Patents

Literature

96results about How to "Influence flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

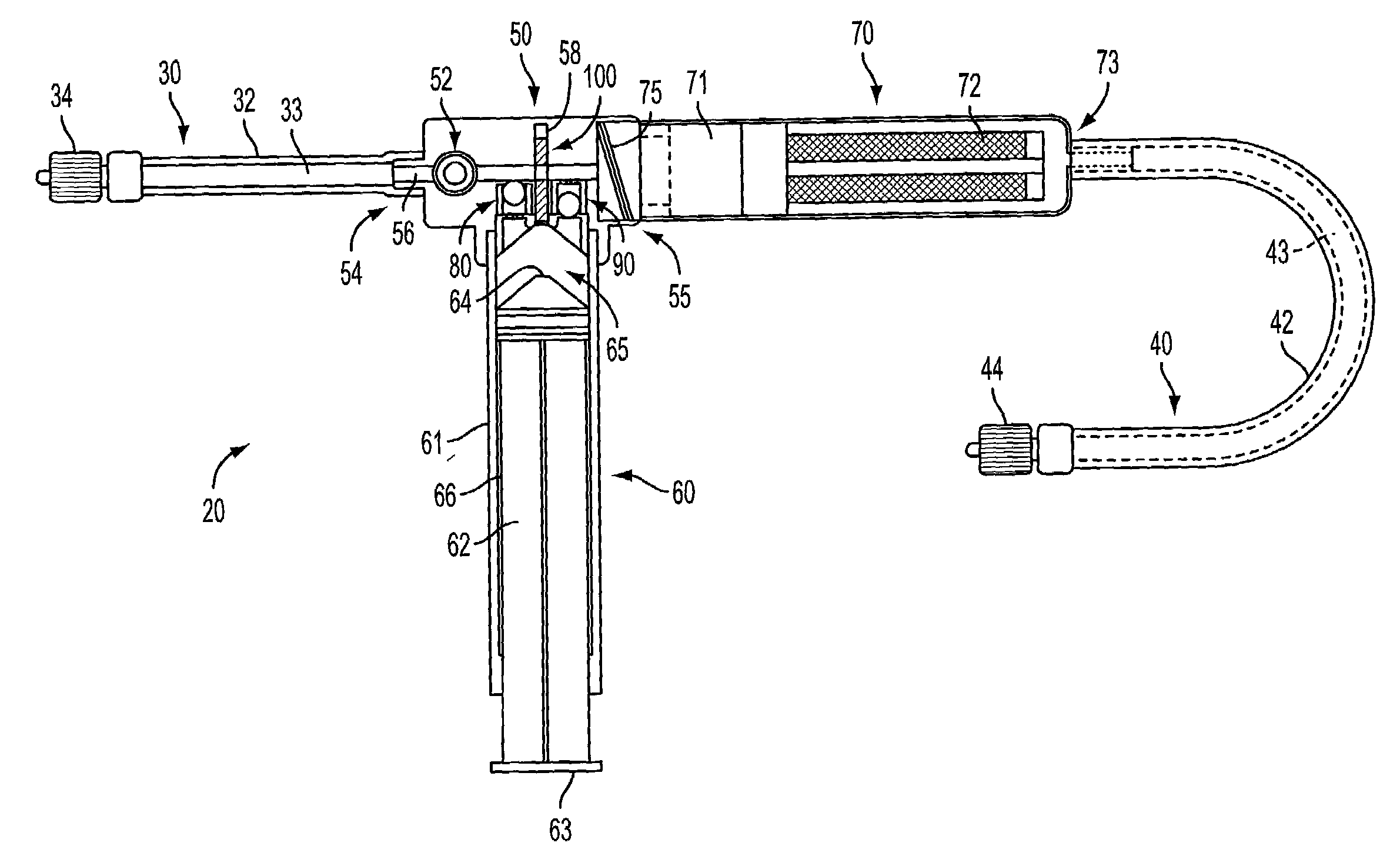

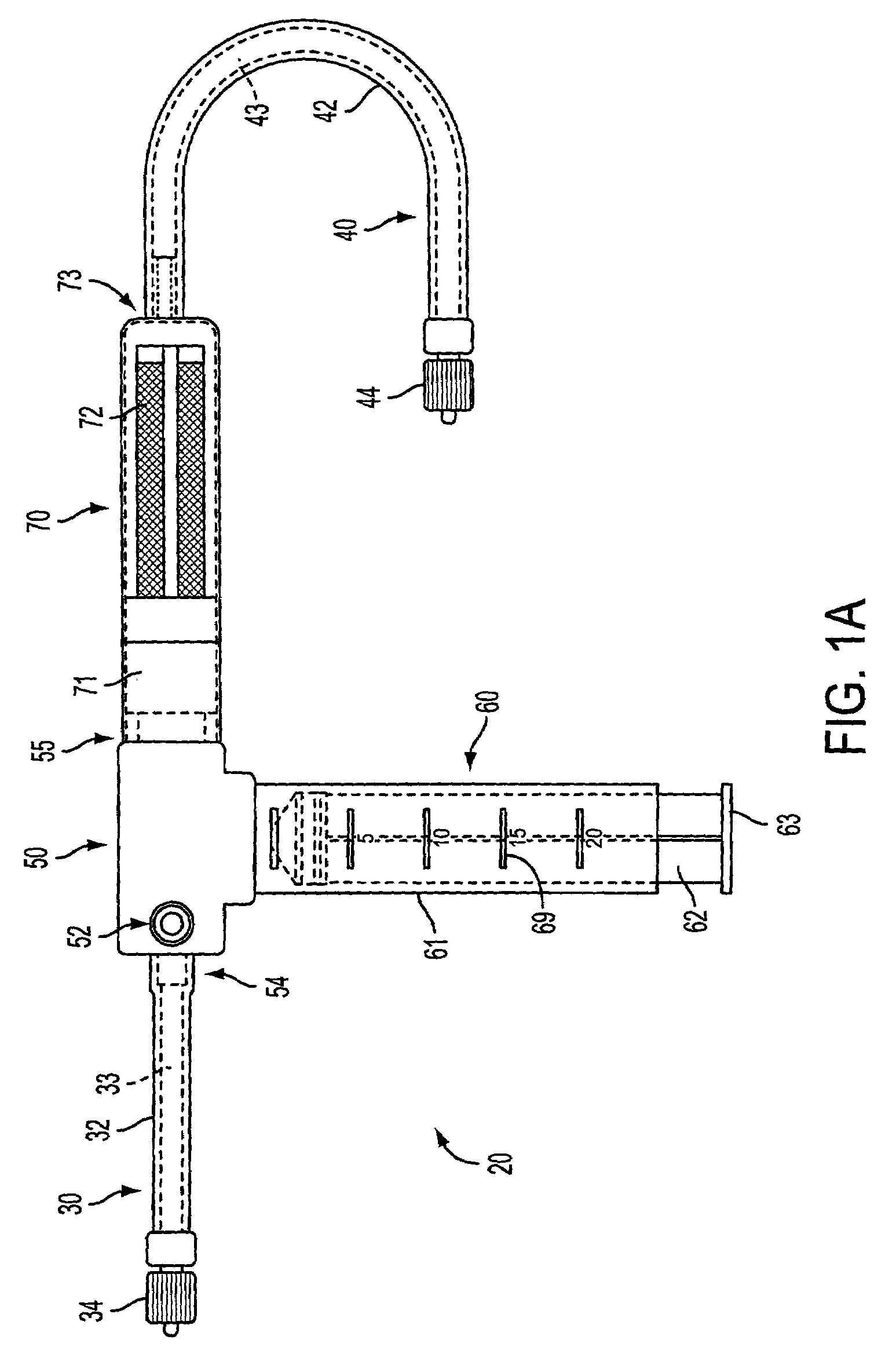

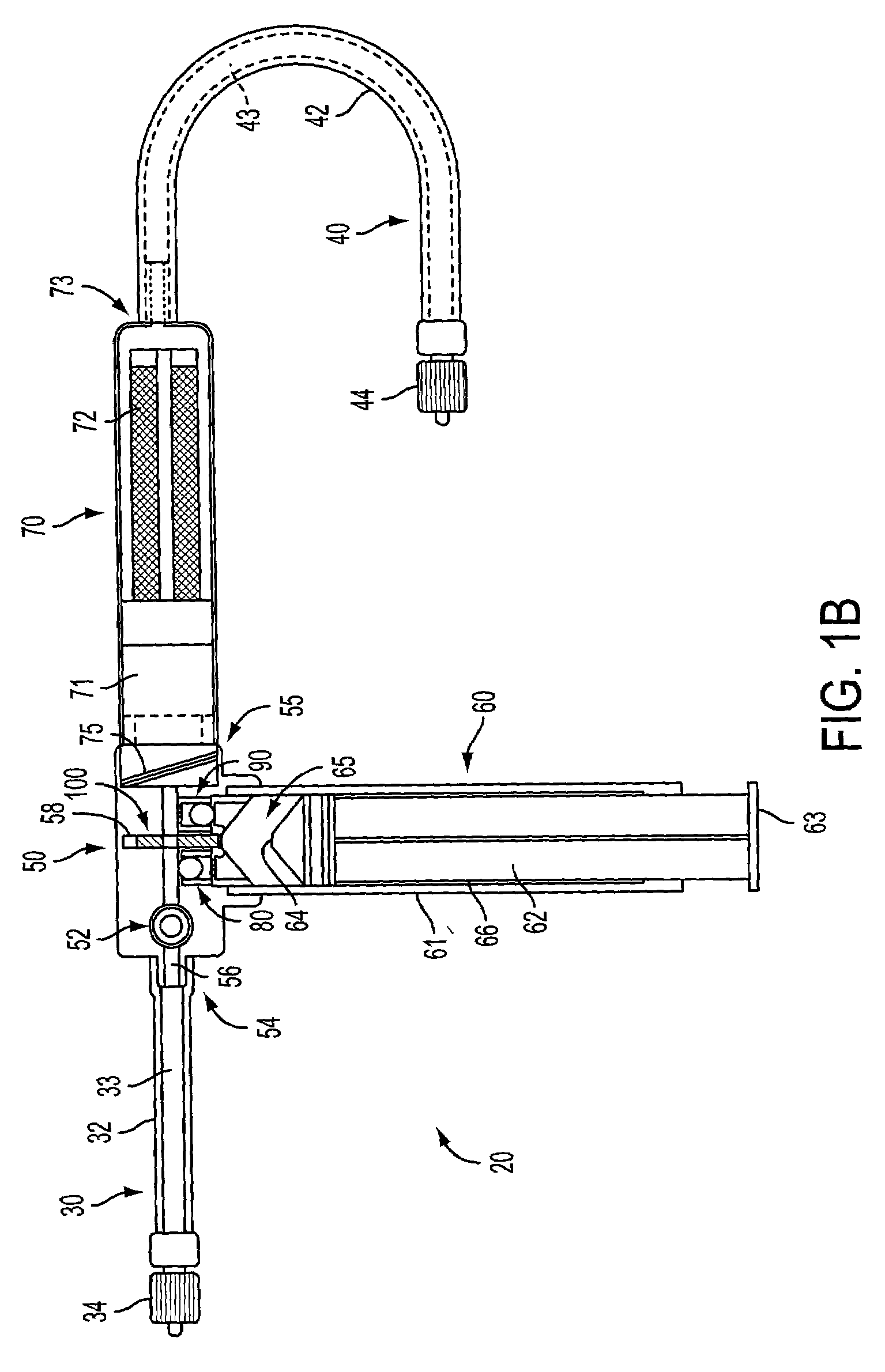

Blood aspiration system and methods of use

The present invention is directed to a blood aspiration system that is configured to enable various types of aspiration through a working lumen of a catheter. The blood aspiration system facilitates natural aspiration by providing a circuit between a patient's arterial and venous vasculature, and also comprises a manually actuated pump configured to selectively vary rates of aspiration in the working lumen. The blood aspiration system further comprises an external port that allows suction-assisted aspiration or infusion through the working lumen, and further comprises a detachable filter that removes emboli prior to reperfusing blood into a patient's venous vasculature.

Owner:WL GORE & ASSOC INC

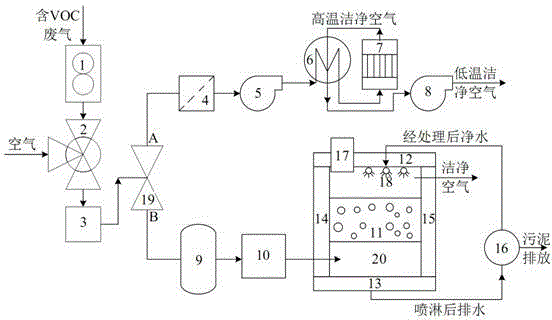

Method for treating organic waste gas in chemical plant

ActiveCN104645798AInfluence flowSave internal reaction spaceDispersed particle filtrationIncinerator apparatusBiological filterThermostat

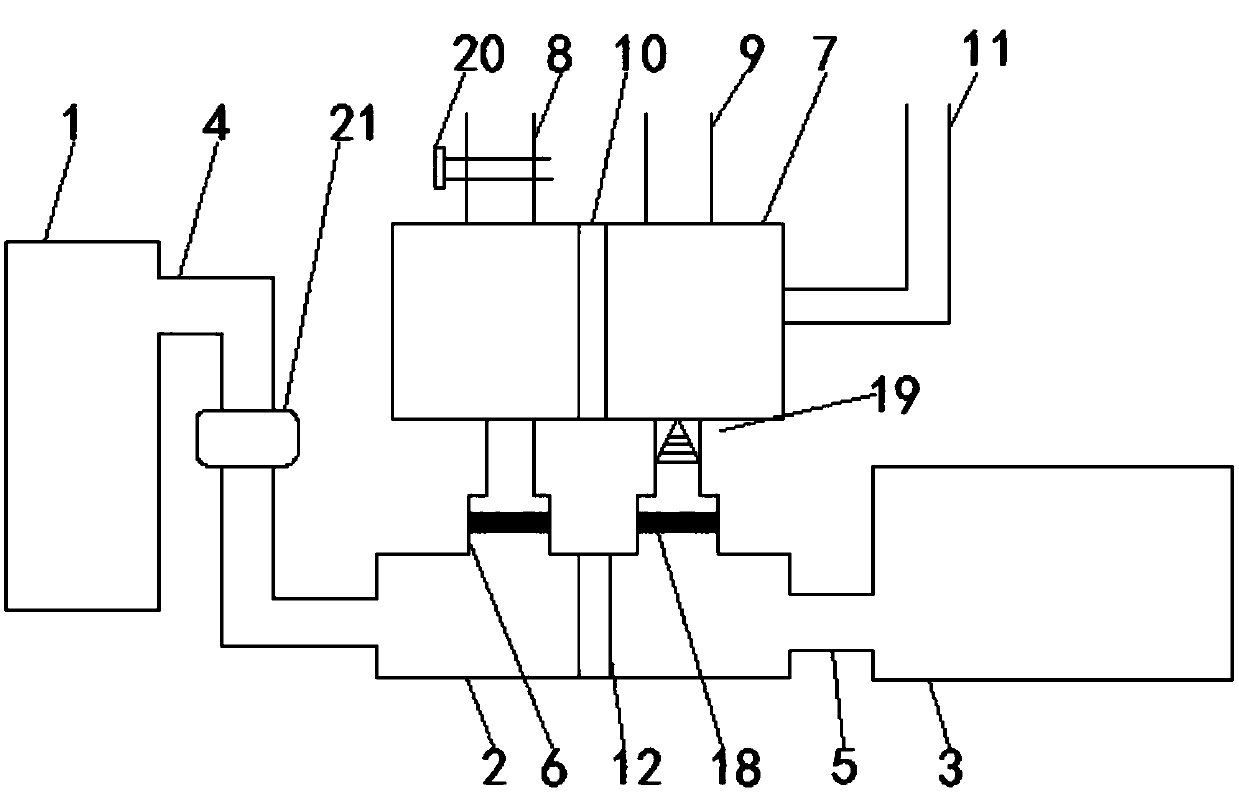

The invention discloses a method for treating organic waste gas in a chemical plant. The organic waste gas sequentially pass through a flowmeter, a flow regulating valve, a concentration monitor, a dust removal flame-retardant device, an air inlet fan, a heat exchanger, a catalyst chamber, an exhaust fan, an alkaline tower, a humidifier, a biological active packing layer containing scrap iron, a 1# electrode, a 2# electrode, a 3# electrode, a 4# electrode, a circulating water system, a thermostat, a spraying system, a three-way valve and a biological filter. According to the method, the concentration of the organic waste gas can be regulated into a proper concentration range of the waste gas treatment system. According to the method, different waste gas treatment methods can be selected according to the concentration of the organic waste gas. In the biological treatment section of the method, acidic substances in the waste gas are removed by adopting an alkali washing method, and the condition that the biological activity is influenced in the biological filter is avoided; and in the biological treatment section of the method, the scrap iron is contained in the packing, the packing is stirred periodically by utilizing the variable electrode magnetism, the phenomena that the gas flow is influenced due to blockage and the reaction is non-uniform are avoided, a stirrer can be replaced, and the inner reaction space is saved.

Owner:广东思创环境工程有限公司

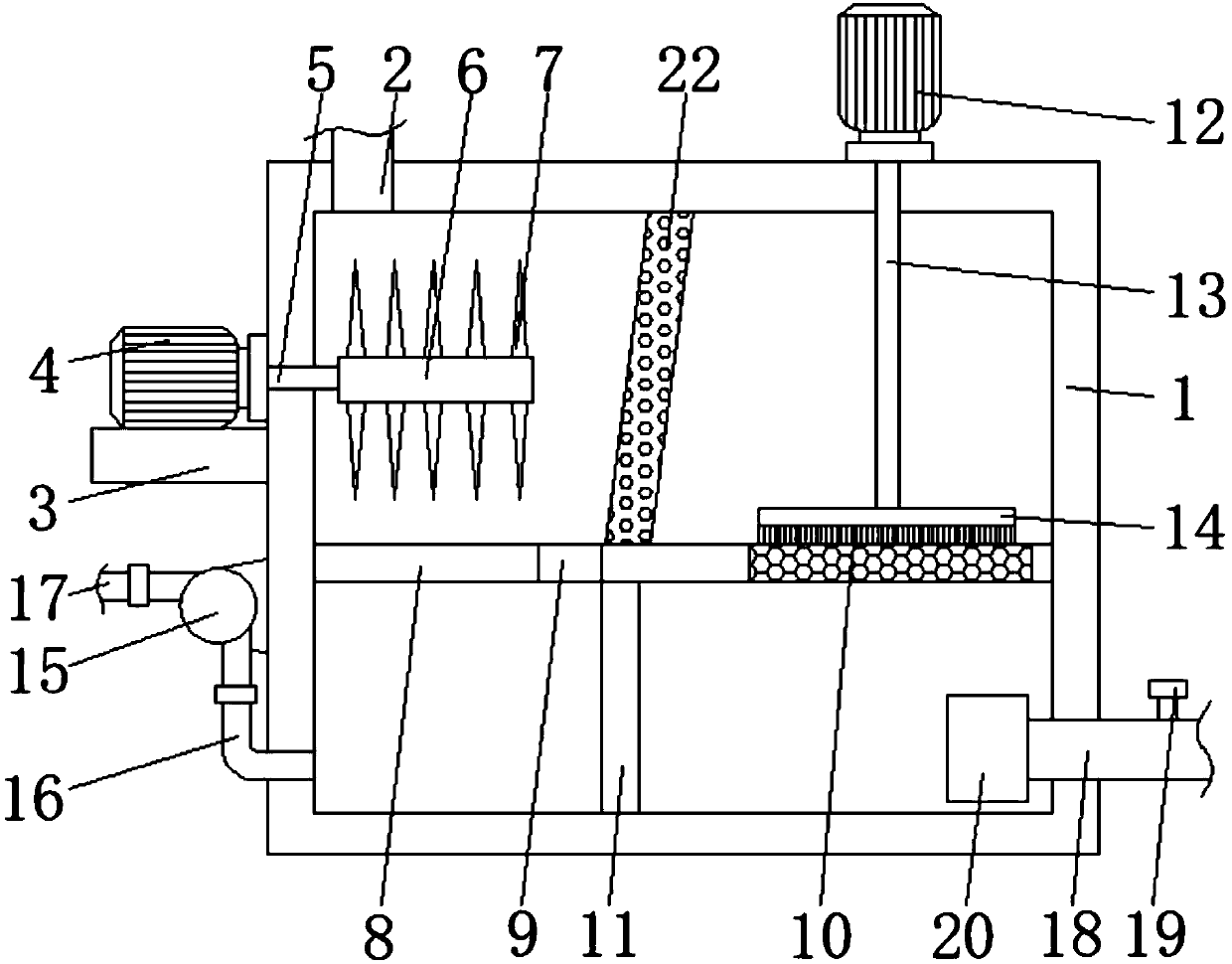

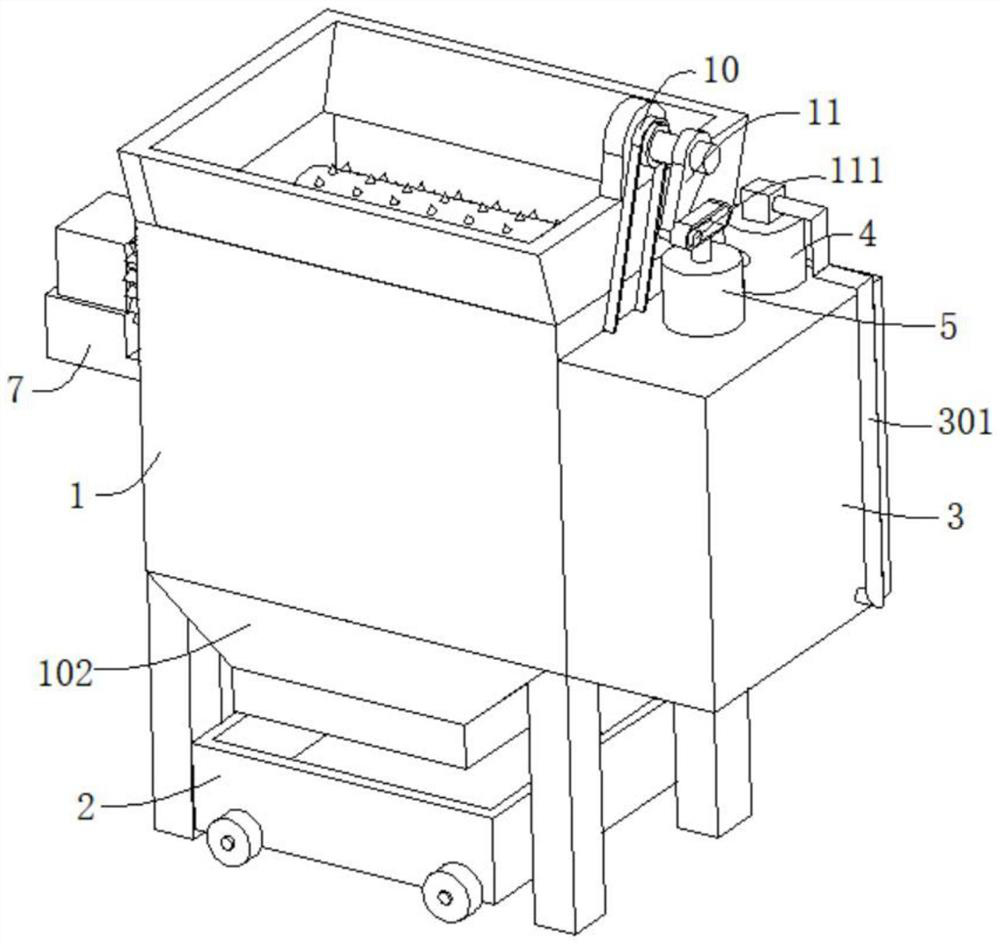

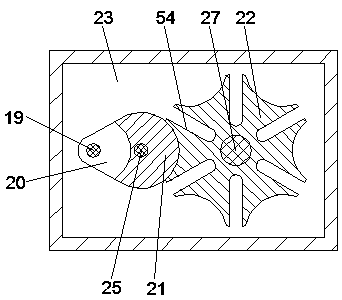

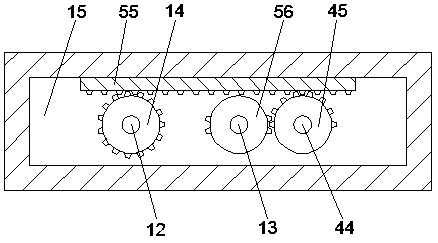

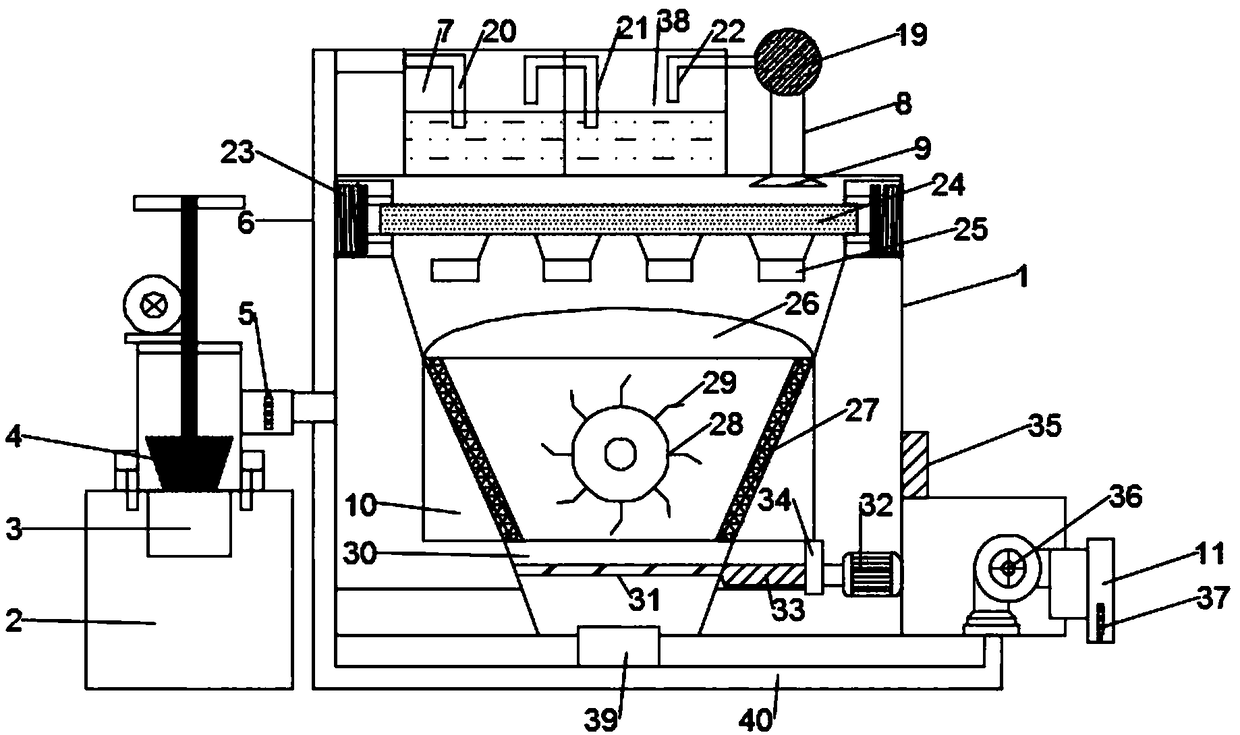

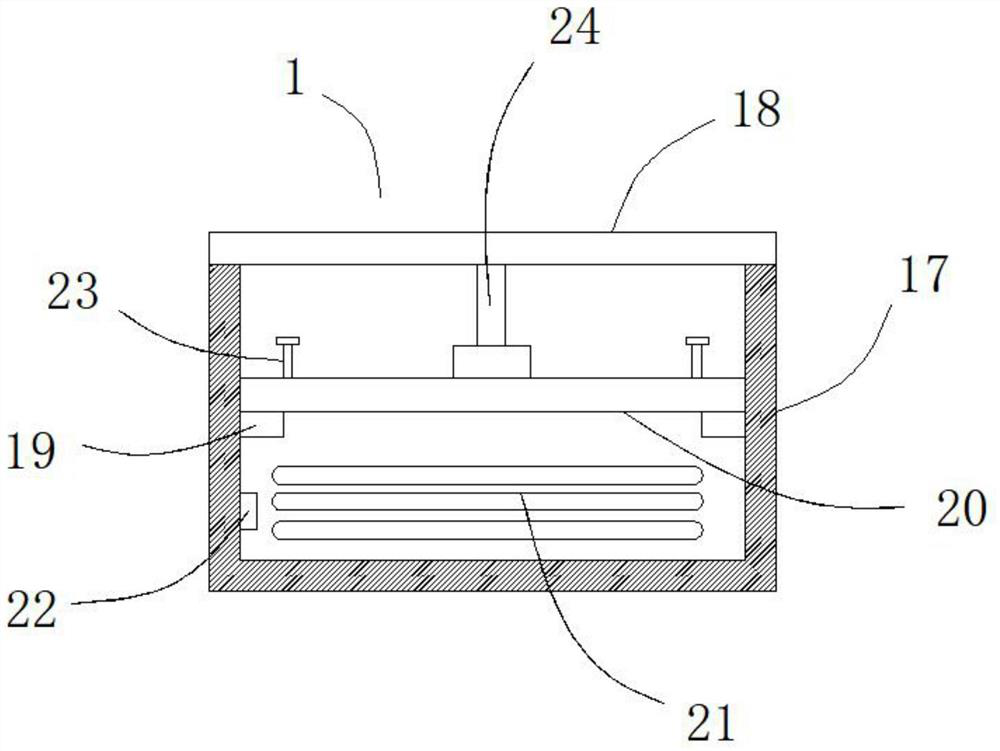

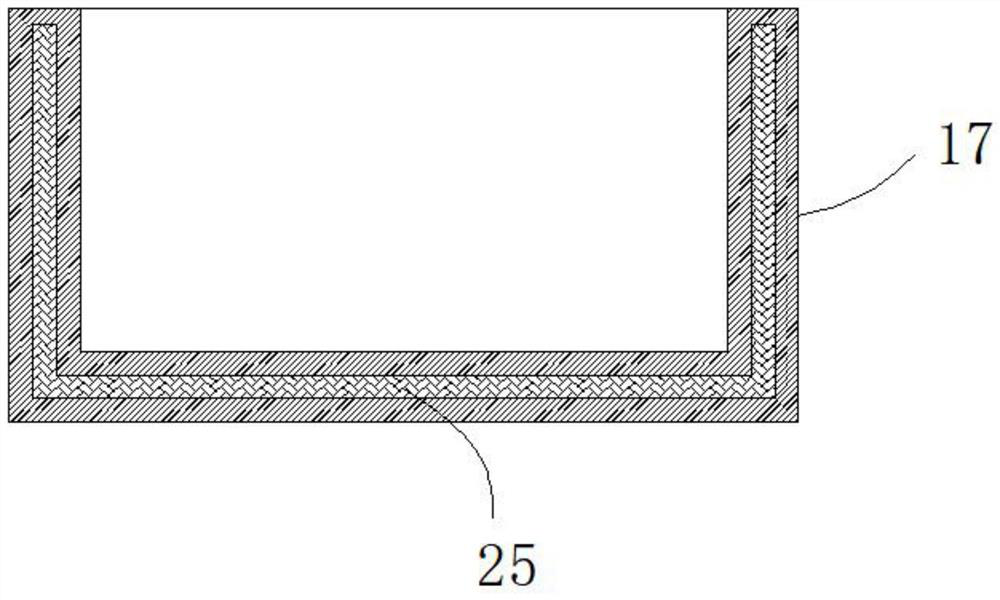

Sewage treatment device for firefighting

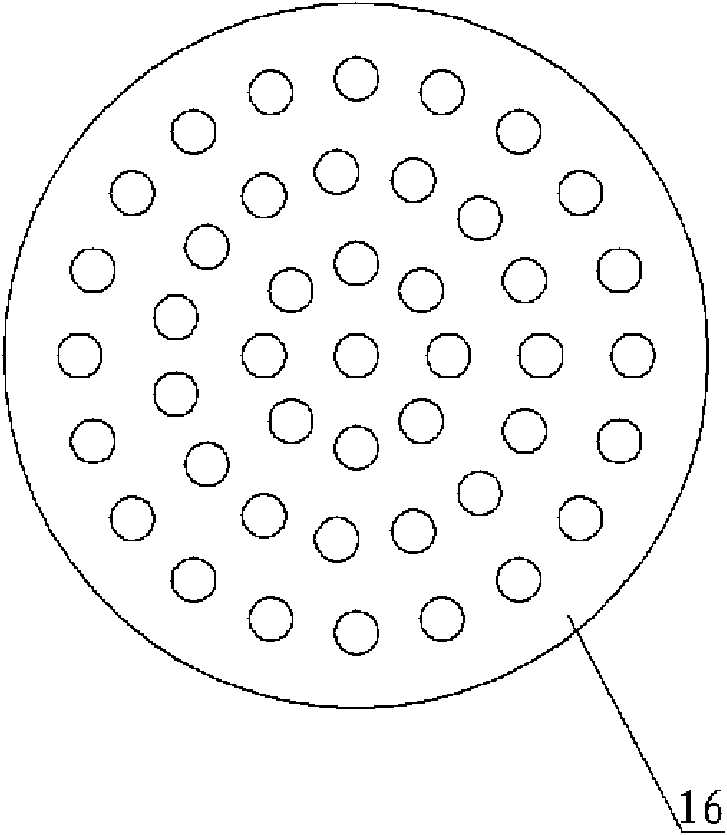

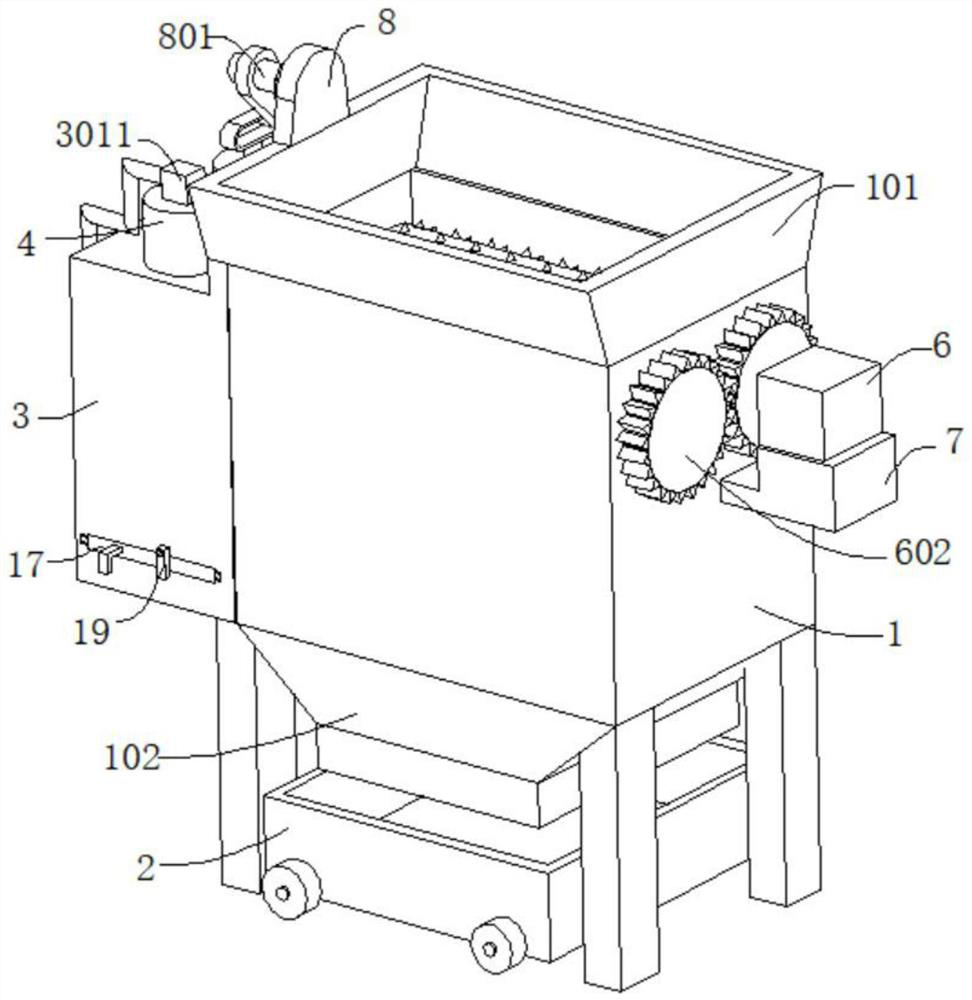

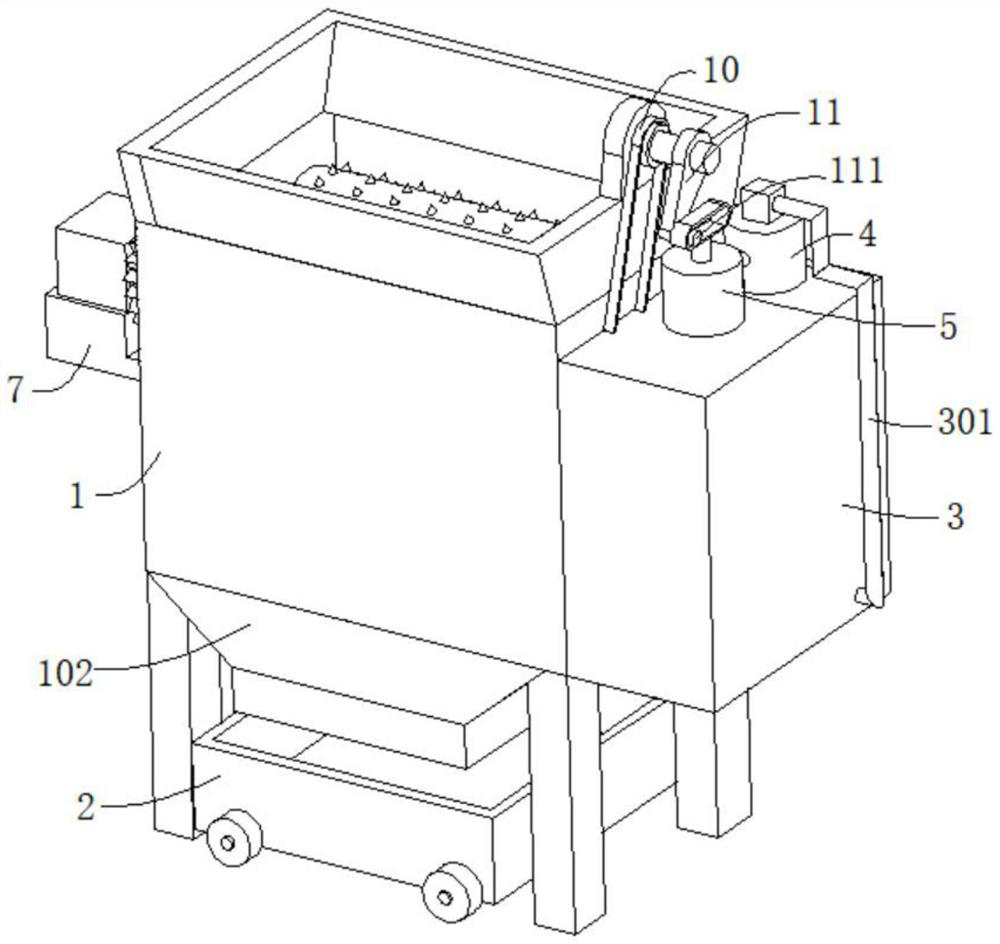

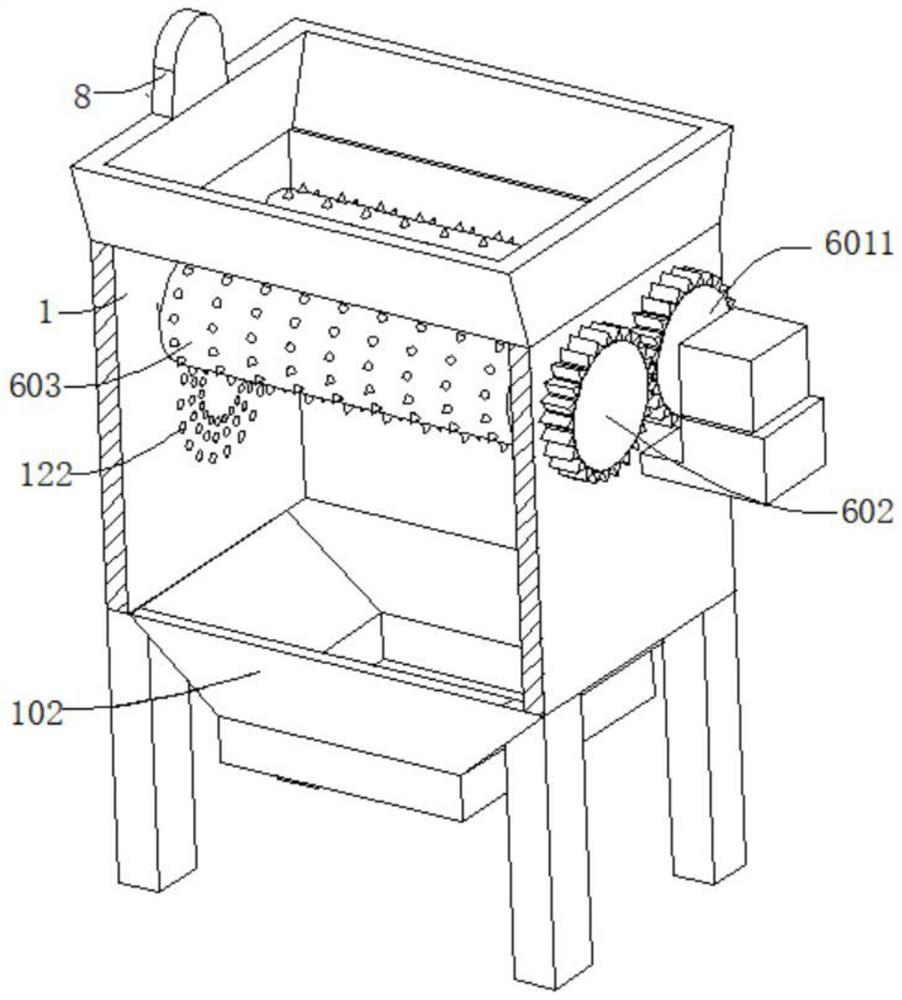

InactiveCN107823943AInfluence flowEfficient crushingGrain treatmentsStationary filtering element filtersSludgeFiltration

The invention relates to the technical field of fire protection, and discloses a sewage treatment device for fire protection, which includes a device body, a water inlet pipe is fixedly installed on the left side of the top of the device body, and a fixed plate is fixedly connected to the left side of the device body. A first motor is fixedly connected to the top of the fixing plate. Under the action of the first motor, the fire-fighting sewage treatment device can effectively crush the relatively large impurities and waste materials pumped into the water inlet pipe, avoiding the large impurities and waste materials from clogging the filter plate and affecting the flow of water. It can filter the crushed waste, and the filtered waste and silt leak into the bottom of the first partition through the leak hole for isolation, and can filter the smaller impurities and waste again. Under the action, it can clean the impurities and waste materials adhering to the filter net, avoiding the situation that the impurities and waste materials are filtered too much to block the filter net, and ensure the efficiency of equipment filtration.

Owner:盱眙正兴包装有限公司

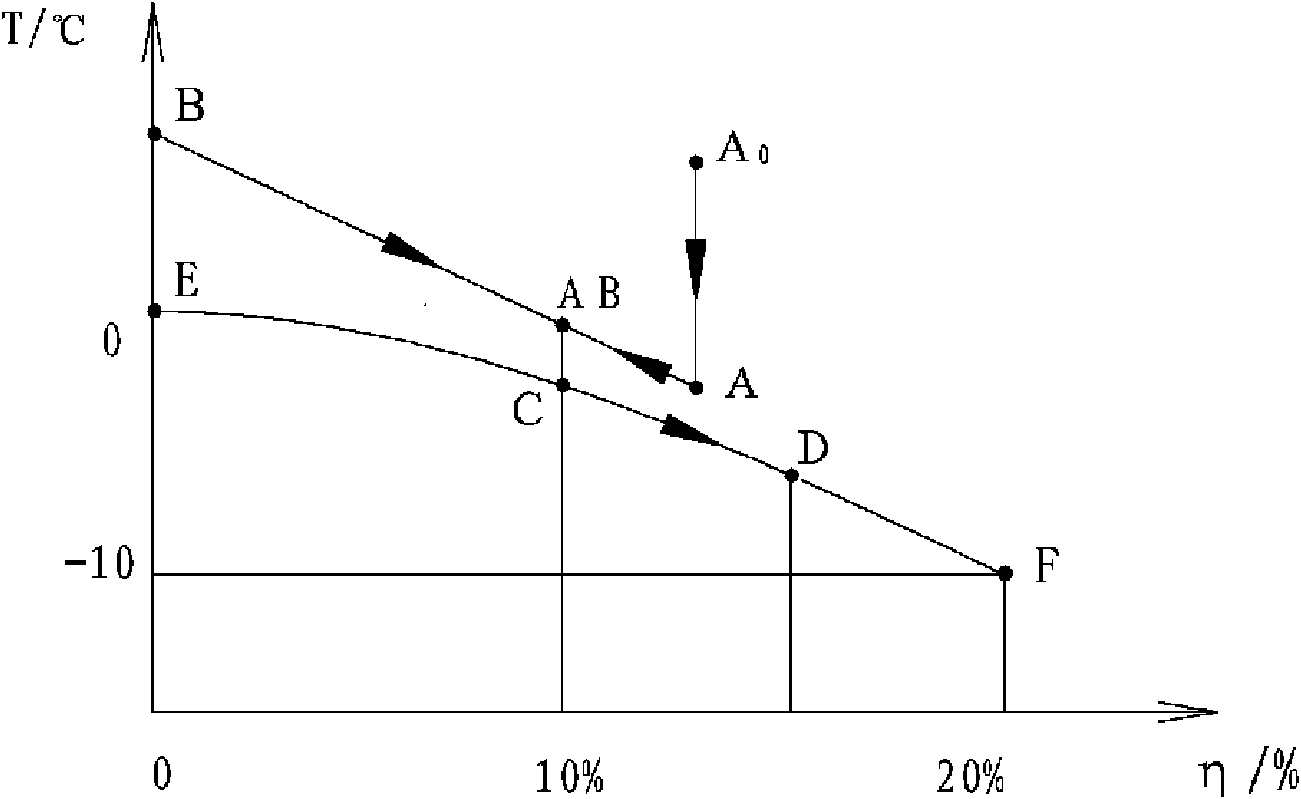

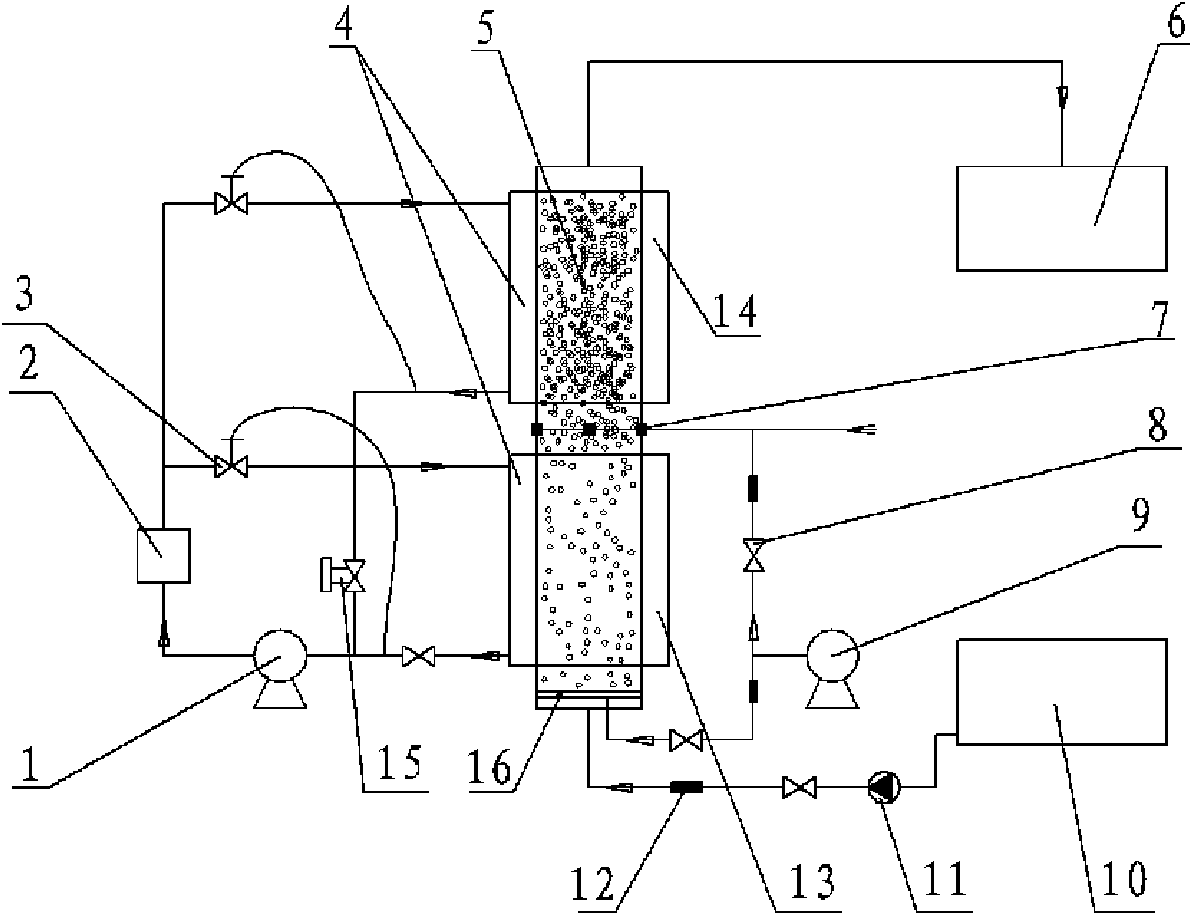

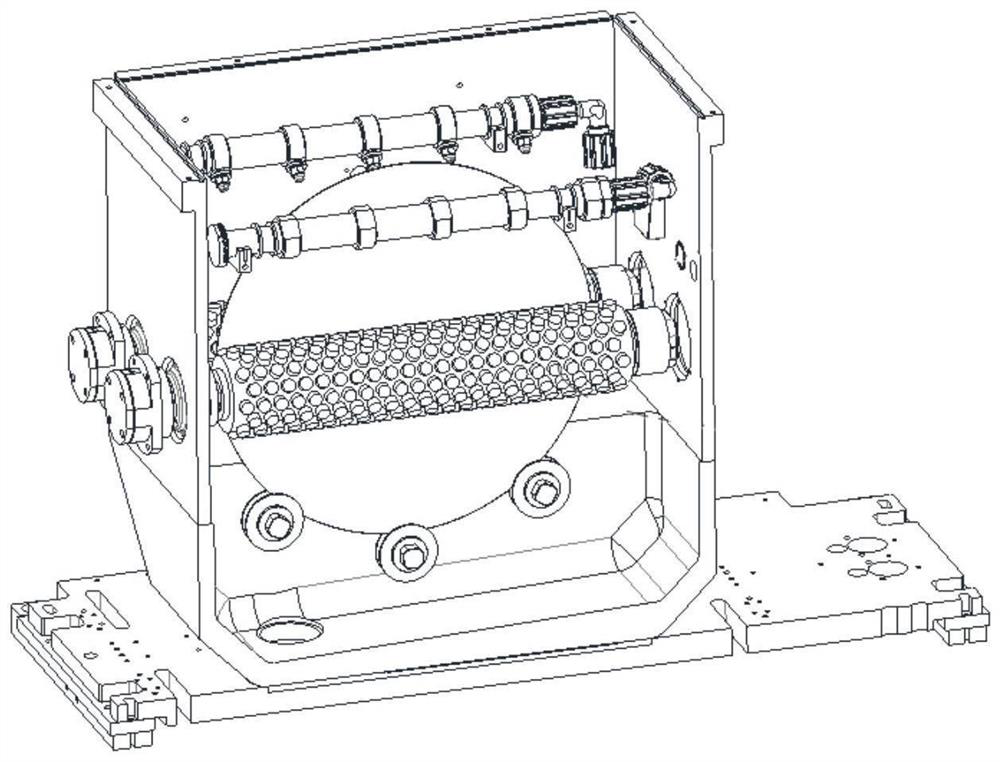

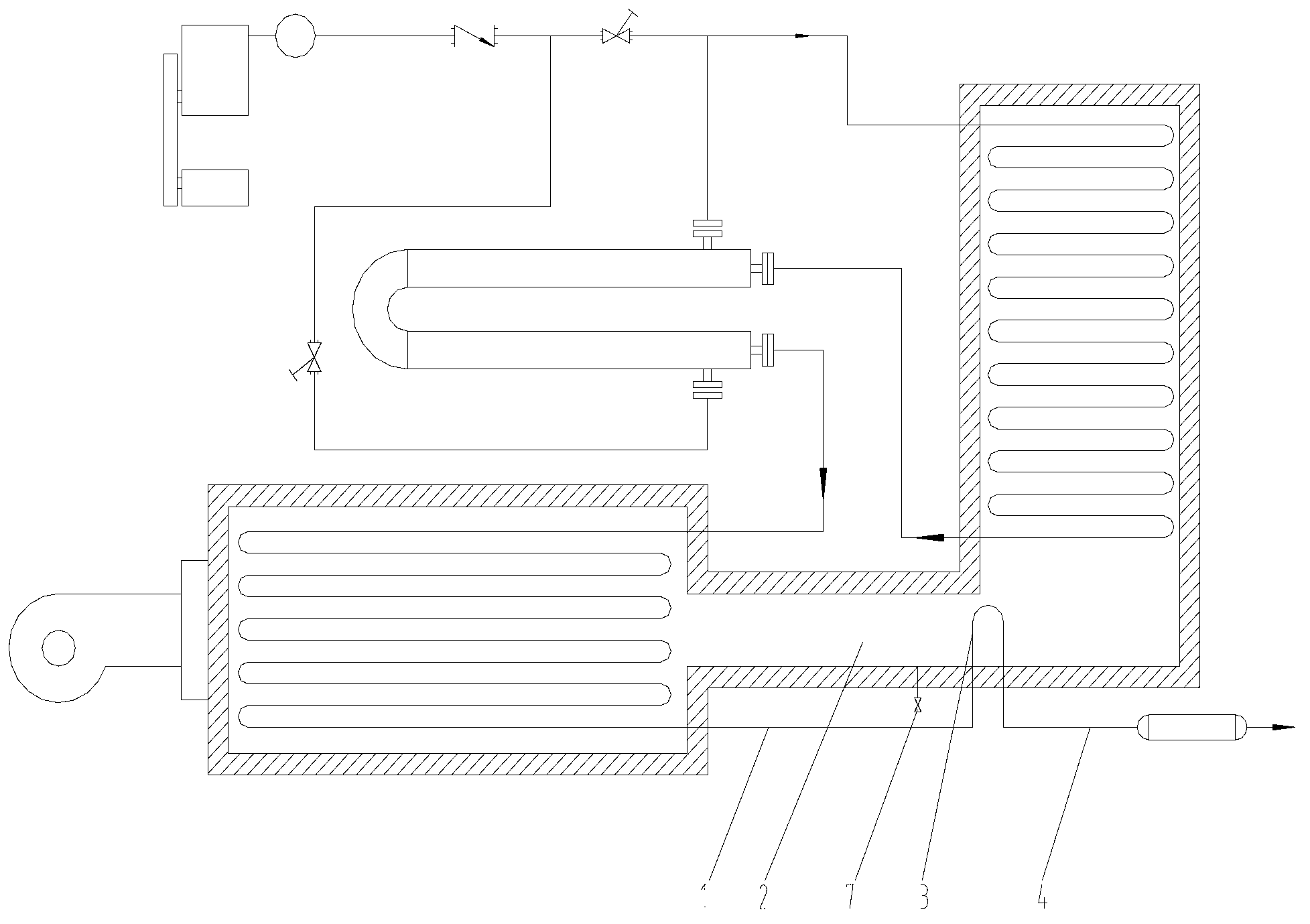

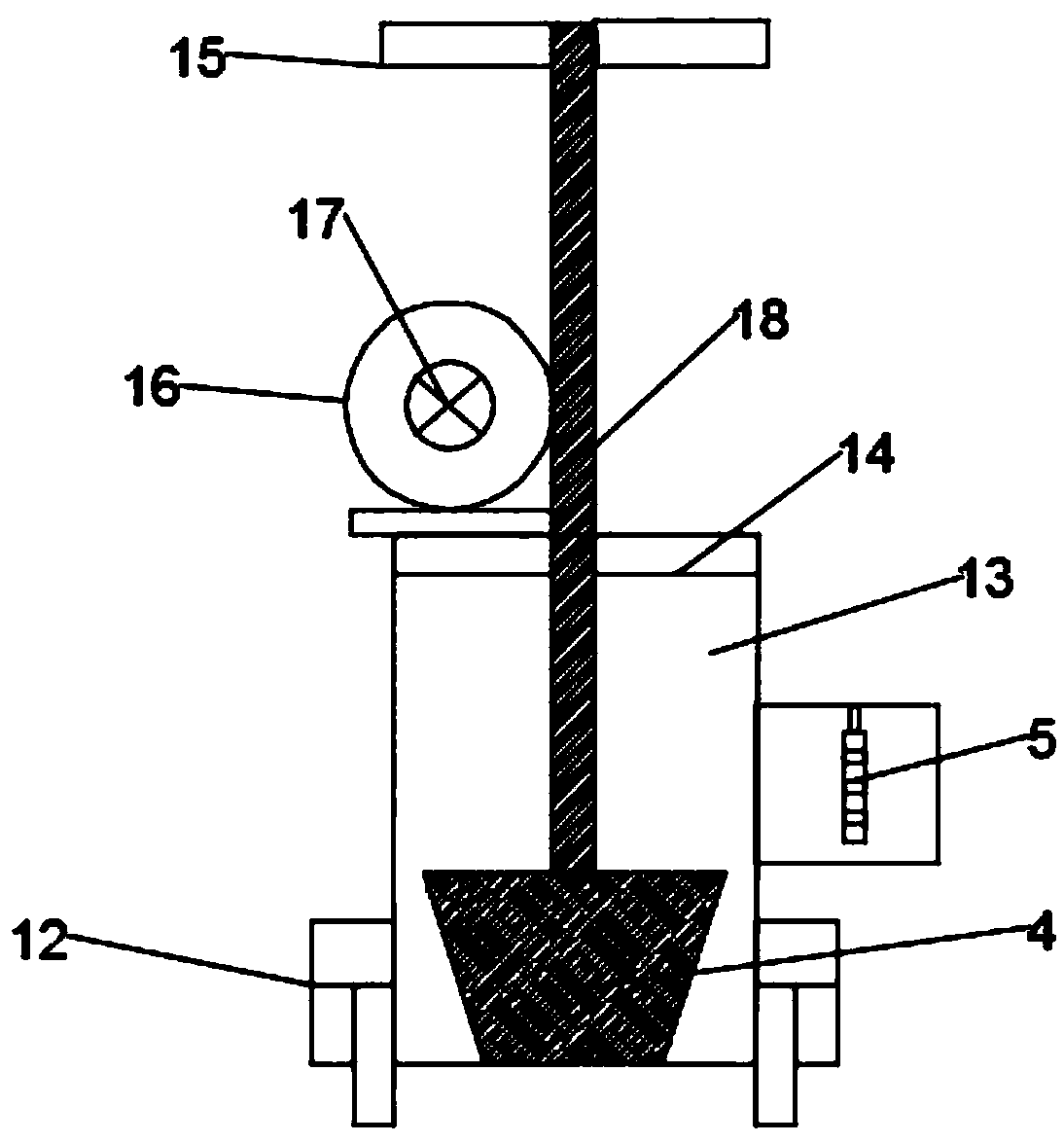

Fluid ice preparation method, preparation equipment and fluidization crystallizer

InactiveCN101660853AReduce concentrationIncrease profitIce productionCompression machines with several evaporatorsDiluentCooling capacity

The invention relates to a fluid ice preparation method, a preparation equipment and a fluidization crystallizer; the preparation method is as follows: firstly, carrying out a first-stage cooling on ice making solution, cooling below 0 DEG C and above minus 15 DEG C; and then injecting diluent into ice making solution to obtain ice making solution with reduced concentration; and finally carrying out a second-stage cooling on reduced ice making solution and continuously cooling to produce fluid ice. A fluid ice crystallization passage of the fluidization crystallizer of the preparation equipment of fluid ice is divided into a first refrigeration section and a second refrigeration section in the flow direction; a first stage evaporator and a second evaporate are respectively and correspondingly arranged at outer sides of the two refrigeration sections; one end of the fluid ice crystallization passage close to the first refrigeration section is provided with an ice making solution inlet and the other end is provided with a fluid ice outlet; a diluent inlet is arranged between the two refrigeration sections. The invention carries out two-stage cooling on ice making solution and reducesthe concentration of ice making solution in the ice making process, thus increasing the utilization rate of cooling capacity and refrigeration efficiency of a refrigeration system.

Owner:HENAN UNIV OF SCI & TECH

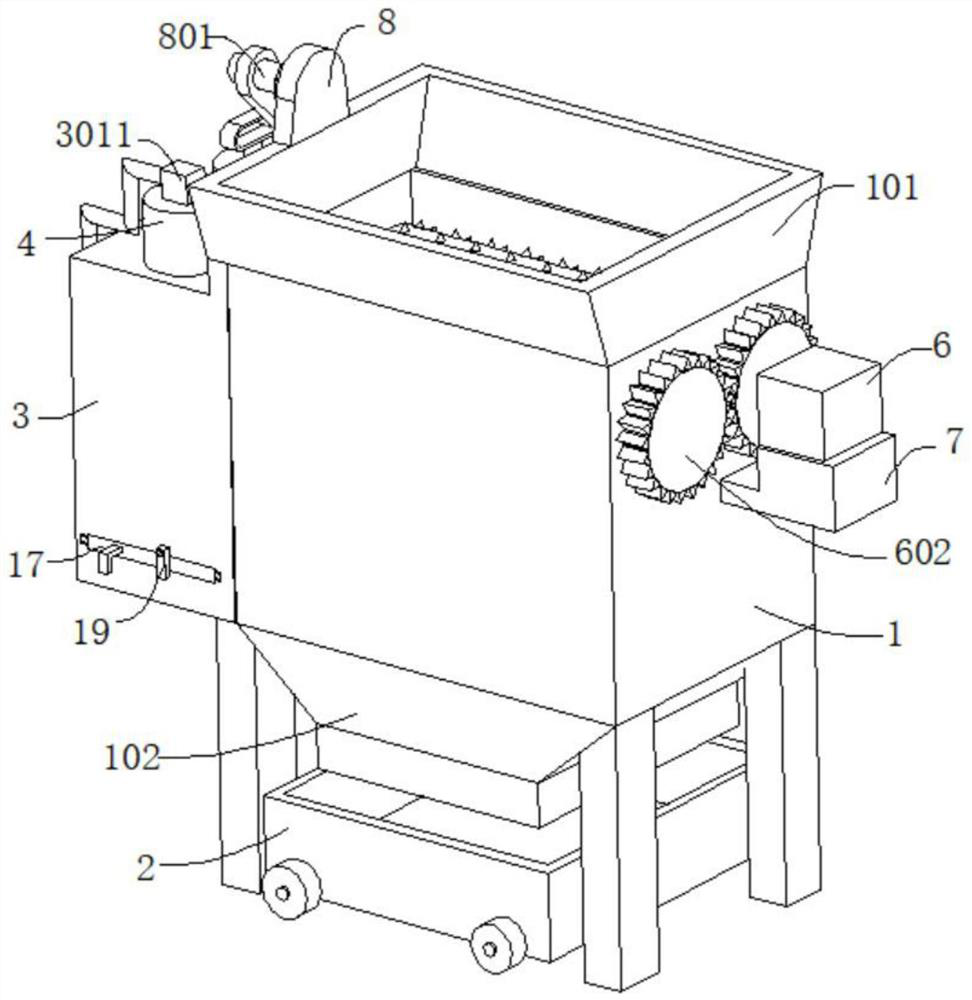

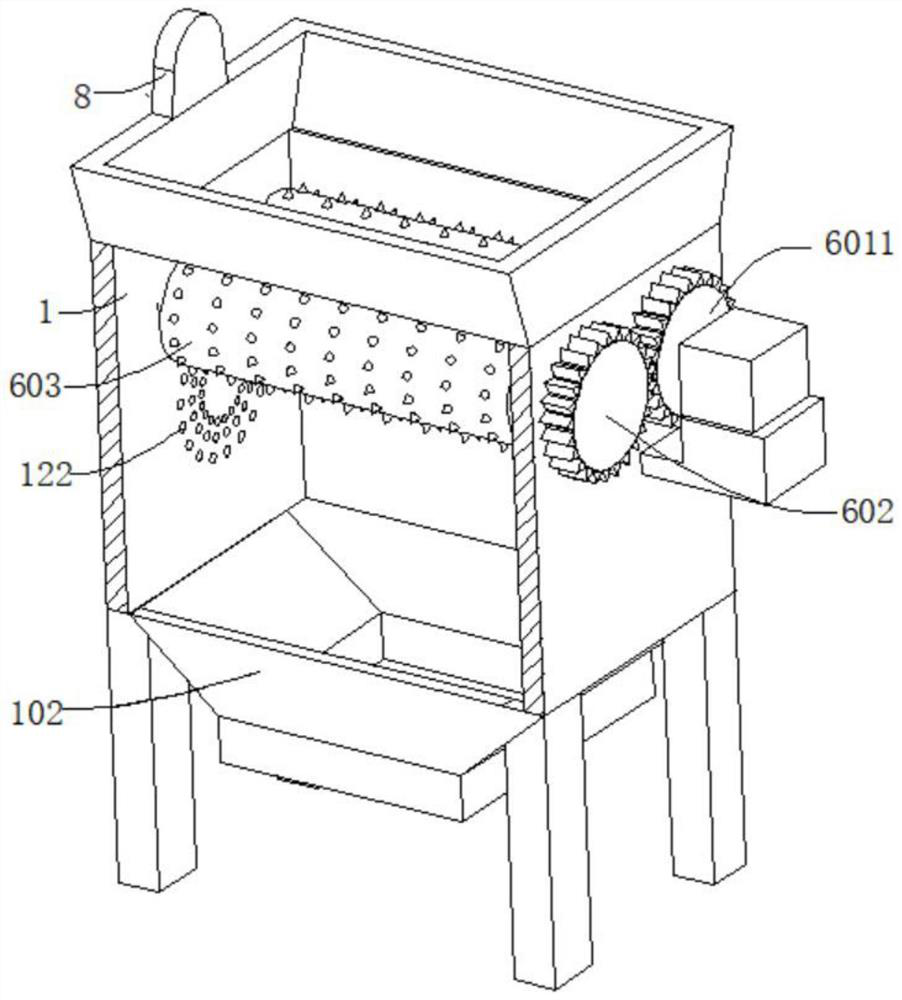

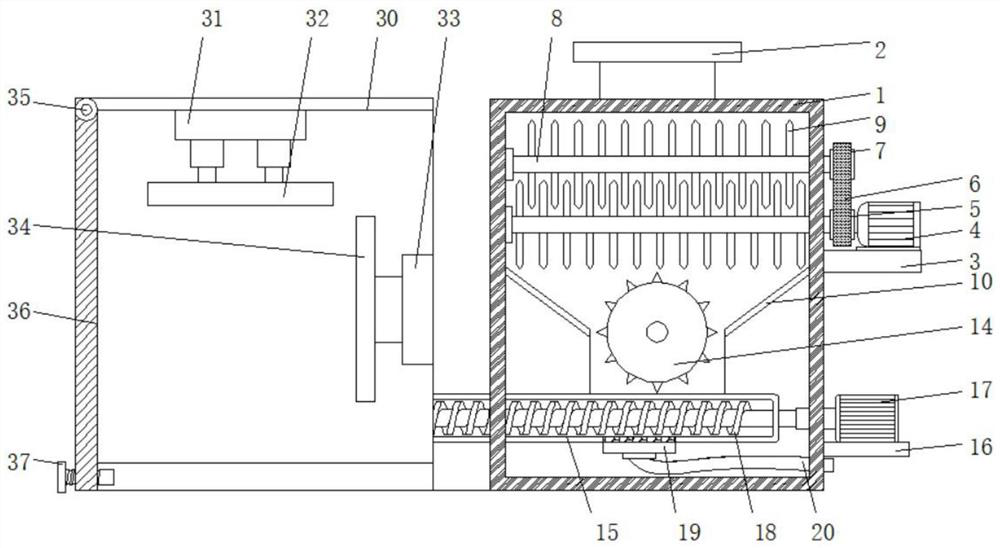

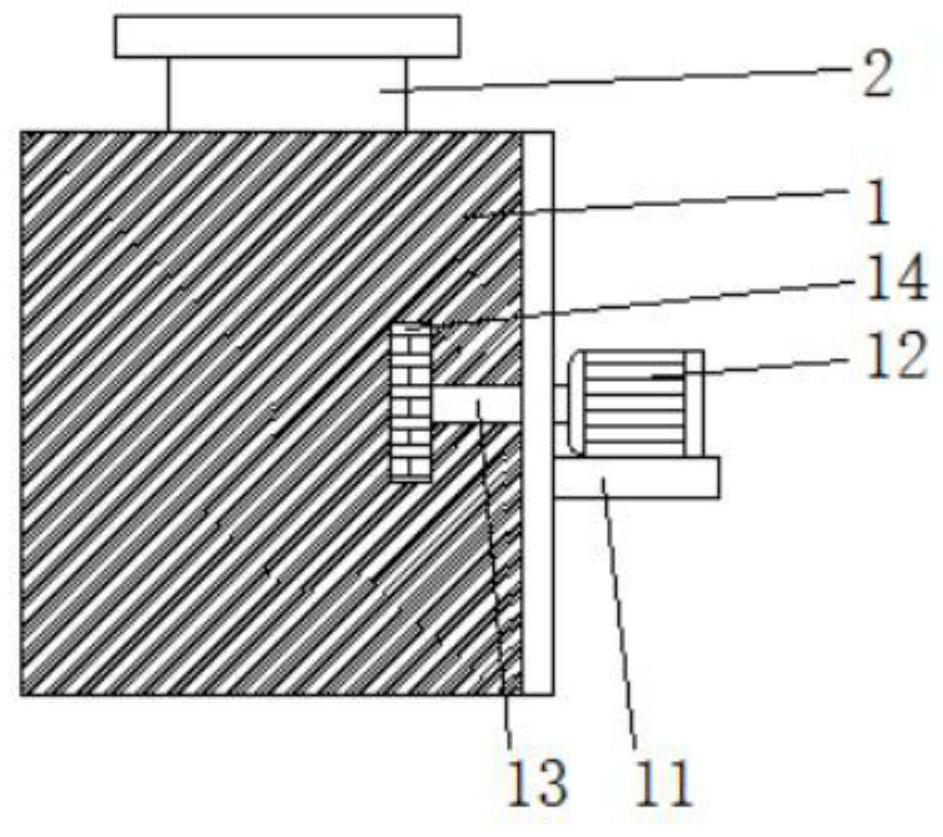

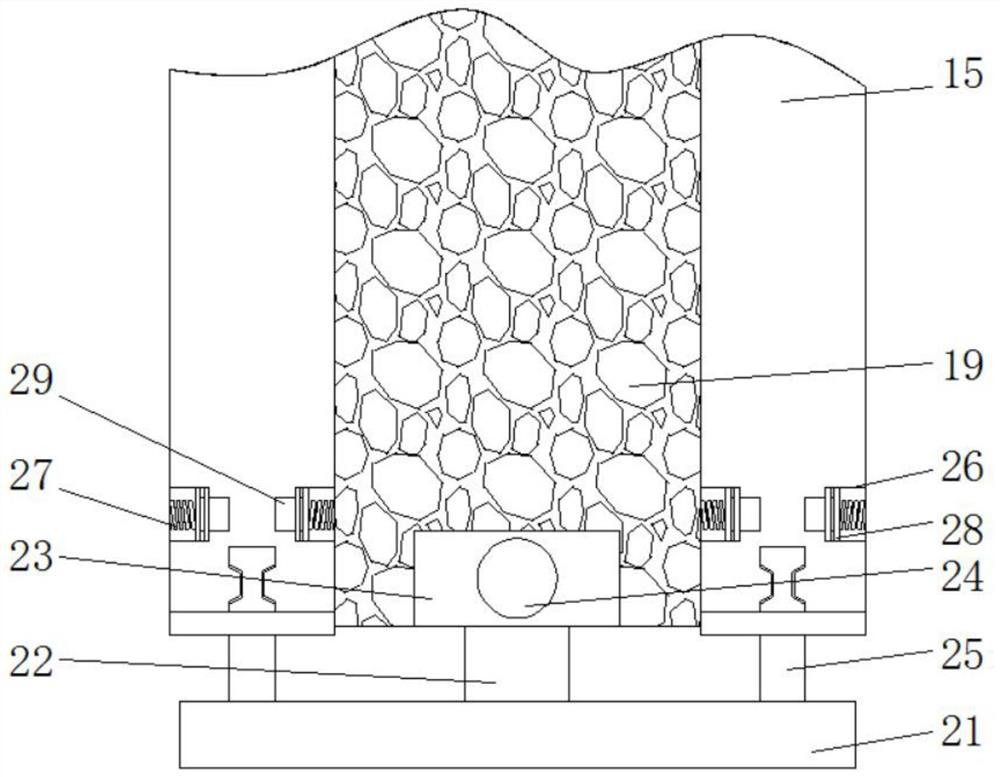

Construction waste crushing device for constructional engineering and using method thereof

ActiveCN111686866AReduce crushing costsEasy to reuseUsing liquid separation agentTreatment involving filtrationRefuse collectionWater resources

The invention discloses a construction waste crushing device for constructional engineering and a using method thereof, and belongs to the technical field of the constructional engineering. The construction waste crushing device for the constructional engineering comprises a crushing box and a waste collecting vehicle, wherein the waste collecting vehicle is arranged at the bottom of the crushingbox, a feeding opening and a discharging opening are formed at the upper side and the lower side of the crushing box, a crushing mechanism is connected to the interior of the crushing box, a dust falling box is connected to the outer wall of the crushing box, a water supplementing box and a water sprinkling box are connected to the interior of the dust falling box, a first pipeline and a second pipeline are connected between the water supplementing box and the water sprinkling box, a water conveying pipe is connected to the bottom of the dust falling box, the end, away from the dust falling box, of the water conveying pipe is connected to the top of the water supplementing box, a water pump is connected to the outer wall of the water conveying pipe, and the water pump is connected to the outer wall of the water supplementing box. According to the construction waste crushing device, water resources for dust fall are reused favorably, the water resources are saved favorably, and the crushing cost of construction waste is reduced.

Owner:徽仁(宁夏)环保科技有限公司

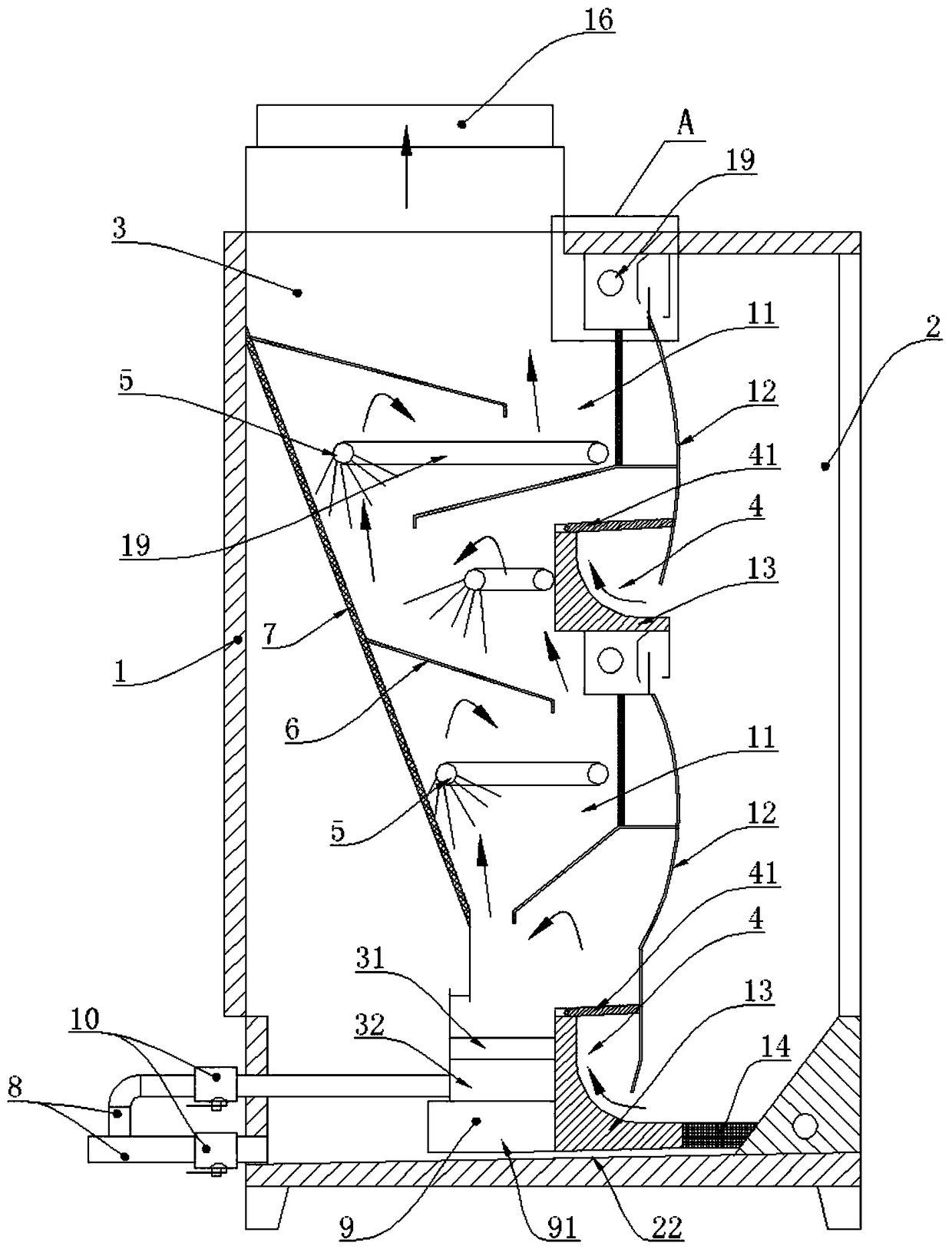

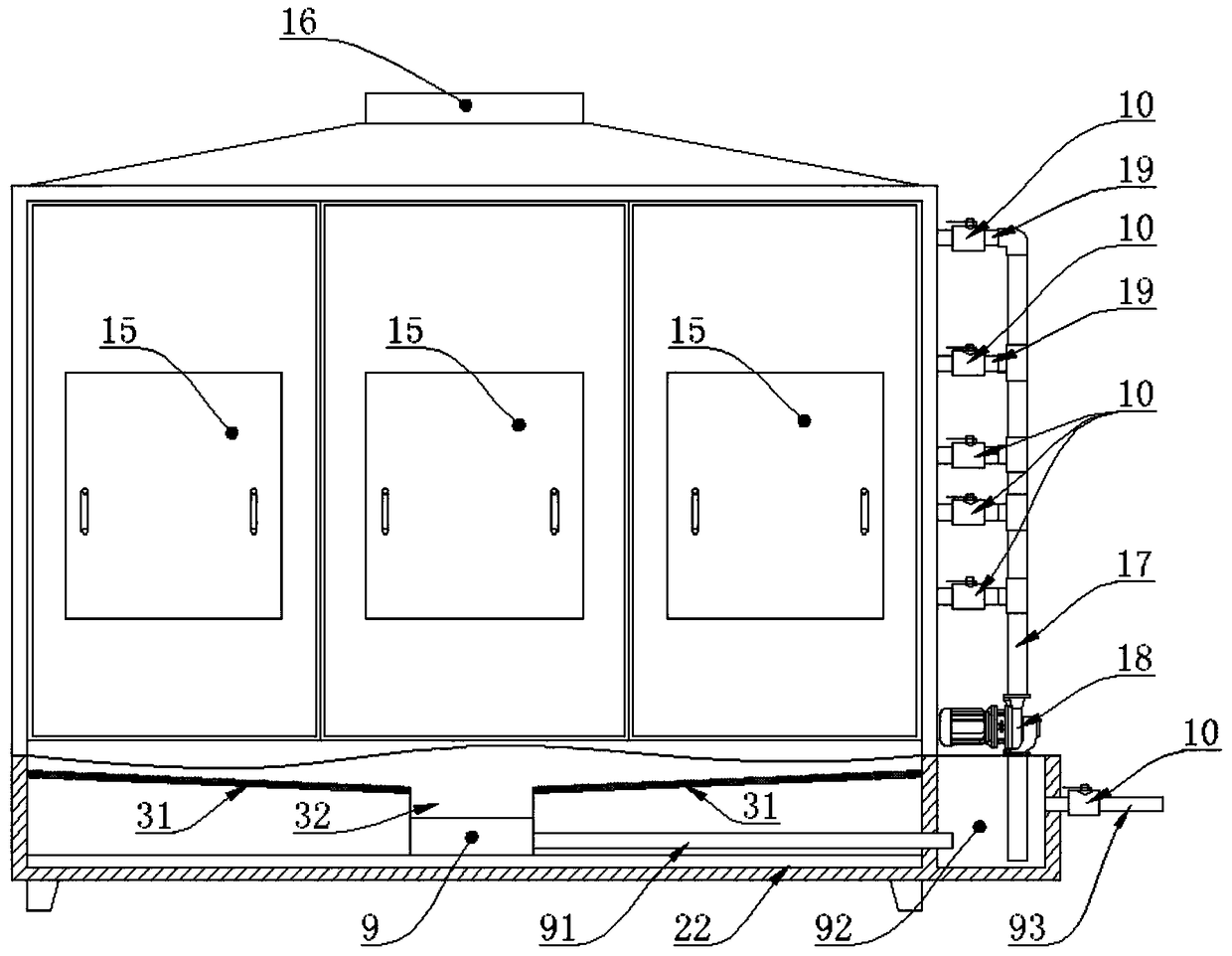

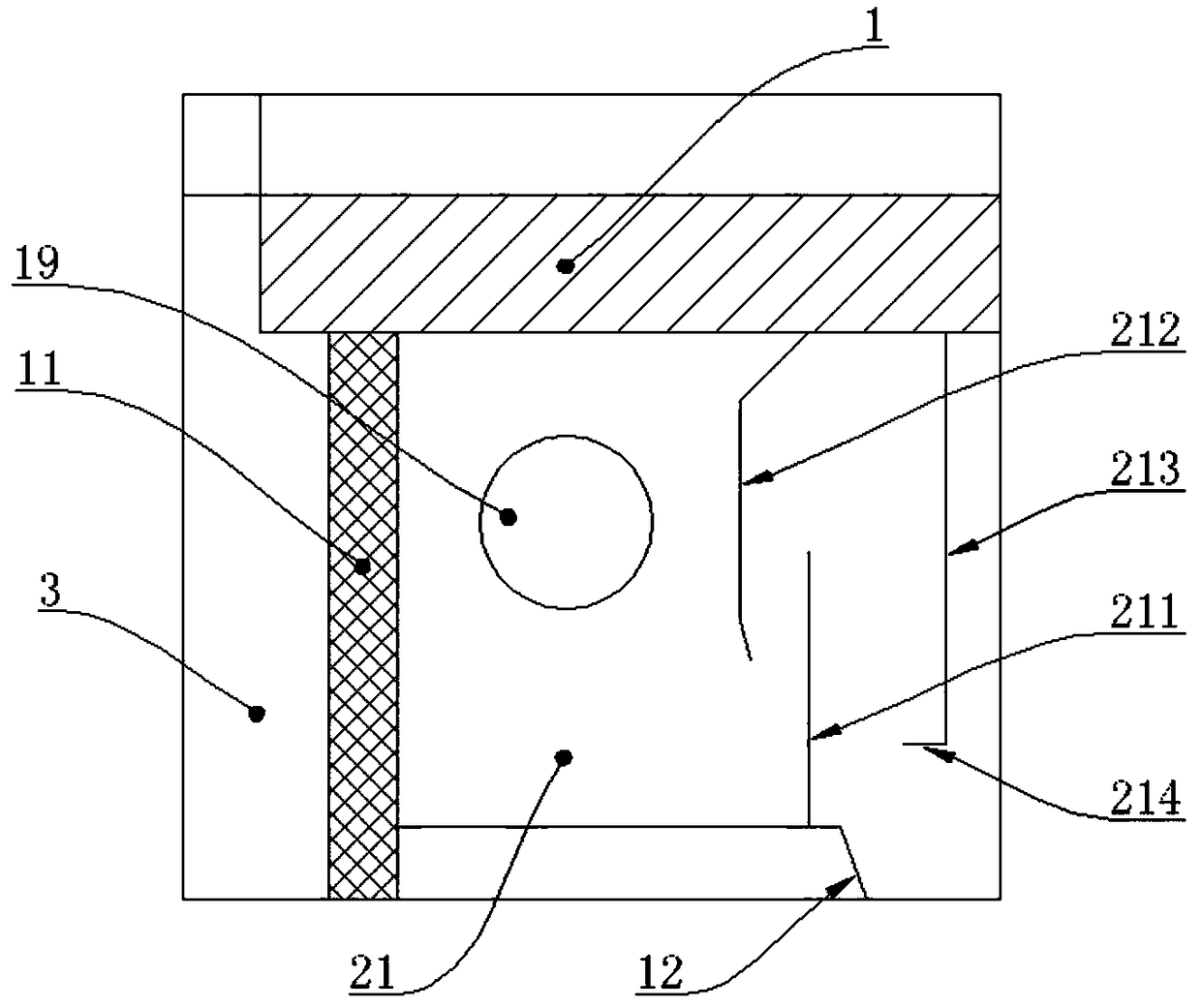

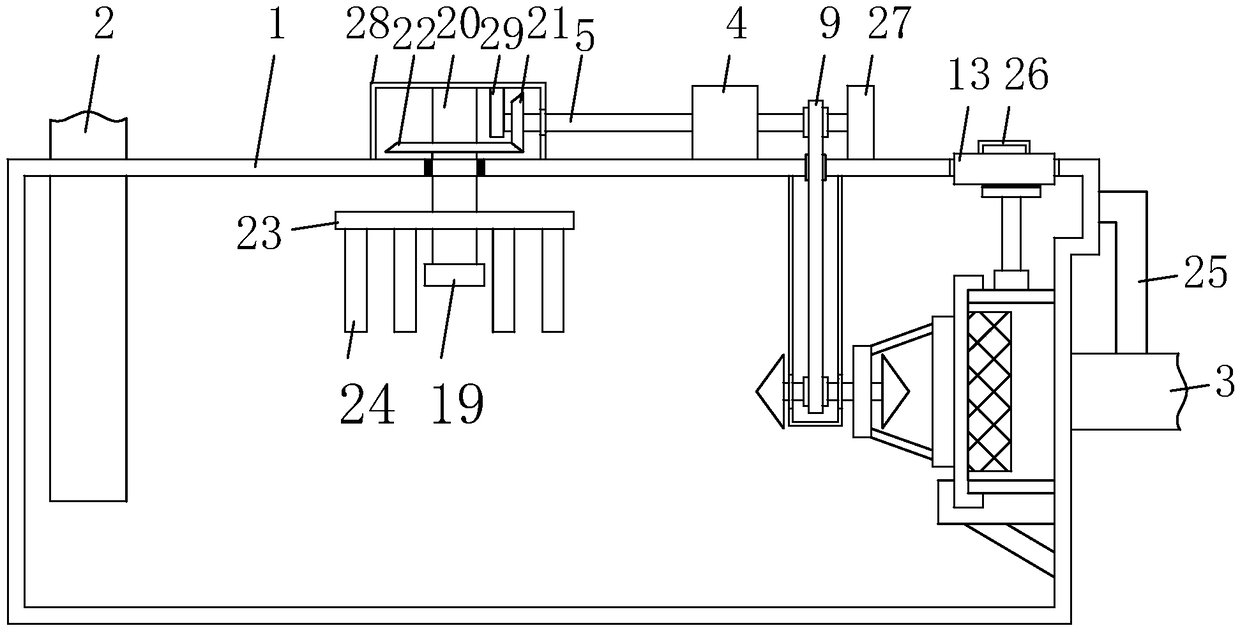

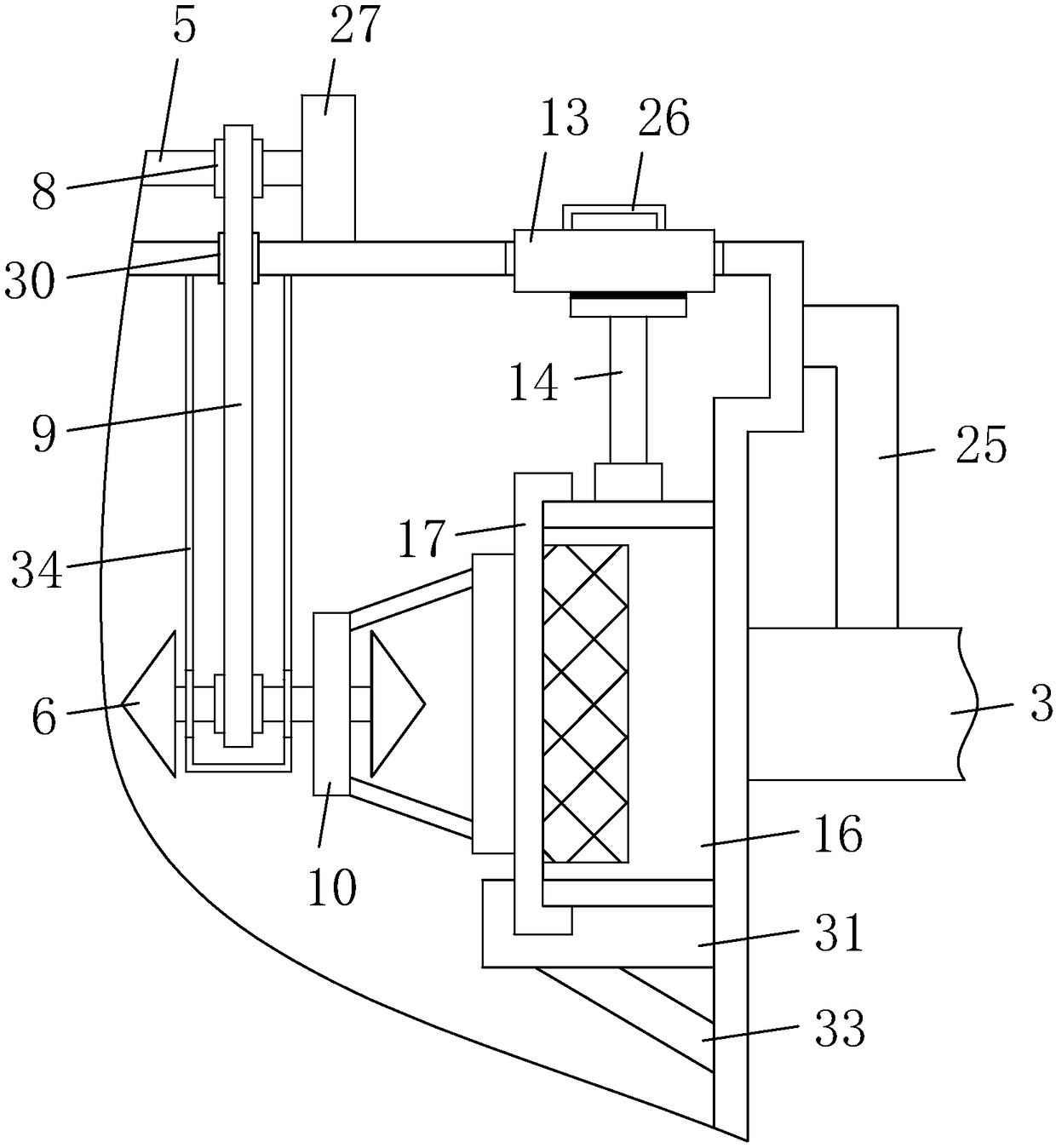

Multistage water spinning paint spraying cabinet

PendingCN109433501AOutstanding and Beneficial Technical EffectsEasy to useSpray boothsDevice formReaction chamber

The invention belongs to the technical field of waste gas treatment equipment, and particularly relates to a multistage water spinning paint spraying cabinet. The multistage water spinning paint spraying cabinet comprises a paint spraying chamber and a reaction chamber. The paint spraying chamber communicates with the reaction chamber through vent holes. A fan is arranged on the reaction chamber.A water outlet trough is arranged above an air inlet chamber. Liquid in the water outlet trough flows out, and a water curtain is formed. The vent holes are formed below the water curtain. The at least two sets of independent vent holes are formed in a cabinet body, the water outlet trough corresponding to the vent holes is arranged in the cabinet body, and a sealing plate used for sealing the vent holes is arranged in the cabinet body. Spraying devices and baffles are arranged in the reaction chamber, the baffles divide the reaction chamber into an S-shaped air flow channel, and liquid sprayed in the spraying devices forms water curtains on the baffles. A filter water trough is arranged at the bottom of the reaction chamber, and the liquid on the baffles is guided into the filter water trough through the baffles. The multistage water spinning paint spraying cabinet is good in cleaning effect, convenient to use and control and capable of being flexibly used conveniently.

Owner:永康市恒久涂装设备有限公司

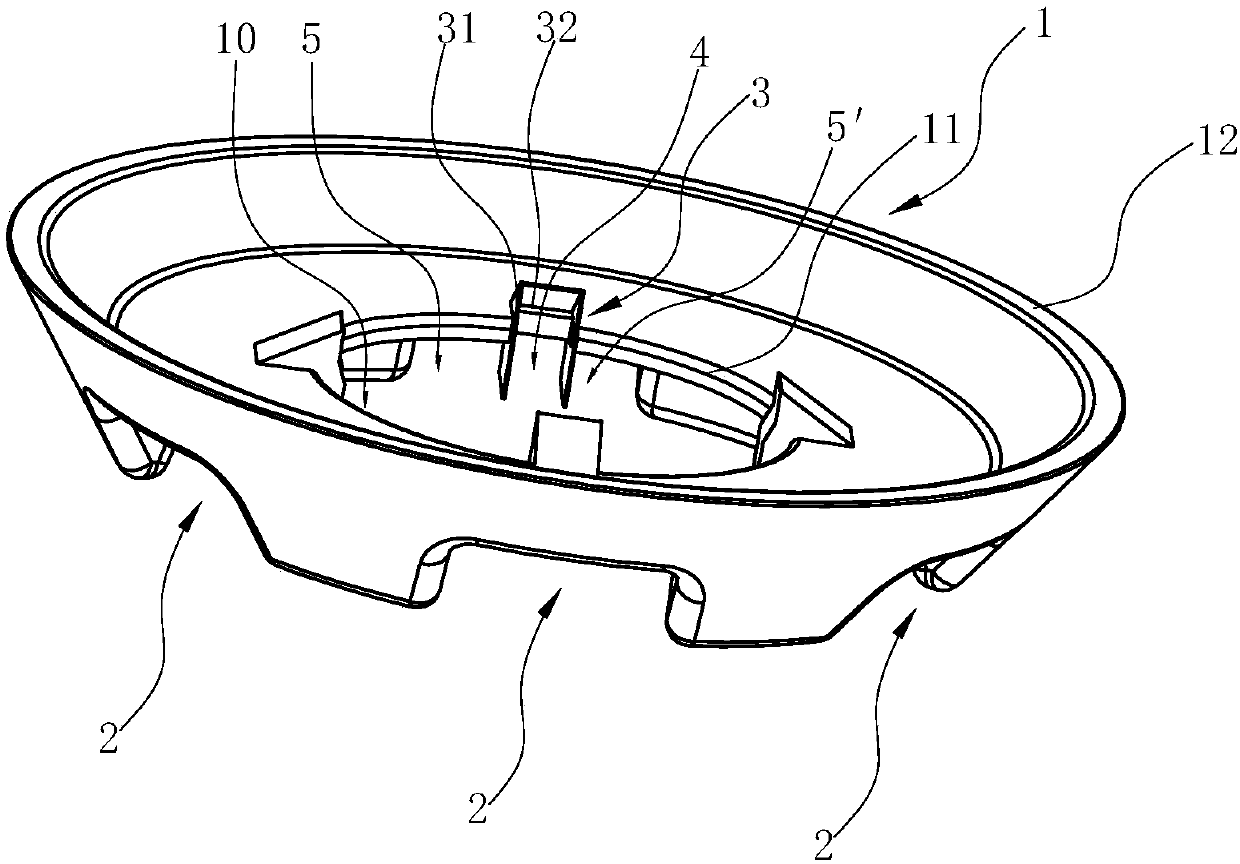

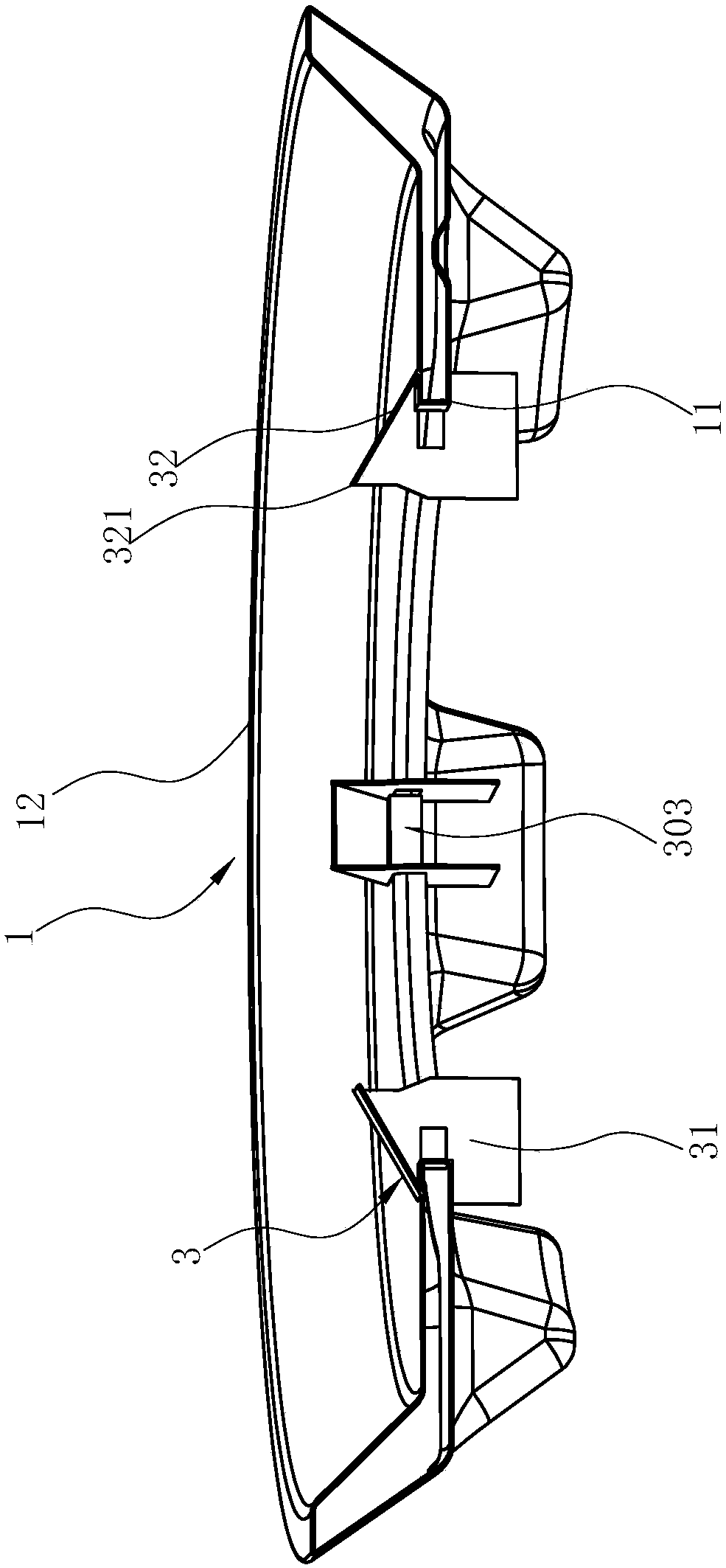

Heat shield for stove and stove using heat shield

PendingCN110425608AAvoid entrainmentEffective Secondary SupplementationDomestic stoves or rangesLighting and heating apparatusCombustorHearth

The invention relates to a heat shield for a stove. The heat shield for the stove comprises an annular shield body and is characterized in that the bottom of the shield body is concave upwards to format least two secondary air replenishing grooves through inside and outside; the bottom of each secondary air replenishing groove is provided with a distributing piece; and each distributing piece comprises two side plates which are vertically arranged at an interval, wherein a first gap is formed between the two side plates, a second gap and a third gap are formed between each of the two side plates and the corresponding secondary air replenishing groove, and a first air replenishing channel, a second air replenishing channel and a third air replenishing channel which are mutually independentare formed. The invention also provides the stove using the heat shield. Compared with the prior art, the heat shield for the stove and the stove using the heat shield have the advantages that the two side plates of each distributing piece can form relatively independent spaces, air forms the three corresponding independent air replenishing channels under the separation effect of the two side plates of each distributing piece, entrainment of hot air flow after combustion and high temperature of a combustor on secondary air in every two side plates is effectively avoided, and the characteristic of higher combustion efficiency is achieved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

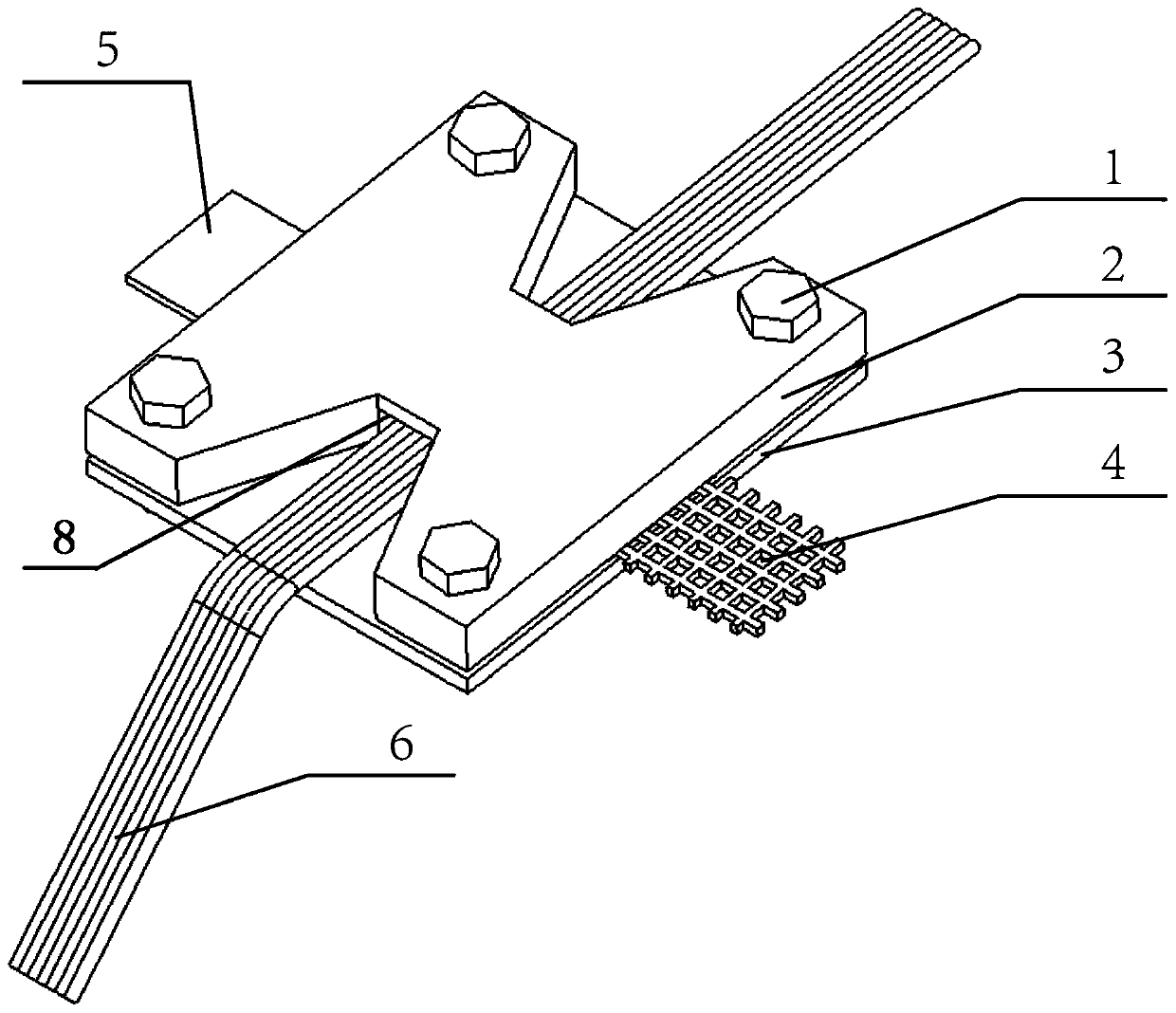

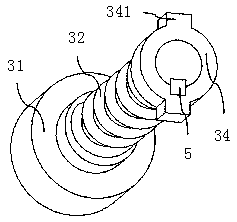

Single-channel line-based hydrogen peroxide membrane-free passive microfluid fuel cell

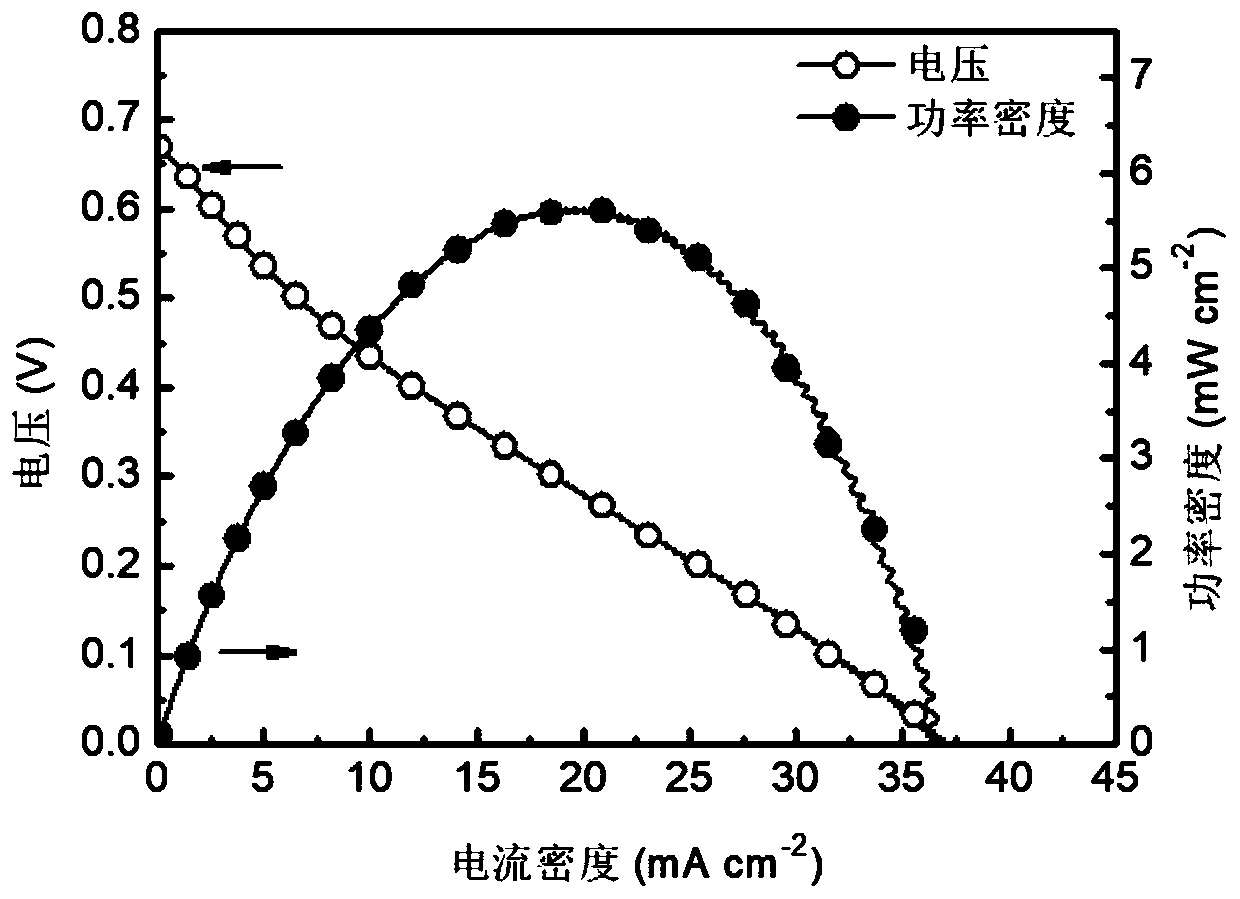

ActiveCN110993983ASimple structureReduce energy consumptionCollectors/separatorsElectrolytic agentFuel cells

The invention discloses a single-channel line-based hydrogen peroxide membrane-free passive microfluid fuel cell which comprises a cover plate, an anode electrode, a cathode electrode, a cotton threadrunner and a support plate. The microfluid fuel cell is characterized in that the anode electrode and the cathode electrode are arranged on the supporting plate in a bilateral symmetry mode, a gap isreserved between the anode electrode and the cathode electrode, and the cotton thread runner is placed on the anode electrode and the cathode electrode; the left part and the right part of the cottonthread runner are respectively overlapped with the cathode electrode and the anode electrode, and a certain height difference is set between an inlet and an outlet of the cotton thread runner; the cotton thread runner is a flow channel for fuel and electrolyte, the fuel and the electrolyte are conveyed to the surfaces of the anode electrode and the cathode electrode by the cotton thread runner, the fuel is hydrogen peroxide, and the cotton thread flow channel is made of a plurality of hydrophilic cotton threads; the single-strand cotton thread is adopted as a runner, passive transportation offuel and an oxidizing agent is achieved through capillary force or the capillary force coupling gravity effect, and the device can be widely applied to the fields of chemical engineering, energy, environmental protection and the like.

Owner:CHONGQING UNIV

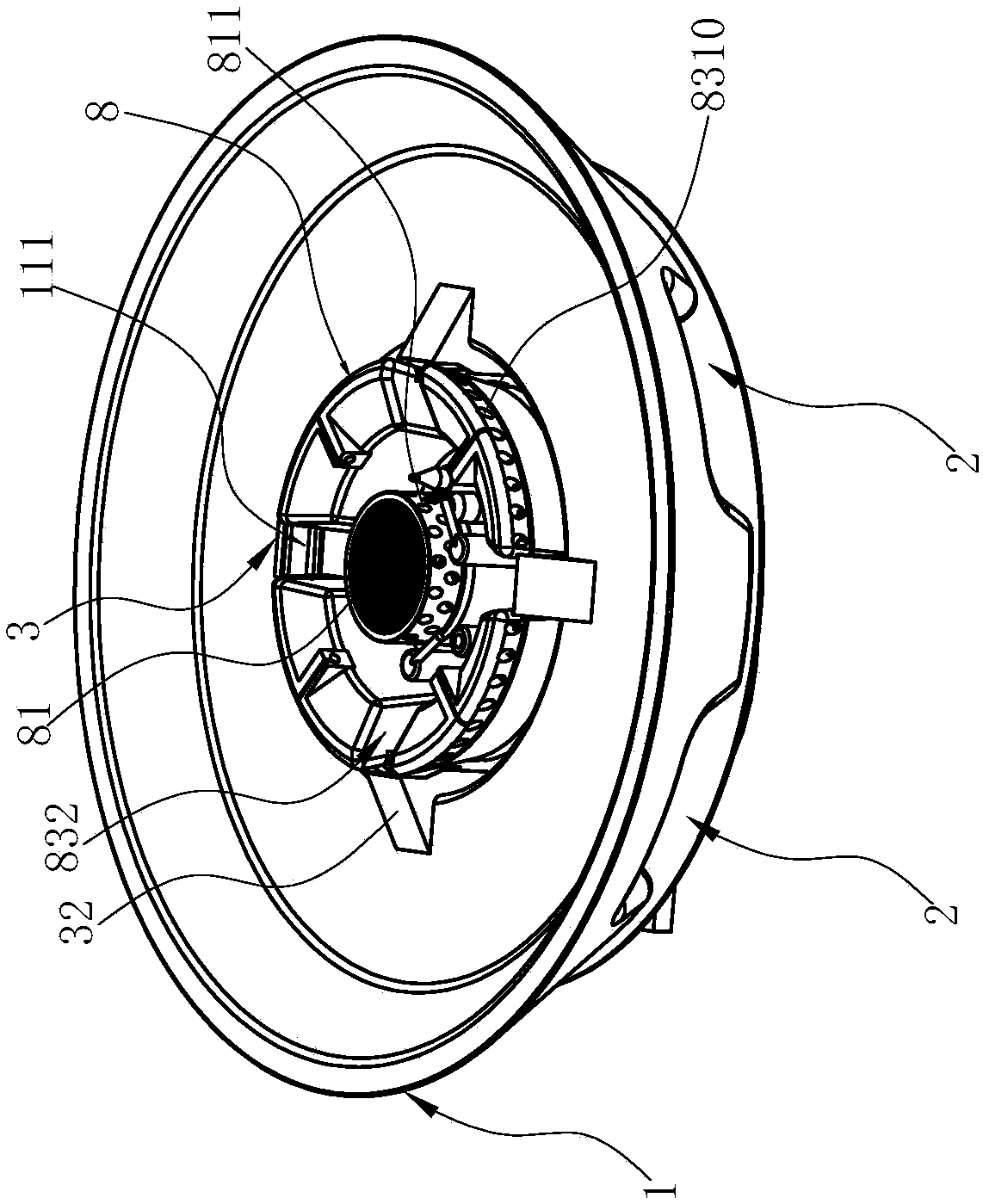

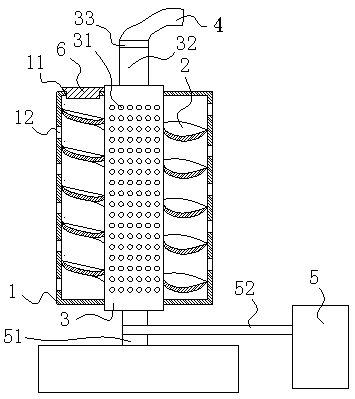

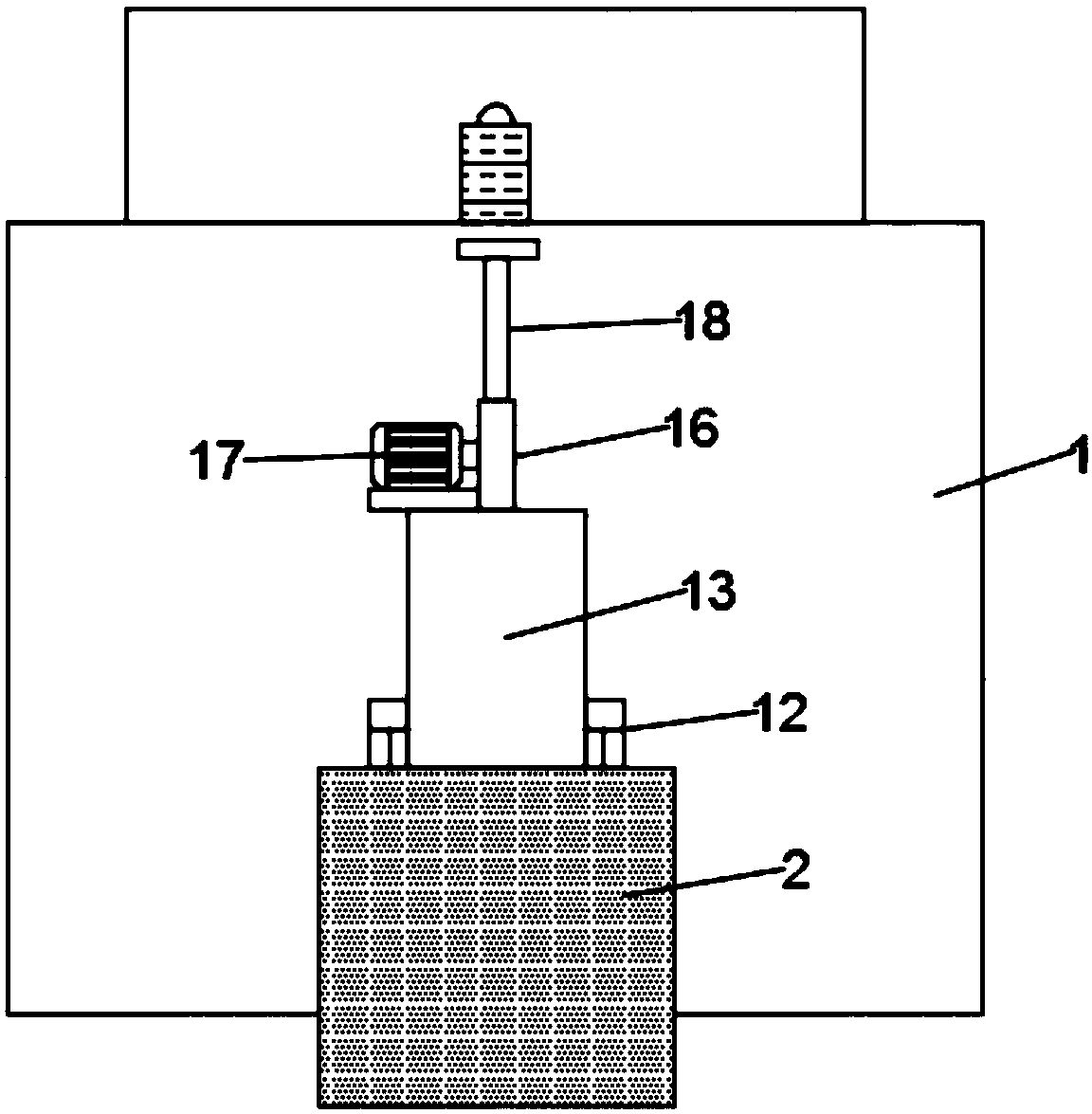

Fruit seed drying equipment

PendingCN107860189AEvenly heatedAvoid scorchingDrying gas arrangementsDrying chambers/containersBall bearingAgricultural engineering

The invention provides fruit seed drying equipment, which has the advantages that fruit seeds can be prevented from being scorched in a drying process, and the drying efficiency is improved. The fruitseed drying equipment comprises a roller, wherein the roller is vertically arranged, a feed opening is formed in the top of the roller, a plurality of air outlets are formed in the side wall of the roller, a propeller which is vertically arranged is fixedly arranged in the roller, a hollow inner barrel is arranged on the axle wire of the propeller, a plurality of air inlets are formed in the sidewall of the hollow inner barrel, an air inlet channel is connected to the upper part of the hollow inner barrel, the air inlet channel is connected with an air inlet pipe by virtue of a ball bearing,a rotating shaft is connected to the lower part of the hollow inner barrel, and the rotating shaft is connected with a motor by virtue of a conveying belt.

Owner:广东嘉能可食品有限公司

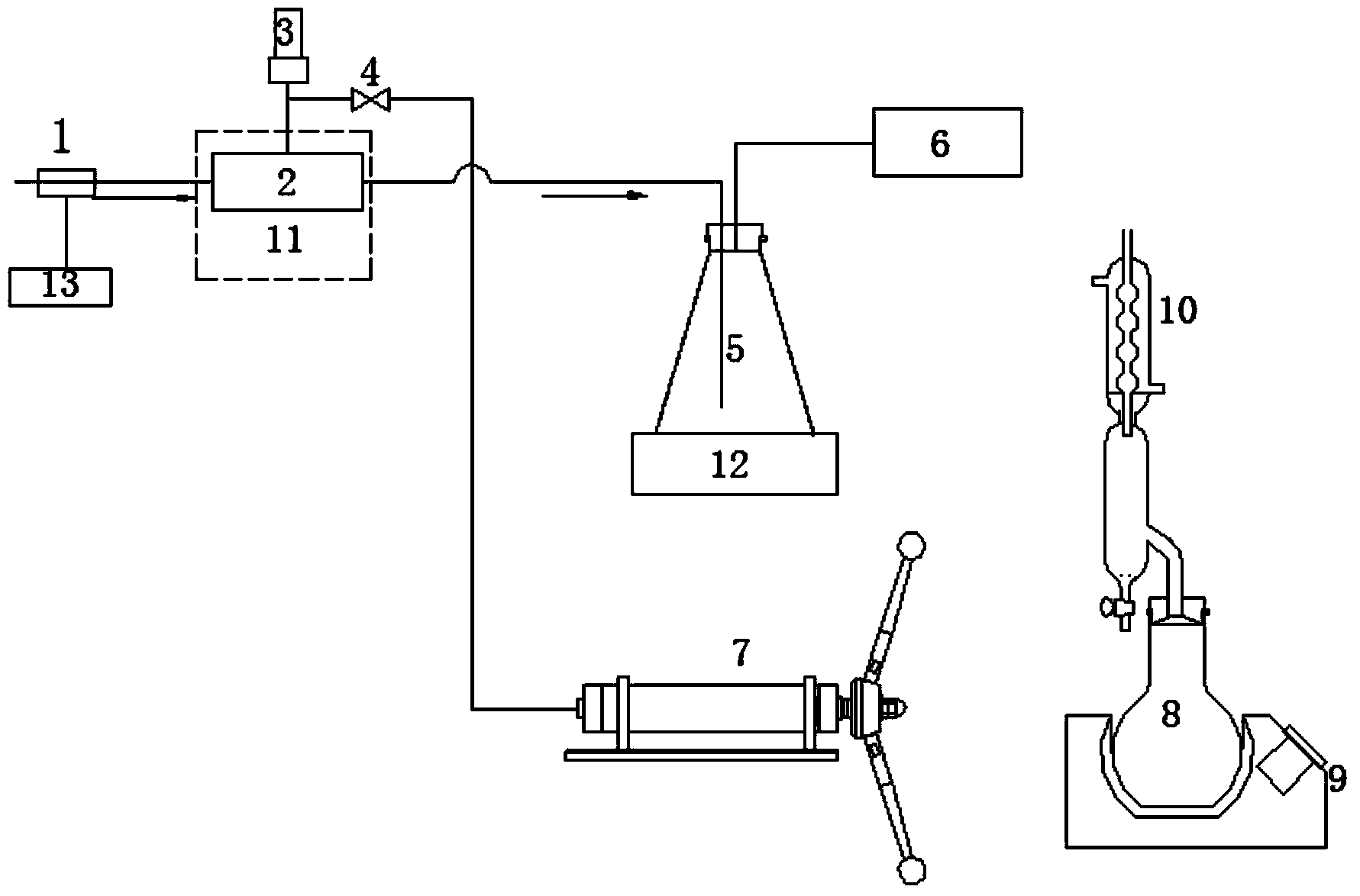

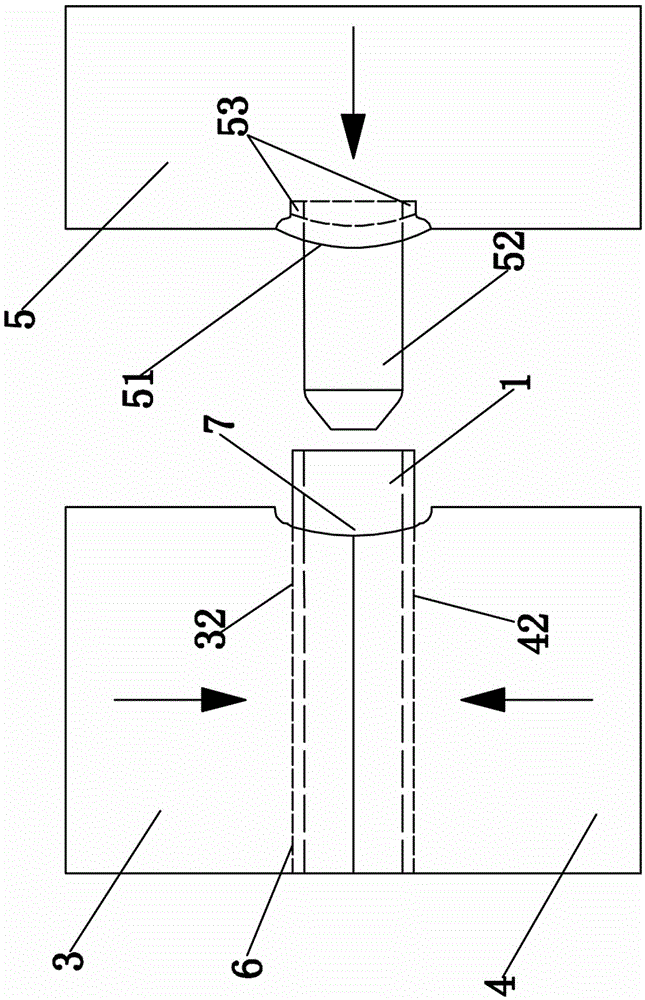

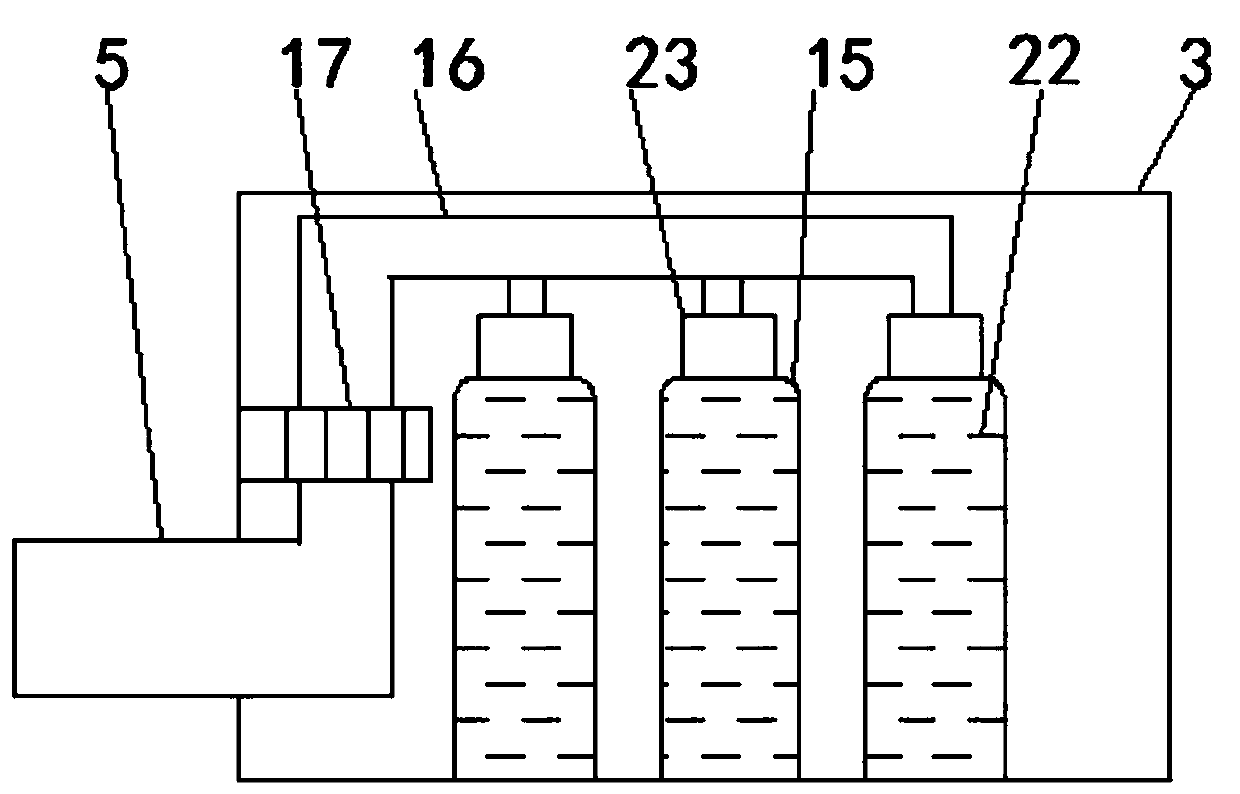

Separating, acquiring and metering method and apparatus for fluid produced in thermal recovery physical simulation experiment on heavy oil

The invention discloses a separating, acquiring and metering method for a fluid produced in a thermal recovery physical simulation experiment on heavy oil. The method comprises the following steps: (1) cooling a high temperature fluid in a high temperature fluid pipeline; (2) connecting the outlet end of the high temperature fluid pipeline passing through a cooling device to a back-pressure valve and controlling back pressure through a pump; (3) allowing a fluid flowing out from the fluid outlet of the back pressure value to pass through the fluid pipeline to the bottom of a separating bottle, allowing gas in the fluid having entered into the separating bottle to enter into a wet gas flow meter through a separating pipeline which is inserted into the upper part of the separating bottle and metering the volume of produced gas; and (4) weighing the mass of residual oil-water mixed liquor in the separating bottle, adding cyclohexane into the separating bottle to dissolve and extract crude oil, separating water by using a separating funnel, putting mixed liquor of crude oil and cyclohexane into a flask and carrying out distillation by using a distillation apparatus so as to evaporate cyclohexane, wherein crude oil is left. With the method and apparatus provided by the invention, the volumes of gas, liquid and oil-water can be respectively metered.

Owner:CNOOC ENERGY TECH & SERVICES

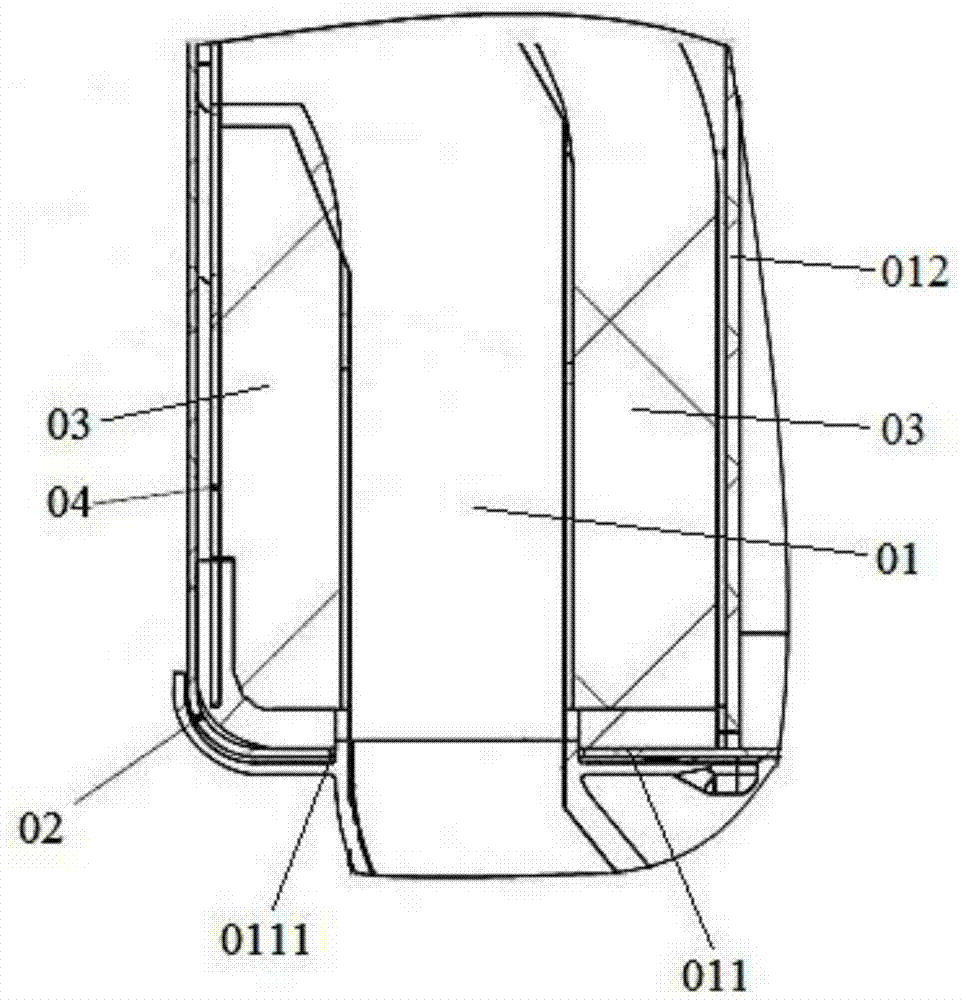

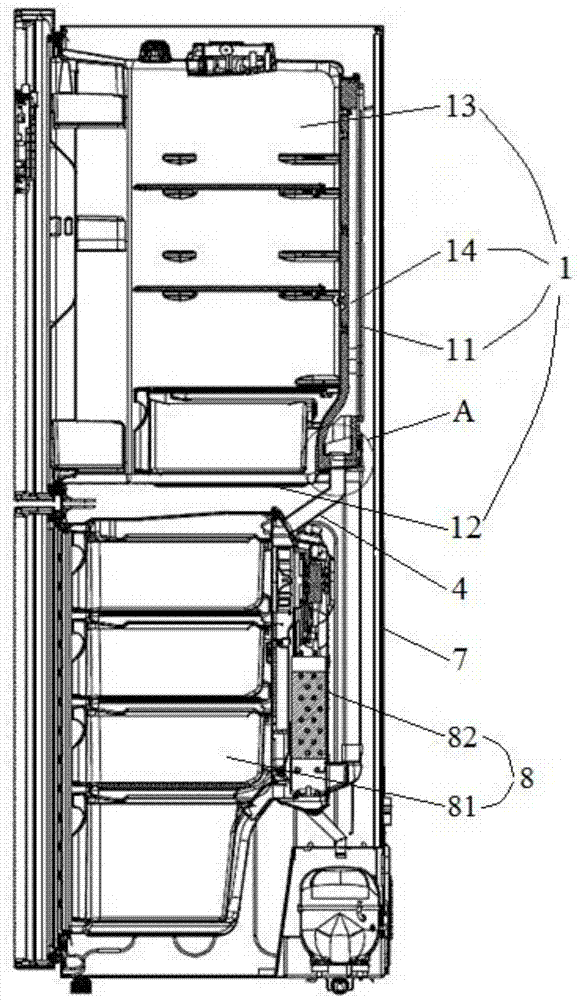

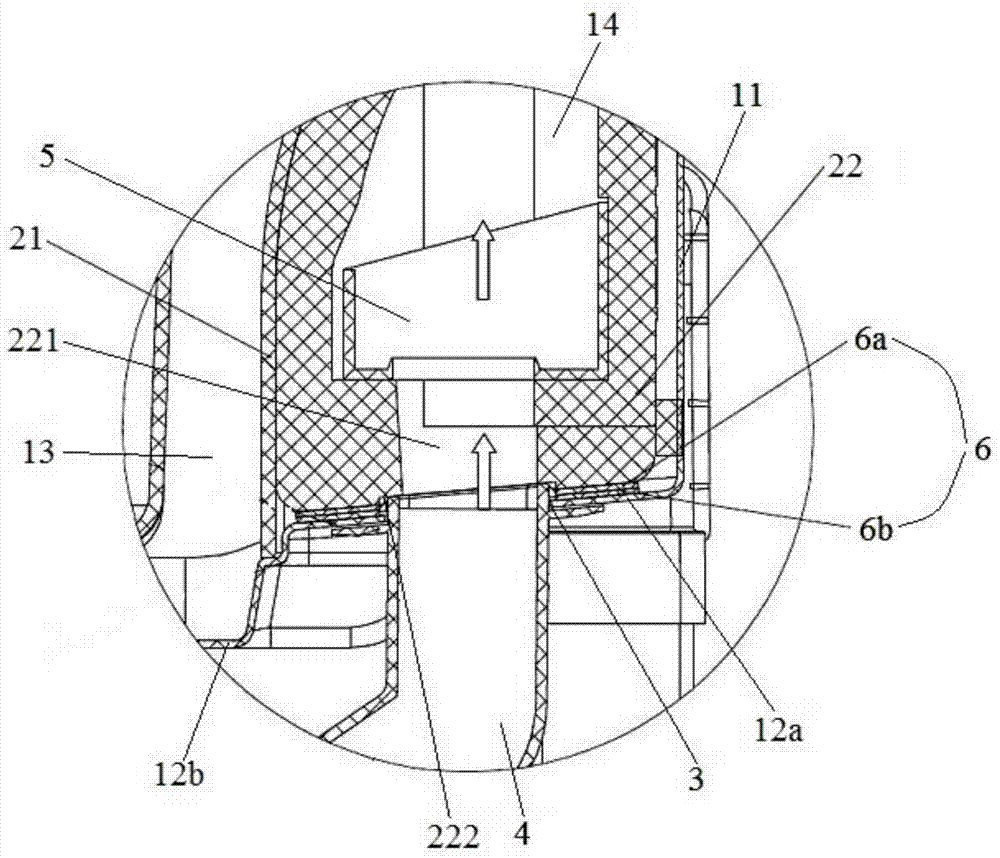

Air cooling refrigerator

ActiveCN104729191AEasy to exportInfluence flowLighting and heating apparatusDomestic refrigeratorsEngineeringCold store

The invention discloses an air cooling refrigerator and relates to the technical field of refrigerators. The air cooling refrigerator aims to solve the problem that in the prior art, because condensate water generated by a refrigeration air duct at a bottom plate cannot be easily led out, after the condensate water is frozen, an air hole is blocked. The air cooling refrigerator comprises a refrigeration box inner container. The refrigeration box inner container comprises an inner container rear wall and an inner container base plate. The refrigeration box inner container is provided with an air duct assembly which is close to the inner container rear wall. The air duct assembly comprises an air duct partition plate dividing a refrigerating box into a refrigerating chamber and a refrigerating air duct area. The part, located in the refrigerating air duct area, of the inner container base plate is an air duct inner container base plate, and the part, located in the refrigerating chamber, of the inner container base plate is a refrigerating chamber inner container base plate. The air duct inner container base plate is provided with an air inlet hole and is inclined. The side, close to the inner container rear wall, of the air duct inner container base plate is higher than the side, close to the refrigerating chamber inner container base plate, of the air duct inner container base plate. The air cooling refrigerator is used for refrigerating and freezing food.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

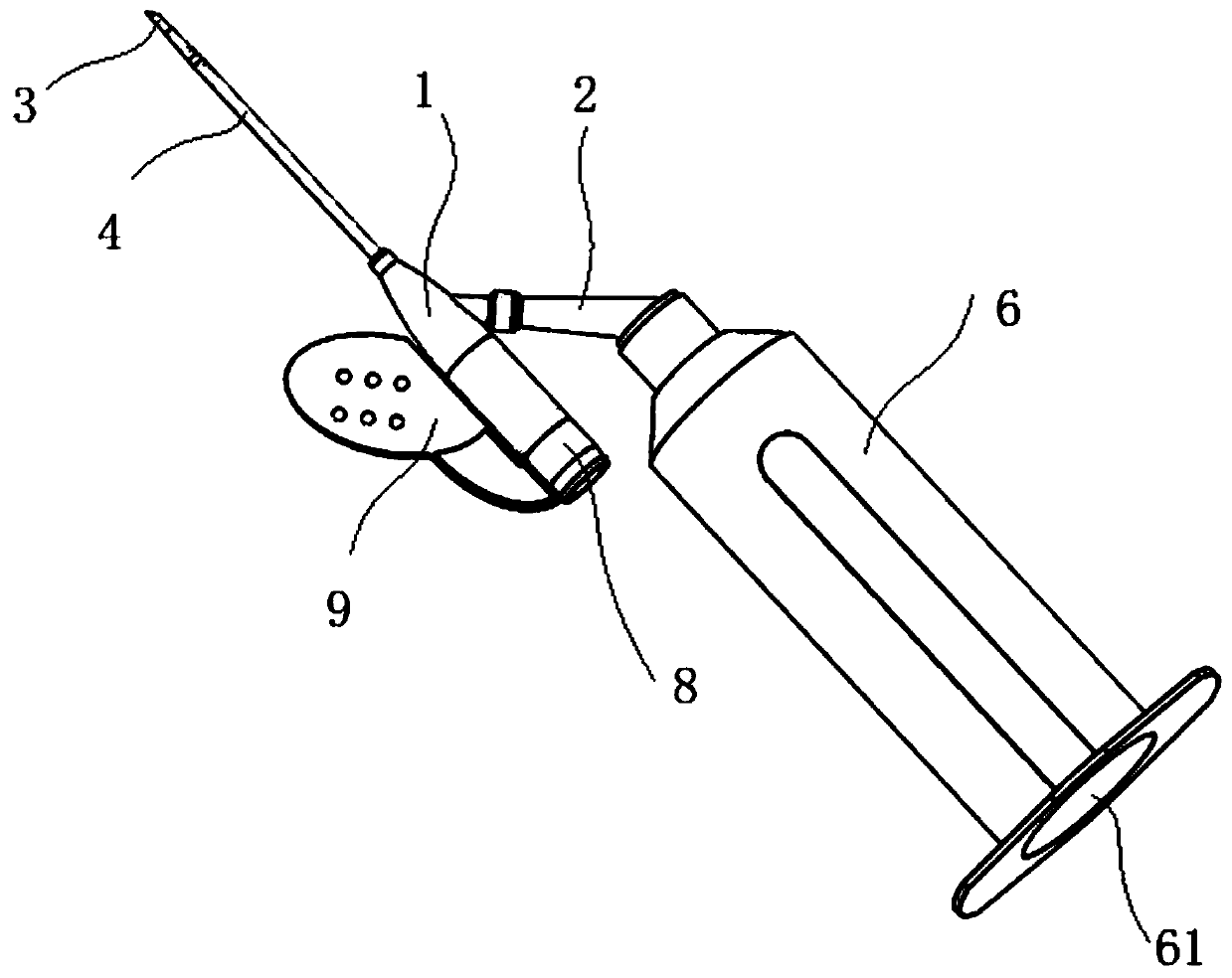

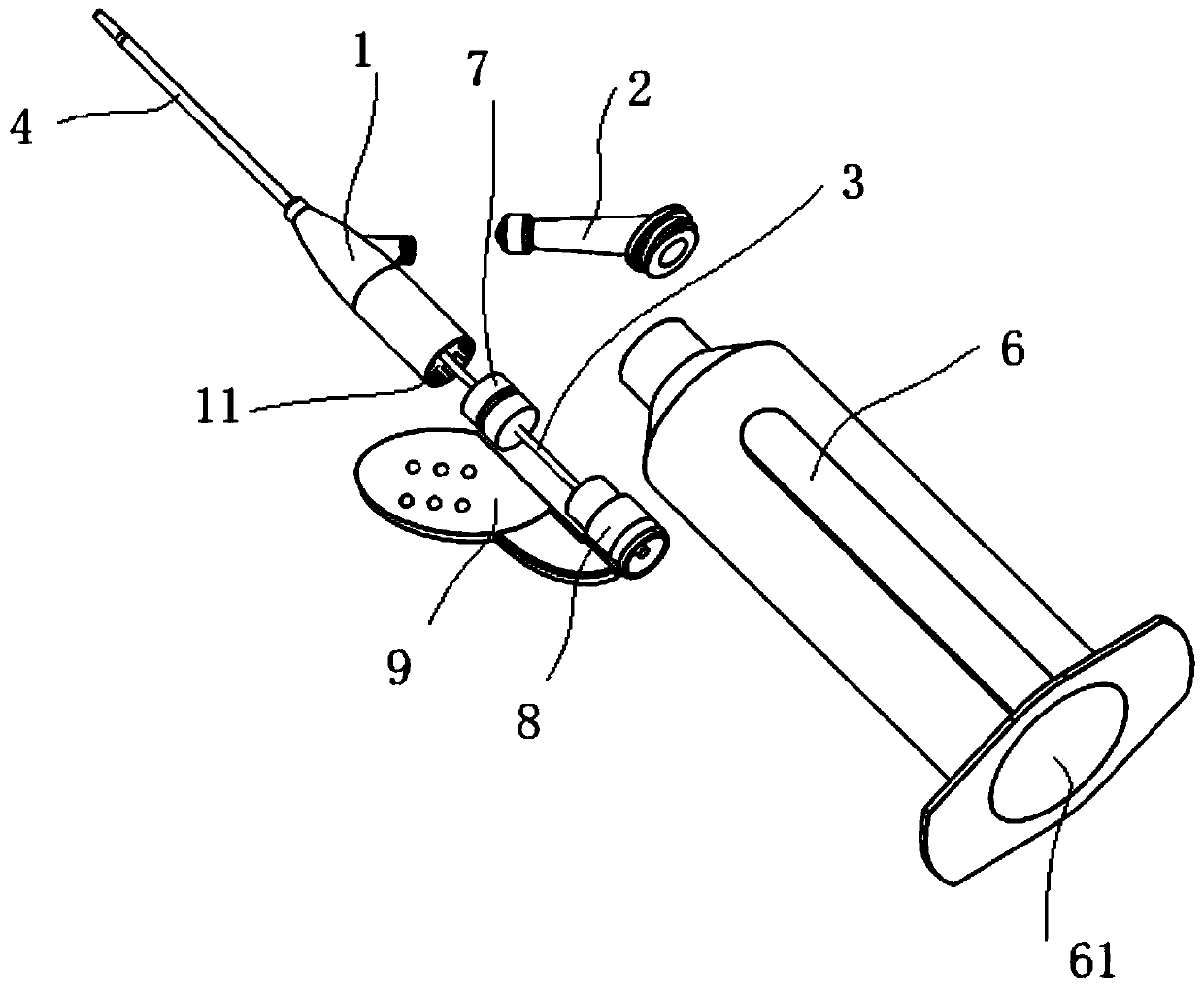

Hemostix

PendingCN110141255ANot easy to bendNot easy to swingSensorsBlood sampling devicesBlood collectionCatheter hub

The invention provides a hemostix. The hemostix comprises a catheter seat, a blood sampling structure and a connecting pipe, wherein an accommodating cavity is formed inside the catheter seat; a catheter for accommodating a puncture needle tube is fixedly arranged at one end of the accommodating cavity; the hardness of the catheter is less than that of the puncture needle tube; the puncture needletube has a first state in which the puncture end extends out of a catheter, and a second state in which the puncture end is retracted toward the catheter seat and is separated from the catheter seat;the blood sampling structure comprises a blood collection needle; the connecting pipe is connected with the catheter seat and the blood sampling structure, and is communicated with the accommodatingcavity and the blood collection needle; and the hardness of the connecting pipe is not less than that of the catheter seat. According to the hemostix, pains of a person waiting for blood sampling canbe relieved in the blood sampling process, blood sampling operation can be performed conveniently, and accuracy of a blood detection result can be improved.

Owner:BEIJING GUANGYAO CENTURY MEDICAL TECH

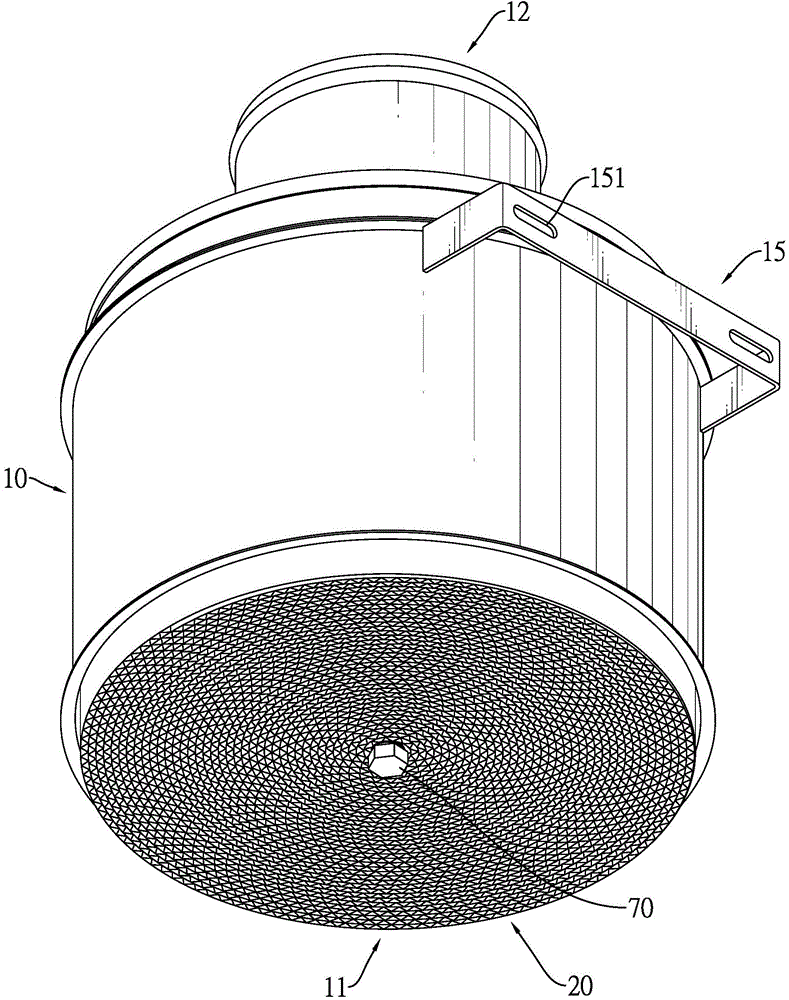

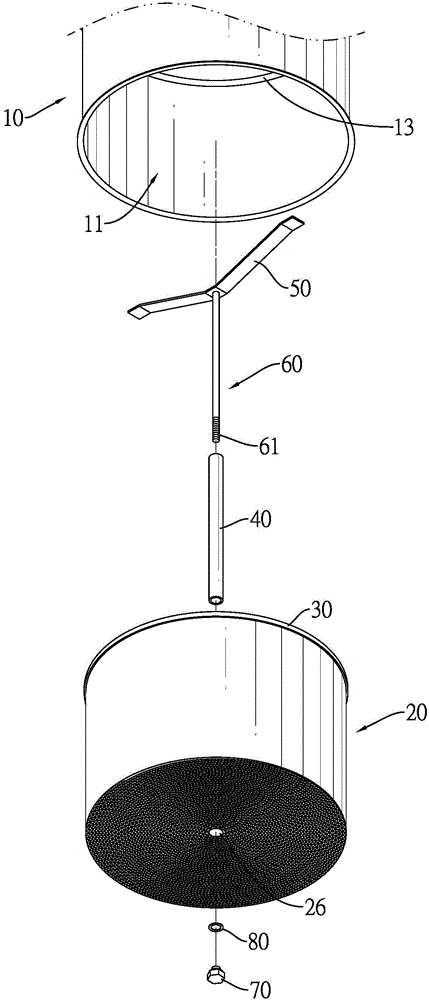

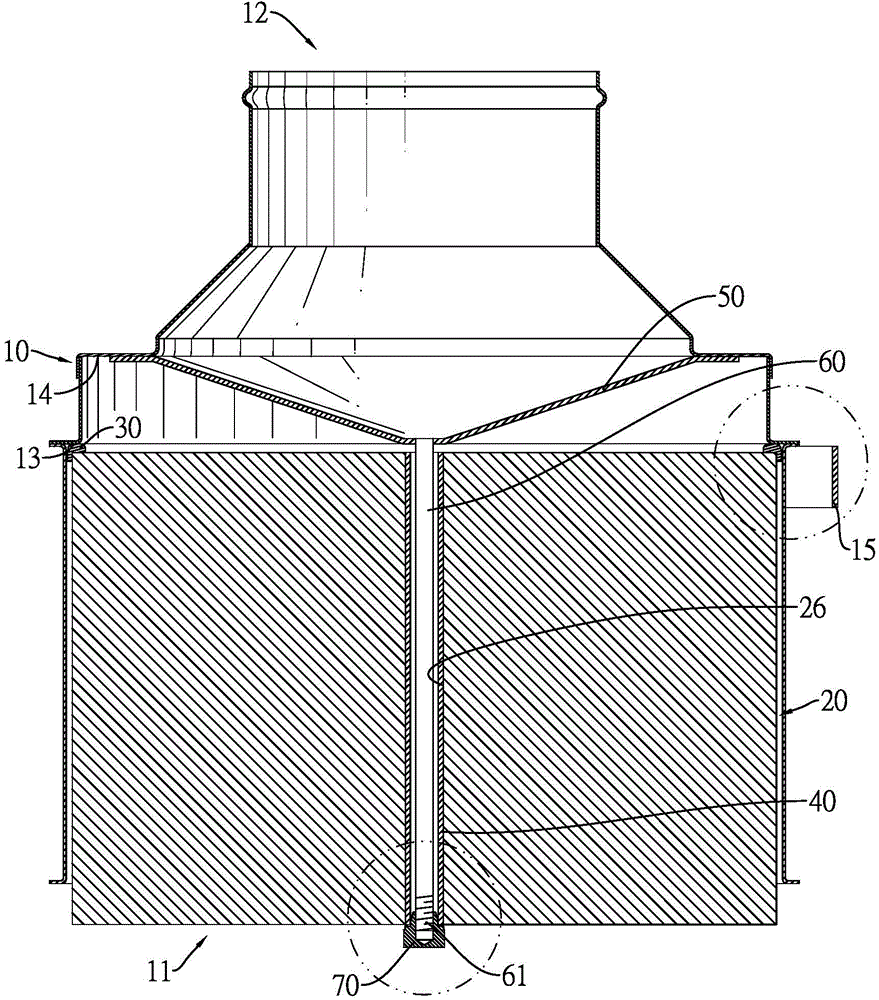

Air filter

ActiveCN105298697AThe process is simple and convenientEasy to installDispersed particle filtrationCombustion-air/fuel-air treatmentAir filterMechanical engineering

An air filter has a housing, a filter core, a resilient abutting element, a sleeve, a threaded rod bracket, a threaded rod and a nut. The axial sealing is achieved by axially compressing the resilient abutting element, such that the user does not have to apply much physical effort to compress the resilient abutting element. The user can easily push the filter core into the housing, and then rotates and tightens the nut, which can axially compress the resilient abutting element. It is easy to apply force on rotating the nut, and better still, the nut can be rotated by an electric tool, which further facilitates the convenience in assembling. Besides, the nut only abuts the sleeve, and the threaded rod bracket does not abut the filter core. Consequently, the filter core is not blocked, thereby making the air smoothly pass through the filter core.

Owner:PROPURE AS

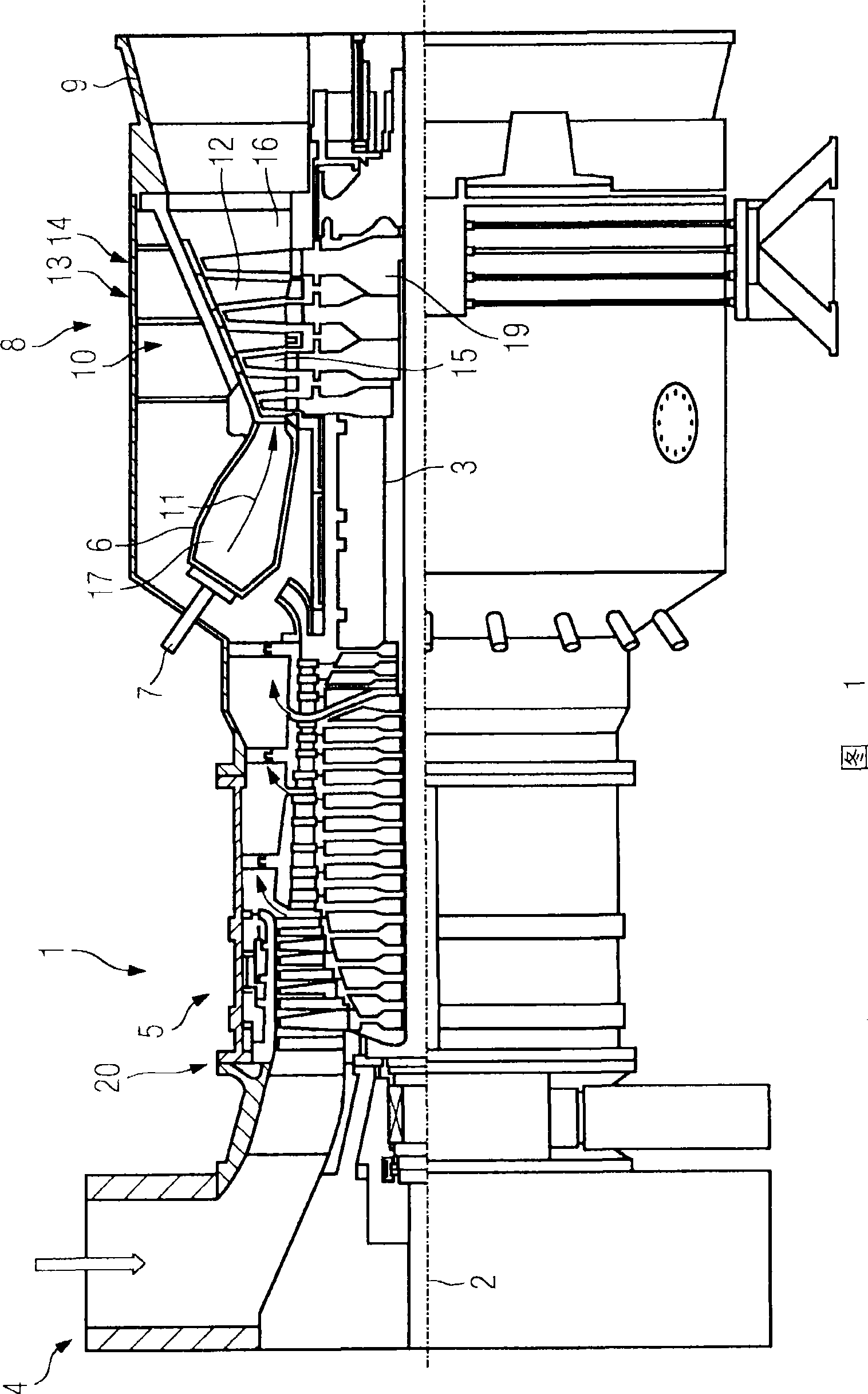

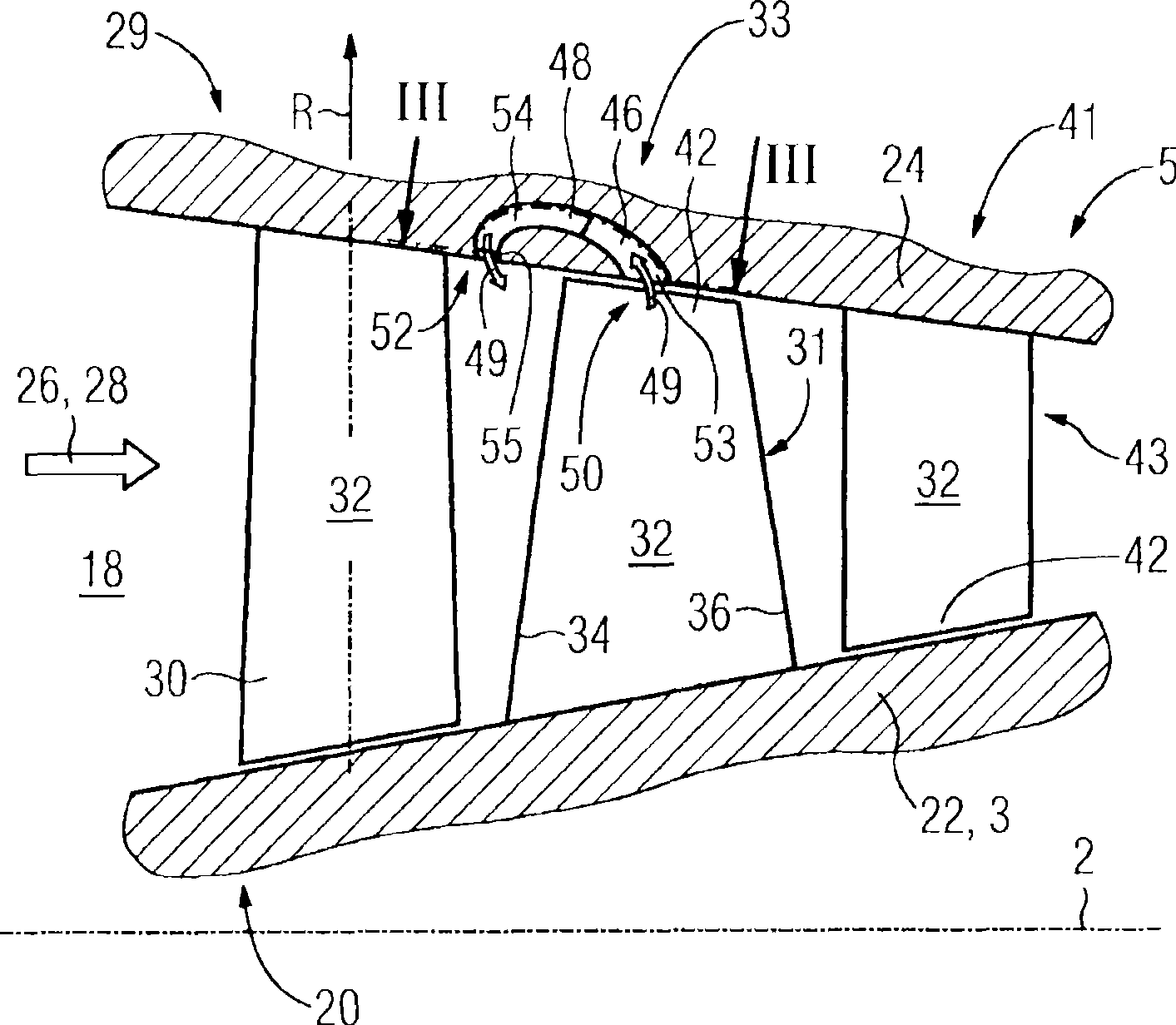

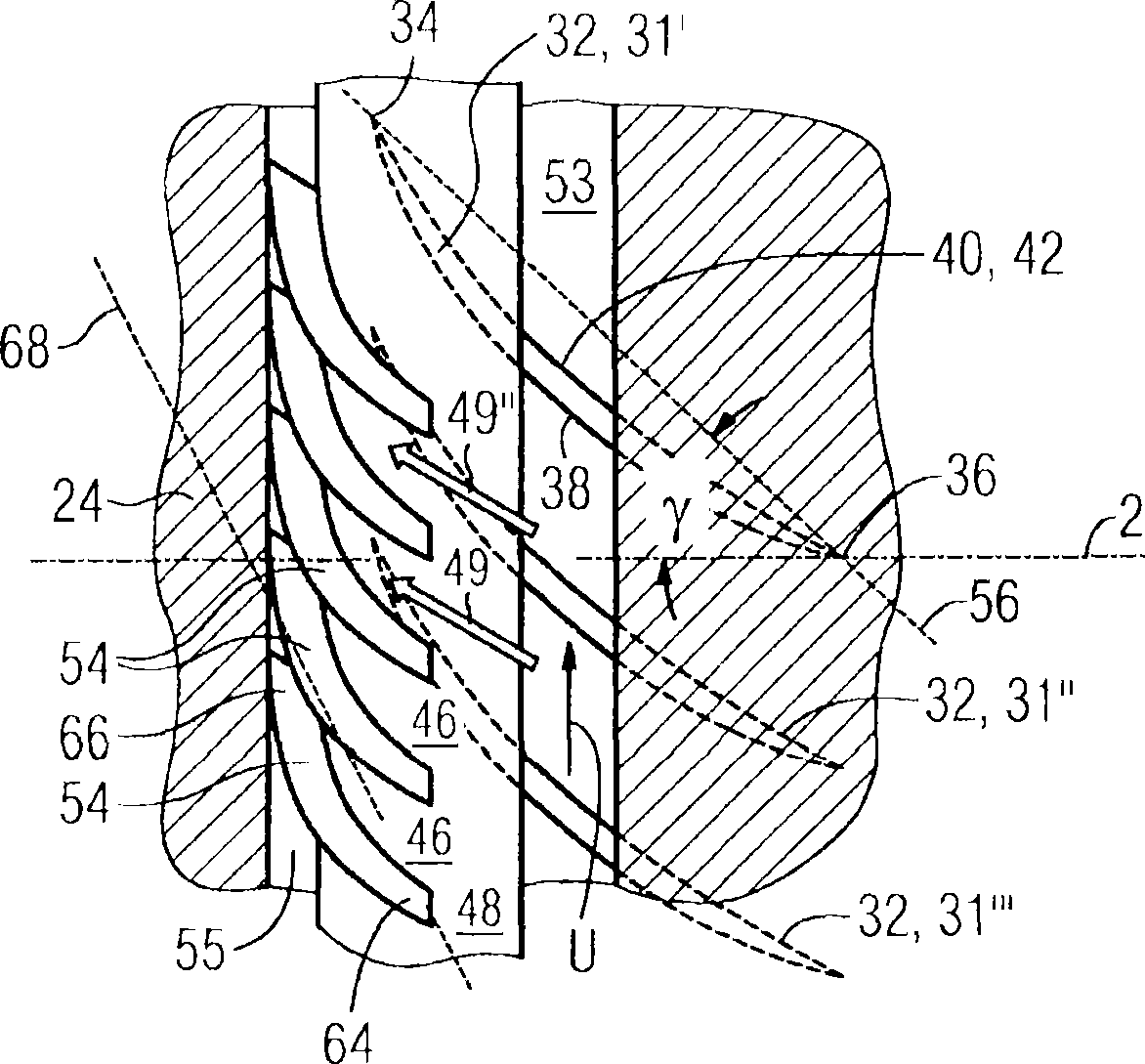

Annular flow duct for a turbomachine through which a main flow can flow in the axial direction

ActiveCN101460707AAvoid flow interruptionGood exercisePump componentsBlade accessoriesCircular motion

The invention relates to an annular flow duct (18) for a turbomachine, said flow duct (18) being arranged concentrically about a machine axis (2) running in the axial direction and being defined by a boundary wall (22, 24) of circular cross section for directing a main flow (26), wherein the boundary wall (22, 24) has a plurality of return flow passages (46) which are distributed over its circumference and through which in each case a partial flow (49) which can be detached from the main flow (26) at a bleed position (50) can be returned to the main flow (26) at a feed position (52) situated upstream of the bleed position (50), and having aerofoils (32), arrranged radially in the flow duct (18), of a blade ring, the aerofoil tips (42) of which lie opposite the boundary wall (22, 24), with a gap being formed in each case, wherein the aerofoils (32) are movable in a predetermined rotation direction (U) along the circumference of the boundary wall (22 ,24). In order to specify a compressor which is insensitive to pumping and flow separations, it is proposed that as viewed in rotation direction (U) the bleed position (50) of each return flow passage lie upstream of the corresponding feed position (52).

Owner:SIEMENS ENERGY AG

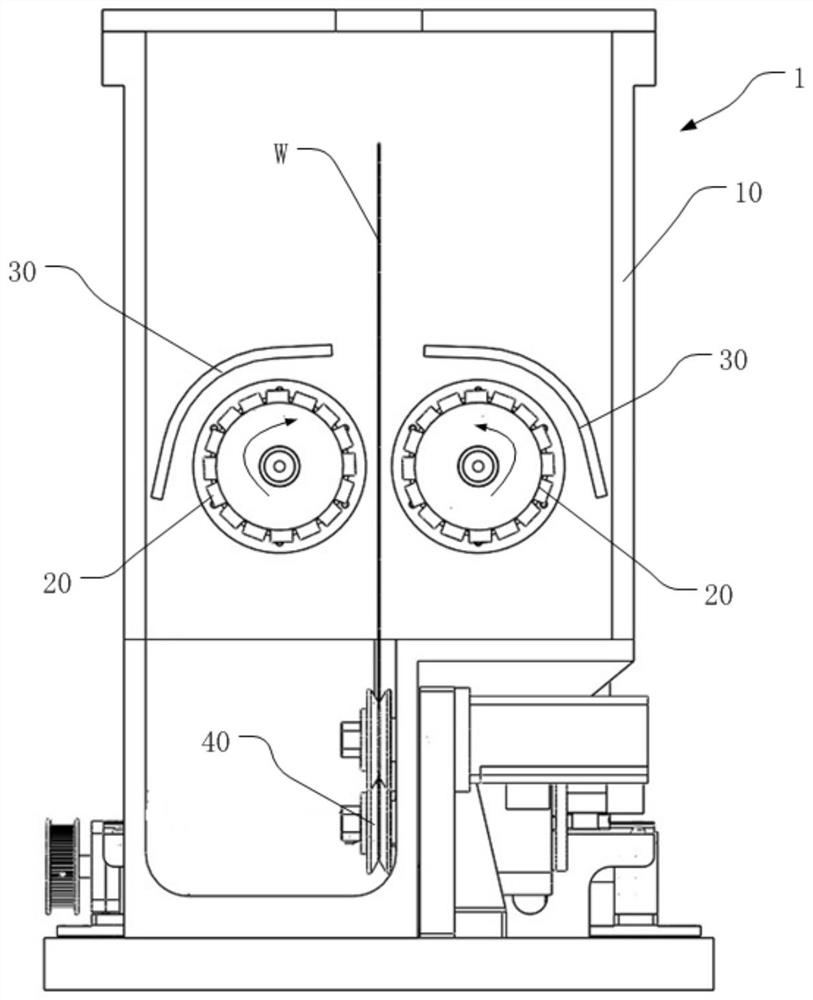

Construction waste crushing device for construction engineering and using method thereof

ActiveCN111686866BReduce crushing costsEasy to reuseUsing liquid separation agentTreatment involving filtrationRefuse collectionArchitectural engineering

The invention discloses a construction waste crushing device for construction engineering and an application method thereof, belonging to the technical field of construction engineering. Among them, a construction waste crushing device for construction projects includes a crushing box and a garbage collection vehicle. The garbage collection vehicle is placed at the bottom of the crushing box. The upper and lower sides of the crushing box are respectively connected with a feed port and a discharge port. It is connected with a crushing mechanism, the outer wall of the crushing box is connected with a dust reduction box, and the dust reduction box is respectively connected with a water replenishment tank and a sprinkler tank, the first pipeline and the second pipeline are connected between the water replenishment tank and the sprinkler box, and the bottom of the dust reduction box is connected with a water delivery pipe , the end of the water delivery pipe away from the dust suppression box is connected to the top of the water supply tank, the outer wall of the water delivery pipe is connected with a water pump, and the water pump is connected to the outer wall of the water supply tank; the present invention is conducive to the repeated use of water resources for dust reduction, and is conducive to saving water resources. Reduce the cost of crushing construction waste.

Owner:徽仁(宁夏)环保科技有限公司

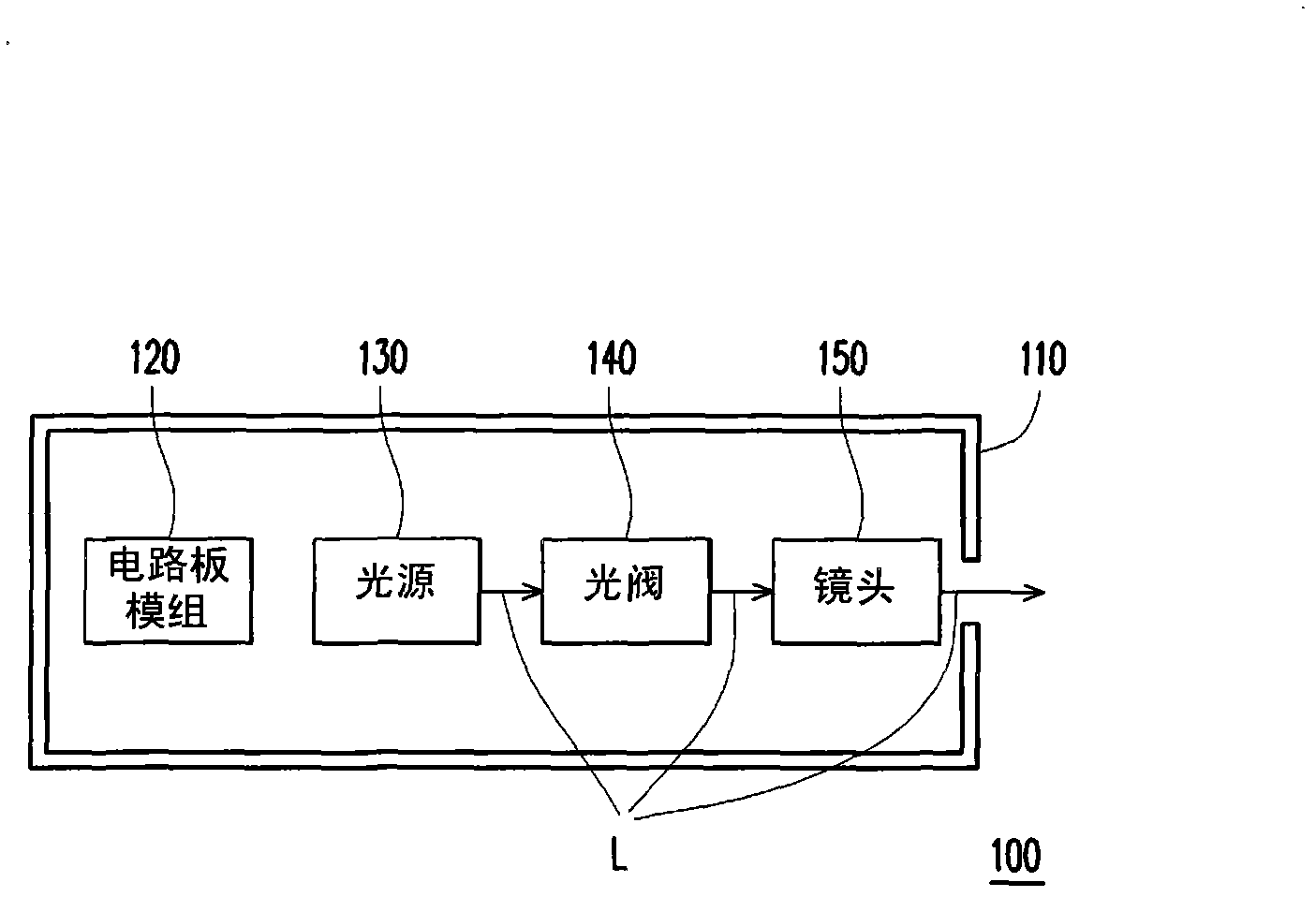

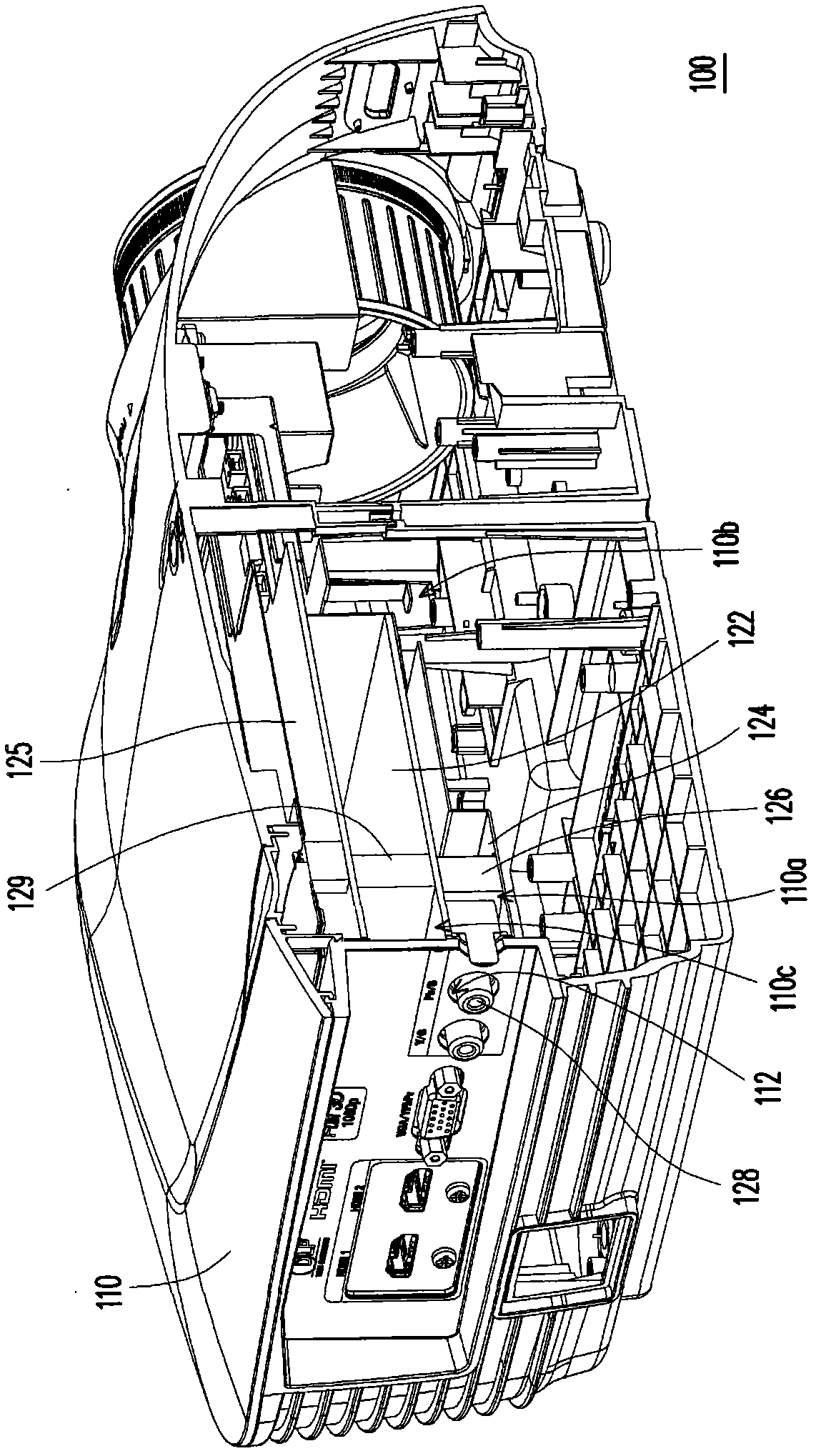

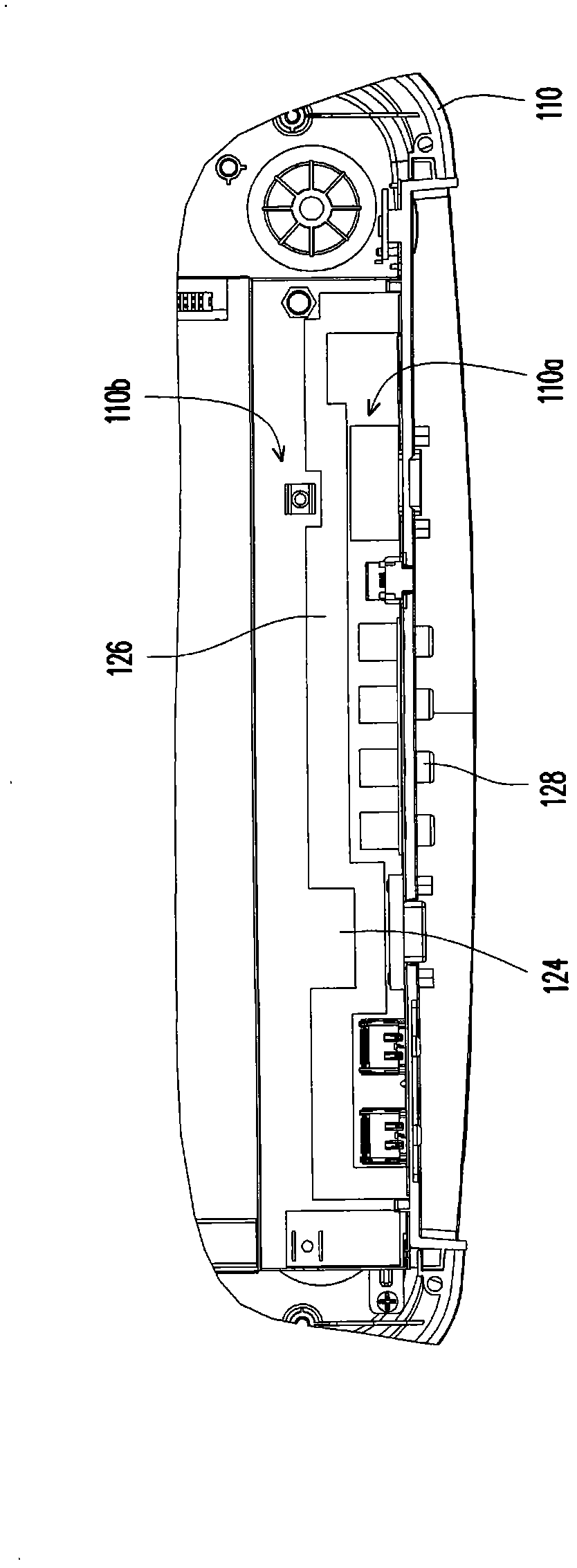

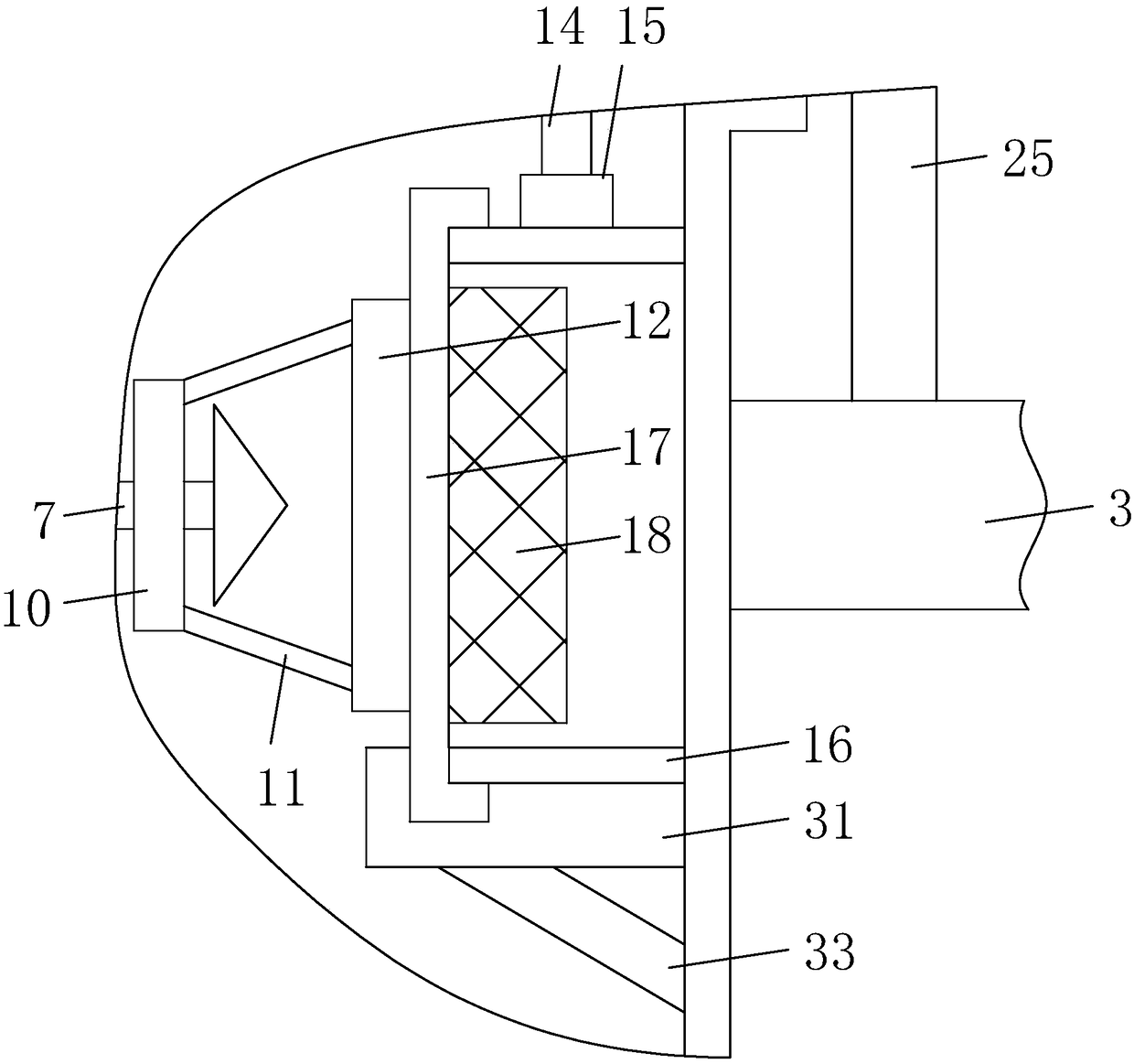

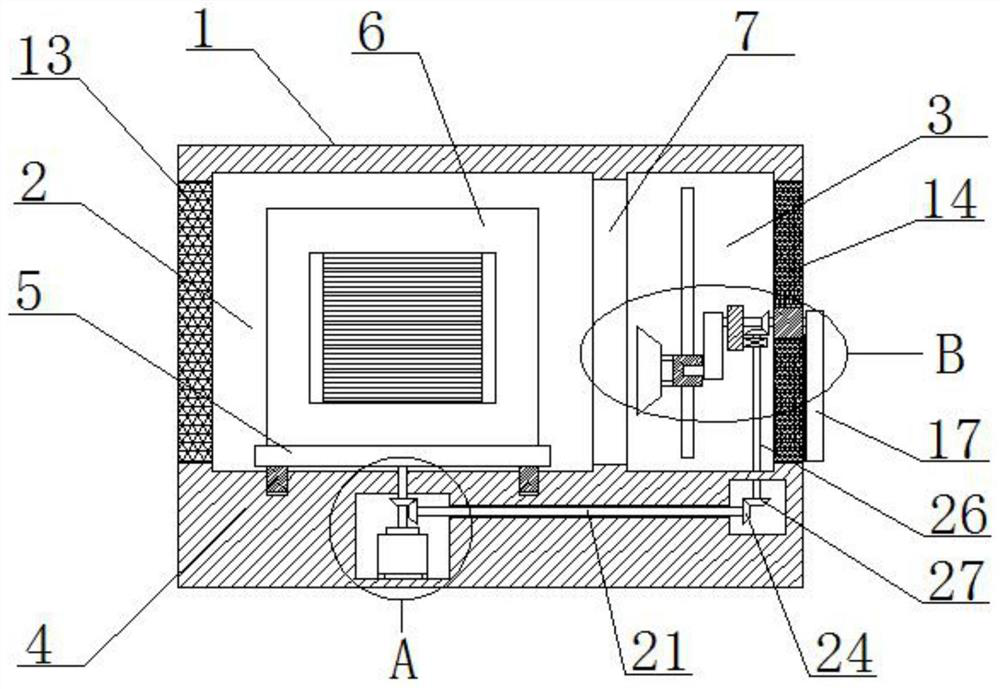

Projection device and circuit board module

InactiveCN102854719AAvoid light leakageGood cooling efficiencyProjectorsElectrical apparatus casings/cabinets/drawersCamera lensEngineering

Provided are a projection device and a circuit board module. The projection device comprises a casing, the circuit board module, a light source, a light valve and a camera lens, and the casing is provided with at least one opening hole. The circuit board module comprises a circuit board, a plate element, an elastic structure and at least one connector. The circuit board and the plate element are arranged in the casing. The elastic structure is clamped between the circuit board and the plate element. The circuit board, the plate element and the elastic structure separate the inside of the casing into a first space and a second space. The first space is separated from the second space through sealing of the elastic structure, and the first space is communicated with the outside through the opening hole. The connector is allocated on the circuit board to be located in the first space, and the connector is exposed out by the opening hole. The light source, the light valve and the lens are allocated in the second space. Light beams sent from the light source reach the lens through the light valve.

Owner:CORETRONIC

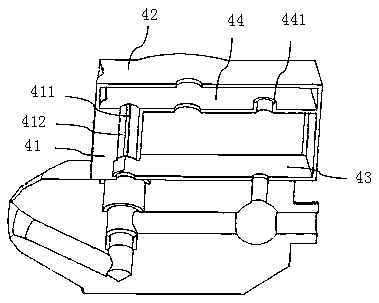

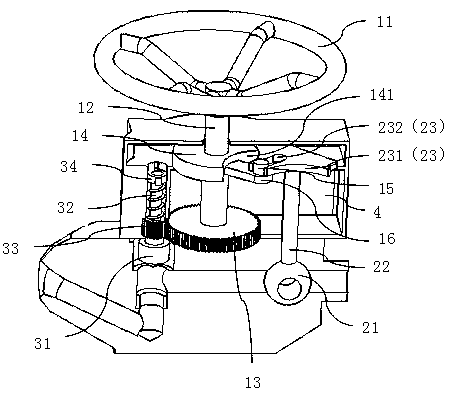

High pressure valve opening and closing device and high pressure valve

PendingCN108692095AGuaranteed sealing reliabilityAvoid erosionPlug valvesOperating means/releasing devices for valvesEngineeringHigh pressure

The invention belongs to the technical field of valves, and discloses a high pressure valve opening and closing device and a high pressure valve. The high pressure valve opening and closing device comprises a hand wheel, a hand wheel shaft fixedly connected with the hand wheel, a ball valve body, a cone valve body, a ball valve rod connected with the ball valve body, and a cone valve lead screw connected with the cone valve body; the end of the hand wheel shaft is connected with a driving gear, and the cone valve lead screw is sleeved with a driven gear, wherein the driven gear and the drivinggear are located at the same height; an inner hole of the driven gear is provided with a threaded structure matched with the cone valve lead screw, and the cone valve lead screw rise and fall in theup-down direction under driving of the driven gear; a groove wheel is mounted at the end of the ball valve rod, and a shifting disc structure is arranged at the middle section of the hand wheel shaftand comprises a shifting disc locking arc capable of being matched with the sunken peripheral edge of the groove wheel, and a cylindrical pin capable of being matched with a radial groove of the groove wheel; and the high pressure valve opening and closing device further comprises a mounting seat used for fixing the heights of the driving gear, the driven gear and the groove wheel. According to the high pressure valve opening and closing device, sequential opening and closing of the ball valve and the cone valve can be achieved, the cone valve is prevented from being eroded by high pressure airflow, and the sealing reliability of a high pressure valve is ensured.

Owner:HUNAN UNIV OF TECH

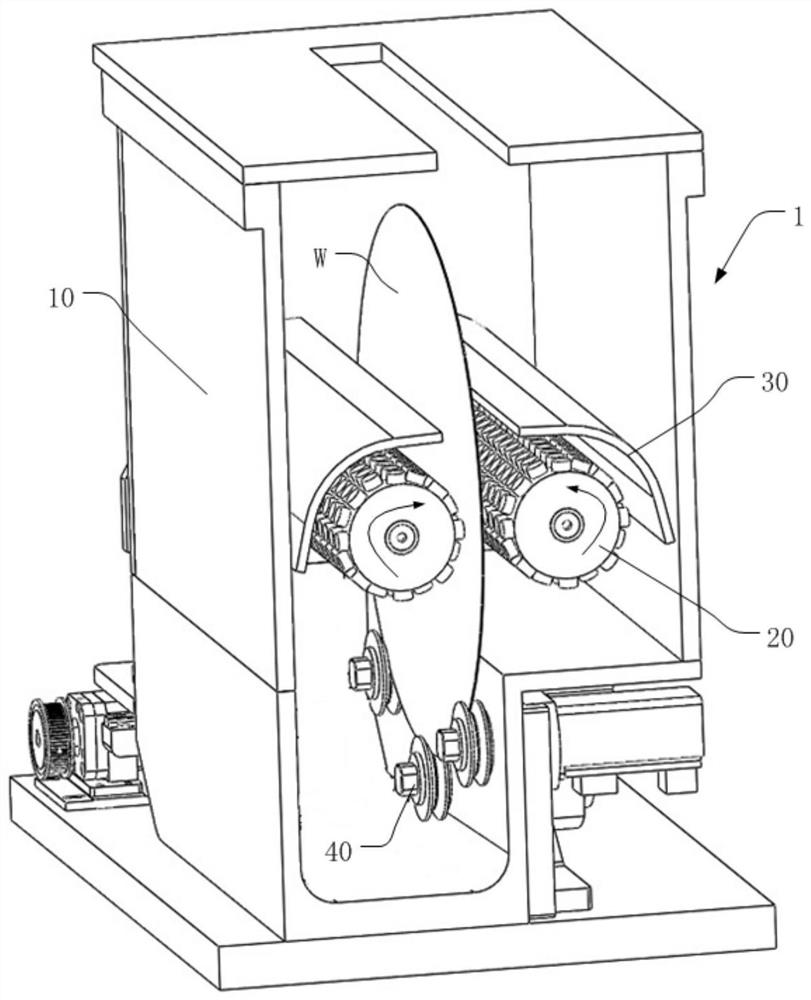

Wafer washing device

ActiveCN112371592AAffect cleaning effectEasy to cleanFouling preventionSemiconductor/solid-state device manufacturingWaferEngineering

The invention discloses a wafer washing device which comprises a shell, a supporting assembly, washing brushes and a protecting plate. The supporting assembly is located in the shell and used for supporting a wafer to be washed in a rotating manner, wherein the wafer is arranged in the vertical direction. The washing brushes are arranged in parallel and at intervals and roll around the axes of thewashing brushes. The protecting plate is arranged on the upper sides of the washing brushes, so that fluid generated by rolling of the washing brushes is stopped from splashing down to the surface ofthe wafer.

Owner:华海清科(北京)科技有限公司

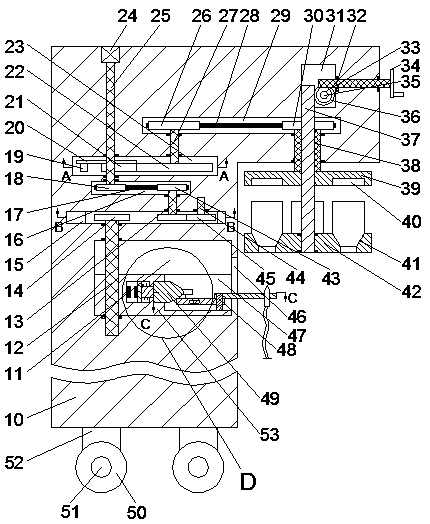

Automatic liquid changing device for medical infusion

ActiveCN111110948AInfluence flowRealize automatic liquid change functionInfusion devicesMedicineDrive shaft

The invention discloses an automatic liquid changing device for medical infusion. The device comprises a machine body, a driving cavity is formed in the machine body, a tight clamping mechanism is arranged below the driving cavity, a first belt wheel cavity is formed below the driving cavity, an intermittent cavity is formed below the first belt wheel cavity, an intermittent mechanism is arrangedin the intermittent cavity, a first driving shaft is rotationally arranged between the first belt wheel cavity and the intermittent cavity, the upper end of the first driving shaft extends into the first belt wheel cavity and is fixedly provided with a first belt wheel, the lower end of the first driving shaft extends into the intermittent cavity and is fixedly provided with a grooved wheel, a second belt wheel cavity is formed below the intermittent cavity, a reciprocating cavity is formed below the second belt wheel cavity, a reciprocating mechanism is arranged in the reciprocating cavity, amoving cavity is formed below the reciprocating cavity, a clamping mechanism is arranged in the moving cavity, a stroke groove with a rightward opening is formed in the right side of the moving cavity, and supporting blocks are fixedly arranged at the lower end of the machine body in a bilateral symmetry mode.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

A kind of waste bin with hydraulic pressure treatment expansion capacity for domestic waste in residential area

ActiveCN108529068BStorage impactAffect transmissionRefuse receptaclesEnvironmental resource managementElectric machine

The invention relates to the technical field of municipal equipment, and discloses a hydraulic treatment capacity expansion dustbin for community household garbage. The hydraulic treatment capacity expansion dustbin comprises crushing equipment, the top of the crushing equipment fixedly communicates with a feeding pipe, a supporting plate is fixedly arranged on the side surface of the crushing equipment, the top of the supporting plate is fixedly provided with a first motor, an output shaft of the first motor is fixedly sleeved with a rotating gear, the outer teeth of the rotating gear are inmeshed connection with a conveying belt, one end of the conveying belt is connected with a positioning gear in a meshed mode, and a connecting rod is fixedly arranged on the side surface of the positioning gear. By utilizing the cooperation of a transmission gear, the conveying belt and the positioning gear, the connecting rod drives cutting teeth to rotate, so that the thrown garbage is smashed,by utilizing the cooperation of a second motor and crushing teeth, the garbage is further crushed, so that the situation that in the garbage storage process, due to the fact that the size of the garbage is excessively large, the area of a garbage storage box for storing the garbage is reduced, and then the storage of the garbage is influenced is avoided.

Owner:HUNAN UNIV OF ARTS & SCI

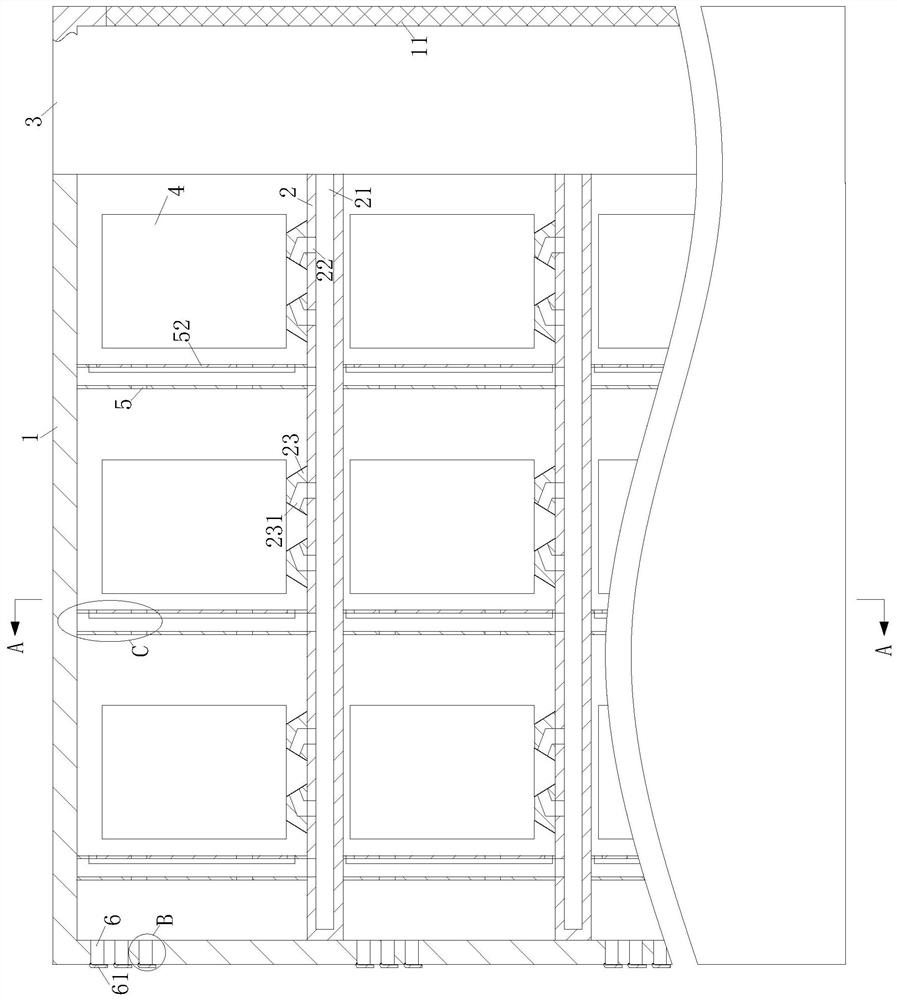

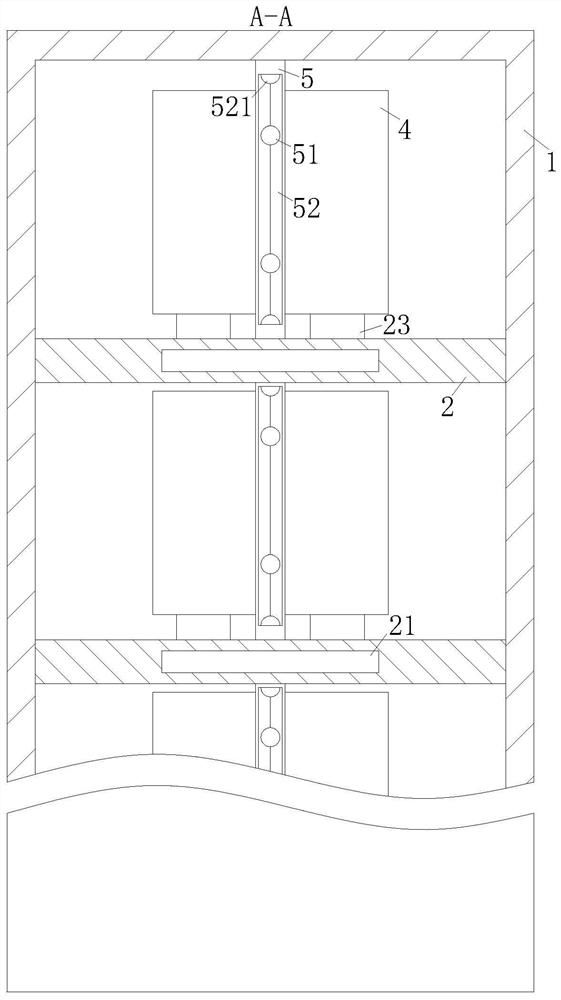

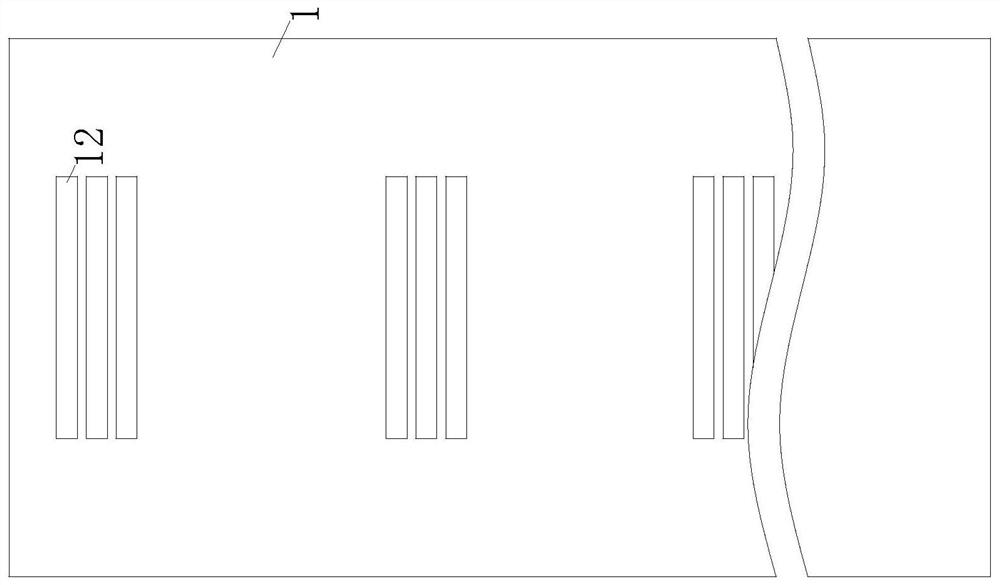

Intelligent temperature control power switch cabinet

PendingCN113690767AImprove cooling efficiencyInfluence flowTemperatue controlSubstation/switching arrangement cooling/ventilationTemperature controlElectric power equipment

The invention belongs to the technical field of power equipment, and particularly relates to an intelligent temperature control power switch cabinet which comprises a cabinet body, partition plates, a cabinet air conditioner, switch equipment, a vertical pipe, an air outlet groove and a temperature sensor. The partition plates are evenly installed in the cabinet body in the vertical direction, and each partition plate is fixedly connected with the inner surface of the side wall of the cabinet body. According to the invention, through the arrangement of the partition plates, an air inlet groove, a trapezoidal convex block and the vertical pipe, cooling air generated by a fan is discharged through a second air blowing opening and a third air blowing opening, so that the surfaces of the switch equipment are cooled, and the heat dissipation efficiency is improved; through the arrangement of an elastic sheet and a wire outlet, the vertical pipe can fix and store a longer wire body or a loose wire body in the switch cabinet, the wire body is prevented from being wound and stacked in the cabinet body to influence the flowing of cooling air, and the heat dissipation efficiency is further improved; and meanwhile, additional wire arranging and wiring equipment is avoided, and the production energy consumption is reduced.

Owner:胡明澳

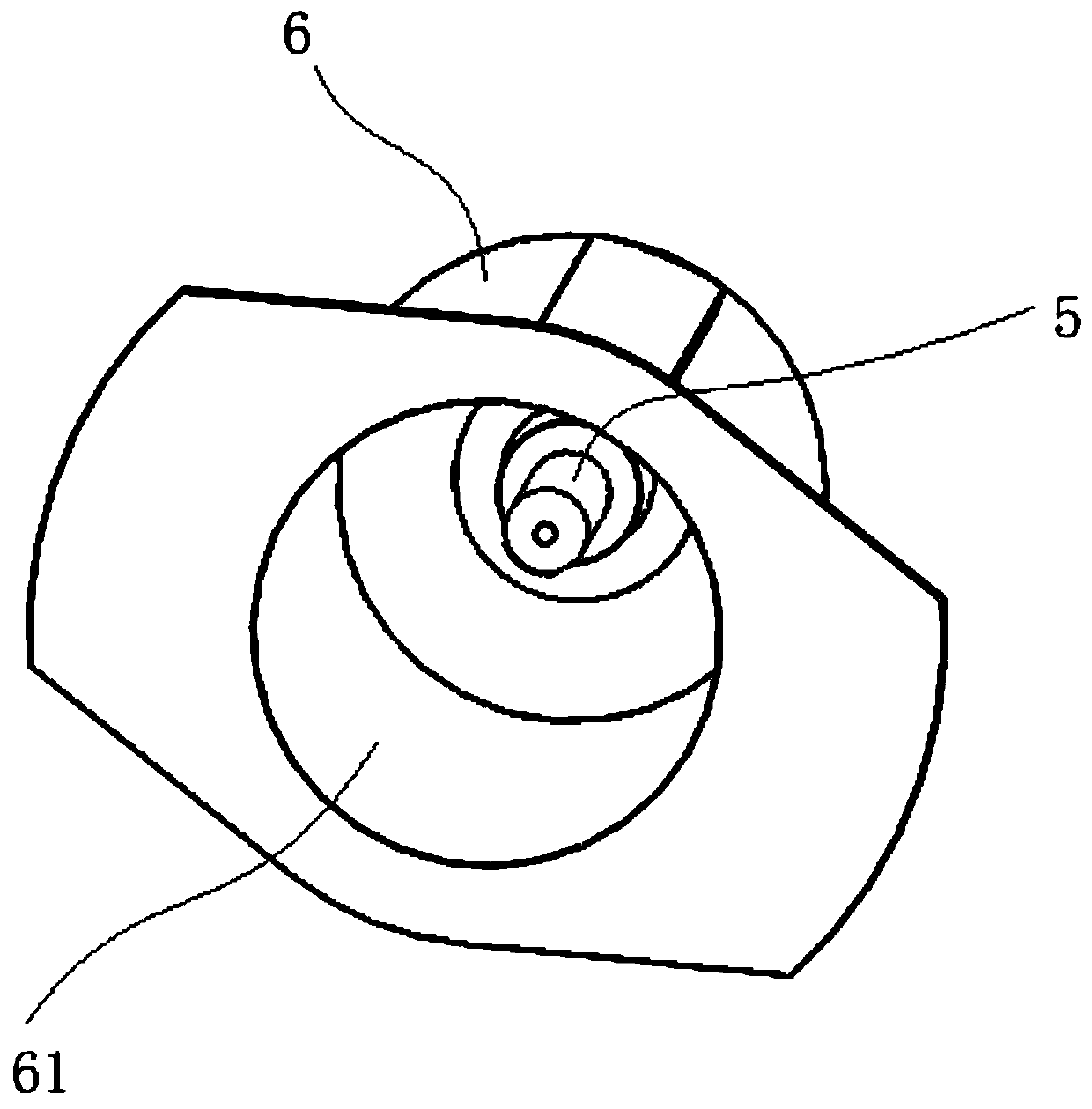

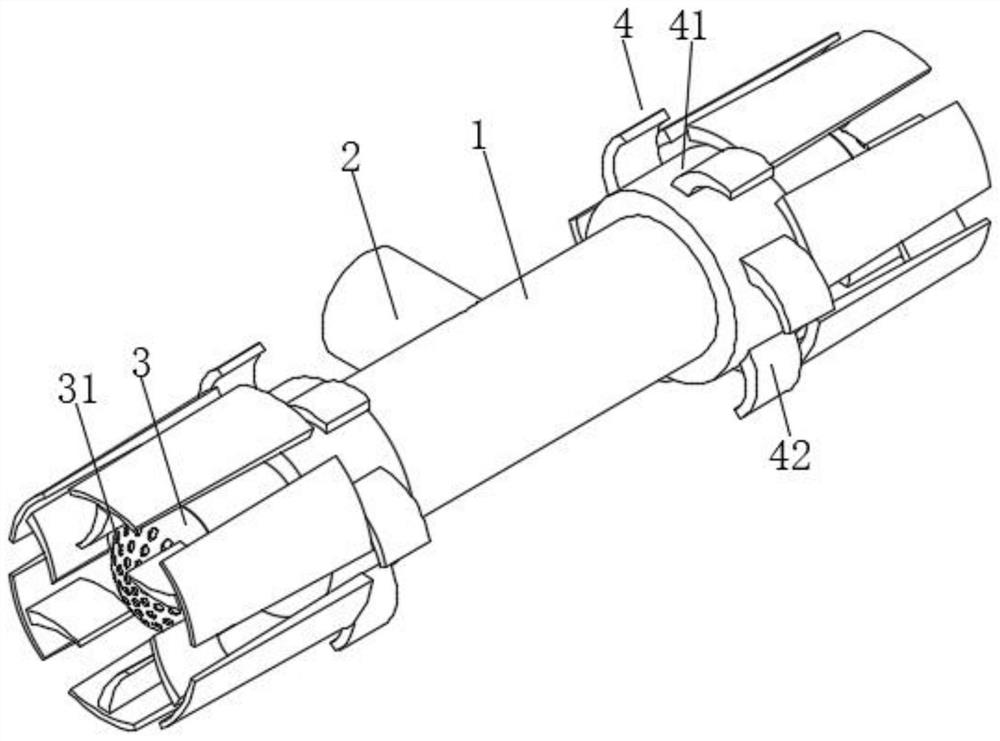

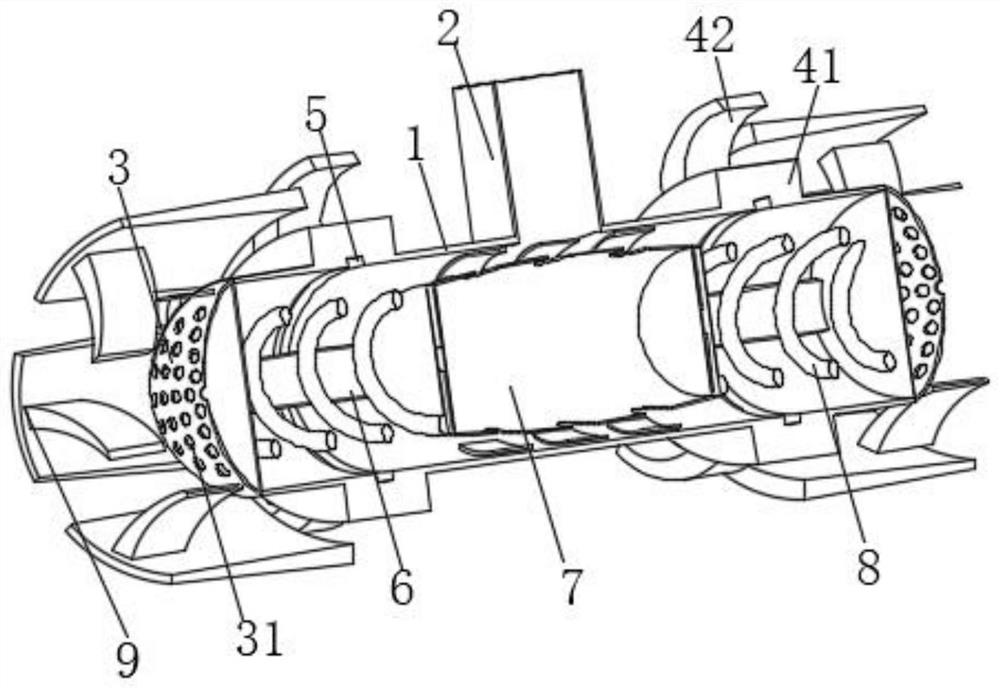

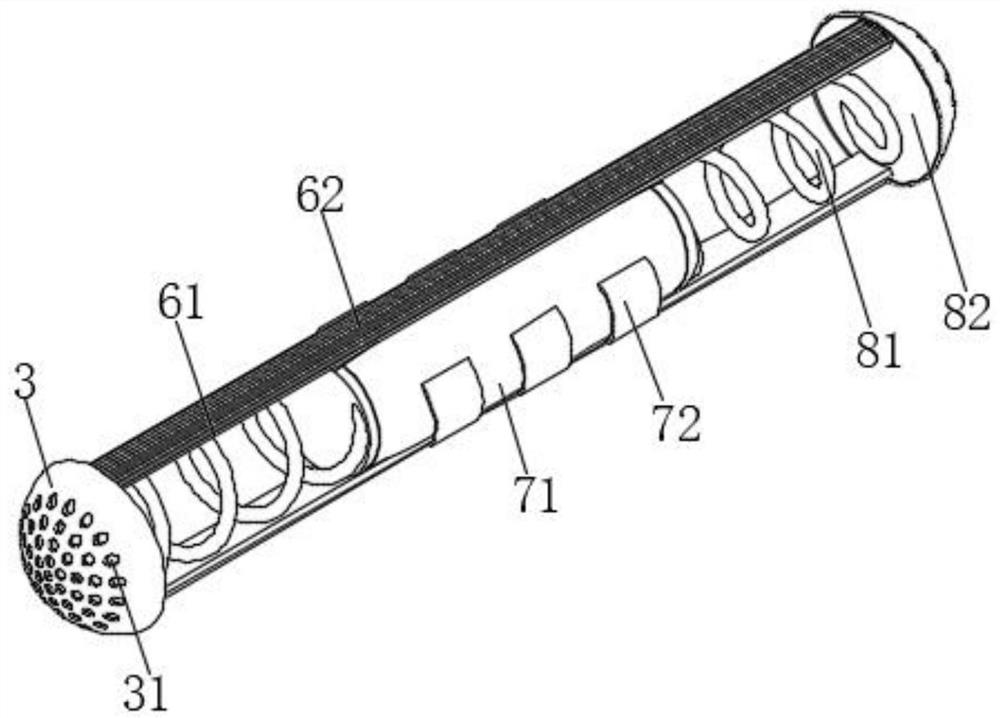

Gas filtering device for energy-saving gas compressor

InactiveCN113738622AInfluence flowImprove the rotation effectPositive displacement pump componentsPositive-displacement liquid enginesGas compressorEngineering

The invention relates to the technical field of pneumatic element equipment, and discloses a gas filtering device for an energy-saving gas compressor. The gas filtering device comprises a filtering outer cavity, an air outlet pipe is arranged at the middle axis of the filtering outer cavity in a communicating manner, arc-shaped cavities are formed in the left end and the right end of the filtering outer cavity, a plurality of air inlet holes are arranged on the arc-shaped cavities, and an auxiliary rotating mechanism is arranged between each arc-shaped cavity and the air outlet pipe. According to the gas filtering device for the energy-saving gas compressor provided by the invention, when gas in air enters a gas flow pushing cavity, under the action of an arc-shaped drainage plate, gas flows according to a certain track through a gas flow groove, so that a whole gas flow pushing mechanism is conveniently pushed to rotate, and under the driving of rotation of the gas flow pushing mechanism, a rotary cleaning mechanism is driven to rotate, so that the interior of the filtering outer cavity is comprehensively cleaned, and the situation that too much dust affects flowing of gas is prevented.

Owner:李世强

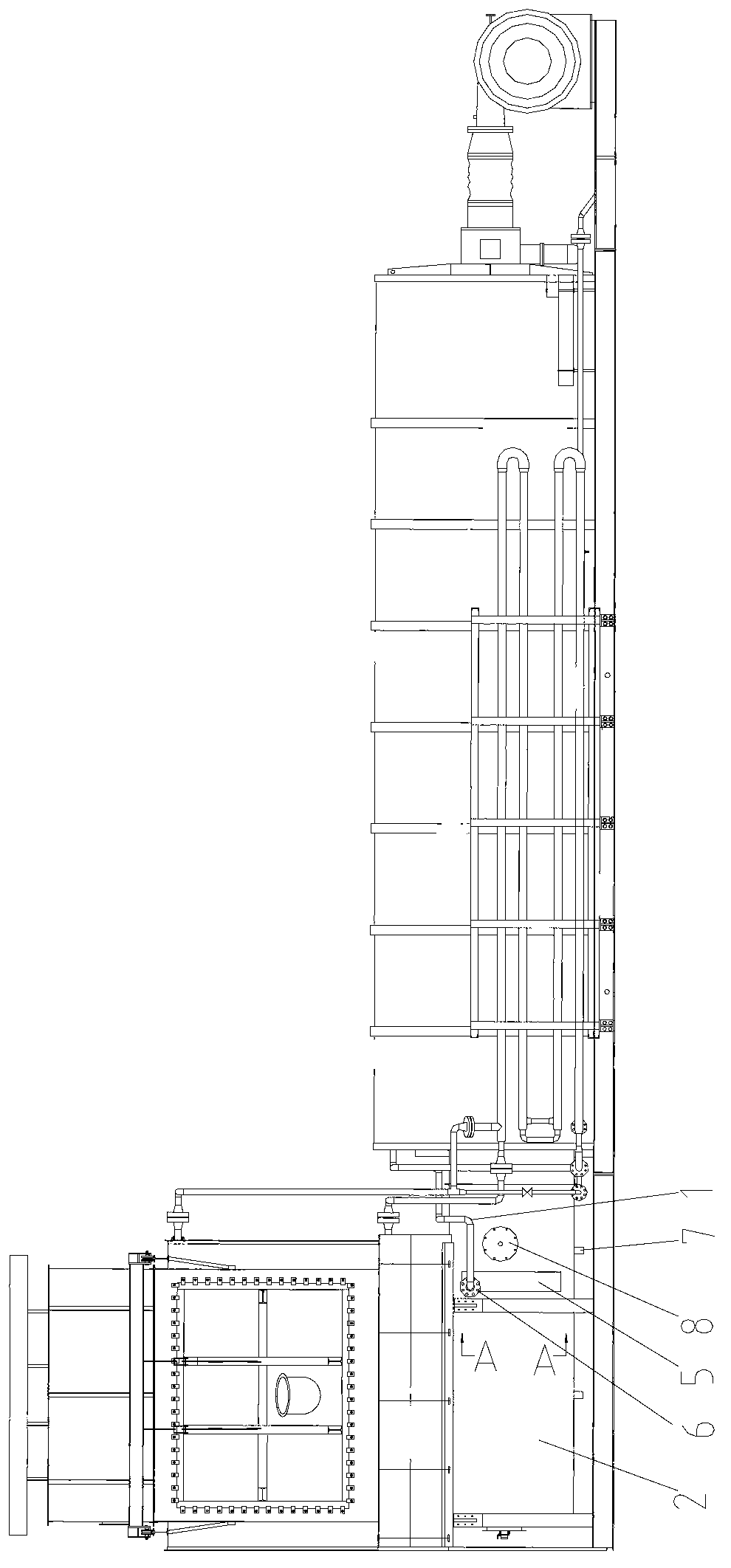

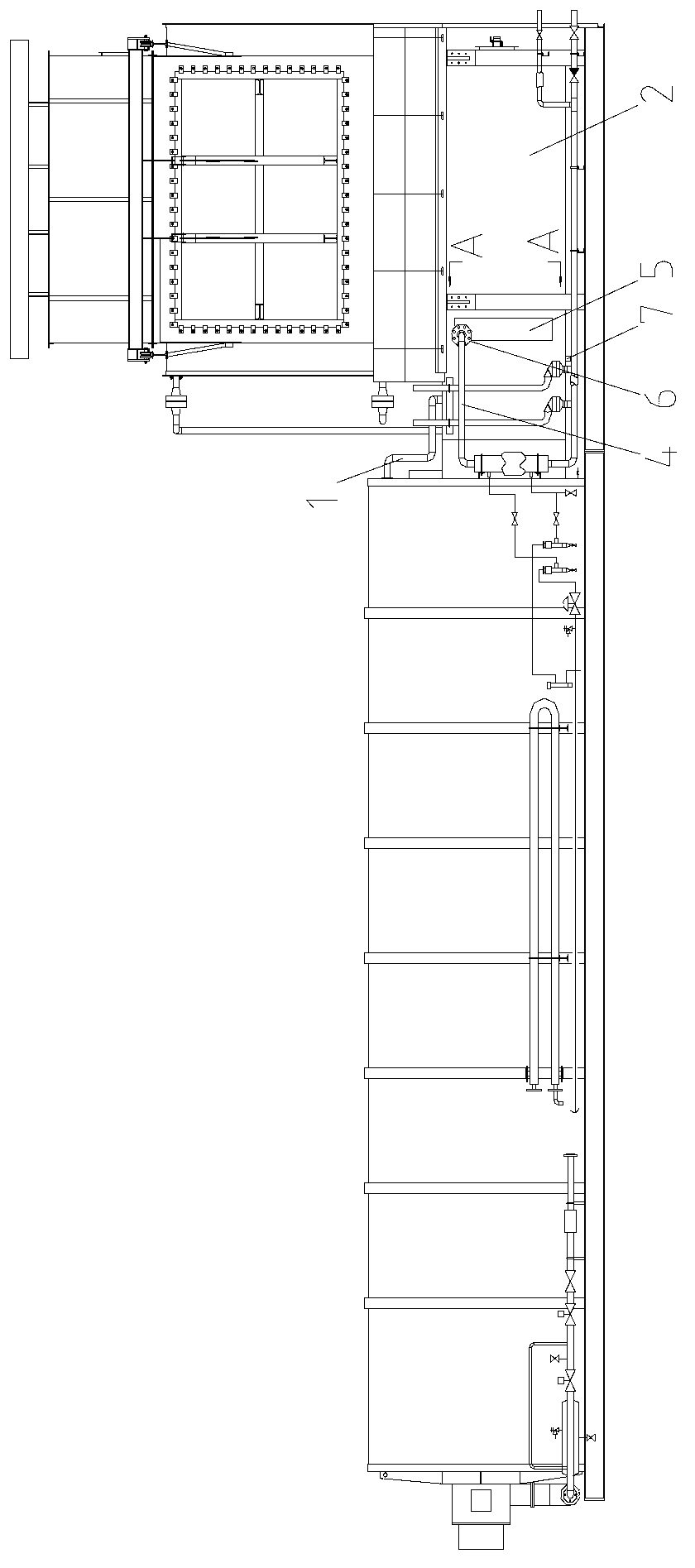

Soot blocking pipe bundle of steam injection boiler for burning residual oil with high silt content

The invention discloses a soot blocking pipe bundle of a steam injection boiler for burning residual oil with high silt content, which comprises soot blocking pipe bundles, a soot blower and a soot exhaust hole, wherein the soot blocking pipe bundles are connected with a soot blocking pipe inlet pipeline and a soot blocking pipe outlet pipeline respectively through flanges at the two ends of the soot blocking pipe bundles; the soot blocking pipe inlet pipeline is connected with a radiation pipe bundle outlet; the soot blocking pipe outlet pipeline is connected with a steam sampling separator inlet; the soot blower is arranged in front of the soot blocking pipe bundles; the soot exhaust hole is formed in the bottom of a transition section; the soot blocking pipe bundles are arranged at the corners of the L-shaped transition sections of the steam injection boiler; straight pipes are arranged in a reciprocating way, and are connected with one another by using elbows; the elbows are arranged in pipe boxes of soot blocking pipes on both sides of the soot blocking pipe bundles; two rows of soot blocking pipe bundles are arranged; pipe banks are arranged vertically; the straight pipes are arranged horizontally; and two rows of pipes are arranged in a staggered way. Most musky coal and large-particle dust in flue gas can be prevented from moving and are deposited at the bottom of the transition section, and molten compounds and most residual flying ash in flue gas can be adsorbed, so that the concentration of flying ash in flue gas at a countercurrent section is lowered, the amount of loose soot accumulated in countercurrent pipe bundles is very small, soot is easy to clear, and normal heat exchange is ensured.

Owner:山东茵温特节能环保科技有限公司

High-efficiency electric automatic dust removal device

ActiveCN108371864ARealize reactive absorptionQuick dust removalCombination devicesGas treatmentFlue gasEngineering

The invention discloses a high-efficiency electric automatic dust removal device. The high-efficiency electric automatic dust removal device comprises a dust removal cavity, a flue gas discharging cavity, a flue gas exhausting opening, a piston valve and a first absorption solution storage box, wherein the flue gas discharging cavity is formed in the left side of the dust removal cavity; the fluegas exhausting opening is formed in the upper part of an inner cavity of the flue gas discharging cavity; a flue gas escaping cavity is arranged above the flue gas discharging cavity; the piston valveis arranged at the lower part of the inner cavity of the flue gas escaping cavity; the position of the piston valve is arranged at the upper part of the flue gas exhausting opening; the right side ofthe flue gas escaping cavity is fixedly connected with a first connection pipe; the upper end of the first connection pipe is fixedly connected with the first absorption solution storage box; a second absorption solution storage box is fixedly mounted at the right side of the first absorption solution storage box. The high-efficiency electric automatic dust removal device has the advantages of reasonable design, high dust removal efficiency and rapid dust removal speed, can prevent a worker from being in direct contact with boiler flue gas and also can prevent the external environment from being polluted by the boiler flue gas; energy saving and environment protection are realized so that the device is suitable for being popularized.

Owner:江苏工腾自控阀门有限公司

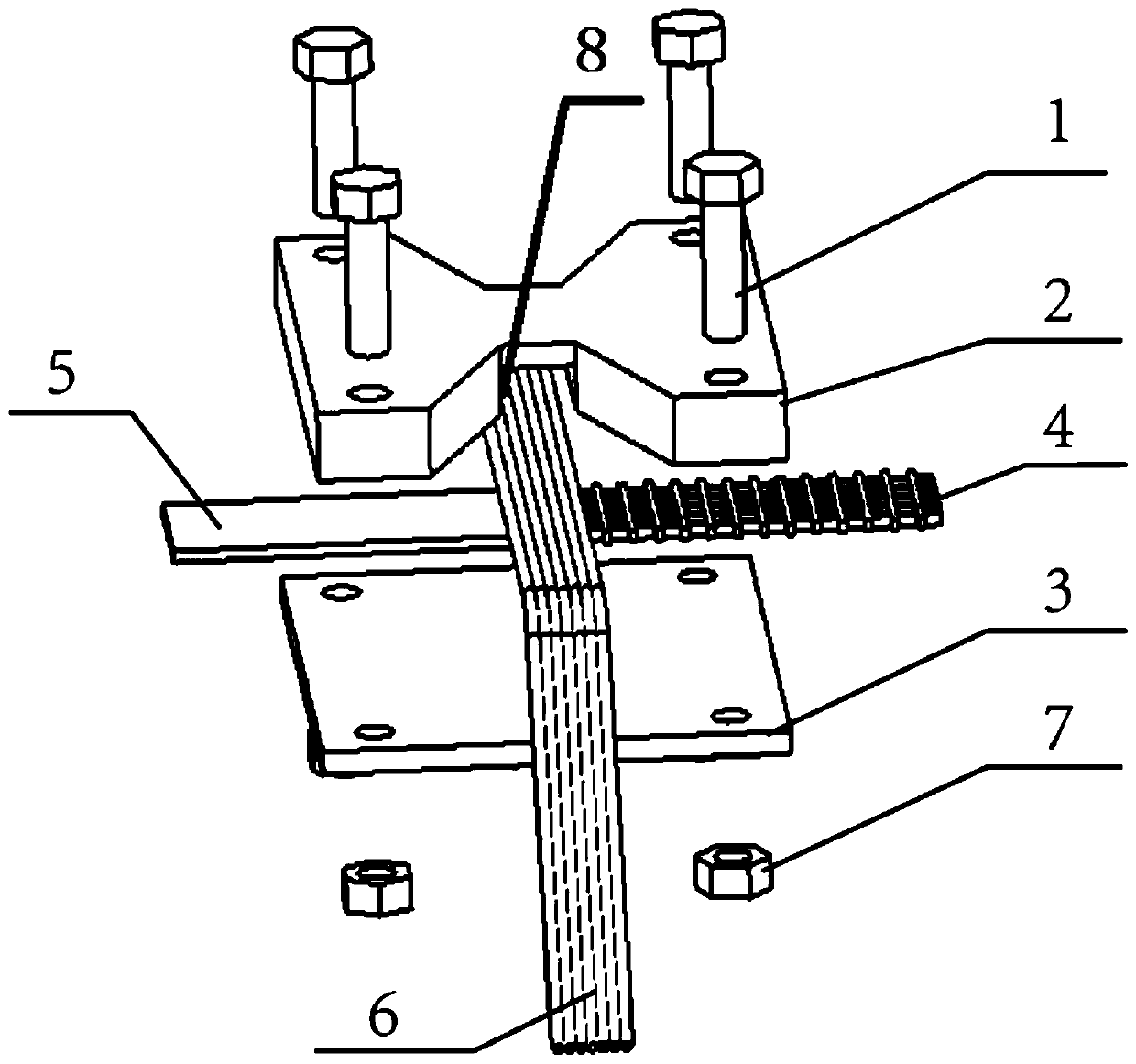

Boss molding process for pipe

InactiveCN105642724AInfluence flowAffect small fitting 1 to impede flowMechanical engineeringExtrusion

The invention relates to a boss molding process for a pipe. The boss molding process for the pipe comprises the following steps that 1, a material is fetched, the pipe to be machined is put on a lower pipe clamping groove of a lower clamp firstly, and the to-be-machined end of the pipe is kept to extend out of a lower half female die of the lower clamp; 2, the pipe is clamped, then an upper clamp and the lower clamp are started to oppositely move for die assembly, the lower half female die and an upper half female die are spliced into a pipe type curve female die, an upper pipe clamping groove of the upper clamp and the lower pipe clamping groove of the lower clamp are spliced into a pipe type cavity and clamps the pipe tightly, and a pipe orifice of the to-be-machined end of the pipe is kept to be aligned at a positioning pin on a stamping die; 3, stamping is conducted, the stamping die is started, an annular stamping concave cavity between the positioning pin and a curve male die starts to stamp the outer wall of the pipe, and an arc-shaped annular boss is formed on the outer wall of the pipe under the extrusion effect of the pipe type curve female die and the curve male die; and 4, the pipe is taken out. Compared with an existing arc-shaped annular boss molding process, the boss molding process for the pipe is simple, low in production cost and high in production efficiency.

Owner:FOSHAN GUANGTENG NEW ENERGY CO LTD

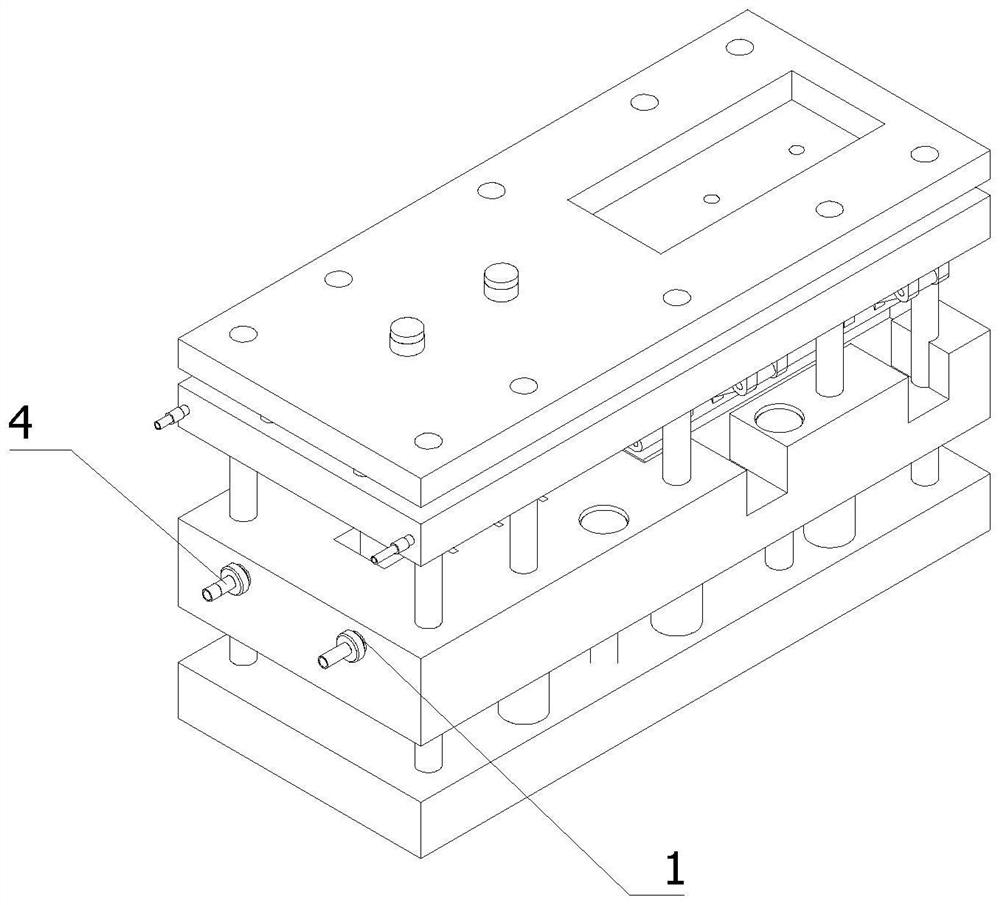

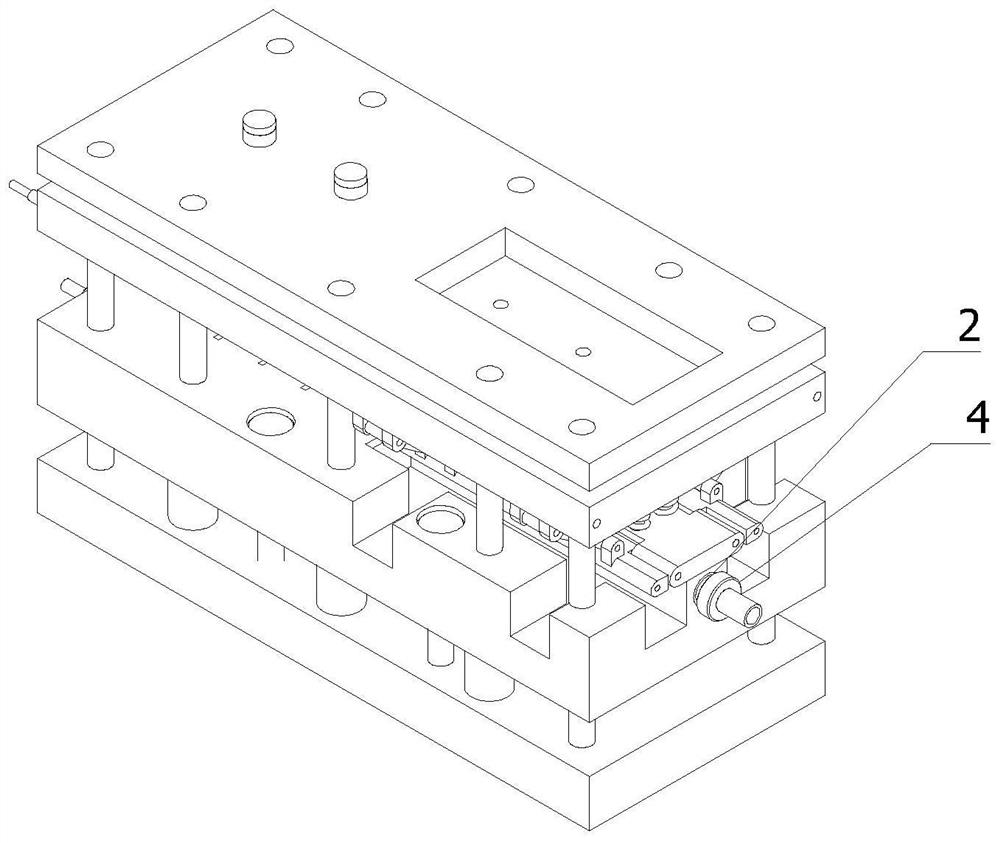

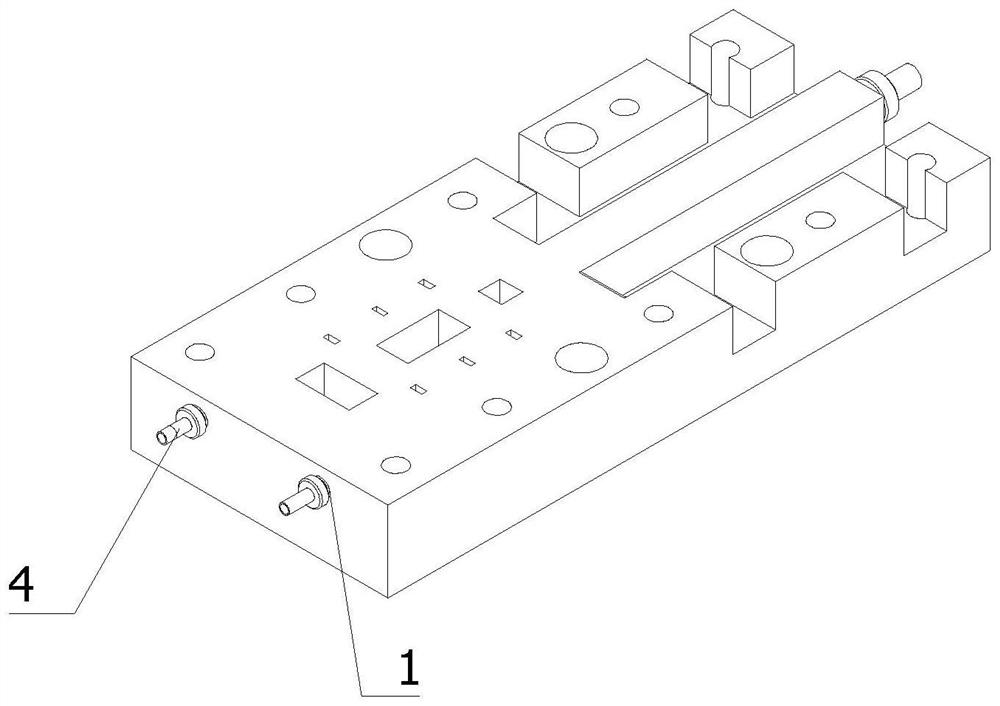

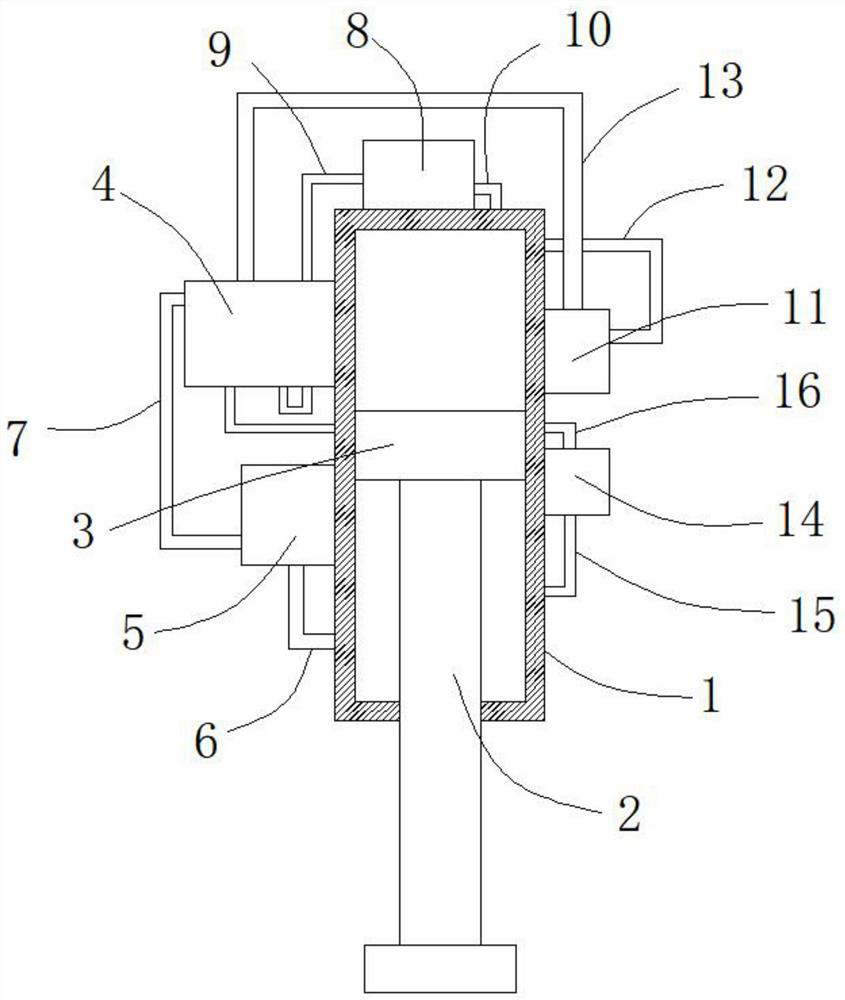

Cooling device of stamping die for automobile parts

PendingCN114178415AThe overall impact is smallEnsure structural stabilityShaping toolsPerforating toolsPunchingEngineering

The invention relates to the technical field of automobile stamping part production, in particular to a cooling device of a stamping die for automobile parts, which comprises a water inlet and a water outlet arranged on the side surface of the die, at least one group of cooling units penetrating through the interior of the die is arranged between the water inlet and the water outlet, and the cooling units are used for directional flow of cooling liquid; the cooling unit comprises two first cooling water channels which are symmetrically arranged, the first cooling water channels are parallel to each other and horizontally extend, the first cooling water channels are arranged in the lower die, and each first cooling water channel is provided with a bending area for avoiding a model punching hole and a positioning pin hole; and the cooling unit further comprises a second cooling water channel, the second cooling water channel is arranged in the upper die and used for dissipating heat for the punch, and the technical scheme solves the technical problem of how to enable cooling liquid to be rapidly cooled in the die while the integrity of the die is not affected.

Owner:宫方方

Hydraulic mechanical equipment with foreign matter removing and preheating functions

InactiveCN112211873ANo cloggingAvoid affecting flowThermal insulationPipe protection by thermal insulationForeign matterHydraulic cylinder

The invention belongs to hydraulic equipment, and particularly relates to hydraulic mechanical equipment with foreign matter removing and preheating functions. The hydraulic mechanical equipment comprises a cylinder body, wherein a piston matched with the inner wall of the cylinder body is mounted in an inner cavity of the cylinder body, a telescopic rod is fixedly connected to the bottom of the piston, and the telescopic rod penetrates through the cylinder body and extends to the outer wall of the cylinder body. An electromagnet is used for attracting metal impurities, so that the metal impurities can be concentrated on the surface of the electromagnet, the situation that a filter screen is blocked is avoided, oil flowing is effectively prevented from being influenced, operation of the hydraulic cylinder is prevented from being influenced, and efficient operation of the hydraulic cylinder is effectively guaranteed.

Owner:江西玉祥智能装备制造有限公司

Sewage filtering equipment with anti-blocking function

InactiveCN108786217AEasy and quick installation and removalEasy to clean and replaceStationary filtering element filtersSewageImpurity

The invention discloses sewage filtering equipment with an anti-blocking function. The sewage filtering equipment comprises a filtering chamber, wherein a water inlet pipe and a water outlet pipe arecommunicated onto the filtering chamber; a servo double-shaft motor is arranged on the filtering chamber; each of two output ends of the servo double-shaft motor is fixedly connected with a rotating shaft; two first installing blocks and a second installing block are fixedly connected onto the inner wall of the filtering chamber; a first rotating shaft is rotationally connected between the two first installing blocks. The sewage filtering equipment has the advantages that when insoluble impurities floating on the sewage are filtered, a scraping plate is used for performing continuous scrapingon the filter screen surface; the filtering speed influence since too many insoluble impurities are adhered on the filter screen is avoided; the rotation of a second round fixing disc and a rotating rod are utilized, so that vortexes can be formed at the surface of water in the filtering chamber; the insoluble impurities floating on the water surface are gathered in the vortexes or near the vortexes; the contact of a large number of insoluble impurities and the filter screen is avoided.

Owner:WENZHOU HAIDENENG ENVIRONMENTAL PROTECTION EQUIP & TECH

Control transformer for low-consumption and energy-saving elevator

InactiveCN113096931AImprove cooling efficiencyImprove cooling effectTransformers/reacts mounting/support/suspensionTransformers/inductances coolingElectrical and Electronics engineeringMechanical engineering

The invention belongs to the field of transformers, particularly relates to a control transformer for a low-consumption and energy-saving elevator, and aims to solve the problems that the service life of an existing transformer is shortened due to the fact that the existing transformer lacks an effective heat dissipation device and is poor in heat dissipation effect. The control transformer comprises a shell and a transformer body, a first mounting cavity and a second mounting cavity are formed in the shell, an annular sliding groove is formed in the inner wall of the bottom of the first mounting cavity, a sliding ring is slidably mounted in the annular sliding groove, a placement plate is fixedly connected to the top of the sliding ring, and the transformer body is arranged at the top of the placement plate. The transformer body can be subjected to larger-area and more comprehensive air blowing heat dissipation, the situation that the transformer body is covered by dust to affect heat dissipation of the transformer body is avoided, meanwhile, cleaning can be conducted on a second dustproof net plate, the situation that the second dustproof net plate is blocked to affect airflow flowing, and consequently the heat dissipation efficiency is reduced is avoided, and the service life of the transformer body is effectively prolonged.

Owner:NANTONG MILANTE ELECTRIC

Breathing-type anaesthesia machine

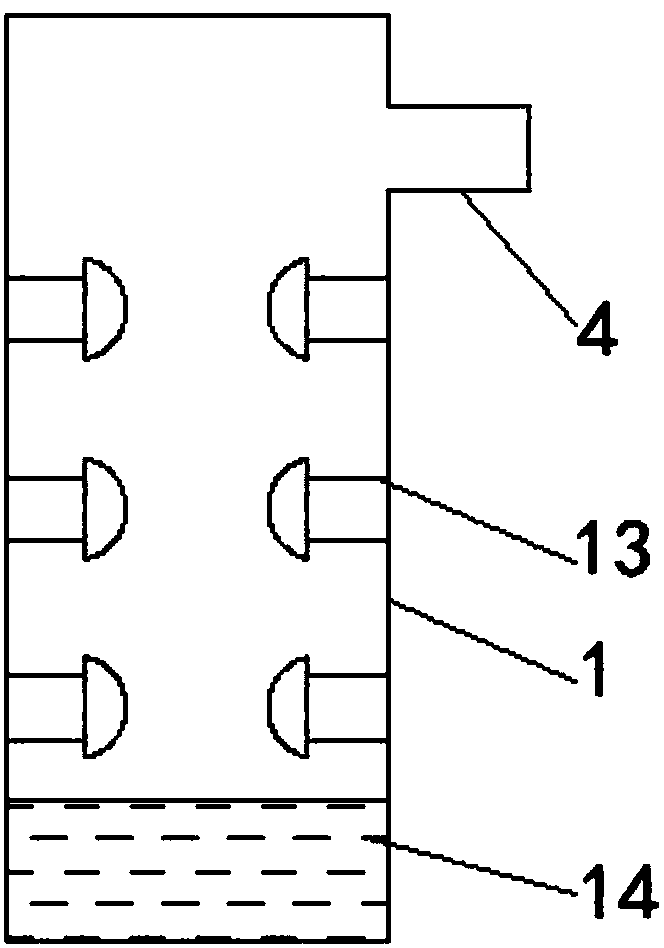

InactiveCN107583156AAvoid backflow phenomenonInfluence flowRespiratorsPulp and paper industryCatheter

The invention discloses a breathing-type anaesthesia machine. The machine includes an accommodating cavity, a collecting box and a reaction chamber; the accommodating cavity, the collecting box and the reaction chamber are arranged sequentially from left to right, a first catheter is fixedly connected between the accommodating cavity and the collecting box, a second catheter is fixedly connected between the collecting box and the reaction chamber, and the top of the collecting box is connected with a breathing machine through one-way valves arranged at equal intervals; the two sides of the topend of the breathing machine are fixedly provided with a breathing air inlet and a breathing air outlet respectively; the center of the inner wall of the breathing machine is connected with a first clapboard, the side, close to one end of the breathing air outlet, of the breathing machine is connected with a fresh air pipe, the end, close to the first catheter, of the inner wall of the accommodating cavity is provided with sprayers arranged in a rectangular array mode, and a settling pond positioned below the sprayers is arranged on the bottom of the inner wall of the accommodating cavity. The breathing-type anaesthesia machine has the advantages that the structure is simple, patients can be directly anesthetized by utilizing breathing of the human body, the pain is relieved, and since the breathing machine is provided with a cleaning device, the breathing machine is convenient to use.

Owner:WUHAN HAOHONG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com