Test apparatus and method for duration performance of safety belt buckle

A technology for seat belt buckle and testing device, which is applied in the direction of measuring device, vehicle testing, mechanical component testing, etc., can solve the problems of high labor intensity, low testing efficiency, long testing cycle, etc., and save working time and structure. Simple, easy-to-install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

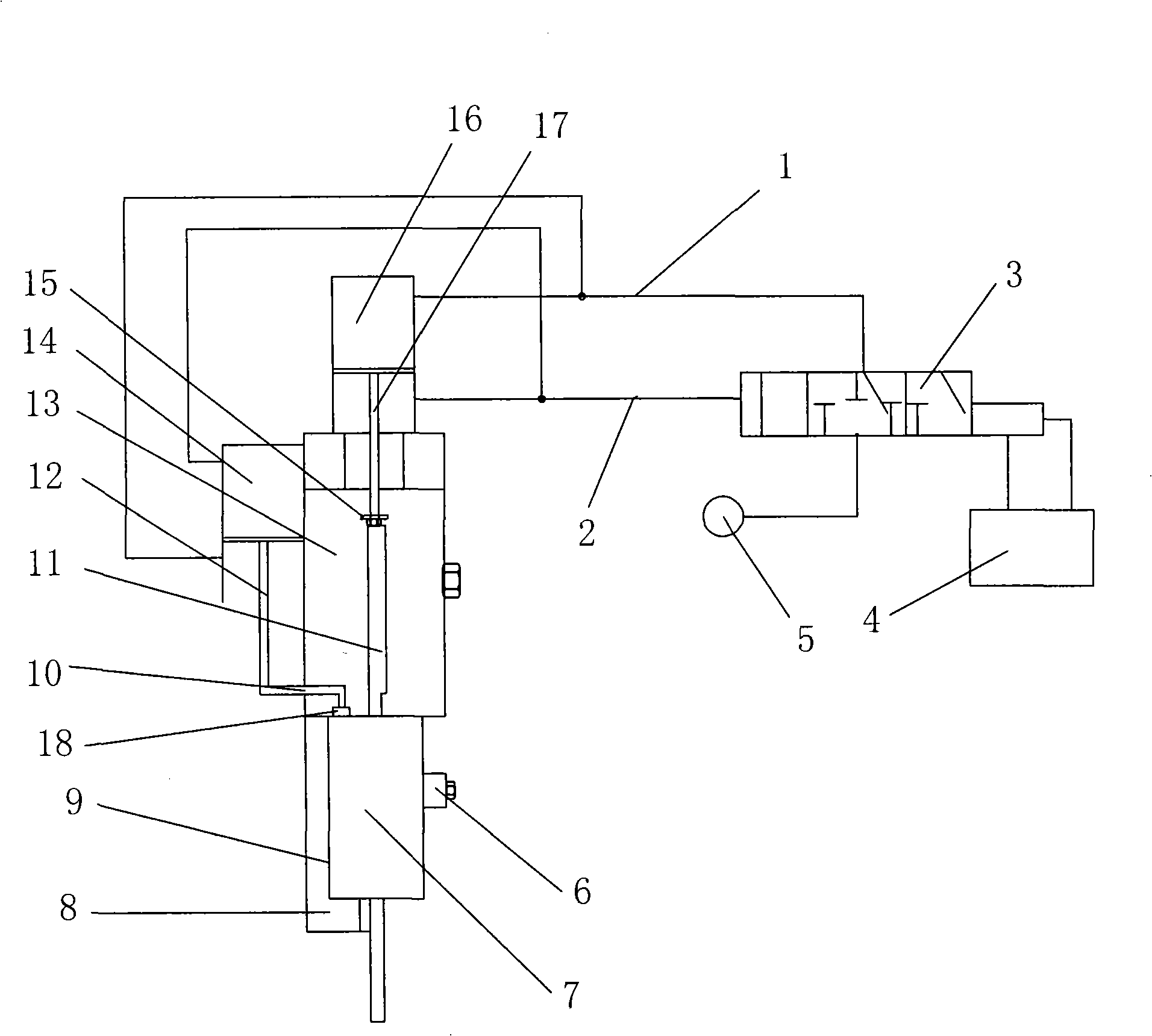

[0022] Such as figure 1 As shown, the structure of a seat belt buckle durability test device includes a buckle fixture 8, a deadbolt fixture 13; the first power element for actuating the buckle 7 to open and lock, and the actuating deadbolt 11 plugging action the second power element; and a control device for controlling the operation of the first power element and the second power element. The first power element is a pneumatic element made up of a cylinder 14 , a piston and a connecting rod 12 . The second power element is a pneumatic element made up of cylinder 16 , piston and connecting rod 17 . The control device includes a compressed air power source 5, a two-position three-way solenoid valve 3, and a programmable controller 4; the programmable controller 4 is electrically connected to the two-position three-way solenoid valve 3, and the three ports of the two-position three-way solenoid valve 3 are respectively connected The compressed air power source 5 communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com