Automatic control valve life tester

A technology for automatic control of valves and life tests, applied in the testing of machines/structural components, by measuring the increase and decrease rates of fluids, measuring devices, etc., to achieve the effects of ensuring safety, increasing the frequency of experiments, and improving the response speed

Inactive Publication Date: 2010-08-25

SHANGHAI INST OF SPECIAL EQUIP INSPECTION & TECHN RES

View PDF5 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Whether it is the user, the valve manufacturer or the testing organization, if they want to understand and master the reliability of the valve quality in a short period of time, they must rely on the valve life test device. However, there is no ideal device for testing it at present.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

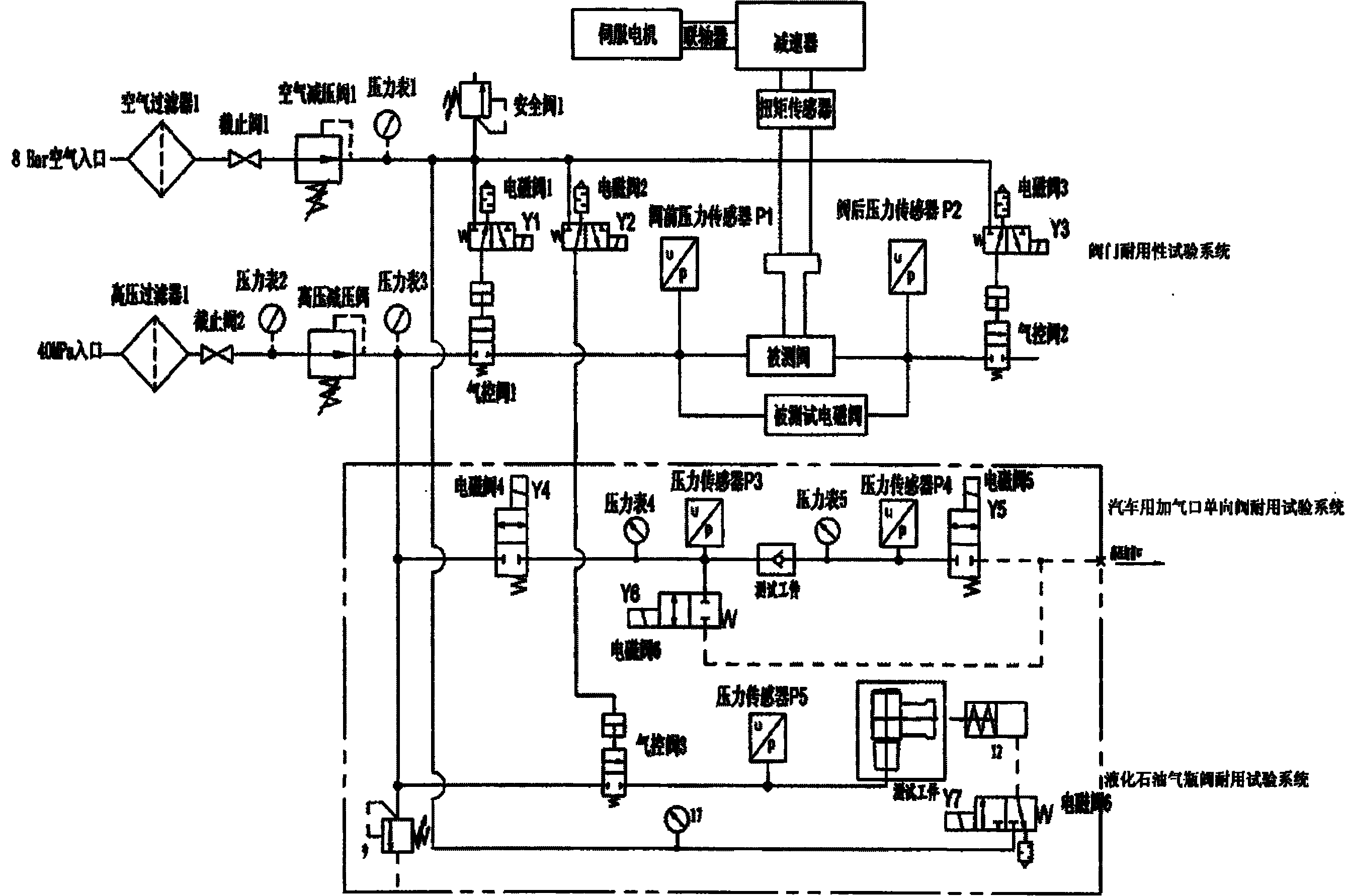

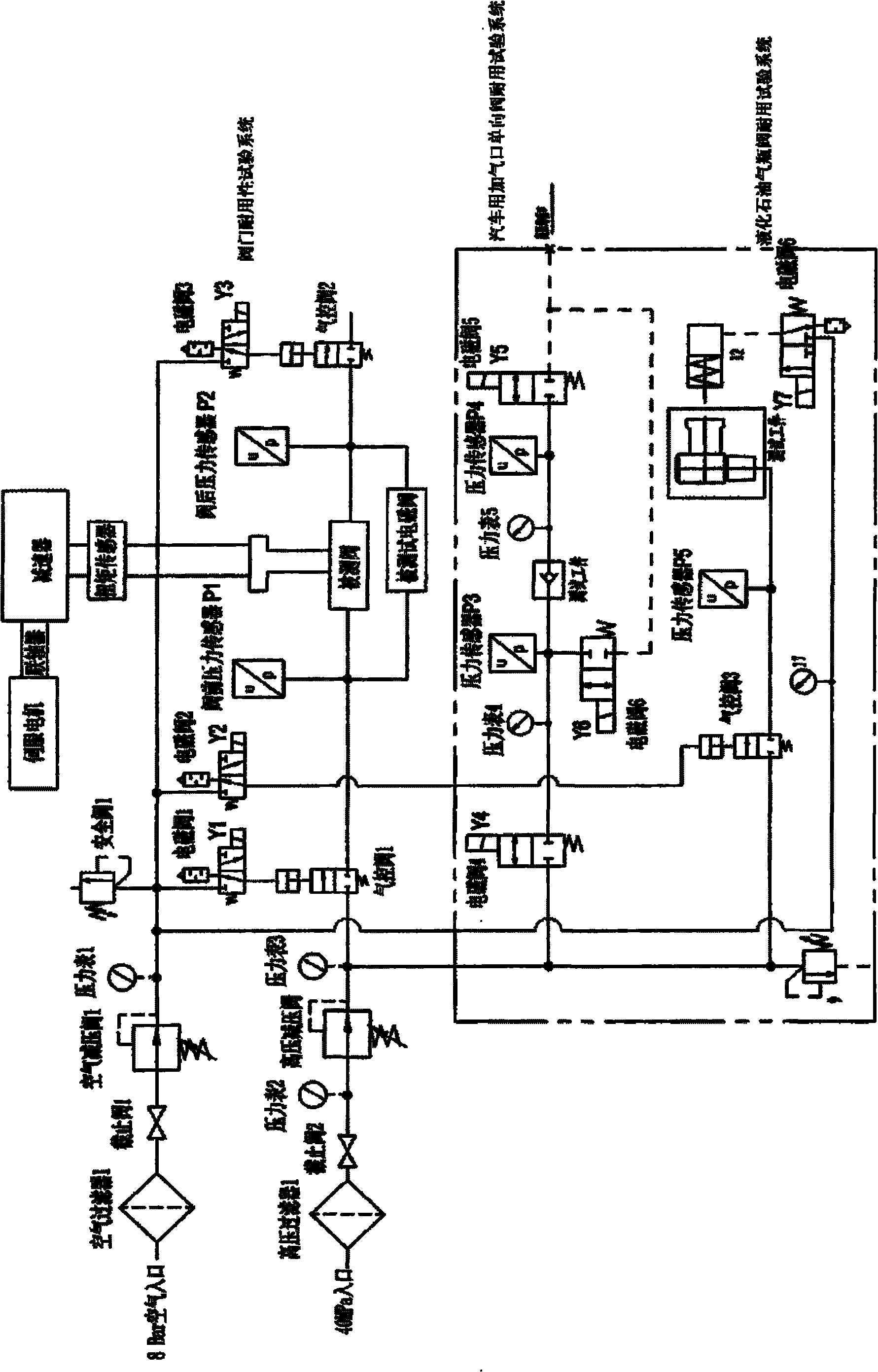

The invention relates to an automatic control valve life tester, which mainly comprises a control system and a durability tester, wherein the durability tester comprises a valve durability testing system, an automotive gas charging-port one-way valve durability testing system and a liquefied petroleum gas cylinder self-closing device durability testing system. The tester is mainly used for the test of the opening and closing of a valve and the total travel torque and the durability tests of a self-closing device, an automotive gas charging port one-way valve and a liquefied petroleum gas cylinder. The three systems in the durability tester are positioned in the same frame and independent of one another and controlled by different software interfaces. When the automatic control valve life tester is used for testing the life of the valve, the test can be completed quickly, numerical values such as the pressure, the time and the test times are displayed in the test process, the test result can be stored automatically and also can be printed, and the test result can automatically stored after power is cut off.

Description

technical field The invention relates to the field of valve durability testing, in particular to an automatic control valve life testing machine. Background technique Valve life is an important indicator of valve quality and reliability assessment. At present, there are more than 4,000 valve factories in my country. When the wear between the valve plate and the valve seat reaches a certain level, the valve will leak beyond the standard after it is closed. Therefore, many products will not expose quality problems in a short period of time. After a period of use, their quality defects will appear. Whether users, valve manufacturers or testing organizations want to understand and master the reliability of valve quality in a short period of time, they must rely on valve life test devices. However, there is no ideal device for testing them. Contents of the invention The technical problem to be solved by the present invention is to provide an automatic control valve life testi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M19/00G01M3/28G01M99/00

Inventor 徐维普杨金富罗晓明袁弈雯吴俭

Owner SHANGHAI INST OF SPECIAL EQUIP INSPECTION & TECHN RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com