Coastal area concrete reinforcement erosion situation electrochemical test method

A technology of concrete reinforcement and testing method, which is applied in the electrochemical test of the corrosion state of concrete reinforcement, and the electrochemical test of the corrosion state of concrete reinforcement in coastal areas, can solve the problem that the criterion is not accurate enough, the operability is not good, and the current density cannot judge the reinforcement. Early corrosion and other problems, to achieve the effect of complete technical conditions and comprehensive and accurate criteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

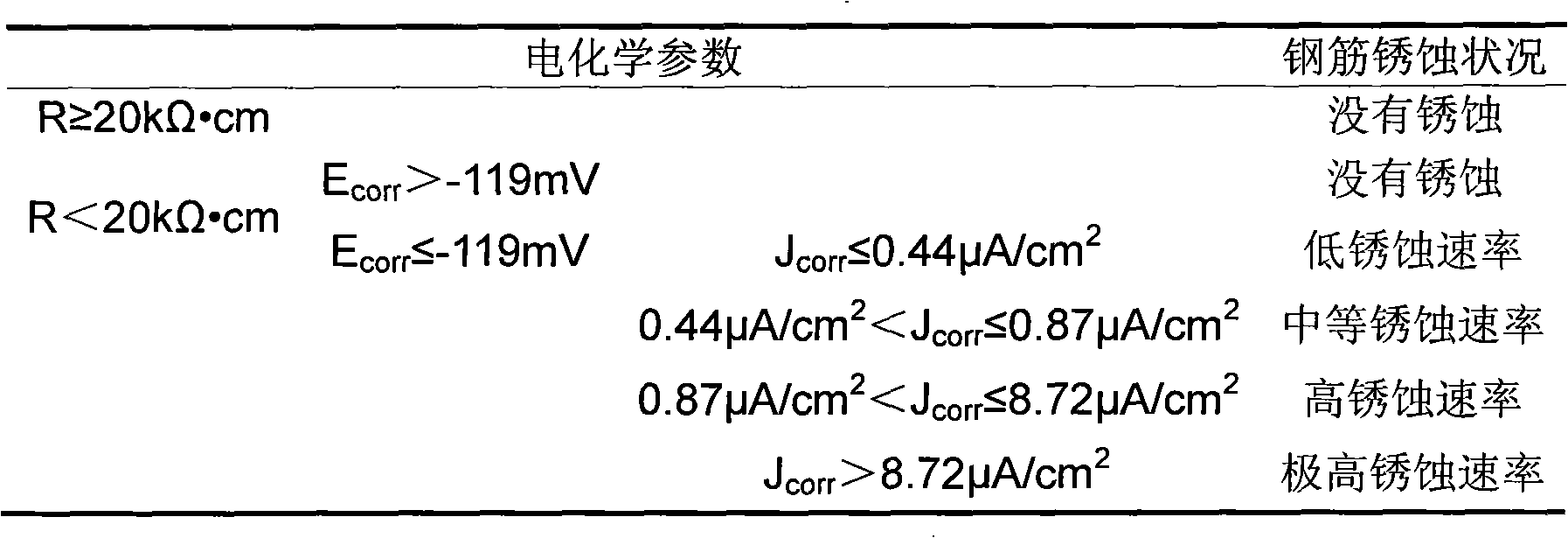

[0032] The laboratory prepares reinforced concrete samples, and the concrete samples are cured under conditions that simulate the coastal environment. Respectively detect the resistivity R, E of different samples corr and steel corrosion current density J corr (The guarantee rate of the presumed value is 95%). The concrete specimens in different corrosion stages were damaged, and the mortar around the steel bar was taken for sample preparation, and the SEM electron microscope element analysis and visual inspection were carried out. The analysis results are shown in Table 1.

[0033] Among them, the corrosion potential of the steel bar was measured with a silver-silver chloride electrode.

[0034] Table 1 Electrochemical parameters and microscopic test data of reinforced concrete in different corrosion stages

[0035]

[0036] Note: * indicates that the data of these 4 specimens come from E in No. 2 test corr Test piece data less than -119mV

[0037] It can be seen from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com