Method for detecting corrosion of concrete bar in reinforced concrete

A technology for corrosion of reinforced concrete and steel bars, which is applied in the directions of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc. It can solve the problem that the sampling depth of concrete powder is difficult to accurately determine, the corrosion state of steel bars cannot be accurately judged, and the concrete protective layer is damaged, etc. problem, to achieve the effect of intuitive measurement, simple structure and simple measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

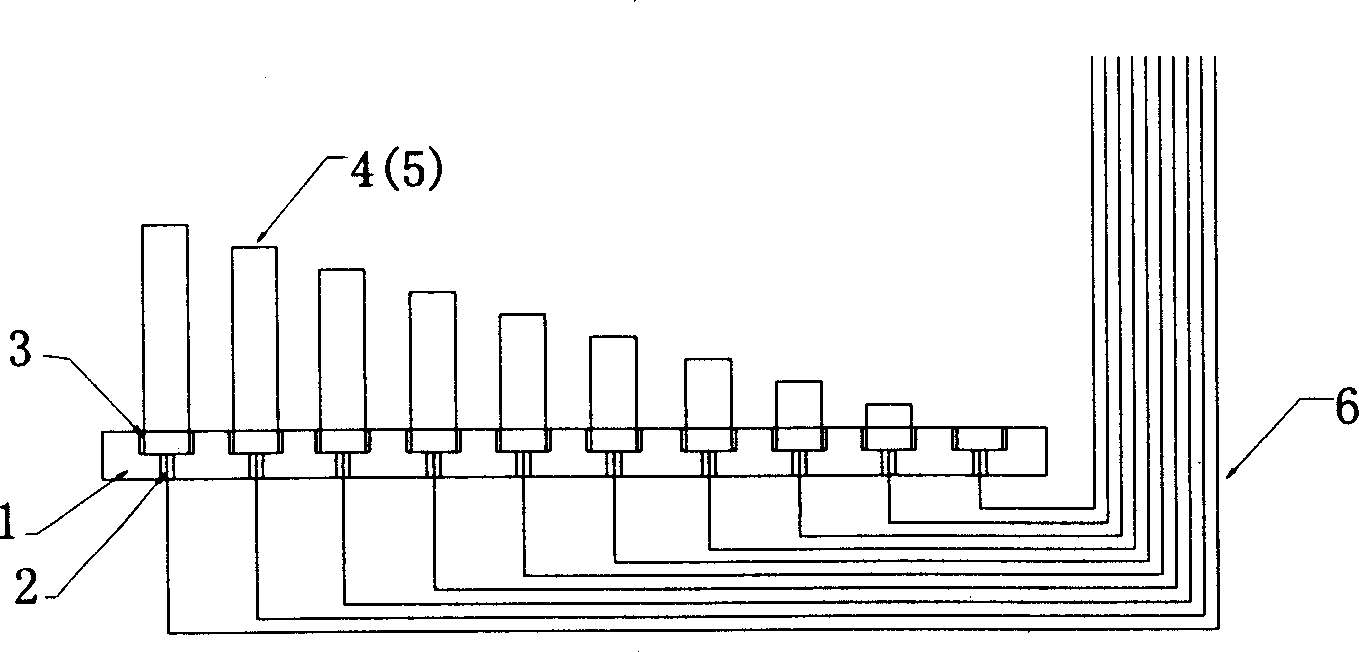

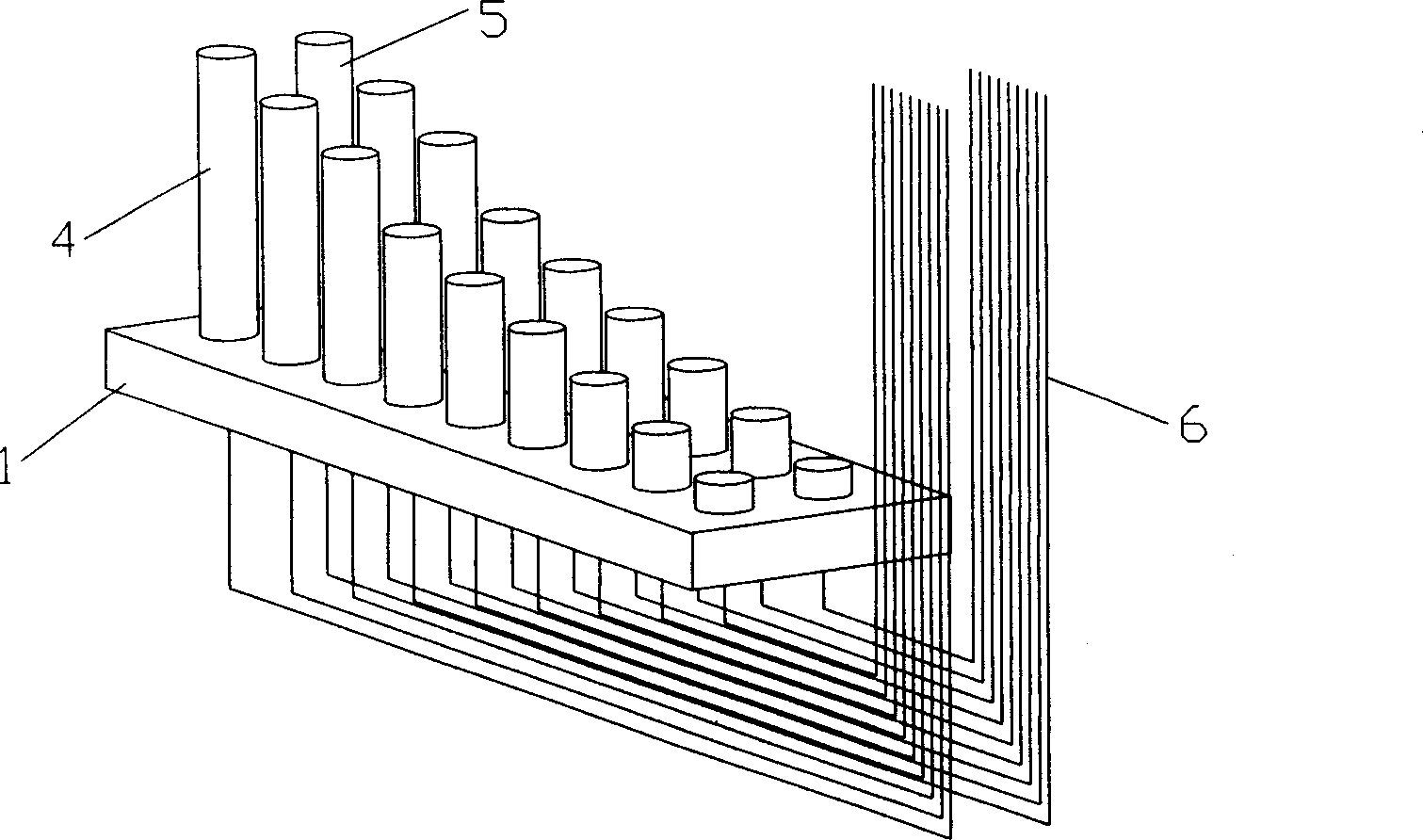

[0032] The sensor structure that the present invention adopts is as figure 1 , figure 2 shown.

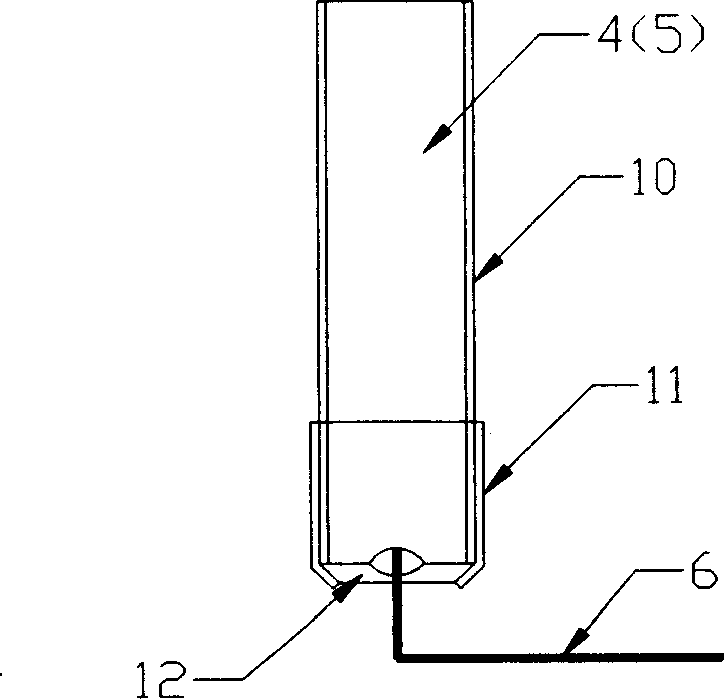

[0033] Select the same steel bar as the used steel bar material of the project, and process it into a steel bar 4 of a certain diameter with a lathe. , 10, 5mm). Simultaneously make a stainless steel rod 5 with the same diameter and the same length as the steel bar 4. An end face welding lead 6 to each steel bar 4 and stainless steel bar 5, and as image 3 As shown, heat-shrinkable tube 11 is put on the end face and side of the wire connection, and sealed with adhesive tape 10 and epoxy resin 12, and then the above steel bar 4 and stainless steel bar 5 are fixed on the base 1 with epoxy resin 12 In the fixed groove 3. Note: The fixed end is the end surface where the wire 6 is welded, and the wire 6 is led out from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com