Patents

Literature

250 results about "Reinforcement corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Initiation of reinforcement corrosion. The reinforcement corrosion is initiated, when the products formed on steel do not protect them any more (depassivation), because they become more porous. So, a first criterion of corrosion initiation corresponds to the change of the nature of these products.

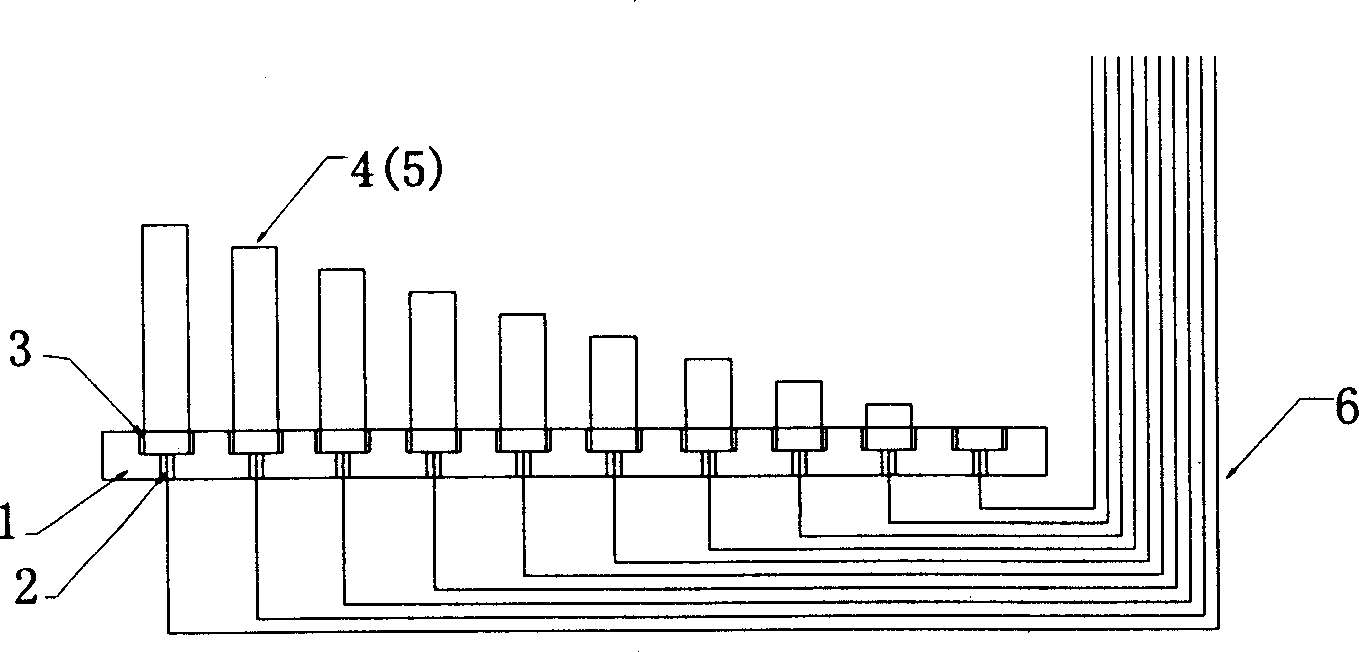

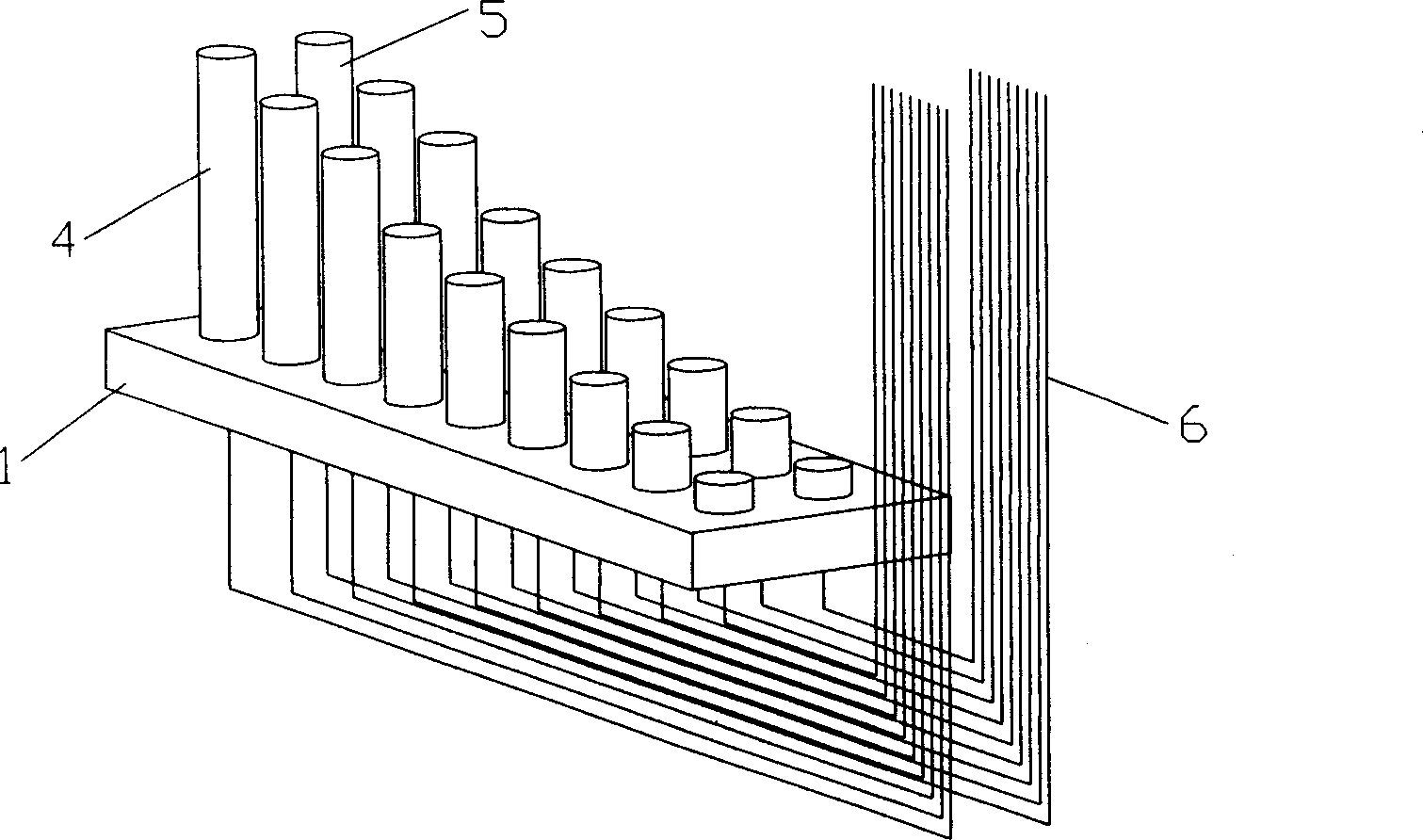

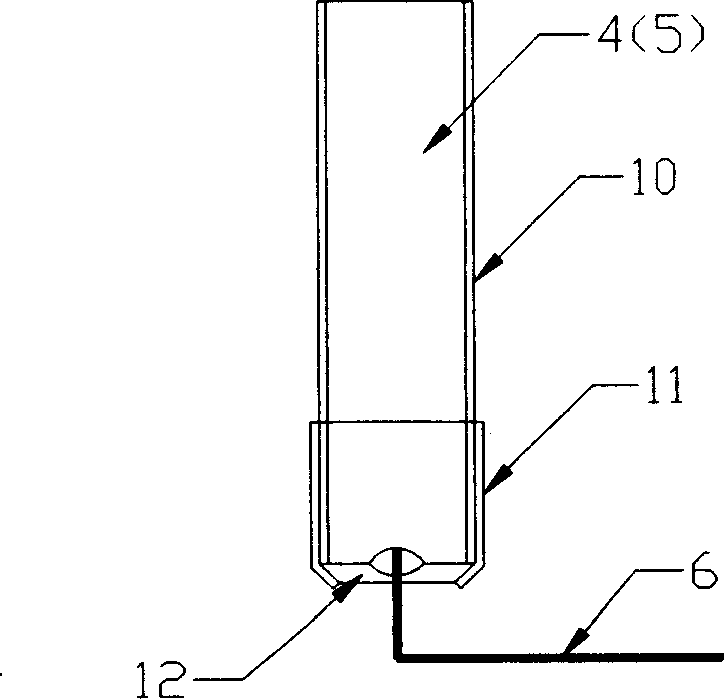

Method for detecting corrosion of concrete bar in reinforced concrete

InactiveCN1438478AAccurately determineAccurately determine the depthWeather/light/corrosion resistanceMaterial electrochemical variablesRebar corrosionMaterials science

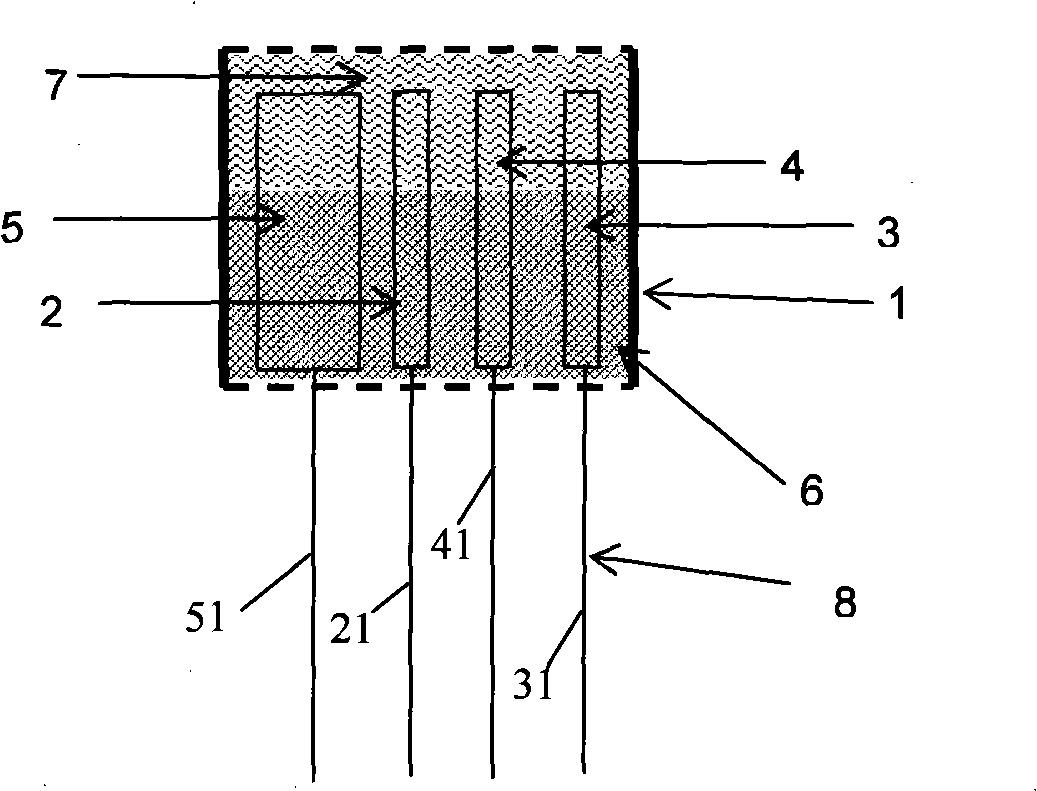

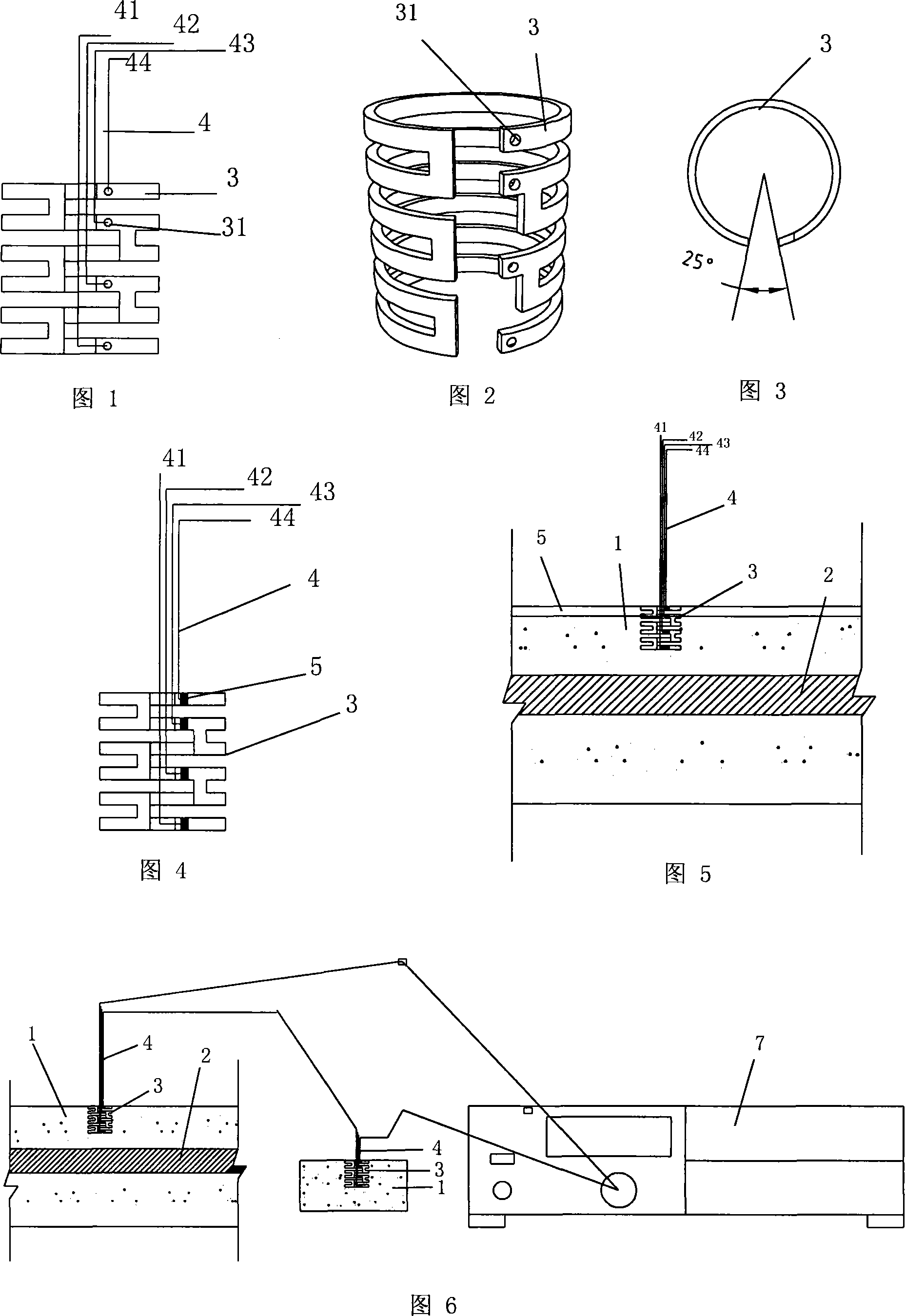

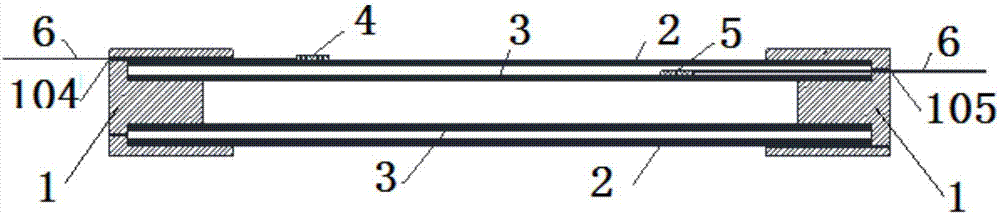

The method directly measures the corrosion happened on reinforcing steel bars in real time. The sensor comprises several reinforcing steel bars with non equal lengths, the stainless steel bars having same quantities and lengths as of the reinforcing steel bars, the base seat and the conducting wires. The reinforcing steel bars and the stainless steel bars in stepped appearance are fixed in the fixed slot in the base seat of the sensor side by said. The conducting wires are leaded out and numbered from the threading hole in the middle of the fixed slot. In the time of construction, the said sensors are embedded into concretes. While in the period of the constructions being used, the data from the sensors are collected regularly.

Owner:SHANGHAI JIAO TONG UNIV

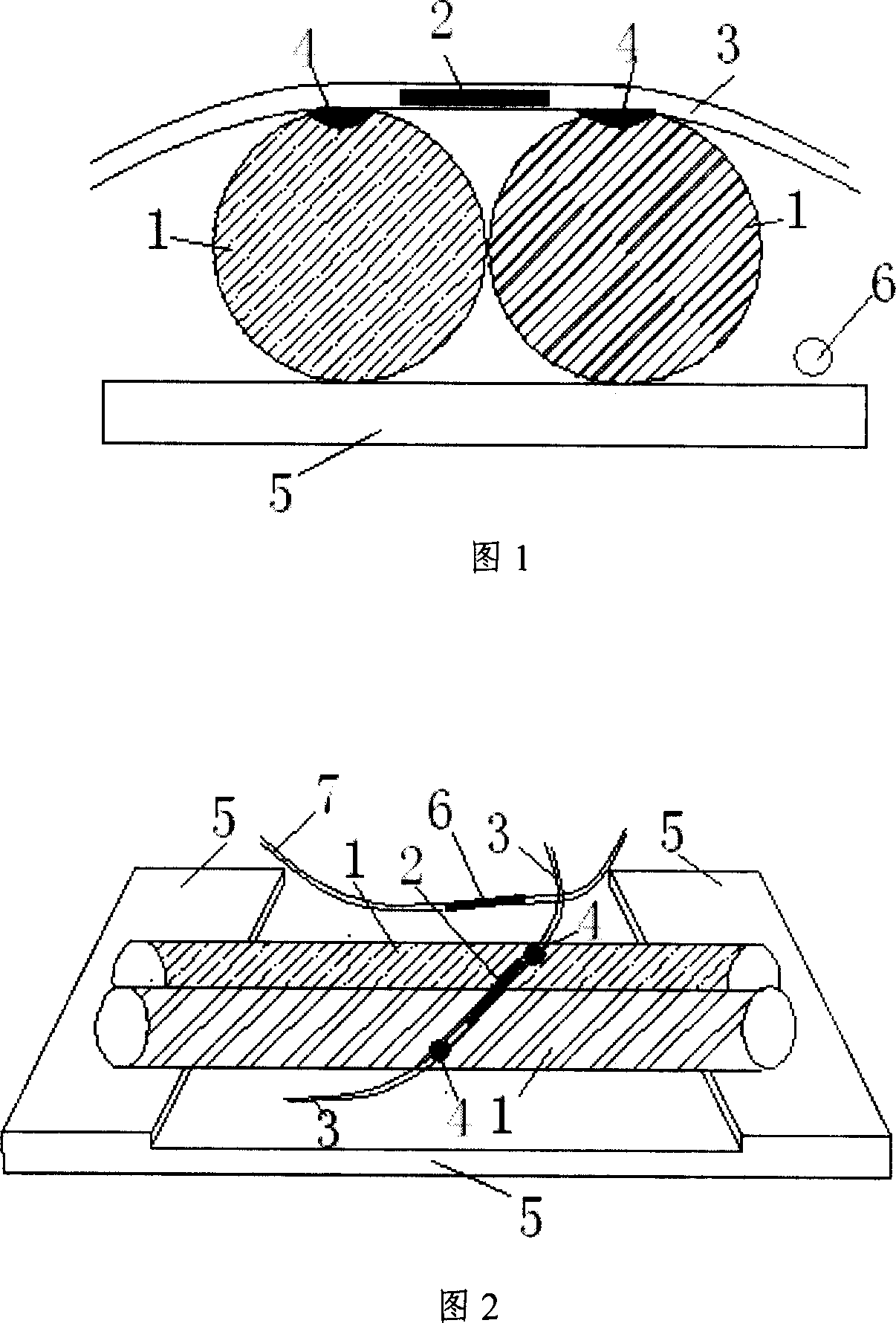

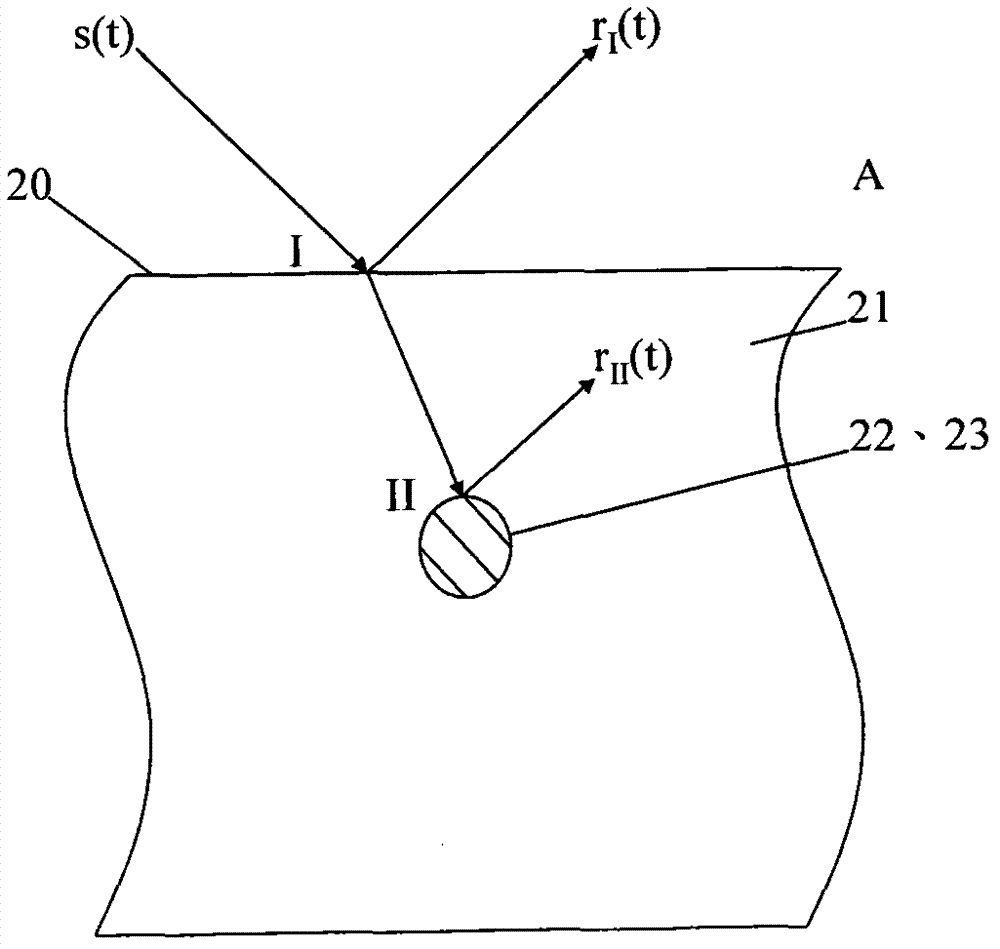

Method for testing steel corrosion of reinforced concrete members

InactiveCN101008620ASimple structureAccurately determineFoundation testingOptically investigating flaws/contaminationFiberRebar corrosion

This invention relates to one steel concrete structure anti-erosion test method in structure engineer field, which comprises the following steps: a, sensor processing to parallel two steel bars in same materials for fixing and sticking the stress fiber grating to top end and putting one free temperature compensation fiber grating connected by the compensation fiber and sealing on shell; b, positioning the sensor and drilling it into concrete with stress fiber and temperature compensation connected to spectrum; c, monitoring by periods to test grating wave length volume and speed to infer anti-erosion degree and speed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

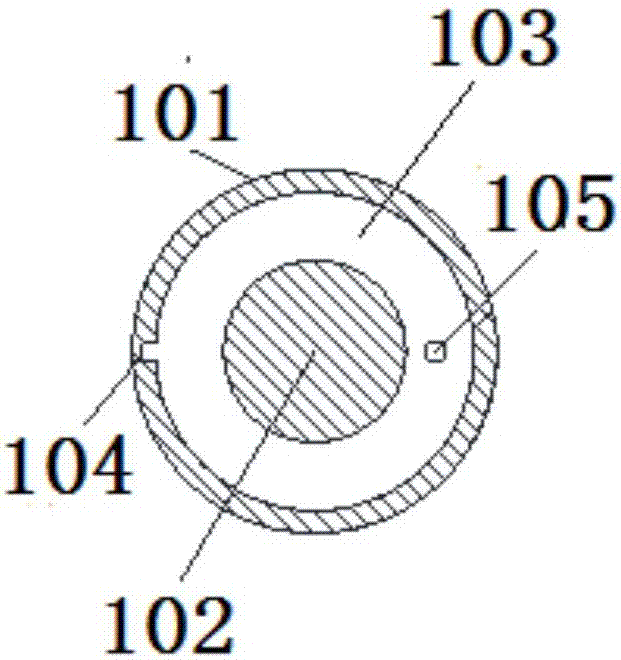

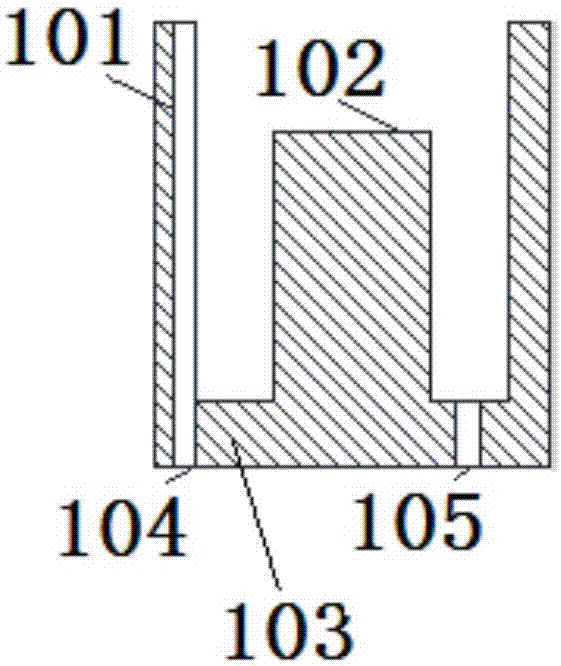

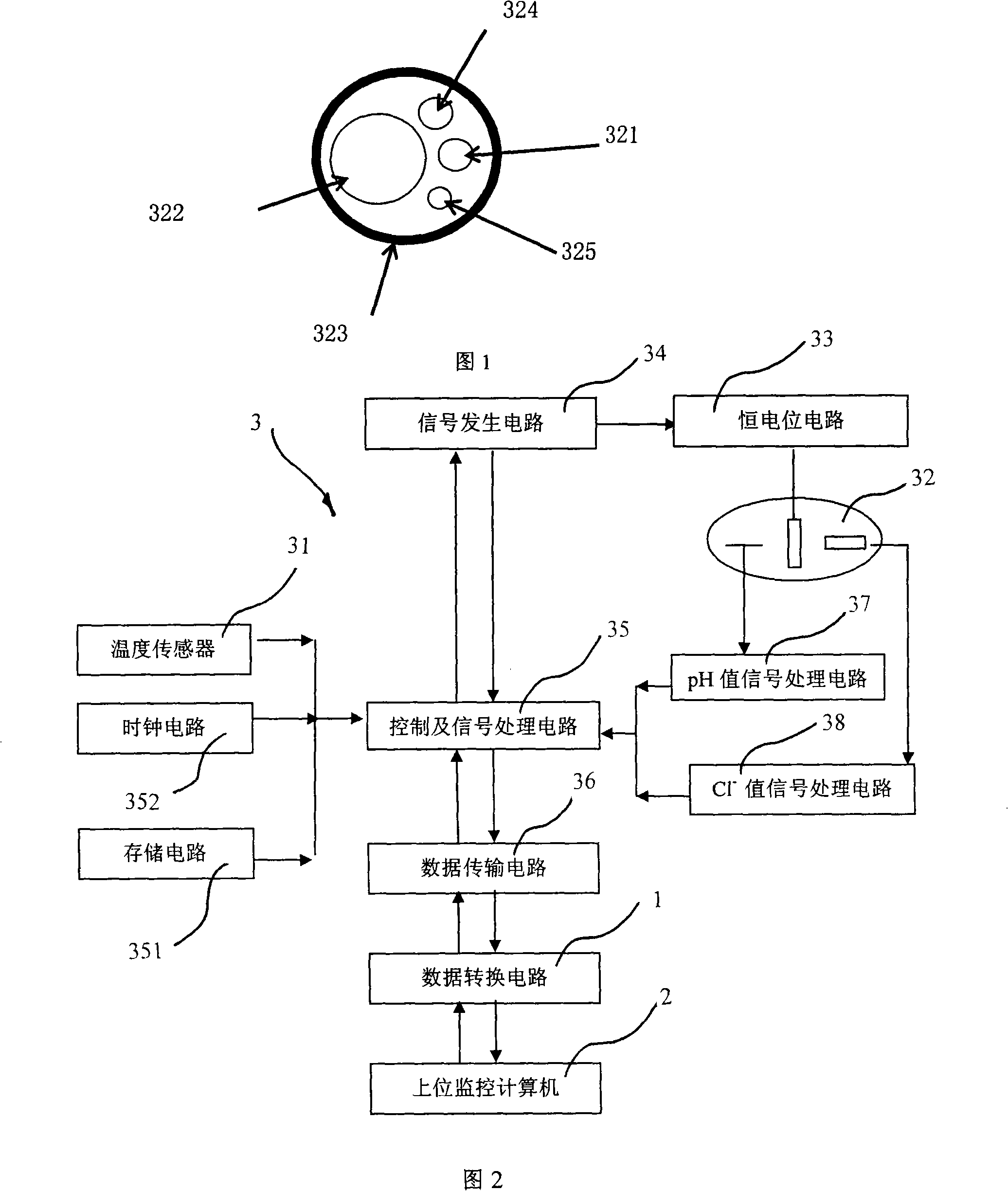

Multifunctional sensor for monitoring reinforced concrete structure erosion

InactiveCN101334353AImprove responsivenessImprove reliabilityWeather/light/corrosion resistanceMaterial electrochemical variablesRebar corrosionCarbonization

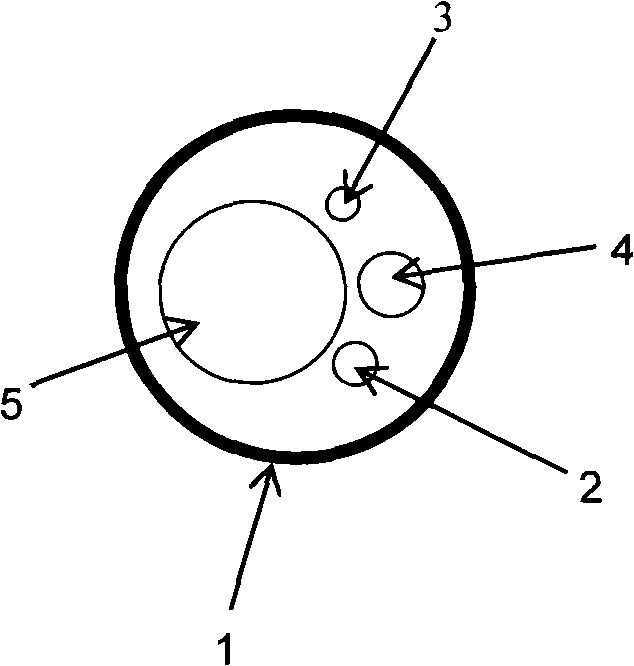

The invention discloses a multifunctional sensor that is used for monitoring the corrosion of a reinforced concrete structure, relating to a sensor, and provides a multifunctional sensor that is used for monitoring the corrosion of a reinforced concrete structure and can simultaneously monitor electrochemical corrosion parameters of carbonization of concretes, Cl<-> concentration, corrosion status and corrosion speed of reinforcement metals and the like on the spot, as well as a preparation method of the multifunctional sensor. The multifunctional sensor is provided with a metal shell, a Cl<-> probe, a pH probe, a reinforcement metal electrode, a MnO2 reference electrode and external guide lines. The Cl<-> probe, the pH probe, the reinforcement metal electrode and the MnO2 reference electrode are prepared separately, and then arranged in the shell. The external guide lines of each probe and each electrode are connected with and extend from the metal shell, each probe and each electrode are sealed and fixed with the metal shell, and insulating materials are exposed at the upper ends of each probe and each electrode and the ends exposing outside are covered by pervious materials; connecting parts between the external guide lines and the metal shell are sealed.

Owner:XIAMEN UNIV

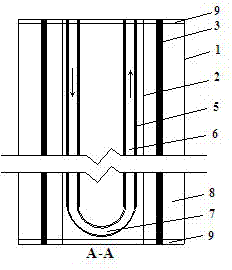

Construction method for precast energy pile

ActiveCN103485332ASolve the loss of densitySolve stacking problemsHeat pumpsBulkheads/pilesPile capArchitectural engineering

A construction method for a precast energy pile is characterized in that a heat transfer tube is embedded into a hollow steel tube, the hollow steel tube replaces a traditional solid reinforcement and serves as a main reinforce ement of the precast pile, and for being connected with the heat transfer pipe in the precast pile, a heat transfer elbow and a heat transfer tube joint are embedded into a precast pile shoe and a precast pile cap. As the heat transfer tube is embedded into the hollow steel tube, the technical problems of mutual interference, poor concrete compactness, reinforcement corrosion, effect on the overall bearing capacity of a pile foundation and the like caused by binding and embedding of the heat transfer tube and the main reinforcement are effectively solved. Moreover, the embedded tube is higher in survival rate, a large number of piles are conveniently stacked and safely transported, construction period is short, and underground space and construction cost are saved.

Owner:HOHAI UNIV

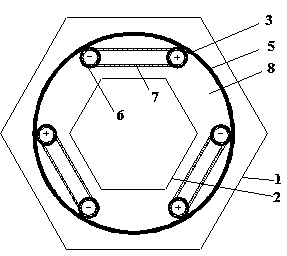

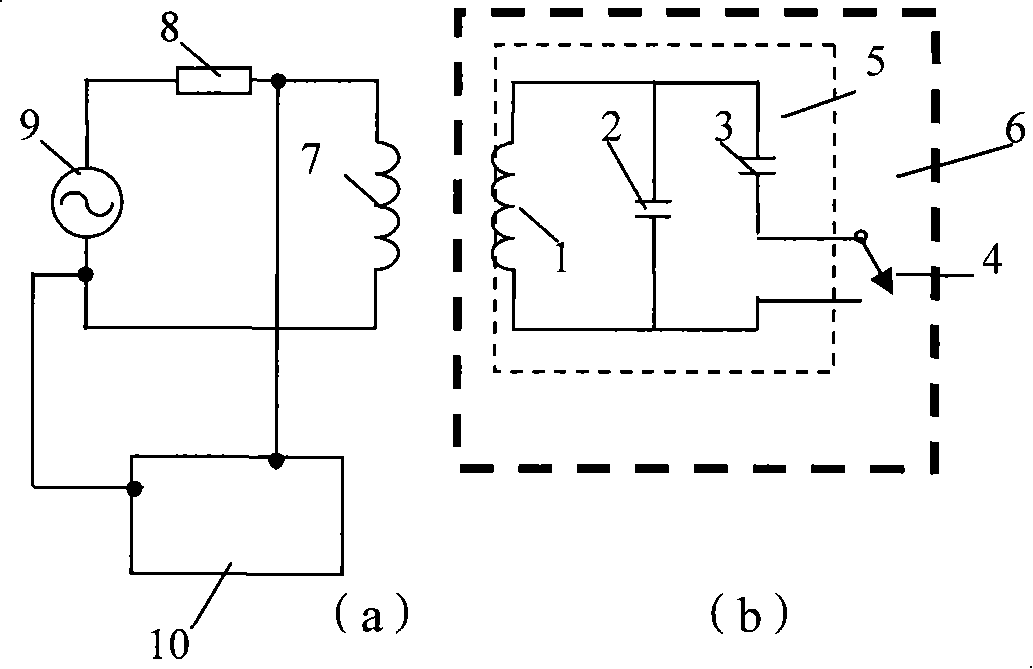

Concrete reinforcement erosion wireless detecting method and sensor

InactiveCN101246116AReduce workloadAccurate detectionWeather/light/corrosion resistanceTransmission systemsCapacitanceRebar

A concrete reinforcement corrosion wireless testing method and a sensor belong to the field of the concrete reinforcement corrosion detecting technique. The sensor comprises a sensing part and a reading part. The sensing part is mainly a resonance circuit which comprises at least one capacitance that is connected to the two ends of the inductance coil after series-connection to the switch of the steel wire, and the switching-off and switching-on of the steel wire switch is controlled by whether the steel wire is corroded and disconnected; the reading part works with the LC oscillating circuit, according to the principle of the resonance circuit the resonance frequency of the sensing part is measured through the phase frequency characteristic curve of the impedance in order to judge whether the steel wire is corroded and broken. The invention can more accurately confirm the degree of the reinforcement corrosion and the speed by embedding sensing part at the vicinity of the electric field at the inner part of the concrete under the precondition that the concrete is not damaged, realizes the wireless transmission of the corrosion signal inside and outside the concrete, and can be applied to the detecting and evaluating of the durability of the reinforced concrete structure in the structural engineering field.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Construction method for embedding pipe in ground source heat pump pouring pile reinforcement cage

ActiveCN103383018AReduce load capacityImprove compactnessPipe laying and repairHeat pumpsHeat transmissionArchitectural engineering

The invention discloses a construction method for embedding a pipe in a ground source heat pump pouring pile reinforcement cage. A steel pipe is used for substituting for a solid reinforcing steel bar as the main rib of a pouring pile reinforcement cage, and a heat transmission pipe is embedded in the steel pipe, as a result, problems caused by binding and embedding the heat transmission pipe and the reinforcement cage, including mutual interference, high probability of corrosion of a reinforcing steel bar, effect on overall bearing capacity of a pile foundation and the like, are solved. Compared with the traditional way of binding and embedding the heat transmission pipe and the reinforcement cage, the construction method is higher in survival rate of embedded pipe, compactedness of concrete is high, and embedment of the heat transmission pipe surely does not lower the overall bearing capacity of the pile foundation; compared with another traditional way of drilling and pipe embedding, the construction method greatly shortens construction period and saves underground space and engineering cost. The construction method is simple in construction process, strong in operability, convenient for quality control, and remarkable in economic benefit and heat transmission effect.

Owner:HOHAI UNIV

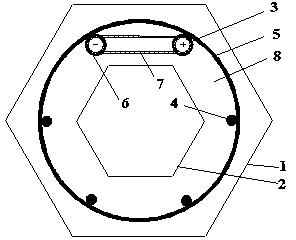

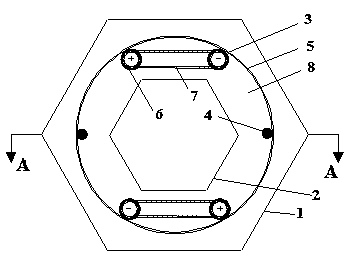

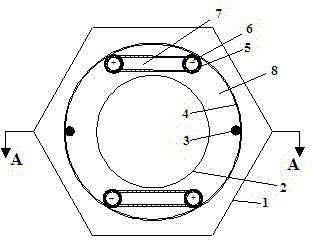

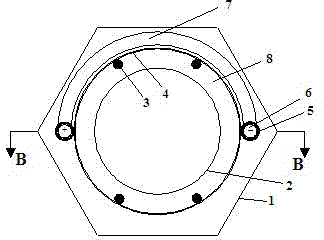

Prefabricated hexagonal energy pile and manufacturing method thereof

ActiveCN103498470AGuaranteed force characteristicsGuaranteed StrengthHeat pumpsOther heat production devicesPre stressArchitectural engineering

The invention discloses a prefabricated hexagonal energy pile and a manufacturing method of the prefabricated hexagonal energy pile. Solid steel bars are used as pre-stressed main reinforcements of the prefabricated pile, hollow steel pipes are used as constructional main reinforcements of the prefabricated pile, and heat transfer pipes are embedded in the hollow steel pipes; the exterior of a pile body where the heat transfer pipes are embedded is in the shape of a hexagon, and the interior of the pile body where the heat transfer pipes are embedded is in the shape of a circle; the heat transfer pipes are connected by heat transfer elbows to form U-shaped loops at the bottom of the prefabricated pile; the heat transfer pipes are arranged at sharp corner positions where the wall thickness is large, namely, the six corners of the hexagon. The heat transfer pipes are embedded in the hollow steel pipes, and therefore the technical problems of mutual interference, poor concrete compactness, reinforcement corrosion, influences on the overall bearing capacity of a pile foundation and the like caused by binding and embedding of the heat transfer pipes and the main reinforcements are effectively solved; besides, the survival rate of the embedded pipes is higher, a large number of pile bodies can be conveniently stacked and safely transported, a construction period is short, underground space is saved, and construction cost is lowered.

Owner:HOHAI UNIV

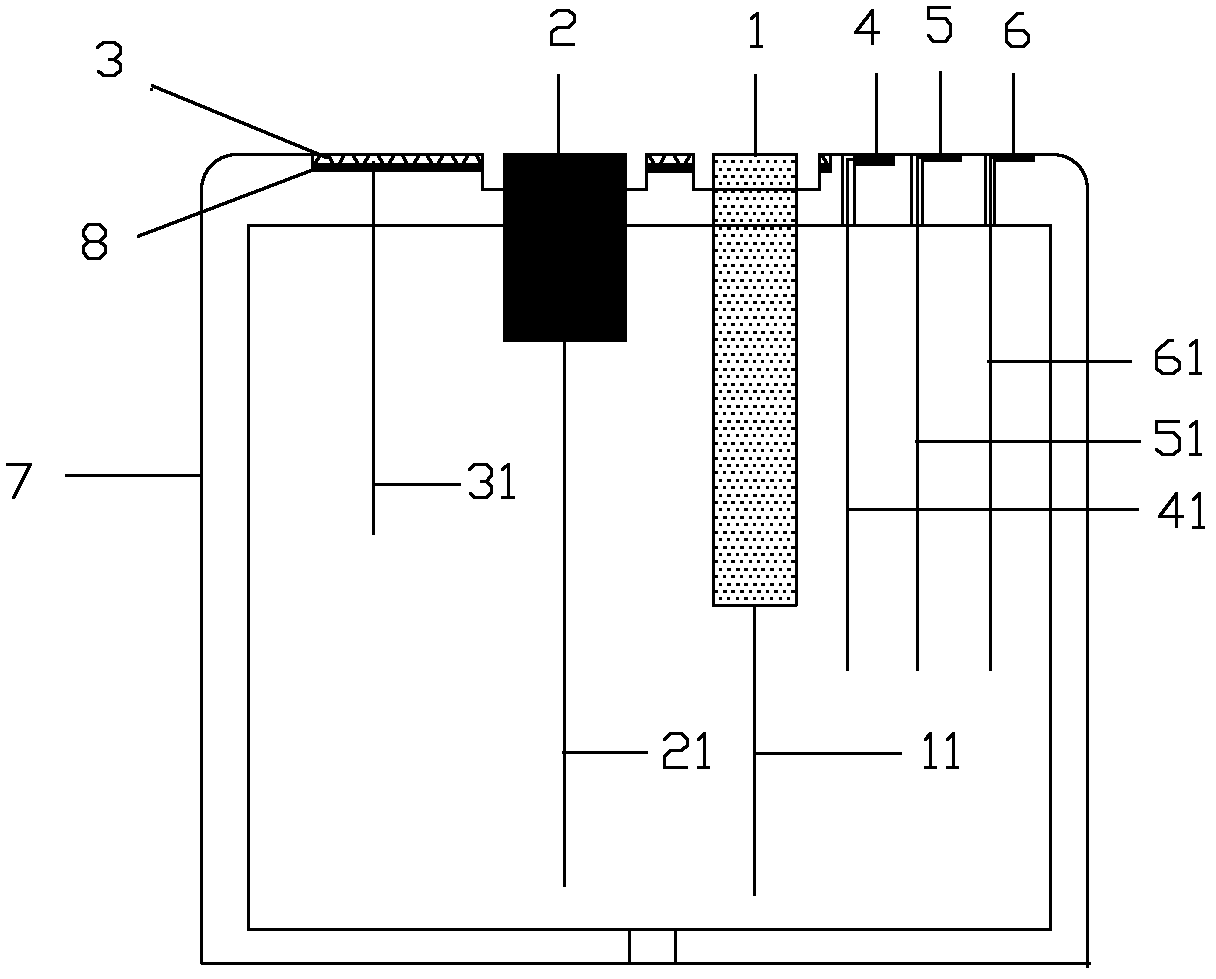

Real-time monitoring sensor for durability of concrete structures and fabricating method thereof

ActiveCN102680387ACorrosion rate real-time monitoringAccurate monitoring of corrosion rateWeather/light/corrosion resistanceMaterial electrochemical variablesElectrical resistance and conductanceRebar corrosion

The invention discloses a real-time monitoring sensor for durability of concrete structures. The real-time monitoring sensor comprises a sensor shell, and further comprises a reference electrode, a rebar electrode, an auxiliary electrode, a chlorion probe, a pH probe and a concrete resistivity probe. The auxiliary electrode is laid on the upper surface of the shell, at least parts of the reference electrode, the rebar electrode, the chlorion probe, the pH probe and the concrete resistivity monitoring probe are exposed out of the upper surface of the sensor shell to serve as detecting ends, and the other ends are connected with copper cables which penetrate through the sensor shell from top to bottom and stretch out of the shell. According to the real-time monitoring sensor, not only corrosion rate, chlorion concentration and pH of rebar, but also concrete resistivity can be monitored in real time; further, system resistance can be compensated during the monitoring of rebar corrosion current density, and corrosion rate of rebar can be monitored more accurately by the monitoring of concrete resistance.

Owner:CCCC FOURTH HARBOR ENG INST +3

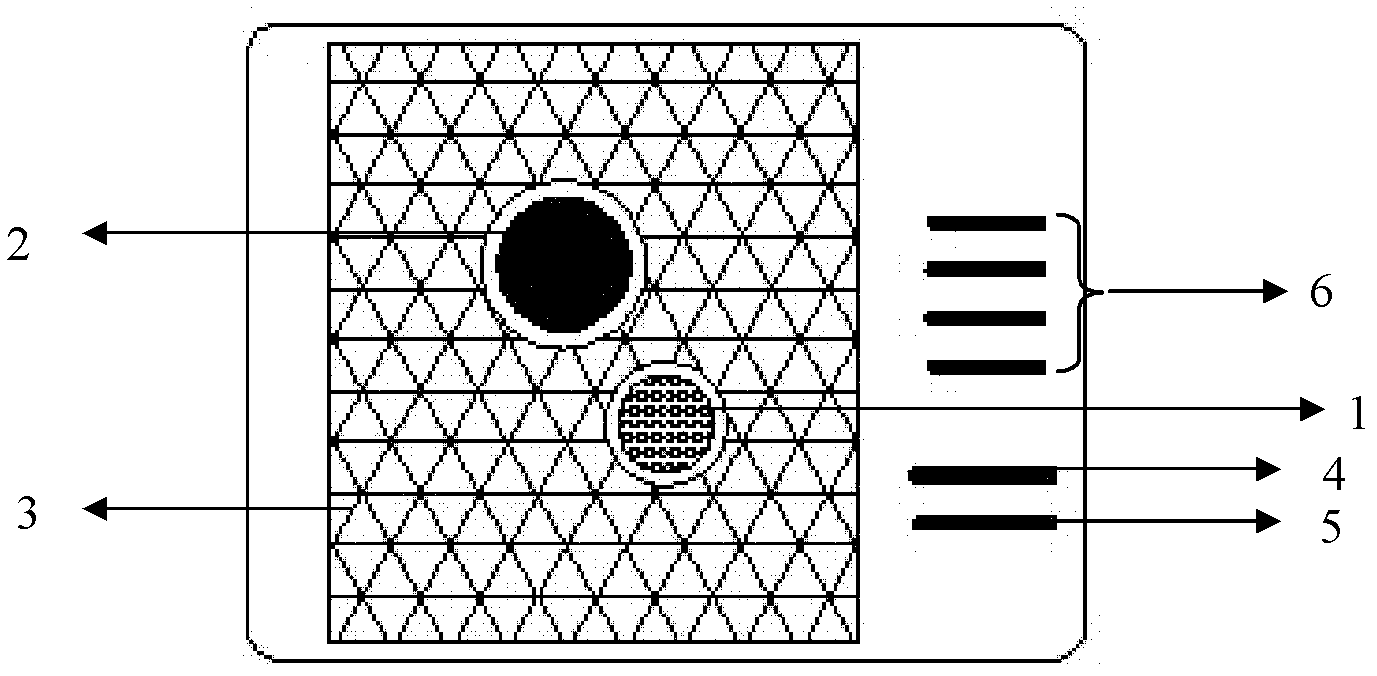

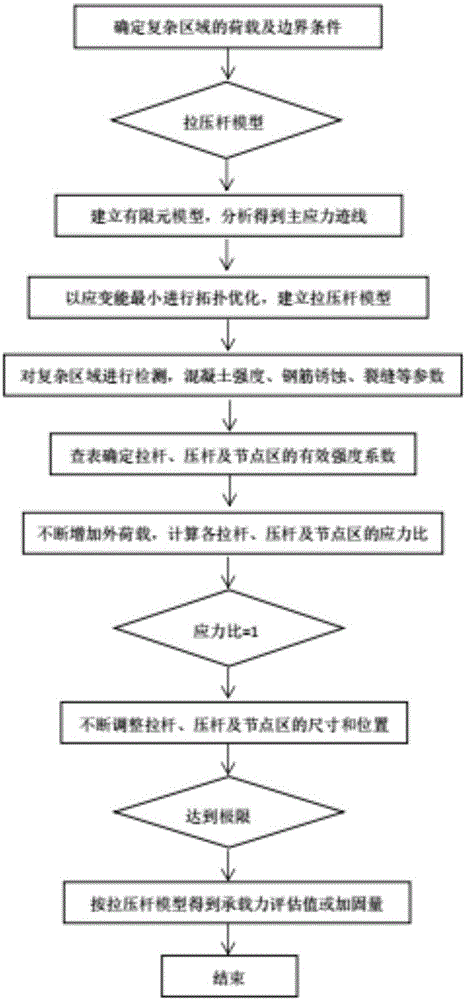

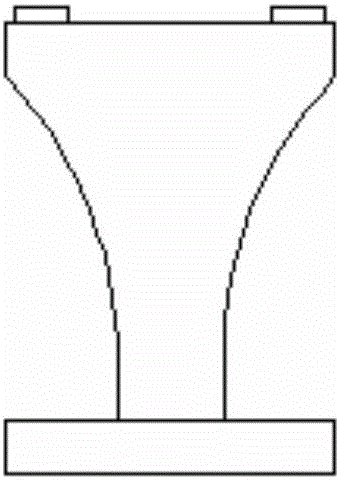

Bearing capacity assessment and reinforcement calculation method for complex region of existing concrete bridge

InactiveCN105956256AAddress usability issuesSolve complexitySpecial data processing applicationsNODALCarbonization

The invention discloses a bearing capacity assessment calculation method for a complex region of an existing concrete bridge. The method comprises the steps of determining load and boundary conditions of the complex region for diseases such as reinforcement corrosion, concrete cracking, carbonization and the like appearing in the complex region; establishing a pull rod model and a press rod model of the complex region; according to a detection result, further determining reduction coefficients of a pull rod, a press rod and a joint after the diseases are considered; making a calculation according to a pull rod strength control rule, a press rod strength control rule and a joint strength control rule to obtain a minimum bearing capacity value; and finally, according to a bearing capacity assessment result, determining a reinforcement load transfer model, continuously adjusting the positions of the reinforced pull rod, press rod and joint, or continuously increasing the reinforcement amounts of the pull rod and the press rod until the usage requirements are met. According to the method, the problems of inapplicability of a section method in calculating the complex region of concrete, complex calculation for a finite element method and difficulty in arrangement of reinforcement are solved and the bearing capacity of a complex region of an old bridge can be accurately estimated.

Owner:HOHAI UNIV

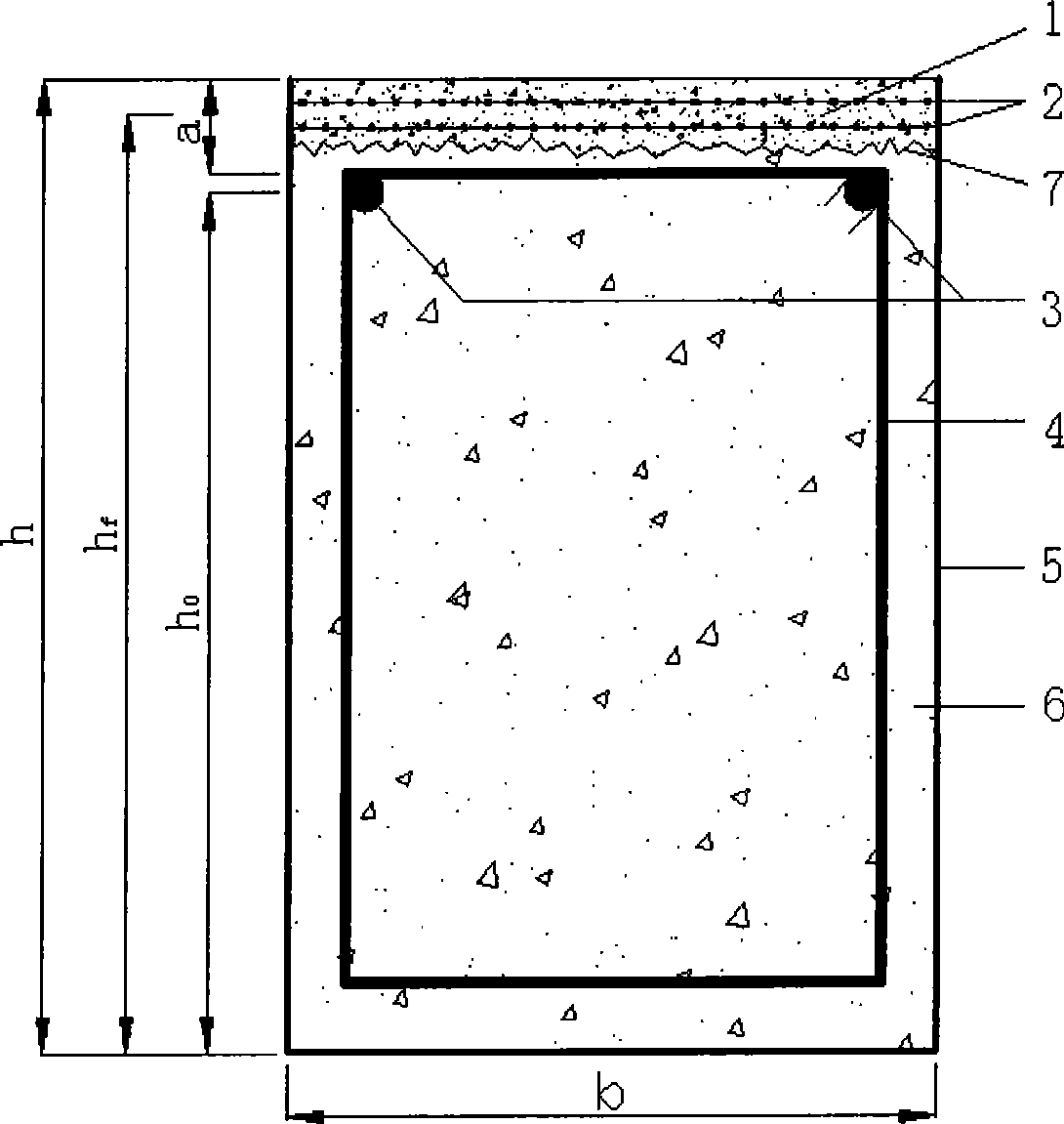

Construction structure for textile reinforced composite reinforced bar concrete and manufacturing method thereof

InactiveCN101481930AHigh strengthLimit or improve cracksSolid waste managementBuilding reinforcementsFiberRebar corrosion

The invention belongs to the technical field of concrete reinforcement, relating to utilizing fiber mesh grids to enhance the concrete strength. The arrangement of structural reinforcing steel, the thickness of concrete protective layers of main stress ribs and the grade of the concrete strength of the invention are designed according to the design criterion of a reinforced concrete structure. The invention is characterized in that before the initial setting of the concrete, fine concrete and the fiber mesh grids are cast on the outer side of the stretched and drawn area of the structure or the external surface of a large-scale integral structure, the total thickness of the fiber mesh grids and the fine concrete ranges from 10mm to 20mm, concrete with equal thickness of external surfaces are replaced, and the fiber mesh grids are evenly distributed in the fine concrete. The grid type or the plate type structure of the invention can adopt the structure of replacing partial reinforcing steel with the fiber mesh grids. The invention can effectively control cracks and solve the problems of concrete cracking and reinforcing steel corrosion, and has the advantages of firm bonding of the boundary surfaces of the fine concrete and the concrete, light self weight, low production cost, corrosion resistance, safe and durable usage, etc.

Owner:DALIAN UNIV OF TECH

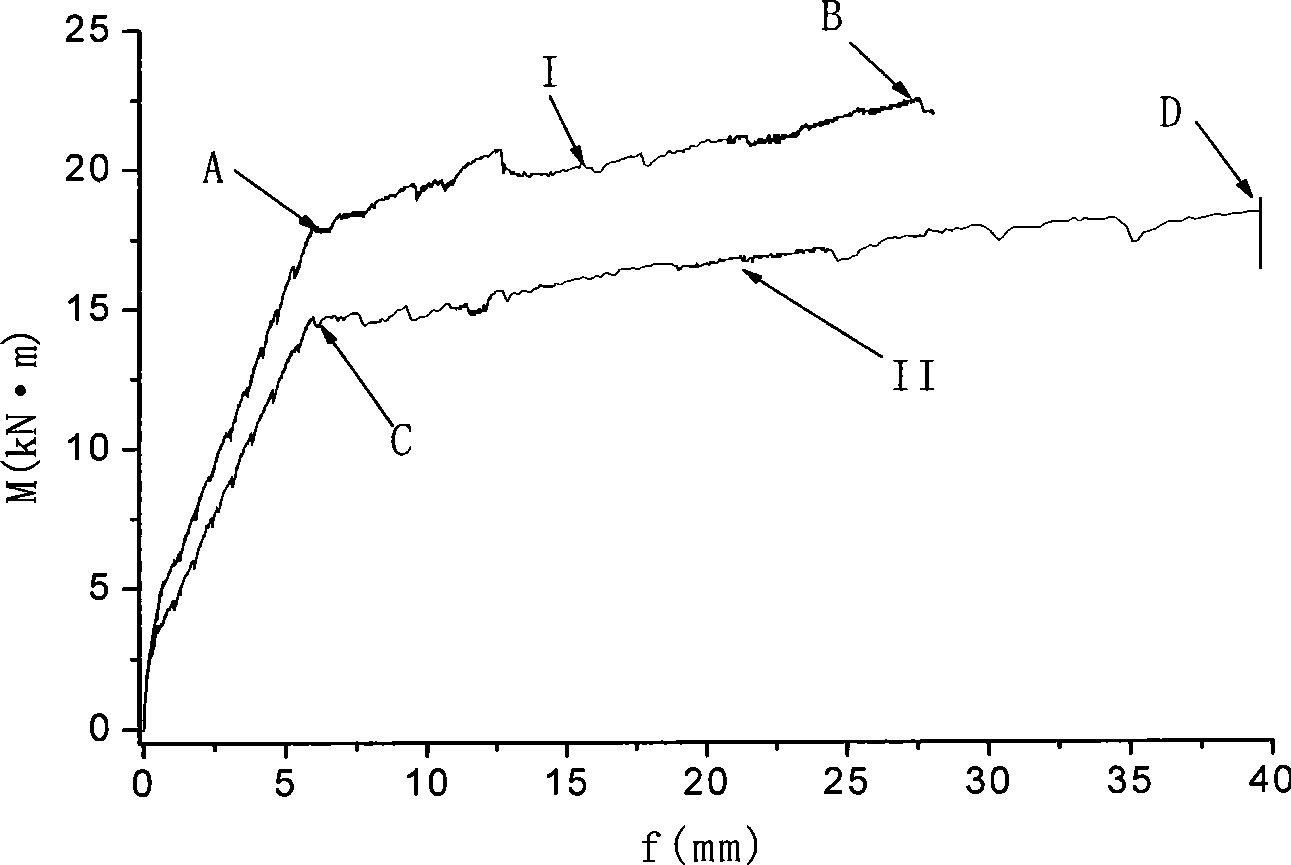

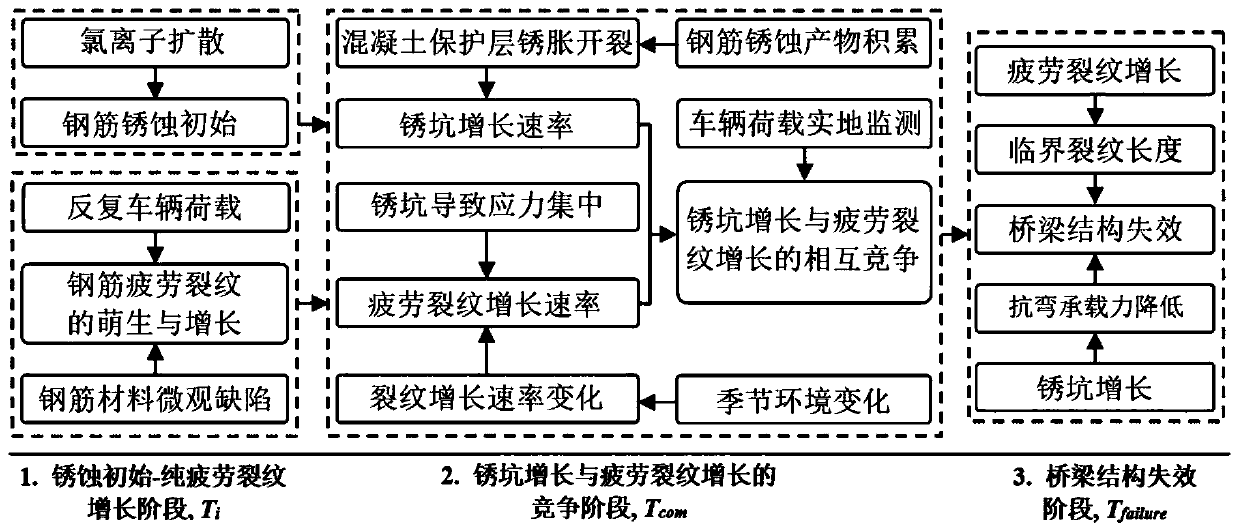

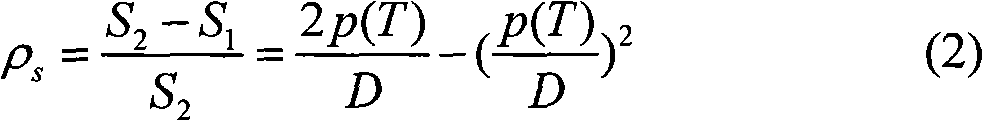

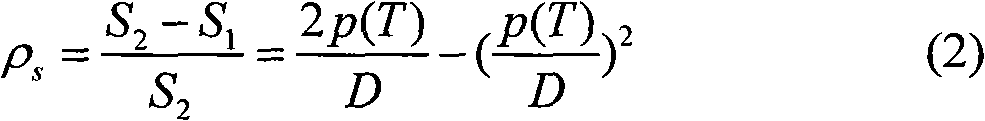

Method for predicting service life of reinforced concrete bridge under conditions of seasonal corrosion and fatigue coupling

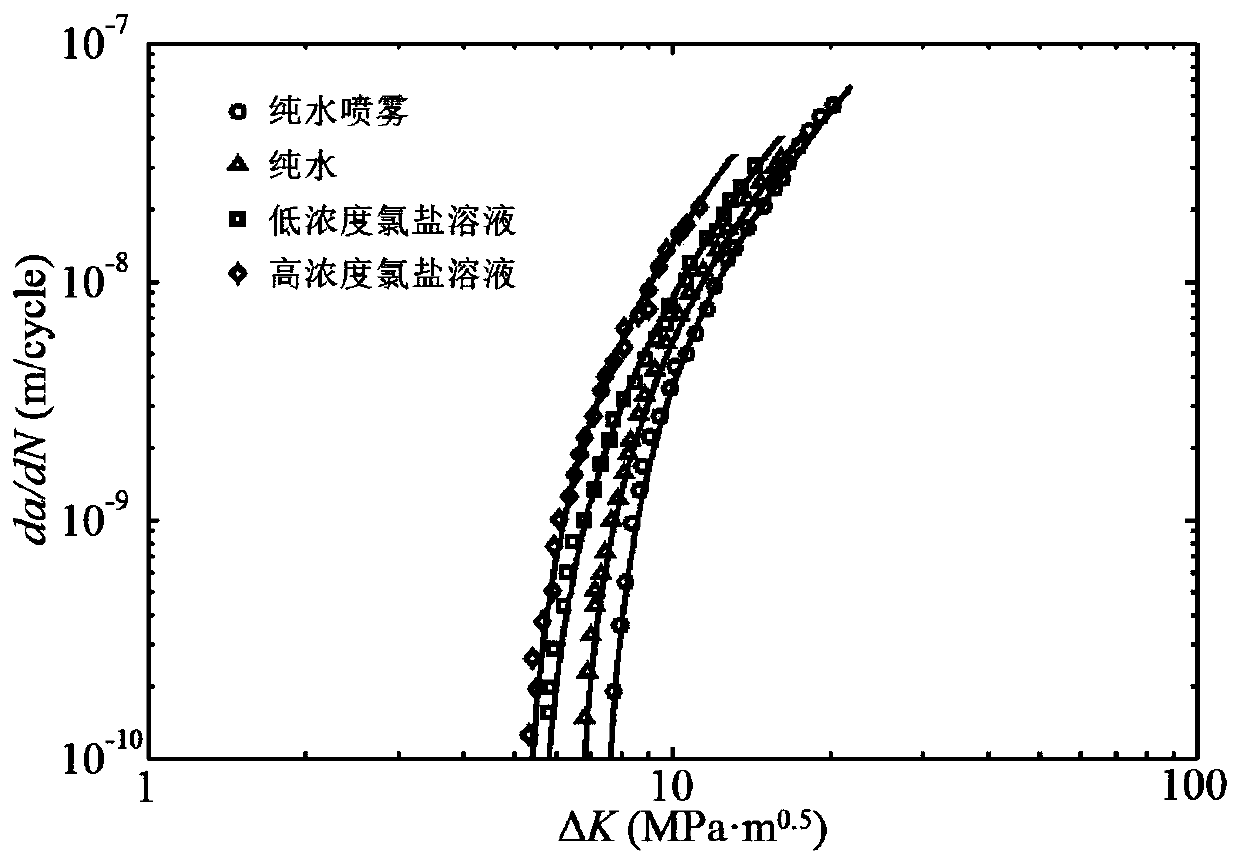

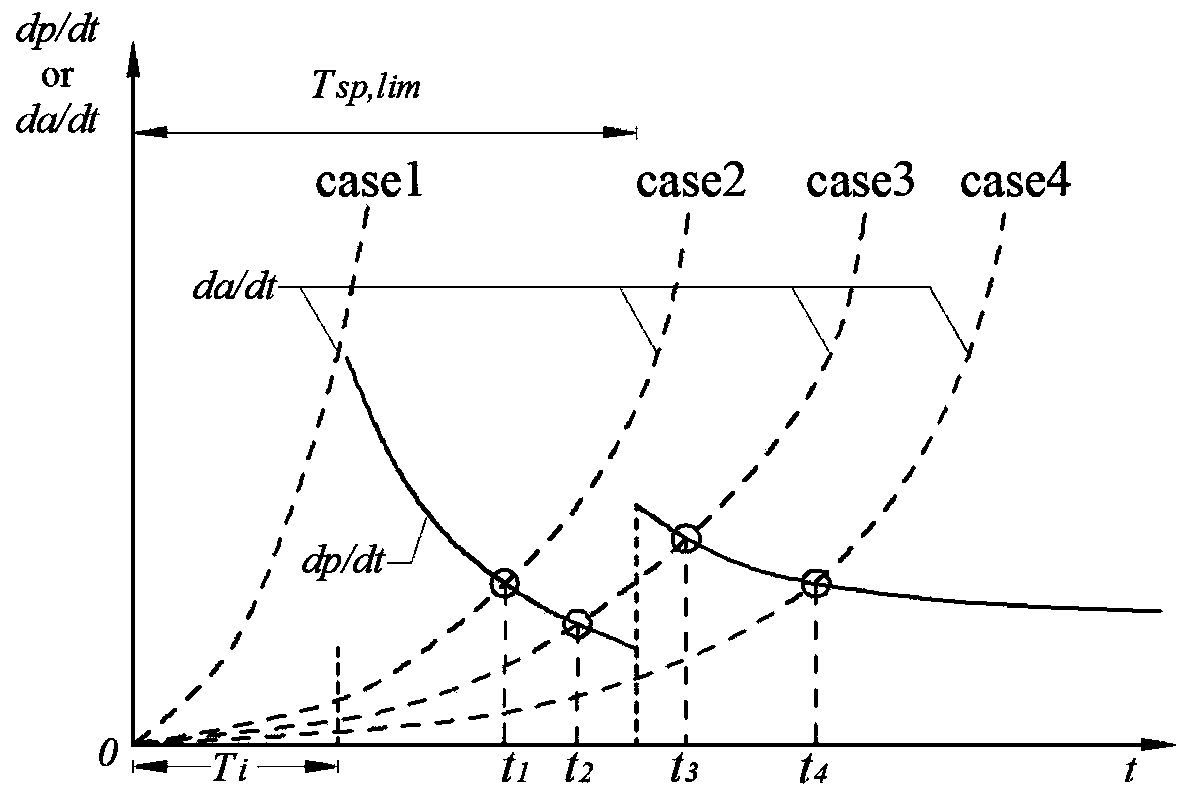

ActiveCN109827855AEnables corrosion fatigue life assessmentNovel forecasting methodWeather/light/corrosion resistanceMaterial testing goodsStress concentrationRebar

The invention discloses a method for predicting the service life of a reinforced concrete bridge under the conditions of seasonal corrosion and fatigue coupling. The method comprises the steps: dividing the service life of the reinforced concrete bridge into three stages: corrosion initiation-pure fatigue crack development stage, a rust pit and fatigue crack competing development stage and a structure failure stage; establishing an initial reinforcing steel bar corrosion model and a rust pit growth model based on the Fick second diffusion law and the consideration of the influence of concreterust expansion cracking damage; testing and simulating a reinforcing steel bar crack propagation rule under the influence of a four-season environment, and determining fatigue crack growth characterization parameters; constructing a stress intensity factor model considering the influence of stress concentration, and proposing a steel bar corrosion fatigue crack growth analysis method correspondingto a four-season environment; enabling the structural failure criterion to be clear, combining with the vehicle load observation information, performing the systematic consideration of the competitive coupling relation between rust pit growth and fatigue crack growth, judging a failure mode in real time, and achieving the prediction of the service life of the bridge. The method is novel and reasonable, and can provide technical support for safety assessment of the concrete bridge.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for monitoring of steel bar corrosion in real time

InactiveCN102445452AAvoid damageSolve monitoring problemsOptically investigating flaws/contaminationFiberRebar corrosion

The invention discloses a method for real-time monitoring of steel bar corrosion. The method comprises the following steps: (a) coating a layer of rust conversing paint on a surface of a steel pipe packaged fiber grating strain sensor and controlling a temperature in a coating environment at 0-40 DEG C and an air relative humidity at no more than 80%; (b) polishing a surface of a selected steel bar by a grinder to realize a flattening and smooth surface and keeping for usage; (c) pasting the steel pipe packaged fiber grating strain sensor obtained from the step (a) on a polished position of the steel bar to be used in the step (b); and (d) carrying out real-time monitoring on a wavelength drift amount by a fiber grating demodulator, meanwhile laying a steel pipe packaged fiber grating temperature sensor for monitoring change of temperature and completing temperature compensation. The invention can not only monitor early stage steel bar corrosion in a structure but also have good protection effect on the fiber grating sensor during a monitoring process and have strong realizability.

Owner:SHENYANG JIANZHU UNIVERSITY

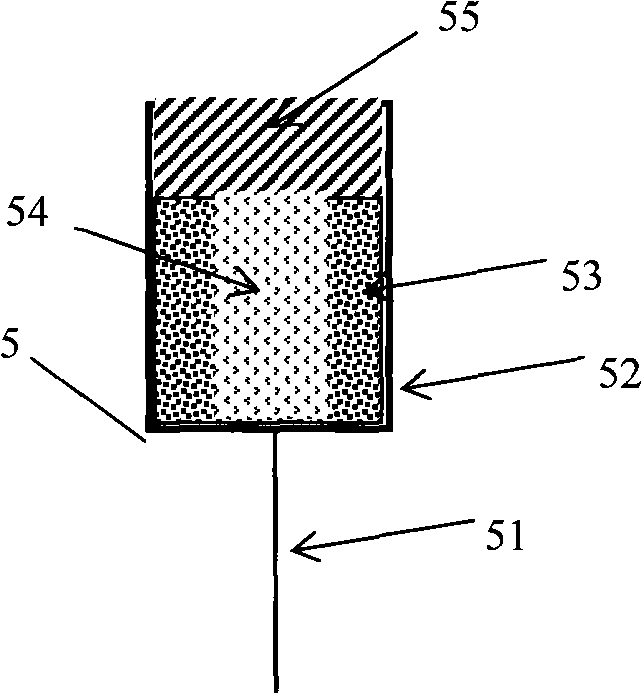

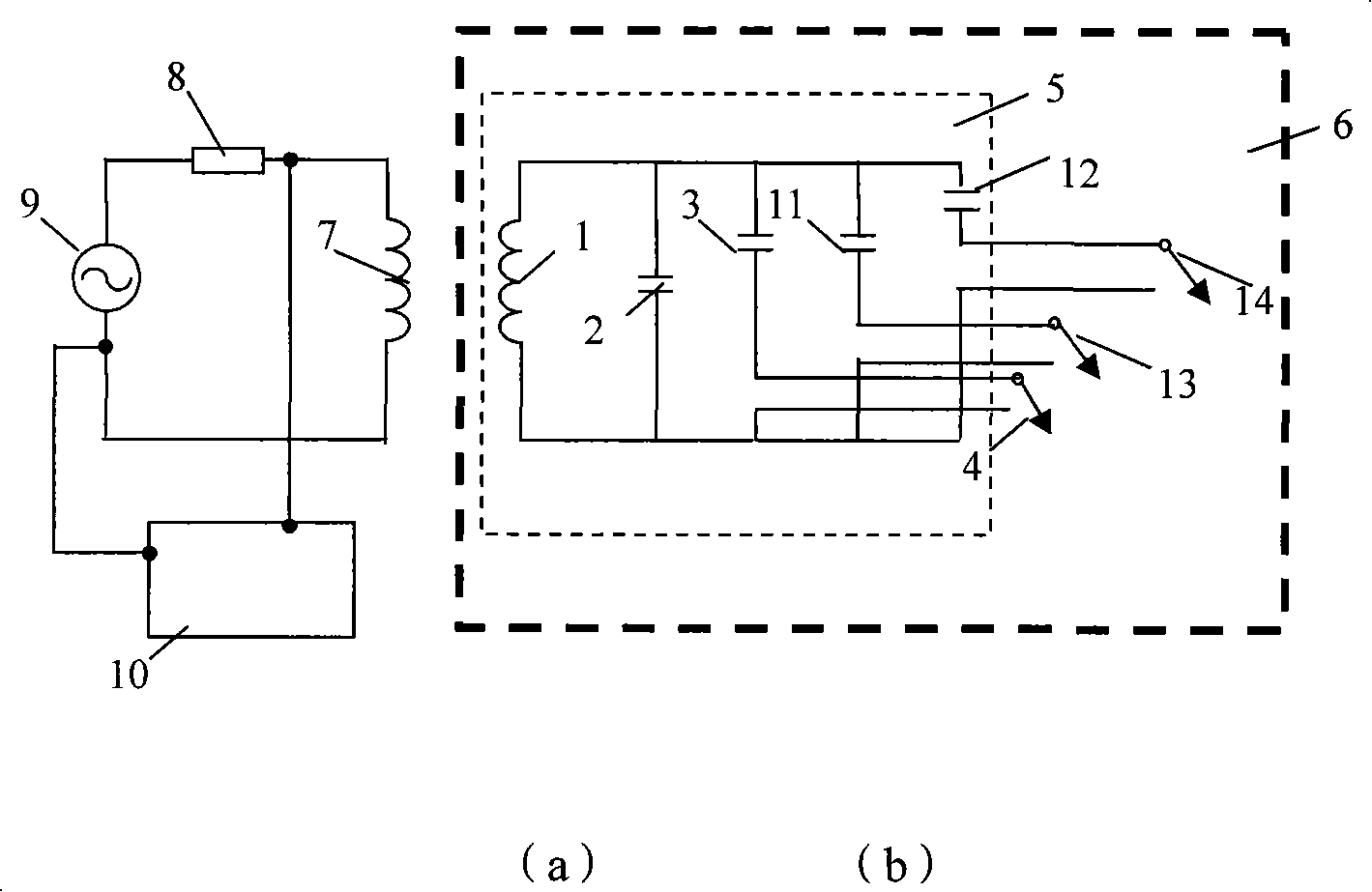

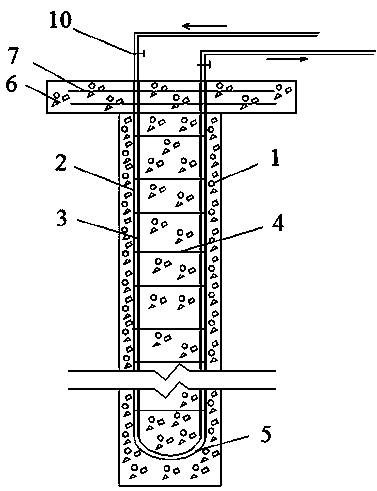

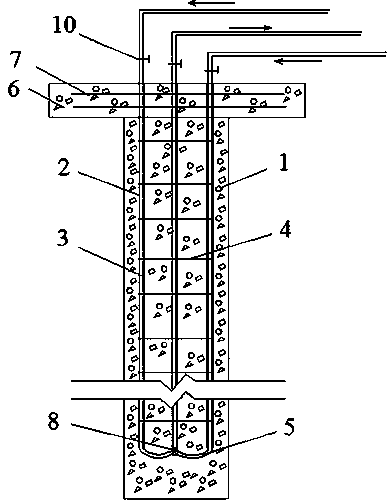

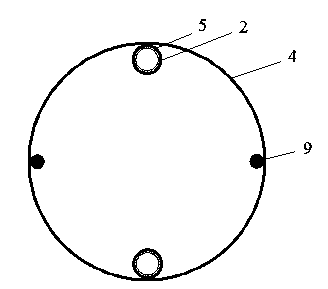

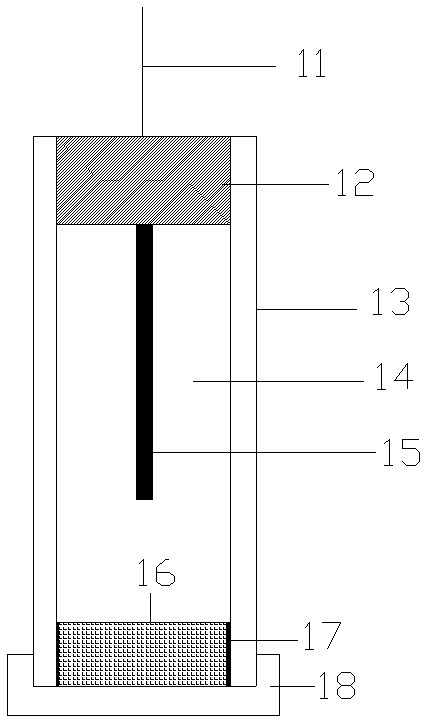

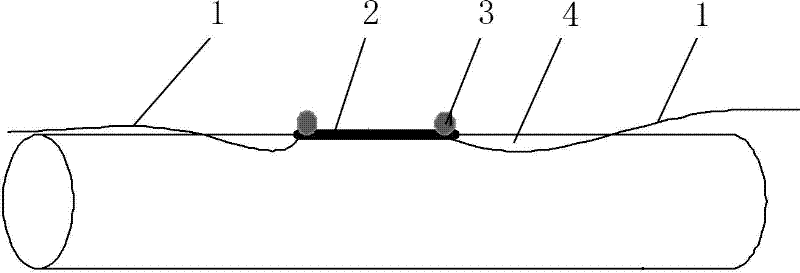

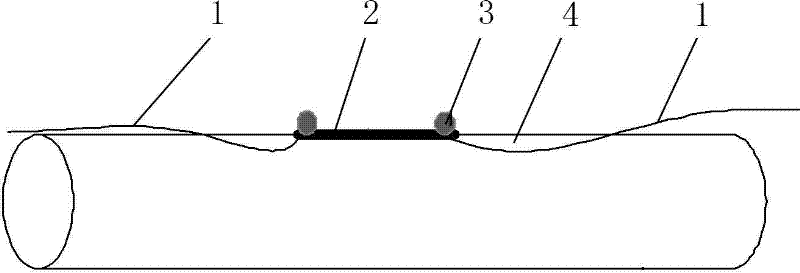

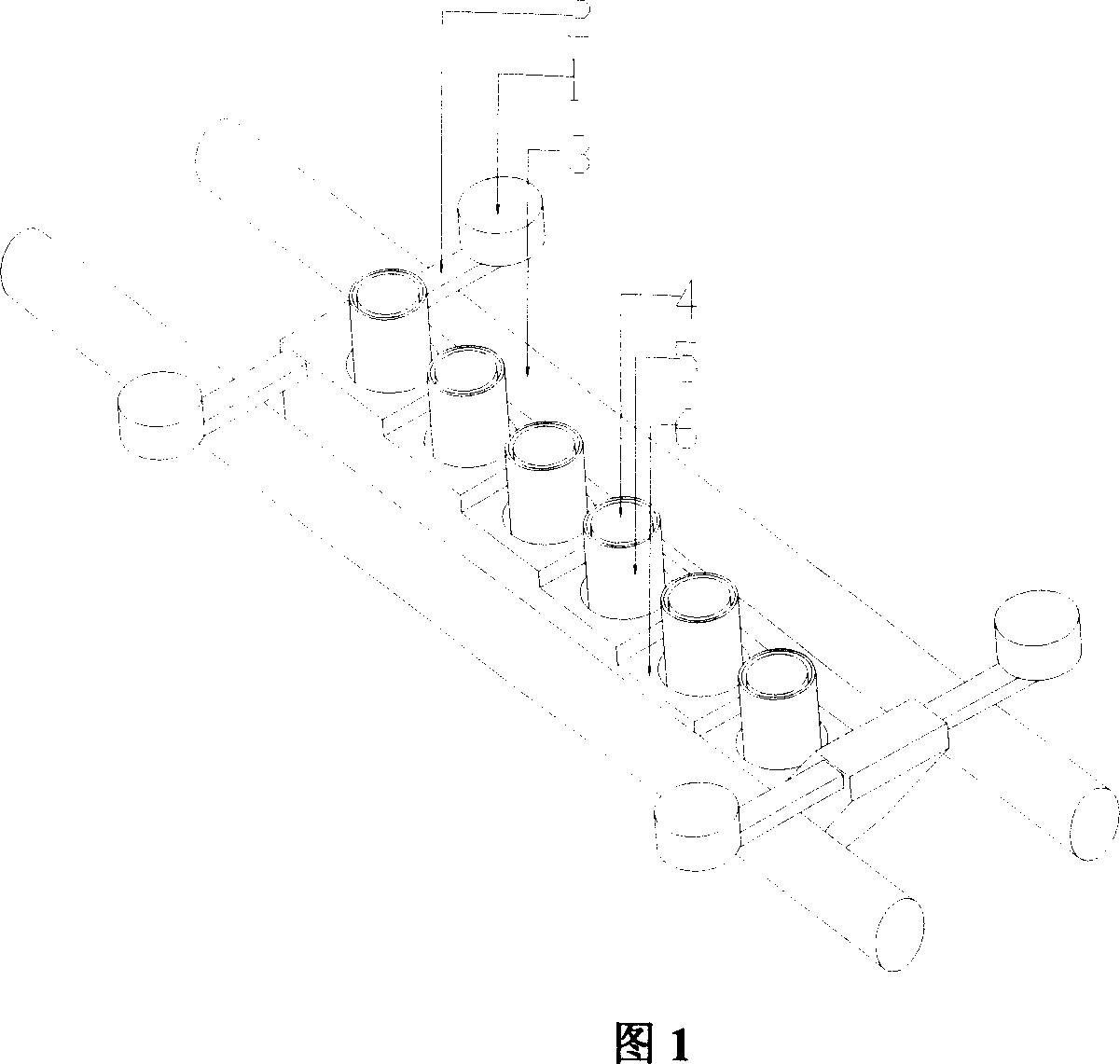

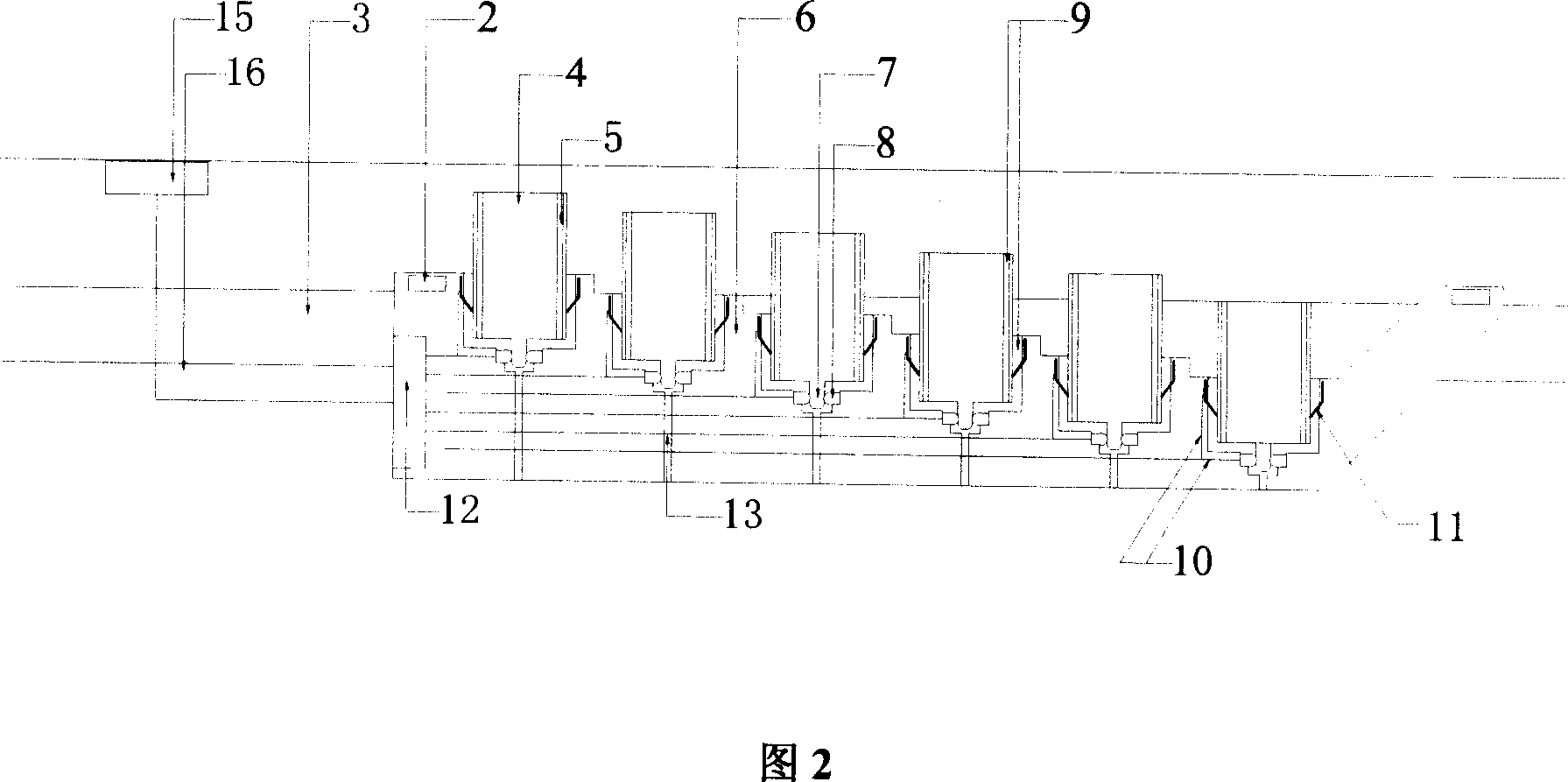

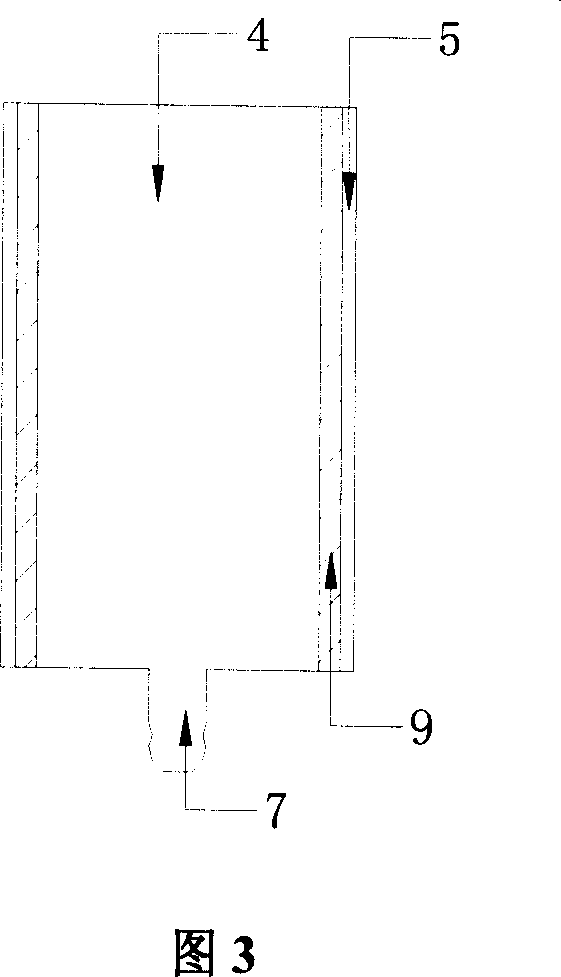

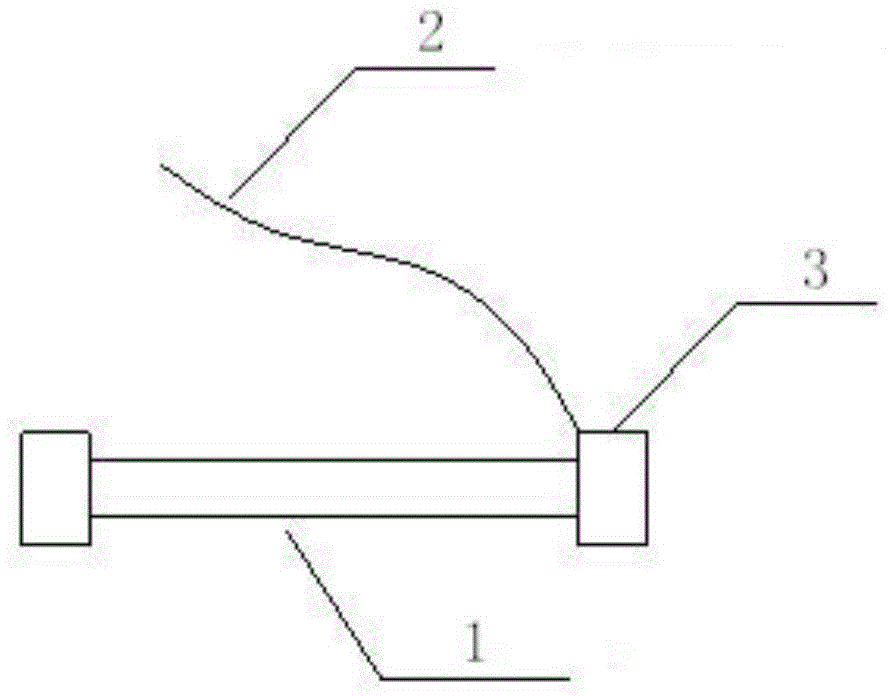

Long term monitoring sensor for steel bar corrosion in steel concrete member

InactiveCN1945278AEffective guardianshipReduce distanceWeather/light/corrosion resistanceMaterial electrochemical variablesRebar corrosionData acquisition

The long term monitoring sensor for corrosion of steel bar in steel concrete member consists of electrode rods in the same length, pedestal, wires and sacrificed anode. The electrode rods are fixed in the sensor pedestal in stepped form, and the wires are connected through leaf springs to the anode and cathode of the electrode rods. During construction, the monitoring sensor is embedded into the concrete for subsequent regular data acquisition. In the case of finding out corroded steel bar in some electrode rod, the steel bar is protected via the cathode protector. The present invention can perform non-destroying detection of the steel bars in different depth and determine the frontal surface distance of the invading corrosive medium.

Owner:SHANGHAI JIAO TONG UNIV

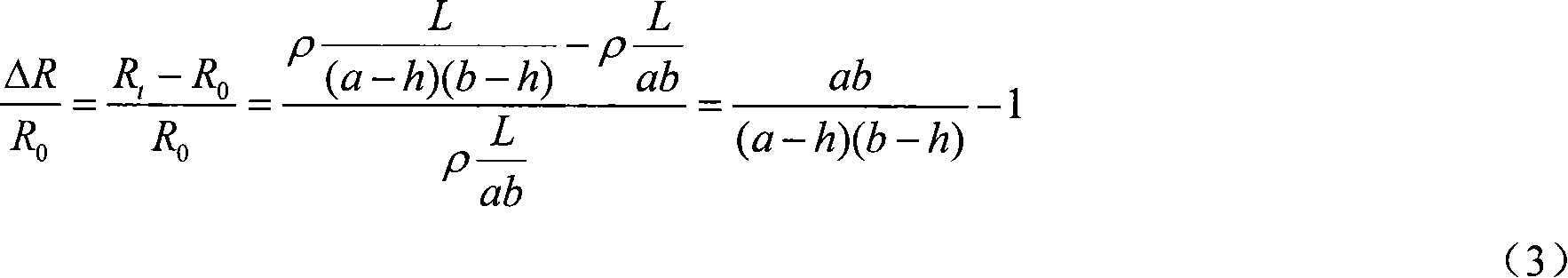

Steel reinforcement corrosion sensor and preparation method and its detection method for reinforcement corrosion

InactiveCN101216412ASimple structureLow costWeather/light/corrosion resistanceMaterial analysis by electric/magnetic meansRebar corrosionElectrical resistance and conductance

The invention provides a steel bar corrosion sensor with simple structure and lower cost, a preparation method thereof, and a steel bar corrosion detection method capable of accurately and nondestructively detecting the distance between a hazardous frontal surface and the steel bar in specific corrosion environment on the premise of not damaging concrete surface. The steel bar corrosion sensor comprises a base body and an extraction wire, wherein the base body has a spiral layered distribution in the vertical direction and is provided with longitudinal openings. The preparation method comprises removing screw thread of a steel bar, and cutting to obtain the base body; drilling holes at different heights on the base body; and connecting the extraction wire with the holes and sealing to obtain the steel bar corrosion sensor. The detection method comprises the following steps of: respectively arranging the sensors at different sections of a concrete component, periodically collecting data of the steel bar corrosion sensors at the different positions by a low-resistance tester within the service period of the concrete component, periodically measuring and recording, and determining the corrosion state of the steel bar to be detected to obtain the environmental corrosion condition of concrete.

Owner:XIAMEN UNIV

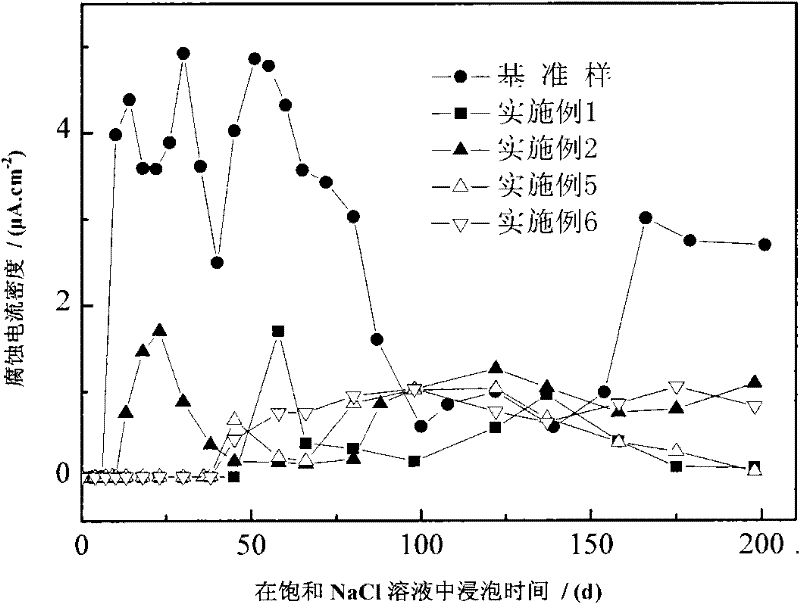

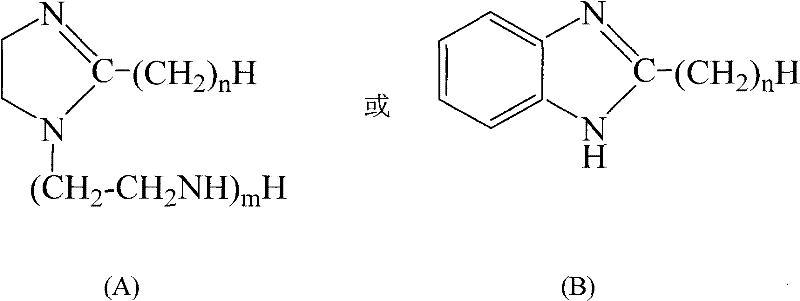

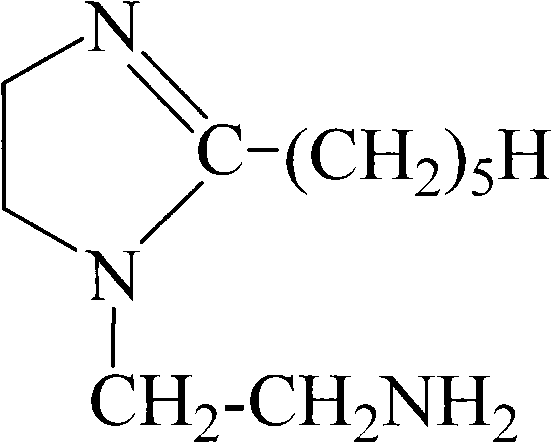

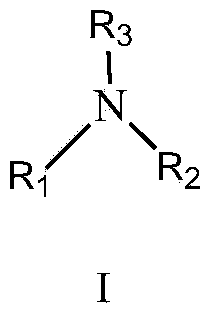

Doped all organic corrosion inhibitor for steel bar in concrete

The invention relates to the field of building materials, in particular to a doped all organic corrosion inhibitor for a steel bar in concrete. The corrosion inhibitor comprises the following components in percentage by weight: 5 to 30 percent of imidazoline derivative, 5 to 15 percent of organic alcohol, 0.3 to 1.5 percent of organic metal salt and 60 to 85 percent of water. During use, the corrosion inhibitor in recommended using amount is directly added into water to be dissolved and mixed, and the corresponding using amount of water when the concrete is poured is subtracted according to the proportion of the water in the components simultaneously; and the addition amount of the corrosion inhibitor is calculated in the amount of cement required by each cubic meter of concrete structure. The corrosion inhibitor can effectively reduce and slow down the corrosion of the steel bar in the concrete, reduces the damage of chloride ions to the surface passivation property of the steel bar so as to slow down the corrosion of the chloride ions to the steel bar, and can be widely applied to industrial and civil reinforced concrete buildings in offshore areas, harbors, wharfs and coastal areas.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

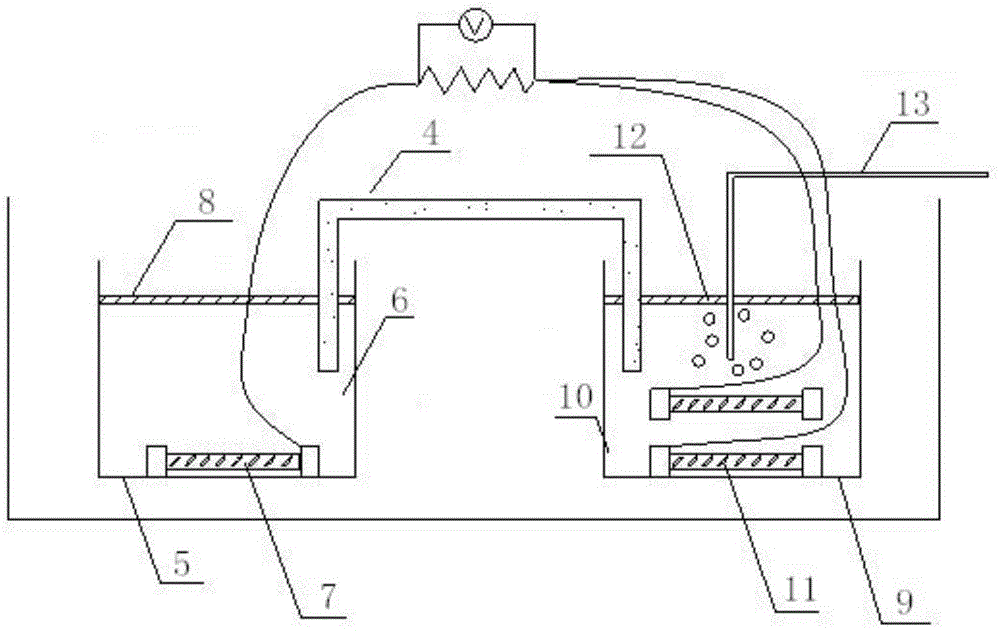

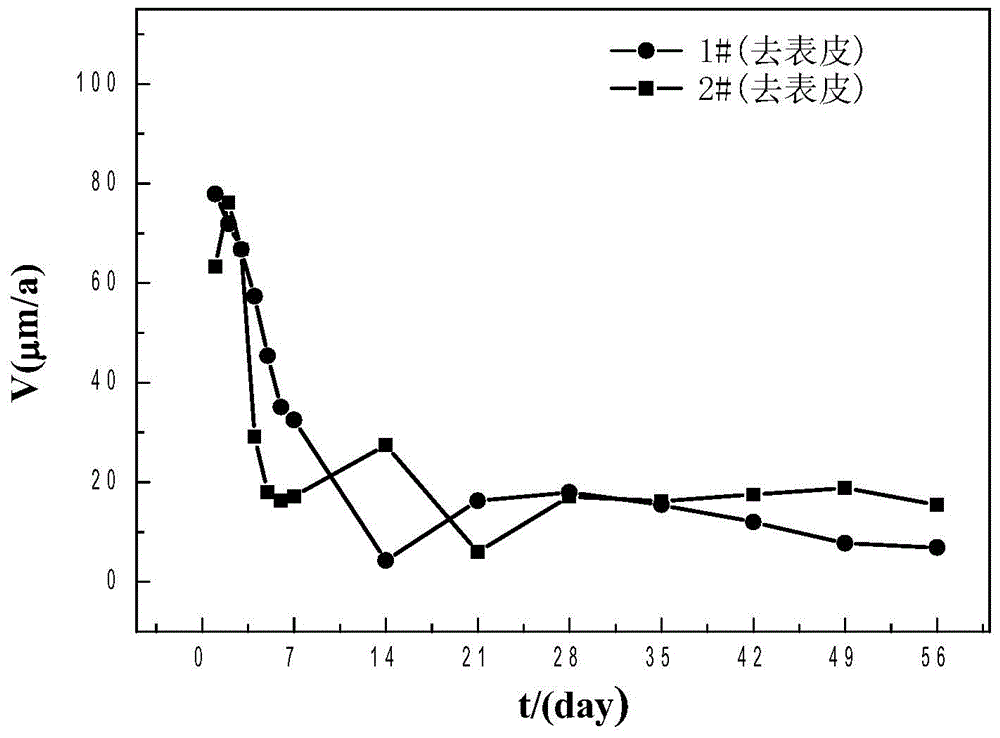

Experimental device and testing method for rapidly determining corrosion rate of reinforcing steel bars

ActiveCN104568732AProof of validityCrevice corrosion does not occurWeather/light/corrosion resistanceExperimental testingTest sample

The invention discloses an experimental device and a testing method for rapidly determining the corrosion rate of reinforcing steel bars. The method comprises the following steps: I, preparing a test sample; II, preparing a solution; III, establishing a device; IV, installing the test sample; and V, testing the test sample. The invention provides an experimental device and a testing method for rapidly determining corrosion rate of reinforcing steel bars by adopting a macro battery, no gap corrosion of the test sample in testing can be guaranteed, the experimental testing accuracy is high, the consistent testing results can be shown by performing electrochemical linear polarization testing to the reinforcing steel bars and service environment sample feeding testing to reinforcing steel concrete test samples, and the efficiency of the testing method can be effectively proven.

Owner:NANJING IRON & STEEL CO LTD

Methods of preventing corrosion

ActiveUS20090020186A1Avoid corrosionInhibiting corrosion in the cooling systemFireproof paintsAntifouling/underwater paintsRebar corrosionPre treatment

The invention provides a method for pre-treating a metal surface with a corrosion inhibitor prior to painting, a method for inhibiting corrosion in a cooling system, wherein the cooling system includes a metal surface and a coolant; and a method for inhibiting corrosion of a reinforcement steel in concrete wherein the method comprising the step of adding to a concrete mixture an anti-corrosive mixture.

Owner:PIGMENTAN

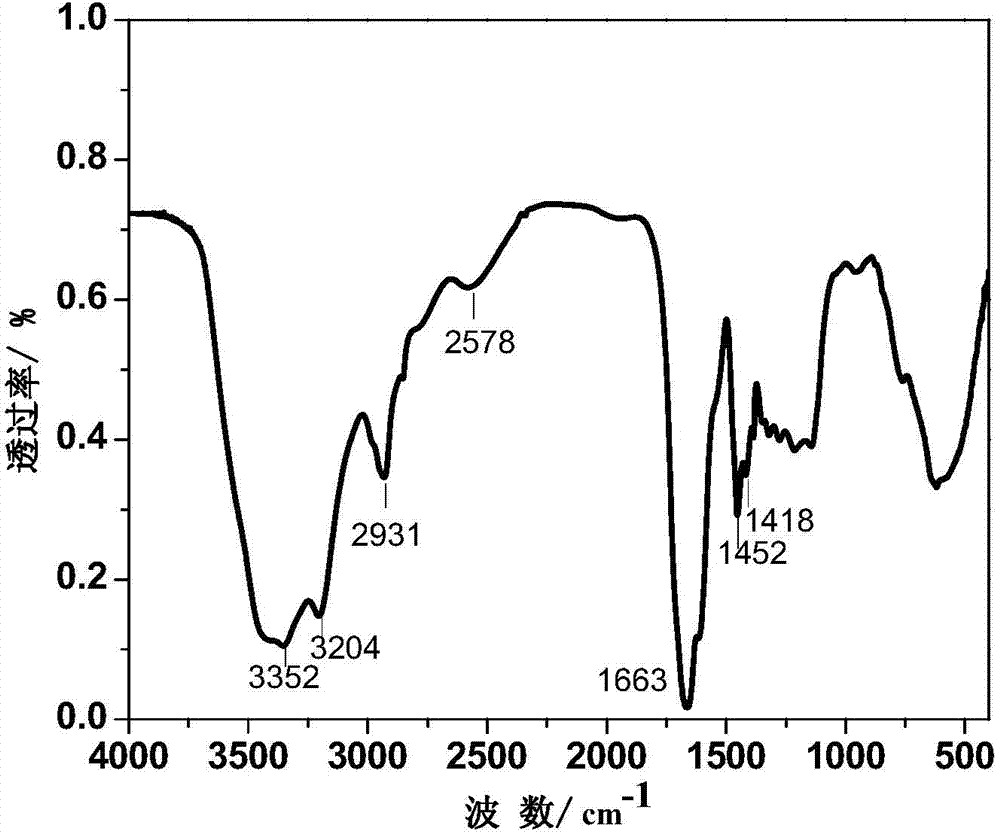

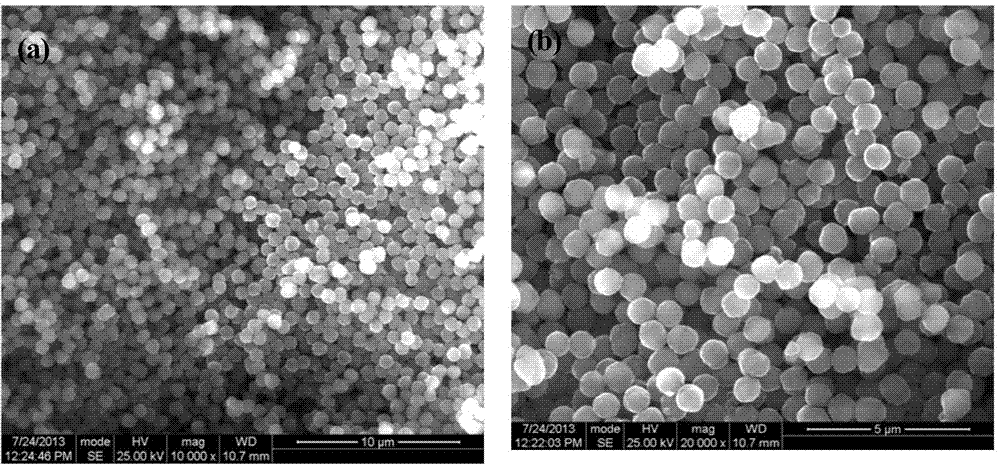

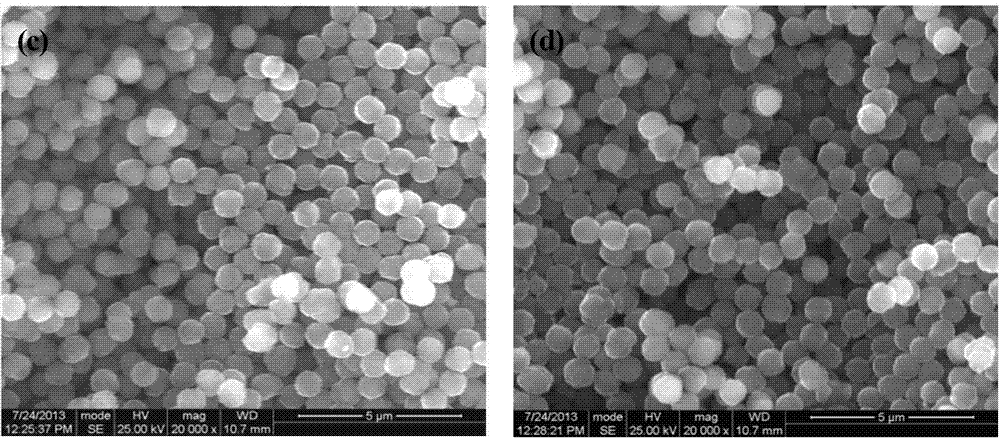

Corrosion inhibitor gel microsphere with intelligent pH value controlled release function and its preparation method and use

InactiveCN104725563AQuick Response FeaturesSignificant volume swelling behaviorPh controlMicrosphere

The invention discloses a corrosion inhibitor gel microsphere with an intelligent pH value controlled release function and its preparation method and use. A polyelectrolyte with a fast environment pH value response rate is used as a coating material and through one-step polymerization, the corrosion inhibitor gel microsphere with an environment pH controlled release function is prepared. The preparation method comprises that acrylic acid (or methacrylic acid), acrylamide (or methacrylamide) and N-N-methylene bisacrylamide (MBA) as raw materials undergo a solution deposition polymerization reaction to produce the corrosion inhibitor gel microsphere with an environment pH controlled release function. The corrosion inhibitor gel microsphere has submicron particle size, structured morphology, smooth surface, even size, good monodispersity, high drug loading amount and a fast environment pH change response rate. The corrosion inhibitor gel microsphere has wide application prospects in the fields of a corrosion system with large system pH fluctuation, self-repairing anticorrosion coating preparation and concrete reinforcement corrosion protection.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

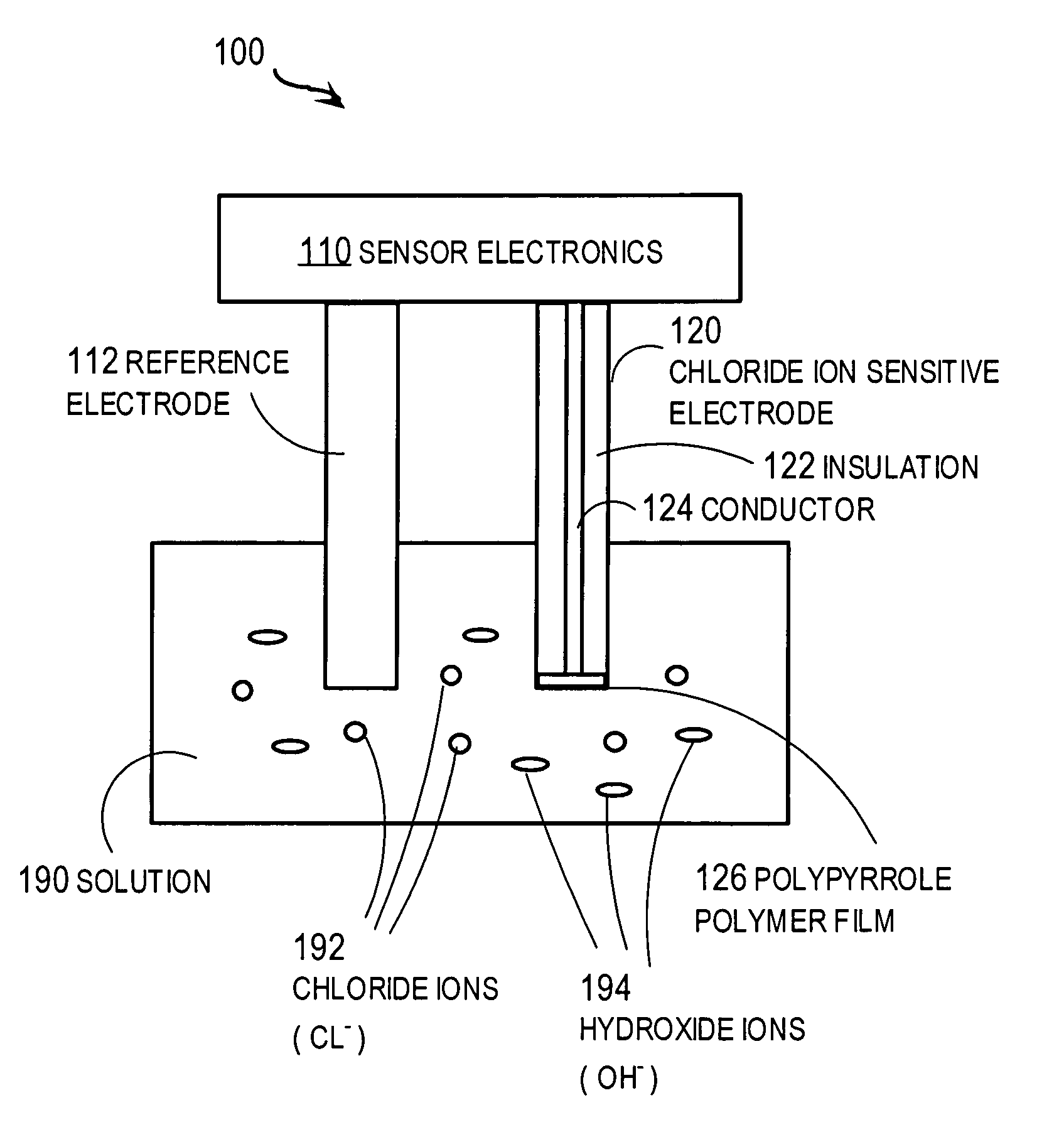

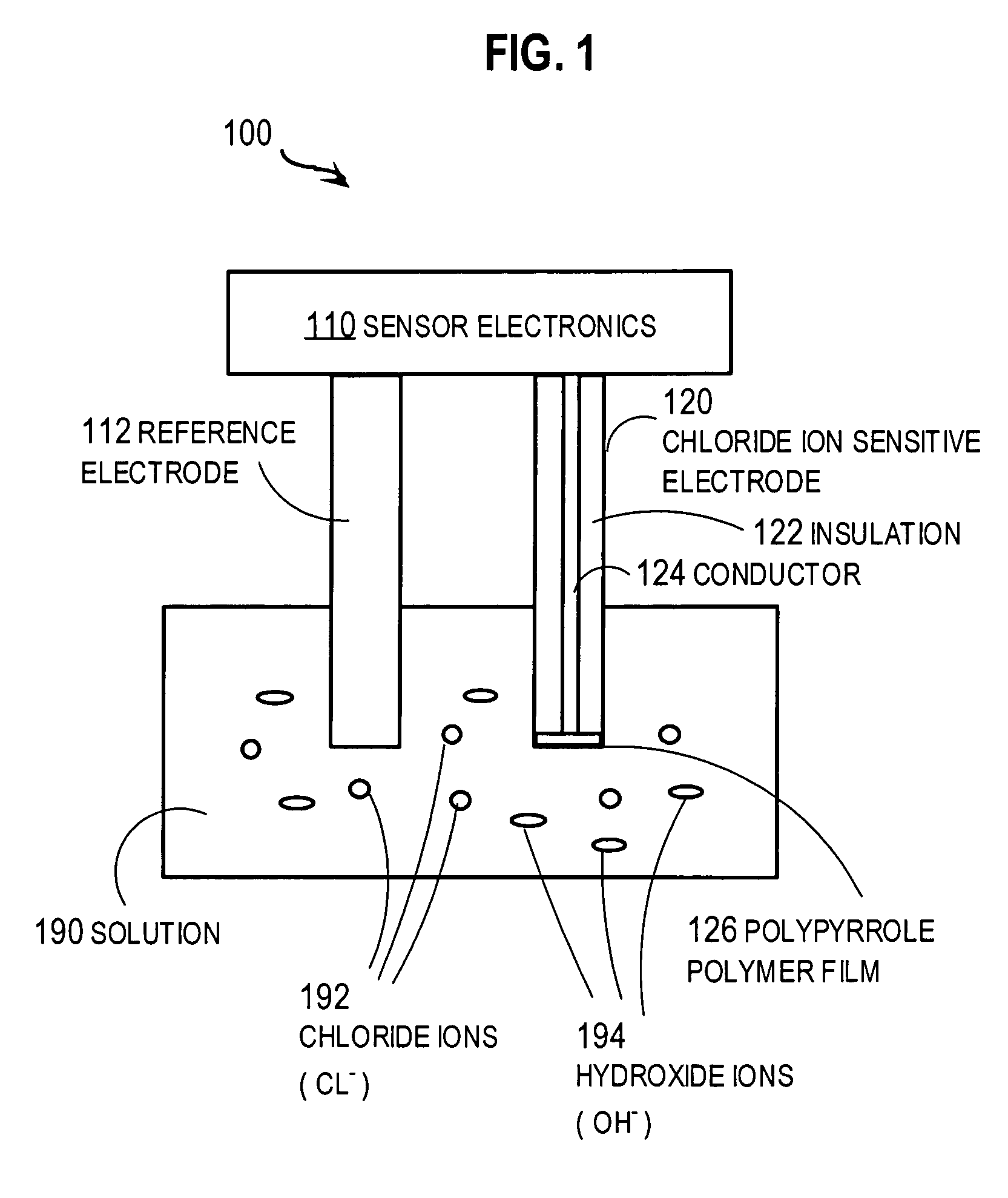

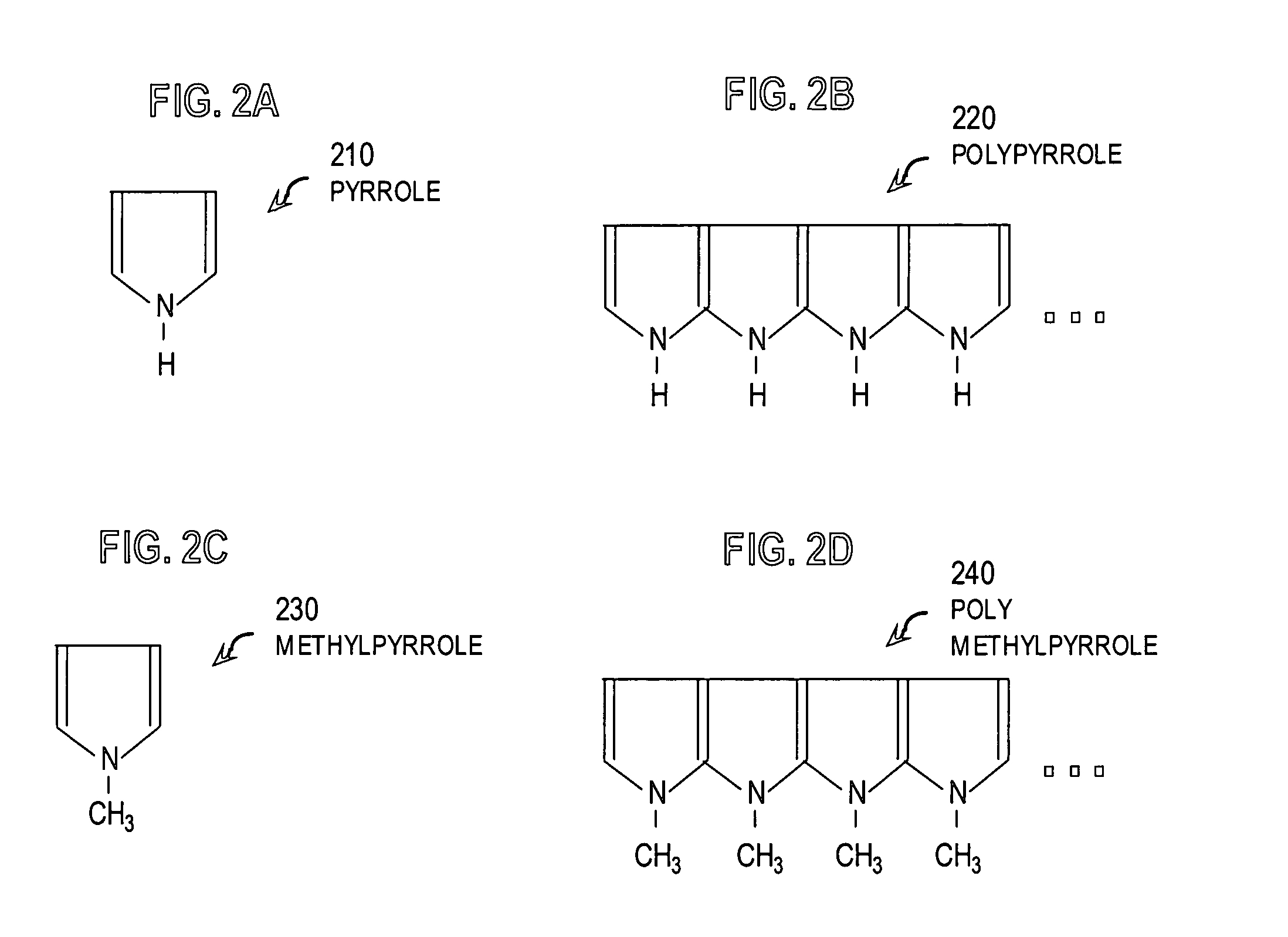

Techniques for sensing chloride ions in wet or dry media

InactiveUS7063781B2Electrolysis componentsWeather/light/corrosion resistanceRebar corrosionConductive polymer

Techniques are provided for measuring chloride ion concentration in a medium. The techniques allow measurements to be made in dry or alkaline media, or both. For alkaline conditions, a sensor includes a pair of electrodes and a polymer film imprinted for uptake of chloride ions under alkaline conditions. The film is deposited to be in contact with at least one electrode and the medium. For dry conditions, a sensor includes a pair of electrodes and a conductive polymer film imprinted for uptake of chloride ions. The film is in contact with the pair of electrodes, and is positioned for contact with the medium. An electrical conductivity of the film depends on an amount of chloride ions taken up by the film. Some techniques allow chloride ion measurements over years at sensors embedded in concrete. Such measurements allow the determination of the progress of rebar corrosion in concrete infrastructure.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

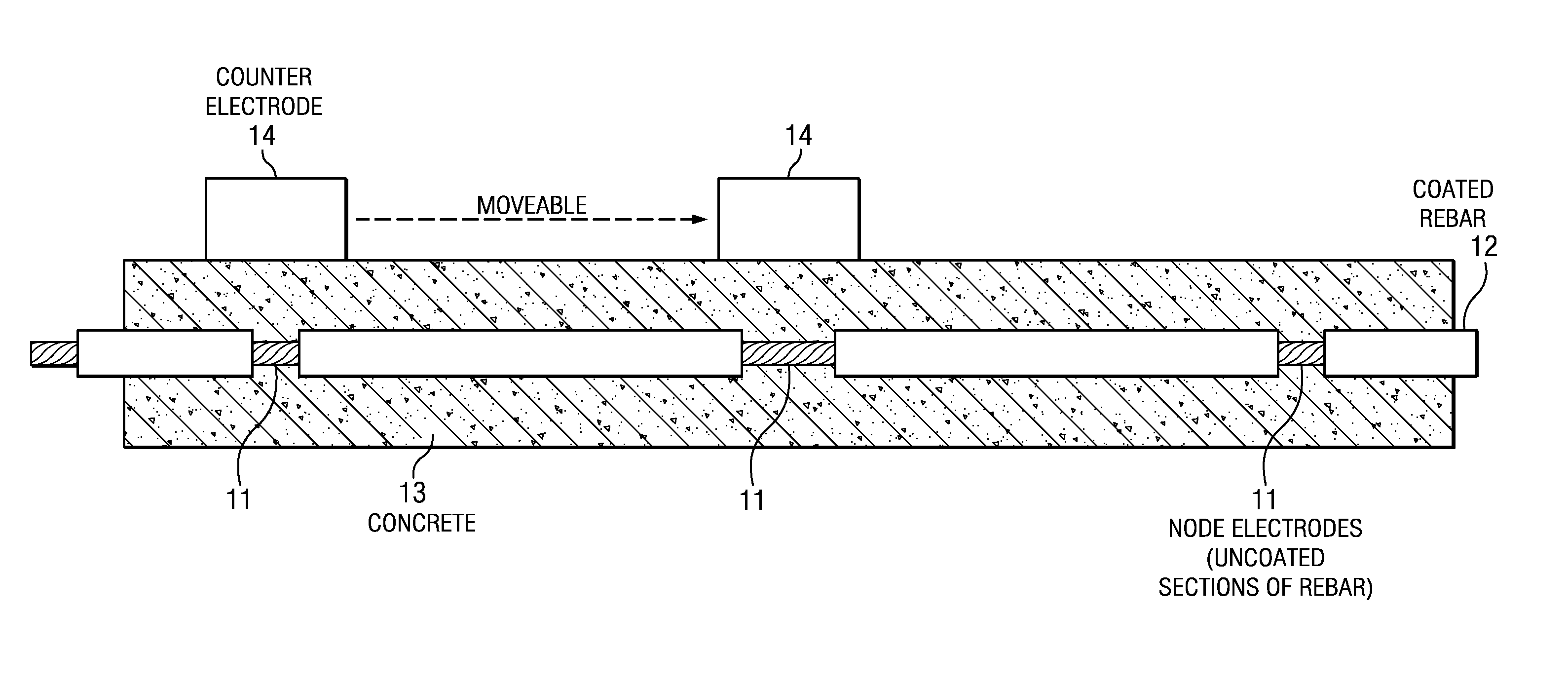

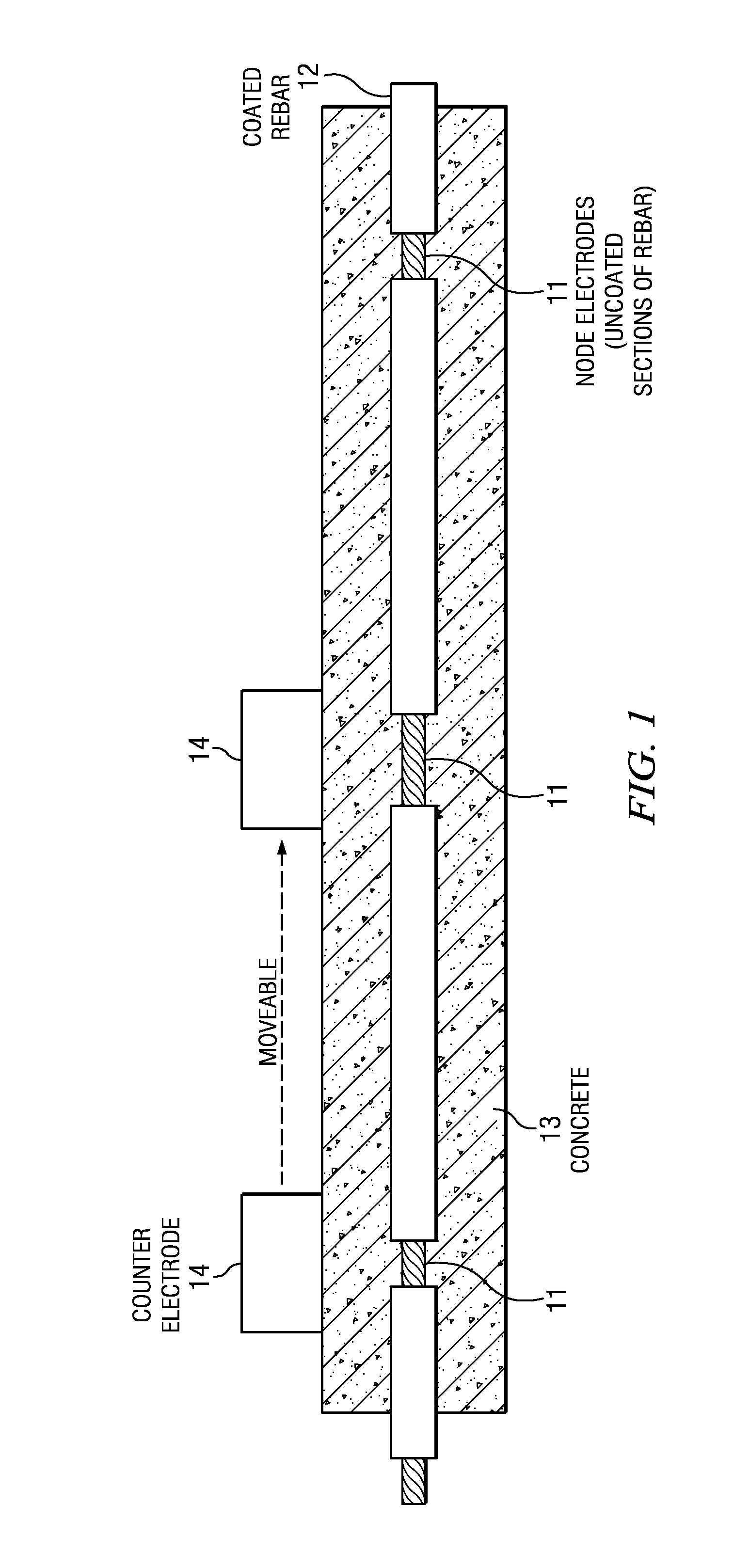

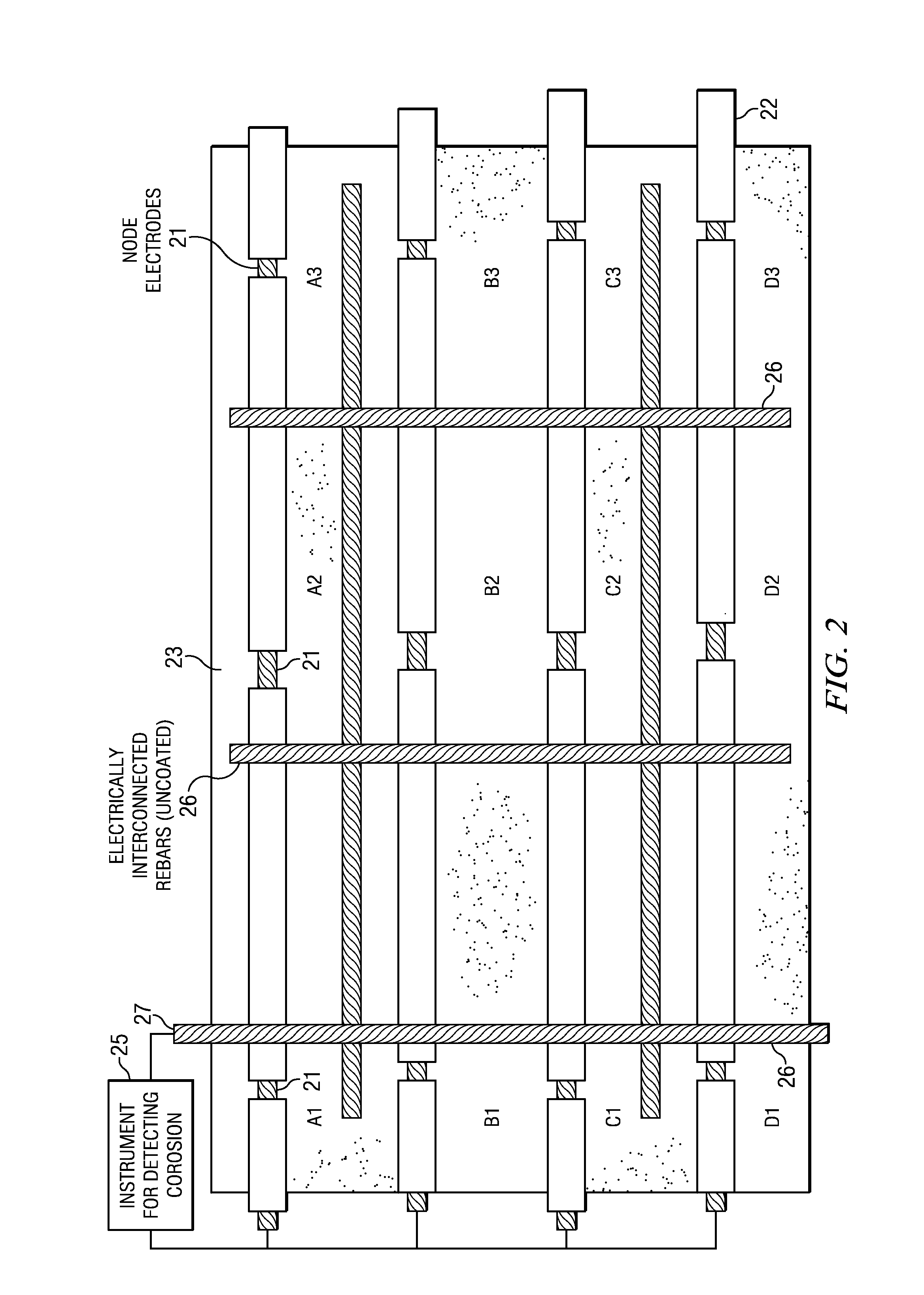

Corrosion Monitoring of Concrete Reinforcement Bars (Or Other Buried Corrodable Structures) Using Distributed Node Electrodes

ActiveUS20120043981A1Weather/light/corrosion resistanceResistance/reactance/impedenceElectricityStructure of the Earth

Systems and methods for real time detection of corrosion of rebars embedded in a concrete structure. Test bars are selected for corrosion testing purposes, and may or may not also be part of the concrete reinforcement structure. These test bars are coated, and exposed sections of these test bars form a network of node electrodes. Electrical measurement from a counter electrode near a node electrode provides an indication of corrosion at that node electrode. Using a system of node electrodes and counter electrodes, a large concrete area may be monitored, and if corrosion is indicated, a methodical selection of electrodes can be used to locate the corrosion. The same concepts may be applied to detect corrosion in buried structures, such as pipelines and tanks.

Owner:SOUTHWEST RES INST

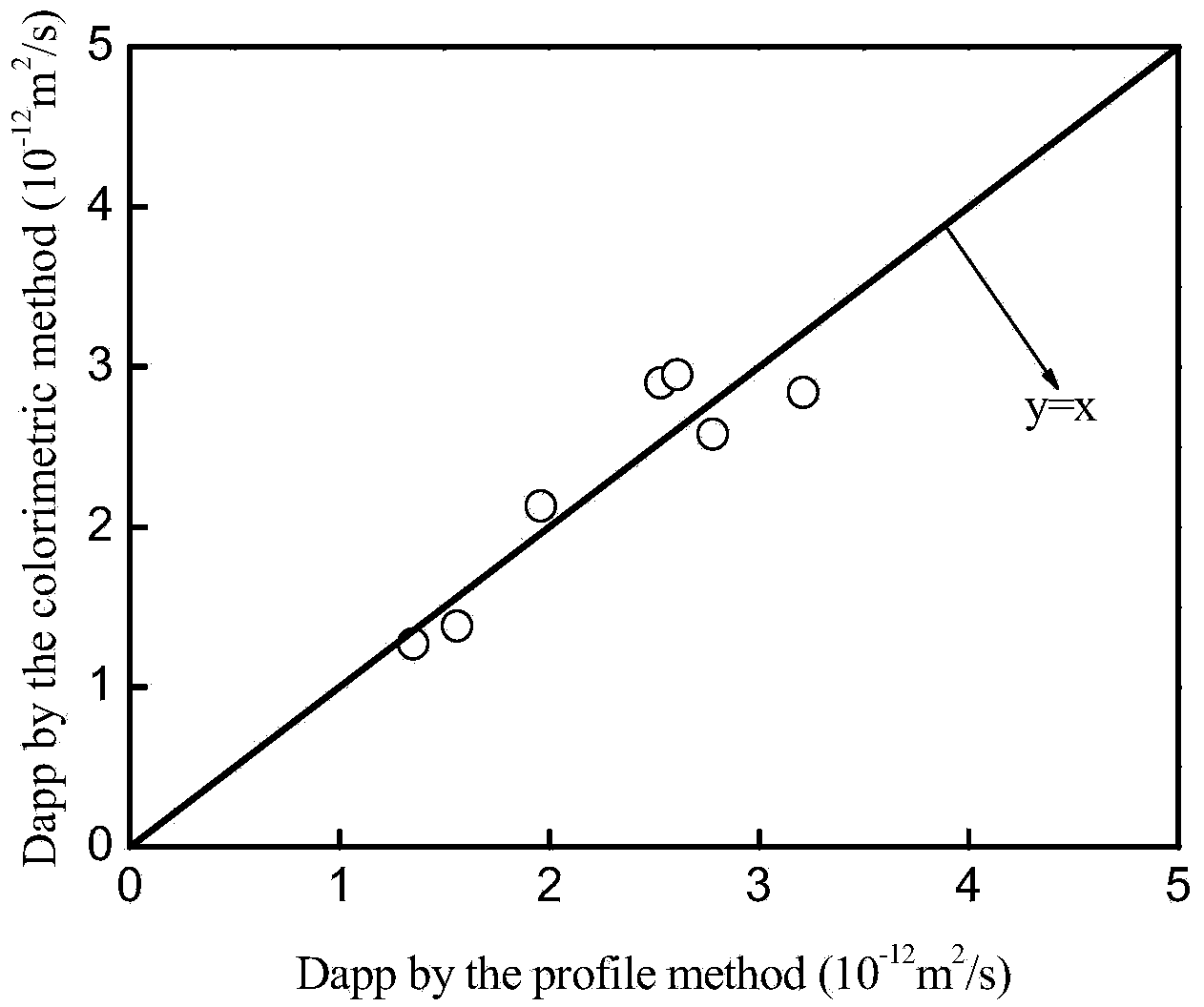

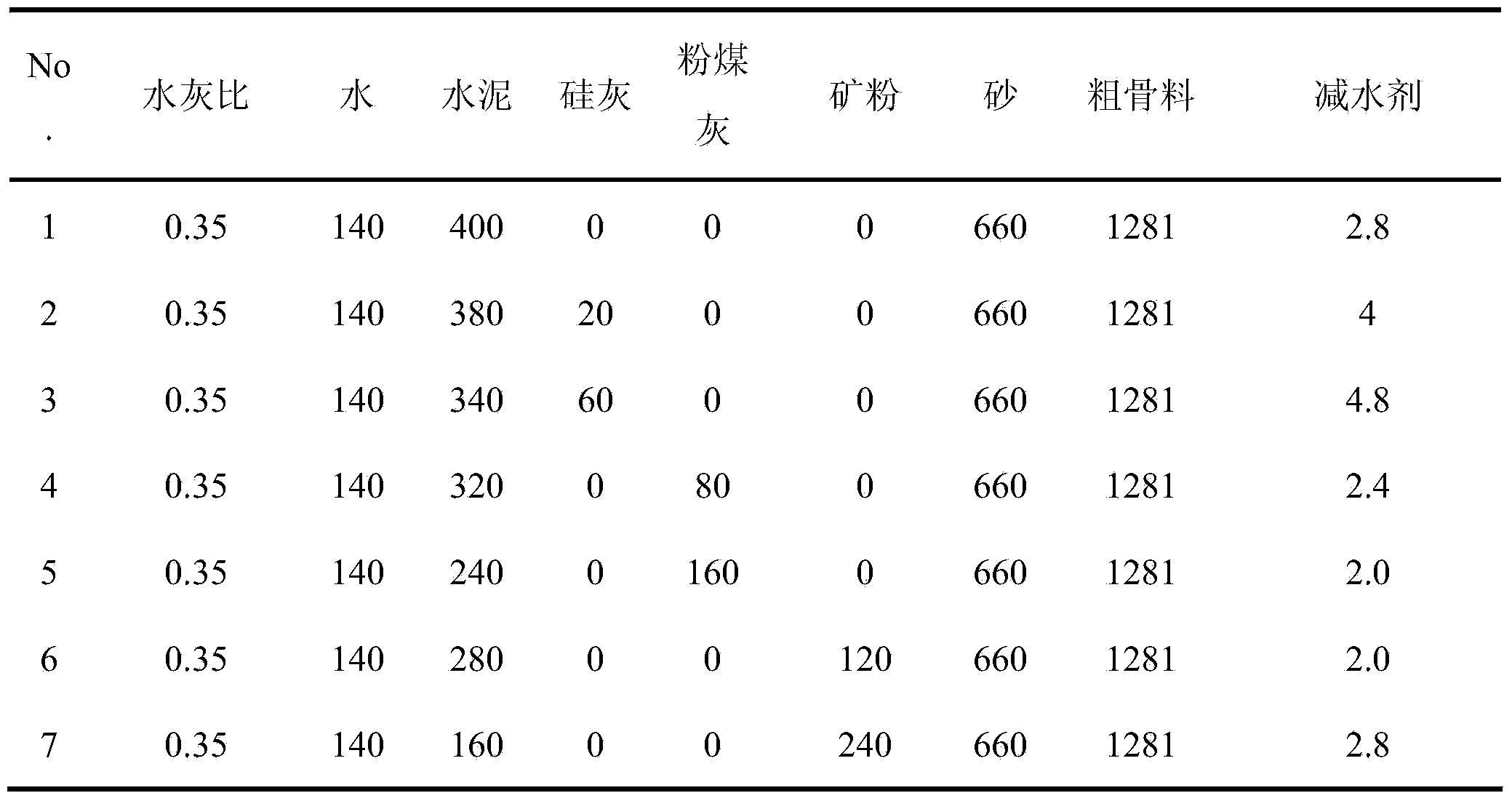

Method for measuring migration depth and apparent migration coefficient of chloride ions in concrete

The invention discloses a method for measuring the migration depth and the apparent migration coefficient of chloride ions in concrete. The method comprises the following steps: selecting a cylindrical test piece by performing core-drilling on a concrete structure to be detected; horizontally arranging the selected cylindrical test piece, splitting the cylindrical test piece along the direction parallel to a penetration surface until the test piece is completely split; spraying 0.05 to 0.2N silver nitrate solution by a vertical section spraying method, wherein the spraying amount is 200 to 400 ml / m<2>, and the ambient temperature is controlled to be 20 to 25 DEG C; after the silver nitrate solution is sprayed for 10 to 40 minutes, drawing a color-changing boundary clearly by using a fountain pen, testing a color-changing depth value every 0.5 to 2cm, and averaging the tested color-changing depth values; according to the obtained color-changing depth value, the Fick's second law, and the water-cement ratio of the concrete, selecting the concentration of the chloride ions at the color-changing boundary, and calculating an apparent diffusion coefficient, wherein the limit chloride ion concentration of the corrosion of a reinforcing steel bar can be used for calculating the remaining life of a detected object.

Owner:HUNAN UNIV

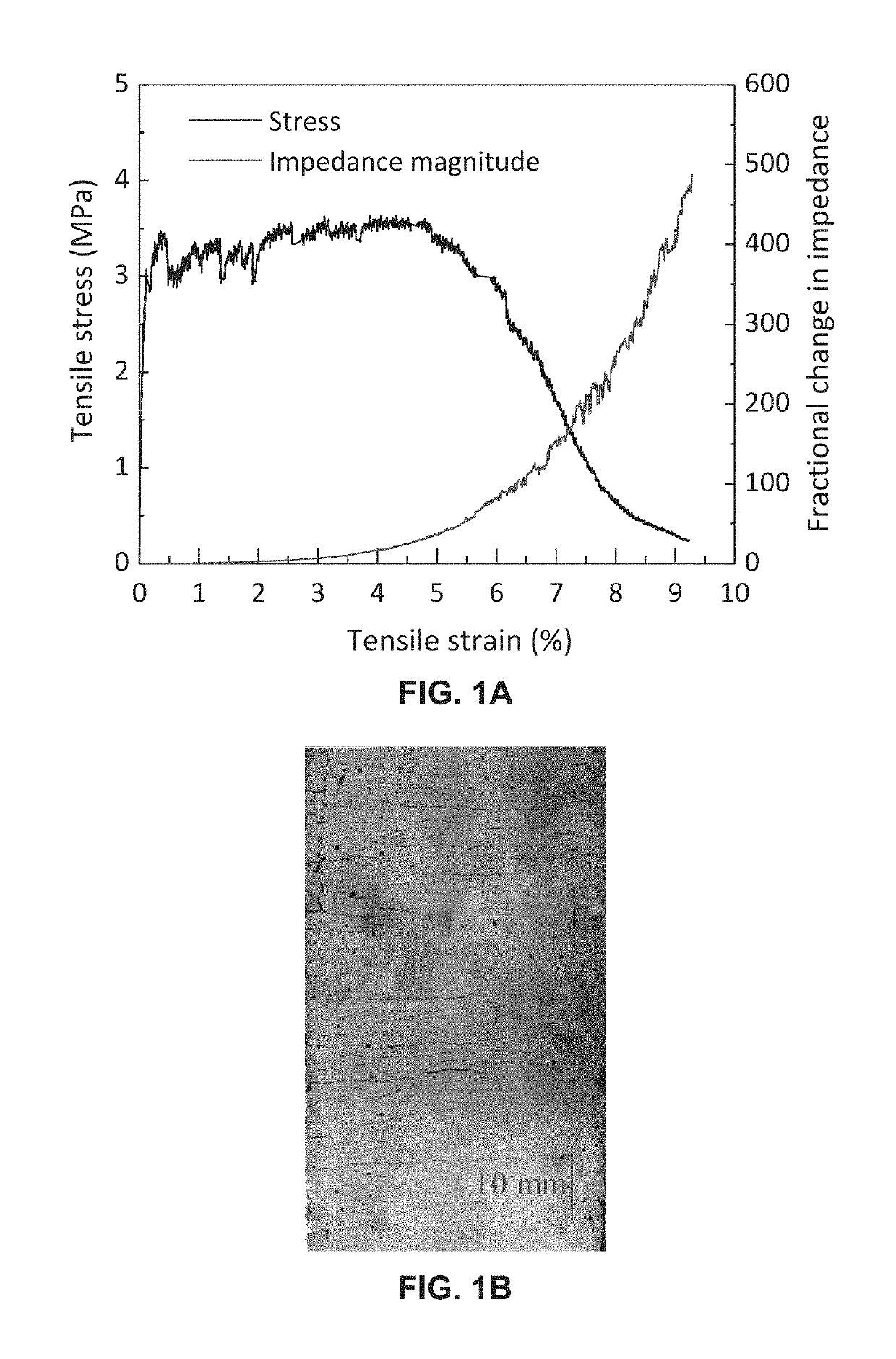

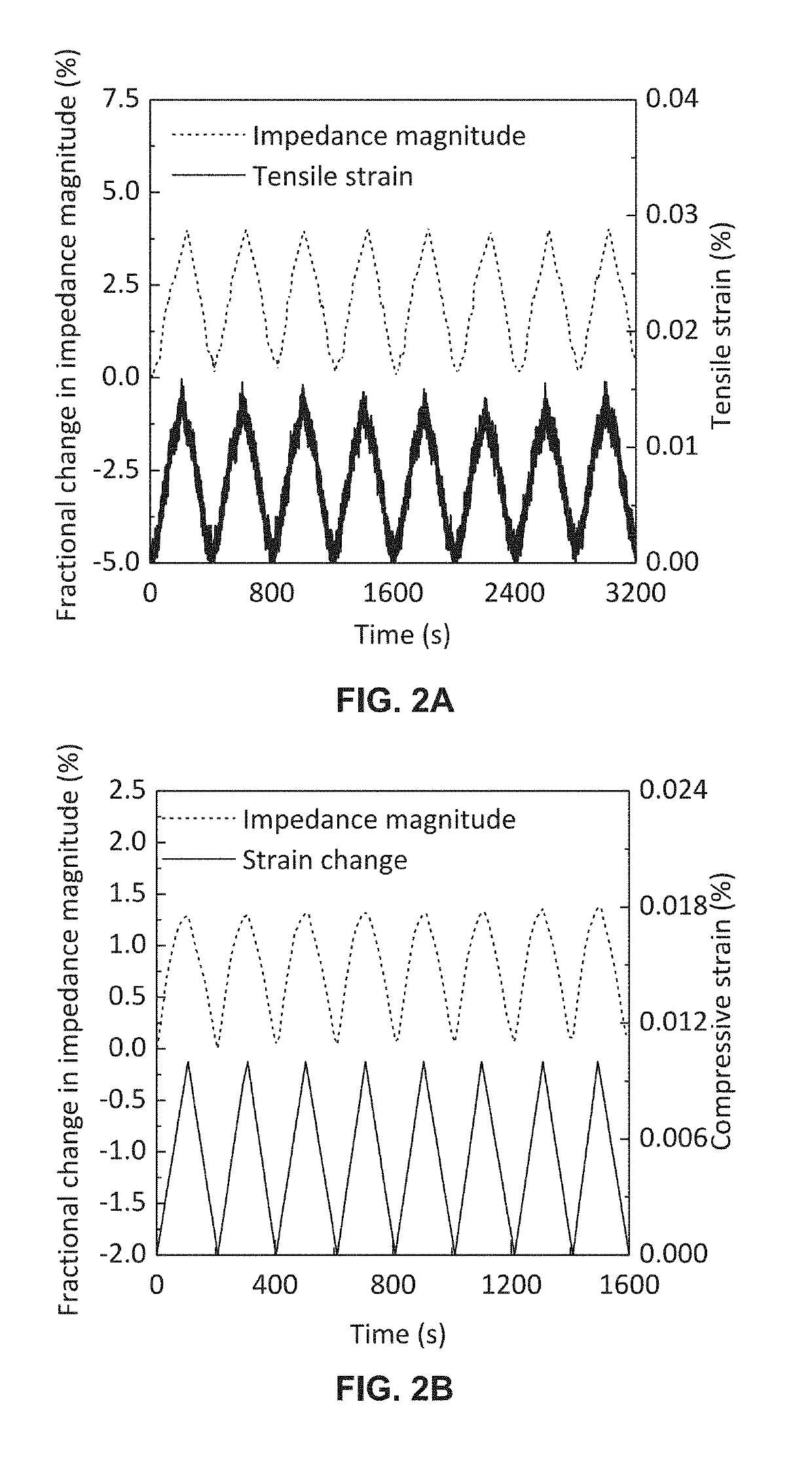

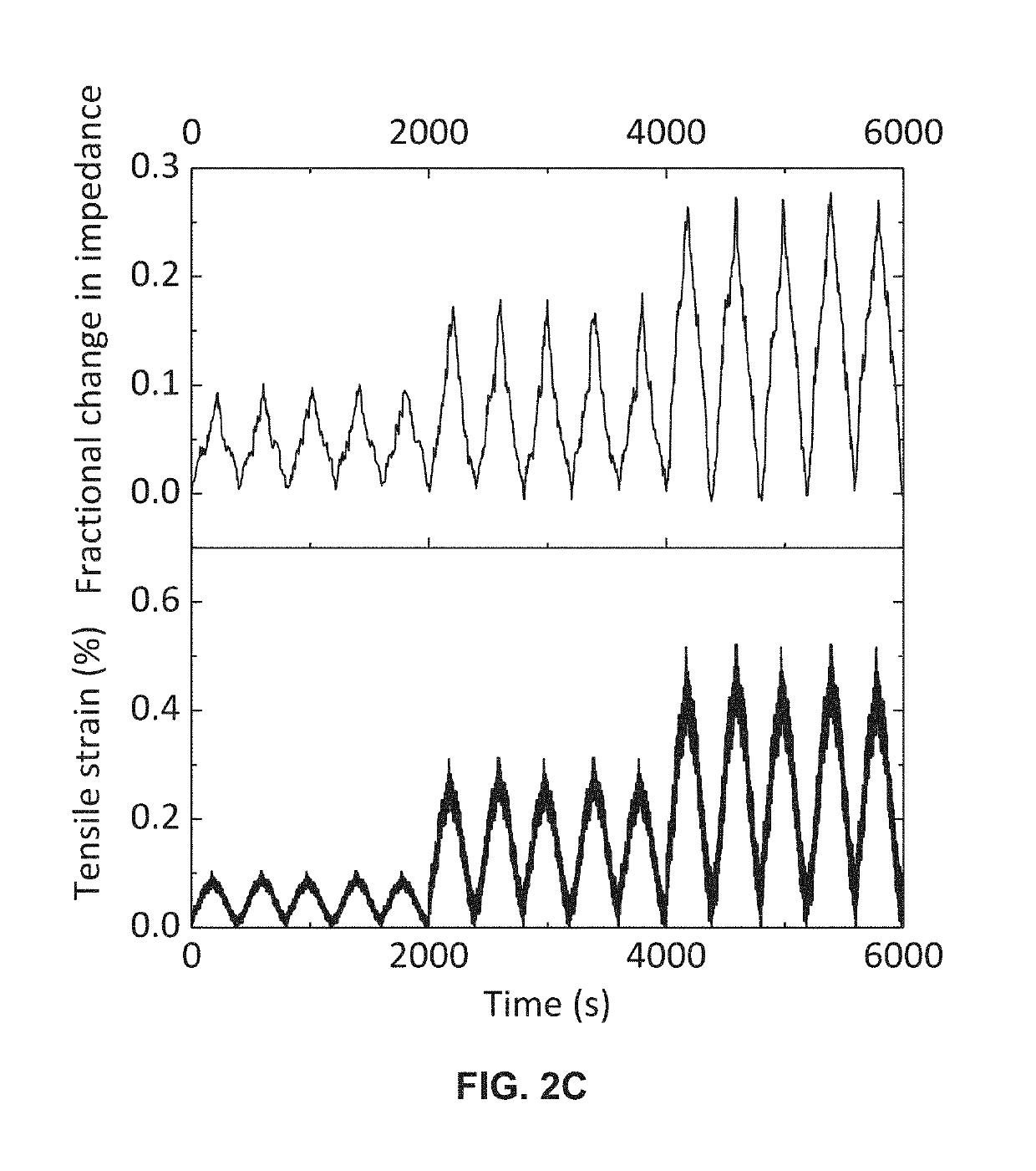

Multi-functional cementitious materials with ultra-high damage tolerance and self-sensing ability

PendingUS20190202738A1Large tensile ductilityLarge fracture energySolid waste managementCeramicwareDamage toleranceRetrofitting

Cementitious materials having high damage tolerance and self-sensing ability are described herein. These materials may replace conventional concrete to serve as a major material component for infrastructure systems with greatly improved resistance to cracking, reinforcement corrosion, and other common deterioration mechanisms under service conditions, and prevents fracture failure under extreme events. These materials can also be used for the repair, retrofitting or rehabilitation of existing concrete structures or infrastructure systems. Furthermore, these materials may offer capacity for distributed and direct sensing of cracking, straining and deterioration with spatially continuous resolution wherever the material is located, without relying on installation of sensors. The present invention relates to multifunctional cementitious structural or infrastructure materials that integrate self-sensing with damage tolerance for improving safety, extending service life, and health monitoring of structures, components, and infrastructure systems.

Owner:RGT UNIV OF CALIFORNIA

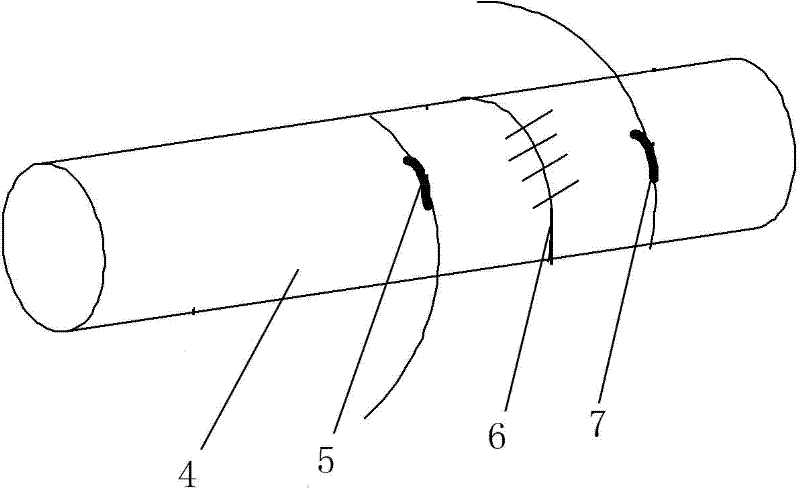

Method for optical fiber sensing monitoring of steel reinforcement corrosion

InactiveCN106918550AAvoid damageImprove accuracyWeather/light/corrosion resistanceUsing optical meansGratingRebar

The invention belongs to the technical field of steel reinforcement corrosion monitoring, and relates to a method for optical fiber sensing monitoring of steel reinforcement corrosion. The method comprises the following steps: making an optical fiber sensing monitoring device, and monitoring the steel reinforcement corrosion condition. A strain measuring grating and a temperature compensation grating are laid in the same step manner, the optical fiber sensor monitoring device and a monitored steel reinforcement are simultaneously poured in a concrete structure to avoid external interference and damages to a corresponding variable fin, the step-shaped optical fiber sensor monitoring device can monitor the corrosion condition of the steel reinforcement with different depths in the concrete structure, the corrosion time and the corrosion degree of the steel reinforcement with different depths are analyzed to know the corrosion time and the corrosion degree of a steel reinforcement to be monitored in the reinforced concrete structure, and bolts with different lengths are selected to control the inclination of the optical fiber sensing monitoring device to realize the real-time and long-term online monitoring of the steel reinforcement corrosion in the concrete structure with different protection layer thicknesses. The method has the advantages of enlargement of the application range, scientific and reliable principle, and accurate and reliable monitoring result.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method for examining corrosion of a steel reinforcement rod embedded in concrete

InactiveUS20060049341A1Improve accuracyIncreased sensitivityRadiation pyrometryMaterial analysis by optical meansGratingFiber Bragg grating

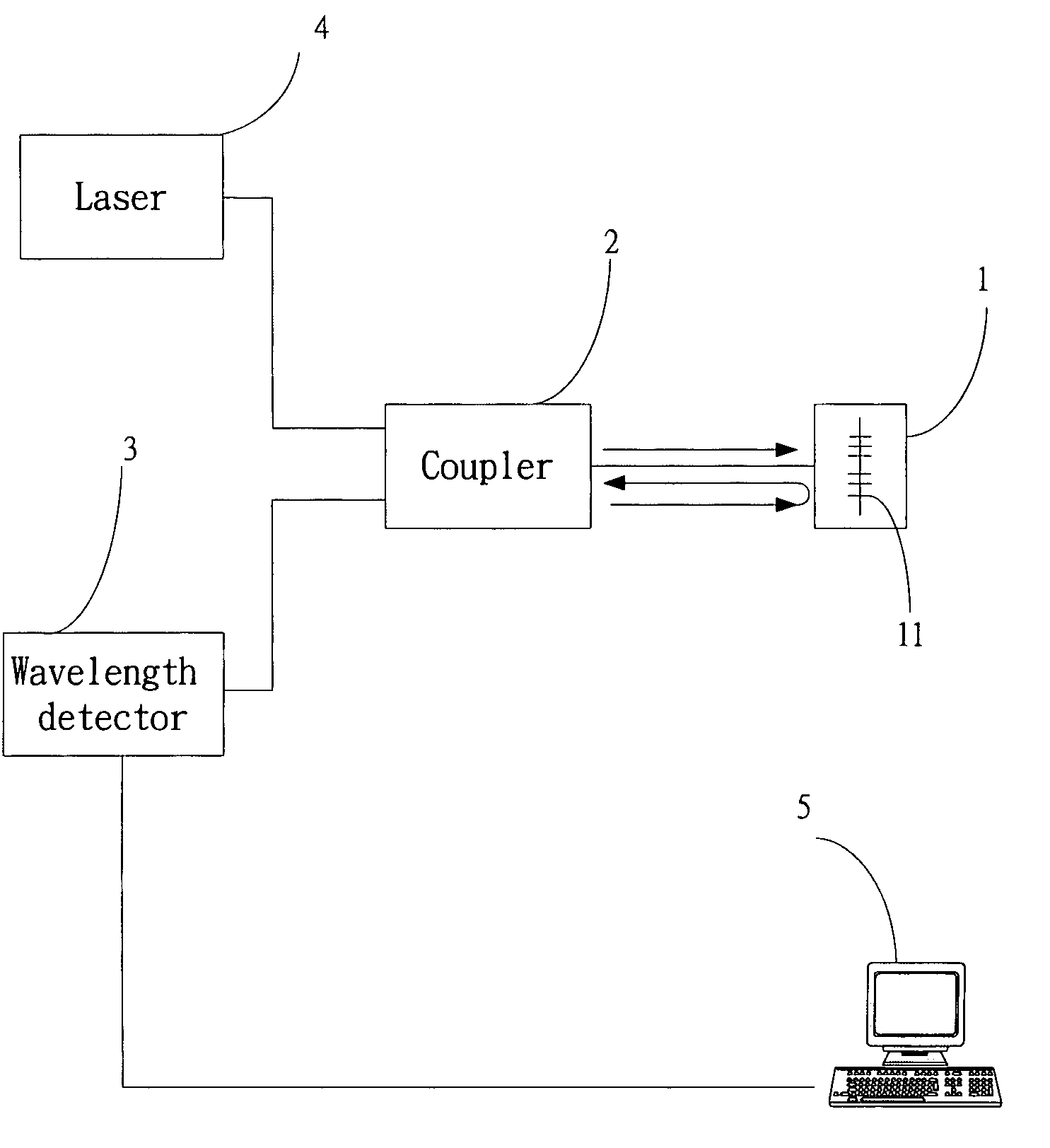

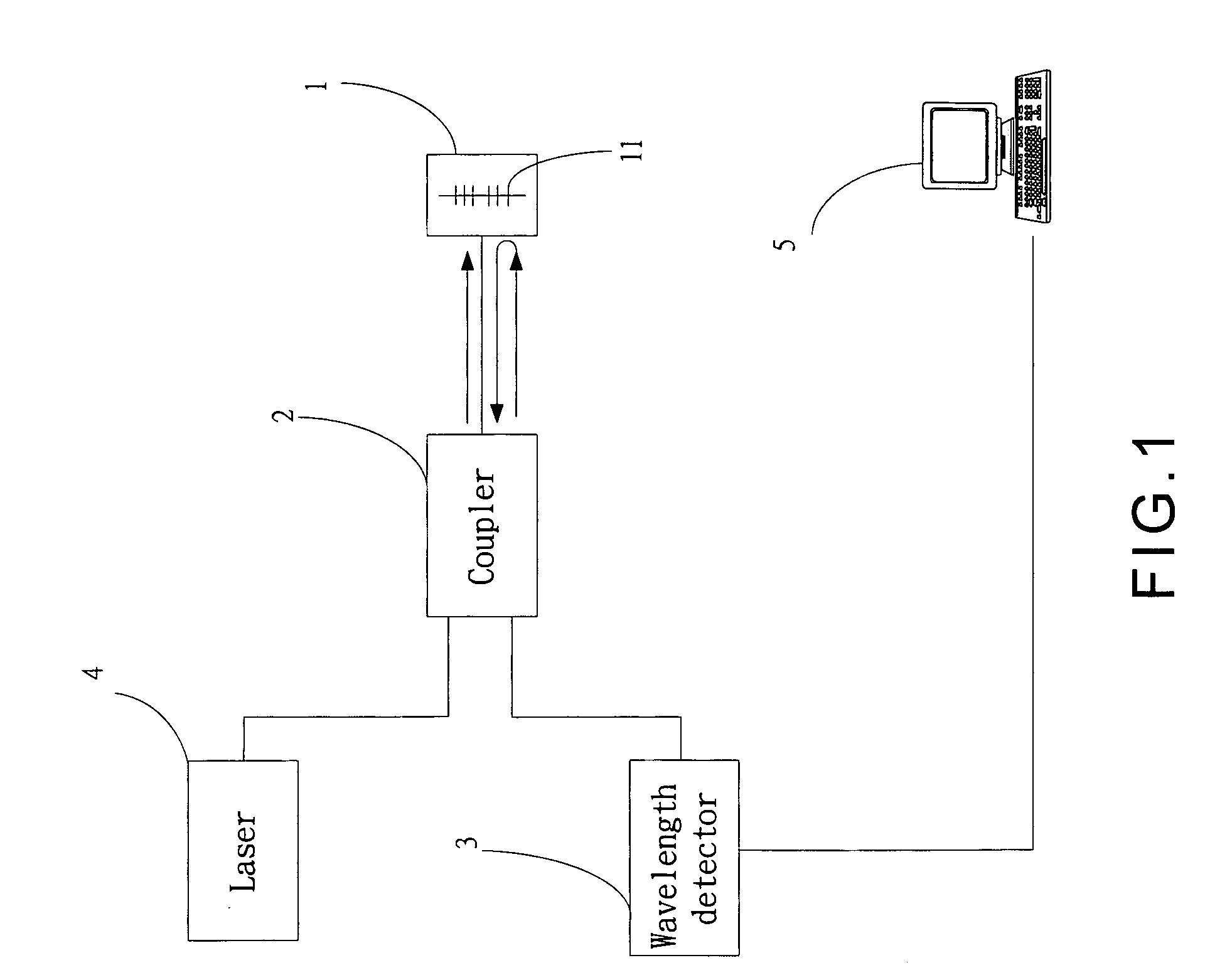

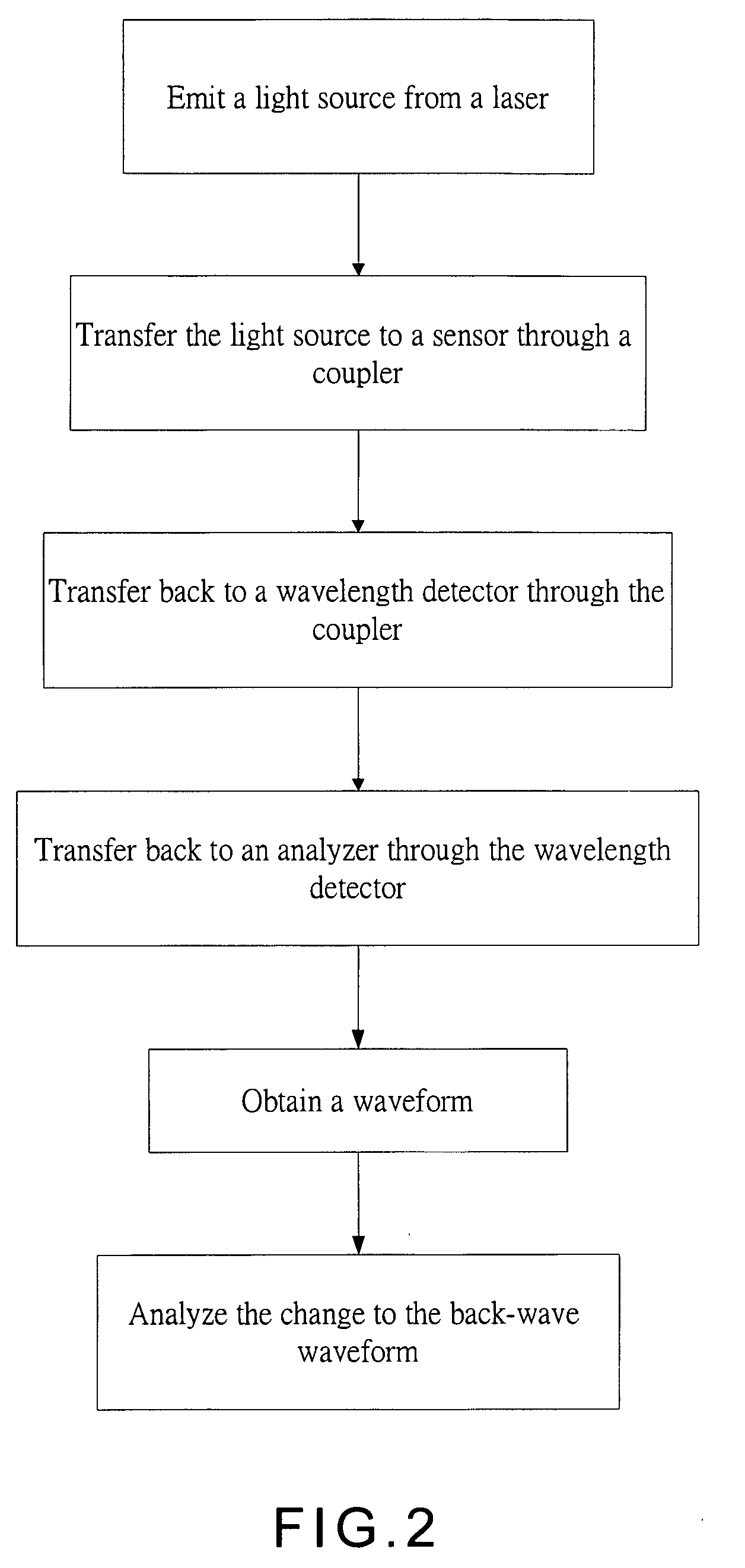

The present invention is a method for examining corrosion on a reinforcement steel. A sensor with a fiber Bragg grating is connected with a coupler; and the coupler is connected with a laser and an analyzer. Apply the sensor at a proper position on the reinforcement steel. A light source of the laser goes to the sensor through the coupler; and then the light passes the sensor and is transferred back to the analyzer. The analyzer can then figure out the strain out of the deformation and swell on the reinforcement steel owing to its corrosion by detecting the drift of the Bragg wavelength of the light. By doing so, the present invention obtains high sensitivity, strong corrosion sustainability and electromagnetic jam prevention so that the accuracy of the detection becomes higher and it can be widely applied to examine the corrosion on the reinforcement steel in a long term.

Owner:NAT CENT UNIV

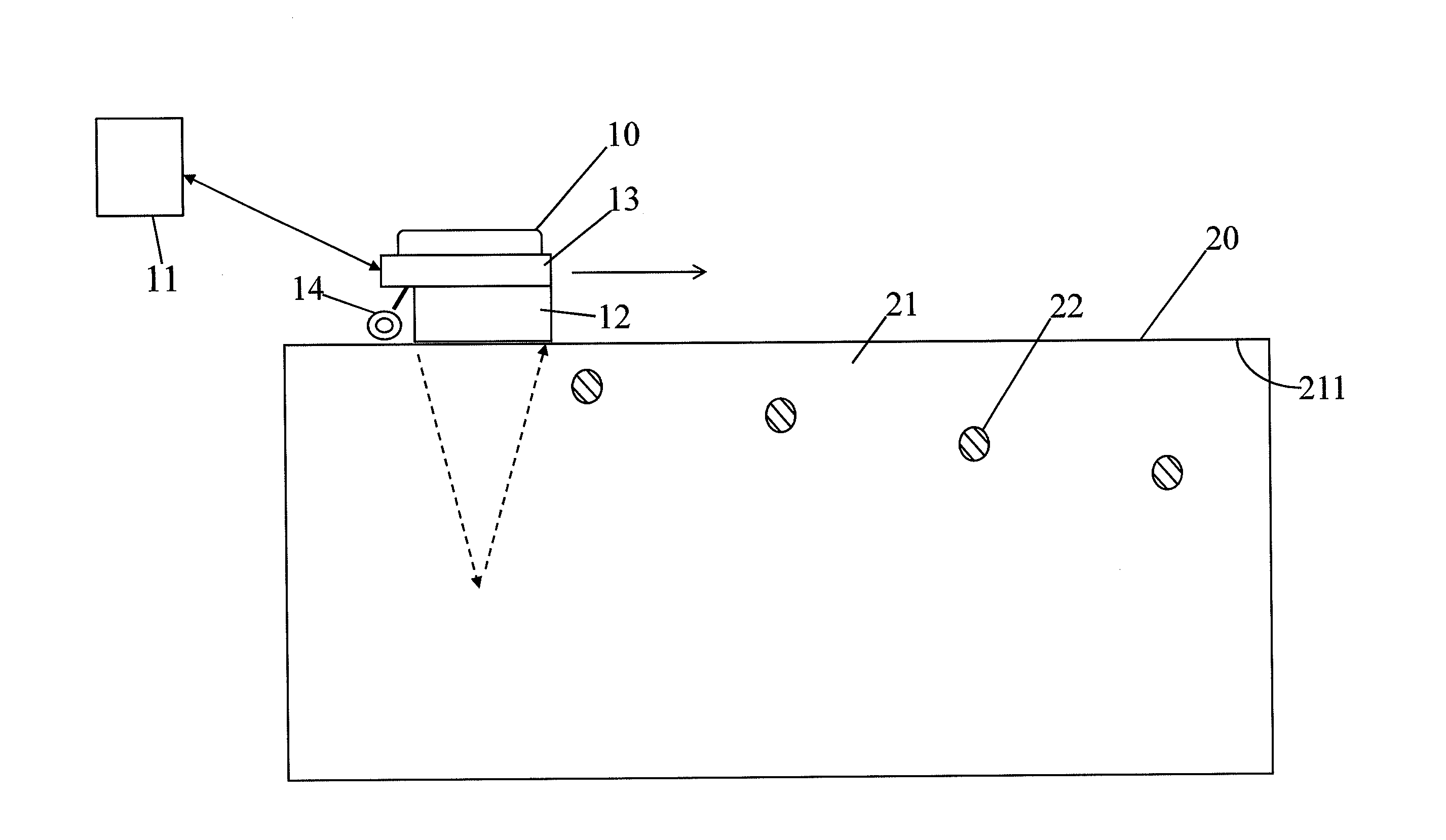

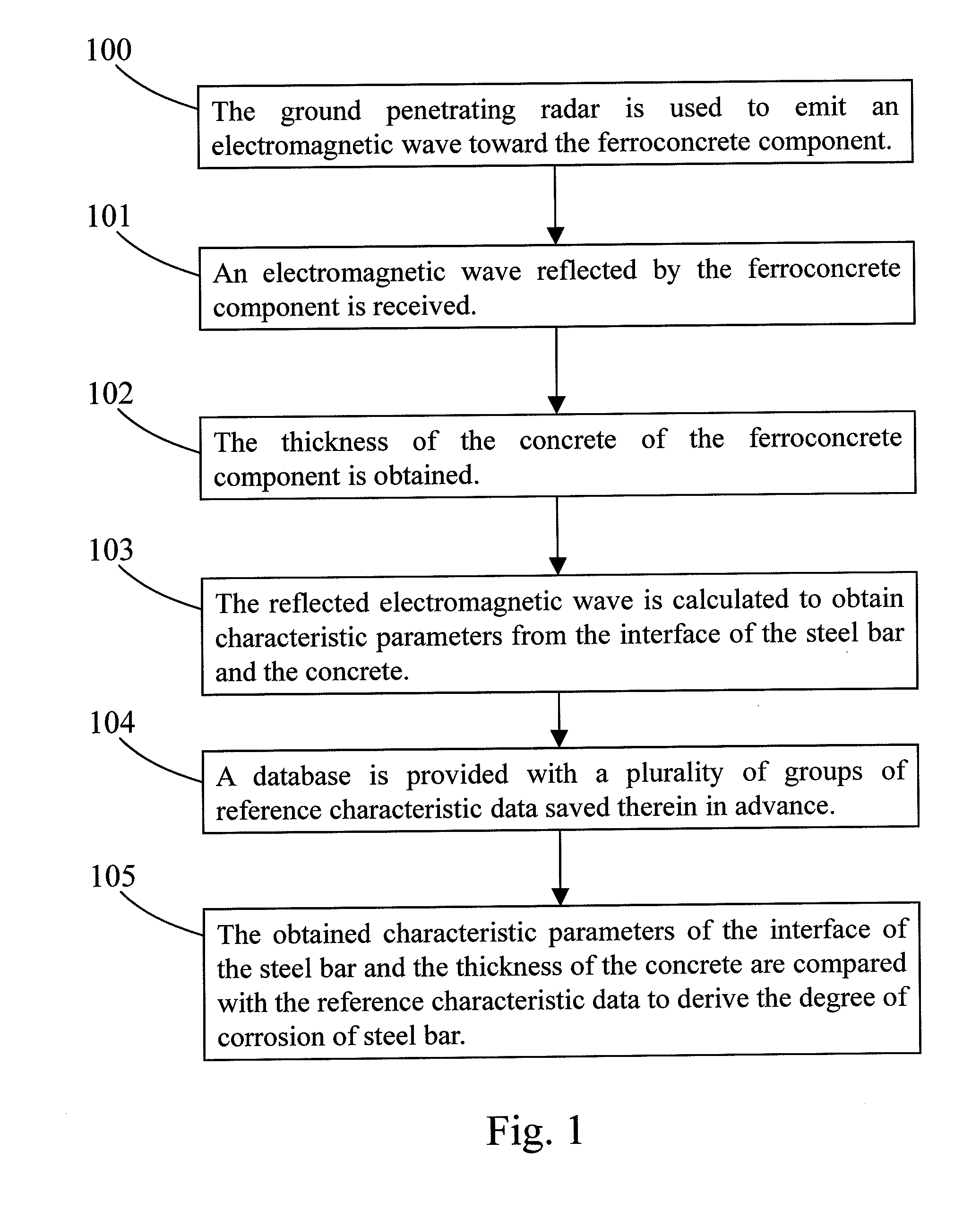

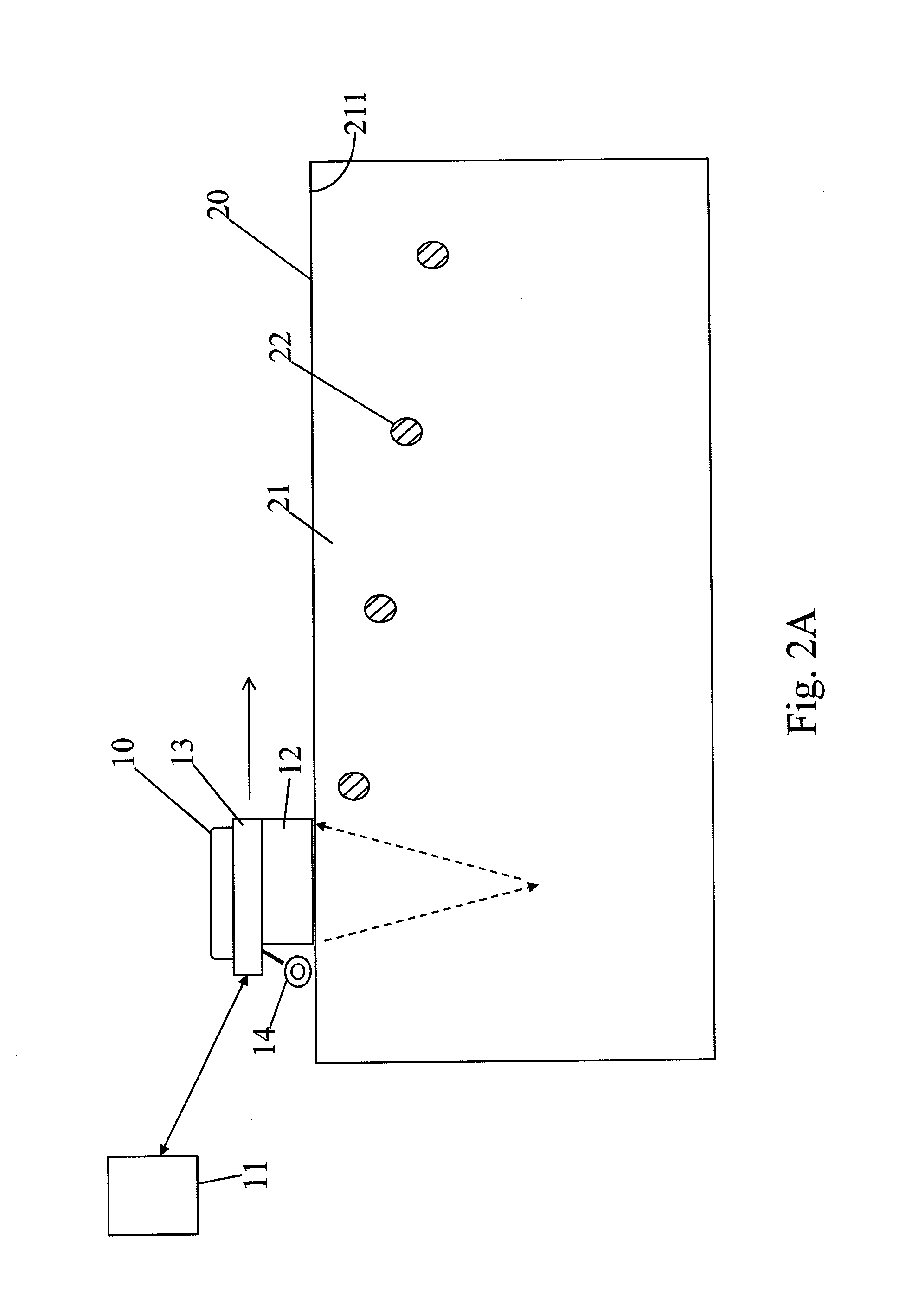

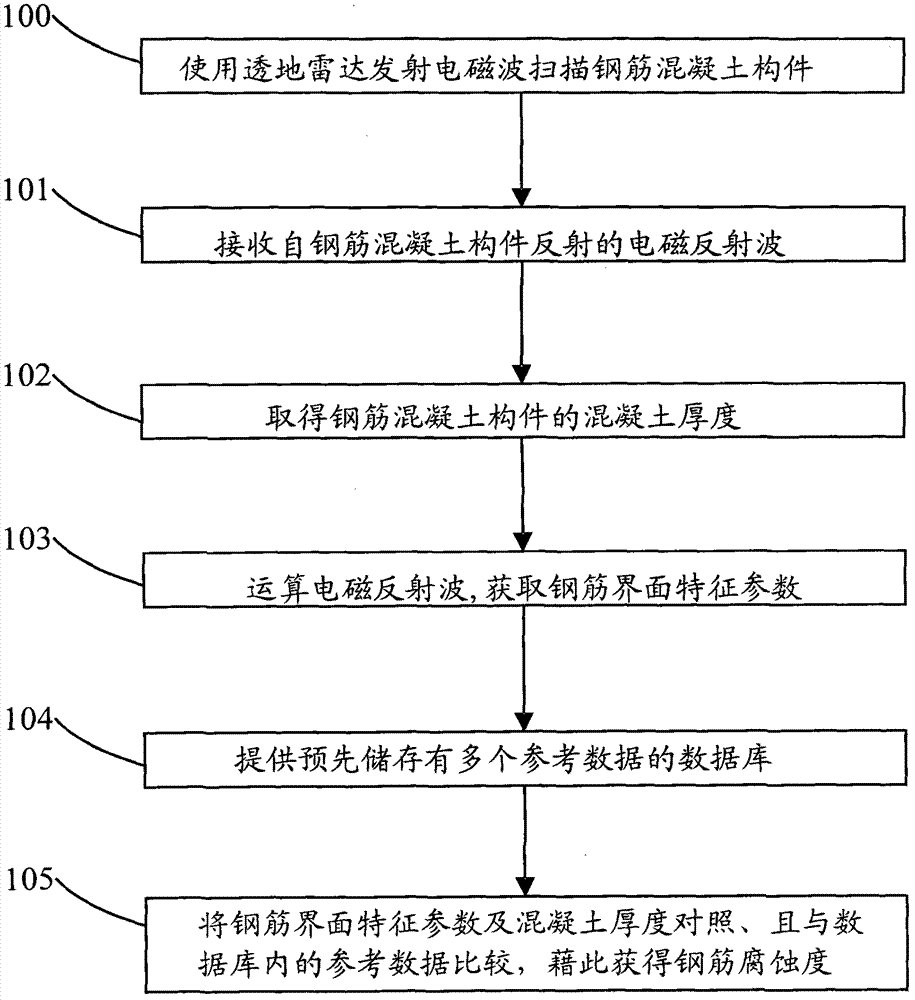

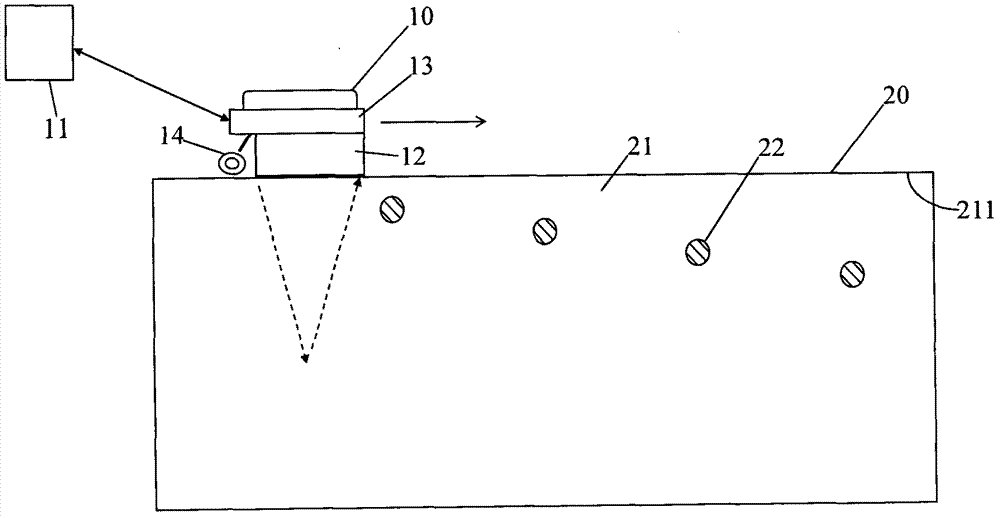

Method of using ground penetrating radar to detect corrosion of steel bars in ferroconcrete components

InactiveUS20120280849A1Improve stabilityDetection using electromagnetic wavesRadio wave reradiation/reflectionRebar corrosionElectrical resistance and conductance

The present invention discloses a method of using ground penetrating radar to detect corrosion of steel bars in ferroconcrete components. The method comprises the following steps. Firstly, a ground penetrating radar is used to emit an electromagnetic wave toward a ferroconcrete component. Then, a reflected electromagnetic wave is received. The reflected electromagnetic wave is calculated to obtain characteristic parameters from the interface of the steel bar and the concrete, wherein the characteristic parameters includes reflection electric potential, specific resistance and corresponding specific electric current from the interface. Reference characteristic data which include reference thicknesses of the concrete versus reference reflected electric potential, specific resistance and corresponding specific electric current from the interface are provided. The obtained interface characteristic parameters and the thickness of the concrete are compared with the reference characteristic data to derive the corrosion condition of steel bars in the ferroconcrete component.

Owner:CHUNG HUA UNIVERSITY

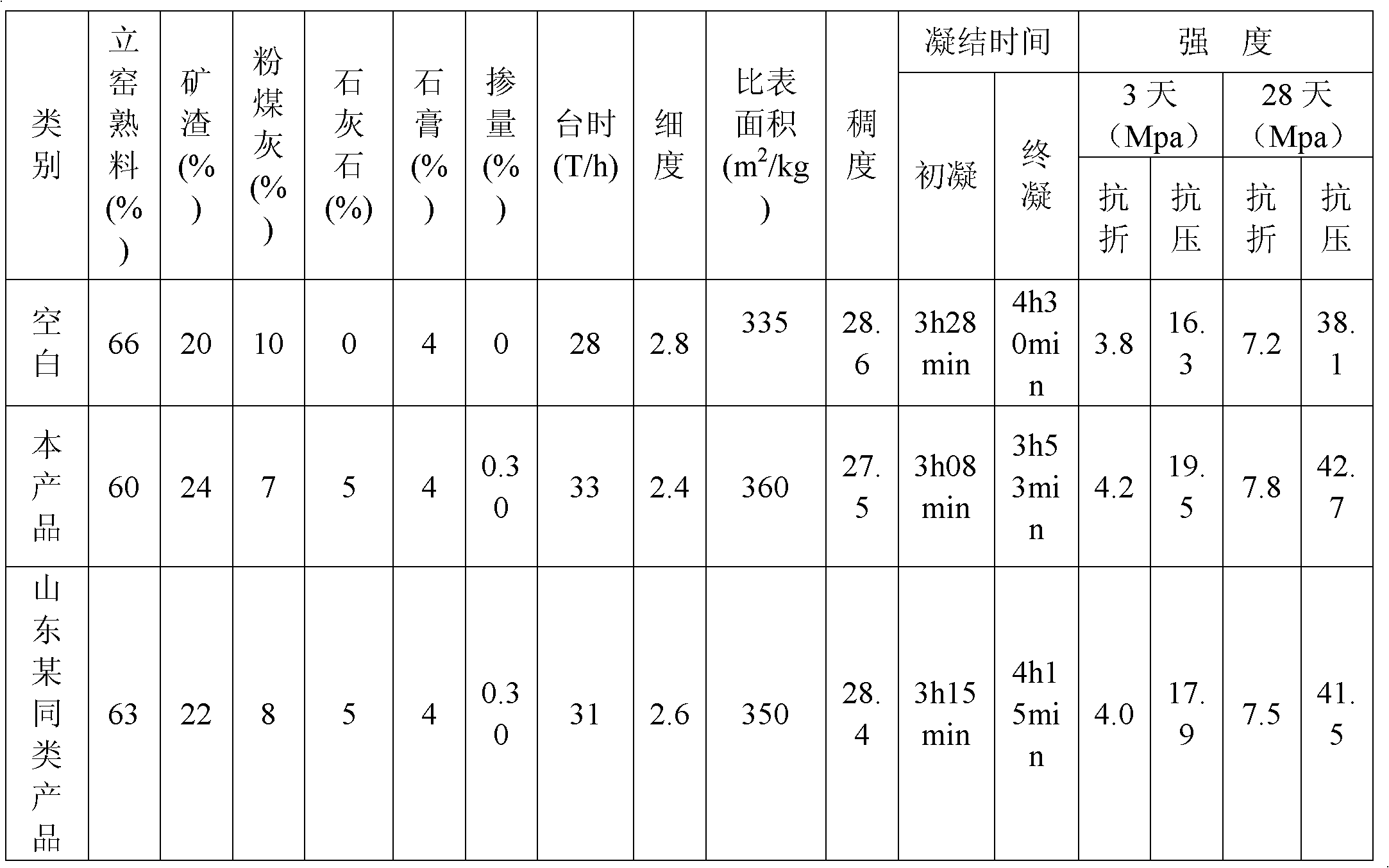

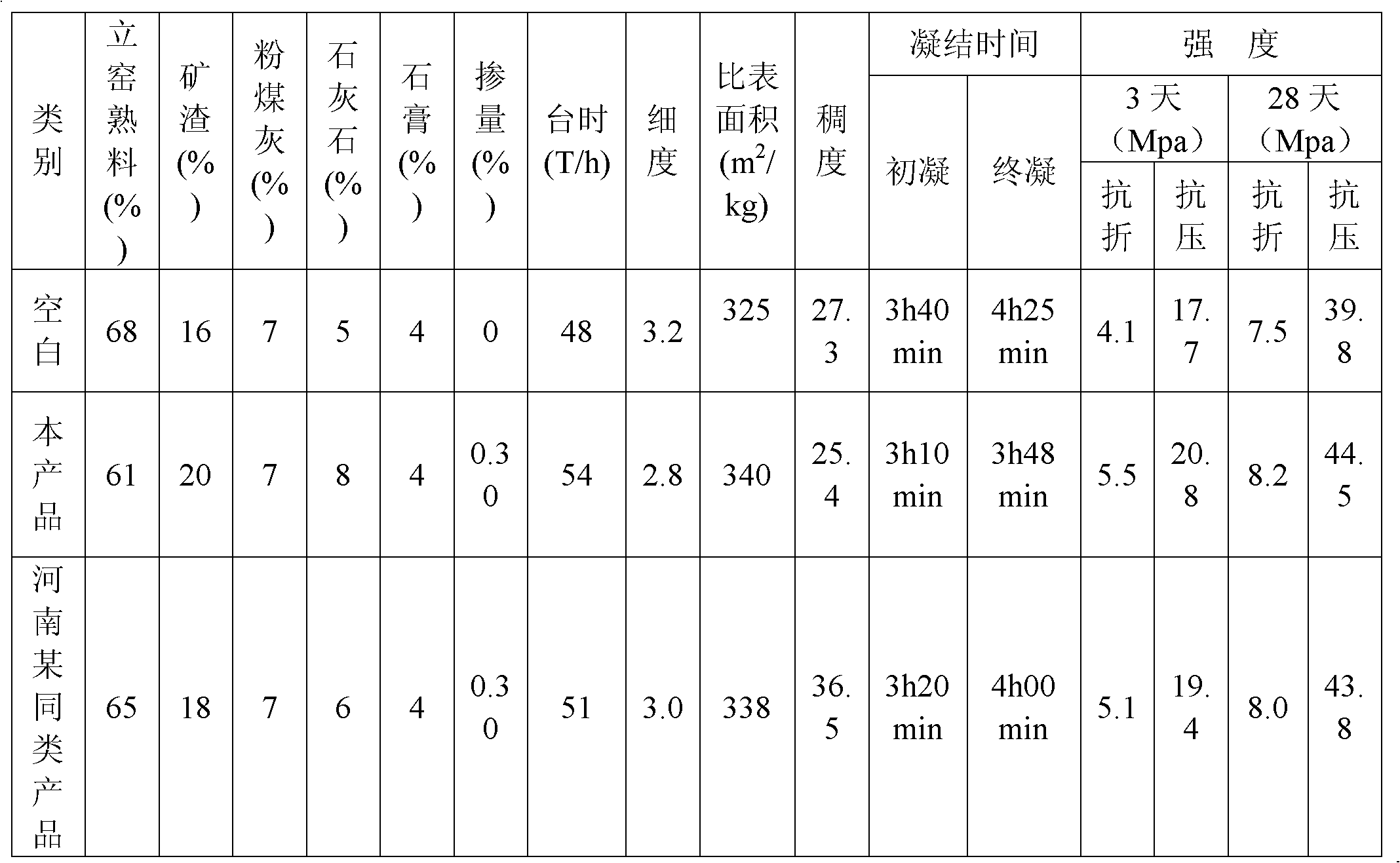

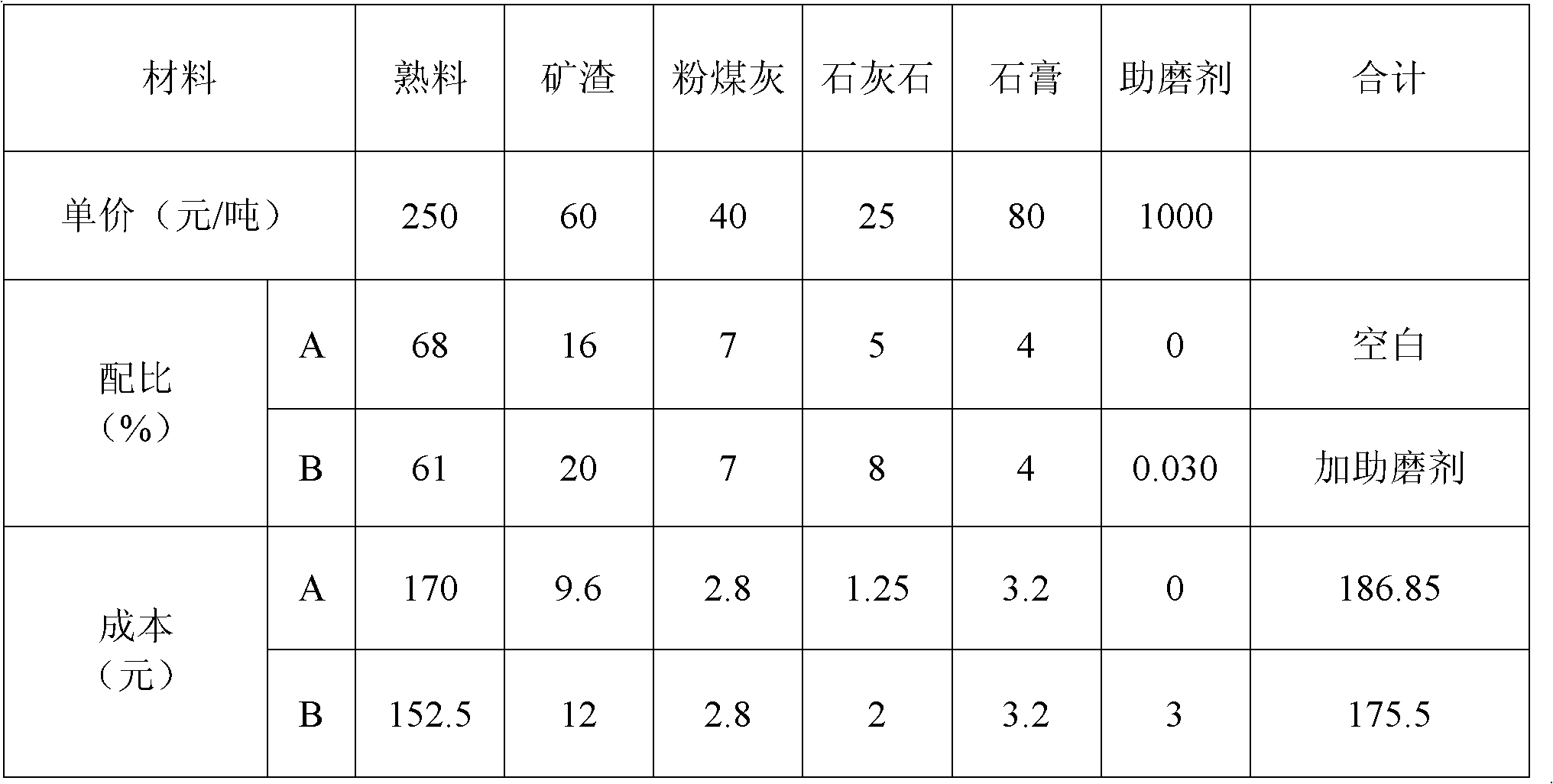

Composite cement grinding aid and preparation method thereof

The invention discloses a composite cement grinding aid belonging to the technical field of building materials and chemical engineering. The composite cement grinding aid comprises the following raw materials in parts by weight: 5-25 parts of reinforcing agent, 40-80 parts of grinding aid, 1-20 parts of surfactant, 1-20 parts of initiating agent, 1-20 parts of blender and 10-40 parts of water reducing agent. The composite cement grinding aid prepared by using the method is favorable for improving various properties of cement, has low blending quantity, is beneficial to environment protection, hardly causes alkali aggregate reaction of concrete and steel reinforcement corrosion, and is beneficial to the durability of the concrete.

Owner:JIANGSU BAIRUIJI NEW MATERIAL

Method of using ground penetrating radar to detect corrosion of steel bars in ferroconcrete components

InactiveCN102768176AIntegrity guaranteedImprove stabilityWeather/light/corrosion resistanceDetection using electromagnetic wavesRebar corrosionReflected waves

The present invention discloses a method of using ground penetrating radar to detect corrosion of steel bars in ferroconcrete components. The method comprises the following steps. Firstly, a ground penetrating radar is used to emit an electromagnetic wave toward a ferroconcrete component. Then, a reflected electromagnetic wave is received. The reflected electromagnetic wave is calculated to obtain characteristic parameters from the interface of the steel bar and the concrete, wherein the characteristic parameters includes reflection electric potential, specific resistance and corresponding specific electric current from the interface. Reference characteristic data which include reference thicknesses of the concrete versus reference reflected electric potential, specific resistance and corresponding specific electric current from the interface are provided. The obtained interface characteristic parameters and the thickness of the concrete are compared with the reference characteristic data to derive the corrosion condition of steel bars in the ferroconcrete component.

Owner:CHUNG HUA UNIVERSITY

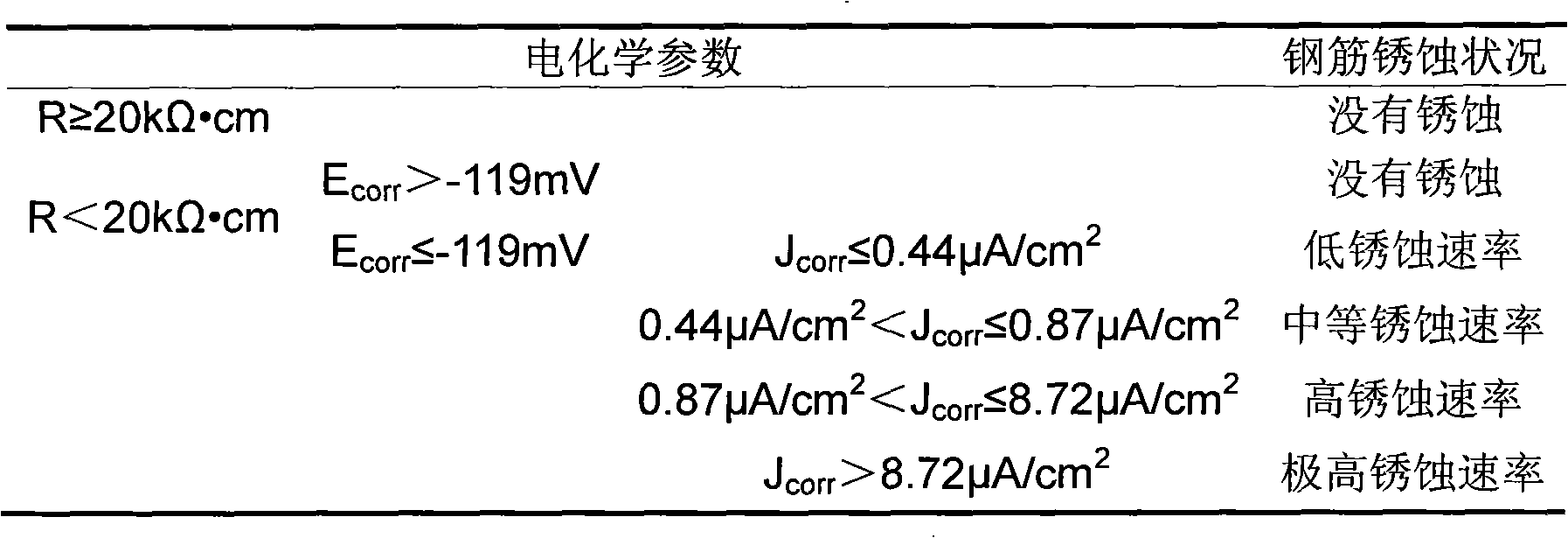

Coastal area concrete reinforcement erosion situation electrochemical test method

InactiveCN101339119AThe criteria are comprehensive and accurateWeather/light/corrosion resistanceMaterial testing goodsRebar corrosionLoss rate

The invention discloses an electrochemical test method of steel bar corrosion in the concrete of coastal area. The test method comprises the following steps: (1) under the concrete condition of the temperature of 0 to 50 DEG C and the relative humidity of 50 percent to 85 percent, the resistance rate R of the concrete is detected; if the estimated value of R is more than or equal to 20kilo-ohm, the passive film of the steel bar in the concrete is not damaged; if the estimated value of R is less than 20kilo-ohm, the second step is adopted; (2) a silver-silver chloride electrode is used for further determining the corrosion potential of the steel bar; if the estimated value of the corrosion potential of the steel bar is more than or equal to minus 119mV, the passive film of the steel bar in the concrete is not damaged; if the estimated value is less than 119mV, the passive film of the steel bar in the concrete is not damaged. The corrosion current density Jcorr of the steel bar in the concrete is further determined; the average corrosion depth and the average section loss rate of the steel bar are calculated. The guarantee rate of the estimated values is 95 percent. The electrochemical test method has the targeted characteristic and comprehensive criteria, and is in particular suitable for estimating the corrosion of the steel bar in the concrete structure without obvious cracking and rust on the surface.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

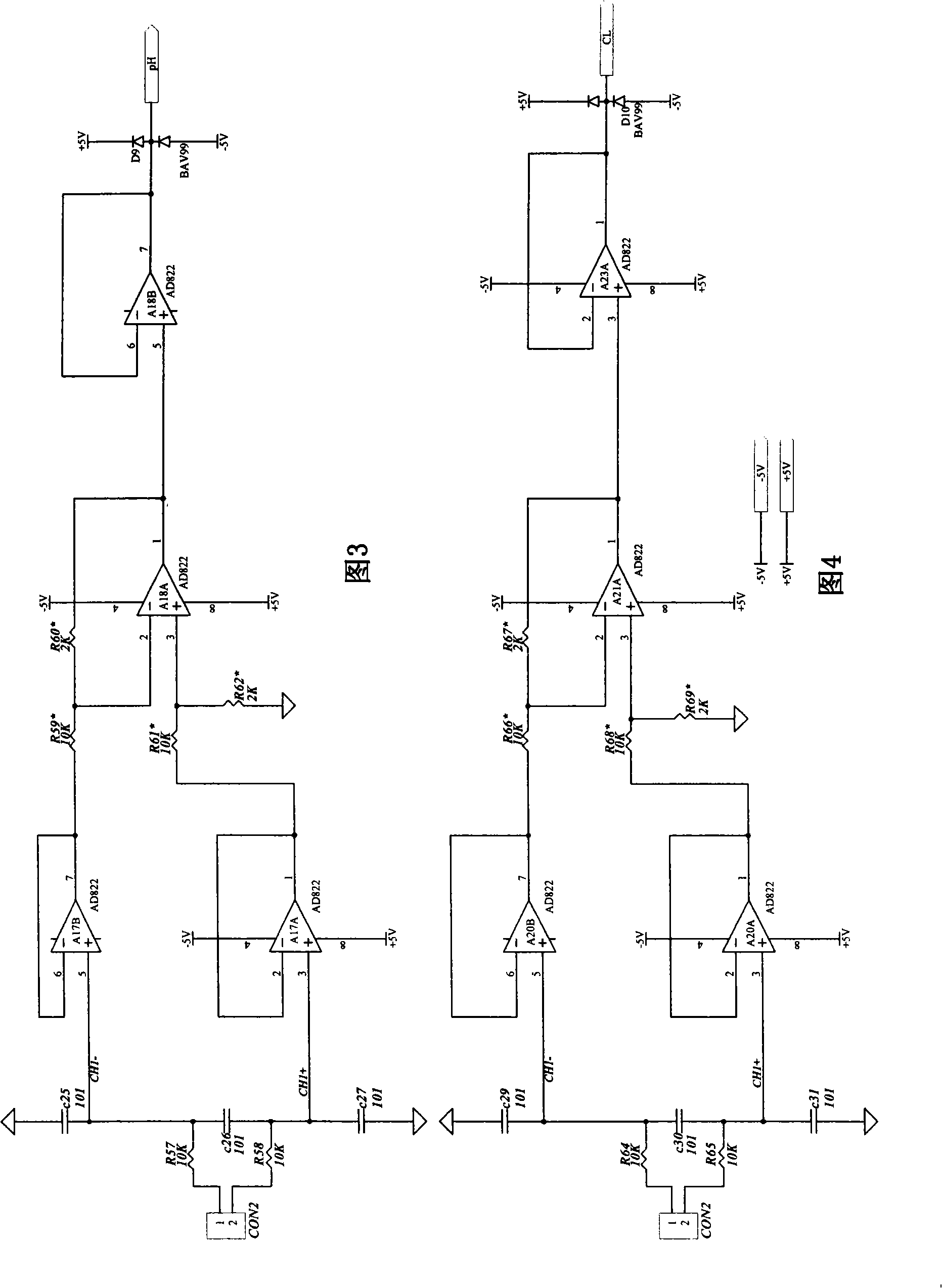

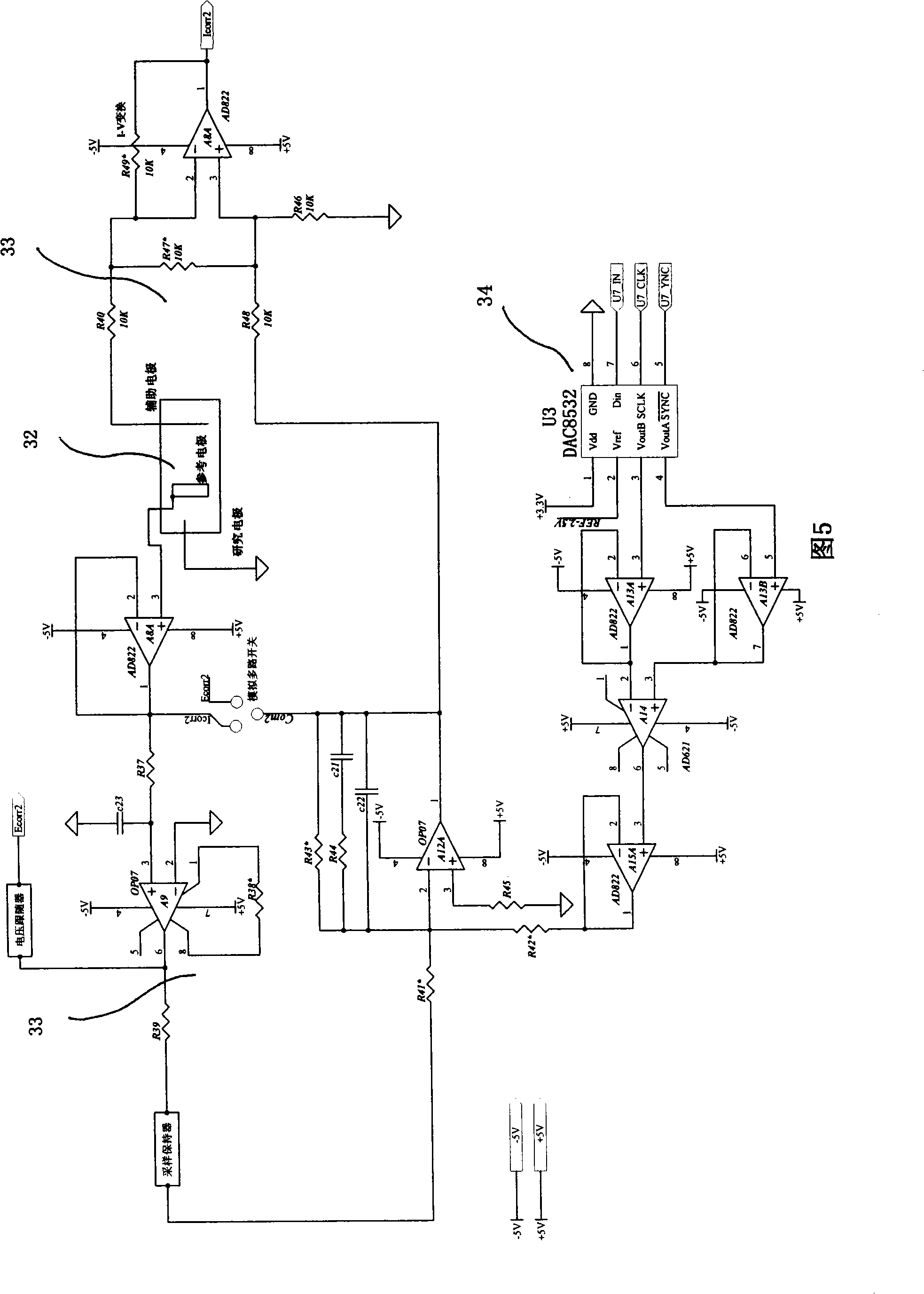

Corrosion on-line monitoring system for reinforced bar in concrete

ActiveCN101315324AHigh precisionHigh sensitivityWeather/light/corrosion resistanceMaterial testing goodsSignal processing circuitsMonitoring system

The invention discloses a system for conducting online monitoring of reinforcement corrosion in concrete. The system comprises a plurality of sensing devices and upper monitoring computers which are arranged at each detecting point in the concrete. The input end of the upper monitoring computer is connected with a data conversion circuit. The system is characterized in that the system further comprises sampled signal processing circuits correspondingly connected with the sensing devices at each detecting point. The sensing device comprises a temperature sensor and a combined sensor which can simultaneously detect pH value, CI<-> ion concentration value, open circuit potential, polarization resistance and corrosion rate function. The signal output end of the sampled signal processing circuit is connected with the signal input end of the data conversion circuit. The system can compensate temperature, eliminate detection error, and improve the precision and sensitivity of a detecting device in the detecting process. Furthermore, at the same time of improving the detection precision, the system greatly simplifies the structure of the circuit. In addition, when a failure in one detecting points occurs, the whole monitoring system can still operate normally.

Owner:宁波科金工业腐蚀监测技术有限公司

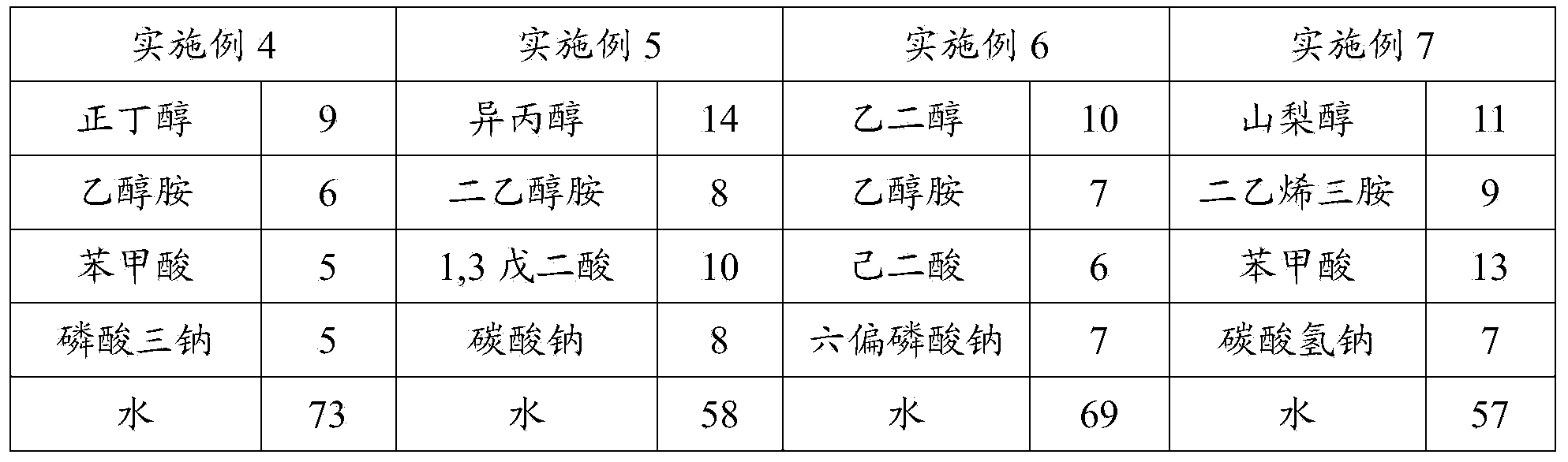

Migrating type composite rebar corrosion inhibitor as well as preparation method and application thereof

InactiveCN103626418AExcellent corrosion and rust resistanceReduce electric fluxRebar corrosionInorganic salts

The invention provides a migrating type composite rebar corrosion inhibitor as well as a preparation method and application thereof. The migrating type composite rebar corrosion inhibitor comprises the following raw materials according to parts by weight: 8-20 parts of fatty alcohol with the boiling point more than or equal to 60 DEG C, 5-11 parts of amine, 4-17 parts of organic acid or inorganic acid which is solid at the normal temperature, 4-8 parts of inorganic salt, and 45-78 parts of water, wherein the inorganic salt is chosen from phosphate or carbonate. The migrating type composite rebar corrosion inhibitor can migrate to the surface of a rebar to form a protection layer on the surface of the rebar, and chloride ions can also be filtered out so as to slow down the corrosion speed of the rebar. The corrosion inhibitor provided by the invention is simple in construction process and low in cost, and the sources of the raw materials are not limited.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com