Method for monitoring of steel bar corrosion in real time

A real-time monitoring and steel corrosion technology, applied in the field of sensing, can solve the problems that bare fiber grating is not suitable for extensive construction of civil engineering, is not suitable for long-term monitoring of steel corrosion, and has shortened life. The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

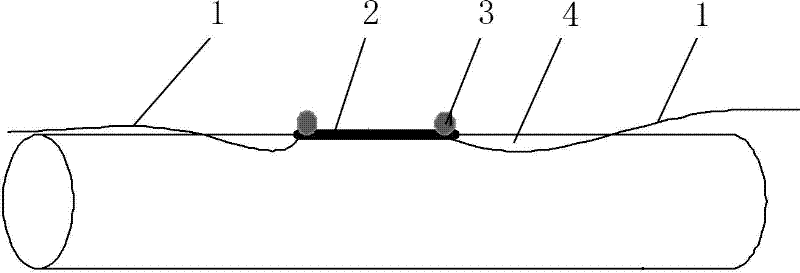

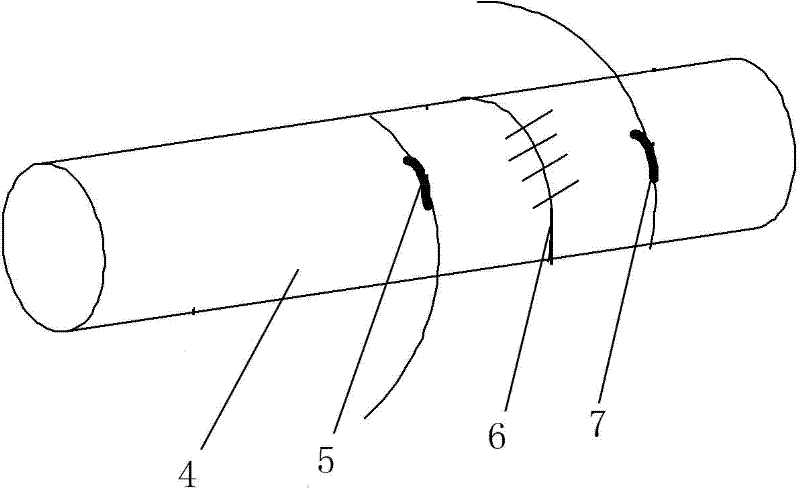

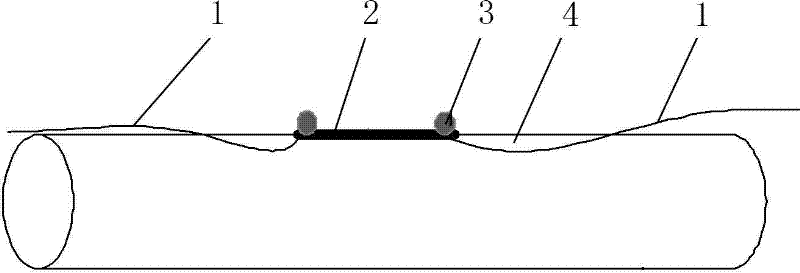

[0028] Such as figure 1 As shown, the method for real-time monitoring of steel corrosion includes the following steps:

[0029] (a) First, coat the surface of the fiber grating strain sensor 2 packaged in steel pipe with a layer of rust conversion paint, and the coating environment is controlled at a temperature of 25°C and a relative air humidity of 80%;

[0030] (b) In order to ensure that the fiber grating strain sensor 2 encapsulated in the steel pipe can fully contact the surface of the steel bar 4 and avoid measurement errors caused by strain transfer, the surface of the steel bar 4 is firstly ground with a grinder, and then further polished with sandpaper to make the steel bar 4 The surface is smoother and smoother. In order to prevent the influence of pollutants such as grinding debris, use absorbent cotton balls dipped in absolute alcohol to scrub the polished area and set aside;

[0031] (c) Paste the fiber grating strain sensor 2 encapsulated in the steel pipe obt...

Embodiment 2

[0034] (a) First, coat the surface of the fiber grating strain sensor 2 packaged in steel pipe with a layer of rust conversion paint. The coating environment is controlled at a temperature of 5°C and a relative air humidity of 60%.

Embodiment 3

[0036](a) First, coat the surface of the fiber grating strain sensor 2 packaged in steel pipe with a layer of rust conversion paint, and the coating environment is controlled at a temperature of 40°C and a relative air humidity of 20%; the rest is the same as in Embodiment 1, and will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com