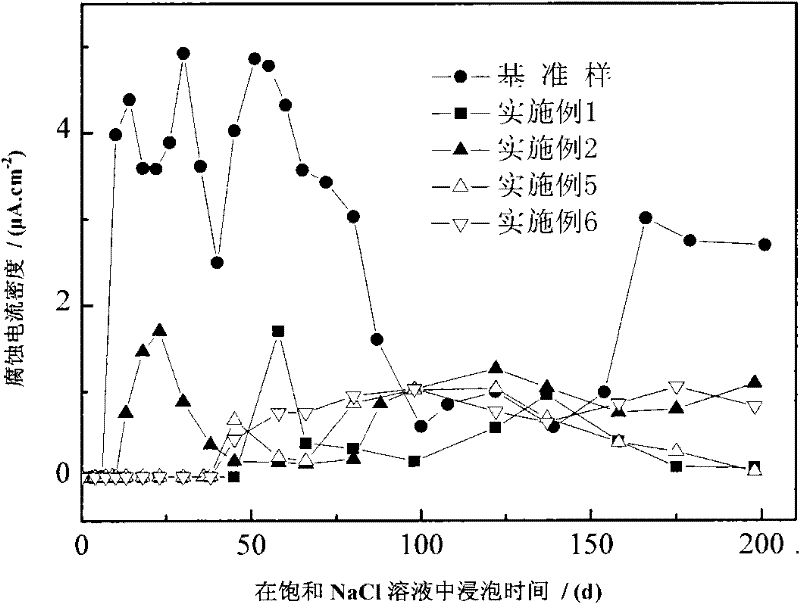

Doped all organic corrosion inhibitor for steel bar in concrete

A technology of concrete steel bars and rust inhibitors, which is applied in the field of building materials, can solve the problems of human health and harmful rust inhibitors, and achieve the effects of prolonging the corrosion time, being convenient to use, and slowing down the corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

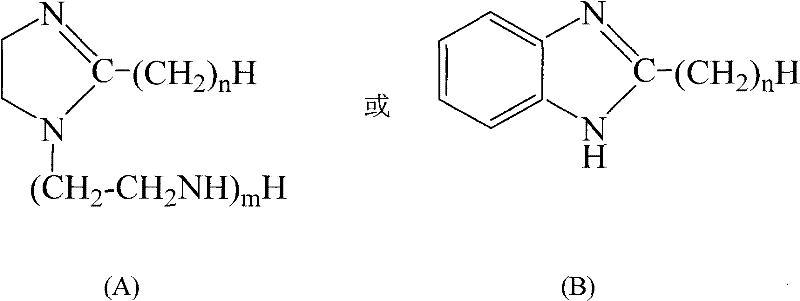

Method used

Image

Examples

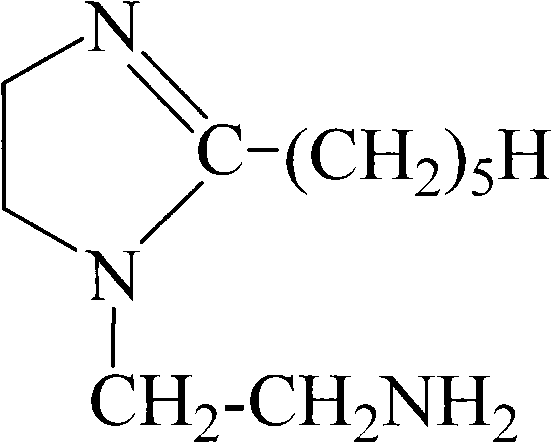

Embodiment 1

[0034] Weigh 5kg of imidazoline A, mix evenly with 10kg of ethanol, add 84.4kg of tap water, stir and dissolve evenly, then add 0.6kg of sodium sorbate, stir and dissolve to obtain the concrete steel bar rust inhibitor of the present invention.

[0035] In the present embodiment, the specific structure of the imidazoline A compound is as follows:

[0036]

Embodiment 2

[0038] Take by weighing 15kg imidazoline A, after mixing 10kg ethylene glycol, add 74kg of tap water, after stirring and dissolving evenly, add 1kg of aluminum stearate again, after stirring and dissolving, the concrete reinforcement rust inhibitor of the present invention is obtained.

[0039] In the present embodiment, the specific structure of the imidazoline A compound is as follows:

[0040]

Embodiment 3

[0042] Take by weighing 30kg imidazoline B, after mixing 5kg isopropanol evenly, add 64.7kg of tap water, after stirring and dissolving evenly, add 0.3kg calcium stearate again, after stirring and dissolving, the concrete steel bar corrosion inhibitor of the present invention is obtained.

[0043] In the present embodiment, the specific structure of the imidazoline B compound is as follows:

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com