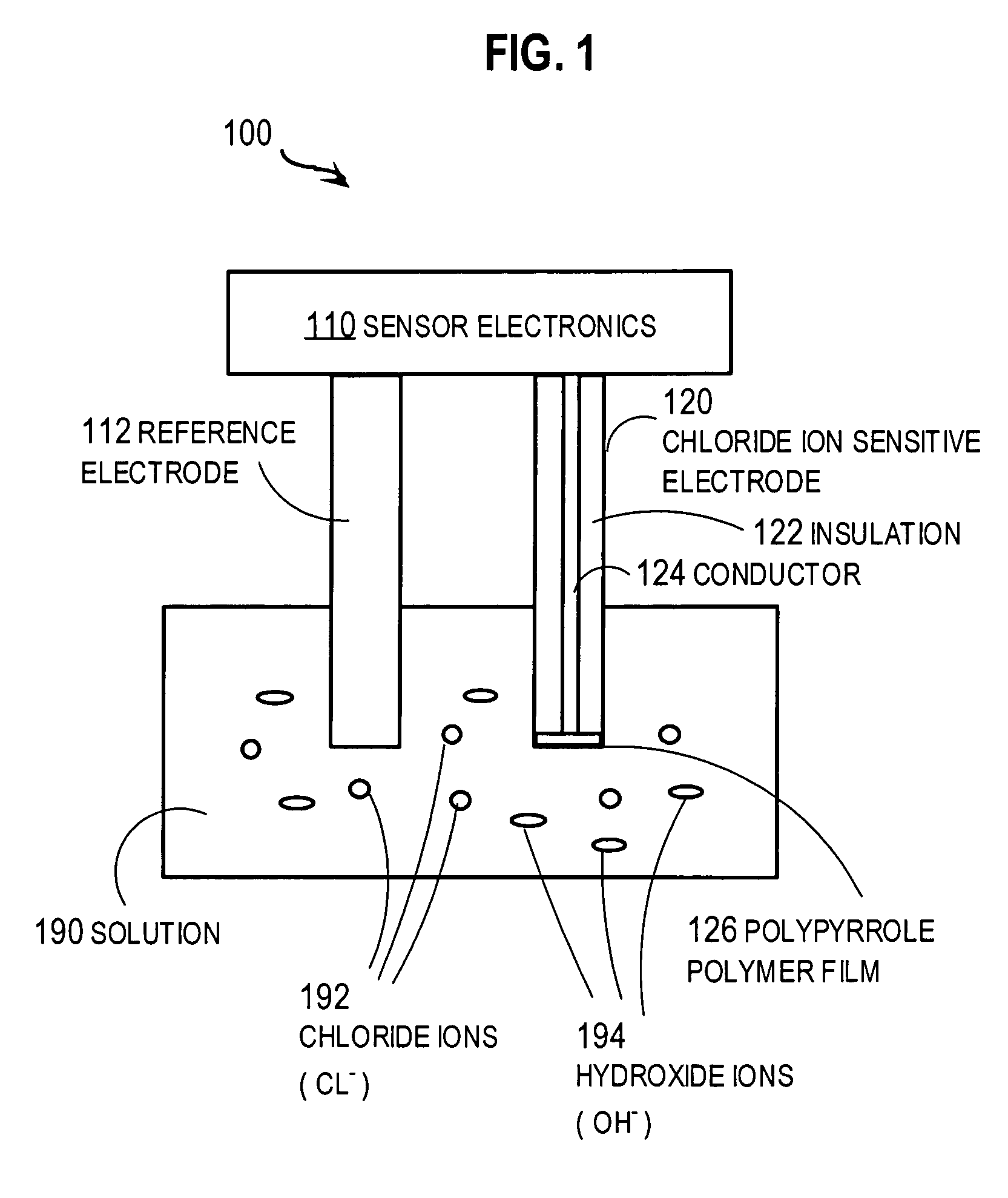

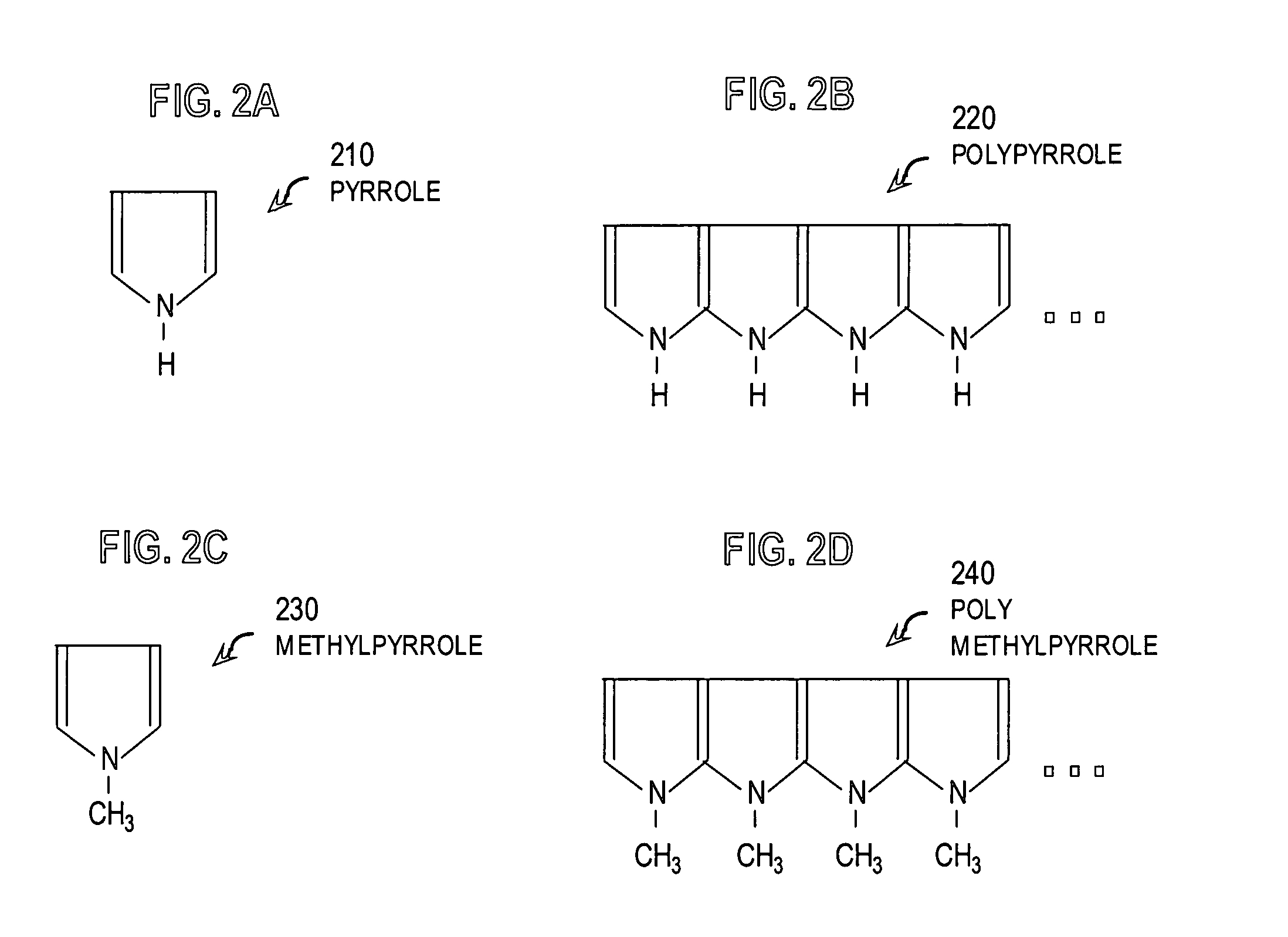

Techniques for sensing chloride ions in wet or dry media

InactiveUS7063781B2Electrolysis componentsWeather/light/corrosion resistanceRebar corrosionConductive polymer

Techniques are provided for measuring chloride ion concentration in a medium. The techniques allow measurements to be made in dry or alkaline media, or both. For alkaline conditions, a sensor includes a pair of electrodes and a polymer film imprinted for uptake of chloride ions under alkaline conditions. The film is deposited to be in contact with at least one electrode and the medium. For dry conditions, a sensor includes a pair of electrodes and a conductive polymer film imprinted for uptake of chloride ions. The film is in contact with the pair of electrodes, and is positioned for contact with the medium. An electrical conductivity of the film depends on an amount of chloride ions taken up by the film. Some techniques allow chloride ion measurements over years at sensors embedded in concrete. Such measurements allow the determination of the progress of rebar corrosion in concrete infrastructure.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

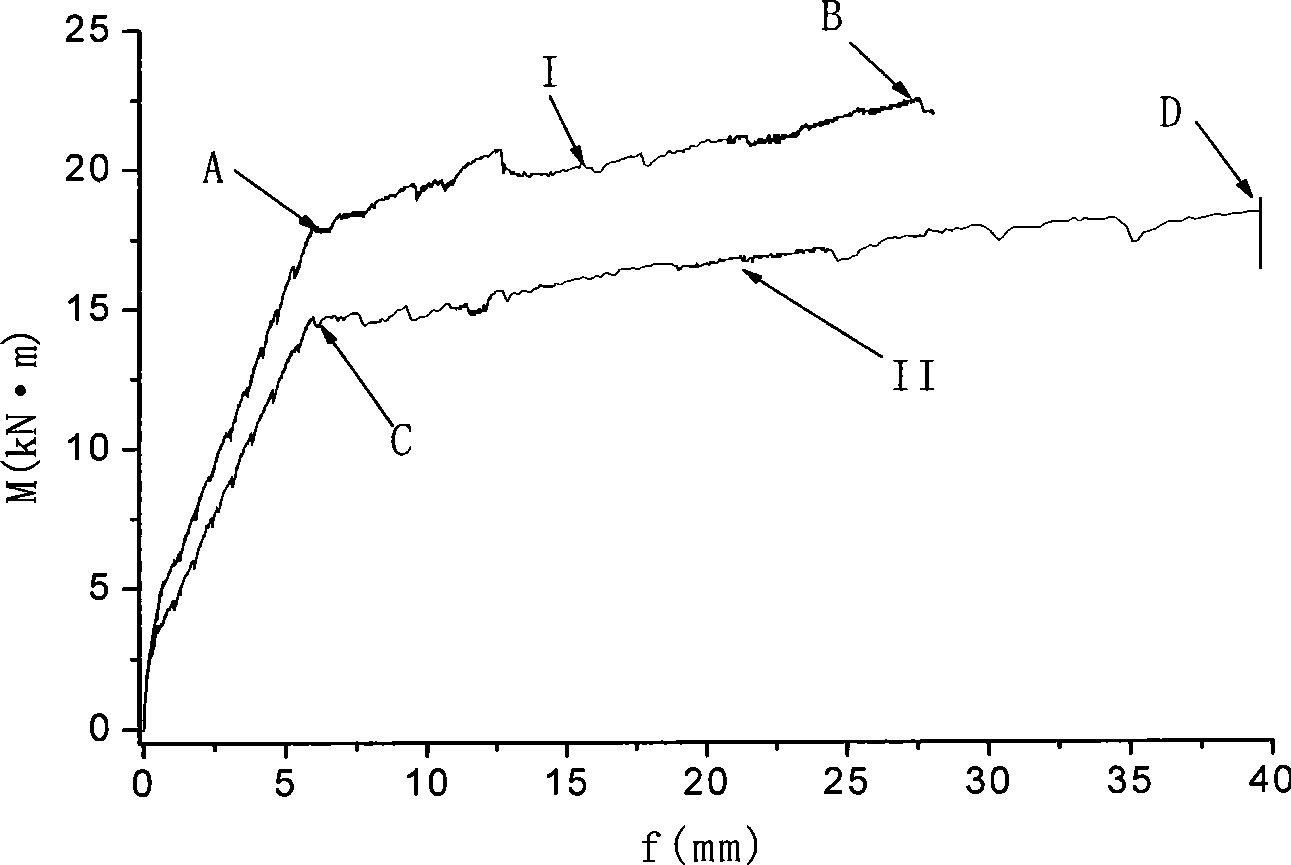

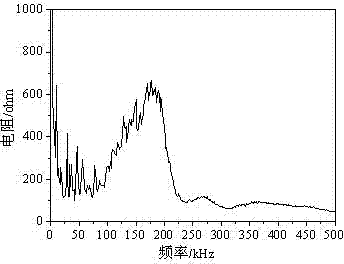

Piezoelectric sensor for steel-bar corrosion monitoring and steel-bar corrosion monitoring method

InactiveCN103575769AEnable long-term monitoringRealize long-term non-destructive monitoringWeather/light/corrosion resistanceMaterial resistanceRebar corrosionFirming agent

The invention relates to a piezoelectric sensor for steel-bar corrosion monitoring and a steel-bar corrosion monitoring method, and belongs to the technical field of monitoring of an intelligent sensor in a reinforced concrete structure. The sensor is composed of piezoelectric ceramics, an electrode face, an encapsulation layer composed of cement, epoxy resin and curing agent, and shielded conducting wires. The monitoring method based on the sensor comprises the following steps: coupling the piezoelectric sensor and steel bars by adopting a mixture of cement, epoxy resin and curing agent as a bonding agent, testing an electrical impedance-frequency spectrogram of the sensor at different periods, then carrying out root-mean-square deviation calculation, and taking a calculation result as quantification index of judging the condition of steel-bar corrosion inside concrete. The piezoelectric sensor provided by the invention has the characteristics of simpleness in preparation, convenience in use, good in durability and the like; the monitoring method based on the sensor has the characteristics of being accurate, reliable, convenient and intuitive.

Owner:UNIV OF JINAN

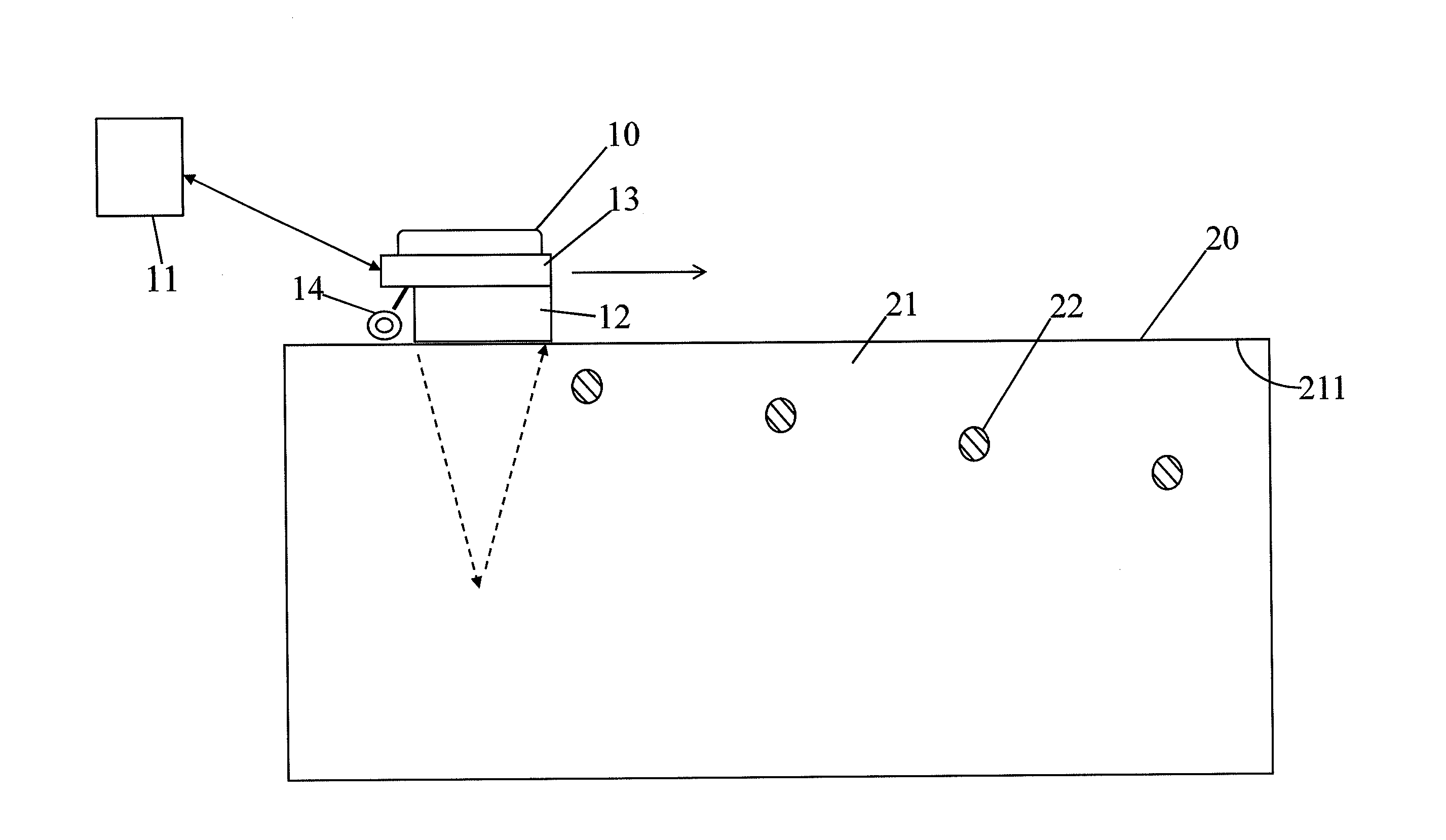

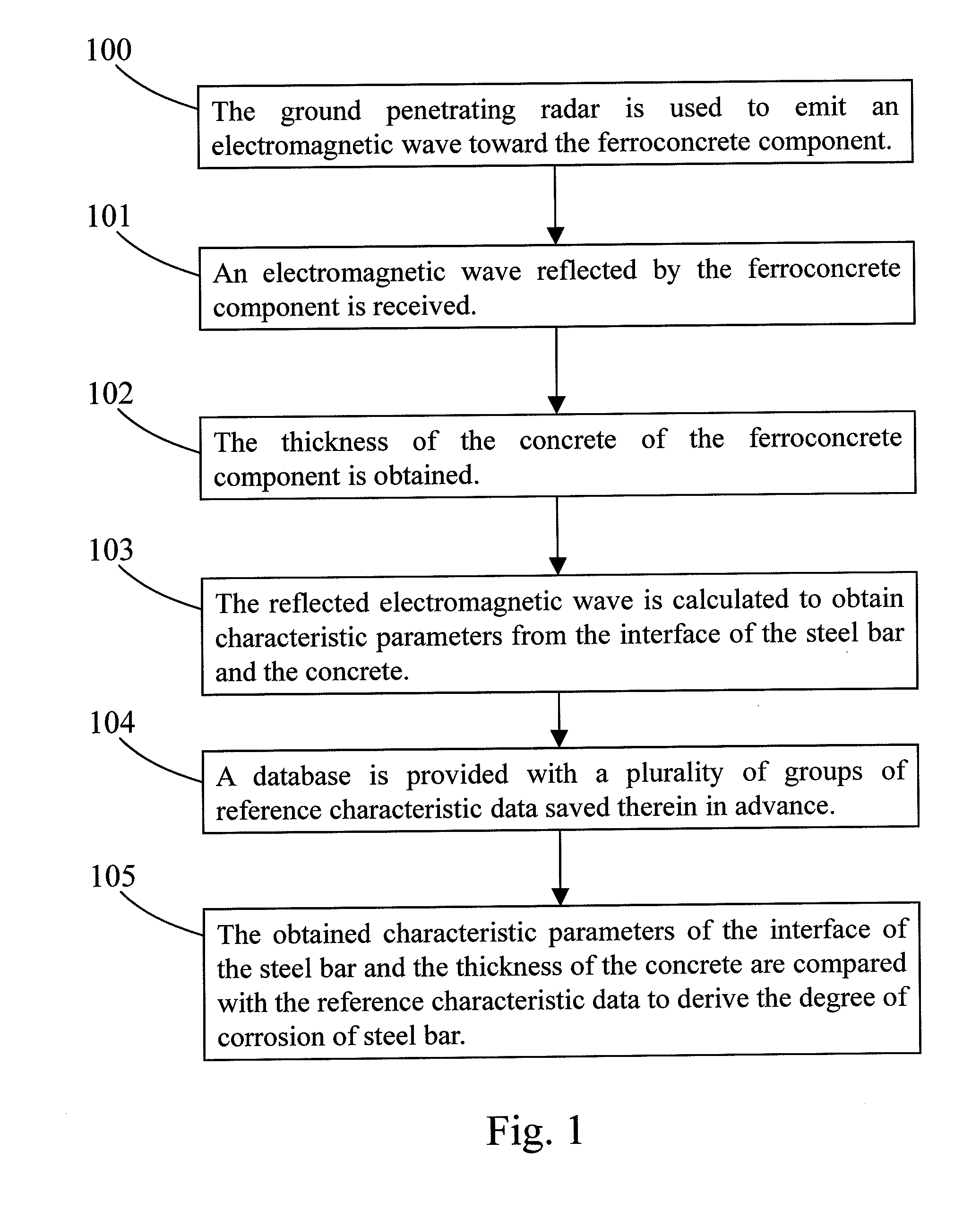

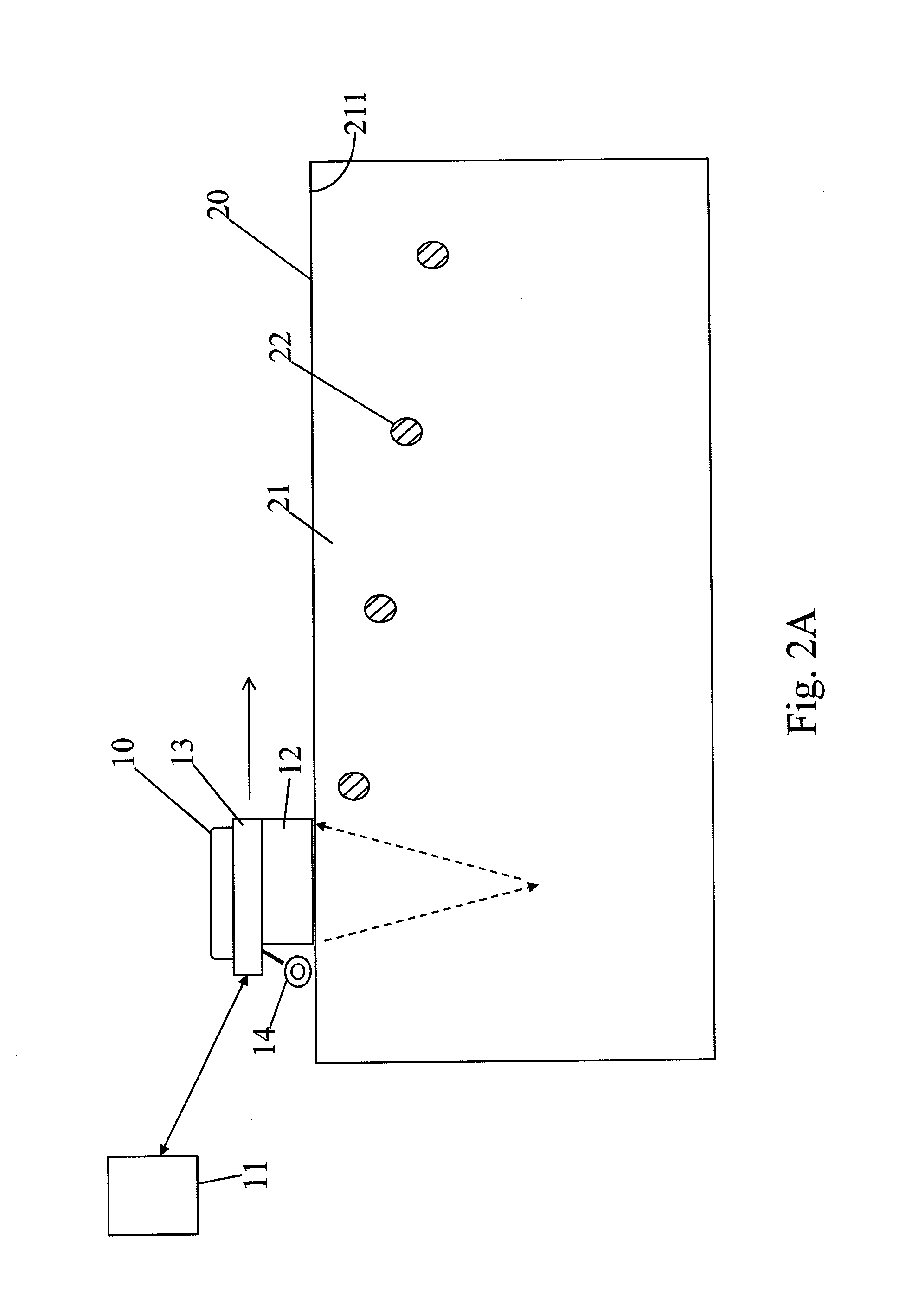

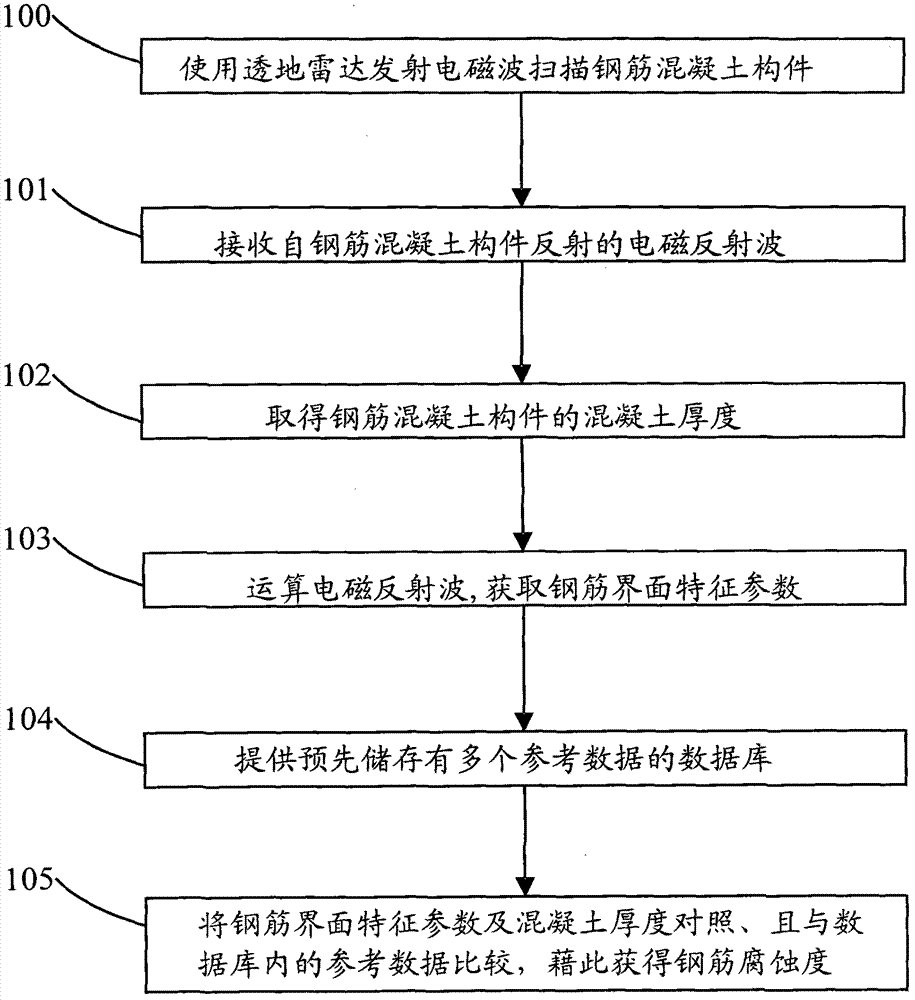

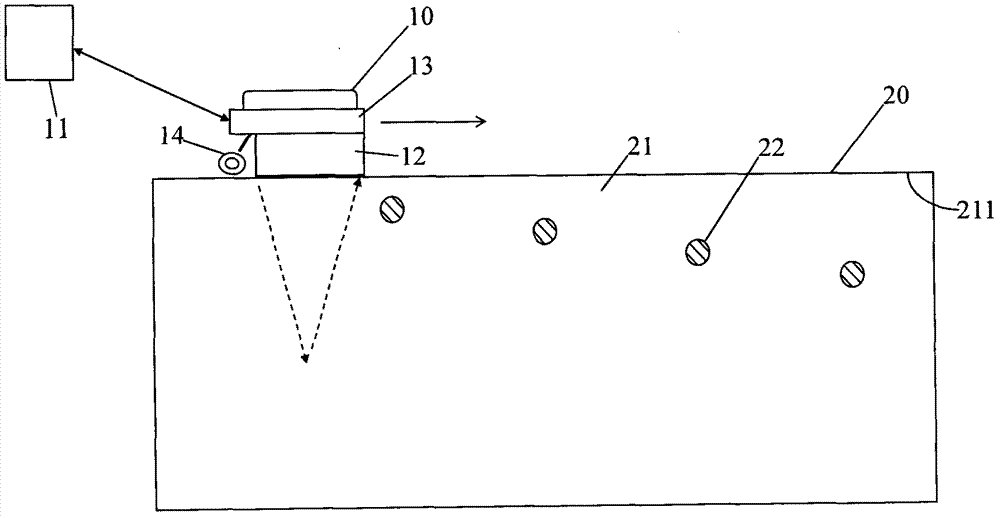

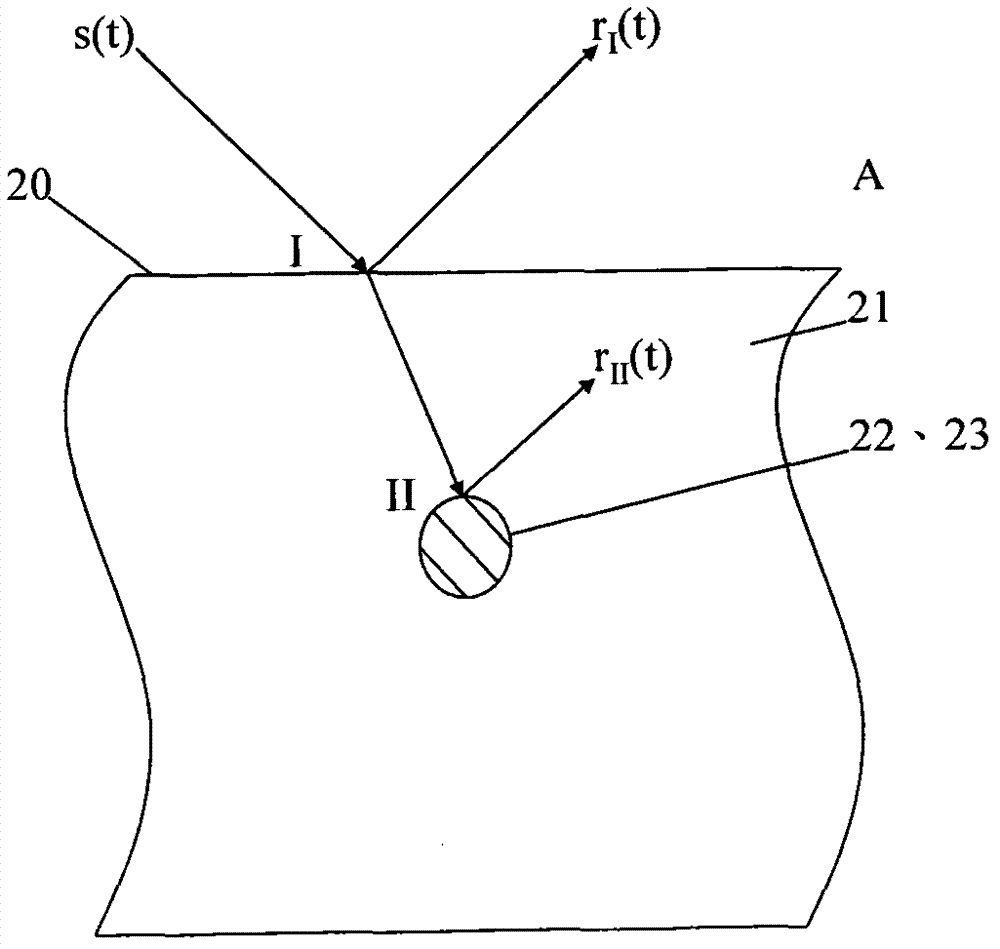

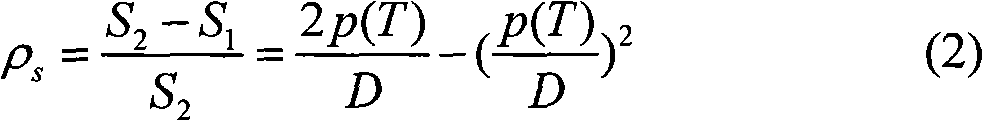

Method of using ground penetrating radar to detect corrosion of steel bars in ferroconcrete components

InactiveUS20120280849A1Improve stabilityDetection using electromagnetic wavesRadio wave reradiation/reflectionRebar corrosionElectrical resistance and conductance

The present invention discloses a method of using ground penetrating radar to detect corrosion of steel bars in ferroconcrete components. The method comprises the following steps. Firstly, a ground penetrating radar is used to emit an electromagnetic wave toward a ferroconcrete component. Then, a reflected electromagnetic wave is received. The reflected electromagnetic wave is calculated to obtain characteristic parameters from the interface of the steel bar and the concrete, wherein the characteristic parameters includes reflection electric potential, specific resistance and corresponding specific electric current from the interface. Reference characteristic data which include reference thicknesses of the concrete versus reference reflected electric potential, specific resistance and corresponding specific electric current from the interface are provided. The obtained interface characteristic parameters and the thickness of the concrete are compared with the reference characteristic data to derive the corrosion condition of steel bars in the ferroconcrete component.

Owner:CHUNG HUA UNIVERSITY

Method of using ground penetrating radar to detect corrosion of steel bars in ferroconcrete components

InactiveCN102768176AIntegrity guaranteedImprove stabilityWeather/light/corrosion resistanceDetection using electromagnetic wavesRebar corrosionReflected waves

The present invention discloses a method of using ground penetrating radar to detect corrosion of steel bars in ferroconcrete components. The method comprises the following steps. Firstly, a ground penetrating radar is used to emit an electromagnetic wave toward a ferroconcrete component. Then, a reflected electromagnetic wave is received. The reflected electromagnetic wave is calculated to obtain characteristic parameters from the interface of the steel bar and the concrete, wherein the characteristic parameters includes reflection electric potential, specific resistance and corresponding specific electric current from the interface. Reference characteristic data which include reference thicknesses of the concrete versus reference reflected electric potential, specific resistance and corresponding specific electric current from the interface are provided. The obtained interface characteristic parameters and the thickness of the concrete are compared with the reference characteristic data to derive the corrosion condition of steel bars in the ferroconcrete component.

Owner:CHUNG HUA UNIVERSITY

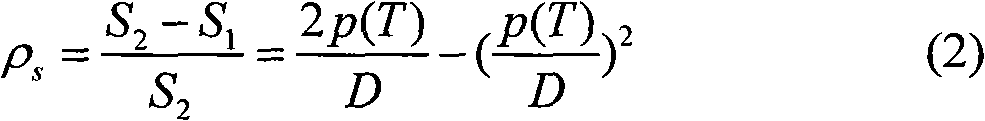

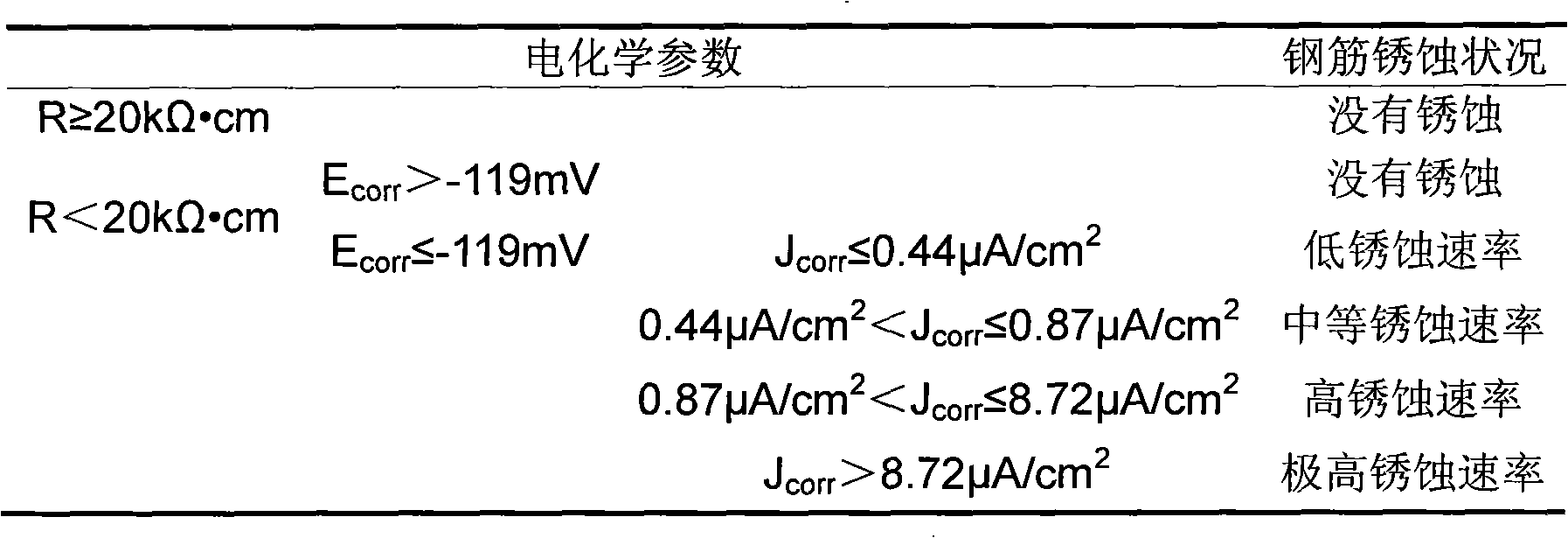

Coastal area concrete reinforcement erosion situation electrochemical test method

InactiveCN101339119AThe criteria are comprehensive and accurateWeather/light/corrosion resistanceMaterial testing goodsRebar corrosionLoss rate

The invention discloses an electrochemical test method of steel bar corrosion in the concrete of coastal area. The test method comprises the following steps: (1) under the concrete condition of the temperature of 0 to 50 DEG C and the relative humidity of 50 percent to 85 percent, the resistance rate R of the concrete is detected; if the estimated value of R is more than or equal to 20kilo-ohm, the passive film of the steel bar in the concrete is not damaged; if the estimated value of R is less than 20kilo-ohm, the second step is adopted; (2) a silver-silver chloride electrode is used for further determining the corrosion potential of the steel bar; if the estimated value of the corrosion potential of the steel bar is more than or equal to minus 119mV, the passive film of the steel bar in the concrete is not damaged; if the estimated value is less than 119mV, the passive film of the steel bar in the concrete is not damaged. The corrosion current density Jcorr of the steel bar in the concrete is further determined; the average corrosion depth and the average section loss rate of the steel bar are calculated. The guarantee rate of the estimated values is 95 percent. The electrochemical test method has the targeted characteristic and comprehensive criteria, and is in particular suitable for estimating the corrosion of the steel bar in the concrete structure without obvious cracking and rust on the surface.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

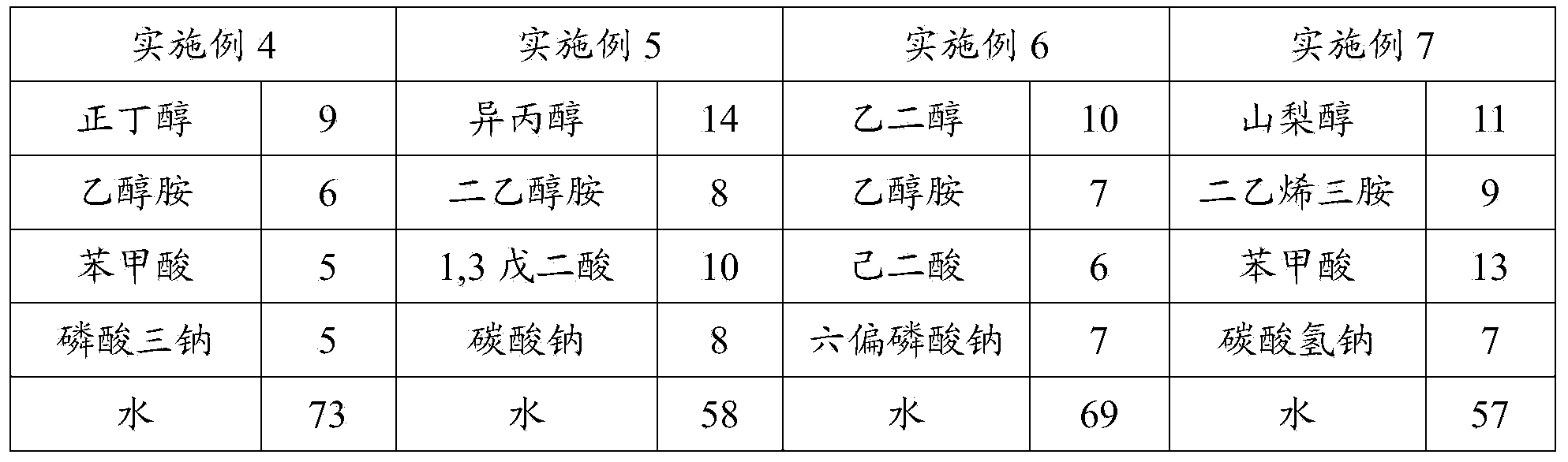

Migrating type composite rebar corrosion inhibitor as well as preparation method and application thereof

InactiveCN103626418AExcellent corrosion and rust resistanceReduce electric fluxRebar corrosionInorganic salts

The invention provides a migrating type composite rebar corrosion inhibitor as well as a preparation method and application thereof. The migrating type composite rebar corrosion inhibitor comprises the following raw materials according to parts by weight: 8-20 parts of fatty alcohol with the boiling point more than or equal to 60 DEG C, 5-11 parts of amine, 4-17 parts of organic acid or inorganic acid which is solid at the normal temperature, 4-8 parts of inorganic salt, and 45-78 parts of water, wherein the inorganic salt is chosen from phosphate or carbonate. The migrating type composite rebar corrosion inhibitor can migrate to the surface of a rebar to form a protection layer on the surface of the rebar, and chloride ions can also be filtered out so as to slow down the corrosion speed of the rebar. The corrosion inhibitor provided by the invention is simple in construction process and low in cost, and the sources of the raw materials are not limited.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

Roaming mobile sensor platform for collecting geo-referenced data and creating thematic maps

ActiveUS9377528B2Improve securityEliminate needRoad vehicles traffic controlNavigation instrumentsRebar corrosionBridge deck

Owner:NORTHEASTERN UNIV

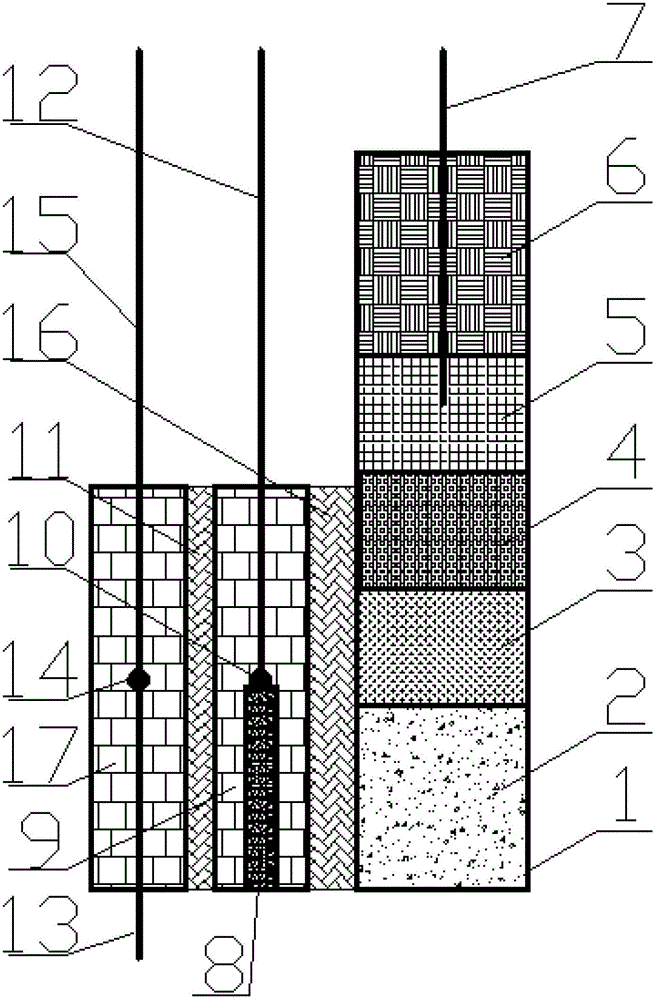

Sensor device for long-term monitoring of reinforcement corrosion conditions and applied inside concrete

InactiveCN102721642ACorrosion Condition MonitoringGet the corrosion current densityWeather/light/corrosion resistanceRebar corrosionPlatinum

The invention discloses a sensor device for the long-term monitoring of reinforcement corrosion conditions and applied inside concrete. The sensor device consists of three sensors, wherein one sensor is a reference electrode sensor which can be used inside the concrete, a second sensor is a reinforcement corrosion monitoring electrode sensor which can reflect the reinforcement corrosion conditions inside the concrete, and the last sensor is an auxiliary electrode sensor which can be used inside the concrete. The reference electrode sensor is a layered electrode which is formed by taking manganese dioxide as a main material; the reinforcement corrosion monitoring electrode sensor is a reinforcement electrode which takes reinforcements buried inside the concrete as main materials; and the auxiliary electrode sensor is a micro needle-shaped platinum electrode sensor made from platinum wires. According to the sensor device for the long-term monitoring of the reinforcement corrosion conditions and applied inside the concrete, the corrosion conditions of the reinforcements inside the concrete are reflected through testing electrical signals among the electrode sensors, thus the aim of monitoring the corrosion conditions of the reinforcements inside the concrete is achieved.

Owner:CENT SOUTH UNIV

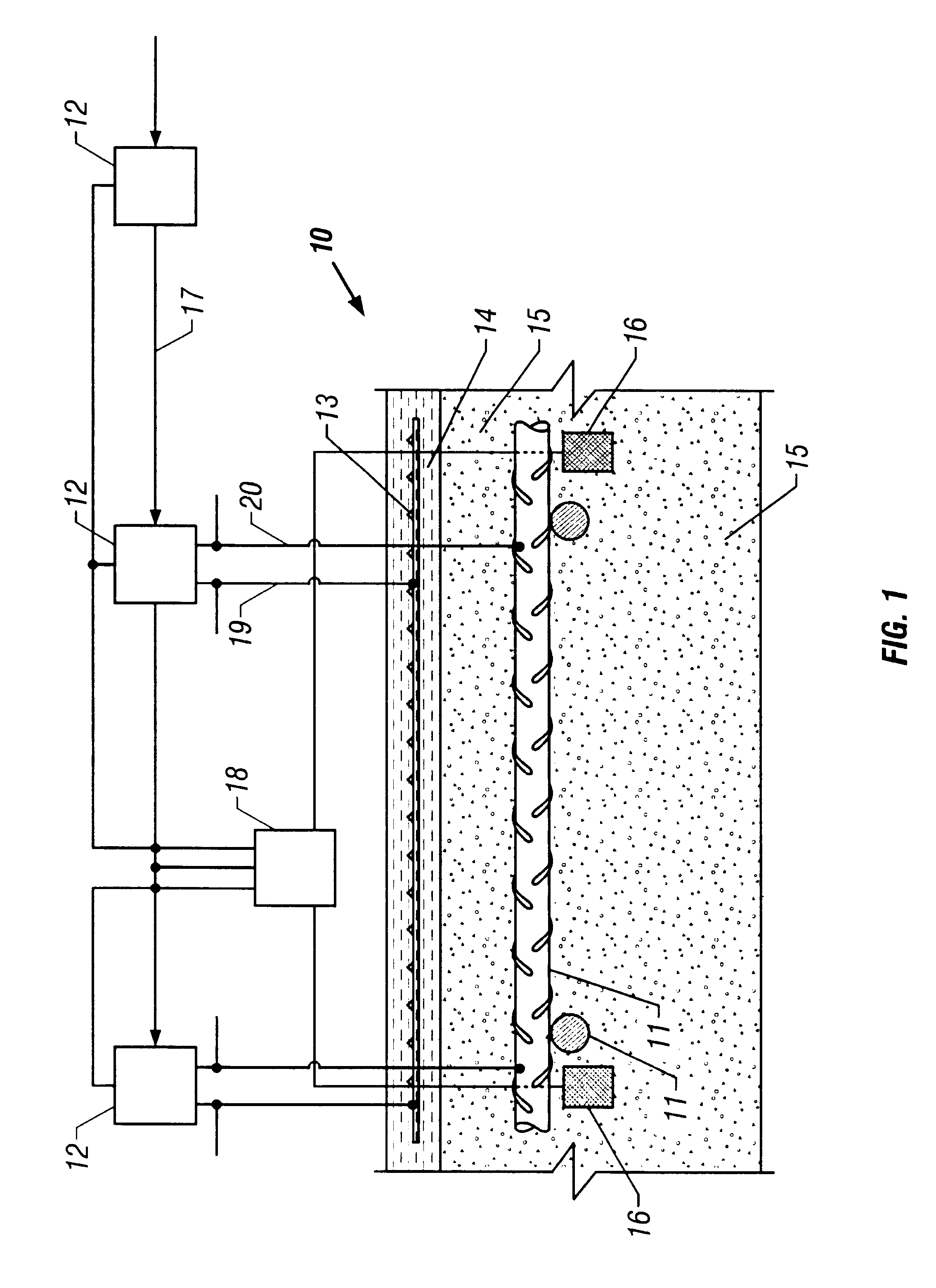

Method of treating corrosion in reinforced concrete structures by providing a uniform surface potential

InactiveUS6398945B1Inhibiting and preventing corrosionEliminate differencesRebar corrosionPower flow

The invention provides a method of inhibiting or preventing corrosion of reinforced steel in concrete by eliminating the differences in surface potentials that result in the total passivation of corrosion activity and create an environment in the steel that does not allow corrosion. The method, optionally includes measuring the active non-uniform surface potential in the steel and passing a DC voltage through the concrete and steel to stop corrosion providing a substantially uniform surface potential on the reinforced steel. The current is controlled and adjusted to send pre-determined amounts of electrical energy to individual areas targeted for treatment. A corrosion potential survey may be conducted to determine the energy requirements necessary for the corrosion condition or a reference electrode may be strategically placed on the concrete structure. The amount of energy passed is sufficient to polarize the reinforcing steel sufficiently to stop corrosion and establish substantially uniform surface potentials on all the reinforcing steel. The invention also includes changing conditions on the surface of steel from a condition of non-uniform surface potential to a condition of substantially uniform surface potential.

Owner:INFRASTRUCTURE REPAIR TECH

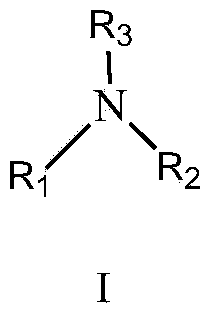

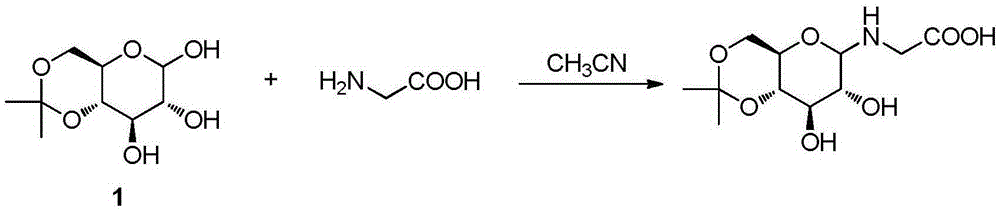

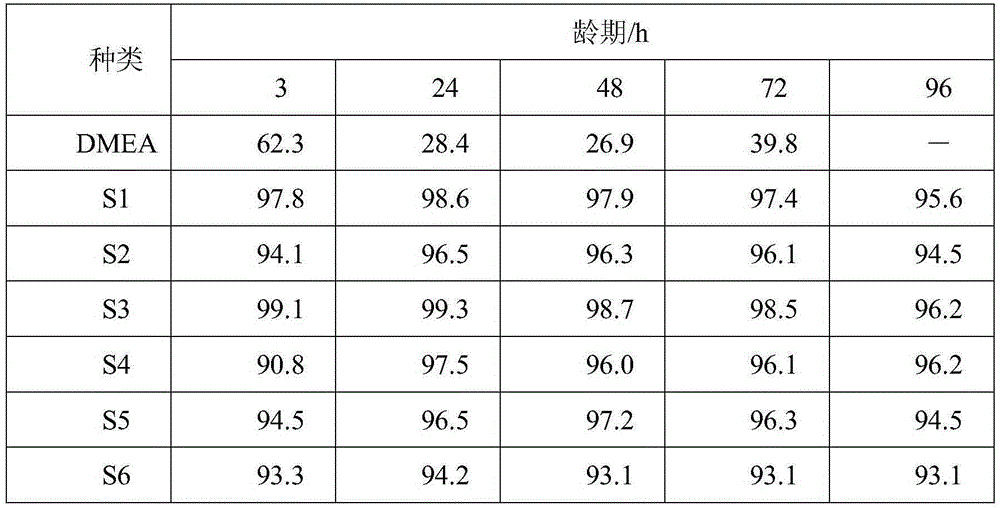

Osamine organic rebar corrosion inhibitor and preparation method thereof

ActiveCN105399783AThe synthesis method is simpleNo stringent conditionsSugar derivativesSugar derivatives preparationRebar corrosionAryl

The invention discloses an osamine organic rebar corrosion inhibitor, which is prepared from hemiacetal hydroxyl containing sugar and amine through condensation, wherein the sugar contains hydroxyl protected or unprotected monosaccharides and disaccharides, and is wide in sources, green and environmentally friendly; and the amine is shown in a formula:, wherein R1 and R2 are independently selected from a linear chain containing 1-15 carbons, a branched chain, ring alkyl, aralkyl, aryl, alkenyl, ether alkyl, amino alkyl, alkyl alcohol, alkylamine, an alkyl carboxylic acid or a hydrogen atom, can be cyclized, and can not be a hydrogen atom simultaneously. According to the invention, a synthesis process is simple, and a prepared corrosion inhibitor has the characteristics of efficient corrosion inhibition, green and environmental friendliness, and has a significant application value and a broad market prospect.

Owner:JIANGSU SOBUTE NEW MATERIALS

Method of treating corrosion in reinforced concrete structures by providing a uniform surface potential

The present invention provides a method of inhibiting or preventing corrosion of reinforced steel in concrete by eliminating the differences in surface potentials that result in the total pasivation of corrosion activity and create an environment in the steel that does not allow corrosion. The method, optimally includes measuring the active non-uniform surface potential in the steel and passing a DC voltage through the concrete and steel to stop corrosion providing a substantially uniform potential on the reinforced steel. The current is controlled and adjusted to send pre-determined amounts of electrical energy to individual areas targeted for treatment. A corrosion potential survey may be conducted to determine the energy requirements necessary for the corrosion condition or a reference electrode may be strategically placed on the concrete structure. The amount of energy passed is sufficient to polarize the reinforcing steel sufficiently to stop corrosion and establish substantially uniform surface potentials on all the reinforcing steel. The invention also includes changing conditions on the surface of steel from a condition of non-uniform surface potential to a condition of substantially uniform surface potential.

Owner:INFRASTRUCTURE REPAIR TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com