Patents

Literature

298 results about "Durability testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

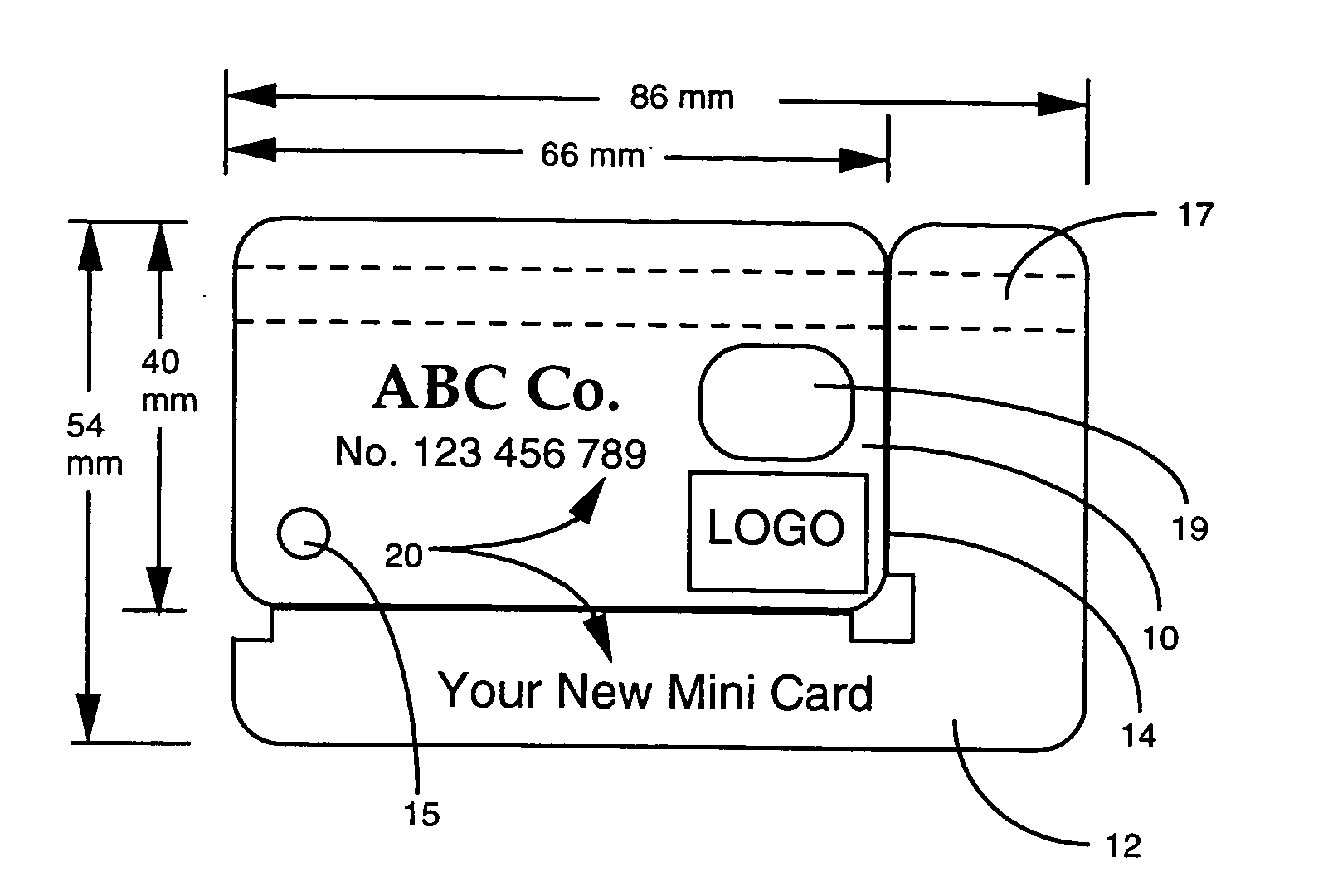

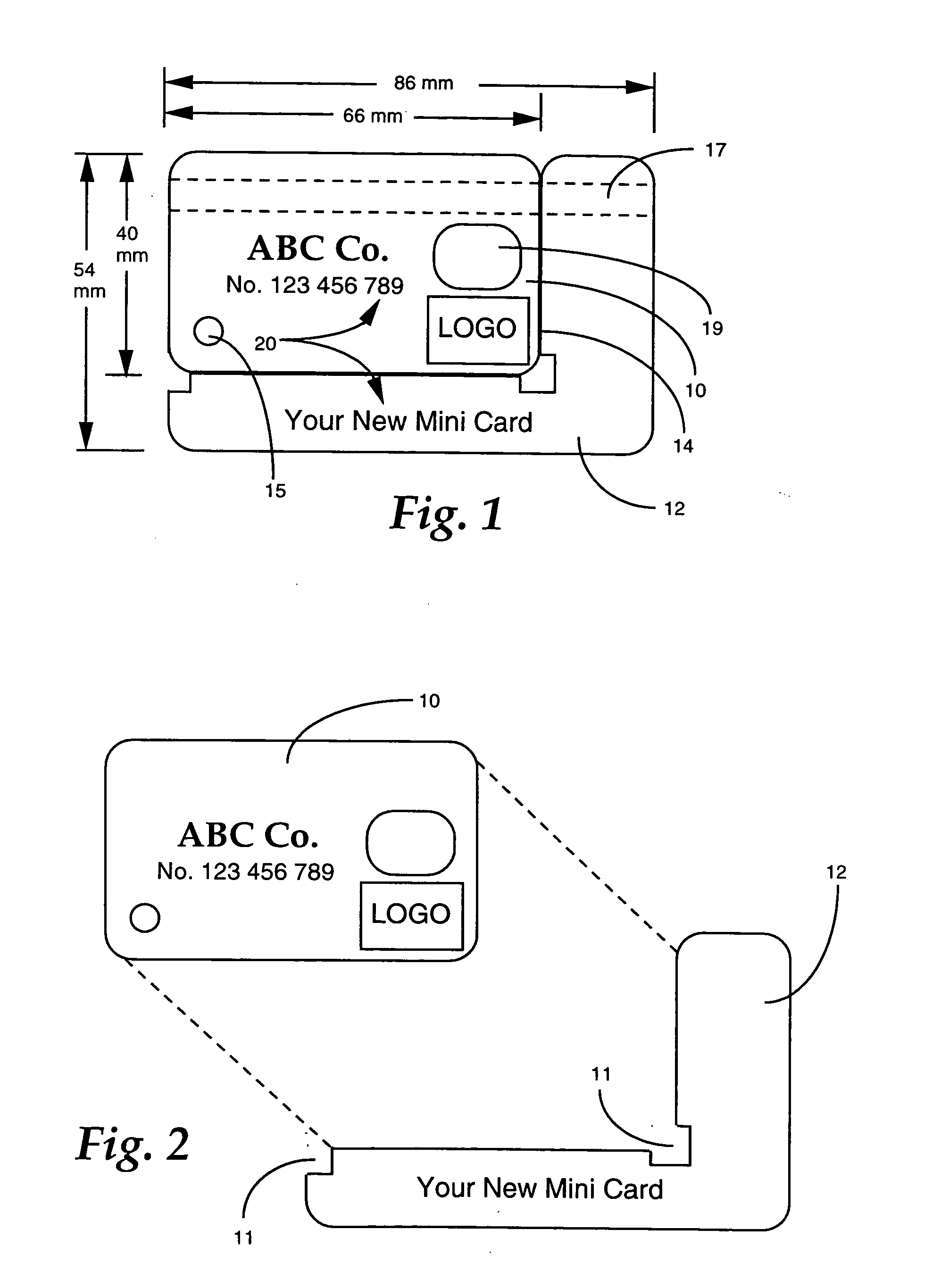

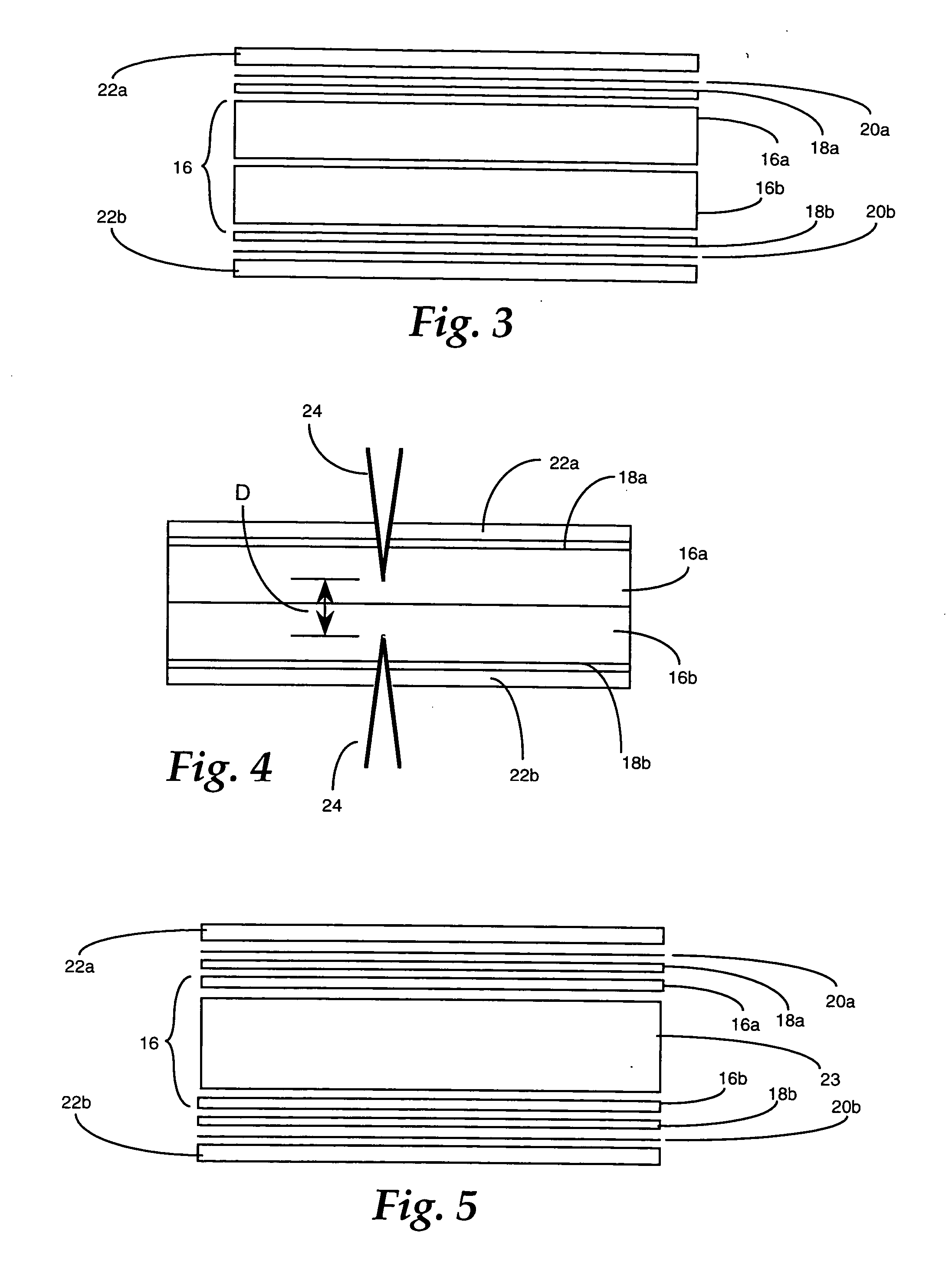

Durable plastic mini card and method for testing its durability

InactiveUS20060011731A1Increased durabilityGreat resistance to failureInformation retrieval from punched cardsRecord carriers used with machinesPolyesterEngineering

A mini card has a size smaller than a card that conforms to established standards, and includes a hole for attachment to a key ring or other external device. Increased durability is provided by means of a substrate that includes a core made of PVC material, sandwiched between two durable layers of polyester material. Printing on these layers is protected by transparent overlay layers made of PVC. The durability of the card is measured by means of a test procedure in which random multi-dimensional motion is imparted to an assembly of the card and an attached weight. The durability is quantitatively indicated by the amount of elapsed time until the weight becomes separated from the card while undergoing the vibrational movement.

Owner:GEMPLU

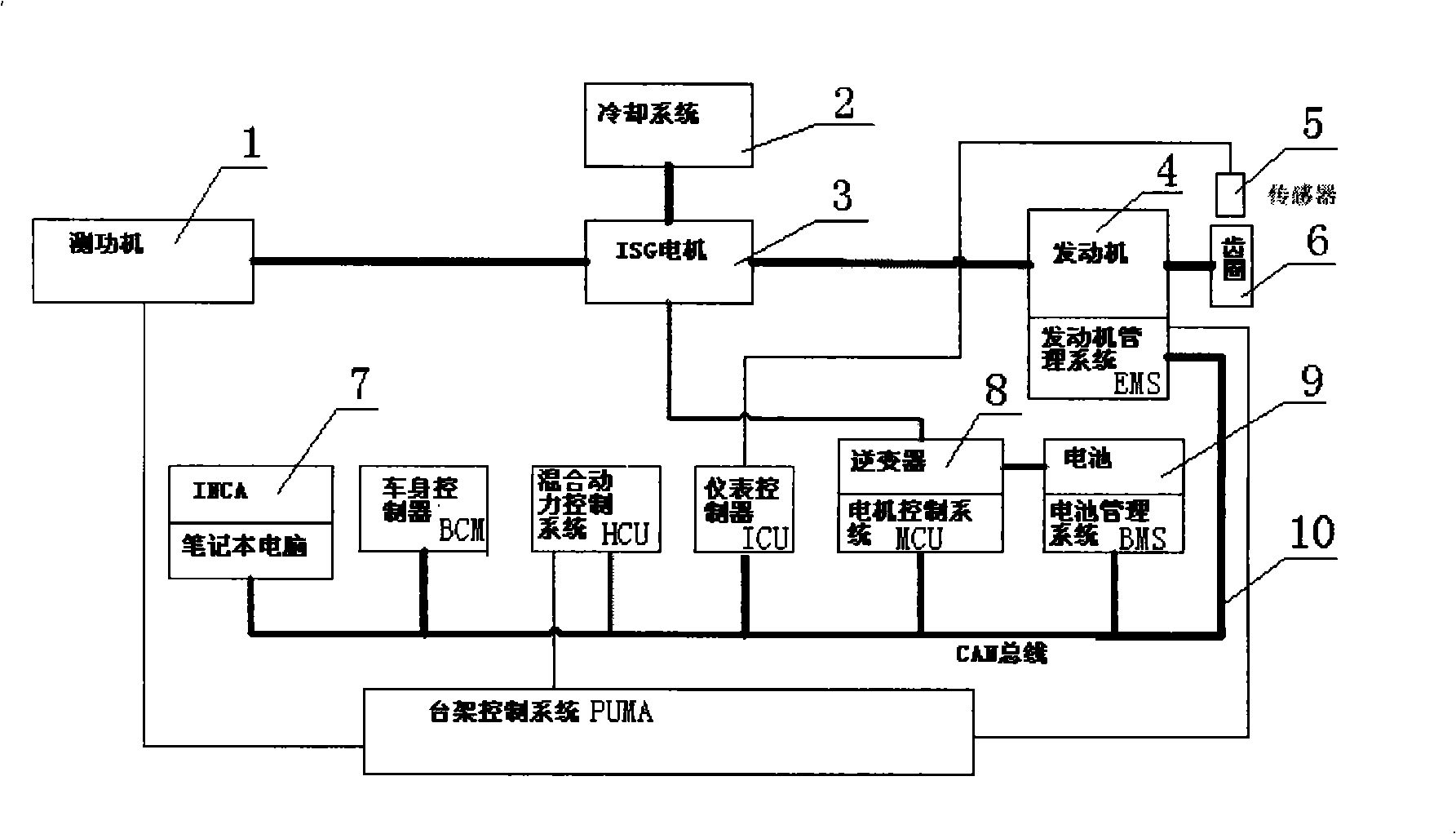

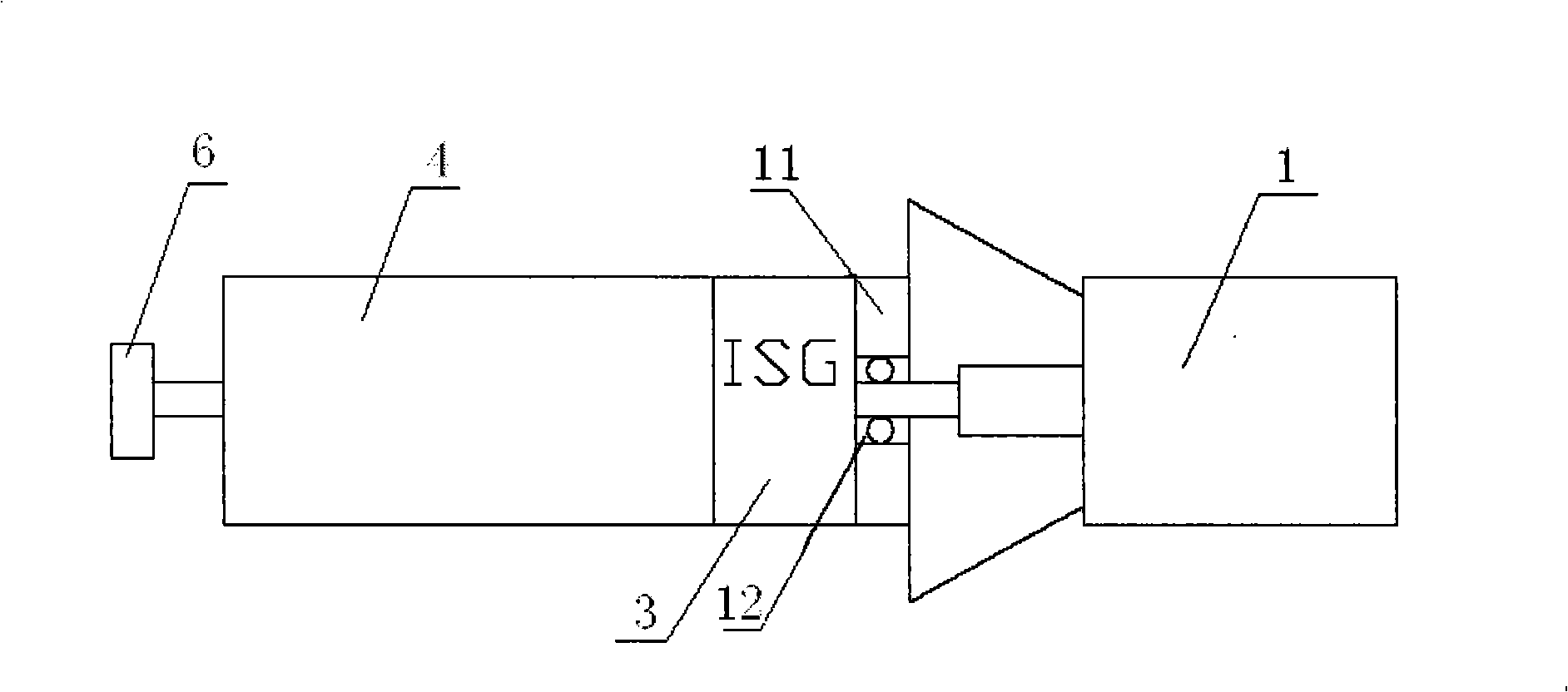

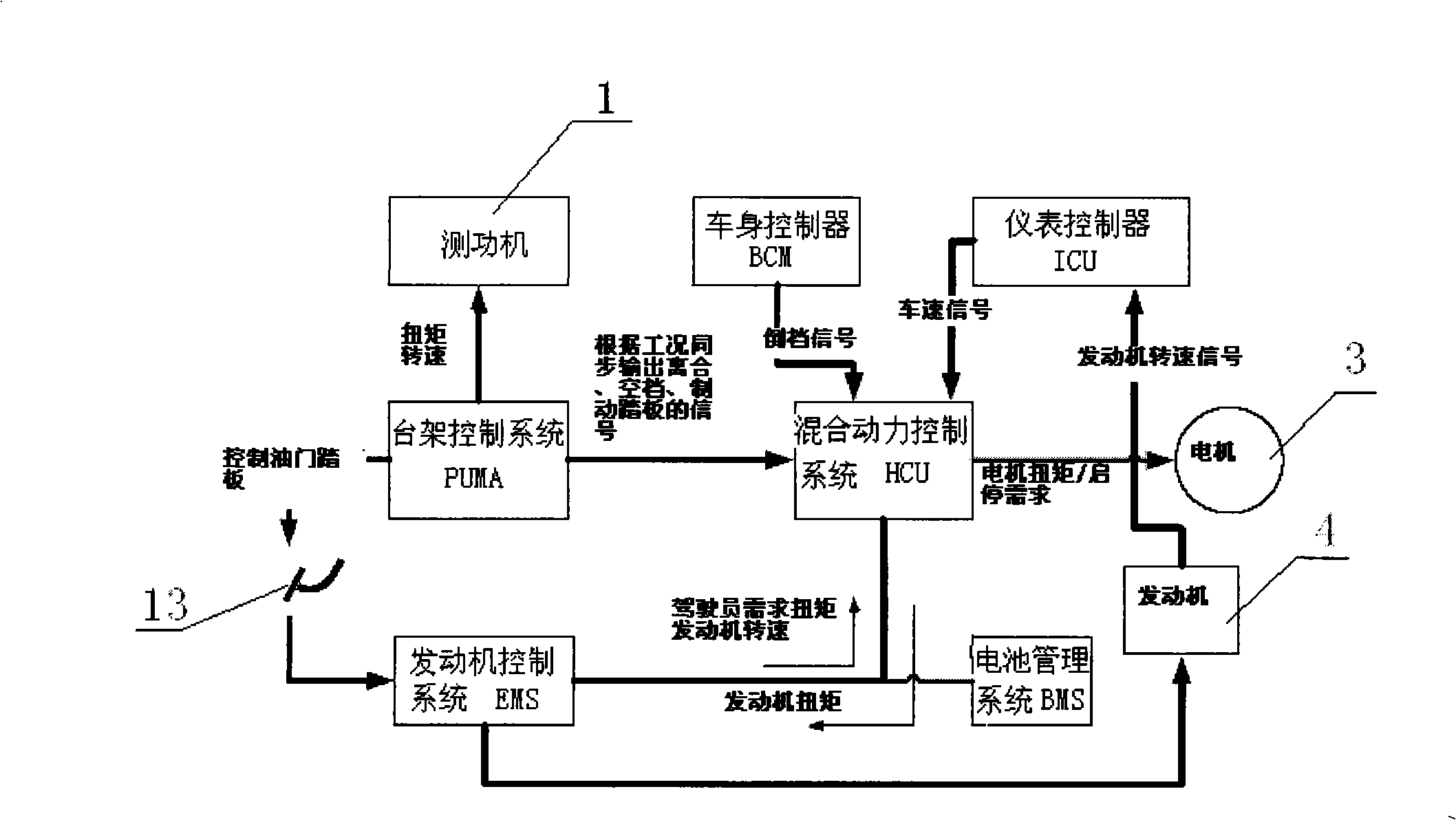

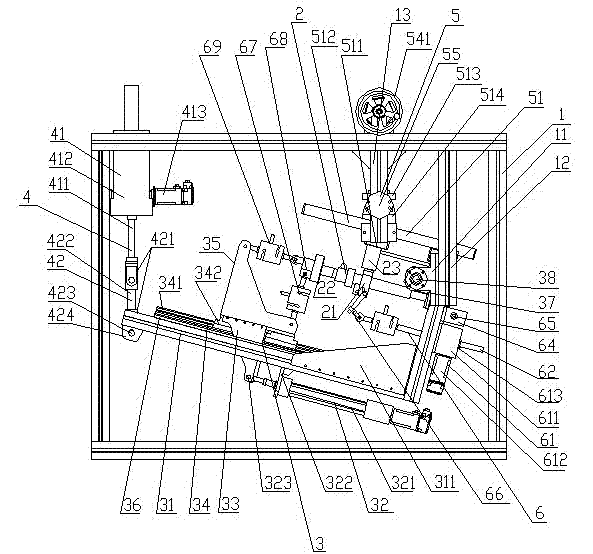

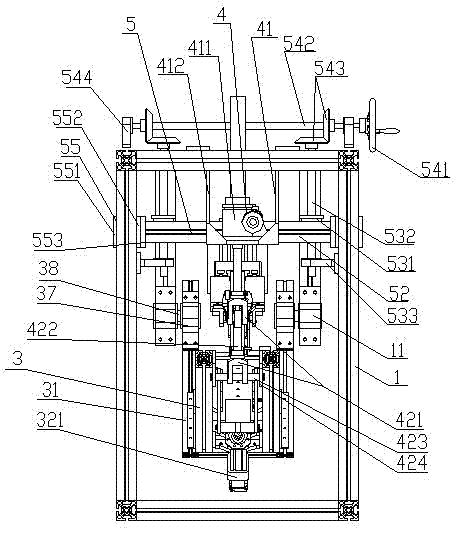

Hybrid power automobile dynamic force assembly durable test stand and test method

ActiveCN101261189AVerify validityVerify reliabilityVehicle testingEngine testingControl signalDynamometer

The invention discloses a hybrid electric vehicle power assembly durability testing frame and a testing method. A dynamometer is connected with an engine and a tooth ring through an ISG motor which is electrically connected with an inverter; a rotation speed sensor which is arranged at the external side of the tooth ring is connected with an instrument controller; a frame control system respectively emits test control signals to a hybrid electric control system, an engine management system and a dynamometer; the hybrid electric control system receives external signals and initiates the requirements of starting or stopping and torque to the engine management system and the motor control system according to a self-control strategy. The frame control system (PUMA) controls the operation of the dynamometer by a pre-arranged speed curve and a torque curve, thus leading the engine to run under the working conditions defined in advance. The distribution of motor torque and engine torque and the auxiliary driving torque of the motor are controlled by the hybrid electric control system according to the rotation speed of the engine and the torque requirement.

Owner:CHERY AUTOMOBILE CO LTD

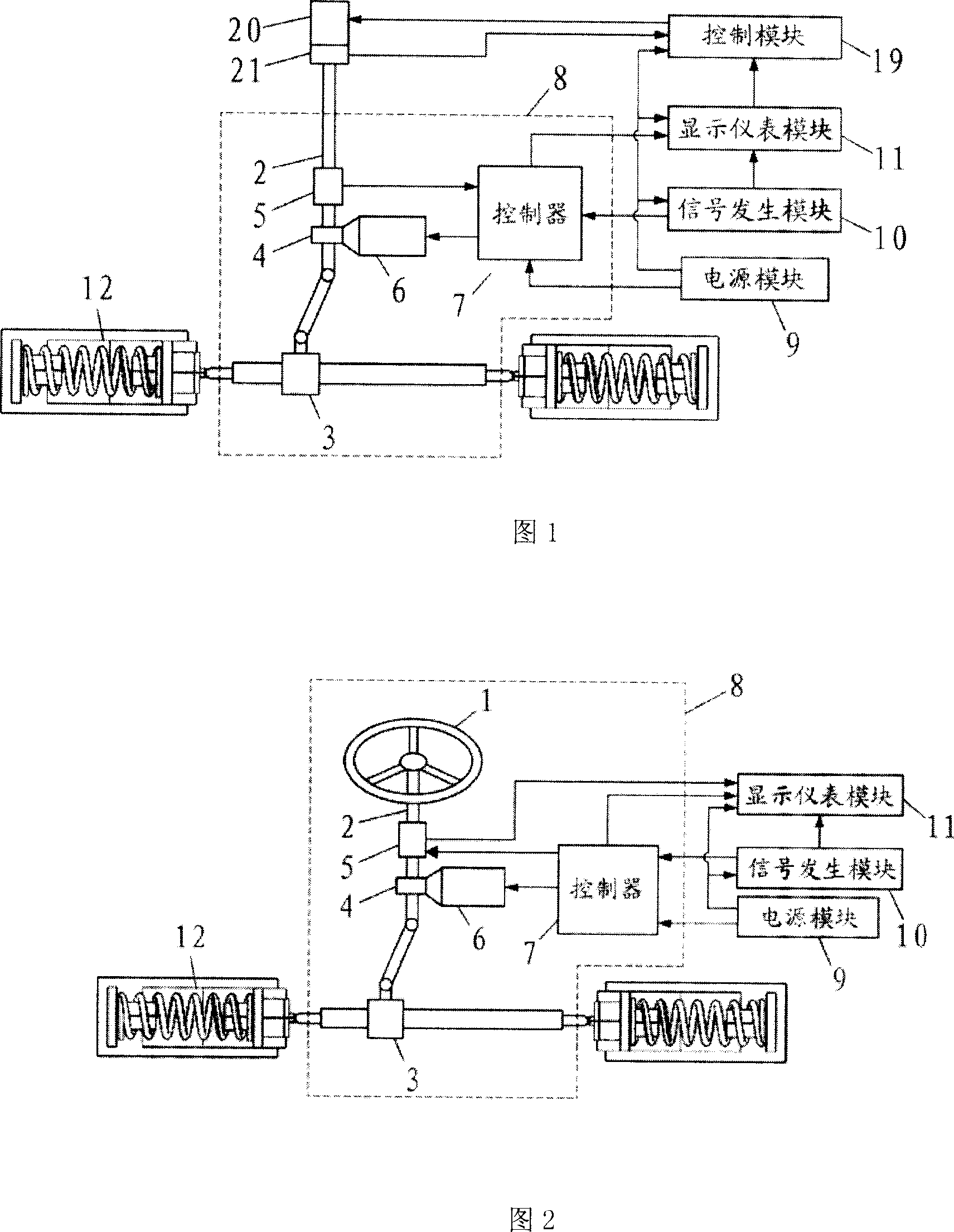

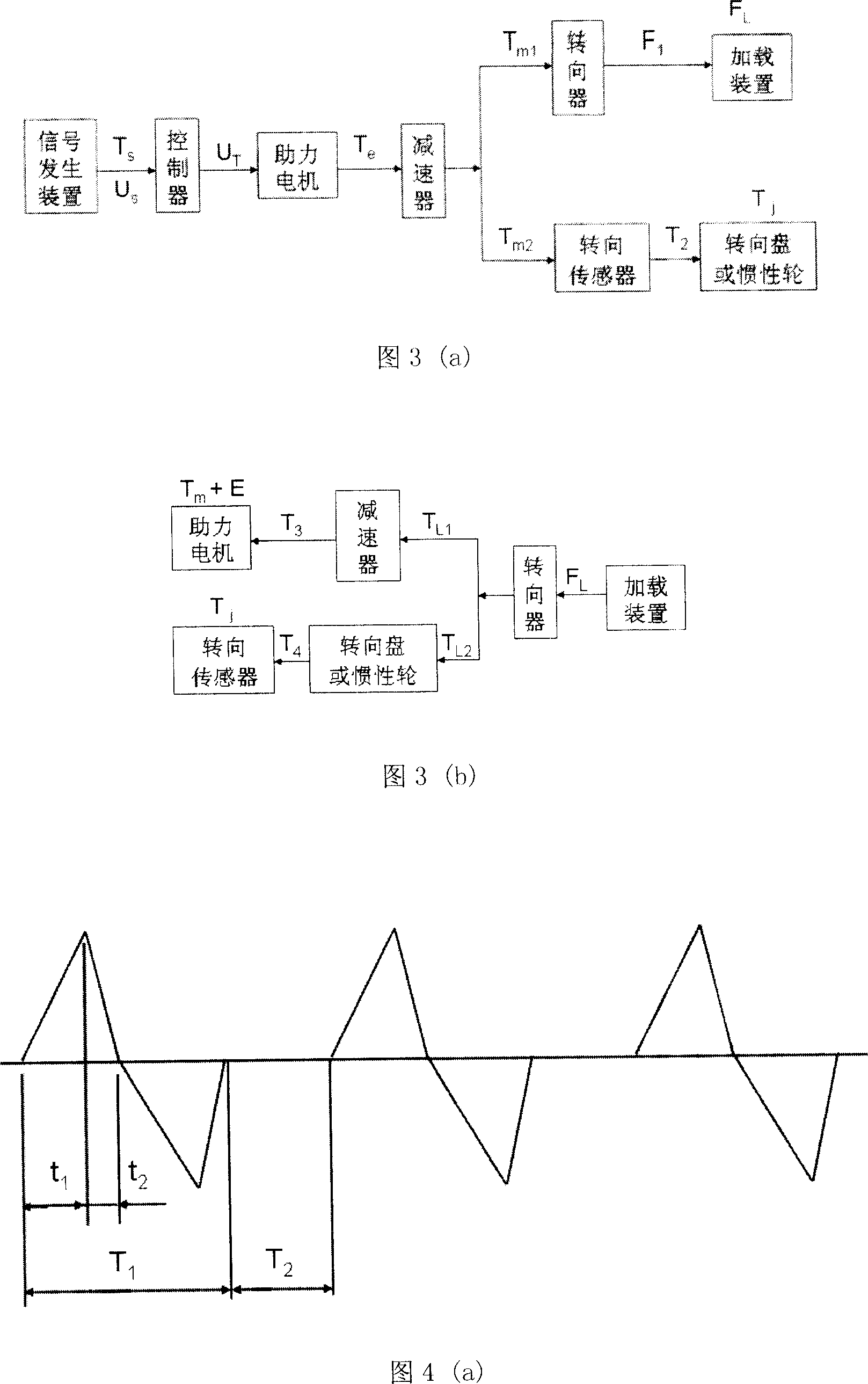

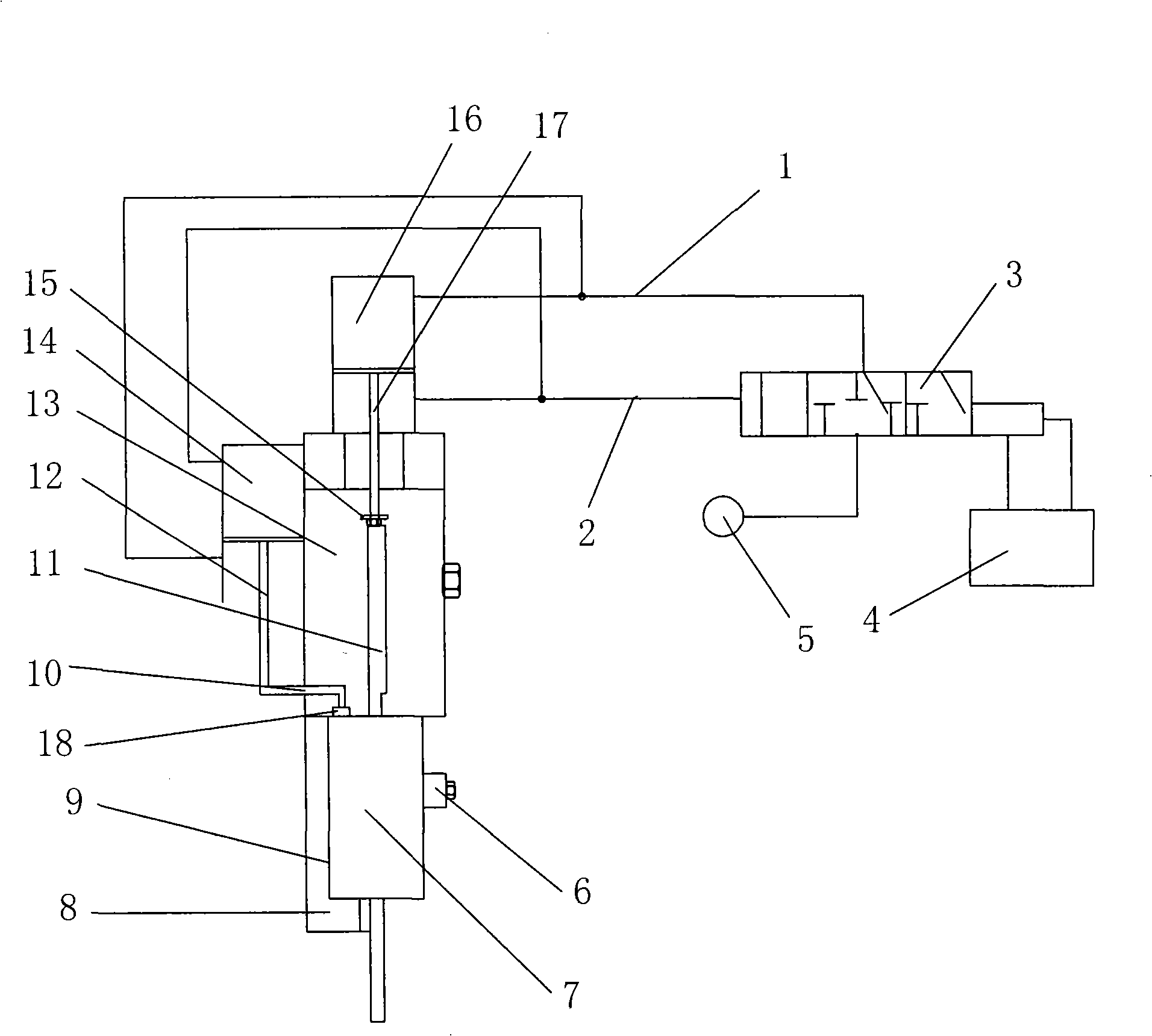

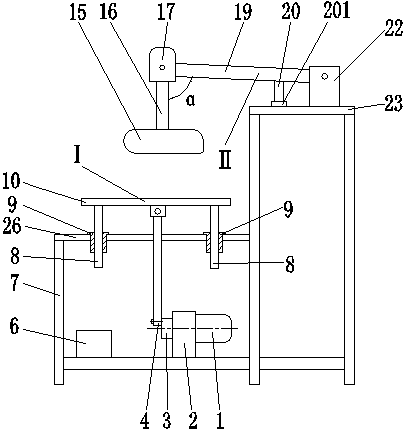

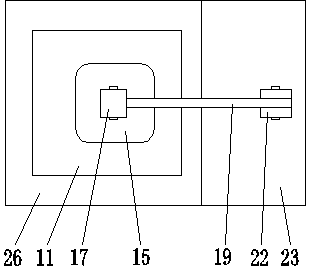

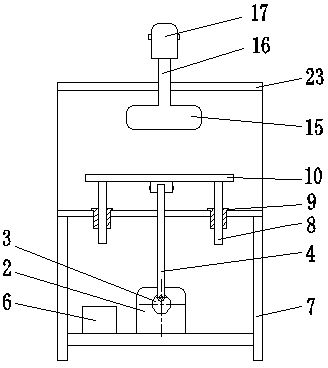

Durability testing stand of electric power-assisted steering system

InactiveCN101017117ASimple structureReduce manufacturing costMachine part testingVehicle steering/rolling behaviourElectric power steeringReduction drive

This invention relates to one motor aid rotation system life test bench, which comprises tested EPS sample, signal generation module, display meter module and load device, wherein, the EPS sample comprises rotation disc, rotation part, rotation sensor and motor bus and controller; controller is to send the voltage signal into motor bus and to sensor with work power and to send the fault signal into display meter module; motor bus is connected with mechanic system through acceleration device with output end connected with load device; signal generation module is connected to controller, display device module.

Owner:TSINGHUA UNIV +1

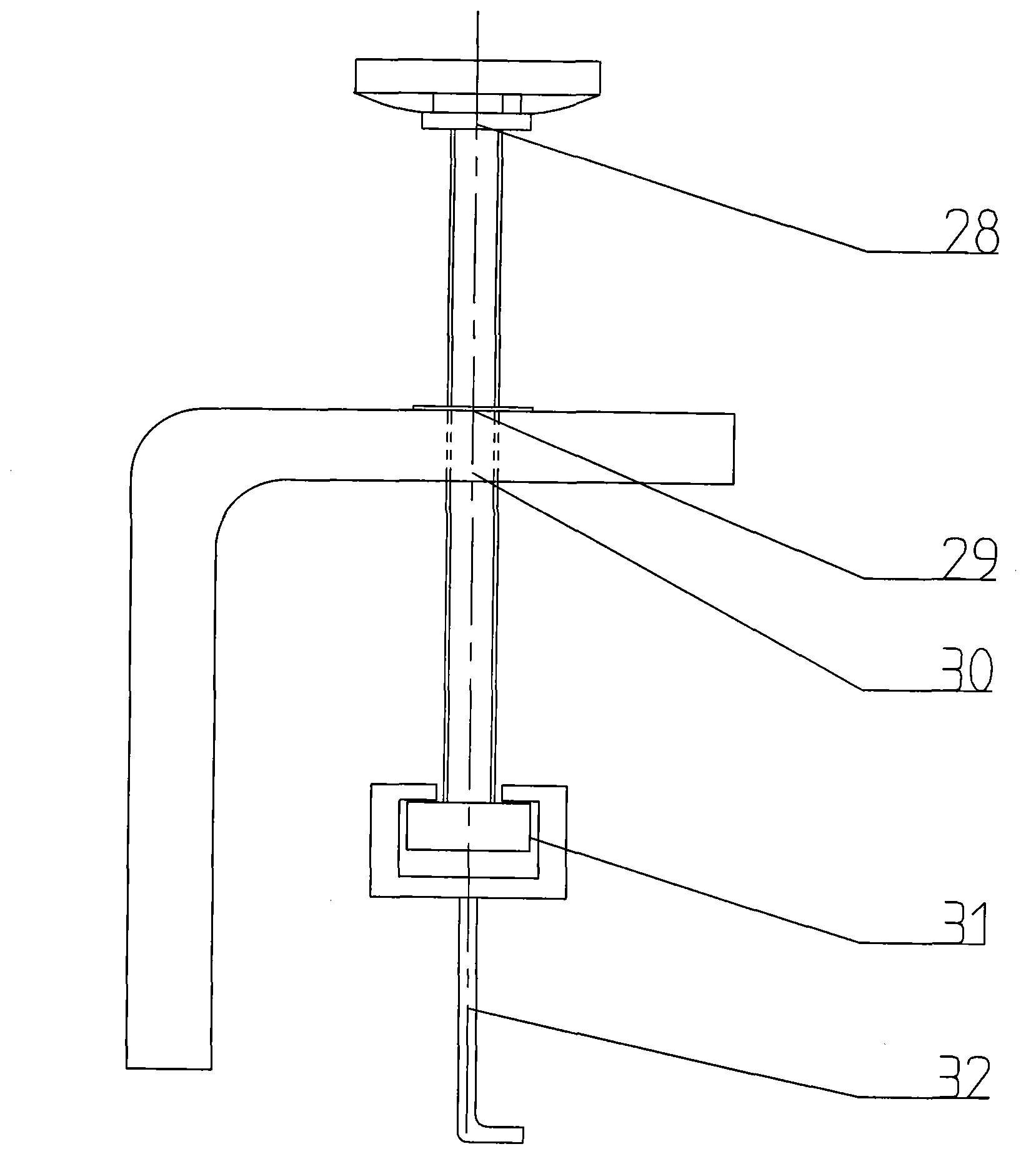

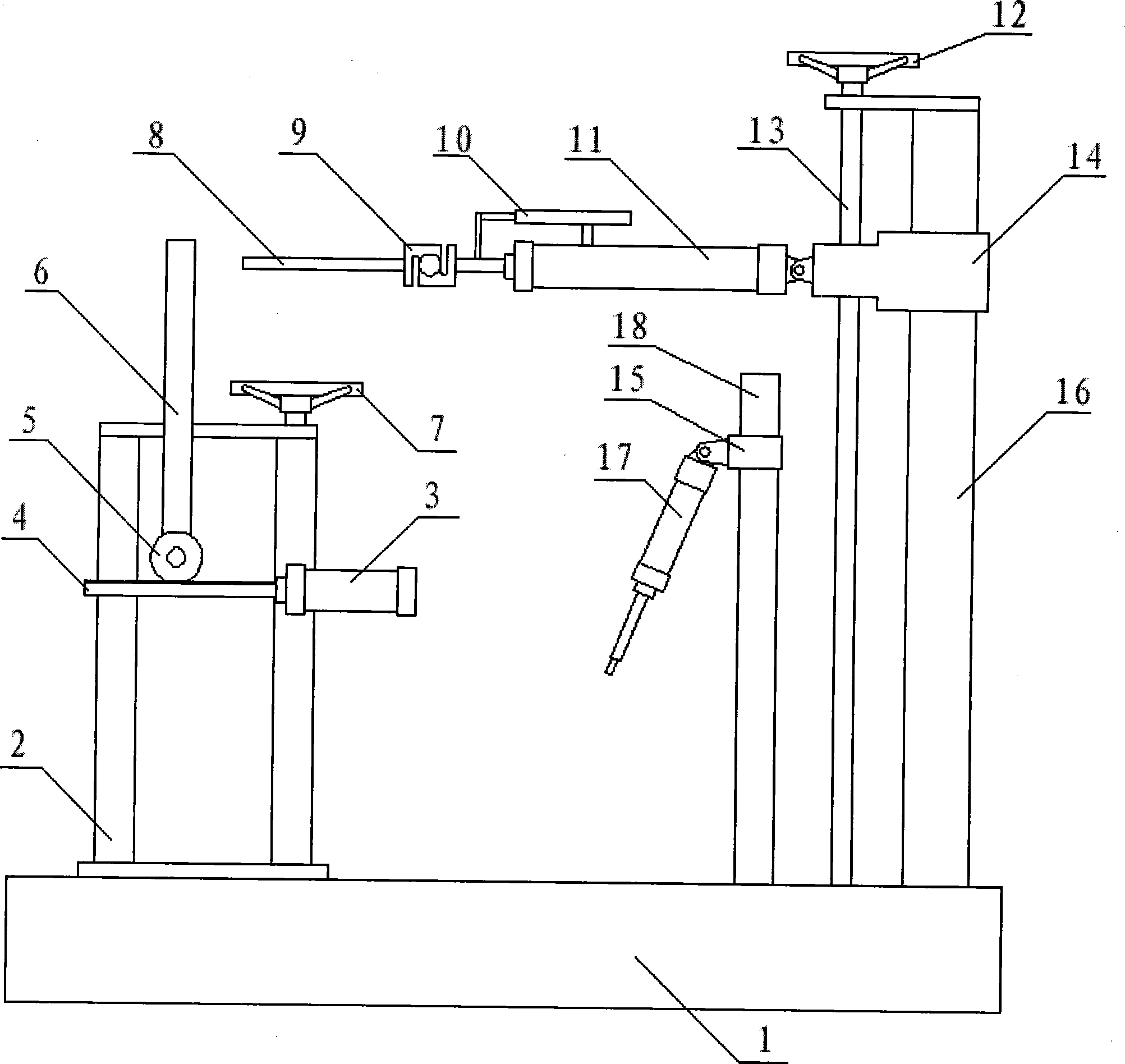

Test apparatus and method for duration performance of safety belt buckle

ActiveCN101403655ASimple structureEasy to installVehicle testingMachine part testingTest efficiencyTest fixture

The invention discloses a safety belt buckle durability testing apparatus, comprising a buckle clamp, a latch-bolt clamp; a first power element actuating the opening-locking actions of the buckle; a second power element actuating the inserting-drawing actions of the latch-bolt and a control device controlling the work of the first power element and the second power element. The safety belt buckle durability testing apparatus is provided with a simple structure, a convenient mounting process, a simple operation process and a practical capability. Adopting the apparatus to test the durability of the safety belt buckle largely enhances the test efficiency and shortens the test cycle and also reduces the manpower used for test.

Owner:CHERY AUTOMOBILE CO LTD

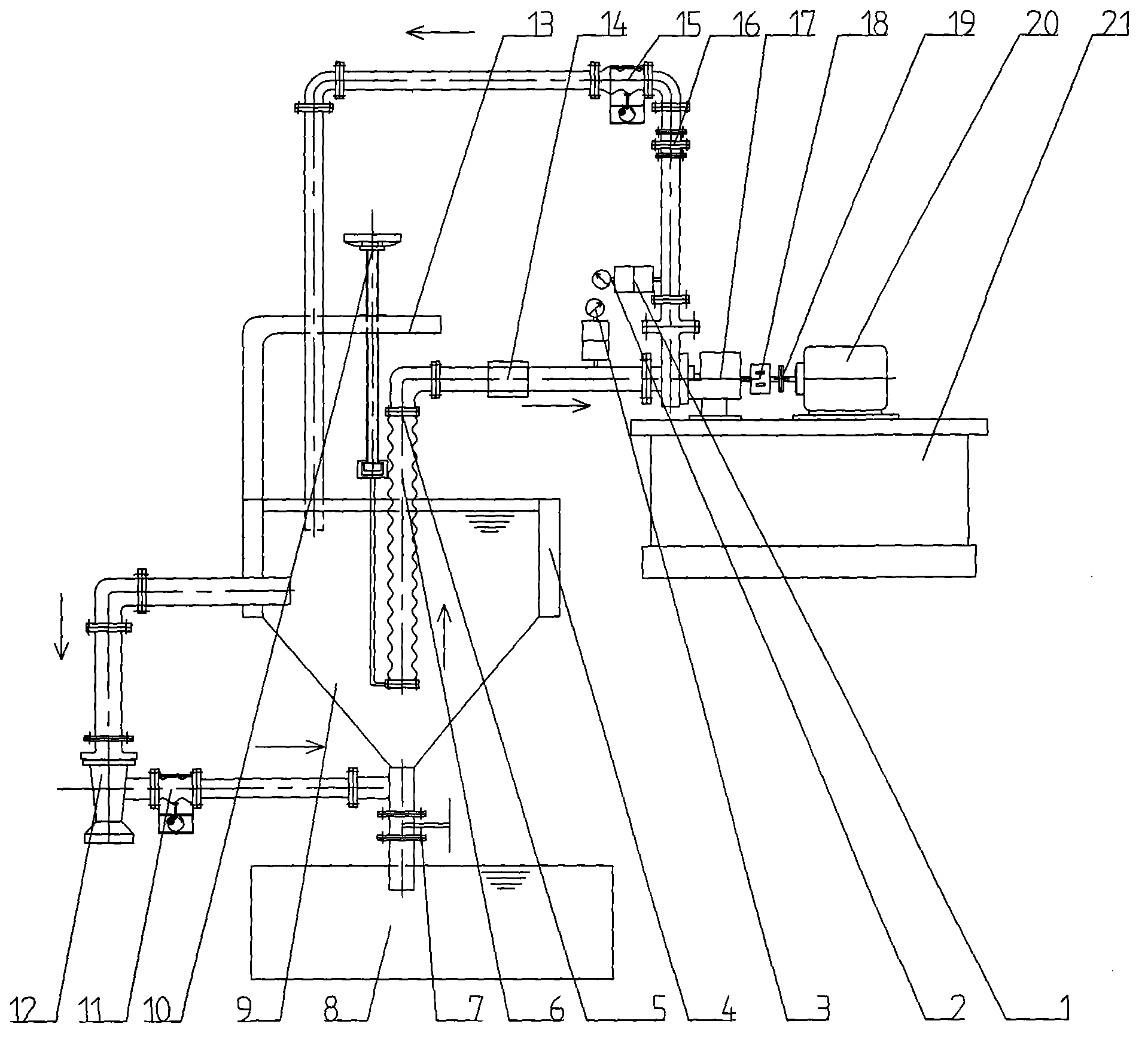

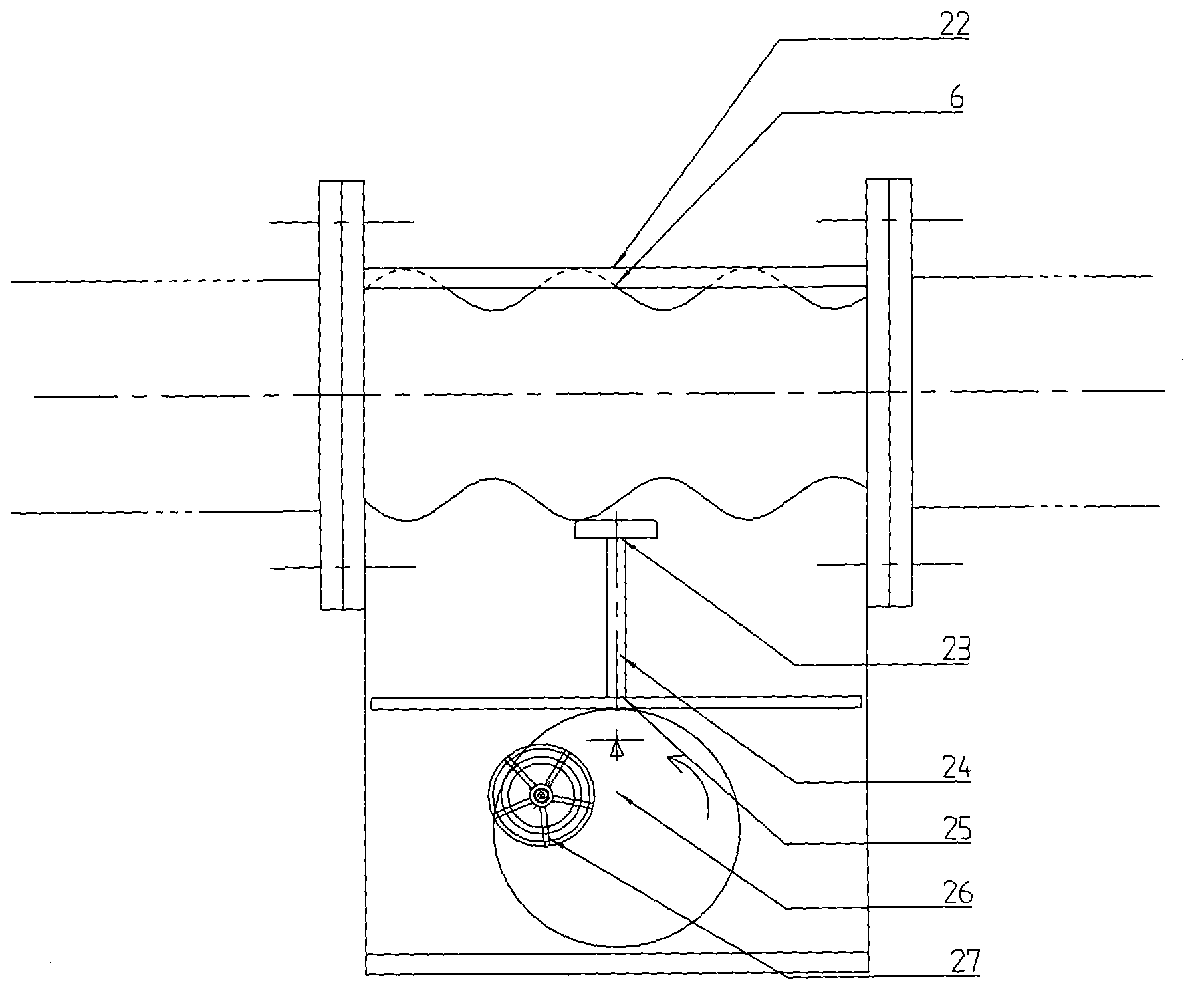

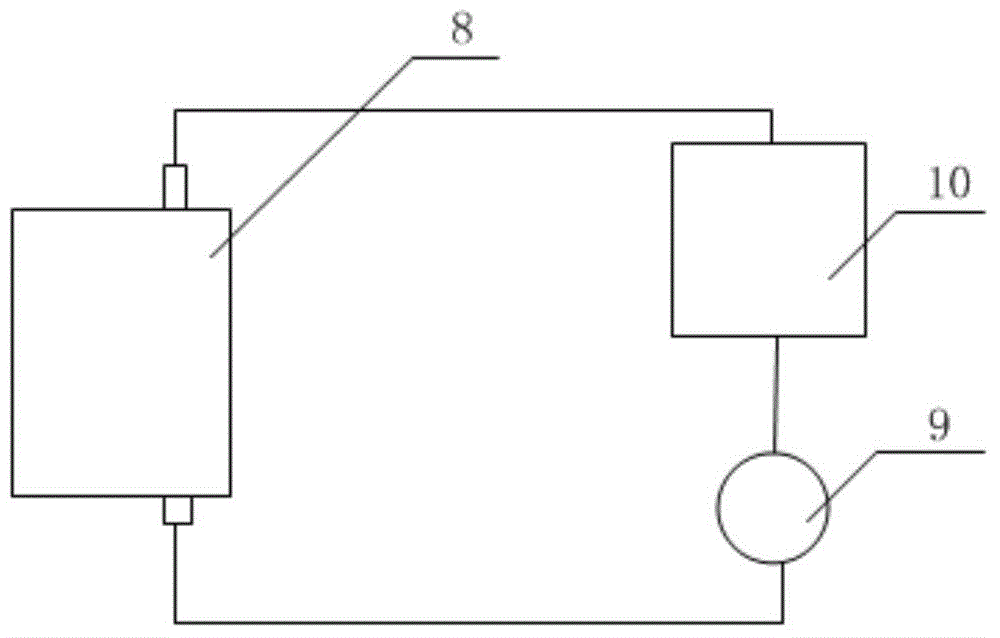

Durability testing device and testing method of solid-liquid two-phase flow pump

ActiveCN103410743ALow priceReduce weightPump controlNon-positive displacement fluid enginesImpellerSolid particle

The invention relates to a durability testing device and testing method of a solid-liquid two-phase flow pump. The testing device is mainly formed by a major loop, a temperature regulation device, a suction height regulation mechanism, a flow regulation device and the like. In an abrasion test of the solid-liquid two-phase flow pump, a bypass circulation system is led in, and the fact that solid particles in media do not deposit is guaranteed. The principle that the open area is reduced by means of elastic deformation of a rubber hose is used, the system flow is conveniently and fast regulated, and abrasion of the device is reduced. Based on an automatic deposition layering law of two-phase flow media, the regulation device at the position of a suction pipe at the inlet of the pump is designed, and the problem of obtaining two-phase flows of different concentrations is resolved. Aluminum alloy radiating fins are welded on the external of a blending tank to meet radiating requirements of a reliability test. According to the durability testing method of the of the solid-liquid two-phase flow pump, an inlet pressure and outlet pressure collection device of a two-phase flow pump system is designed, real-time monitoring and collection of pump pressure are achieved, and the relation between abrasion capacity and performance of an impeller, a pump body and other flow passage components is analyzed through a weighing method or a reverse three-dimensional reproduction technology.

Owner:JIANGSU UNIV

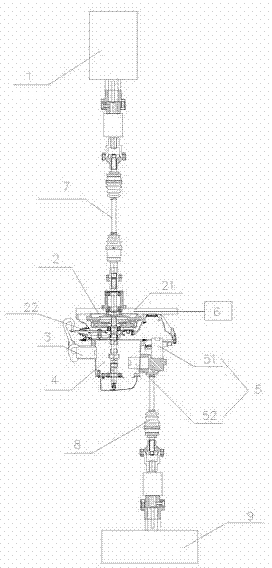

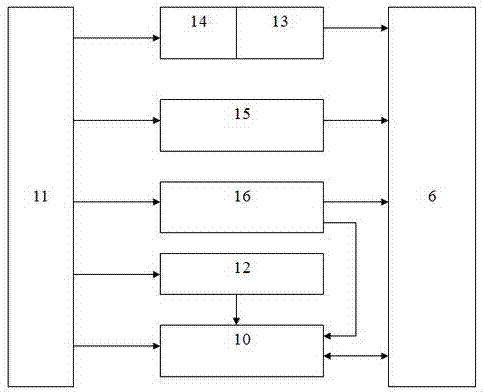

Gear change testing system of AMT (Automatic Mechanical Transmission) speed changer

The invention relates to a durability testing system of a speed changer, and particularly relates to a gear change testing system of an AMT (Automatic Mechanical Transmission) speed changer. The system comprises a speed changer gear-change testing device and a control system which are arranged and connected according to actual vehicle conditions, wherein the control system generates control signals according to the operation startup sequence of a TCU (Transmission Control Unit) controller (6), so that the TCU controller (6) has a working state capable of controlling the gear selecting of the speed changer gear-change testing device. By adopting the technical scheme, the speed changer gear-change testing device has the hardware arrangement which is identical to the structure in the actual vehicle use process, so that the speed changer gear-change testing device can completely simulate actual testing of the clutch operation, gear selecting operation, gear change operation and other links of the vehicle under the control of the control system, and the detecting result is accurate; and under the control of the control system, the speed changer gear-change testing device can simulate the gear increasing and gear decreasing operations between two gears through a manual gear by a driver, thus the testing purpose of repeated gear change is realized.

Owner:BAODING WEIYI AUTOMOBILE CO LTD

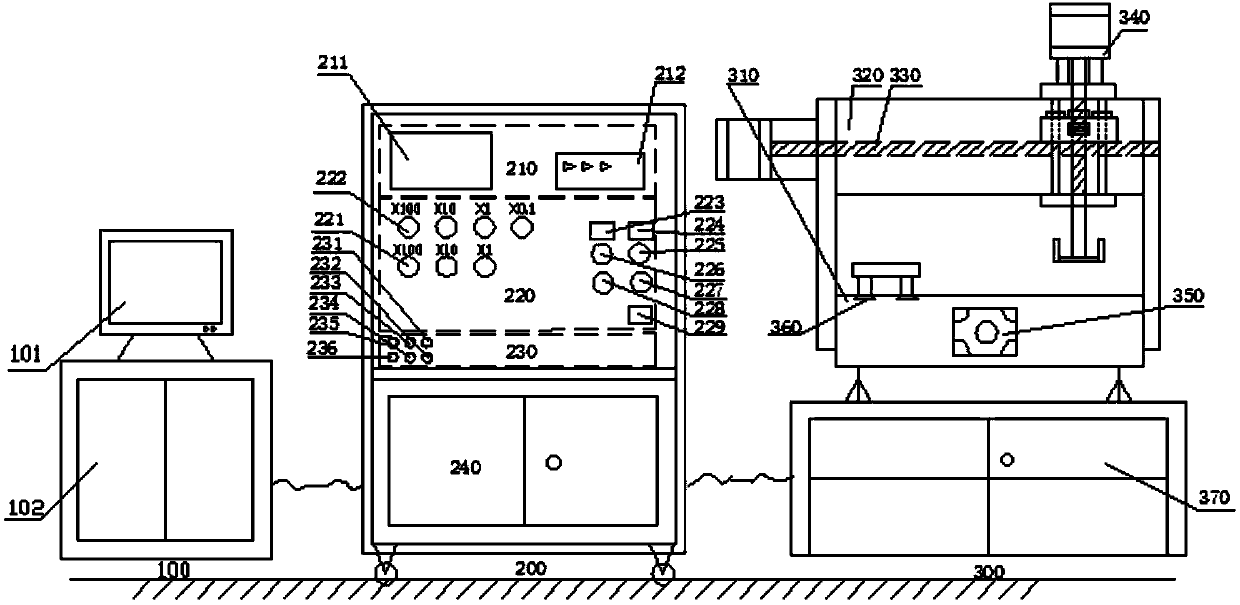

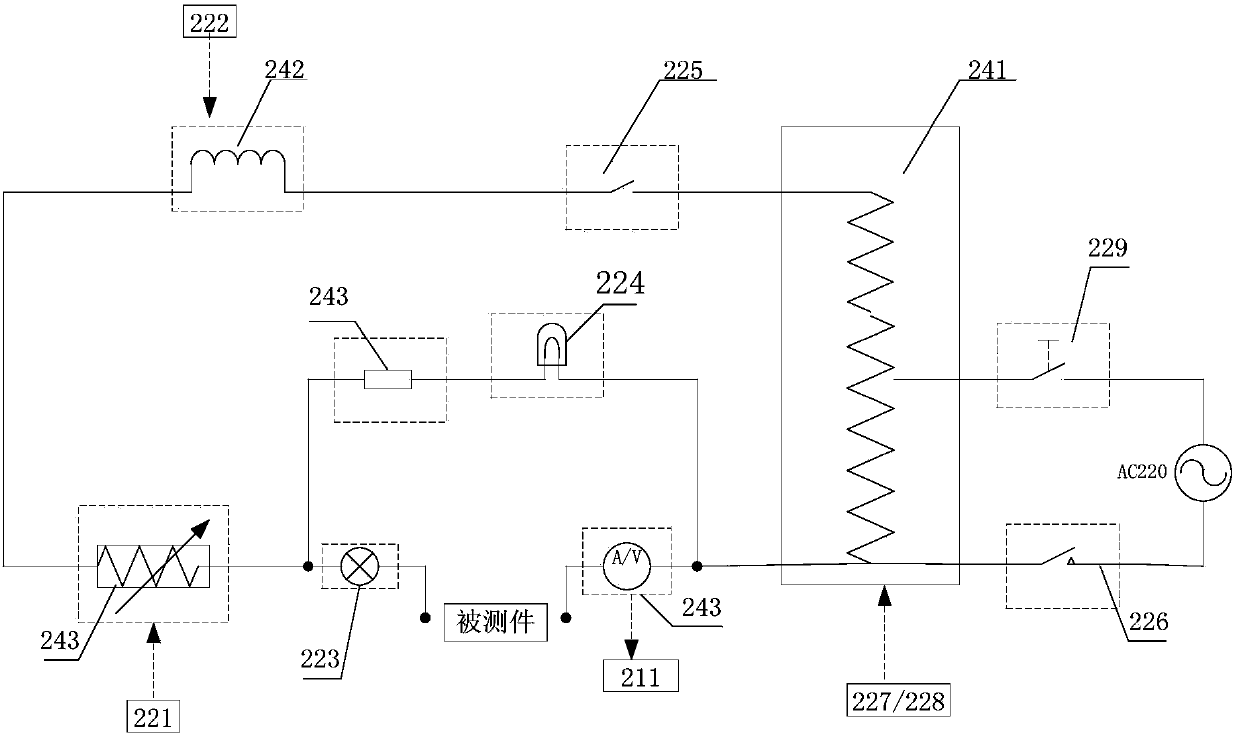

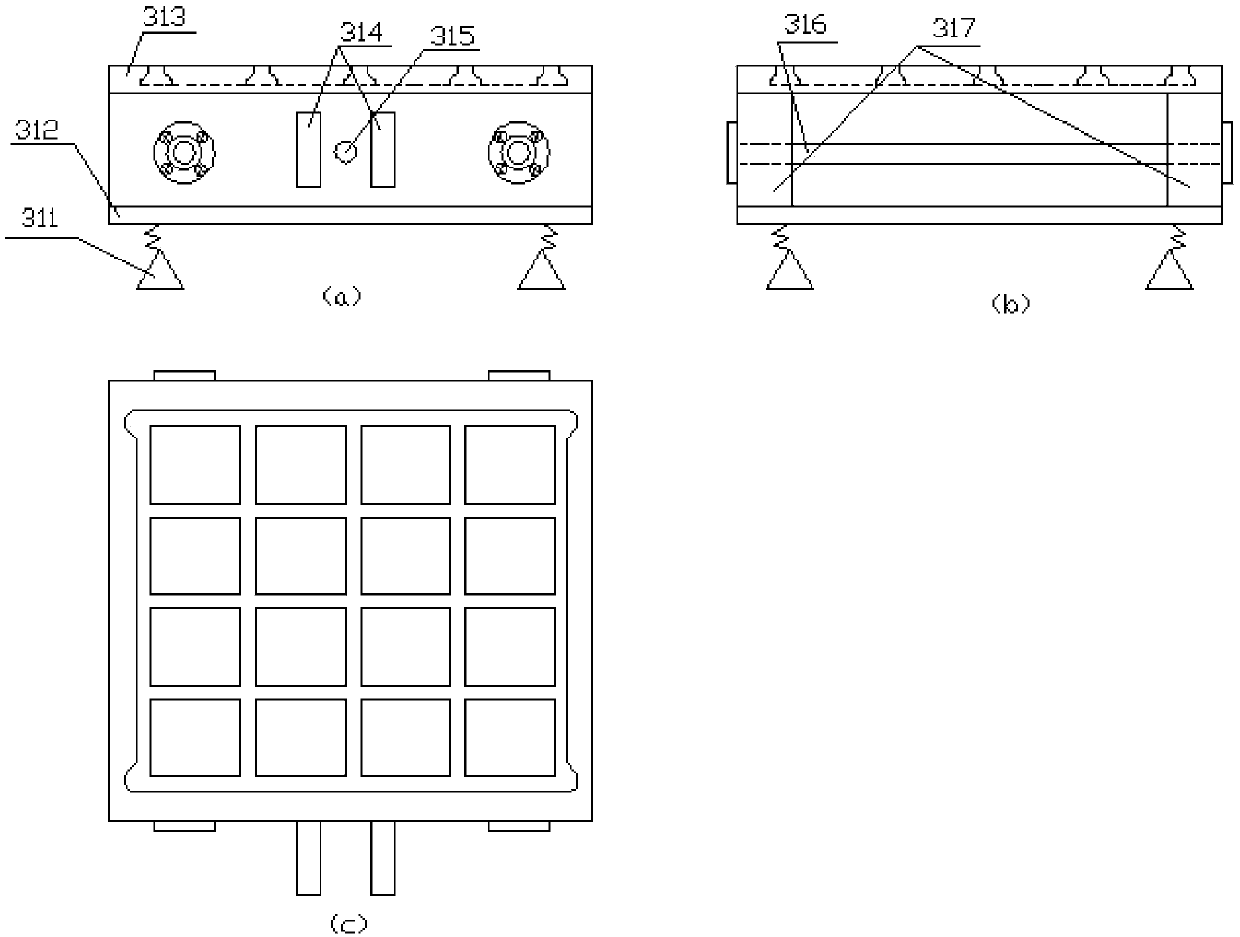

Durability test system and high-efficiency consistency test method for electrical appliance sockets

The invention discloses a durability test system and a high-efficiency consistency test method for electrical appliance sockets used for household and similar purposes. The system consists of an upper computer control device, a lower computer control device and a stepping motor execution operating device, wherein a stepping motor actuator replaces the conventional pneumatic rod actuator, and the disadvantages that the pneumatic rod actuator has heavy operation and maintenance workload and high cost are eliminated. Three-dimensional clamp numerical control positioning has the advantages of continuous testing without interruption, precise positioning and high test result consistency. The test under the control of a corrected elevator speed analogue quantity is implemented referring to an elevator speed curve, wherein the test comprises speed open-loop control of a non-plug sub-stroke and displacement closed-loop control of a plug sub-stroke; the whole process of the corrected elevator speed test does not have acceleration transilience, so that both the test efficiency and the test precision are taken into consideration; in addition, the probability that test equipment is damaged by a rigid mechanical transmission pair of a stepping motor is stopped by the displacement closed-loop control of the plug sub-stroke.

Owner:浙江方圆检测集团股份有限公司

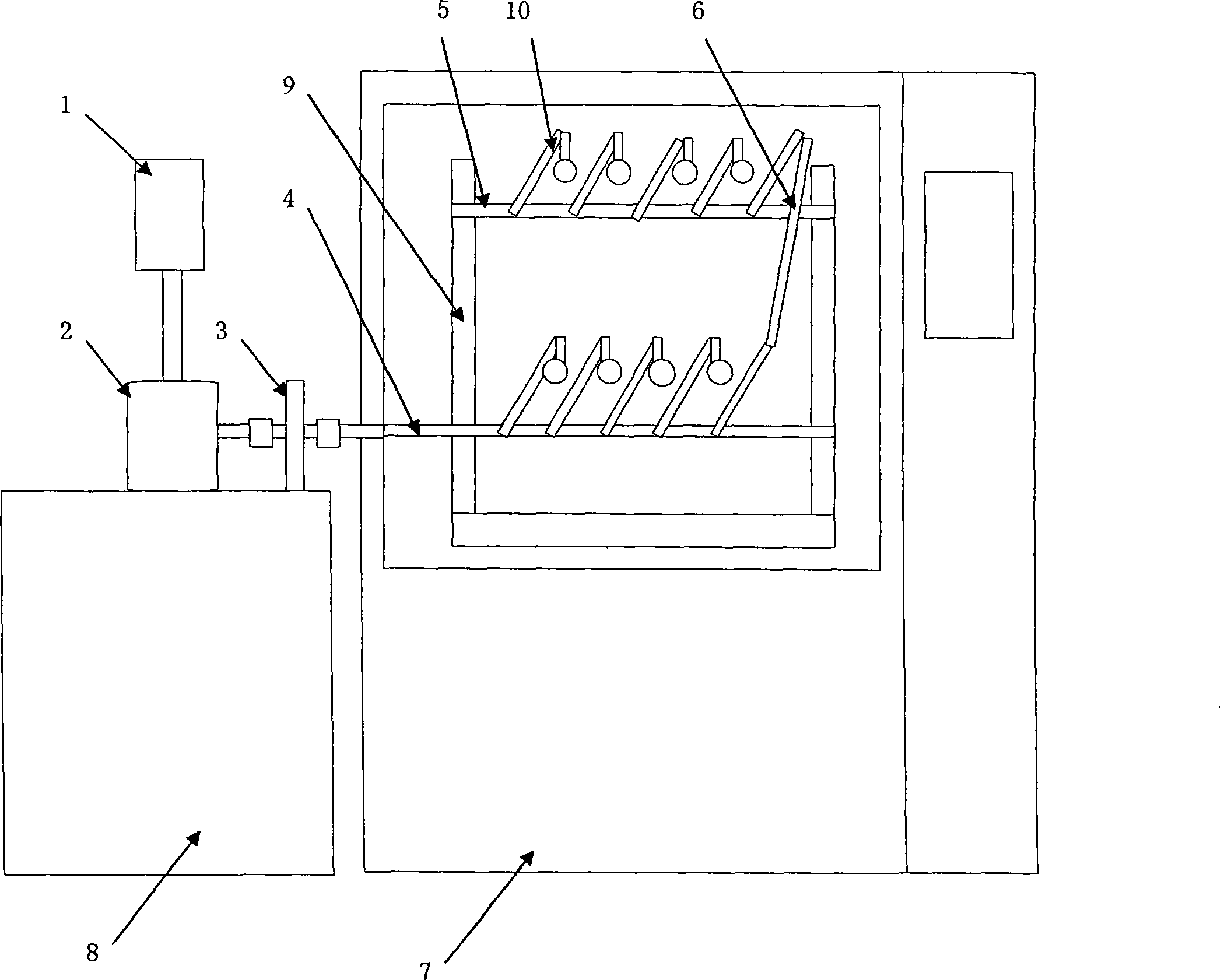

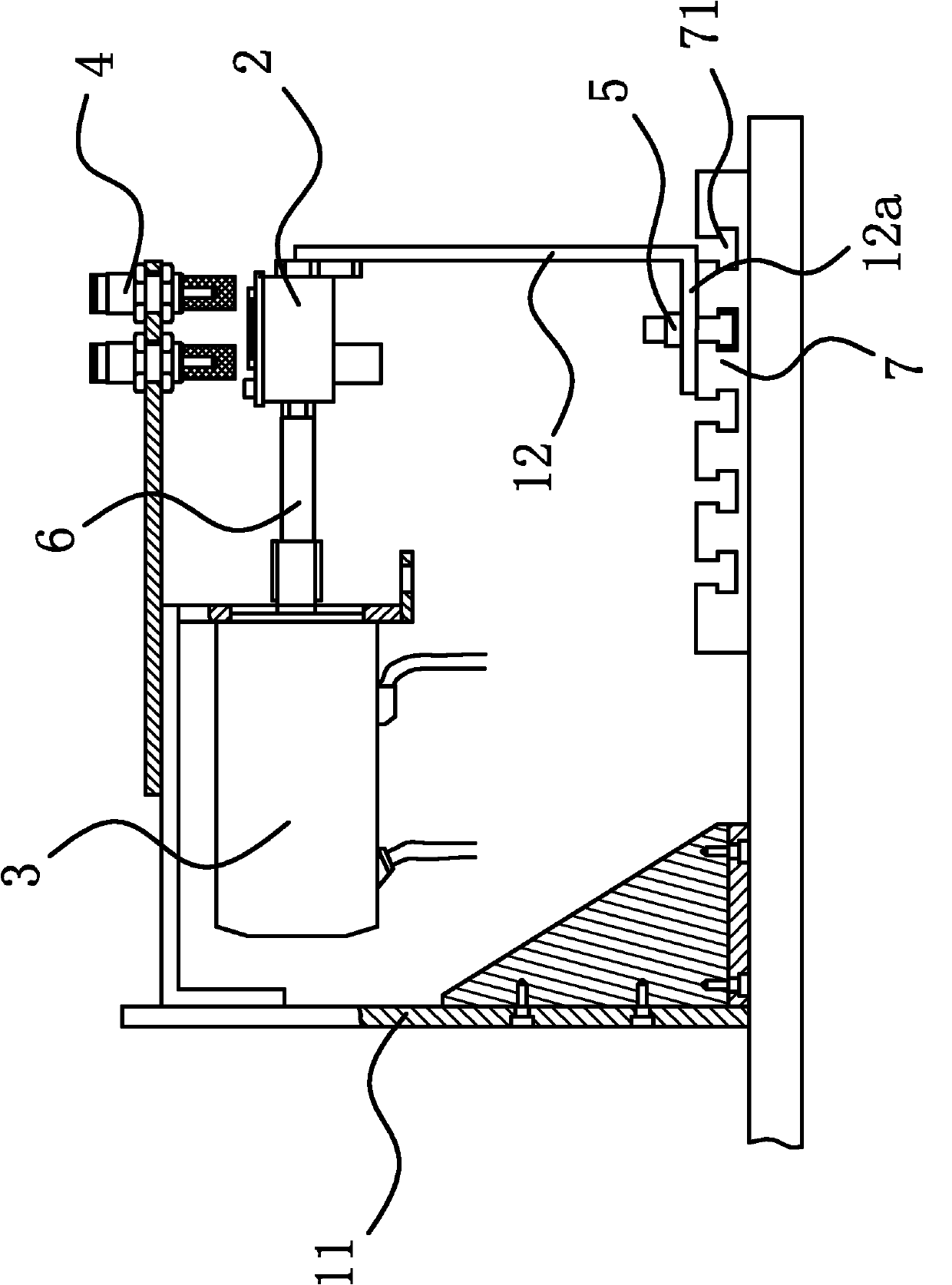

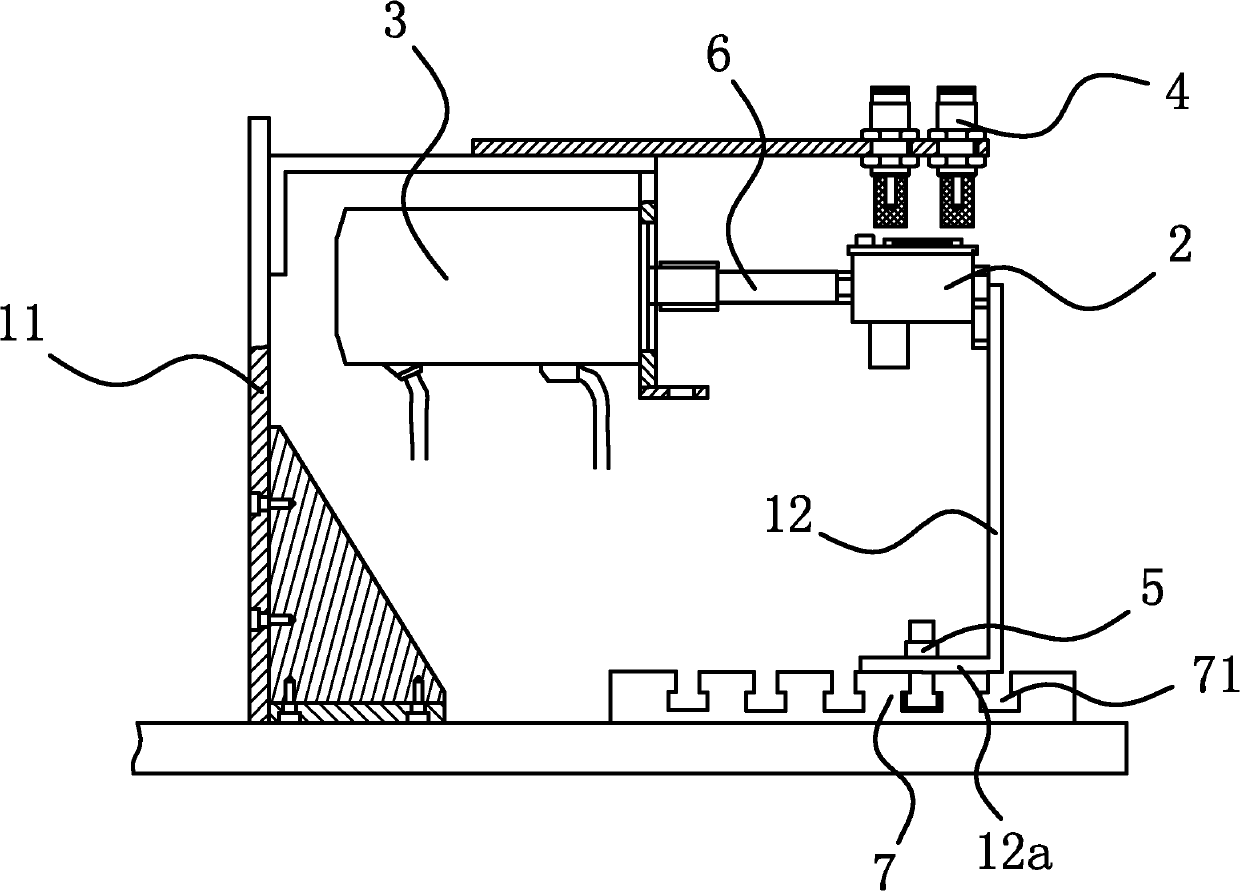

Automobile acceleration pedal durability test machine

InactiveCN101216377AShorten test timeIn line with actual working conditionsVehicle testingControl systemEngineering

The invention discloses a durability testing machine for an automotive accelerator pedal, which comprises a temperature and humidity test chamber, a mechanical transmission device and a test and control system, wherein the mechanical transmission device comprises a mechanical portion and a power portion; the mechanical portion is arranged in the temperature and humidity test chamber and is driven by the power portion; the mechanical portion includes a support, a main rotation shaft arranged on the upper end of the support, a salve rotation shaft arranged on the lower end of the support, and a parallel connection rod arranged on the main rotation shaft and the slave rotation shaft; a plurality of rockers with rollers are respectively arranged on the main rotation shaft and the slave rotation shaft; the test and control system is divided into a control system and a test system; the control system adopts PLC for transmitting program and sending a switcher instruction to control a stem motor to rotate; and an angle encoder is used for detecting the steering position of the rotation shaft. The invention can drive FPM to move back and forth under a certain environment condition to detect the durability of the FPM.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST +1

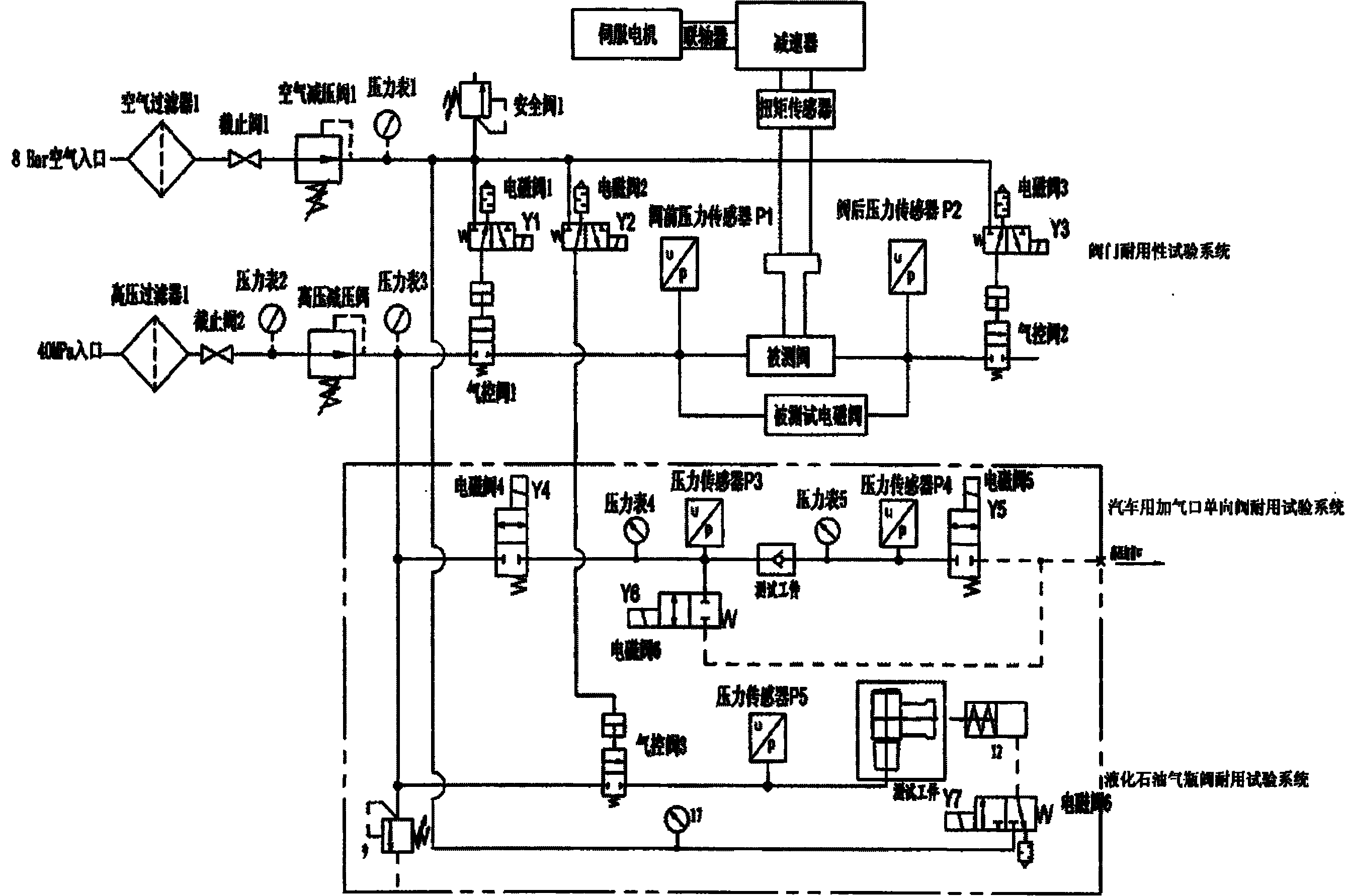

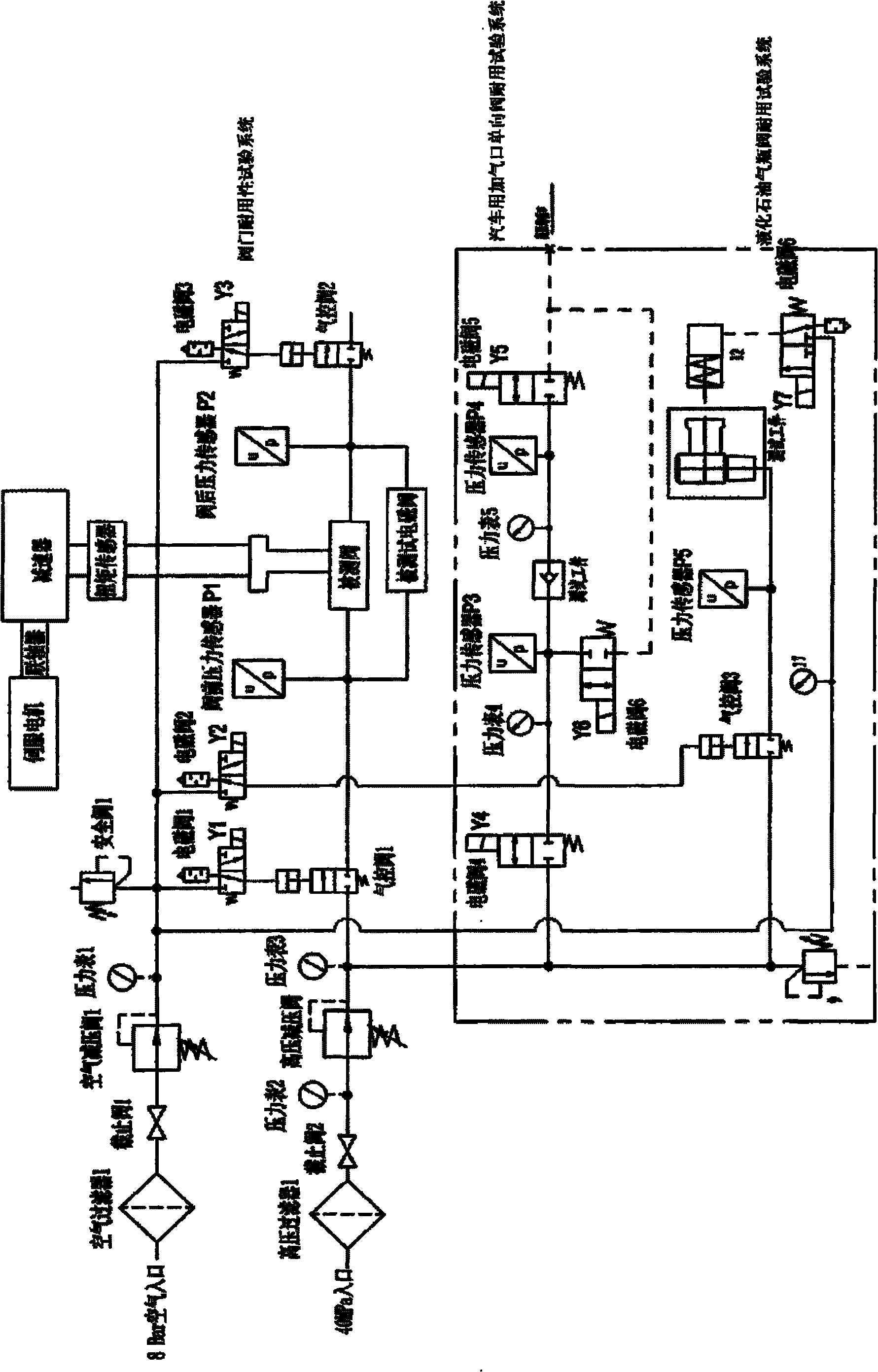

Automatic control valve life tester

InactiveCN101813573ADisplay time in real timeReal-time display of test timesMeasurement of fluid loss/gain rateAutomatic controlPilot system

The invention relates to an automatic control valve life tester, which mainly comprises a control system and a durability tester, wherein the durability tester comprises a valve durability testing system, an automotive gas charging-port one-way valve durability testing system and a liquefied petroleum gas cylinder self-closing device durability testing system. The tester is mainly used for the test of the opening and closing of a valve and the total travel torque and the durability tests of a self-closing device, an automotive gas charging port one-way valve and a liquefied petroleum gas cylinder. The three systems in the durability tester are positioned in the same frame and independent of one another and controlled by different software interfaces. When the automatic control valve life tester is used for testing the life of the valve, the test can be completed quickly, numerical values such as the pressure, the time and the test times are displayed in the test process, the test result can be stored automatically and also can be printed, and the test result can automatically stored after power is cut off.

Owner:SHANGHAI INST OF SPECIAL EQUIP INSPECTION & TECHN RES

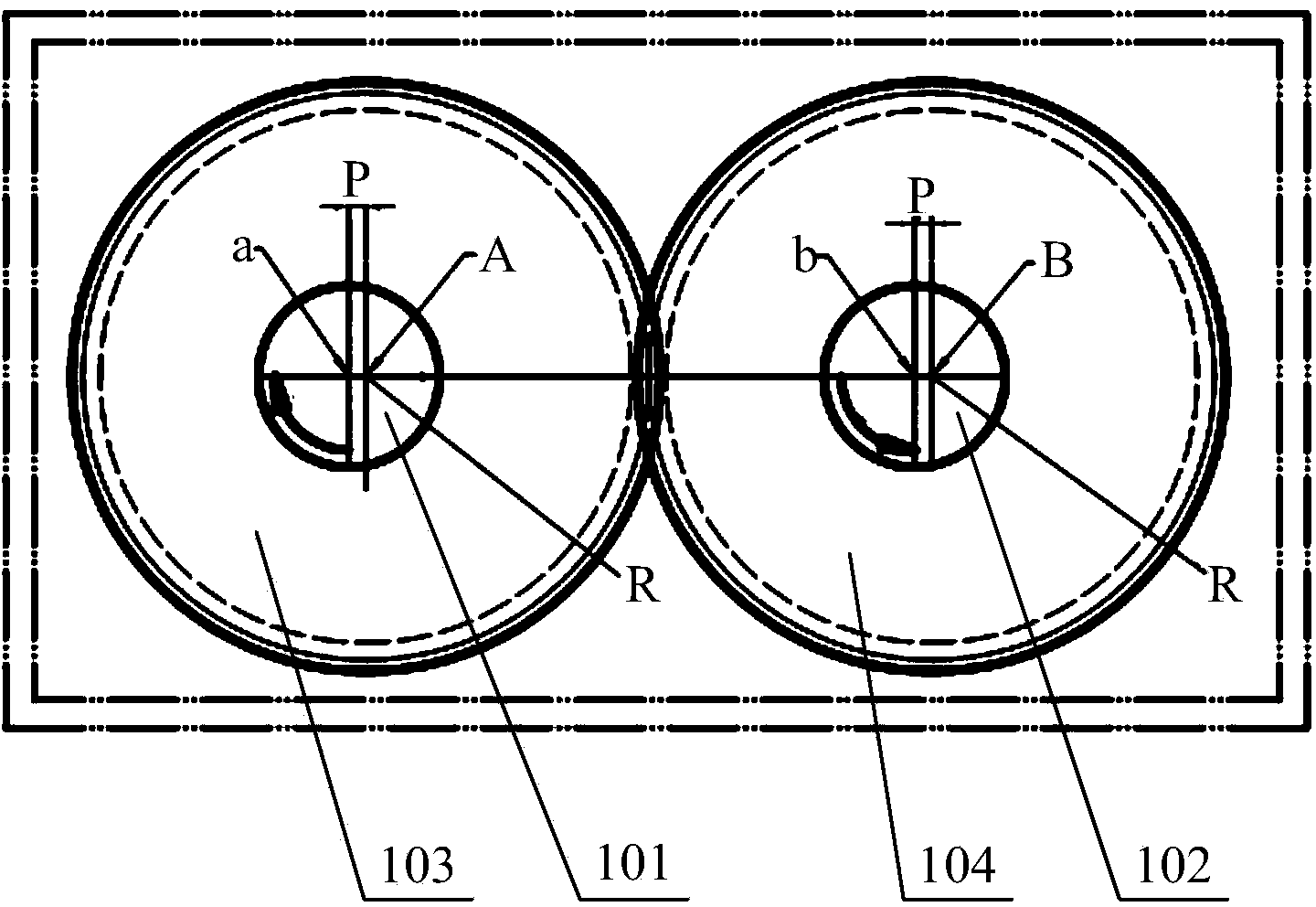

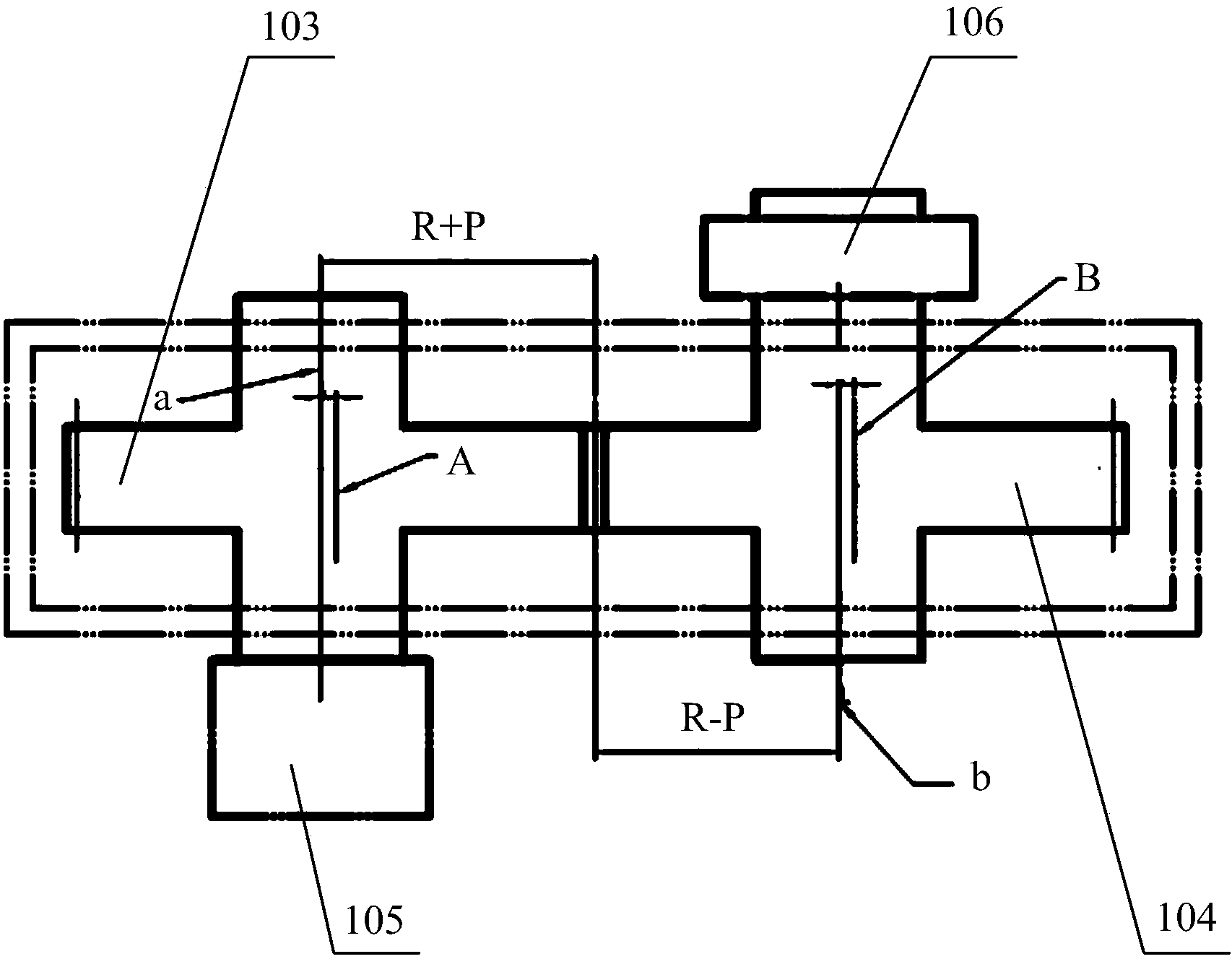

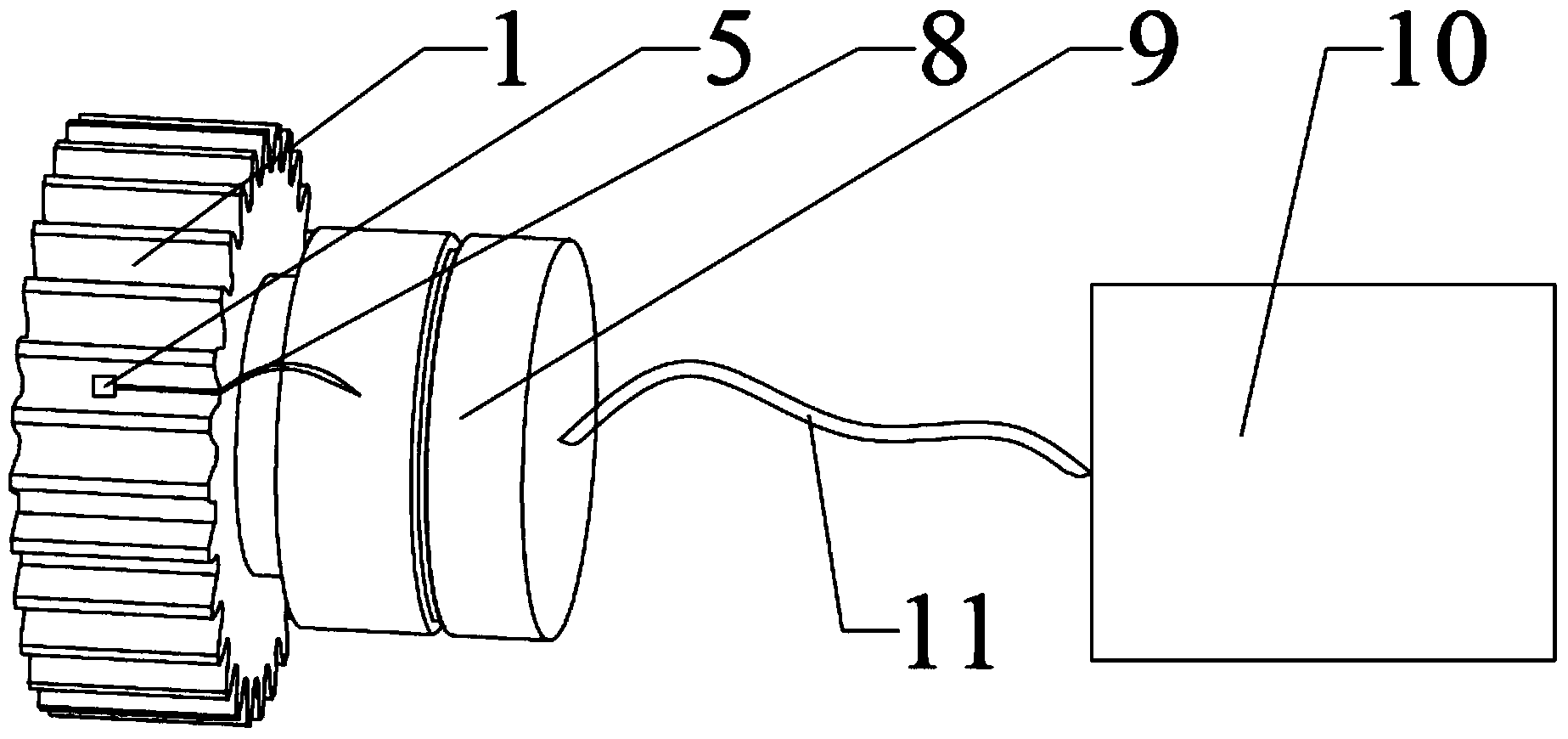

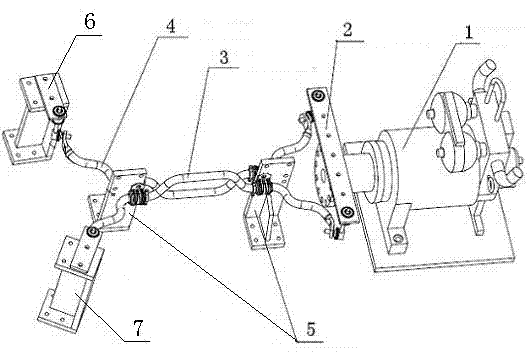

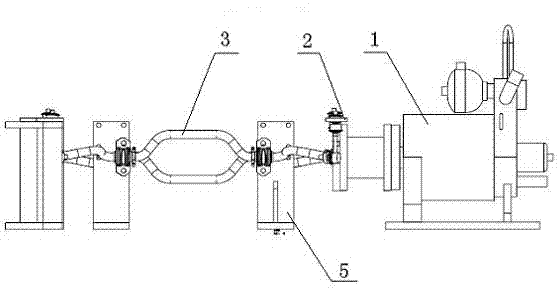

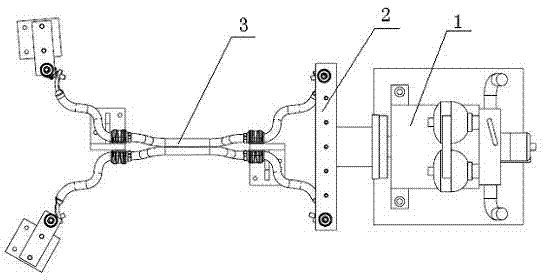

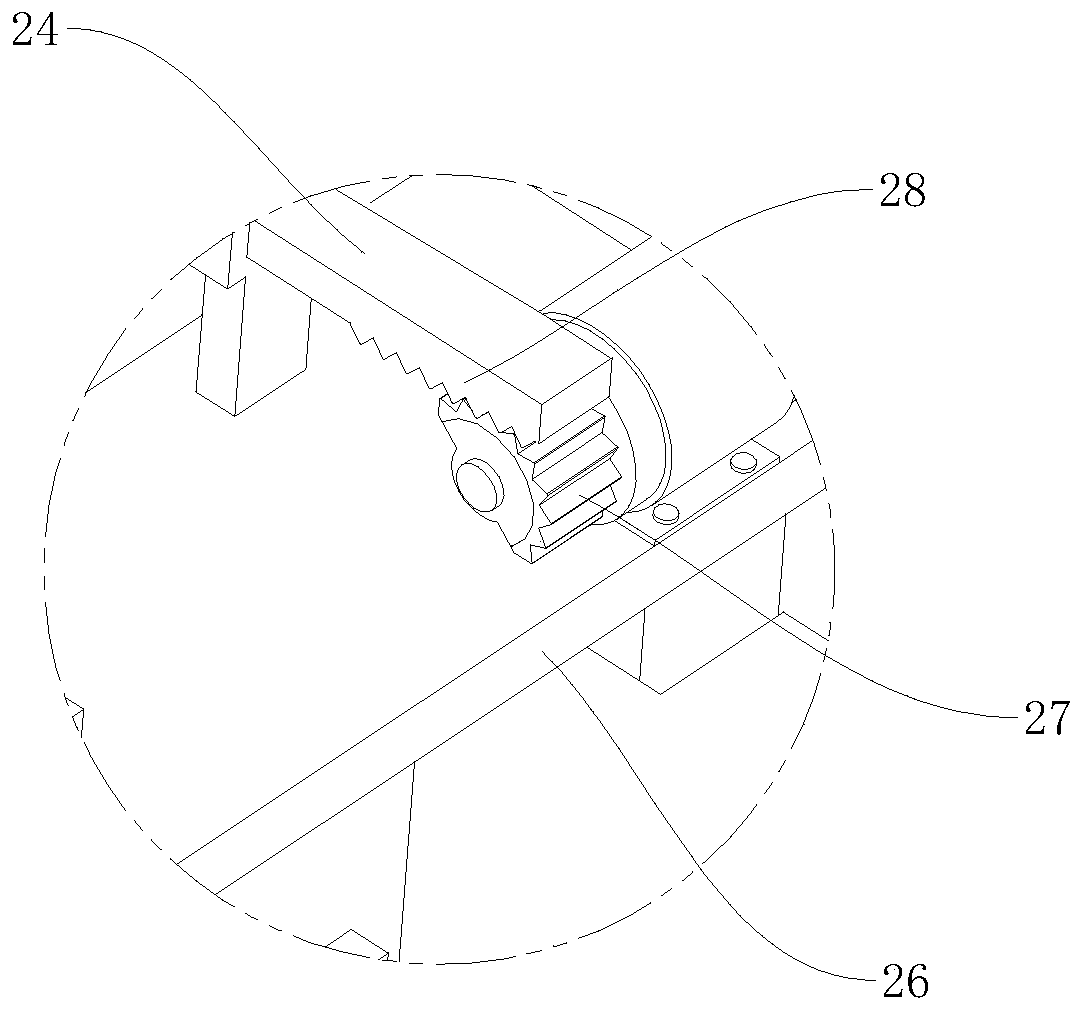

Eccentric gear type torsional vibration exciter and eccentric gear type torsional vibration excitation system

The embodiment of the invention discloses an eccentric gear type torsional vibration exciter comprising a shell; a driving shaft which is rotatably supported on the shell, wherein one end of the driving shaft is used for being connected with a rotation driving component; a driven shaft which is rotatably supported on the shell, wherein one end of the driven shaft is used for installing a tested test piece; a driving eccentric gear which is arranged on the driving shaft; and a driven eccentric gear which is arranged on the driven shaft, wherein the driving eccentric gear is engaged with the driven eccentric gear. Dynamic torsional vibration performance and durability testing can be performed on rotary power transmission component test pieces with a buffering and vibration damping function like an elastic coupler under the dynamic situation of high-speed rotation, and torsional vibration parameters can be adjusted so that torsional vibration bearing and torsional vibration elimination and isolation performance of the test pieces can be detected via simulating a practical working condition, and the fatigue durability life of the test pieces can be detected. The invention also discloses an eccentric gear type torsional vibration excitation system.

Owner:JILIN DAHUA MACHINERY MANUFACTURING CO LTD

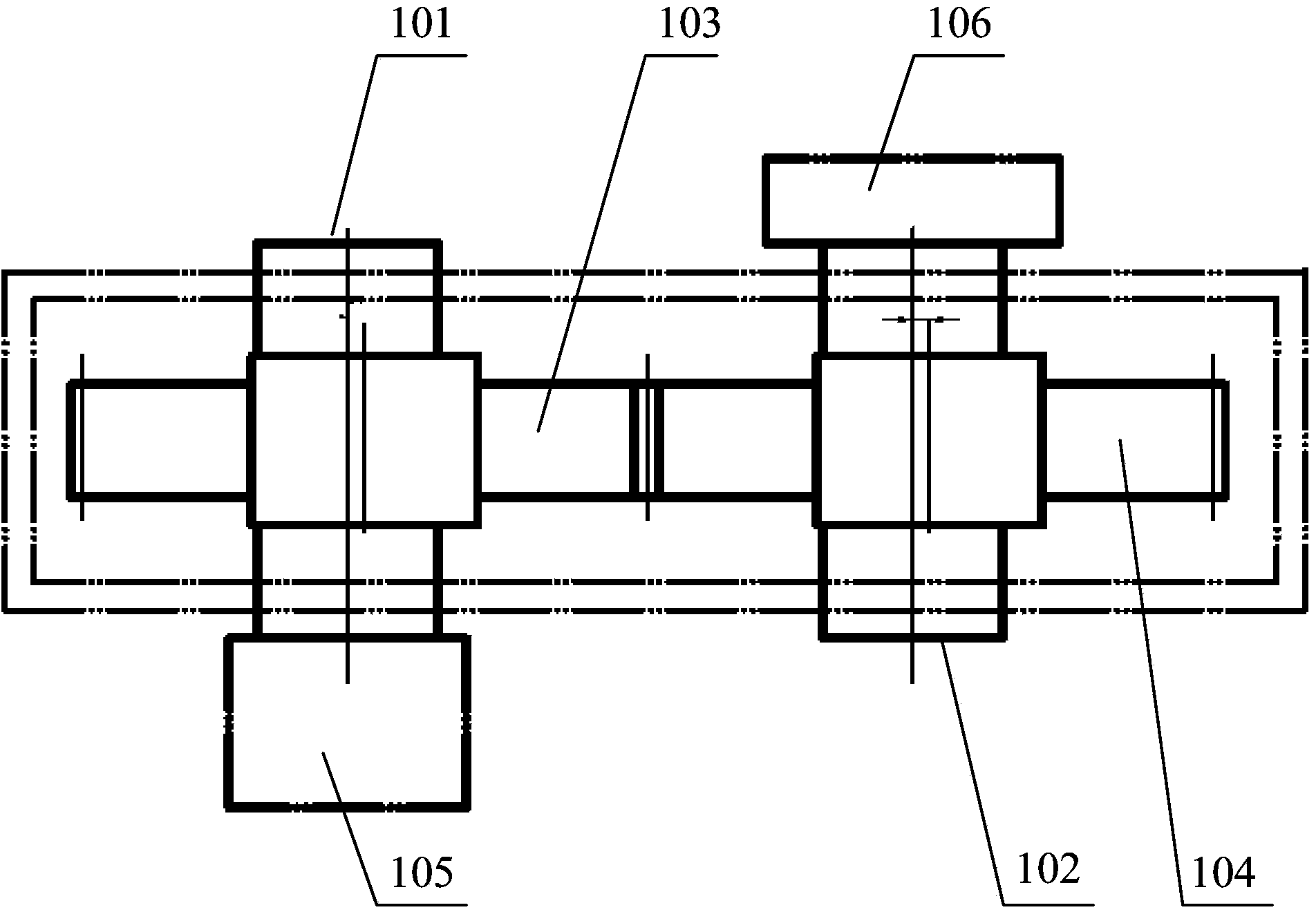

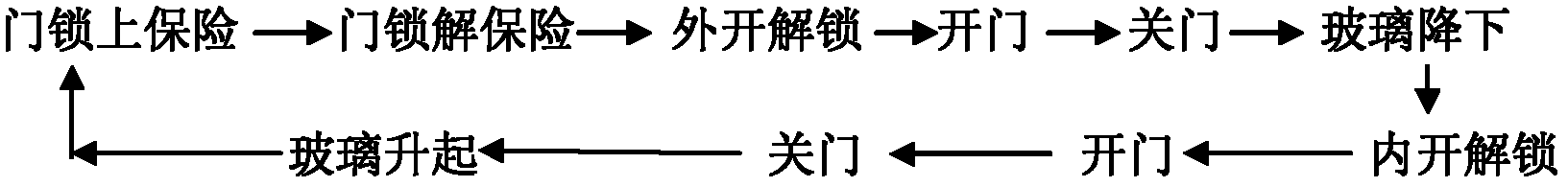

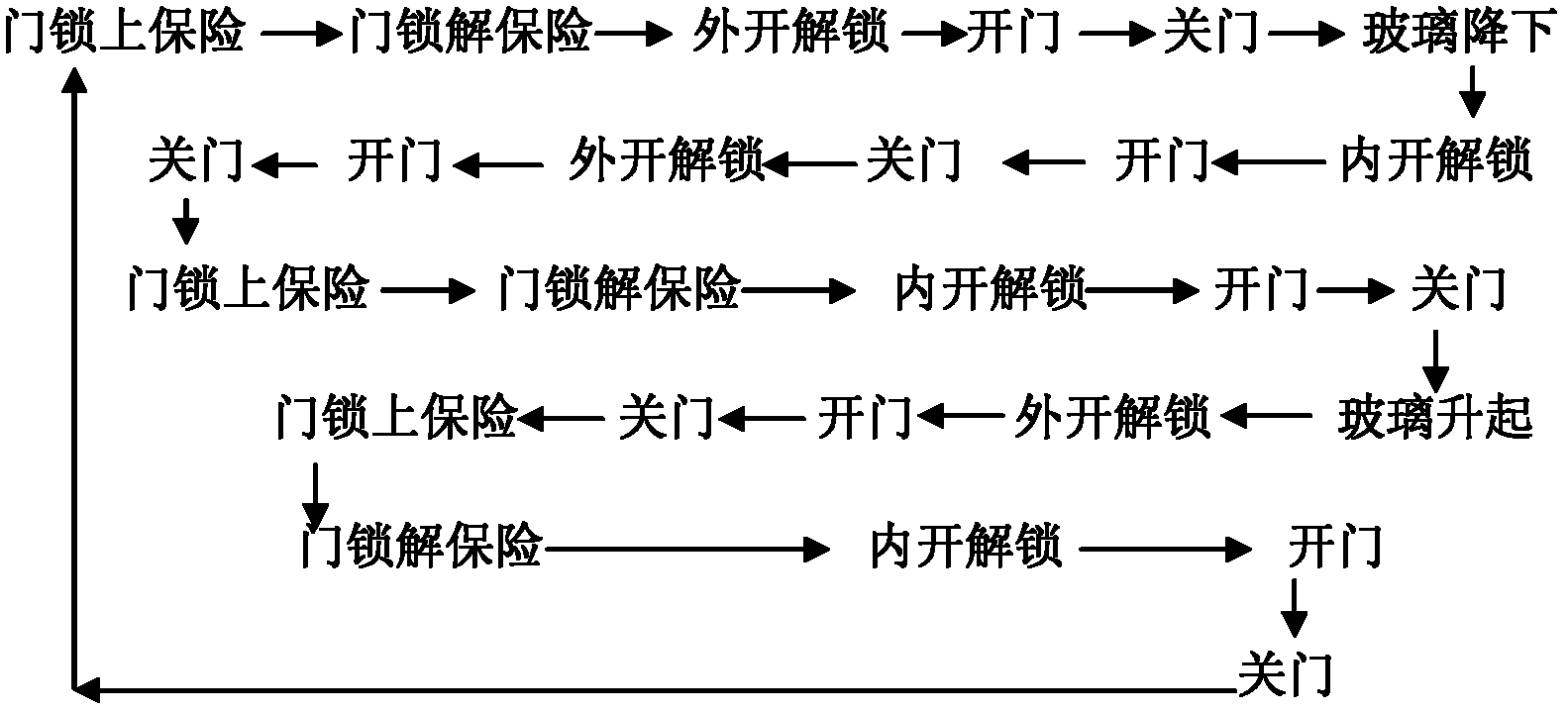

Durability testing method for rotary vehicle door system and durability testing device

ActiveCN102645343ACheck for compatibilityDetection reliabilityVehicle testingMicroprocessorDurability testing

The invention relates to a durability testing method for a rotary vehicle door system and a durability testing device. The durability testing method includes the steps: starting safing for a vehicle door lock after a vehicle door is closed; removing safing for the vehicle door lock; and unlocking the vehicle door, opening the vehicle door and closing the vehicle door when the vehicle door is opened to the largest extent. The durability testing device comprises a vehicle door closing mechanism, an inward opening unlocking mechanism, an outward opening unlocking mechanism, a vehicle door unlocking protector, a vehicle door opening largest position buffering mechanism, a glass lifting controller, a door lock safing or safing removing controller and a microprocessor. By the aid of the durability testing device for the rotary vehicle door system, users' operation action of the rotary vehicle door and control of door opening and closing force can be simulated, so that reliability of the rotary vehicle door system and compatibility of relevant functional parts are effectively detected. The durability testing device has the advantages of fine universality, simple structure, simplicity and convenience in operation and high reliability and safety.

Owner:CHERY AUTOMOBILE CO LTD

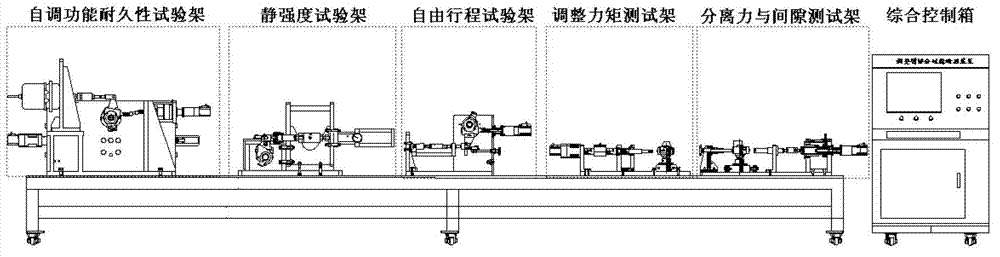

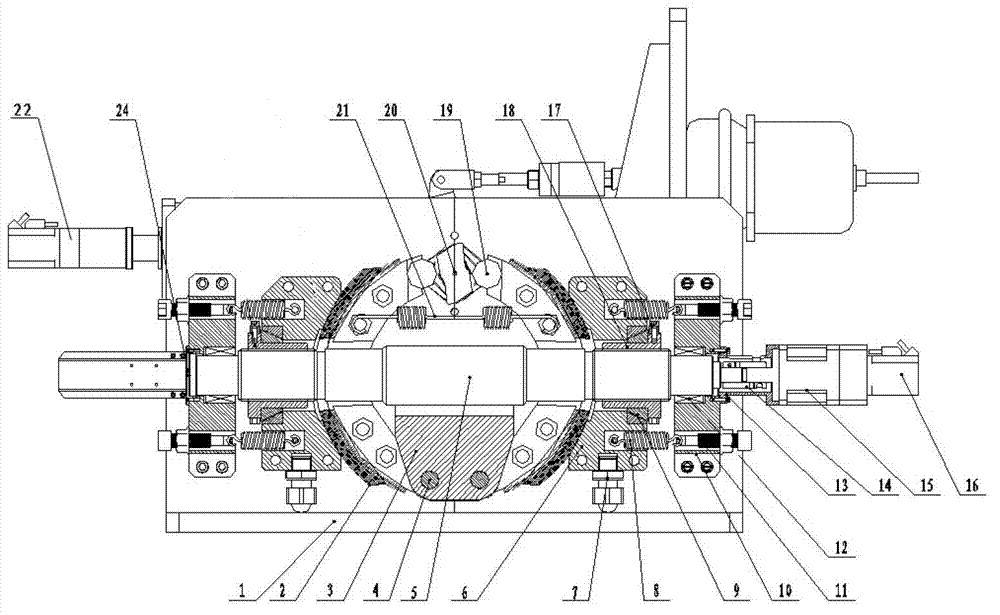

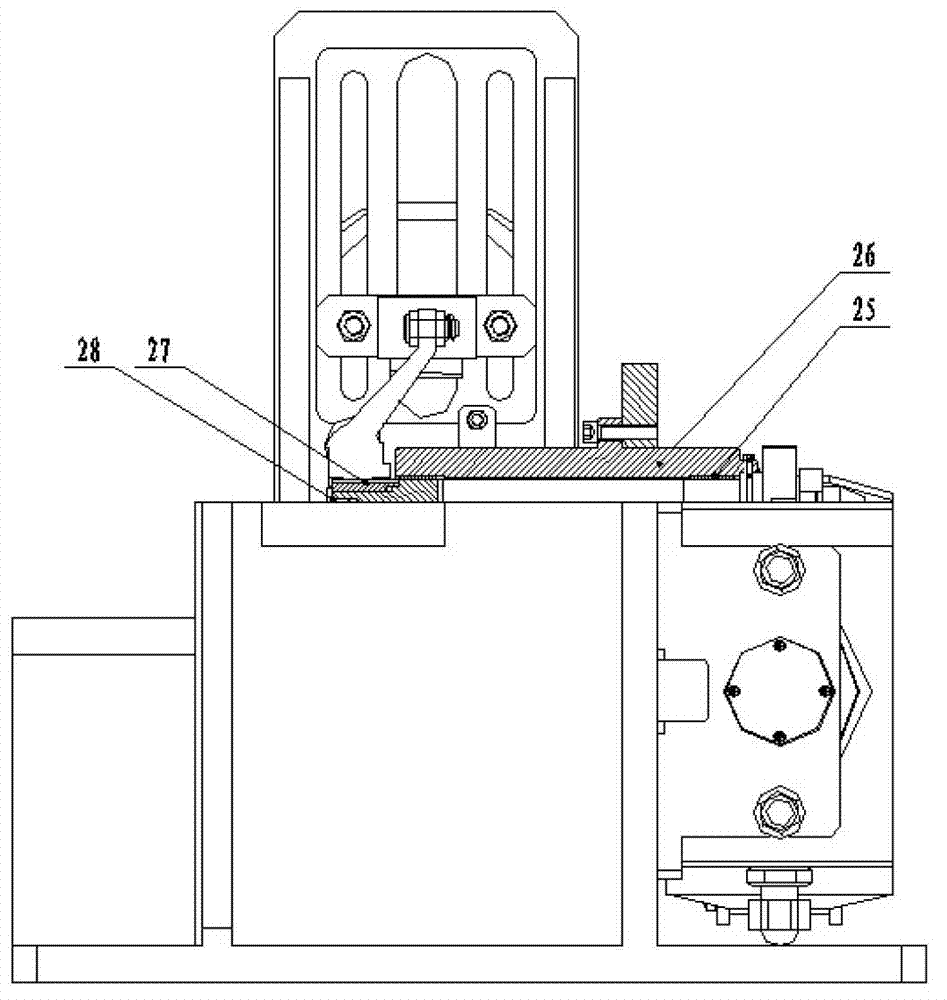

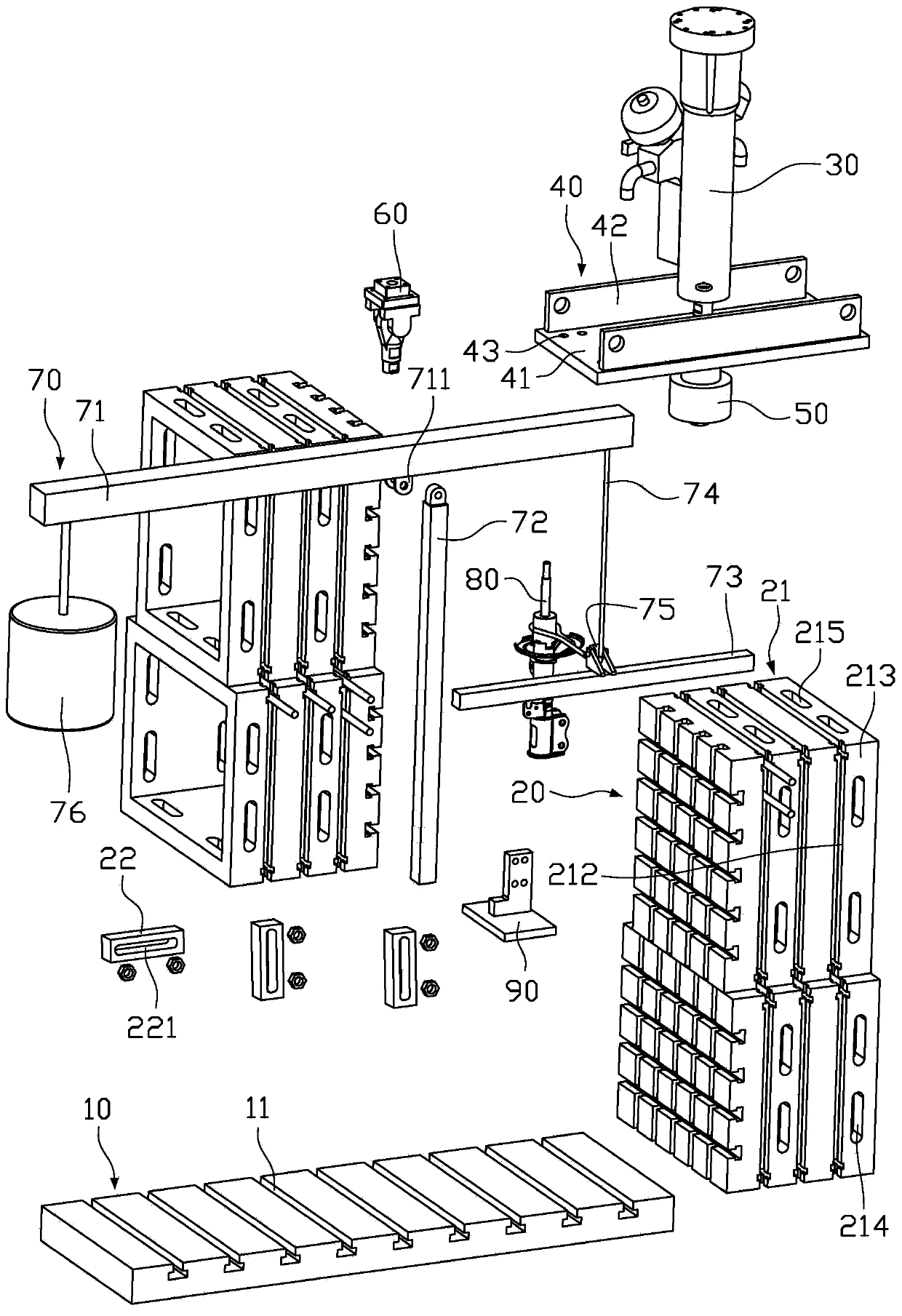

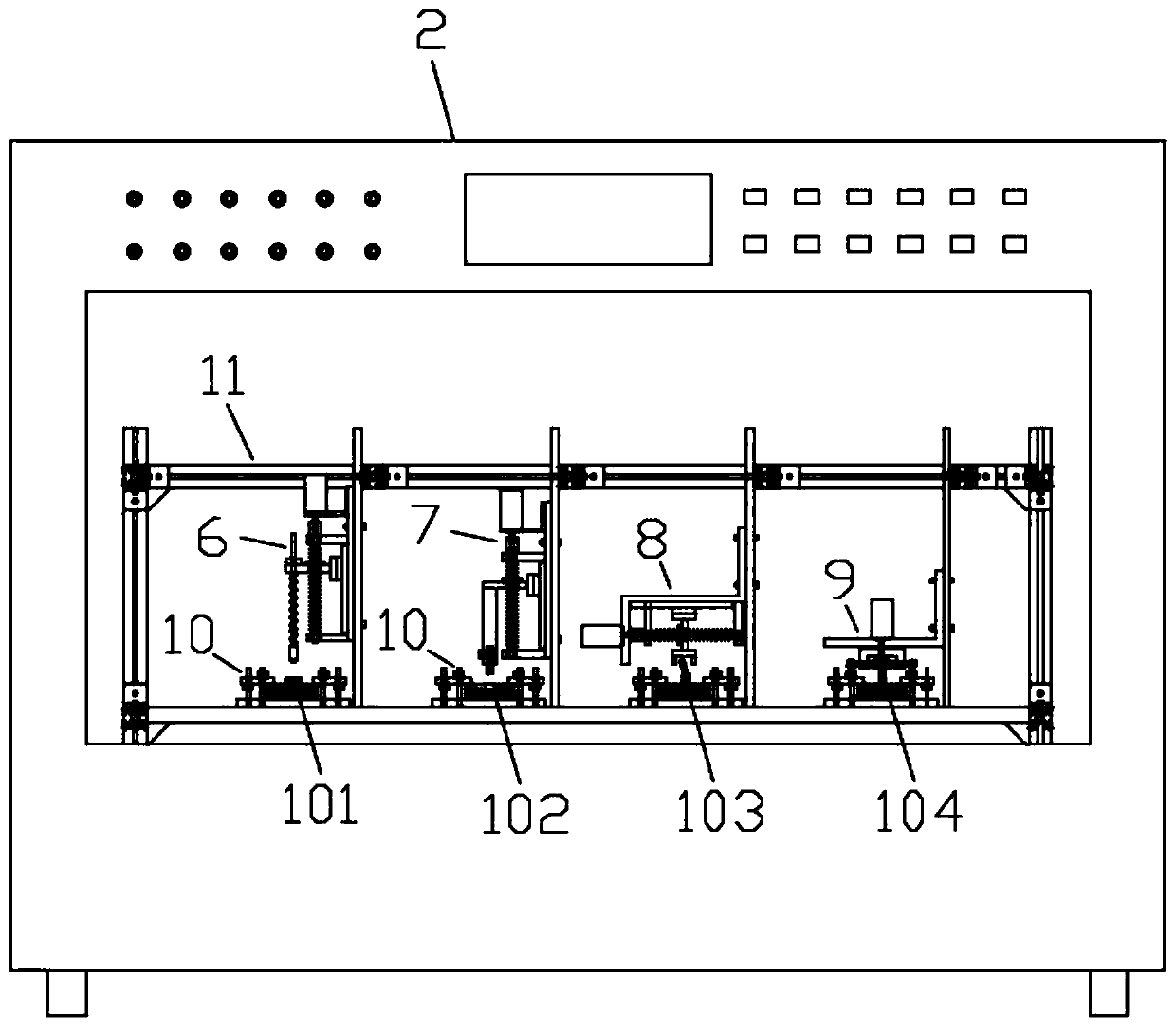

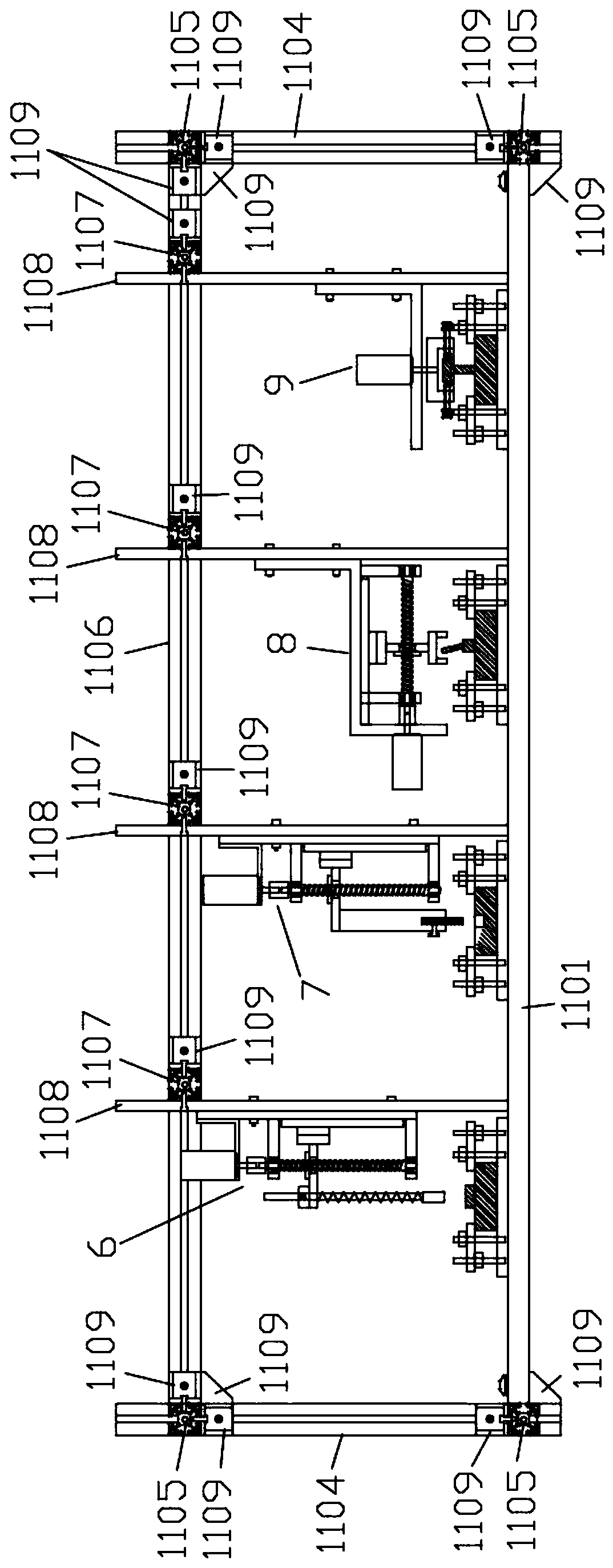

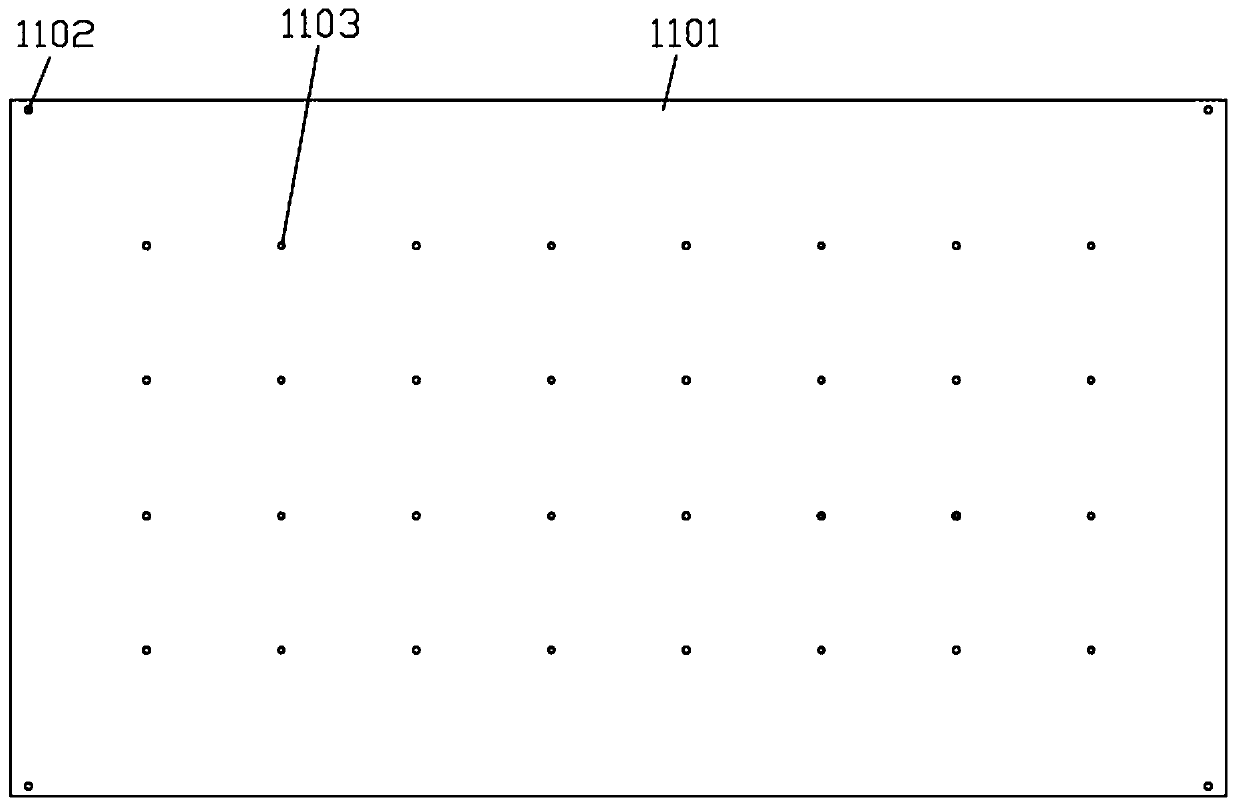

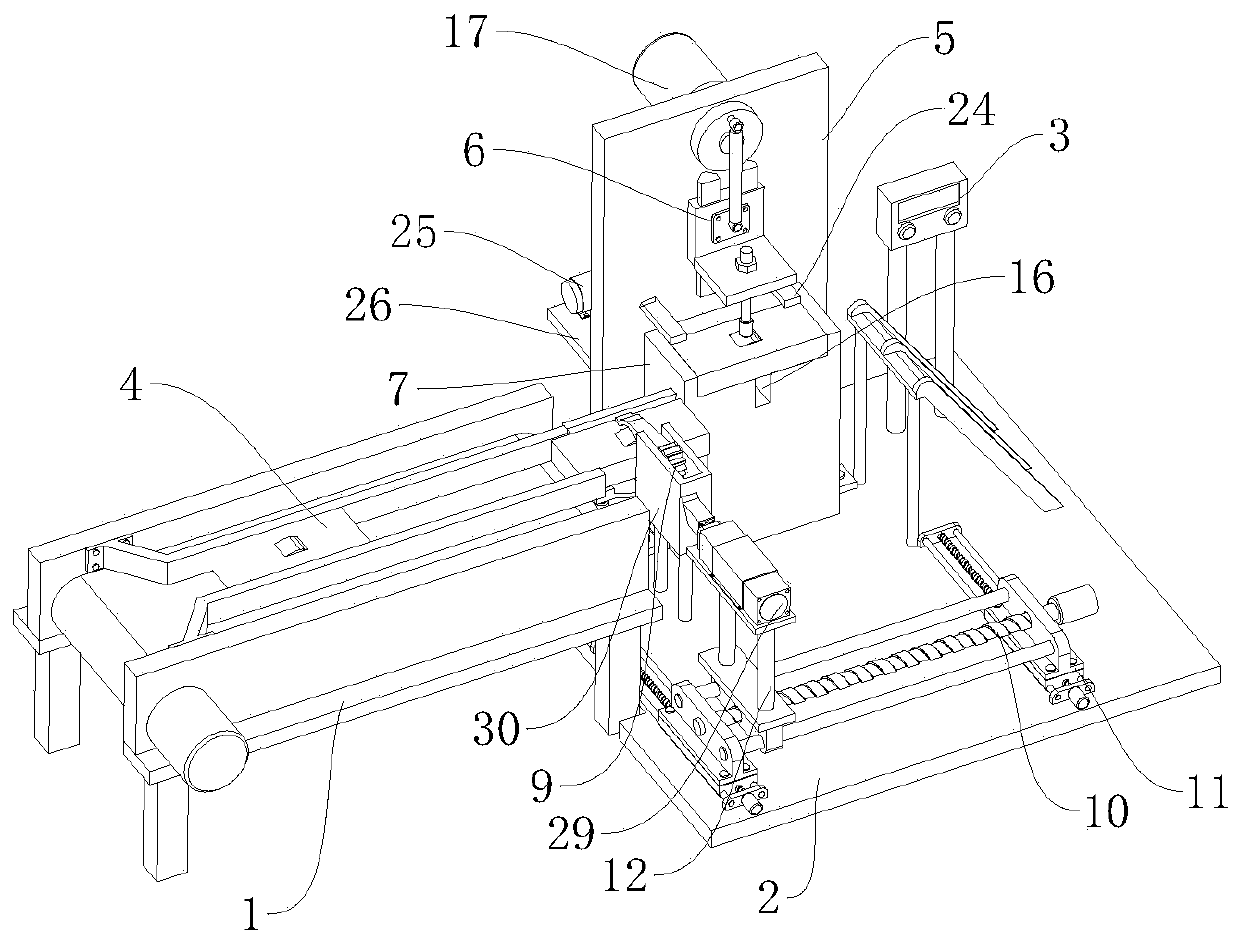

Detection assembly line used for comprehensive performance testing of adjusting arm

ActiveCN103115782ADurability gainReal-time monitoring of movementVehicle testingMotor driveSignal conditioning

The invention discloses a detection assembly line used for comprehensive performance testing of an adjusting arm. The detection assembly line is characterized in that a self-adjusting function durability testing frame, a static strength testing frame, a free stroke testing frame, an adjusting moment testing frame and a separating force and gap testing frame are sequentially fixed on a big supporting rack from left to right. The testing frames on the supporting seat are respectively used for detecting testing tasks of specified items of the adjusting arm. A comprehensive control cabinet is placed on the right side of the supporting seat, communicates with the same through a cable, comprises a PC (personal computer), a data collection system, a motor driving system, a signal conditioning system and other electric auxiliary systems, and is used for controlling the testing tasks of each testing frames, receiving testing data and judging whether performance parameters of the adjusting arm are qualified or not. The detection assembly line used for comprehensive performance testing of the adjusting arm is simple in structure and convenient to operate.

Owner:HANGZHOU WOLEI INTELLIGENT TECH

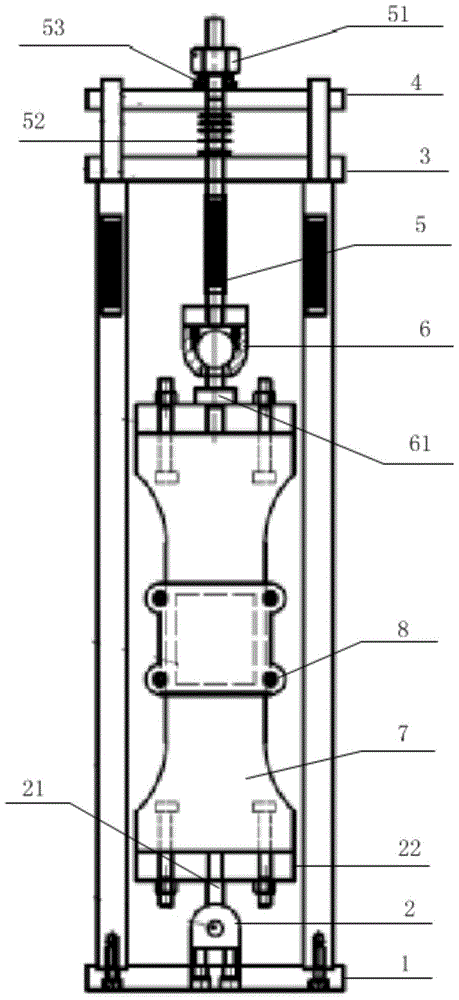

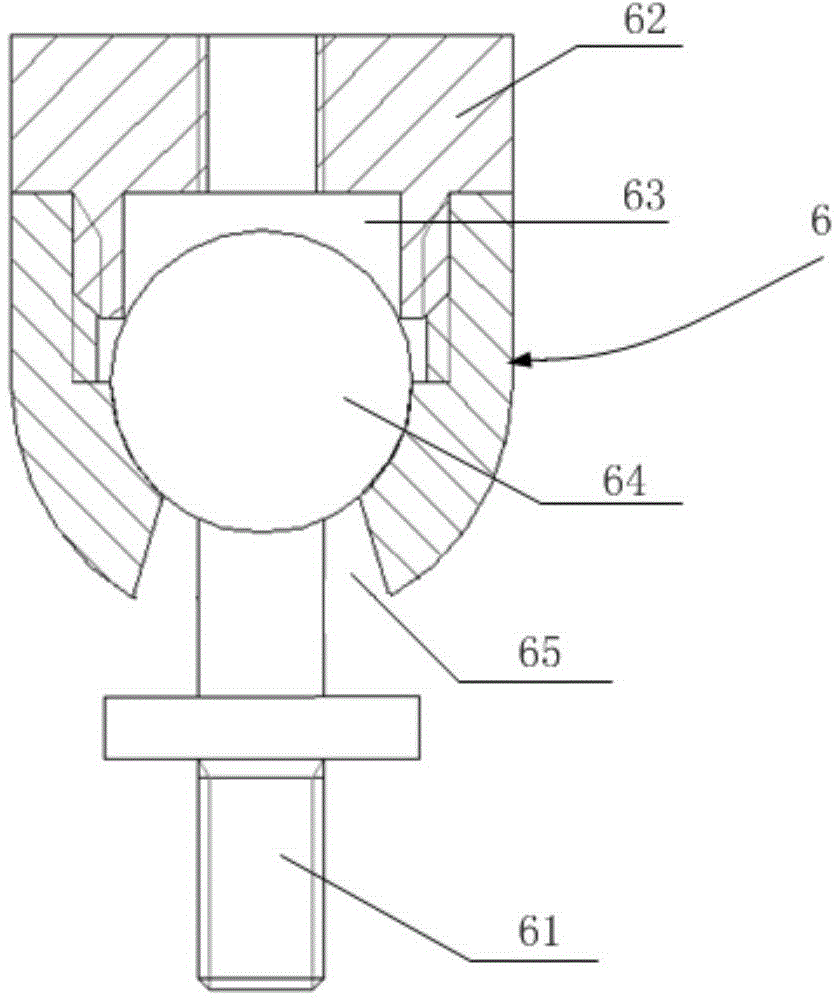

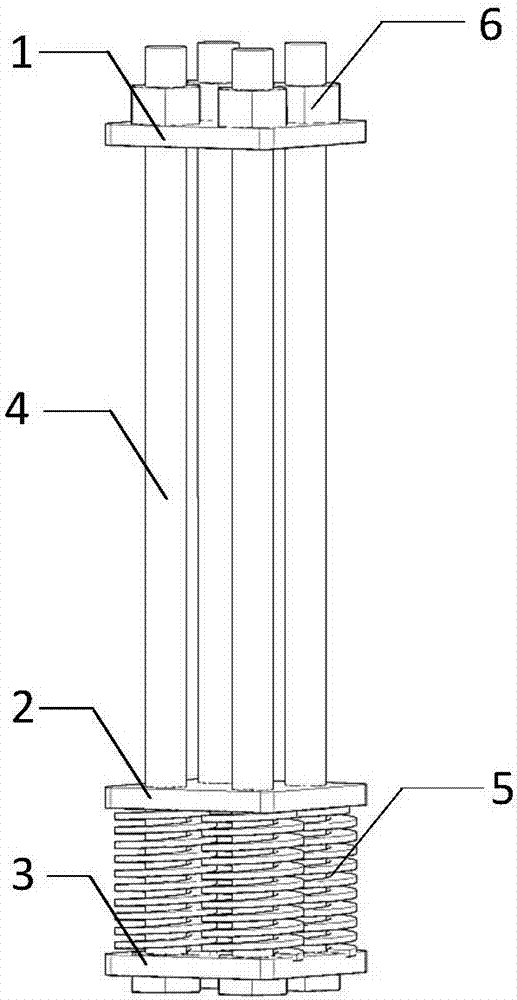

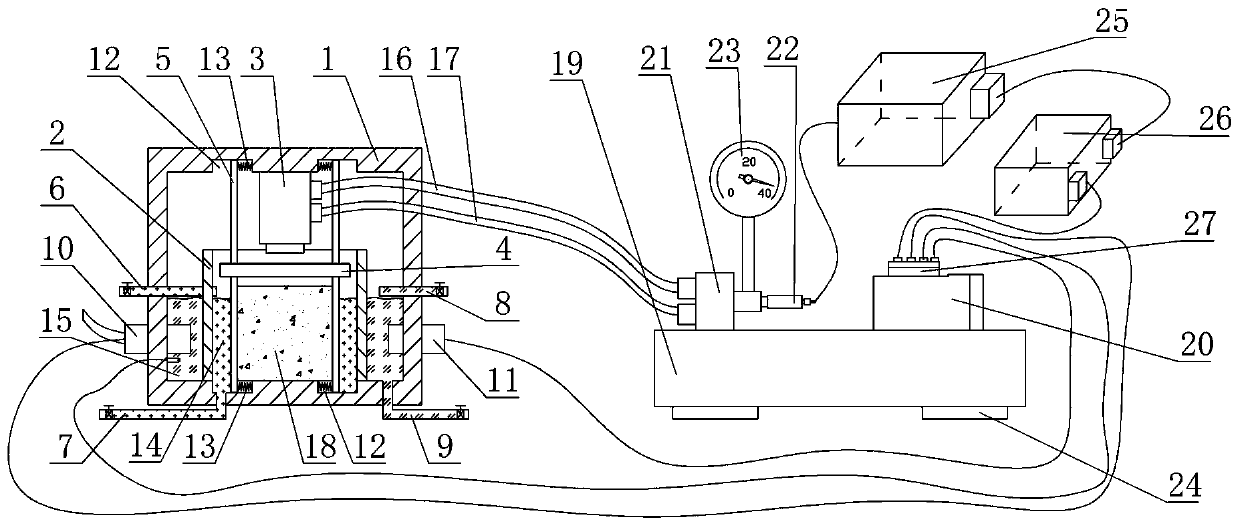

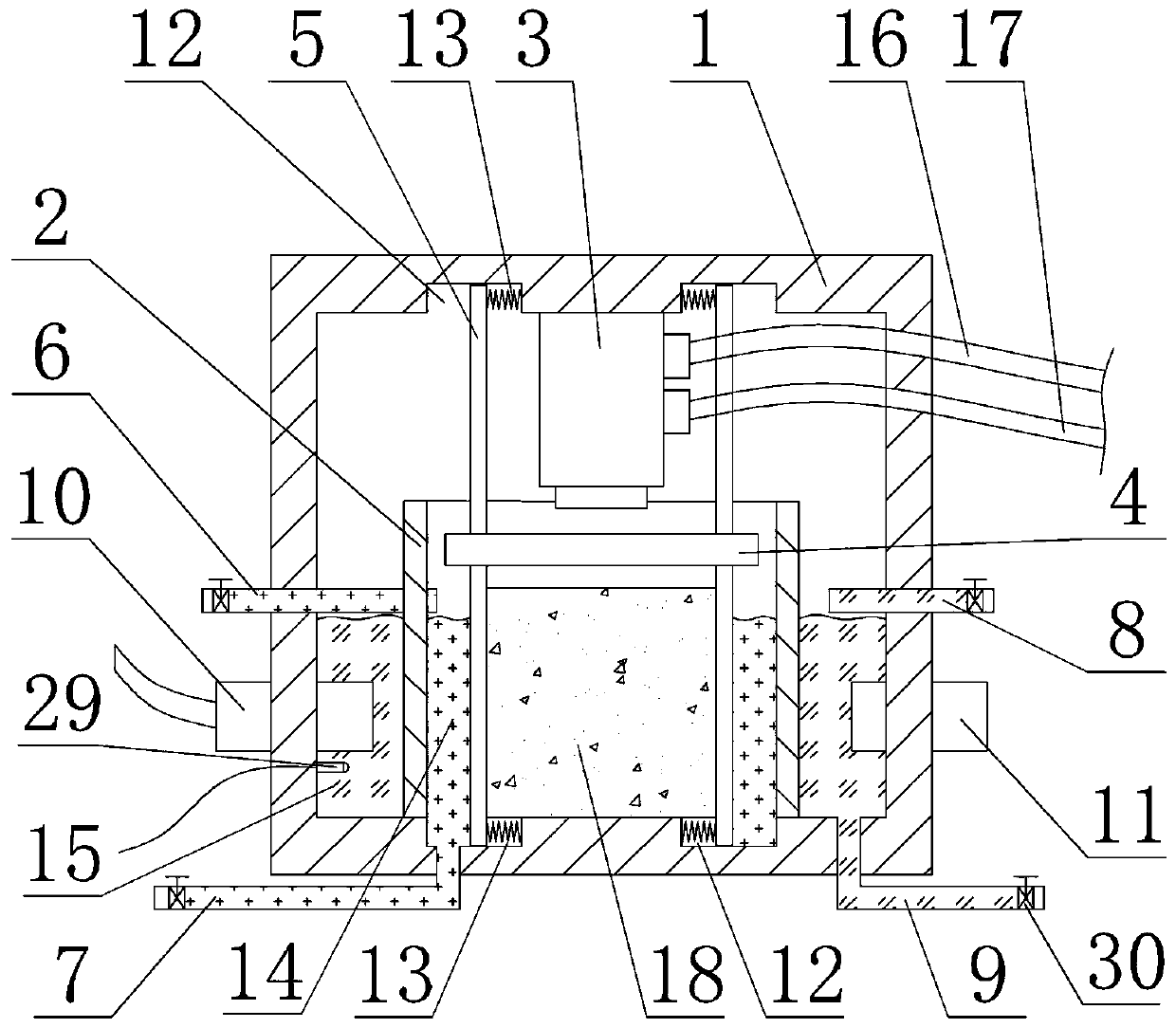

Concrete performance testing device under combined action of constant tensile load and erosion medium

ActiveCN104155185AReduce or eliminate eccentricityAddress stress relaxationWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesConstant stressEngineering

The invention discloses a concrete performance testing device under the combined action of a constant tensile load and an erosion medium, relates to the field of concrete durability testing and solves the problem that an existing testing device cannot implement concrete performance testing under the combined action of a constant stress and medium erosion. The testing device comprises a bottom plate, a connecting base, a first puller, a middle pressure plate, an upper pressure plate, a pull rod, a dish-shaped spring and a medium circulating device, wherein the bottom plate is fixedly connected with an upright; the connecting base is fixed in the middle of the bottom plate; the first puller is hinged to the connecting base and can rotate around the connecting base; the middle pressure plate passes through the upright and is fixed at a limiting point of the upright; the upper pressure plate passes through the upright; the pull rod passes through through holes in the middle pressure plate and the upper pressure plate; one end of the pull rod is connected with a spherical joint; a second puller is connected to the spherical joint; a nut is screwed at the other end of the pull rod; the dish-shaped spring sleeves the pull rod and is positioned between the middle pressure plate and the upper pressure plate; one end of a concrete test piece is connected to the first puller and the other end of the concrete test piece is connected to the second puller.

Owner:CHINA BUILDING MATERIALS ACAD

Control switch durability testing device

ActiveCN101995549ASimple structureEasy to operateStructural/machines measurementCircuit interrupters testingControl switchControl theory

The invention provides a control switch durability testing device, and belongs to the technical field of machinery. The device solves the problem that the conventional control switch durability testing device cannot simultaneously detect warped plate type, key type and knob type switches. The control switch durability testing device comprises a bracket and a clamp arranged on the bracket and usedfor clamping a control switch, wherein a motor is fixed on the bracket, the output shaft of the motor is positioned at the clamp, the bracket is also provided with two cylinders, and the outer ends of piston rods of the cylinders are positioned at the clamp. The control switch durability testing device has the advantages of wide application range, simple structure and the like.

Owner:南通星维海威精密机械有限公司

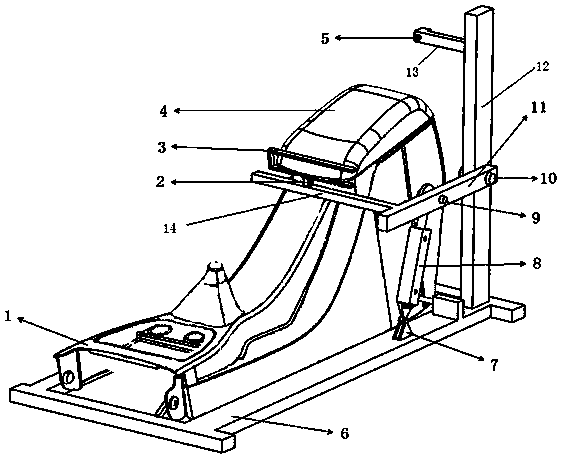

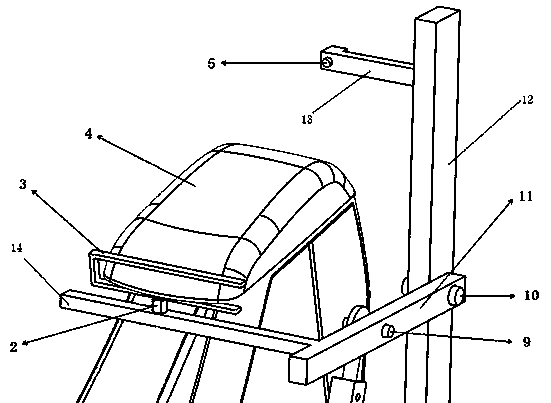

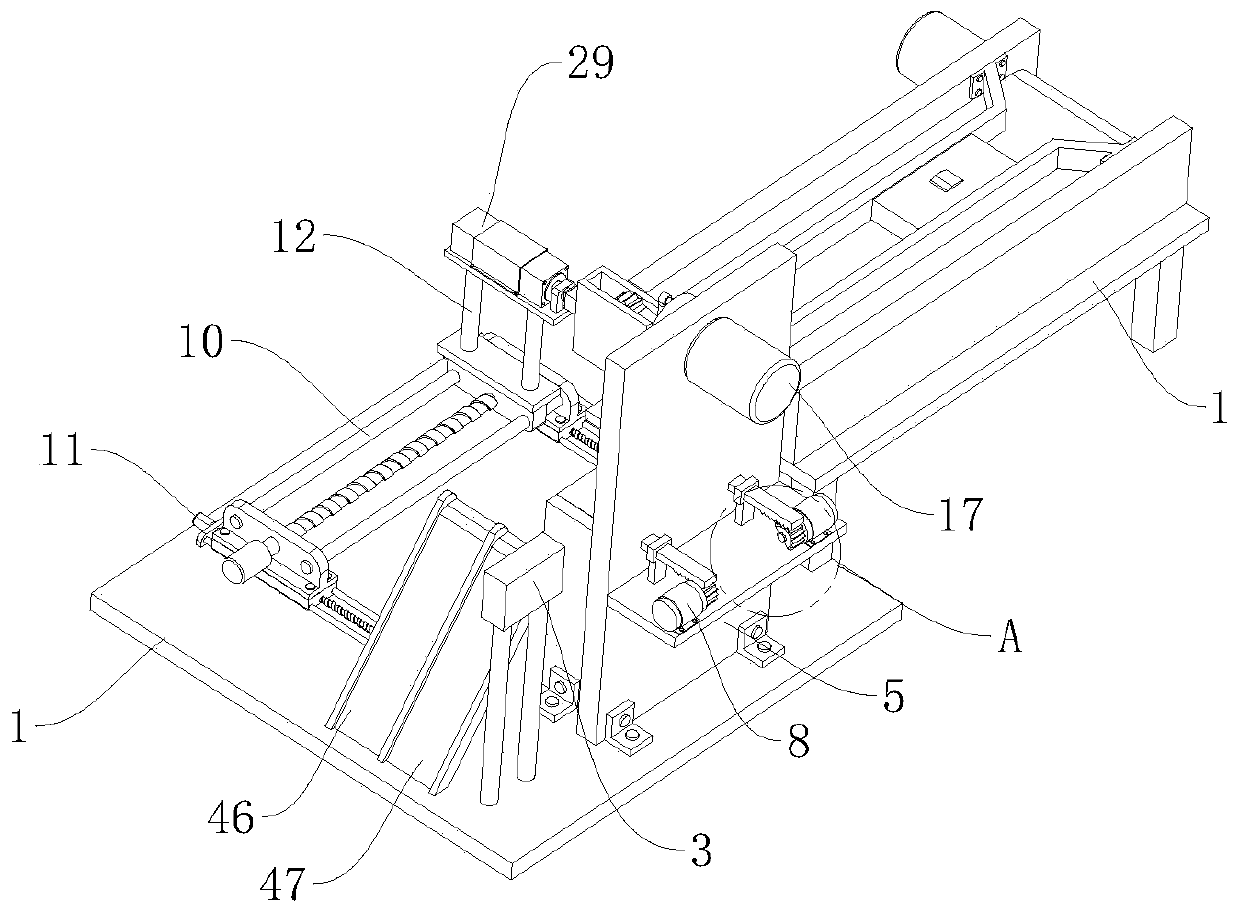

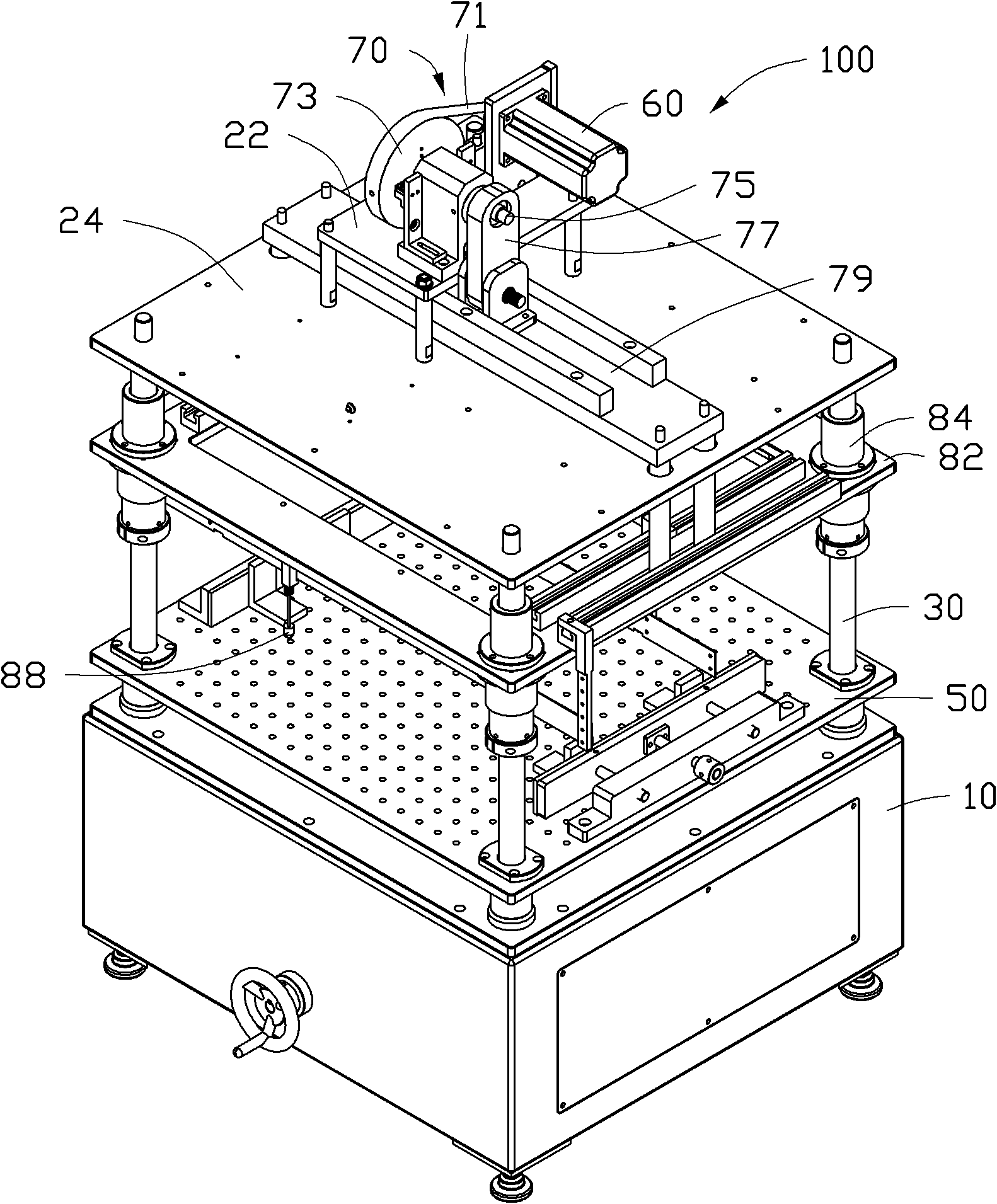

Car seat bump and creep durability testing machine

ActiveCN103364165AAchieve vertical rotationSimple structural designShock testingEngineeringCantilever

The invention relates to a car seat bump and creep durability testing machine which comprises a stand, a bump device and a creep device, wherein the bump device is arranged at the middle lower part of the testing machine; the creep device is arranged at the uppermost part of the testing machine; The car seat bump and creep durability testing machine is characterized in that the bump device further comprises bump guide pillars, sliding bearings, a bump table plate and a panel; the sliding bearings are arranged on the panel; the bump guide pillars are connected with the bump table plate and is matched with the sliding bearings; a bump connecting rod is connected with the bottom surface of the bump table plate by a connecting pin together with a bump connecting rod base; the creep device also comprises a creep connecting rod, a cantilever, a support rod, a cantilever fixing seat and a cantilever table plate; a creep connecting rod is connected with a servo motor; the cantilever is respectively connected with the cantilever fixing seat and the servo motor by a connecting pin; the support rod and the cantilever fixing seat are respectively fixed on the cantilever table plate; the support rod is arranged under the cantilever. The car seat bump and creep durability testing machine is simple, reasonable and compact in structural design, convenient, accurate and reliable in test, and long in service life.

Owner:ZHEJIANG LONGSHENG AUTO PARTS TECH CO LTD

Shock absorber durability testing device

ActiveCN104198165AThe test result is accurateMachine part testingVehicle suspension/damping testingStress conditionsEngineering

The invention provides a shock absorber durability testing device. The shock absorber durability testing device comprises a worktable, a supporting block, an actuating cylinder, a force sensor and a lateral force loading mechanism, wherein the supporting block comprises two supporting parts which are arranged on the worktable; the actuating cylinder is erected between the supporting parts and used for applying vertical force to a shock absorber to be tested; the force sensor is arranged under the actuating cylinder and used for monitoring the change of the damping force of the shock absorber to be tested; the lateral force loading mechanism is arranged on the supporting block and used for applying lateral force to the shock absorber to be tested. The shock absorber durability testing device can be used for either the loading of the vertical force or the loading of the large-load lateral force so that the stress condition of the shock absorber to be tester is closer to the physical truth, and therefore, the testing result can be more accurate.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

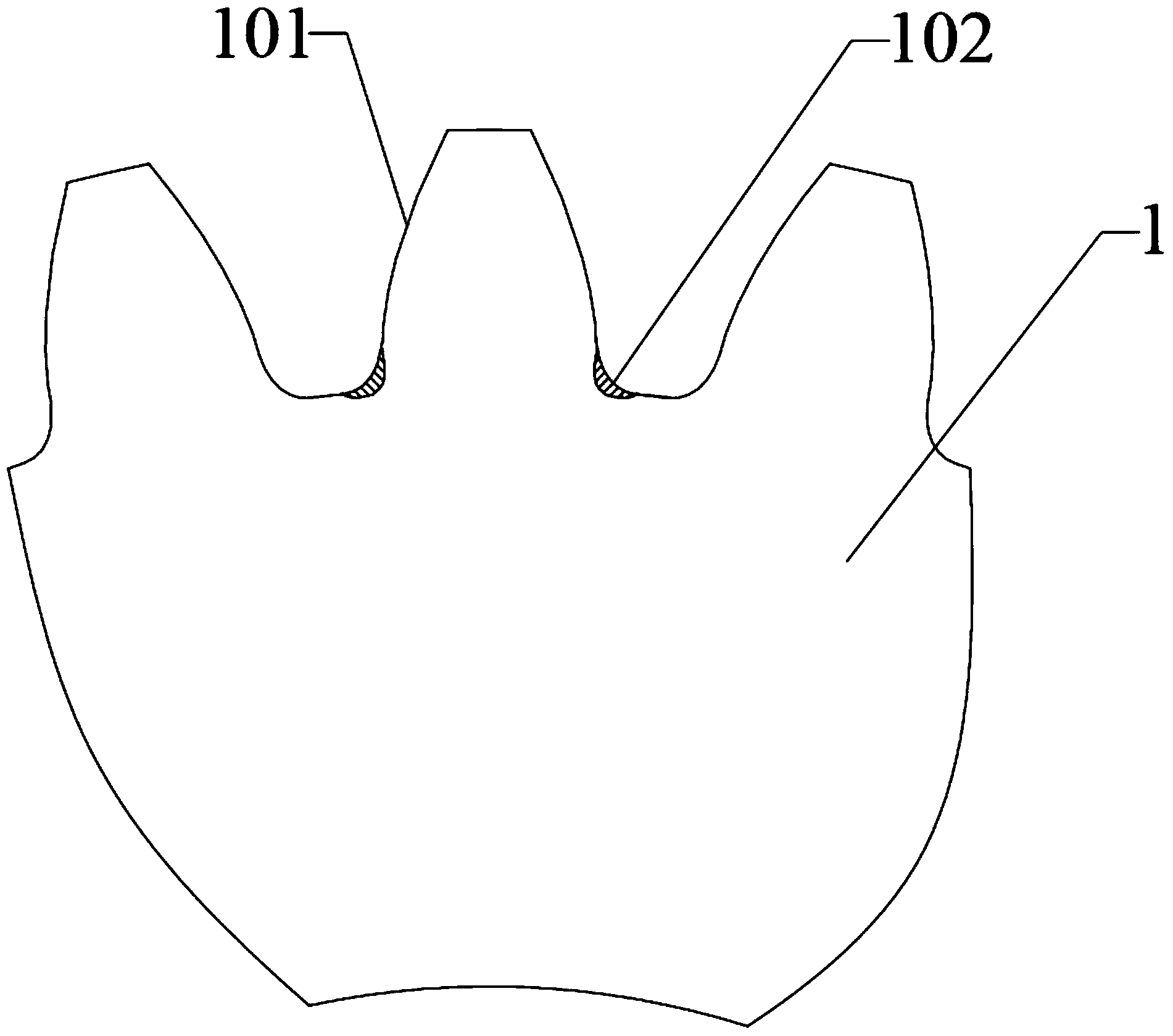

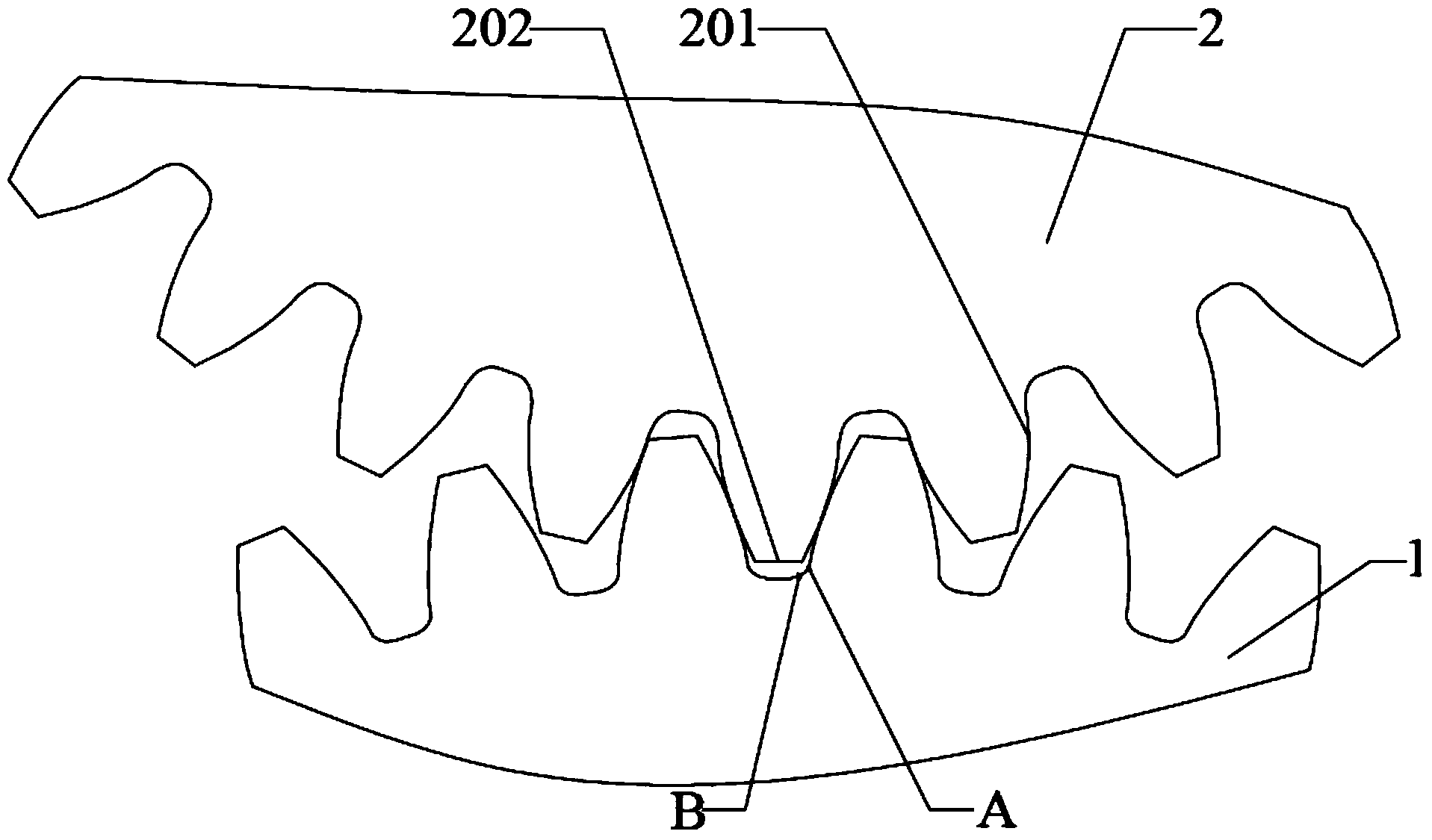

Method and device for testing gear tooth root bending fatigue durability

ActiveCN104266836ABending Fatigue Durability Test ImplementationAccurate Fatigue Durability DataMachine gearing/transmission testingStress pointEngineering

The invention discloses a device for testing gear tooth root bending fatigue durability. The device comprises a strain gage and pressing sheets, the strain gage is attached to the tooth root of a gear to be tested, the pressing sheets are matched with the gear to be tested in shape, the pressing sheets are arranged in tooth grooves of the gear to be tested in a press-fit mode, and a silicon rubber pad is arranged between the pressing sheets and the gear to be tested. The device further comprises a paster sample plate arranged on the tooth face of the gear to be tested in a sleeving mode. The strain gage is connected with a sliding ring through a lead, and the sliding ring is connected with a strain gage meter through a wire. The invention discloses a testing method. The testing method comprises the seven steps of maximum stress point area determining, paster sample plate manufacturing, pressing sheet manufacturing, strain gage pasting and protecting, sample frequency calculating, durability testing and data processing. According to the testing method, the fatigue durability data of a gear product can be accurately carried out, and a design and use basis is provided for a gear transmission device. The testing device can test the gear tooth root bending fatigue durability of different sizes of gears under different working conditions, the structure is simple, operation is convenient, and the testing result is accurate.

Owner:SHAANXI UNIV OF TECH +1

Testing machine for adjusting durability of car steering column

InactiveCN103207072ASolve the technical defects that cannot accurately simulate the operation of the steering wheel by peopleGuaranteed accuracyMachine part testingSteering columnData acquisition

The invention provides a testing machine for adjusting the durability of a car steering column. The testing machine comprises a column clamping apparatus and is configured with a data acquisition and processing system. The column clamping apparatus enables a tested steering column to be mounted according to a real car position and can clamp the steering columns of different models for testing. An axial adjusting apparatus drives a piston rod of the tested steering column to stretch and retract under the traction of an electric cylinder and simulates axial adjustment of the steering column. A radial adjusting apparatus simulates radial adjustment of the tested steering column under the traction of an elevator. An unlocking apparatus simulates unlocking and locking of a user to the steering column. An axial force sensor, a radial force sensor and an unlocking force sensor record measured force of a test. According to the testing machine, the testing method is convenient and efficient, the tested steering column simulates an actual utilization condition accurately for testing, the testing machine suits related ideas about adjusting durability testing of car steering columns, and the accuracy and the stability of the test results are guaranteed.

Owner:SHANGHAI UNIV

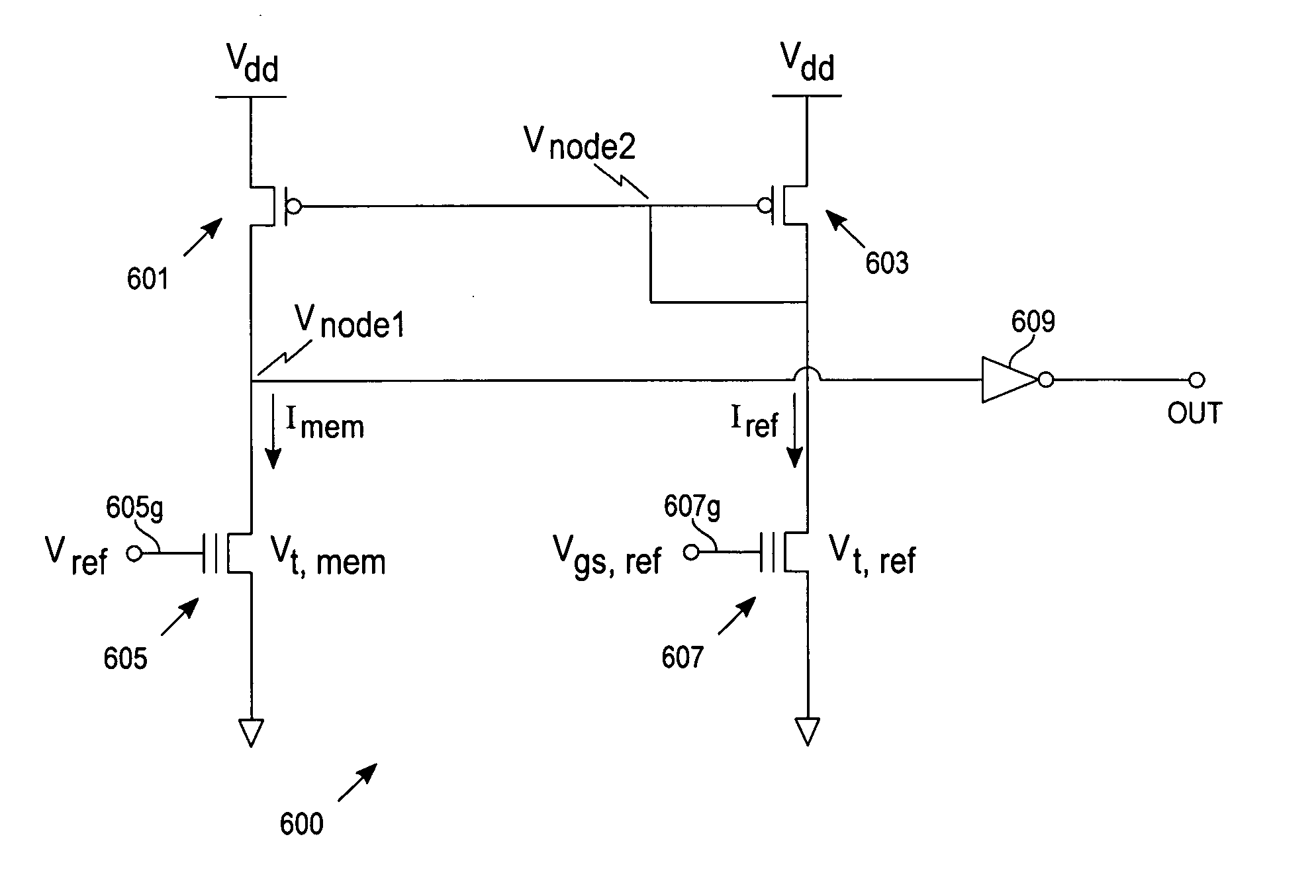

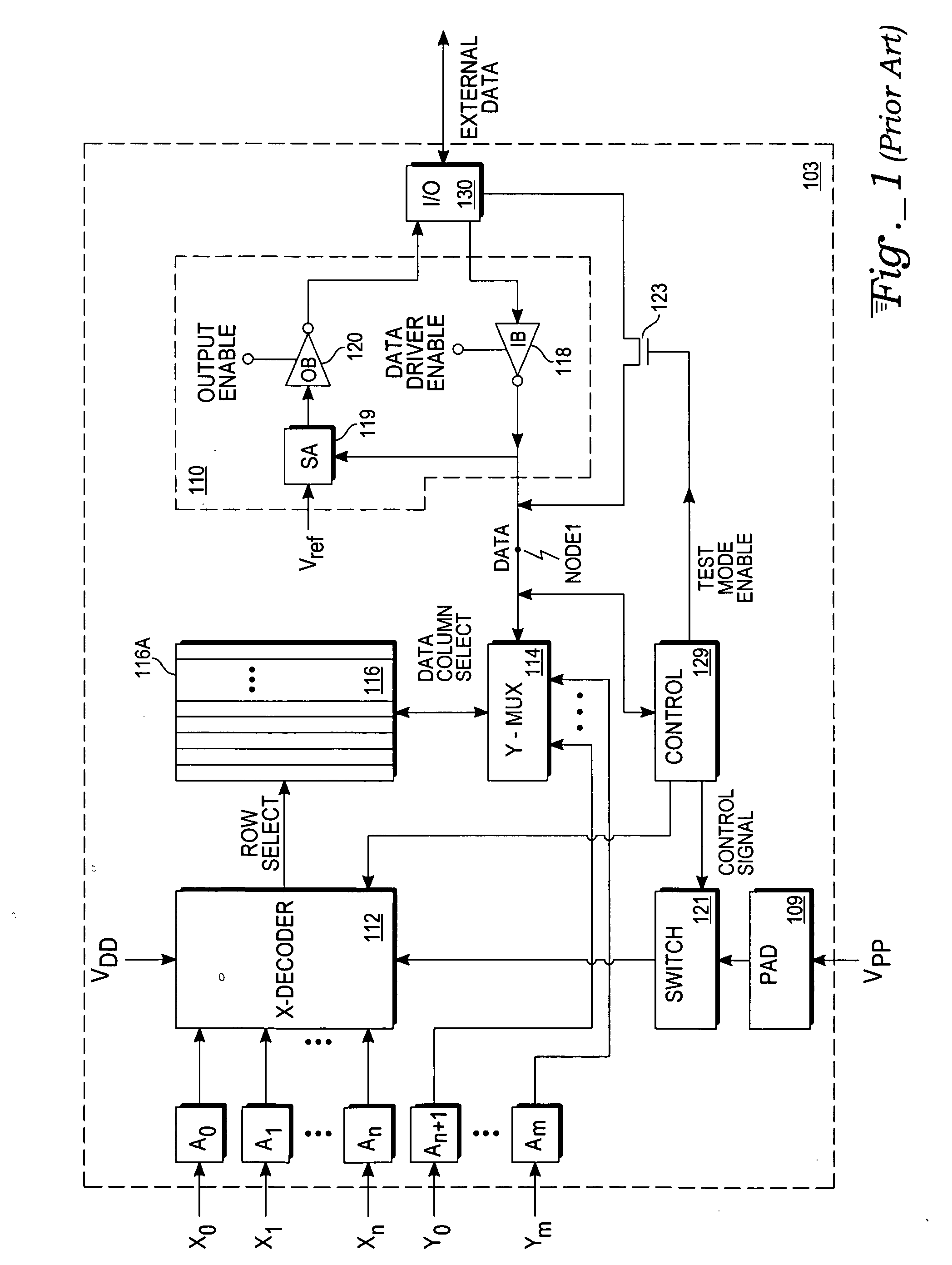

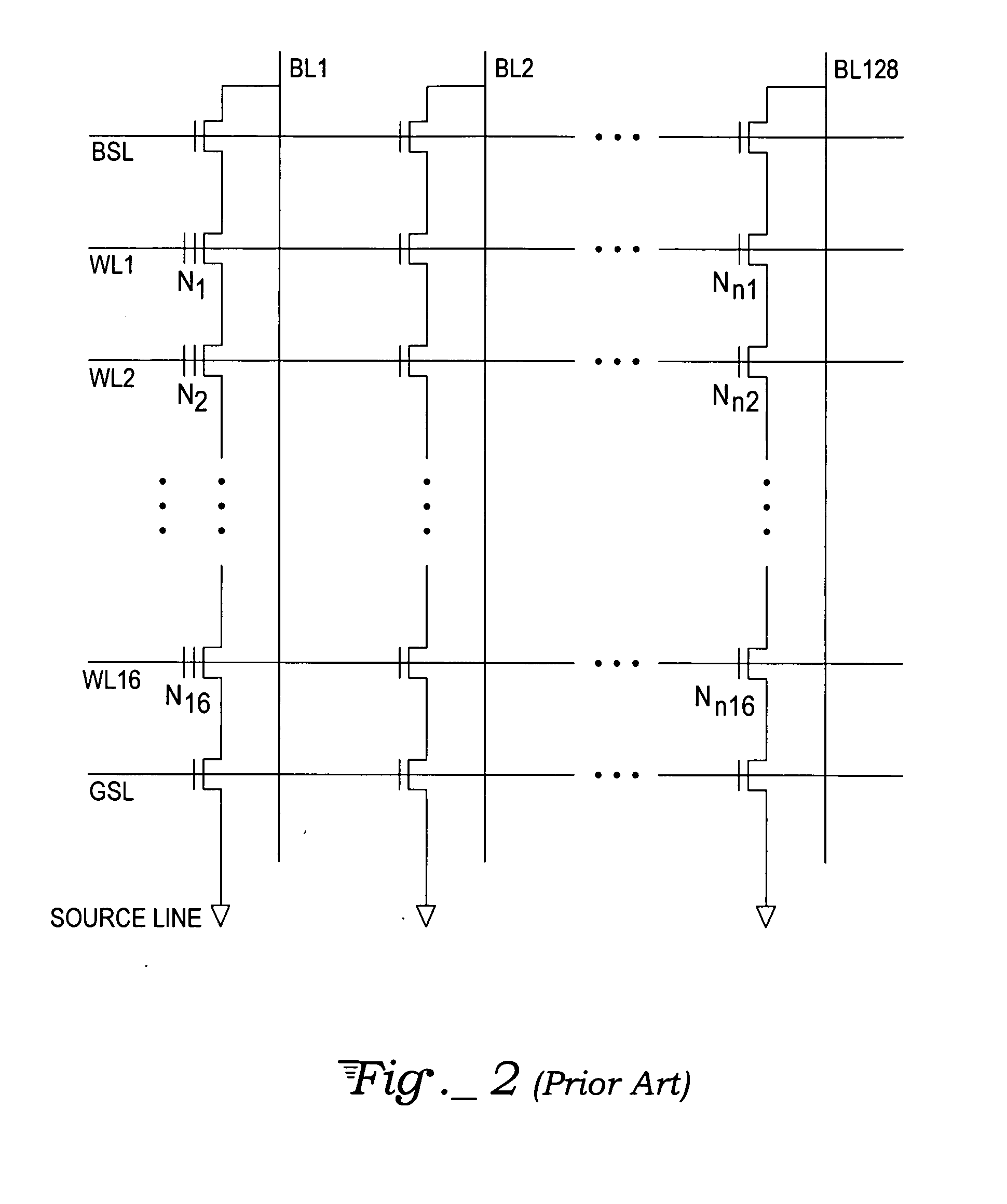

Indirect measurement of negative margin voltages in endurance testing of EEPROM cells

InactiveUS20070237013A1High voltageEndurance or longevity of the cellRead-only memoriesDigital storageEngineeringPositive power

An electronic test structure and method for testing non-volatile memory cells. The structure includes a first transistor coupled in series to a floating gate transistor whereby a source of the first transistor is coupled to a positive power supply voltage and a source of the floating gate transistor is coupled to a power supply ground. A gate of the first transistor is further coupled to a source of the first transistor. A second transistor is coupled in series with a memory cell with a source of the second transistor coupled to a positive power supply voltage and a gate of the second transistor is coupled to the drain of the first transistor.

Owner:ATMEL CORP

Automotive armrest box durability testing device

InactiveCN104236875AReal-time monitoring of opening forceReal-time monitoring of closing forceMachine part testingEngineeringActuator

The invention relates to testing devices, in particular to an automotive armrest box durability testing device. The device comprises a controller, a base, a rocker arm, an actuator and a stand column arranged on the base, wherein a counter is connected to the stand column, one end of the actuator is hinged to the base, the other end of the actuator is hinged to the middle of the rocker arm, one end of the rocker arm is hinged to the stand column, an opening and closing rod is connected to the other end of the rocker arm, the opening and closing rod is connected with an opening and closing frame used for opening and closing an armrest box lid through a force sensor, and the force sensor is connected with the controller. The device has the advantages that the rocker arm can be driven by the actuator to make reciprocating semi-circular motion, then the opening and closing rod is driven to make reciprocating semi-circular motion, so that an armrest box is opened or closed through the opening and closing frame, circulation of opening and closing of the armrest box is achieved, and durability testing of the armrest box lid is achieved finally.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

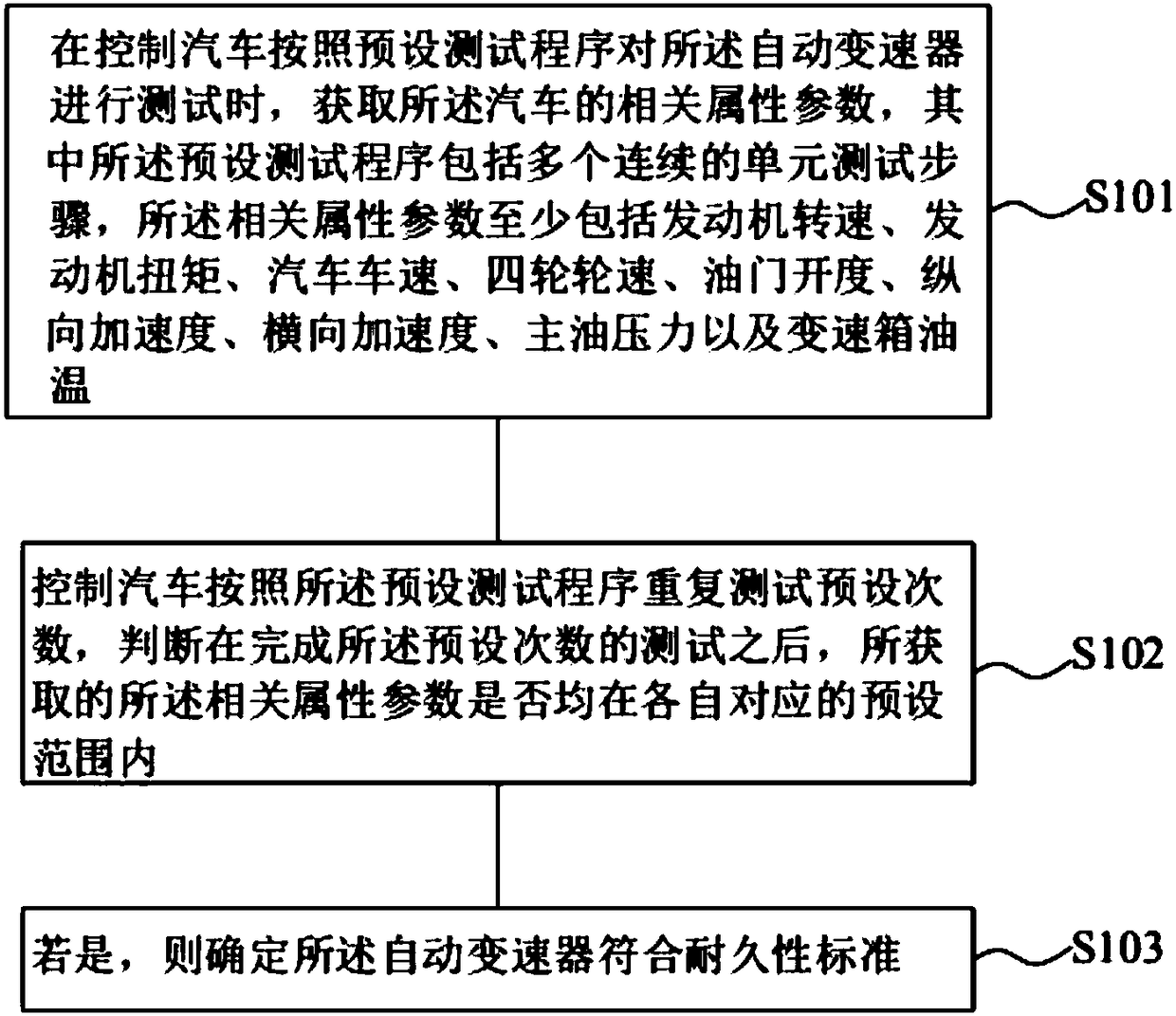

Durability testing method for an automobile automatic transmission

InactiveCN108519232AAccurate analysis and judgmentImprove reliabilityVehicle testingMachine gearing/transmission testingAutomatic transmissionTest procedures

The invention discloses a durability testing method for an automobile automatic transmission. The method includes the following steps: when a vehicle is controlled to test an automatic transmission according to preset test procedures, obtaining related attribute parameters of the vehicle, wherein the preset test procedures include a plurality of continuous unit test steps, and the related attribute parameters include at least engine speed, engine torque, vehicle speed, four-wheel speed, throttle opening, longitudinal acceleration, transverse acceleration, main oil pressure and gearbox oil temperature; controlling the vehicle to repeatedly carry out tests according to preset frequencies and in accordance with the preset test procedures, and judging whether the obtained related attribute parameters are within respective corresponding preset ranges after the tests with the preset frequencies are finished; and if the obtained related attribute parameters are within respective correspondingpreset ranges, determining that the automatic transmission meets durability criteria. According to the durability testing method provided by the invention, the performance of the automatic transmission can be analyzed and judged more accurately and the reliability of a test result can be improved.

Owner:JIANGLING HLDG

Fatigue durability testing device for transverse stabilizer bar

ActiveCN102331338ASimple resultWork reliablyMachine part testingVehicle suspension/damping testingBar productEngineering

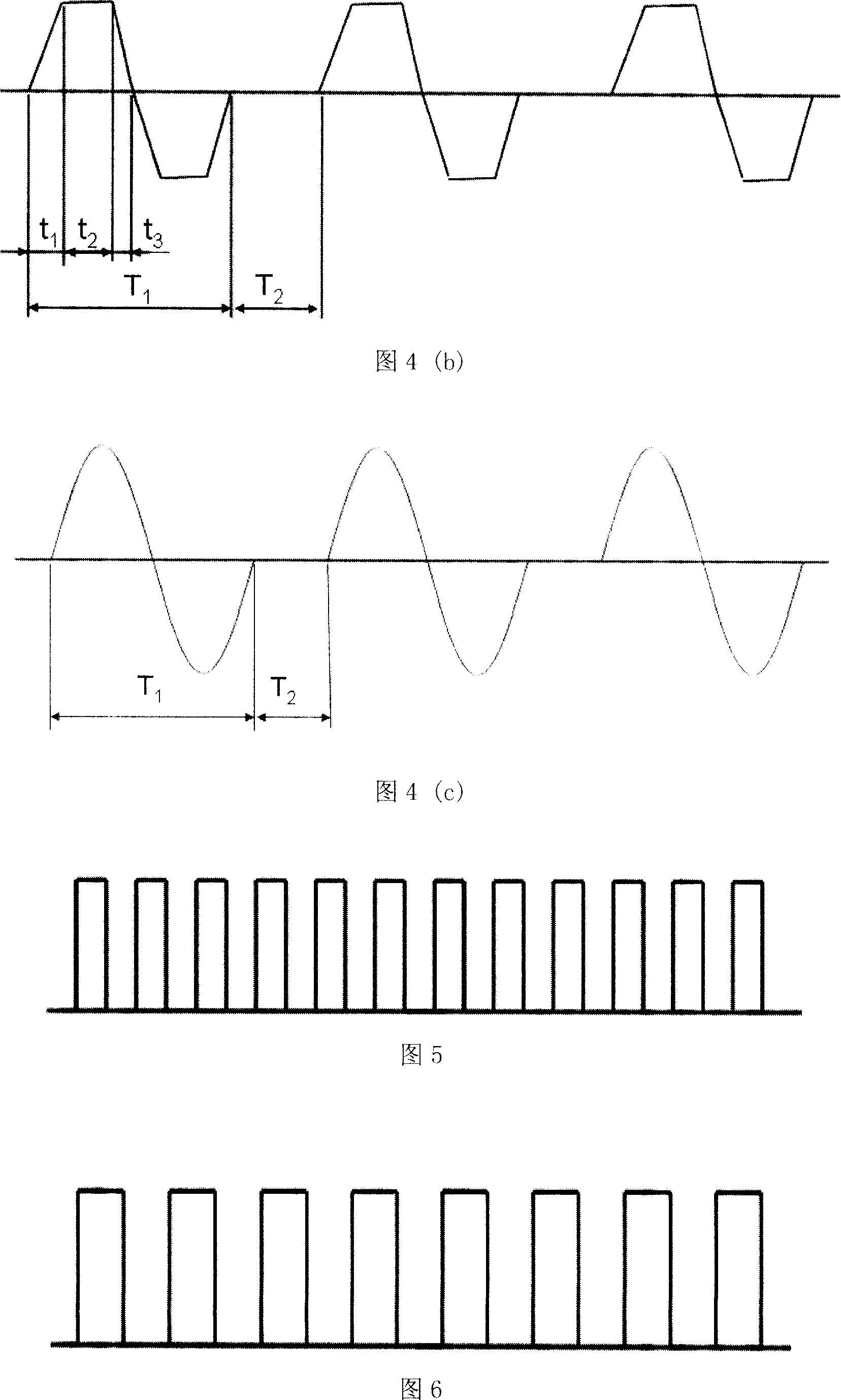

The invention relates to the technical field of mechanical testing equipment, in particular to a fatigue durability testing device, and solves the problem that an automobile transverse stabilizer bar product is subjected to fatigue durability test under various working conditions. The fatigue durability testing device comprises a power device. A torsion driving cylinder is arranged in the power device. An output end of the torsion driving cylinder is provided with a torsion driving swing arm. The torsion driving swing arm is of a strip bar structure, is vertical to the axial center line of the torsion driving cylinder and is eccentrically arranged. The transverse stabilizer bar is provided with two pieces in the horizontal direction. The torsion driving cylinder can load a sinusoidal waveform, triangular wave, random wave or path spectrum signal under the control of a computer. By using the fatigue durability testing device, the test is stable and the efficiency is high. Various actual using working conditions are simulated. The comprehensive cost is relatively low.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Comprehensive durability testing machine for automobile switch

PendingCN110045278AWith temperatureFunctionalMachine part testingEnvironmental/reliability testsControl powerPower flow

The invention relates to a comprehensive durability testing machine for an automobile switch. The comprehensive durability testing machine comprises a high and low temperature environment test box, aprogram-controlled power supply, a test fixture, a fixing fixture, a fixture rack, a motor driver and a motion control card; the fixture rack is movably installed in the box body of the high and low temperature environment test box; the program-controlled power supply, the motor driver and the motion control card are all positioned outside the high and low temperature environment test box; the program-controlled power supply is connected with the automobile switch via a wire; the motor driver is connected with a high and low temperature motor of the test fixture via the wire; and the motion control card is connected with the motor driver via a cable. The comprehensive durability testing machine has the beneficial effects that the comprehensive durability testing machine of the automobile switch has the temperature and humidity adjustment function, can be applied to the tests of the pressing type automobile switch, the plugging type automobile switch, the toggle type automobile switch and the knob type automobile switch, and can judge the success rate of the automobile switch through performing current monitoring on the automobile switch in the test via the program-controlled powersupply.

Owner:广东中创智腾技术服务有限公司

Durability testing machine of automobile seat angle regulator

InactiveCN101446520AQuality improvementSimple structureVehicle testingMachine part testingCar seatAutomatic control

The invention relates to a durability testing machine of an automobile seat angle regulator, which is the characterized in that the durability testing machine comprises a work table, a small bracket, a test cylinder, a rack, a gear, a swing rod, an unlock cylinder, an unlock cylinder bracket and an unlock cylinder installation seat; the small bracket is installed on the work table, the test cylinder is installed on the small bracket, the piston rod of the test cylinder is fixedly connected with the rack, the gear is moveably installed on the small bracket, the gear works with the rack, and the swing rod is fixedly connected to the gear; and the unlock cylinder bracket is installed at the other end of the work table, the unlock cylinder moveably connected with the unlock cylinder installation seat is fixed on the unlock cylinder bracket through the unlock cylinder installation seat, and a plurality of grooves are formed in parallel on the surface of the work table. The invention has the advantages of simple structure and convenient test, and can realize accurate detection to the regulation motion durability of the automobile seat angle regulator and the durability of an alternating load, realize the automatic control, analysis and loading, and ensure the good quality of the finished products.

Owner:KUNSHAN INNOVATION TESTING INSTR CO LTD

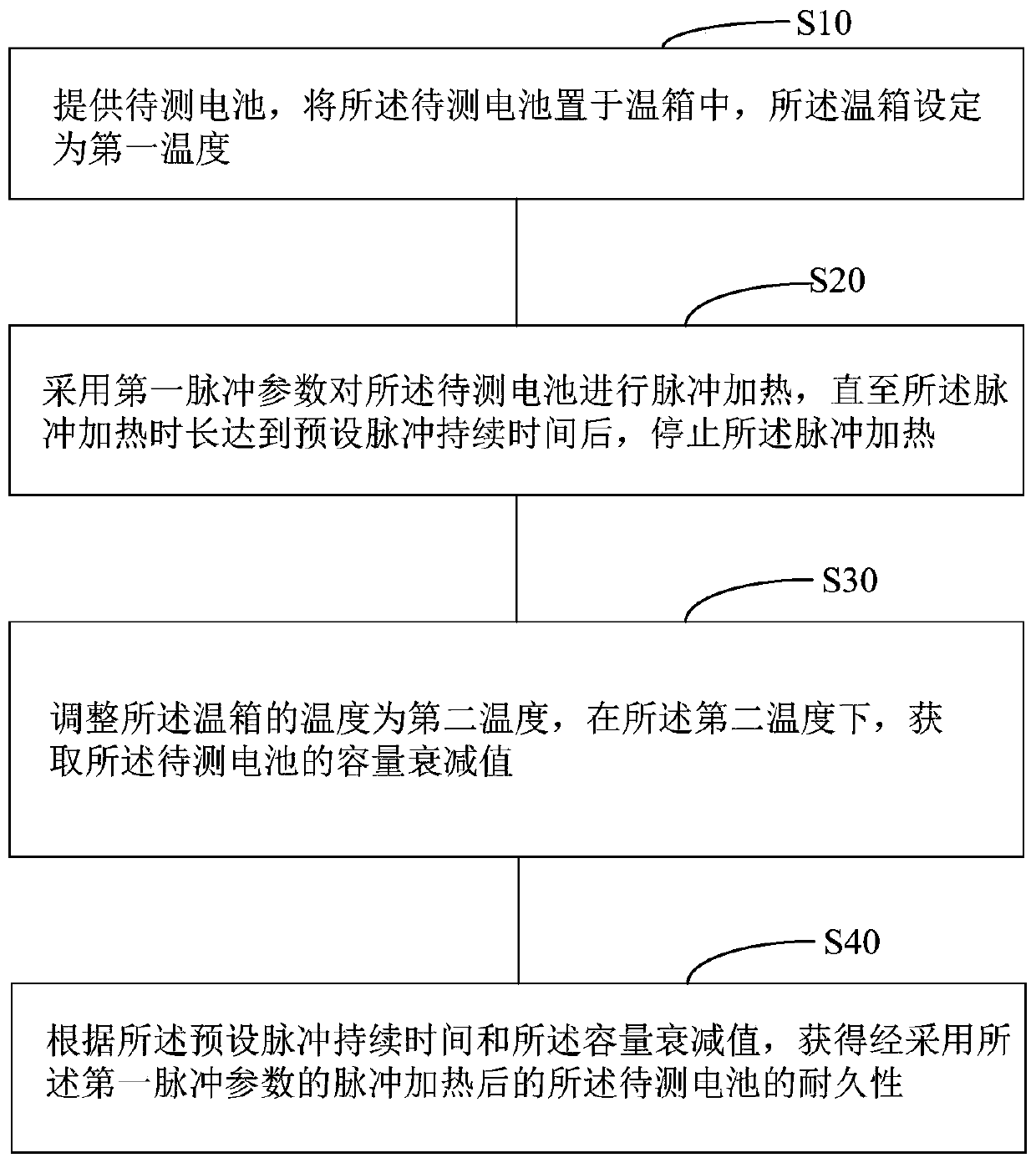

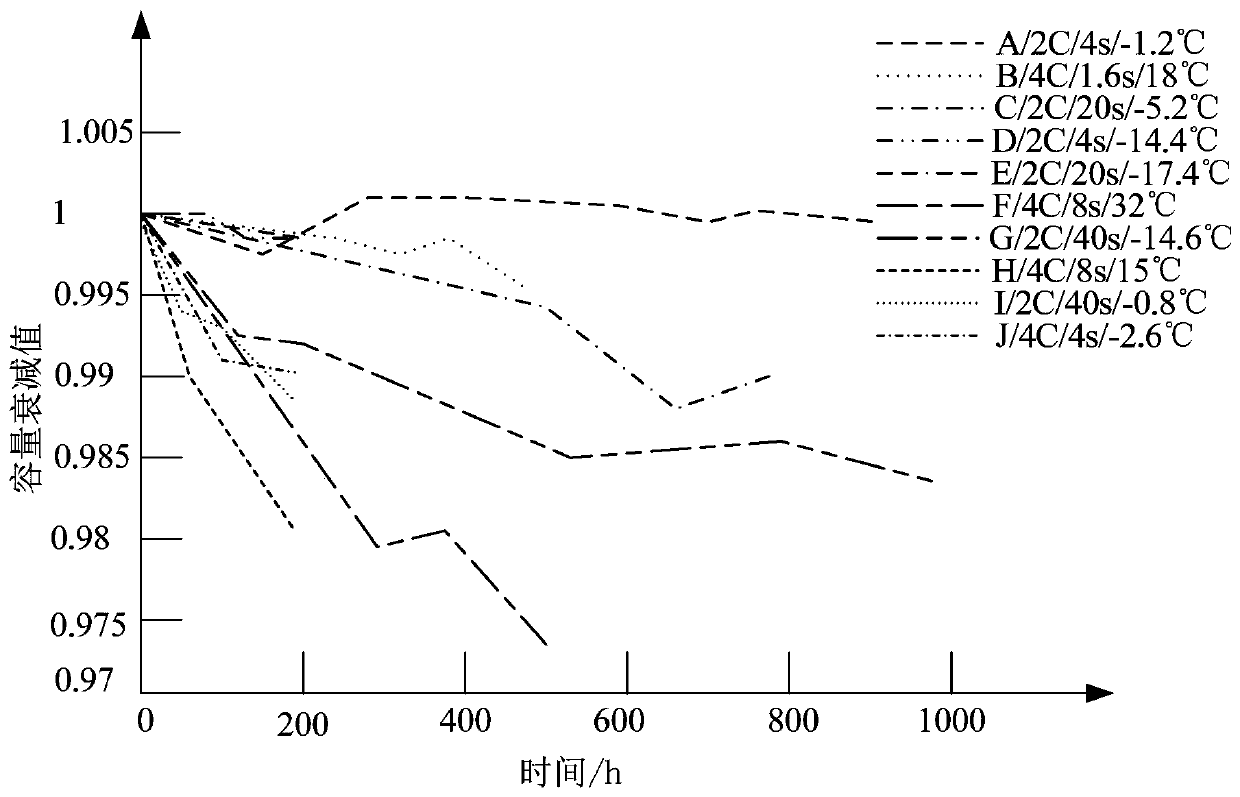

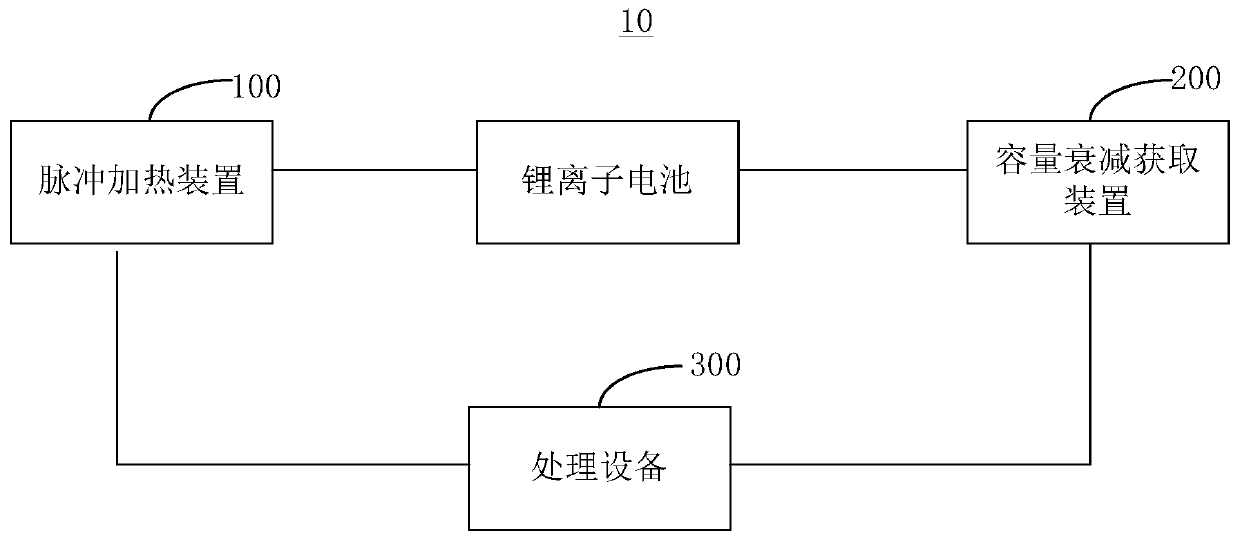

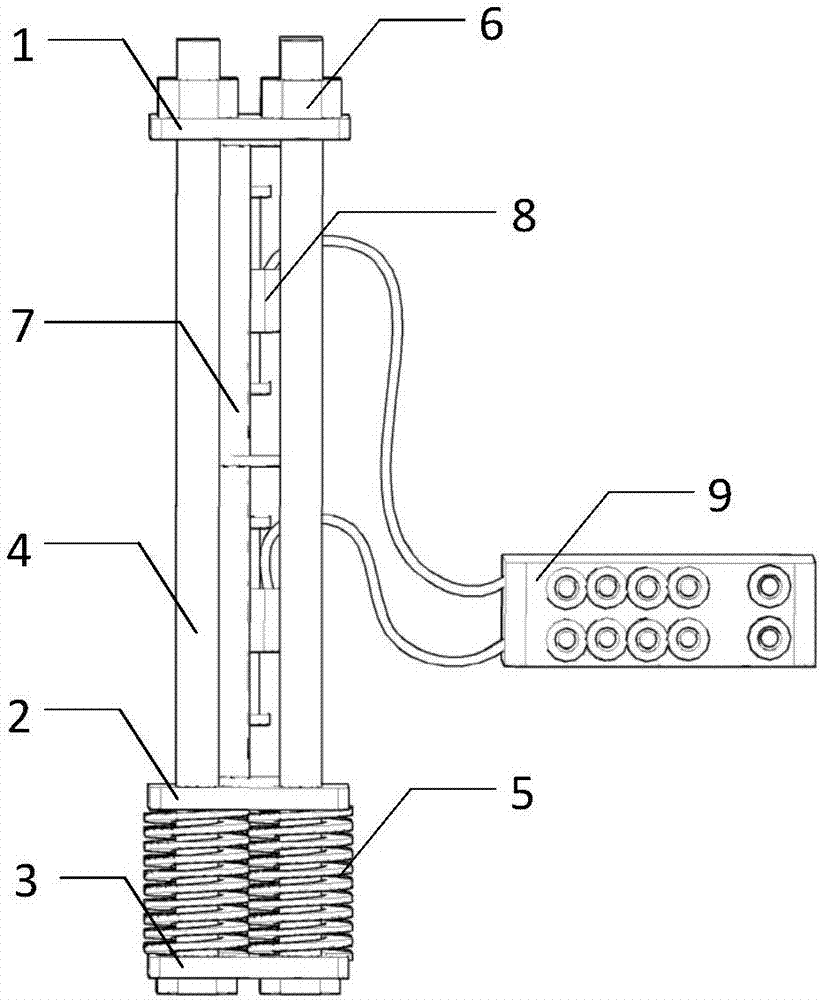

Pulse heating-based battery durability testing method, system and data table generation method

ActiveCN110470992AShorten test timeShorten the test cycleElectrical testingSecondary cells testingTest batteryEngineering

The invention relates to a pulse heating-based battery durability testing method, a pulse heating-based battery durability testing system and a data table generation method. According to the battery pulse heating-based durability testing method, a to-be-tested battery is placed in a temperature box; and the temperature of the temperature box is set to be a first temperature. Pulse heating is performed on the lithium ion battery under a first pulse parameter until a pulse heating duration reaches a preset pulse lasting duration. The temperature of the temperature box is adjusted to be a secondtemperature, the capacity attenuation value of the to-be-tested battery is obtained under the second temperature, and then the durability of the to-be-tested battery is obtained. Before the capacity attenuation value of the to-be-tested battery is tested, continuous pulse heating is carried out; after heating is carried out for a period of time, the temperature rise and heat dissipation of the battery reach stable values, the temperature will not rise continuously; and the pulse heating does not need long-time low-temperature standing. Therefore, a lot of test time is saved, a test period is shortened, and meanwhile, the influence of the temperature of the battery on the durability of the battery can be verified through a lot of experiments.

Owner:TSINGHUA UNIV

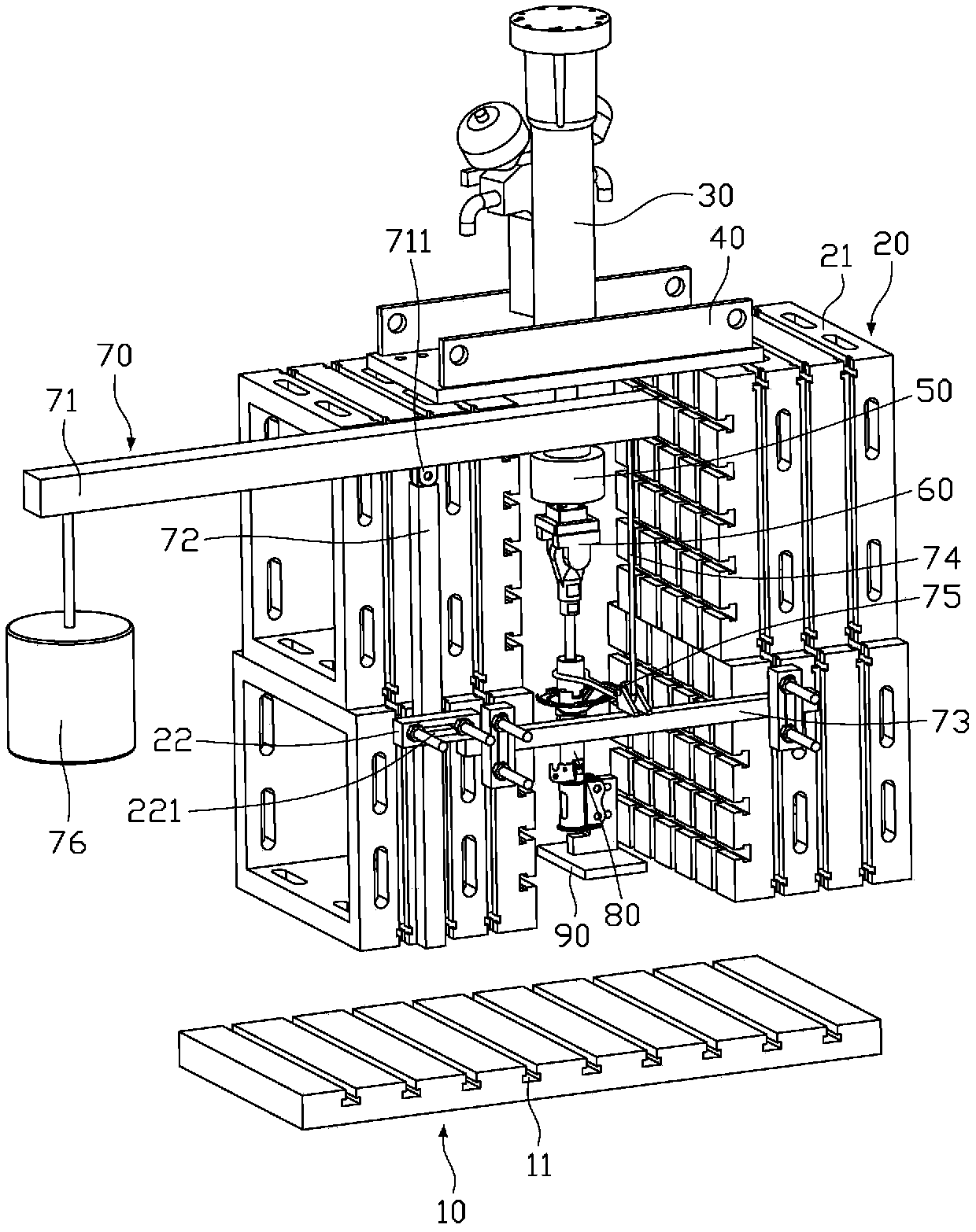

Load and freeze-thaw cycle coupled concrete durability testing device and evaluation method

ActiveCN107543755AKeep abreast of performance changesEnsure safetyMaterial strength using tensile/compressive forcesMaterial thermal analysisFreeze thawingEngineering structures

The invention discloses a load and freeze-thaw cycle coupled concrete durability testing device and an evaluation method. The device comprises a concrete load and freeze-thaw cycle coupling device, aconcrete strain testing system and a freeze-thaw testing machine. The concrete load and freeze-thaw cycle coupling device is placed in the freeze-thaw testing machine for a freeze-thaw cycle couplingtest. Sample strain data is recorded at real time through the concrete strain testing system, and by testing parameters such as rate of strain change, rate of mass change, etc. of a test piece after acertain times of load and freeze-thaw cycle coupling, durability of the concrete is evaluated. According to the invention, durability of loaded concrete (member) serving in severe cold areas can be rapidly tested, and load and freeze-thaw cycle coupling effect in actual service is accurately simulated. The method is simple to operate and is scientific and effective. The invention provides technical support for durability design and material selection of large-scale engineering structures under complex service conditions such as severe cold condition, etc.

Owner:CENT SOUTH UNIV +1

Switch durability testing device

ActiveCN110045275AReduce labor intensityShorten test timeMachine part testingCircuit interrupters testingSoftware engineeringUltimate tensile strength

The invention relates to the field of testing devices, and in particular to a switch durability testing device, comprising a conveyor, a base and a controller, wherein the switch durability testing device further comprises a testing mechanism and a shifting mechanism, the testing mechanism is disposed at one end of the top of the base through a vertical plate so as to perform a durability test ona switch, the shifting mechanism is disposed at the other end of the base to shift the switch, the testing mechanism comprises a driving assembly, a placement table and a pressing assembly, the shifting mechanism comprises a gripping assembly, a first sliding table and two second sliding tables, the clamping assembly, the placement table and the conveyor have the same height, the switch durabilitytesting device provided by the invention replaces the manual test with automatic test, thereby shortening the testing time, accelerating the testing speed, improving the testing efficiency, not onlyimproving the working efficiency and reducing the cost, but also saving labor resources and reducing the labor intensity of workers, and meanwhile, the device has loading and unloading mechanisms on the basis of a testing function, so that the functions are diversified.

Owner:苏州全道通检测技术有限公司

Concrete durability testing device and method under synergistic action of freezing-thawing and loading

PendingCN110006762AAchieve positioningNo movementMaterial strength using tensile/compressive forcesConstant loadFreeze thawing

The invention provides a concrete durability testing device and method under the synergistic action of freezing-thawing and loading. The concrete durability testing device comprises a testing device body, a constant hydraulic source device and a control circuit, the testing device body comprises a freeze-thaw box, a specimen box, a jack, a movable pressing plate, limiting rods, an electric refrigeration unit and an electric heating unit, concrete specimens are placed in the specimen box, the two sides of the concrete specimens are limited through the limiting rods, and the jack is arranged onthe upper part of the freeze-thaw box; and a water inlet pipe and a water outlet pipe are arranged on the specimen box, and a freeze-thaw liquid inlet pipe and a freeze-thaw liquid outlet pipe are arranged on the freeze-thaw box. The concrete durability testing method includes the steps of (a), specimen manufacturing; (b), specimen placement; (c), equipment connection; (d), constant load applying;(e), water and freeze-thaw liquid introducing; (f), freeze-thaw cycle control; and (g), test analysis. According to the concrete durability testing device, a concrete durability test of the concretespecimens under the synergistic action of freezing-thawing circulation and loading can be implemented automatically, the beneficial effects are significant, and the concrete durability test device issuitable for application and popularization.

Owner:SHANDONG JIAOTONG UNIV

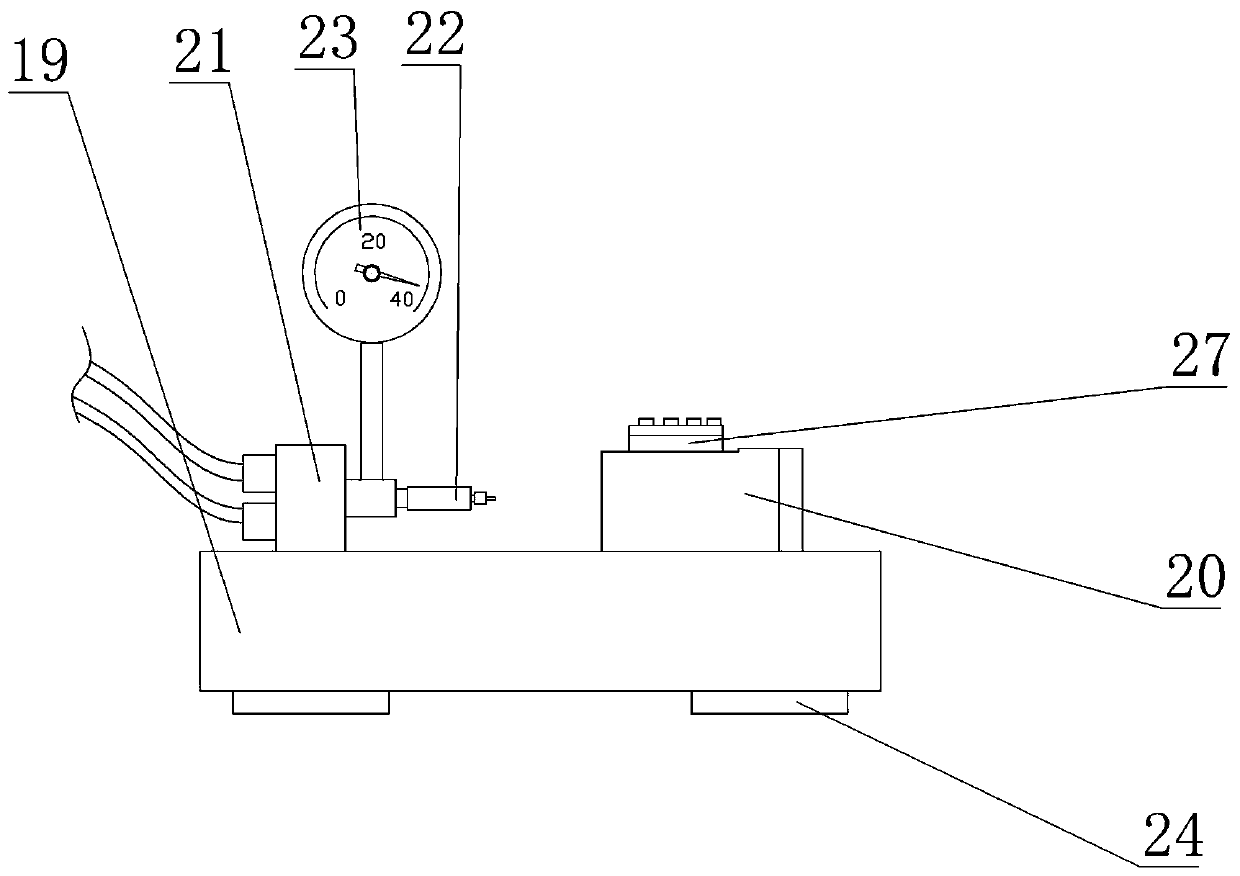

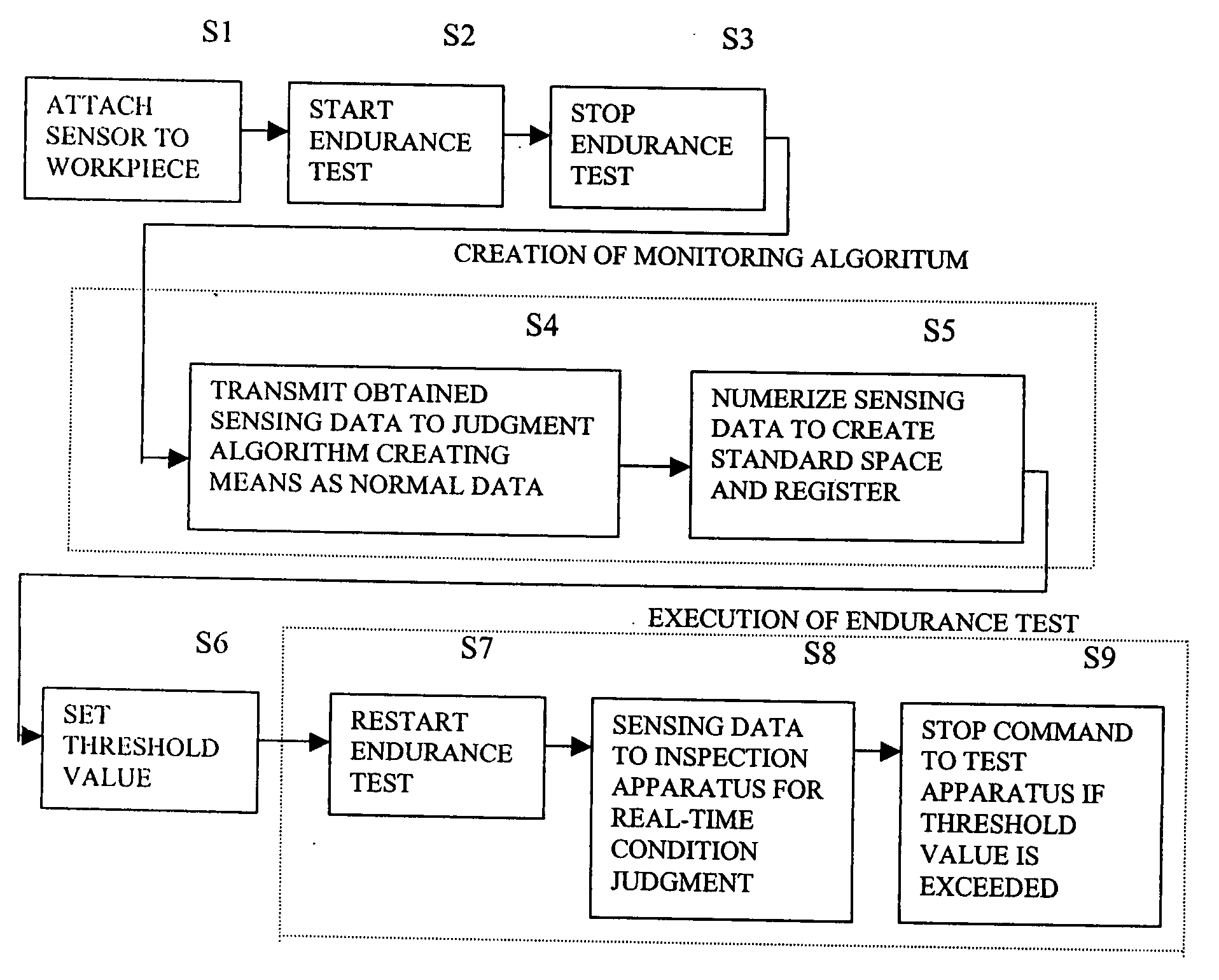

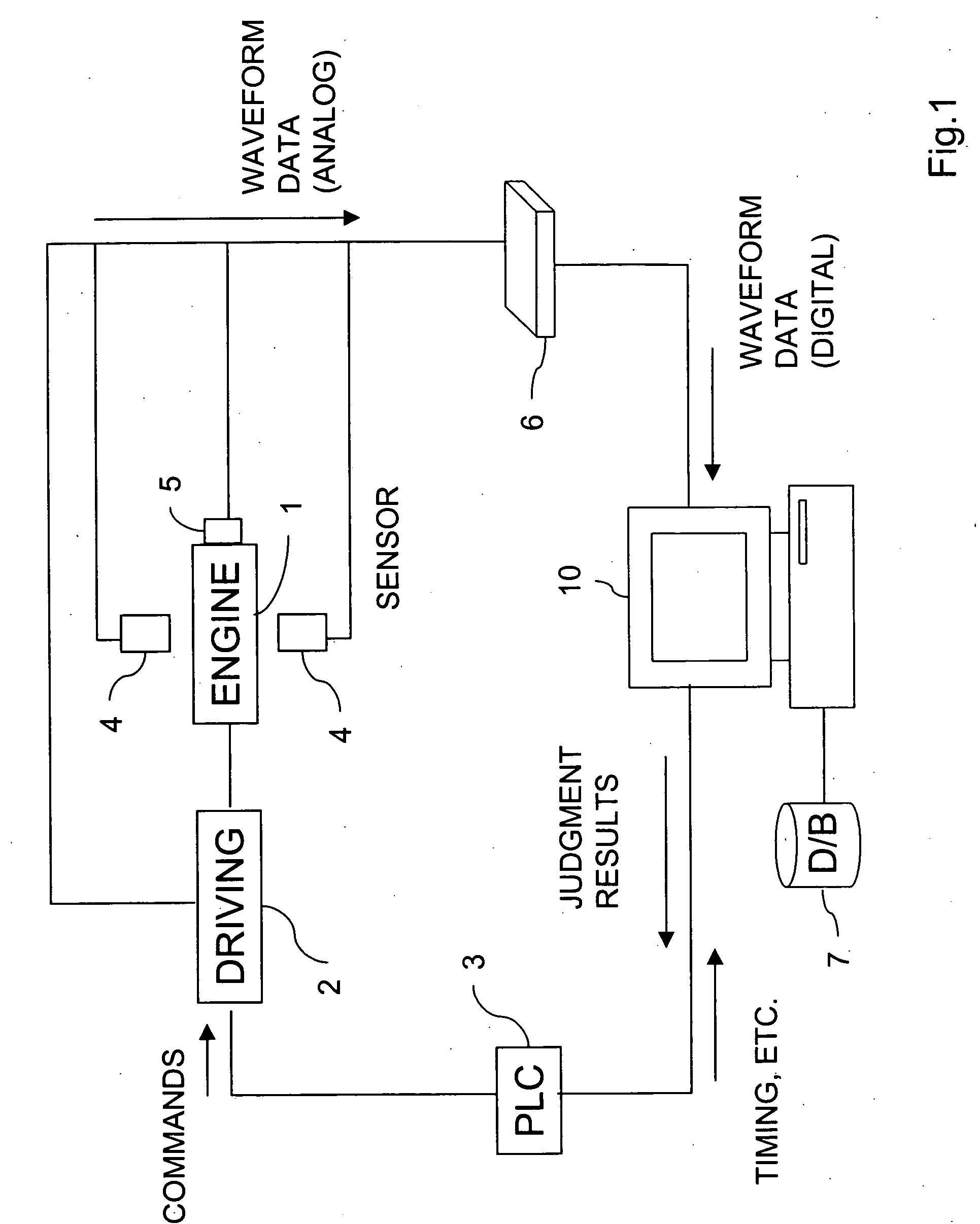

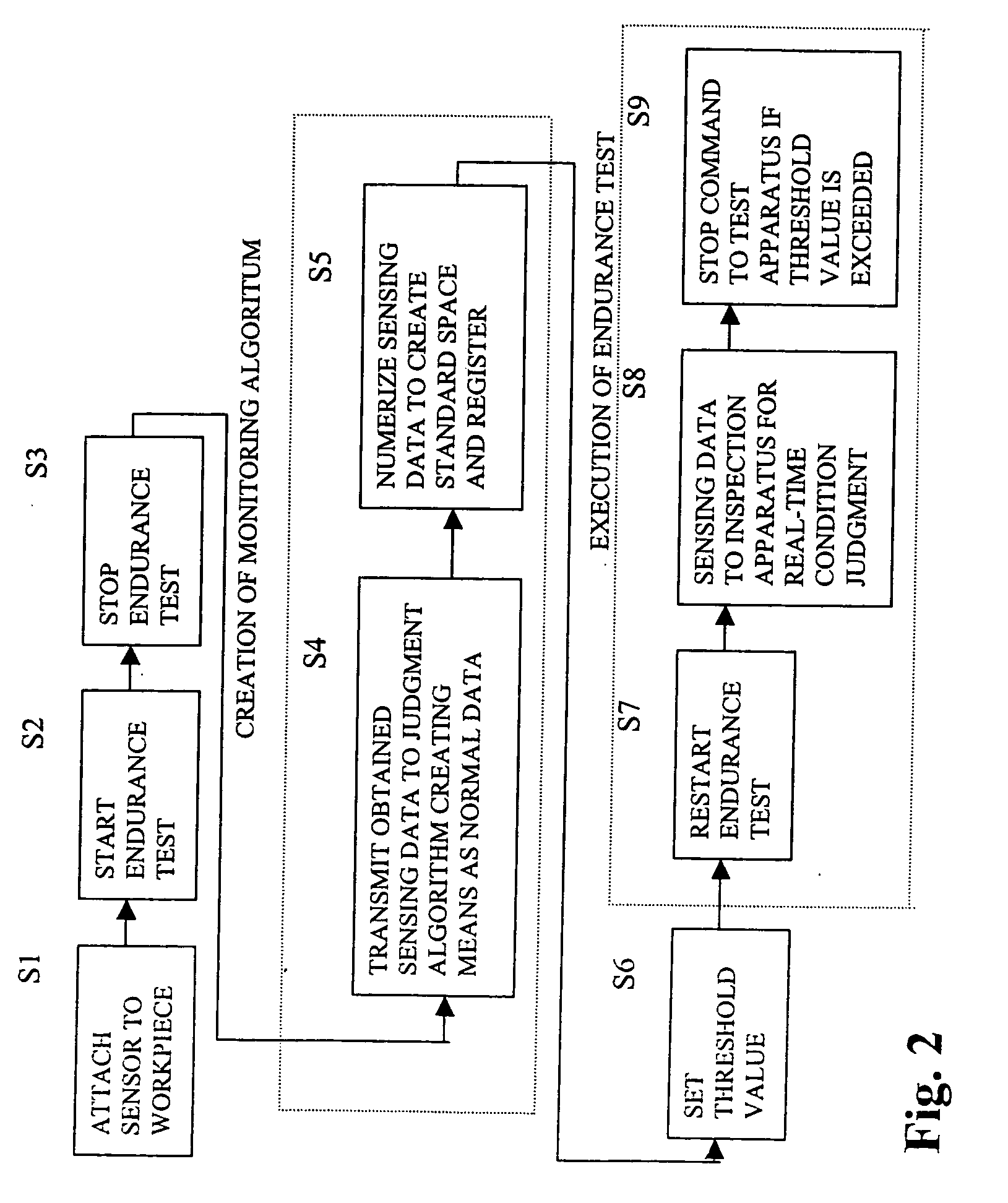

Inspection apparatus, aid device for creating judgement model therefor, abnormality detection device for endurance test apparatus and endurance test method

InactiveUS20060224367A1Accurate judgment modelAccurate judgment modelsLiquid surface applicatorsMaterial analysis using acoustic emission techniquesAcquired characteristicAnomaly detection

An endurance test is carried out after judgment models are created from normal data obtained from test apparatus while operating stably and presence and absence of abnormality in a target object is judged from waveform data obtained during the test and by using the created judgment models. An aid device creates such judgment models automatically by creating divided waveform data by dividing obtained waveform data into portions of unit time, obtaining characteristic quantities in units of the divided waveform data based on a plurality of the divided waveform data for the unit time. The judgment models are created for the unit time based on the obtained characteristic quantities.

Owner:ORMON CORP

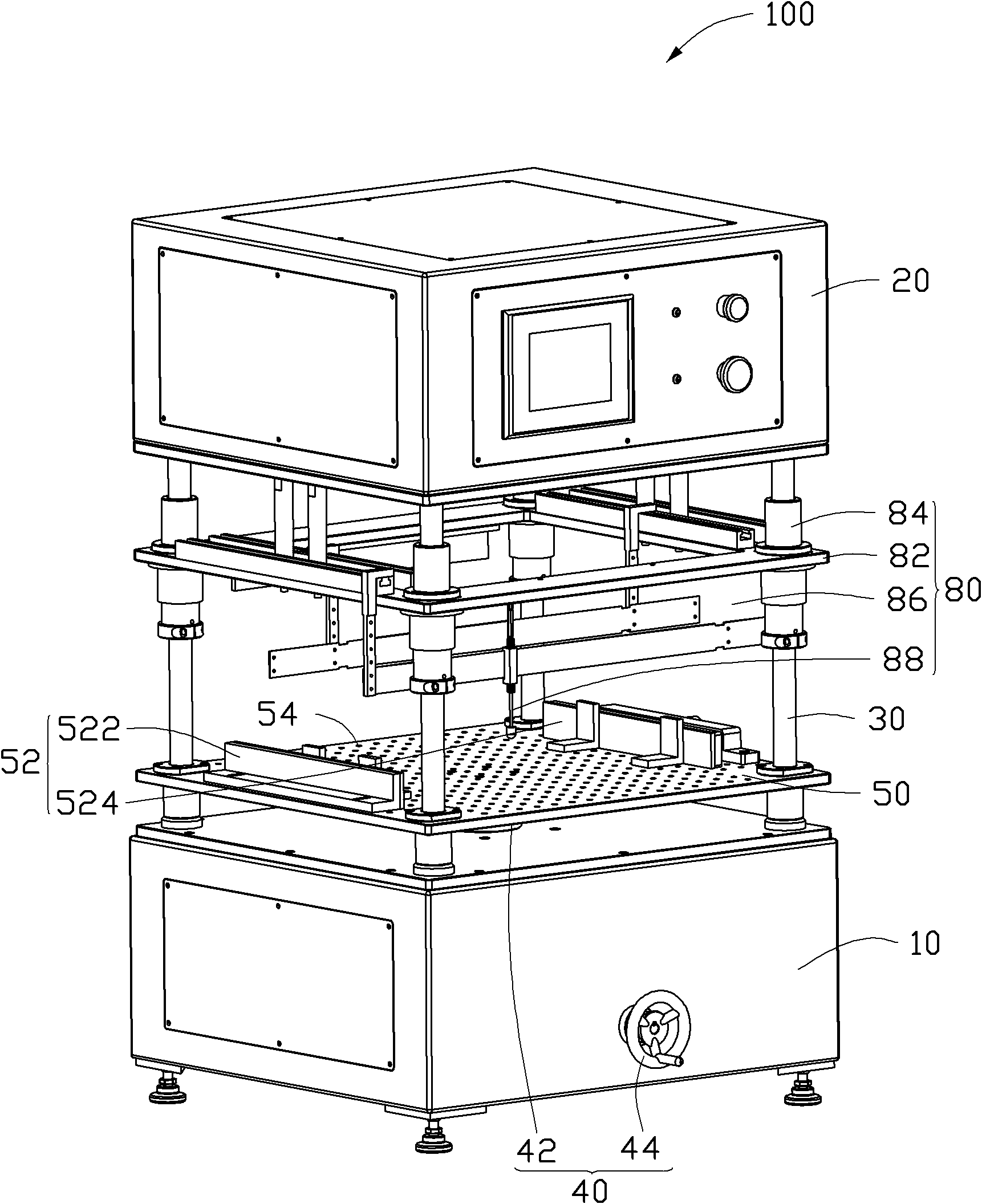

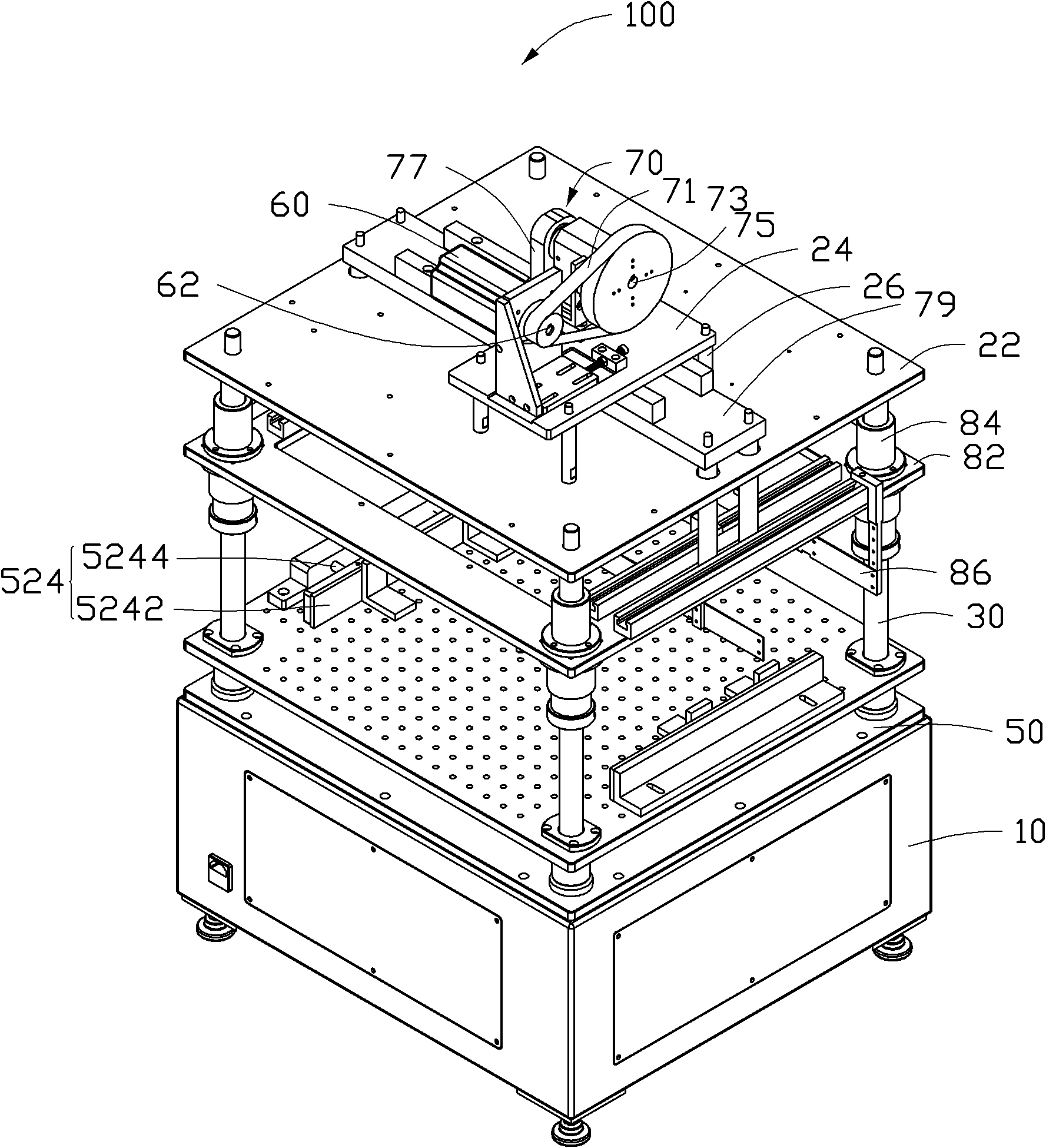

Button durability testing machine

InactiveCN102650562AGuaranteed accuracyRealize fully automatic testingMaterial strength using repeated/pulsating forcesElasticity measurementKey pressingReciprocating motion

A button durability testing machine includes a machine box, a lifting control mechanism and a work table, wherein the lifting control mechanism is mounted on the machine box to drive the work table to vertically reciprocate; the button durability testing machine also includes an electric cabinet, a guide rod, a servo motor, a drive mechanism and a pressing component; the guide rod is fixed between the machine box and the electric cabinet; the work table can be sleeved on the guide rod in a moving way under the control of the lifting control mechanism; both the servo motor and the drive mechanism are mounted in the electric cabinet; and the drive mechanism is used for transmitting the power output by the servo motor to the pressing component and driving the pressing component to vertically reciprocate along the guide rod.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com