Method for testing steel corrosion of reinforced concrete members

A technology for corrosion of reinforced concrete and steel bars, which is applied in the testing of basic structures, basic structure engineering, optical testing flaws/defects, etc. It can solve problems such as the inability to accurately judge the corrosion state of steel bars, the inability to establish corrosion of steel bars, and a single mathematical relationship. To achieve the effect of intuitive measurement, simple structure and easy judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

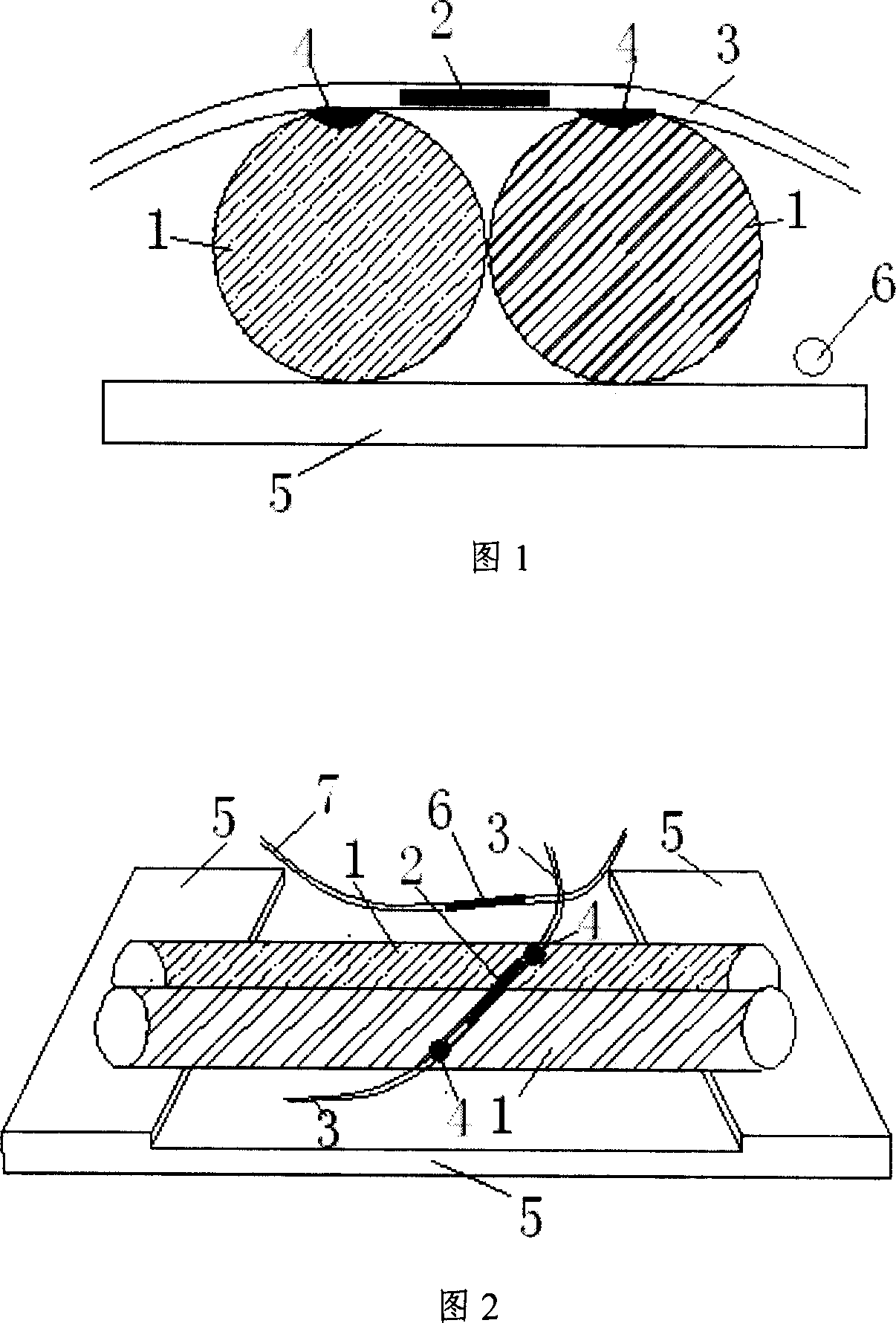

[0028] The sensor structure adopted by the present invention is shown in Fig. 1 and Fig. 2 .

[0029] Select two steel bars 1 of the same material as the steel bars used in the project, about 8cm in length, and slightly smooth the adjacent surface. At the same time, make a stainless steel base 5 with a slightly higher thickness at both ends of the base. Place the steel bars 1 as shown in the figure, and then fill them with permeability A good elastic filler is around the steel bar 1, but the top of the steel bar is reserved to fix the position of the steel bar, and then use epoxy resin 4 to paste the strained fiber grating 2 on the top of the two steel bars 1, and only paste two points, and use The strained optical fiber 3 is led out, the strained optical fiber 3 is covered with a heat-shrinkable tube, the strained optic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com