Concrete reinforcement erosion wireless detecting method and sensor

A concrete steel bar and wireless detection technology, which is applied in the fields of weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., can solve the problems of heavy detection workload, easy damage, and large influence of external factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

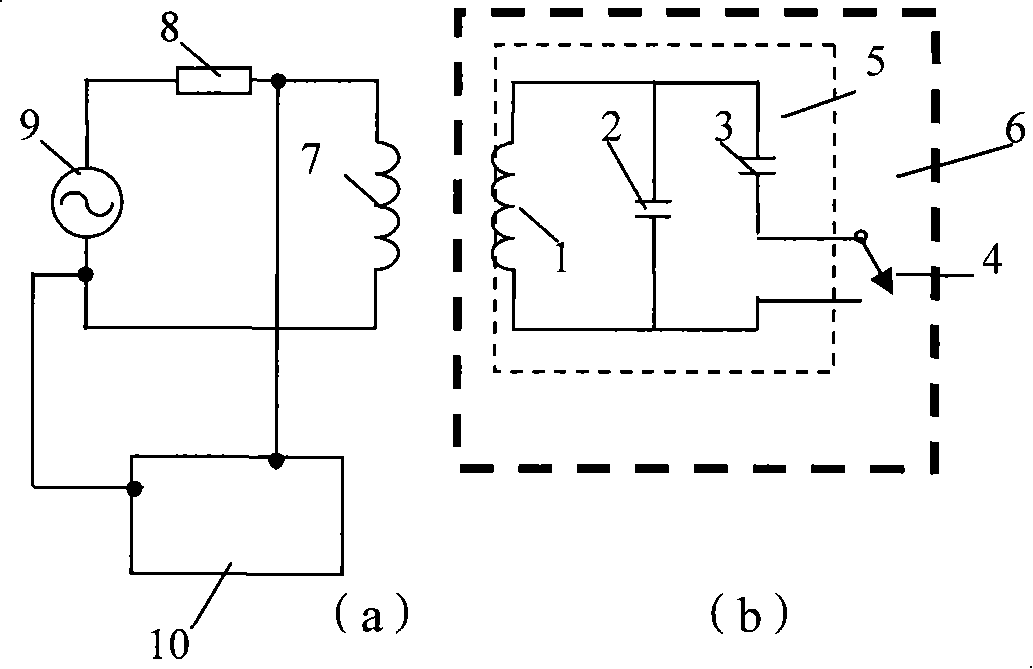

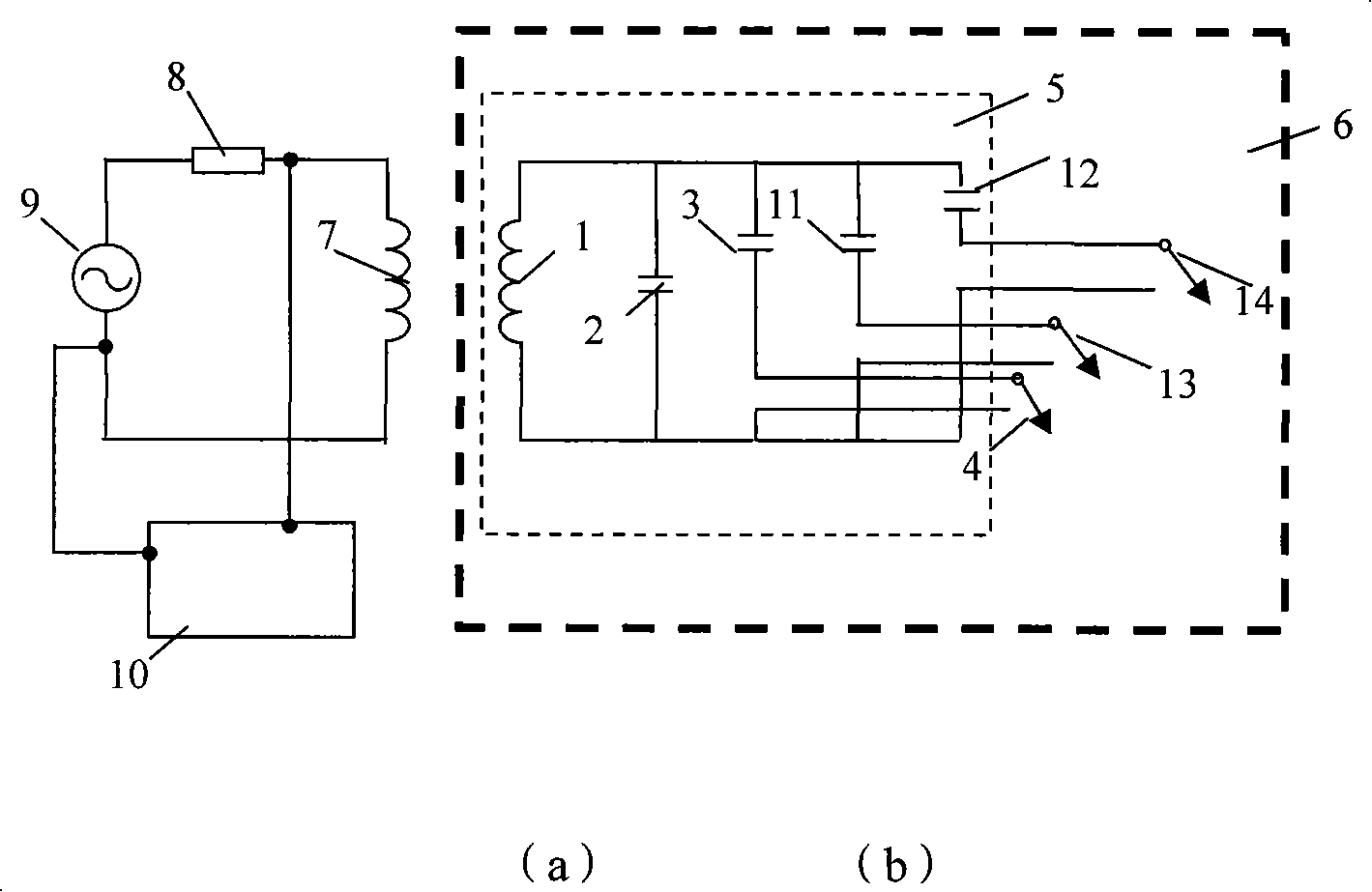

[0016] The sensor structure that the present invention adopts is as figure 1 ,Depend on figure 1 The reading part (a) and the sensing part (b) are composed.

[0017] The method of the present invention specifically comprises the following contents (as figure 1 ):

[0018] (a), sensor production: by figure 1 The reading part (a) and the sensing part (b) are composed.

[0019] The production of the sensor part: select a suitable capacitor, select a thicker enameled wire to wind the plastic core several times to make an inductance coil, and add a magnetic core in the middle of the coil, select the steel wire for detection, and then press as follows figure 1 The circuit shown is connected into a loop, and the steel wire is used as a switch of the loop.

[0020] The steel wire switch I in the sensing part can also be re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com