Patents

Literature

234results about How to "Affect cleaning effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

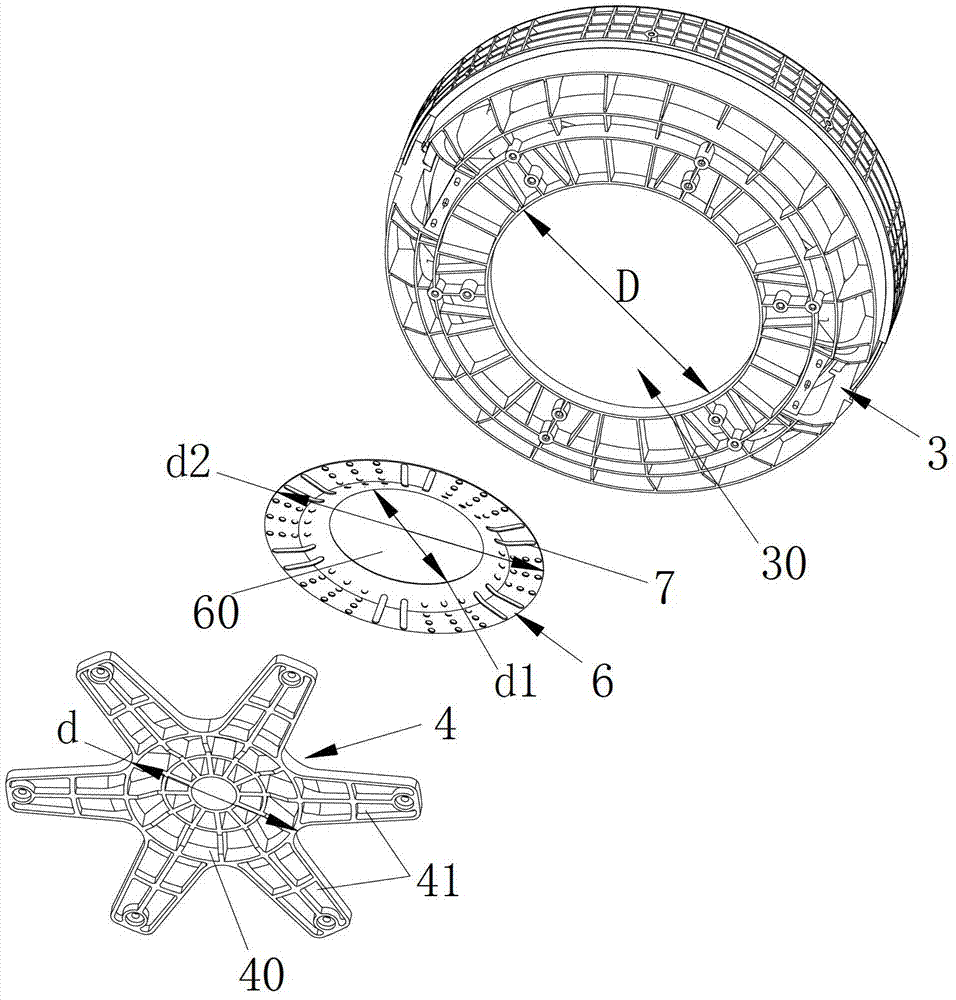

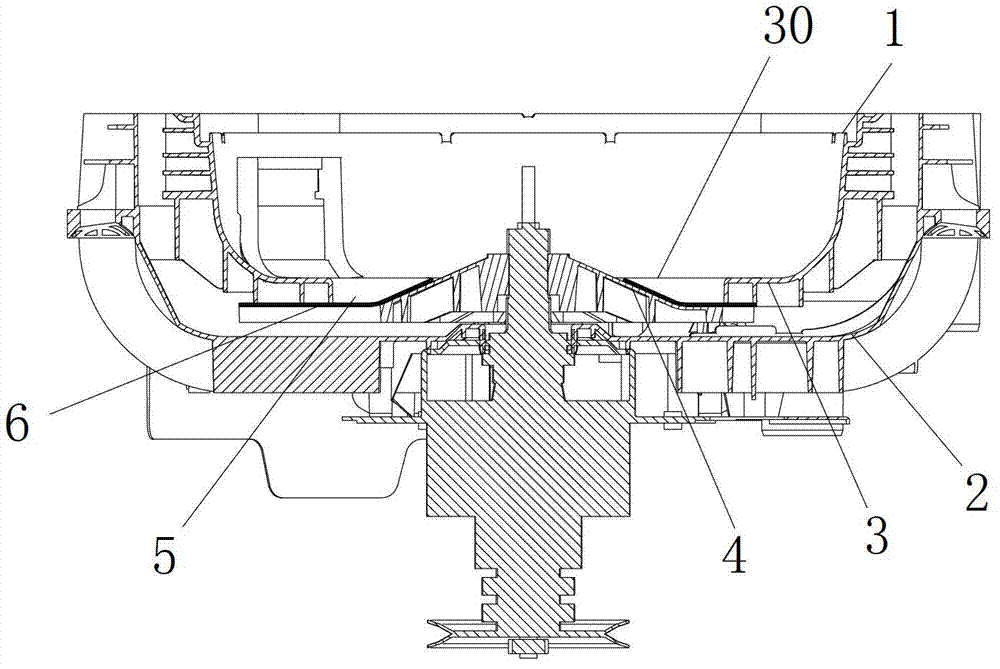

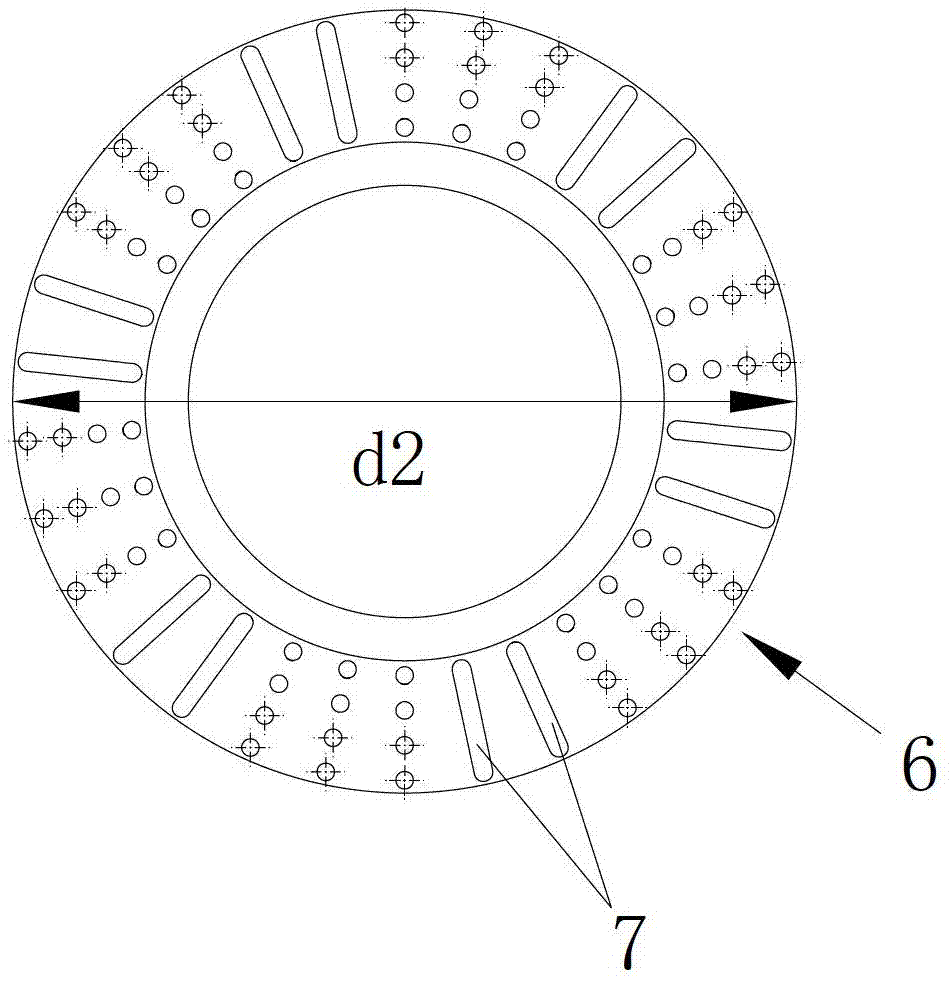

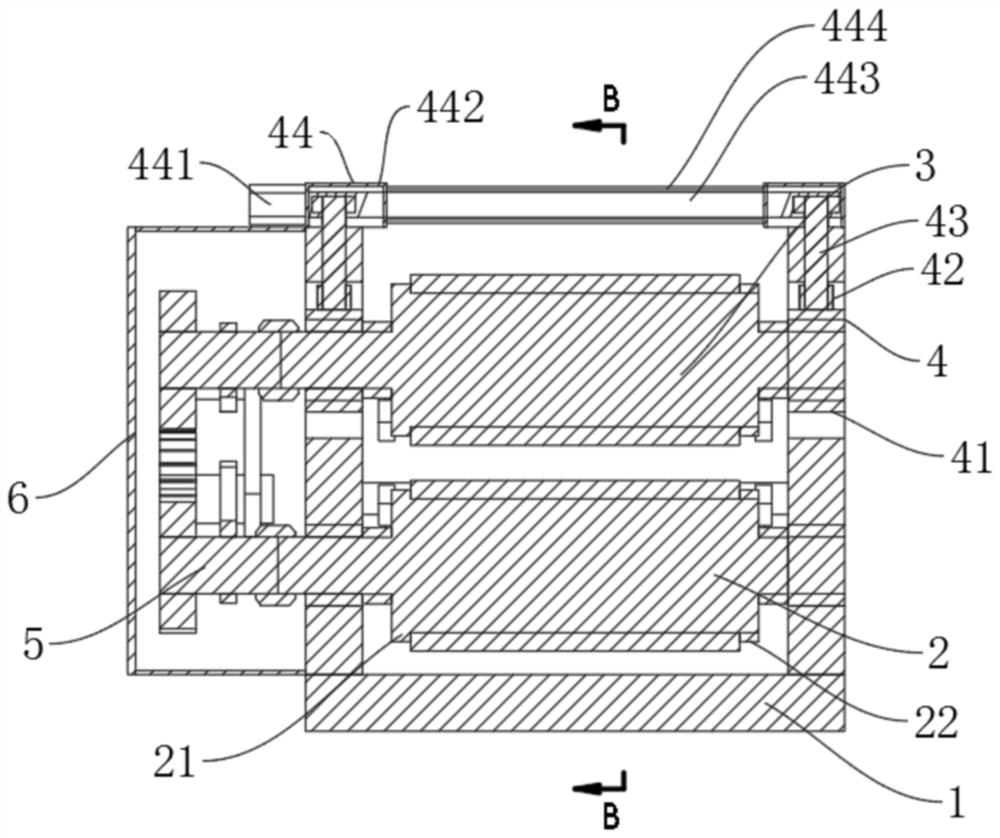

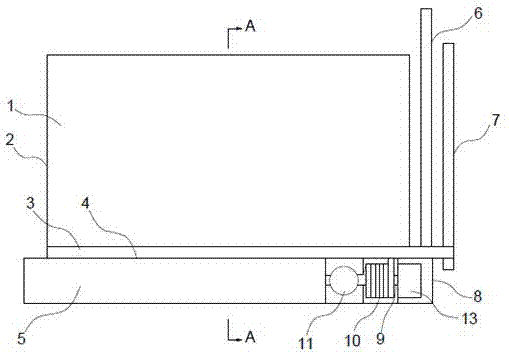

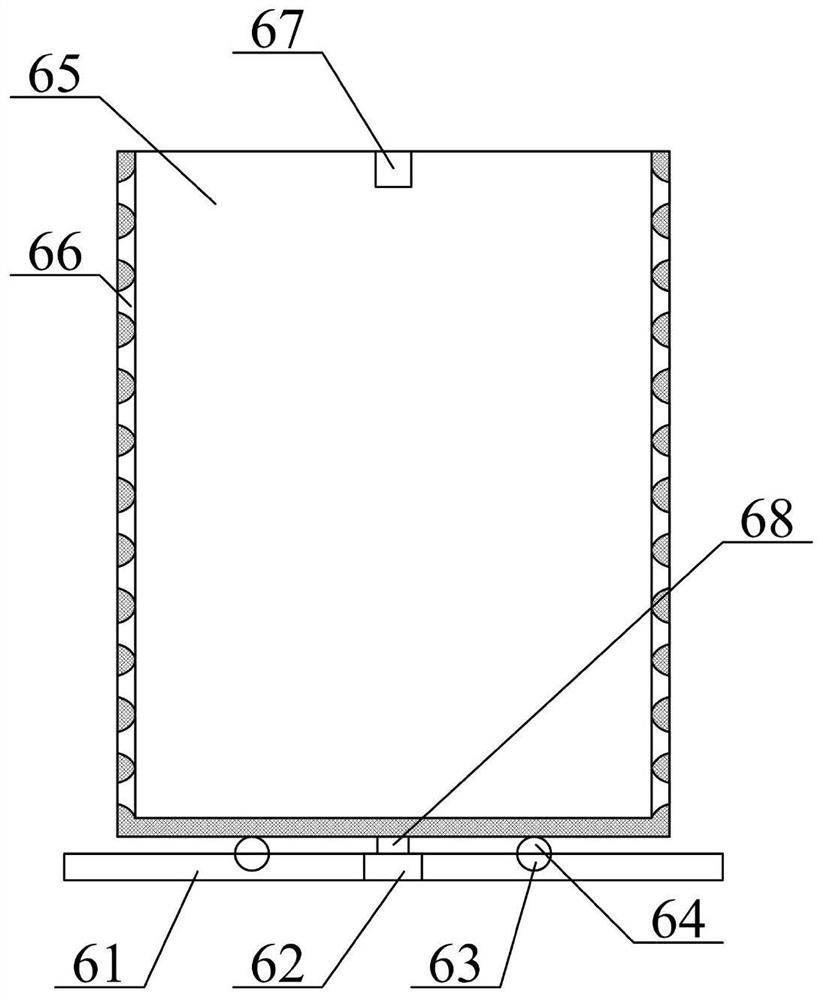

Inner barrel structure of washing machine and washing machine with inner barrel

ActiveCN102733146AImpact collectionGuaranteed effectOther washing machinesTextiles and paperEngineeringPermeable channel

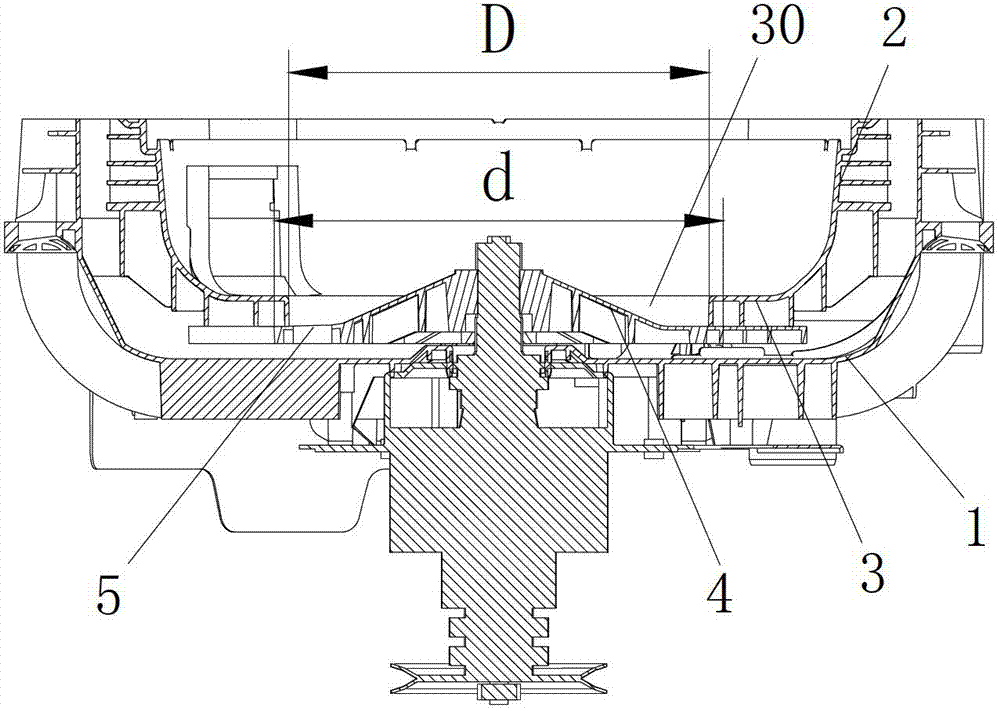

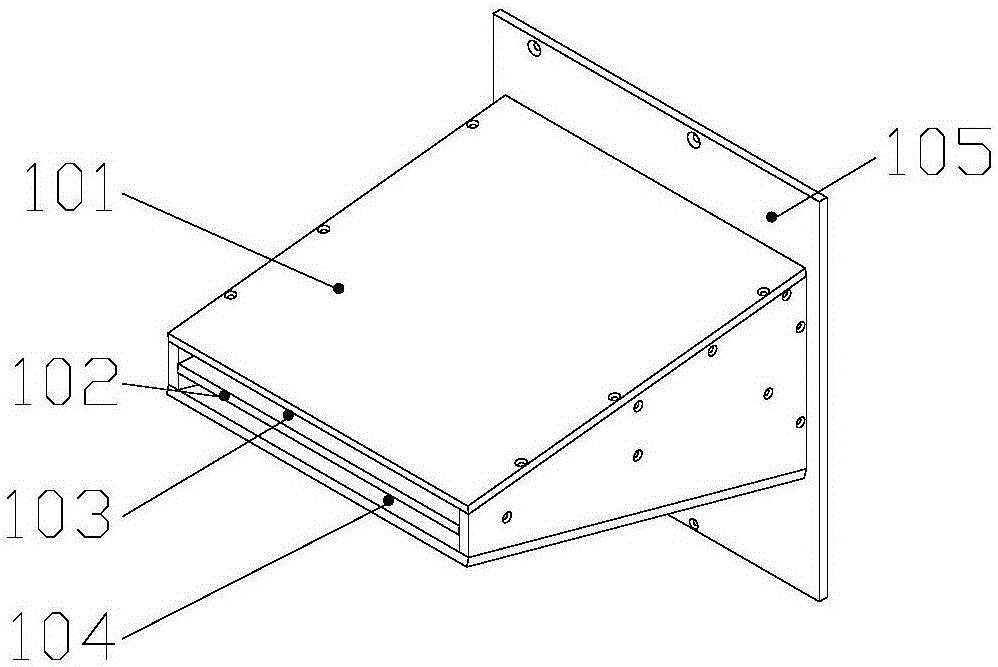

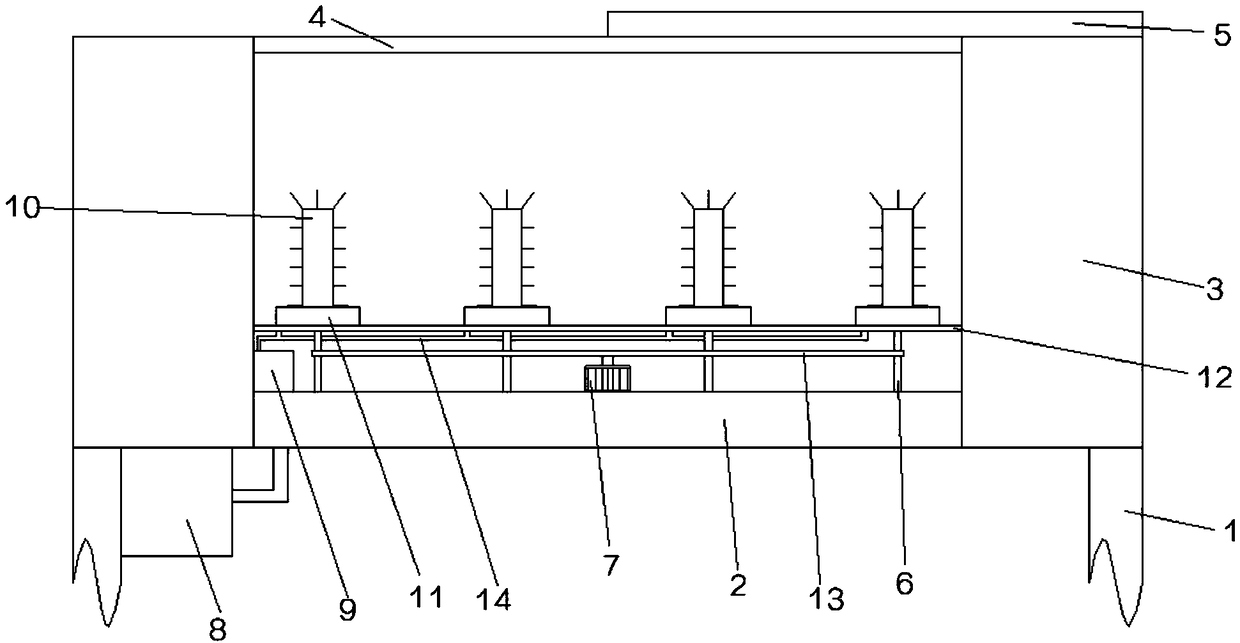

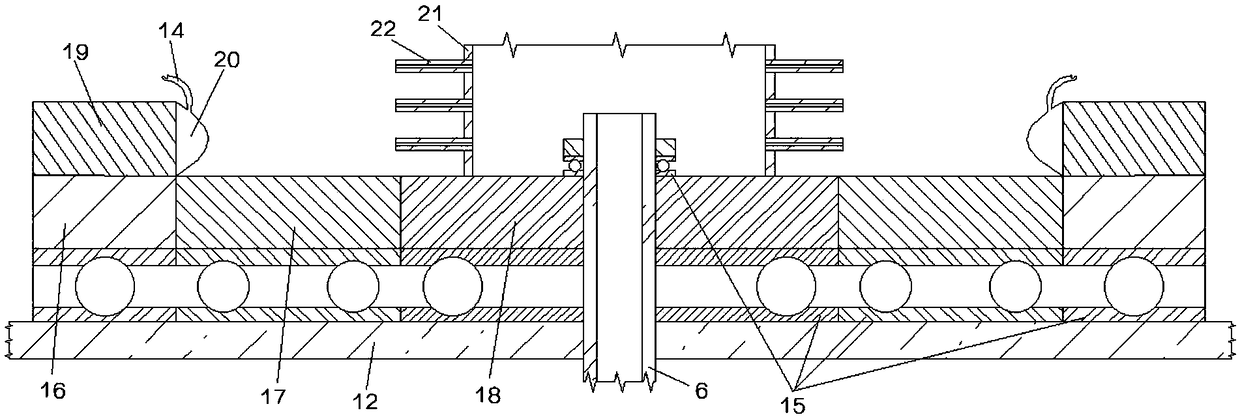

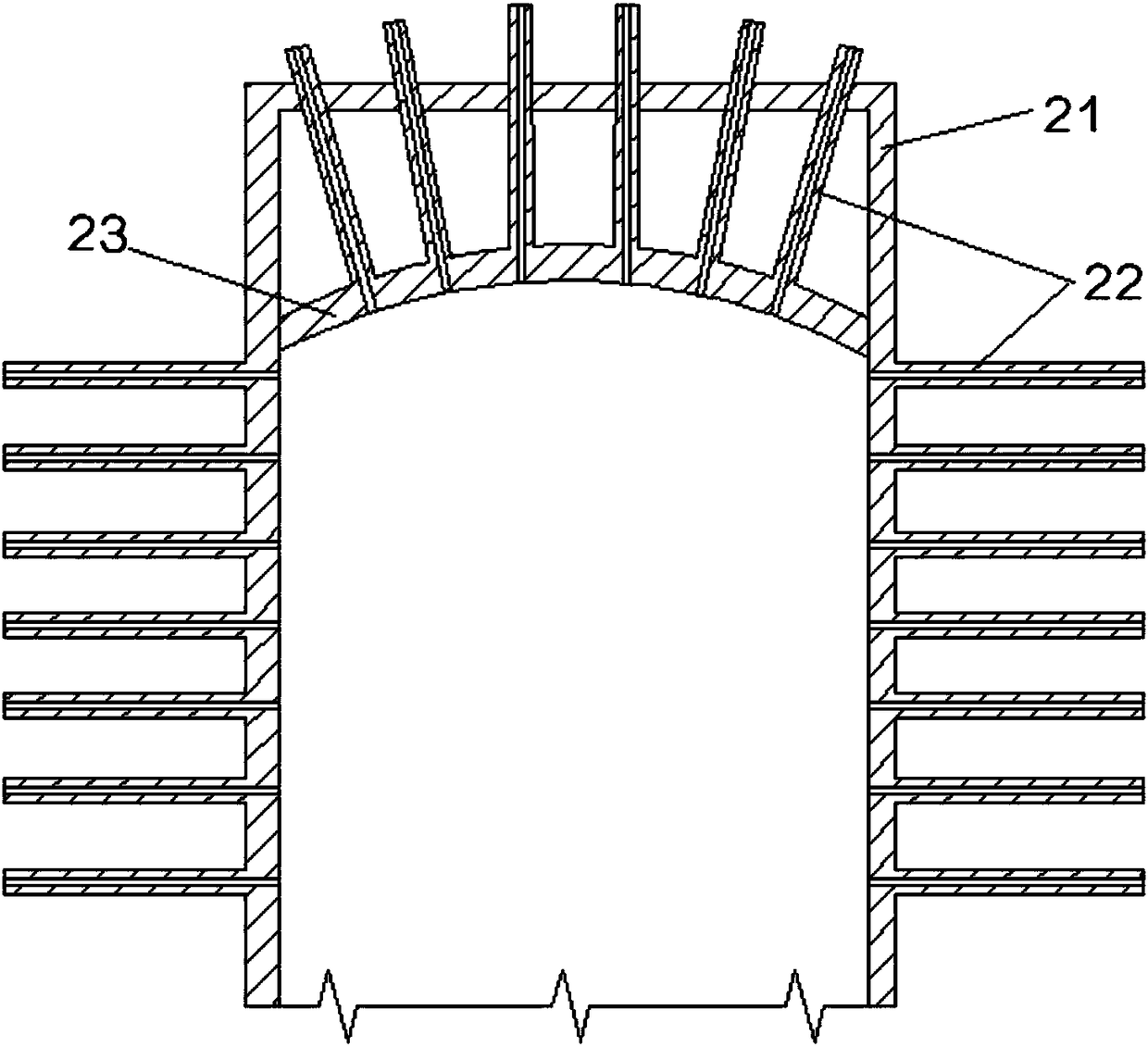

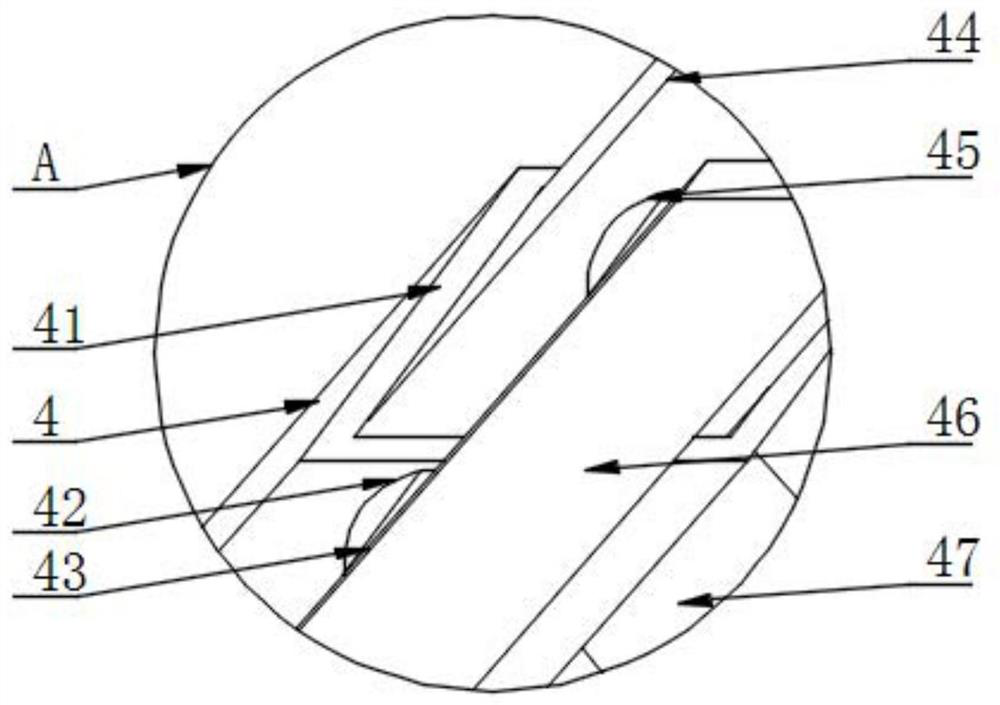

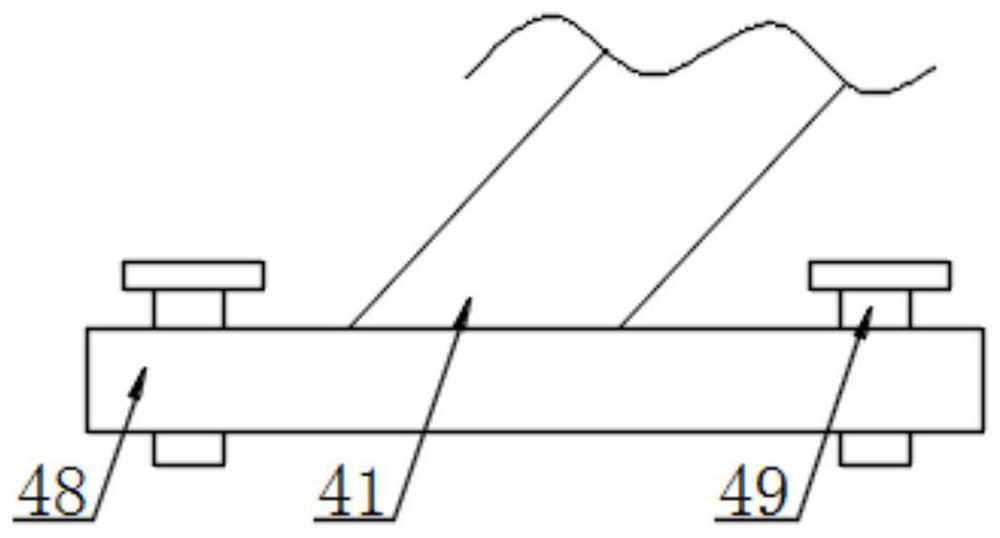

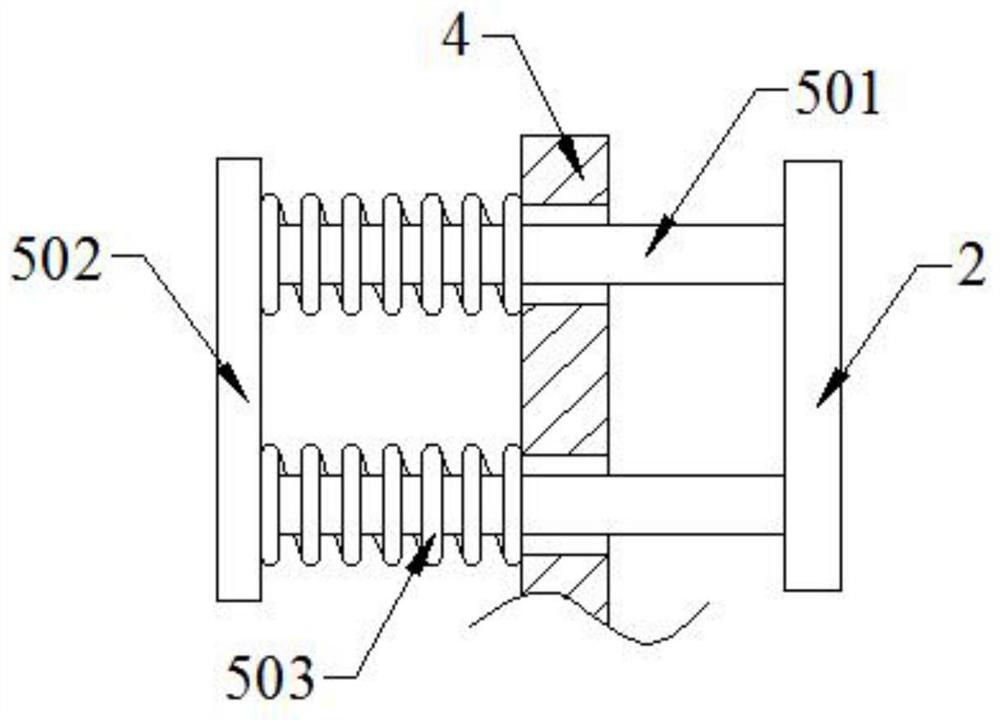

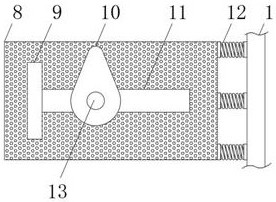

The invention discloses an inner barrel structure of a washing machine and a washing machine with the inner barrel. The inner barrel is coaxially arranged in an outer barrel of the washing machine; cleaning particles for cleaning the walls of the barrels are arranged between the inner barrel and the outer barrel; a flange plate is arranged at the bottom part of the inner barrel; the flange plate and a hollow area at the bottom part of the inner barrel form a permeable channel; a baffle cover for preventing the cleaning particles from entering into the inner barrel via the permeable channel is arranged between the bottom part of the inner barrel and the flange plate; a permeable hole is formed on the baffle cover corresponding to the permeable channel; the baffle cover is a hollow annular cover body; and a protruding main body at the centre of the flange plate correspondingly blocks a hollow position of the baffle cover, and the permeable hole is distributed at the position of the annular cover body corresponding to the permeable channel. According to the invention, the structure of the baffle cover is simple; the installation cost is low; the cleaning particles between the inner barrel and the outer barrel can be prevented from entering into the inner barrel, and the problem that the cleaning particles enter into the inner barrel to affect the barrel wall cleaning effect is avoided.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

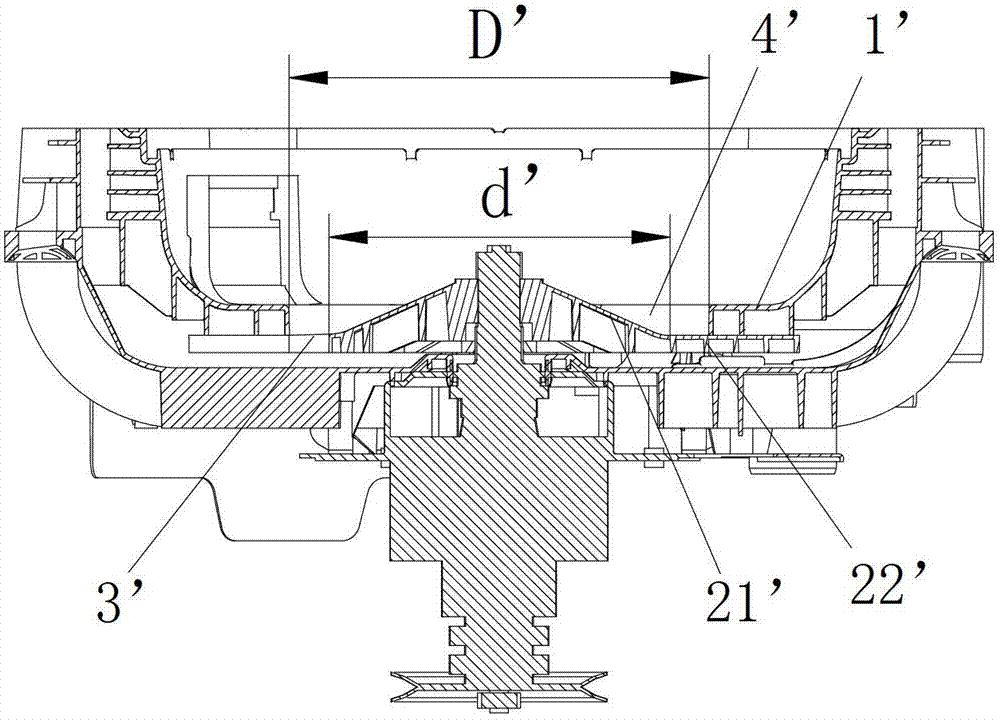

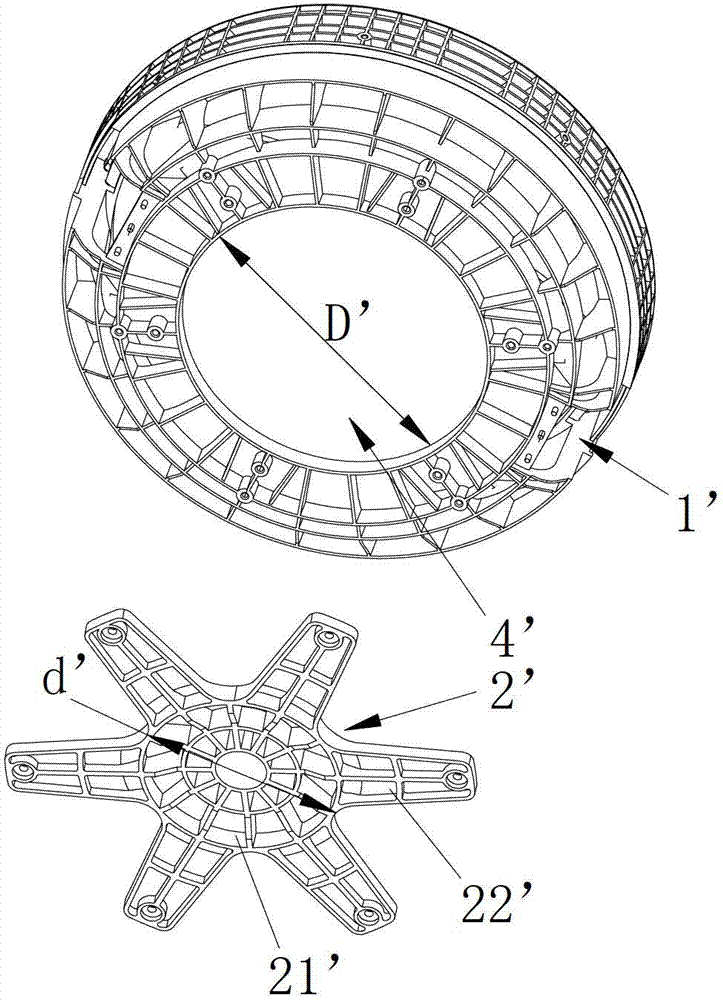

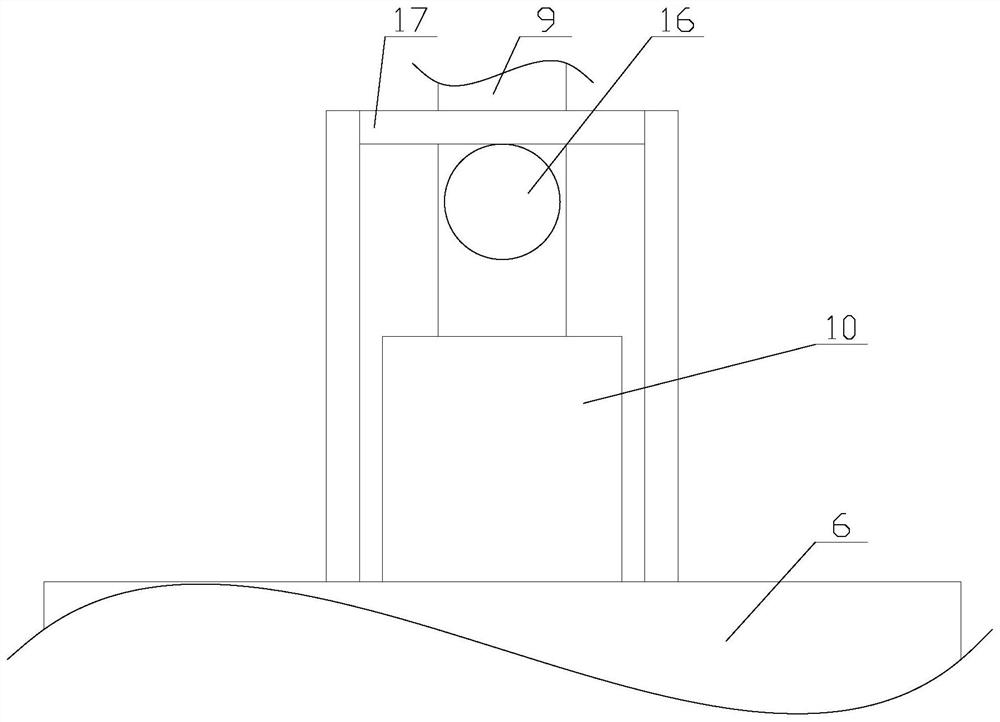

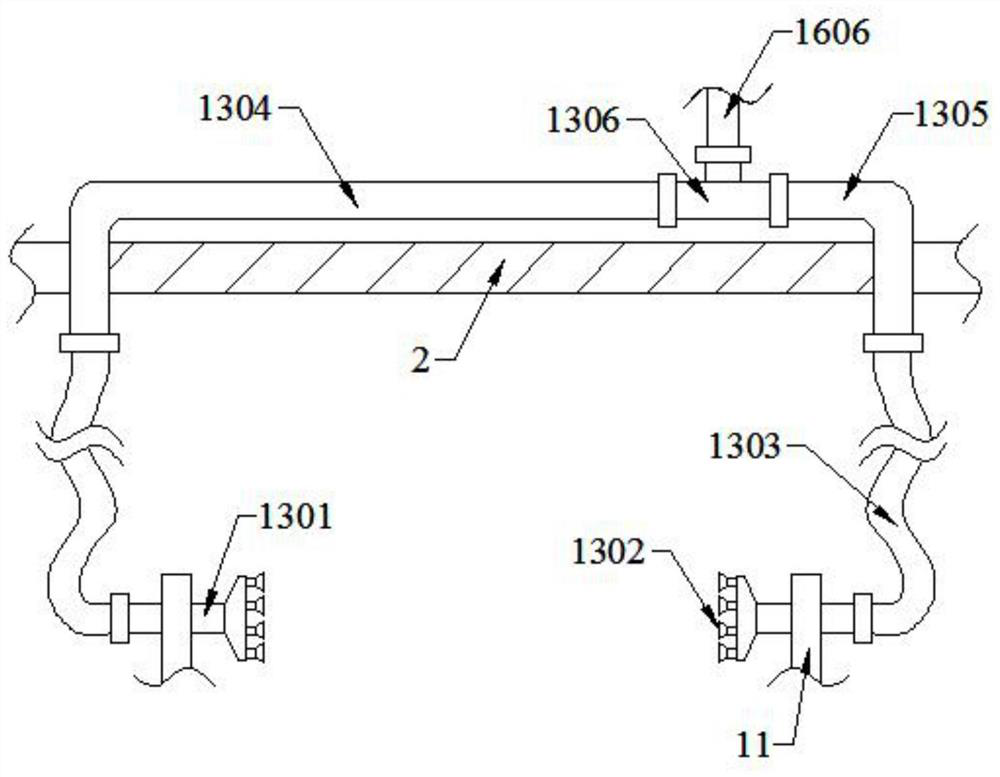

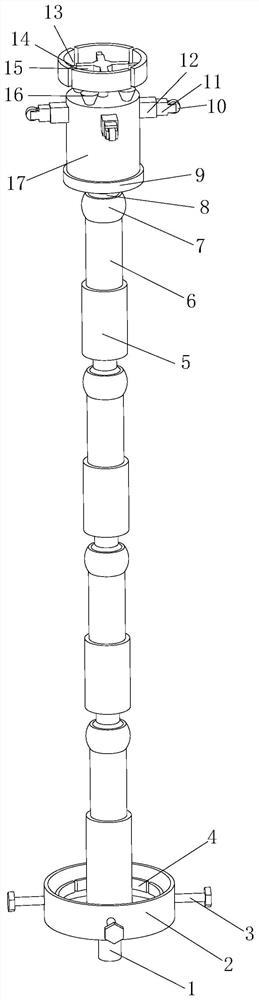

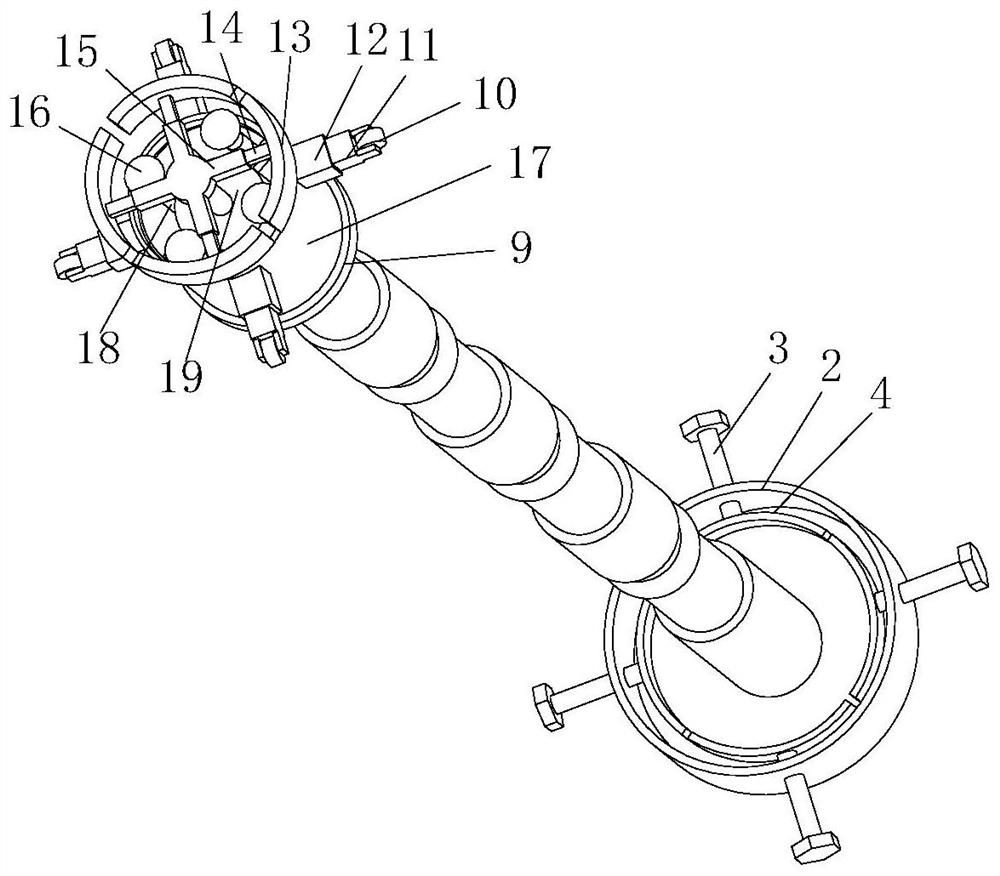

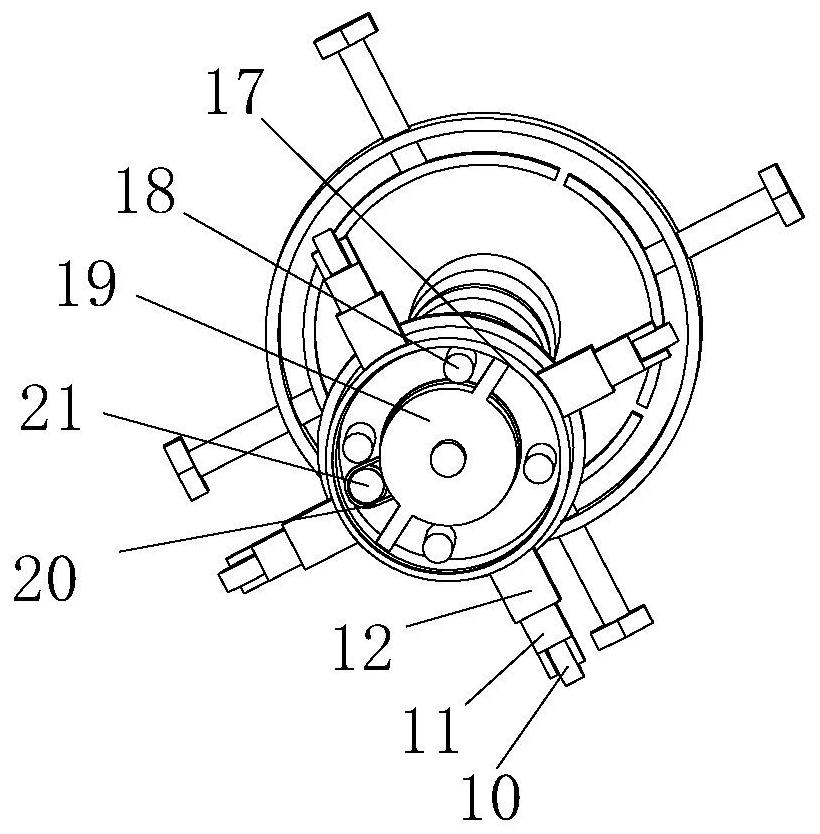

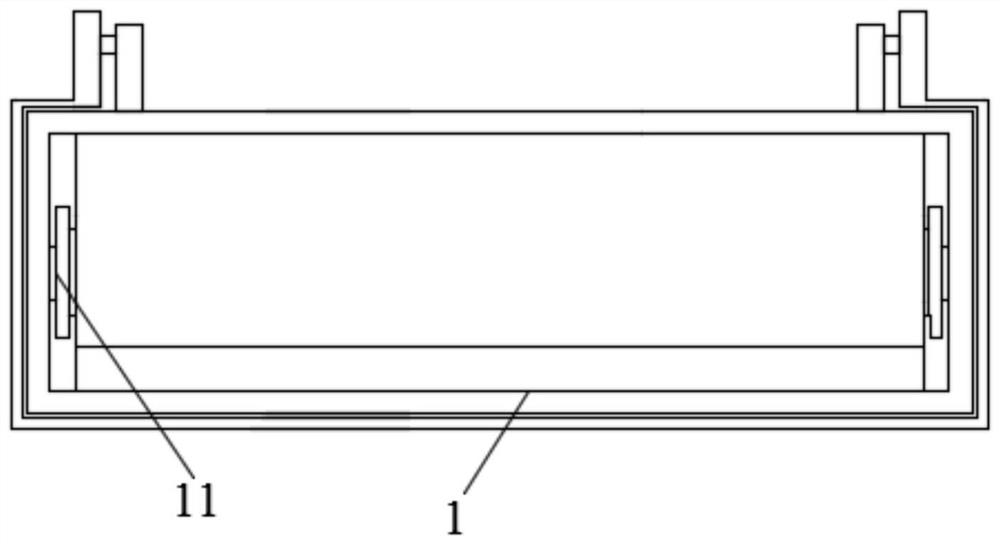

Flange mounting structure at bottom of inner barrel of washing machine and washing machine

ActiveCN102733148AEasy wiringDrain fastOther washing machinesTextiles and paperWater flowEngineering

The invention discloses a flange mounting structure at the bottom of an inner barrel of a washing machine and the washing machine. The washing machine has a function of cleaning barrel walls, and comprises an outer barrel and an inner barrel, wherein cleaning particles floating along with water flow are arranged between the outer barrel and the inner barrel to clean the barrel walls, and a flange capable of preventing the cleaning particles from entering the inner barrel from the bottom is arranged at the bottom of the inner barrel. The flange comprises a main body and mounting legs which are distributed around the main body and are fixed on the inner barrel; an area in the center of the bottom of the inner barrel corresponding to the main body of the flange is an up-down through opening; the diameter of the main body of the flange is more than or equal to the inner diameter of the opening, or is smaller than the inner diameter of the opening; and the size of a gap between the outer edge of the main body of the flange and the inner edge of the opening meets the requirement of preventing the cleaning particles from entering the inner barrel from the gap. The flange mounting structure is simple in structure and low in cost, can prevent the cleaning particles between the inner barrel and the outer barrel from entering the inner barrel, and achieves an effect of preventing the cleaning of the barrel walls from being influenced due to the decrease of the cleaning particles.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

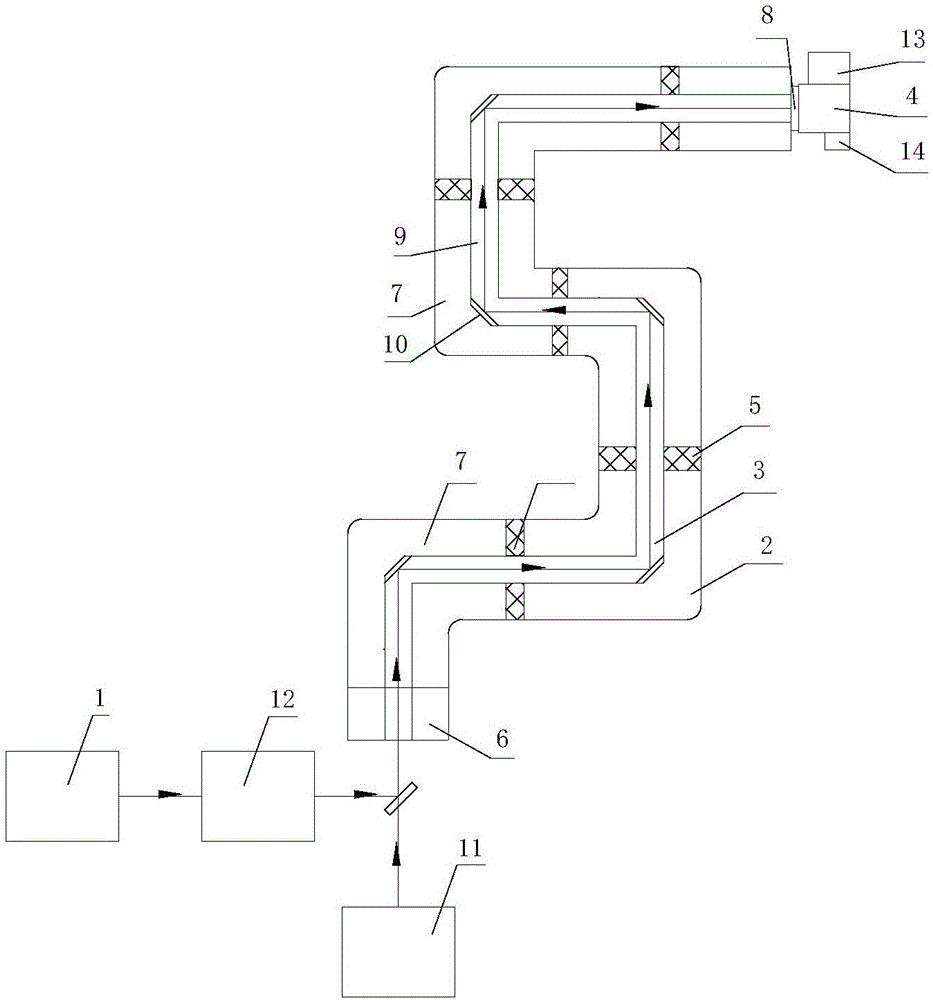

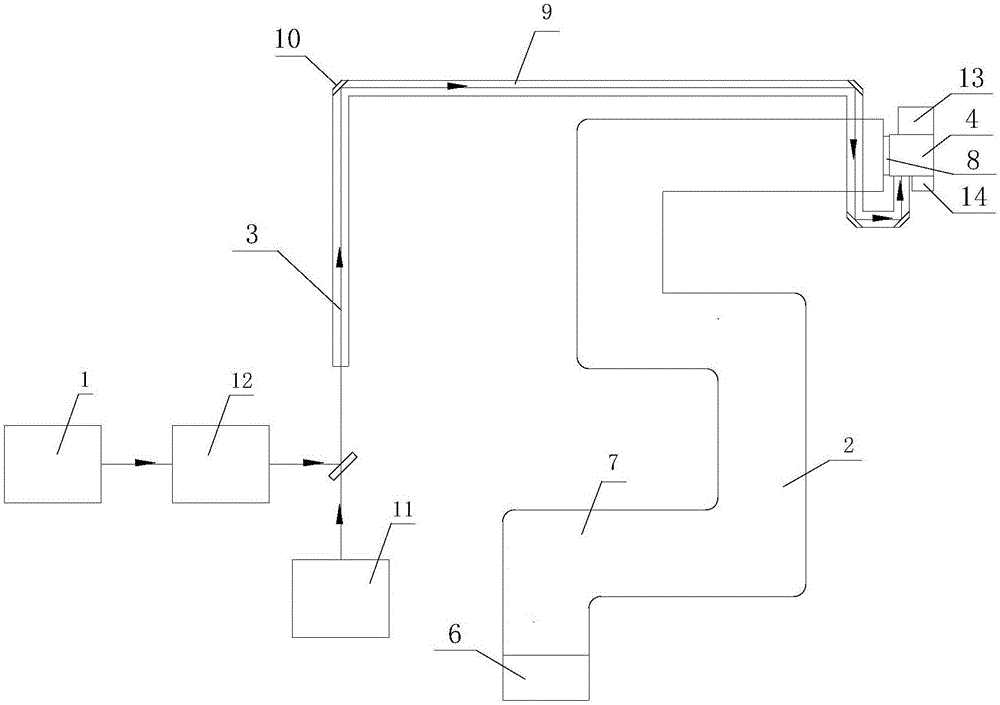

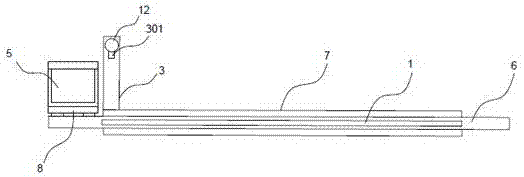

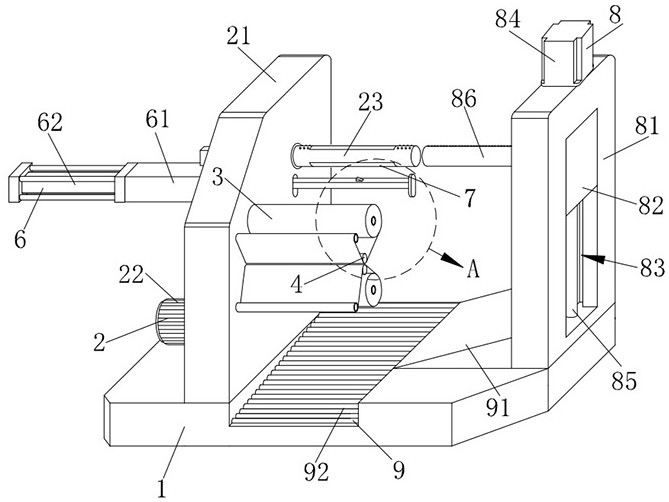

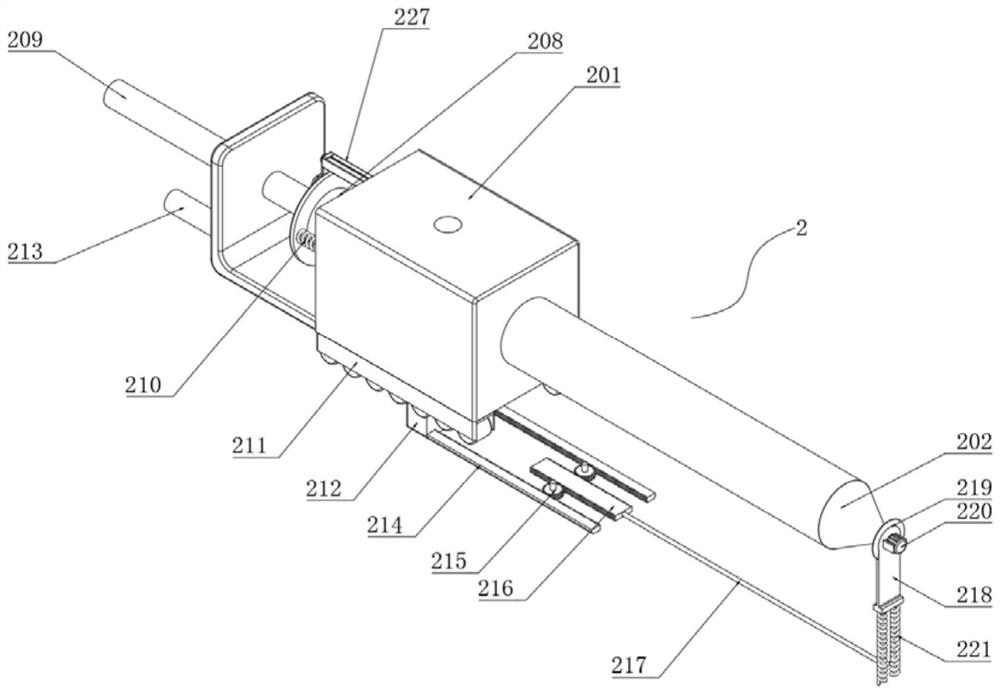

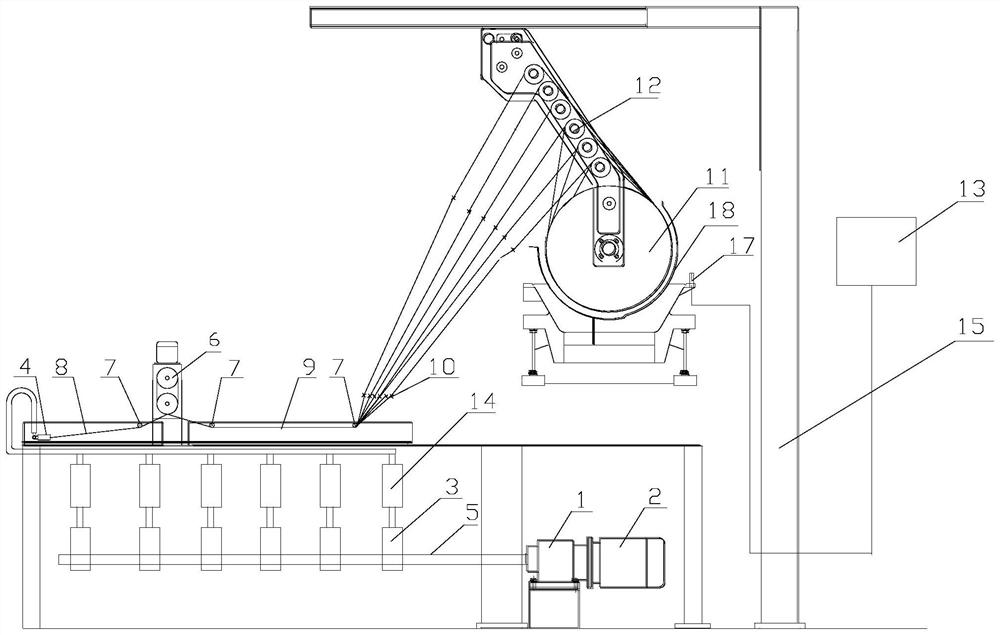

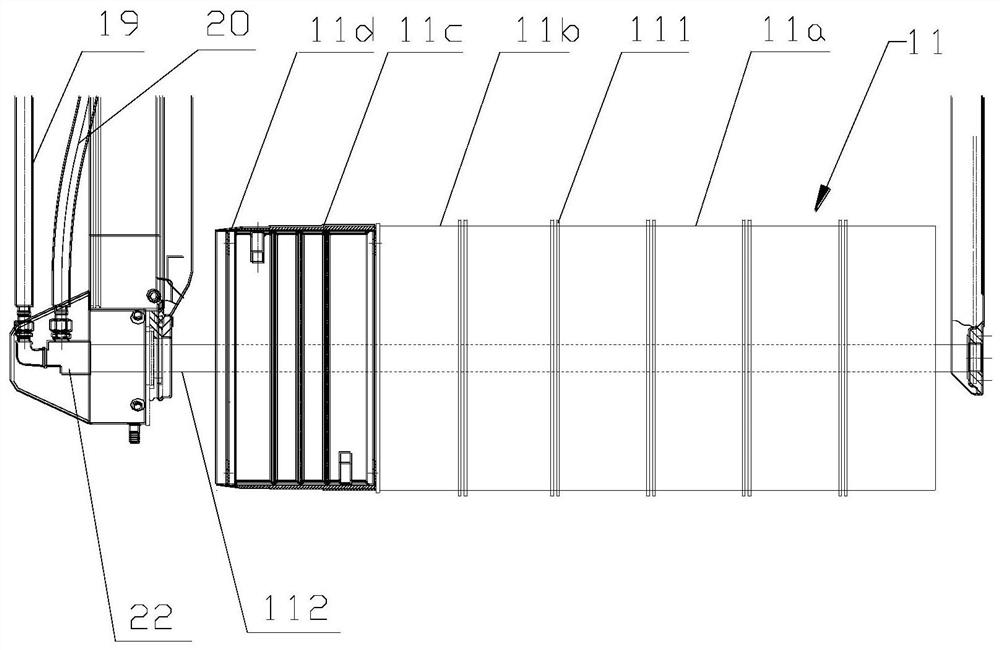

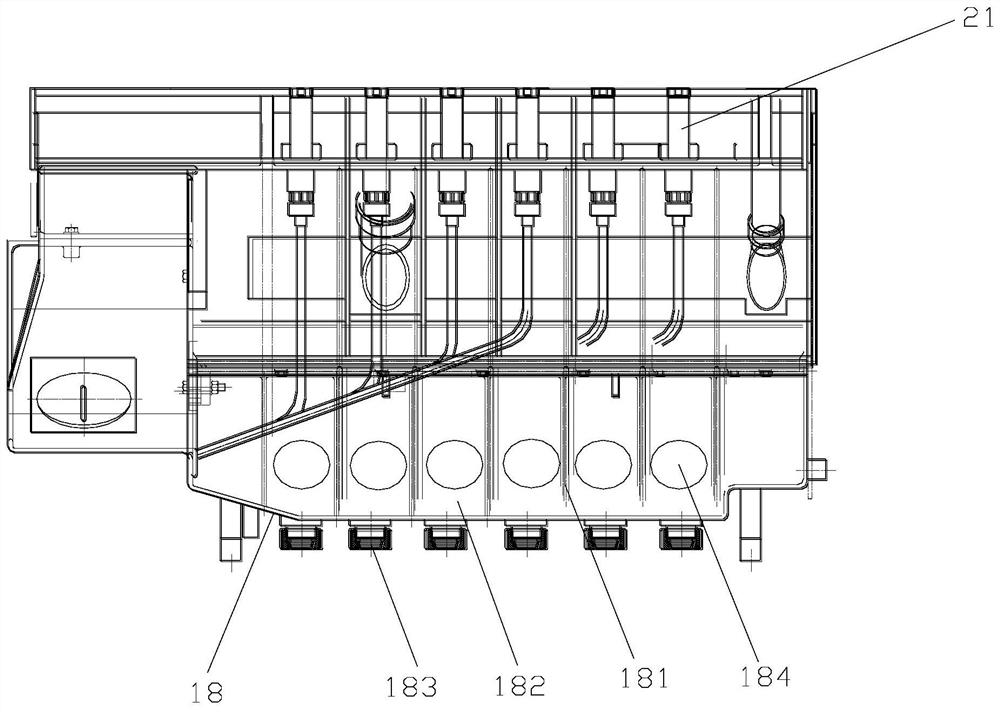

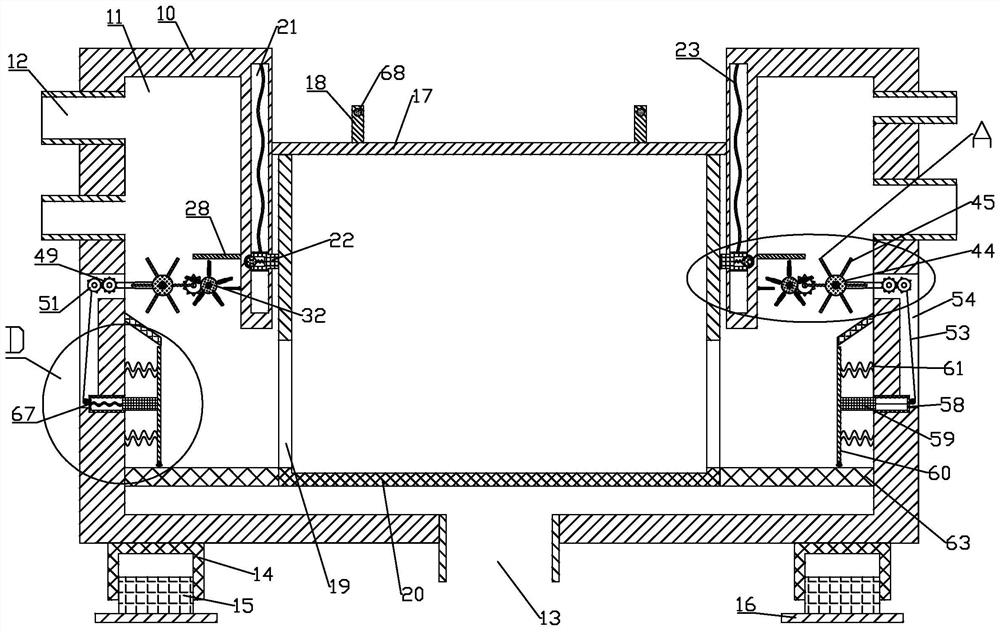

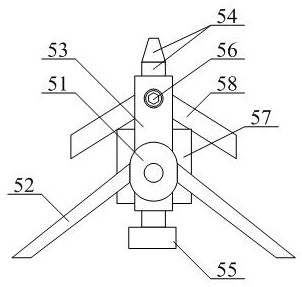

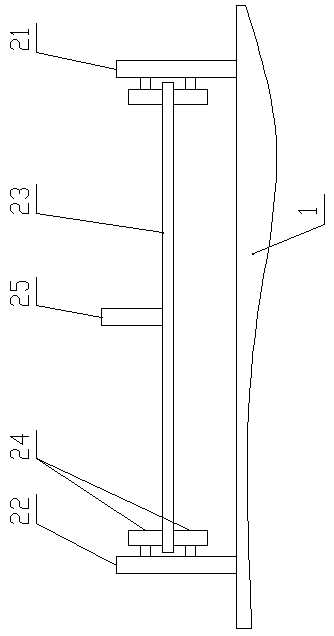

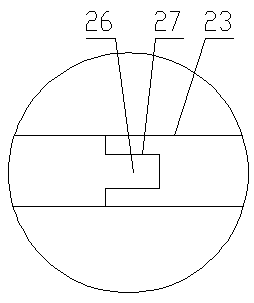

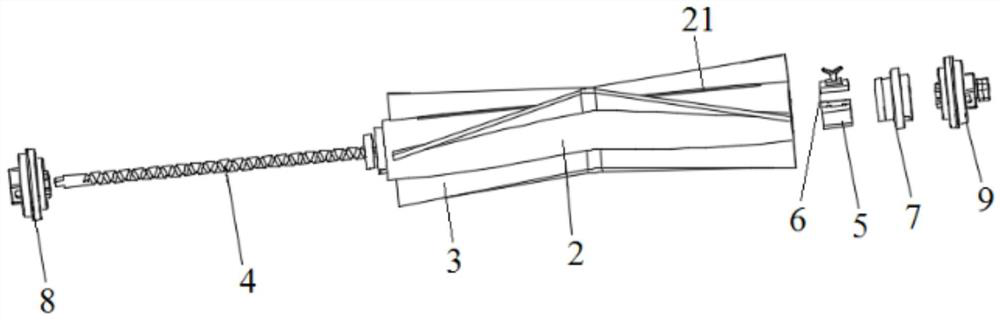

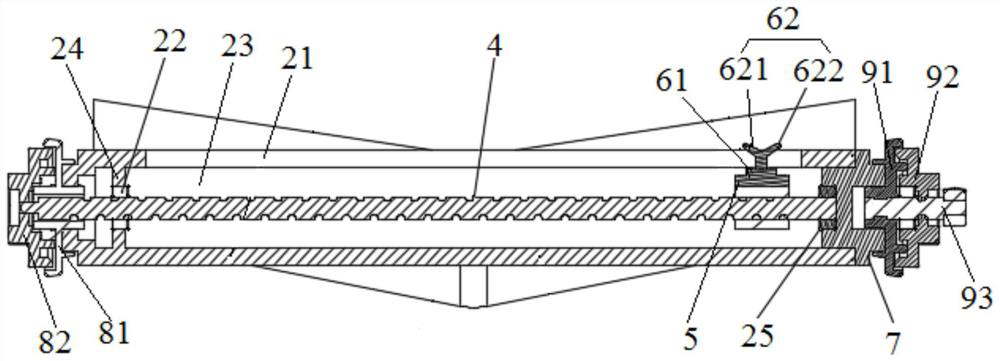

Laser cleaning device based on flexible optical path

PendingCN106733942AIncrease flexibilityImprove cleaning efficiencyCleaning using gasesAutomatic controlRobotic arm

The invention relates to a laser cleaning device based on a flexible optical path. The laser cleaning device comprises a laser, a mechanical arm, a light guide arm and a scanning mechanism, wherein the light guide arm is fixedly connected on the mechanical arm, and can move along with the mechanical arm; the laser is arranged close to one end of the light guide arm; the scanning mechanism is arranged close to the other end of the light guide arm; laser projected from the laser enters the light guide arm from an incident end of the light guide arm and enters the scanning mechanism after being projected from an emergent end of the light guide arm; the scanning mechanism can perform two-dimensional rotation; and the direction of laser entering the scanning mechanism is adjusted, laser penetrates through the scanning mechanism to scan a cleaning part, and cleaning is completed. According to the laser cleaning device, the mechanical arm and the light guide arm are combined, the light guide arm can freely rotate at all angles along with the mechanical arm, a traditional hard optical path is changed into the flexible optical path, flexibility of the device is greatly improved, and automatic control is facilitated.

Owner:WUHAN JINDUN LASER TECH CO LTD

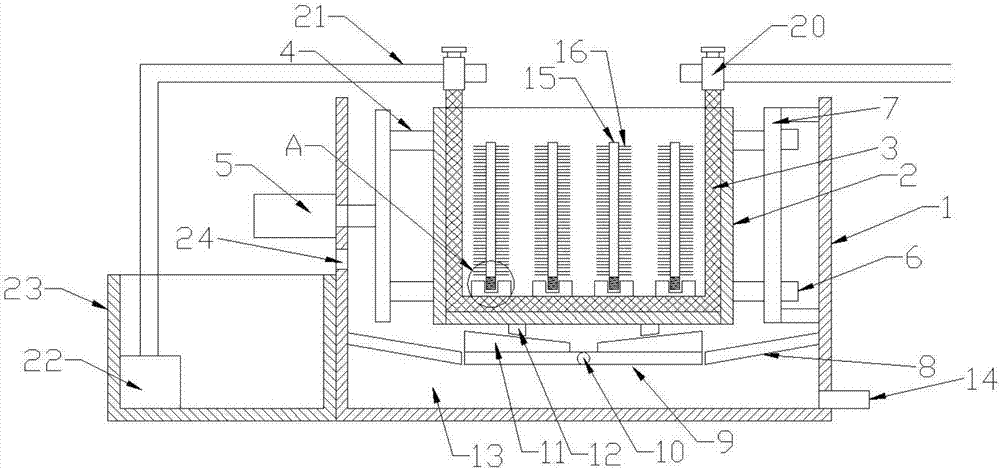

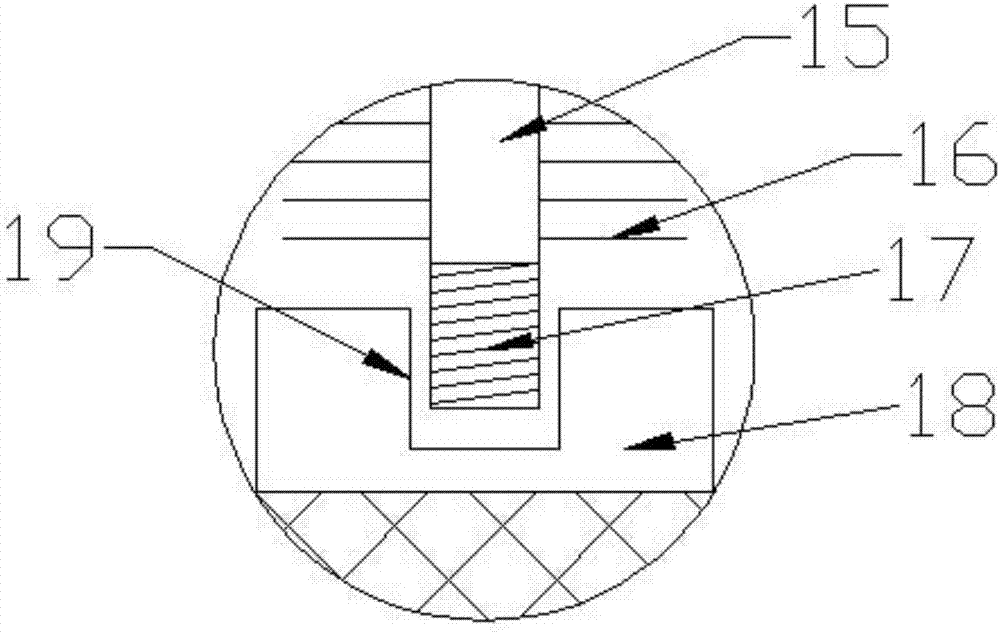

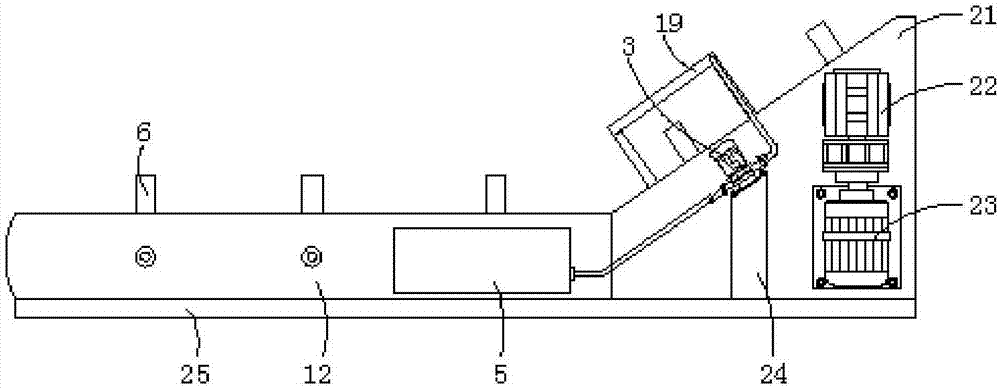

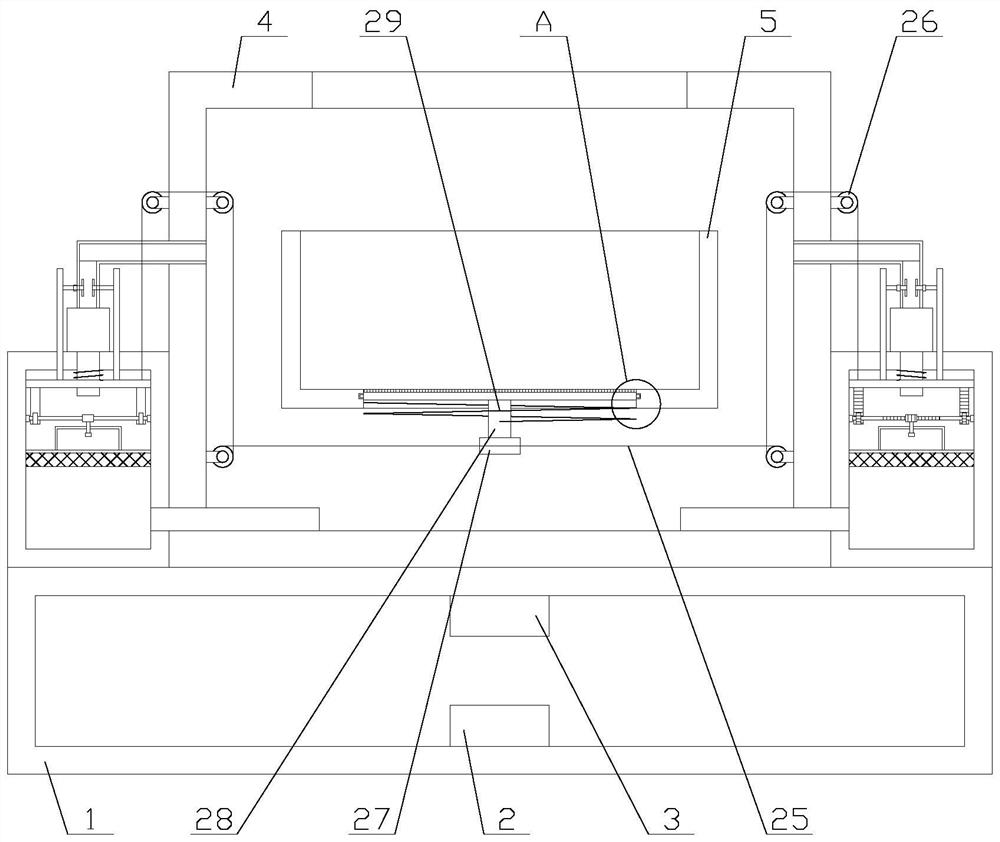

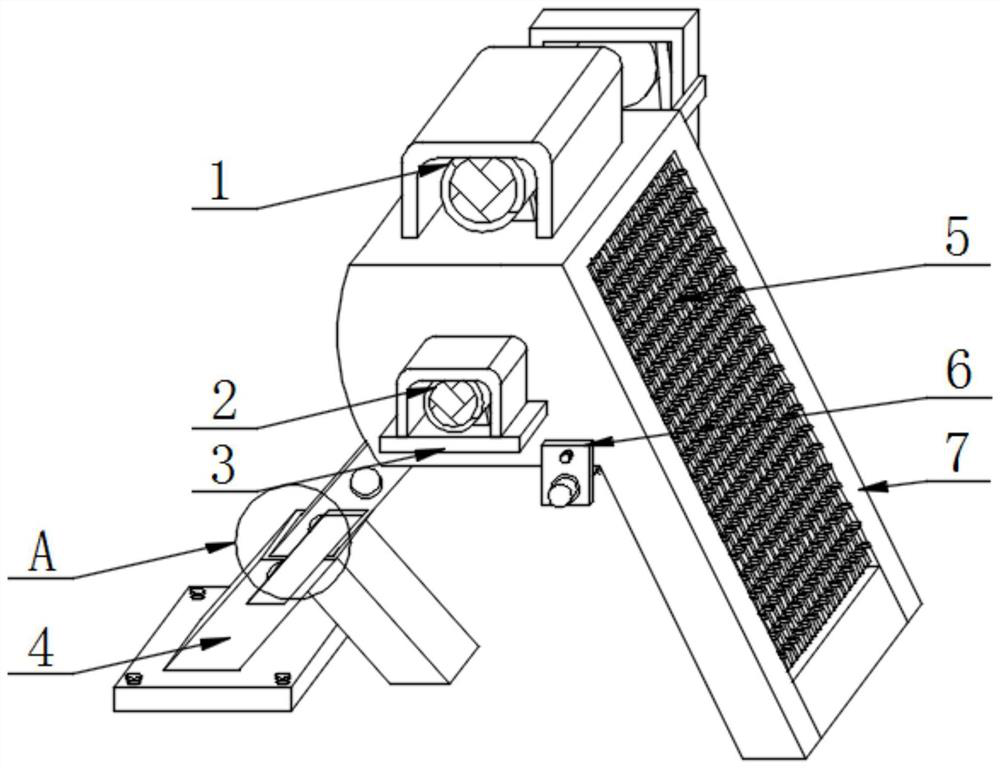

Cleaning and drying device used after silicone rubber key spraying

ActiveCN111672780AIncrease production capacityImprove drying rateDrying solid materials without heatBrushesElectric machineryManufacturing engineering

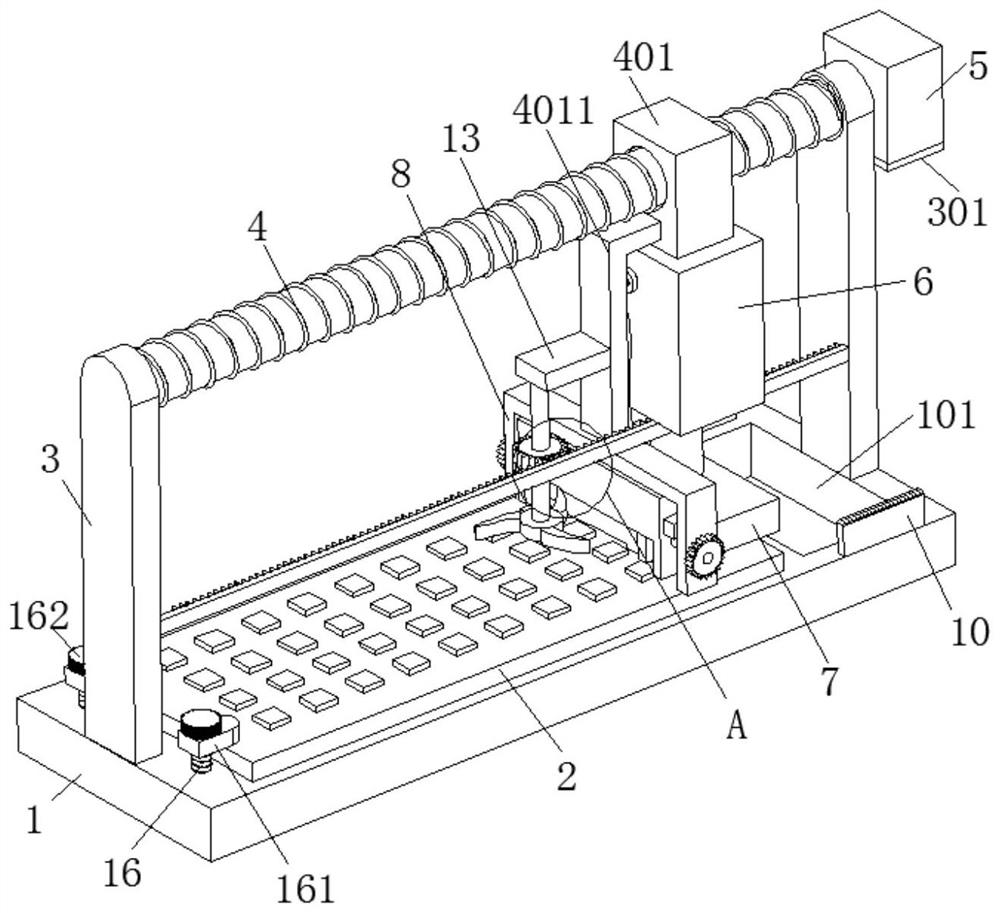

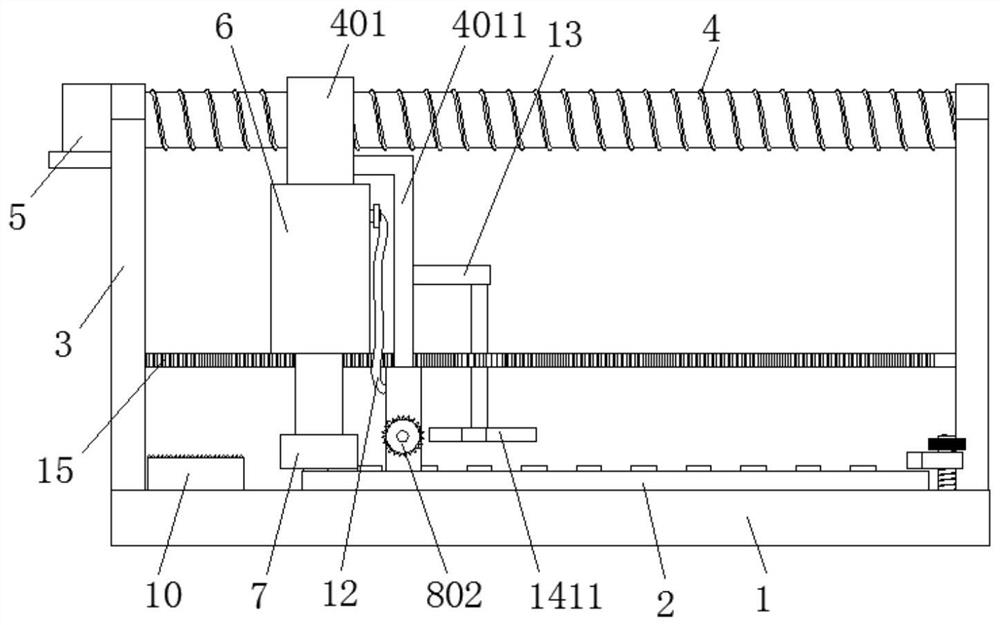

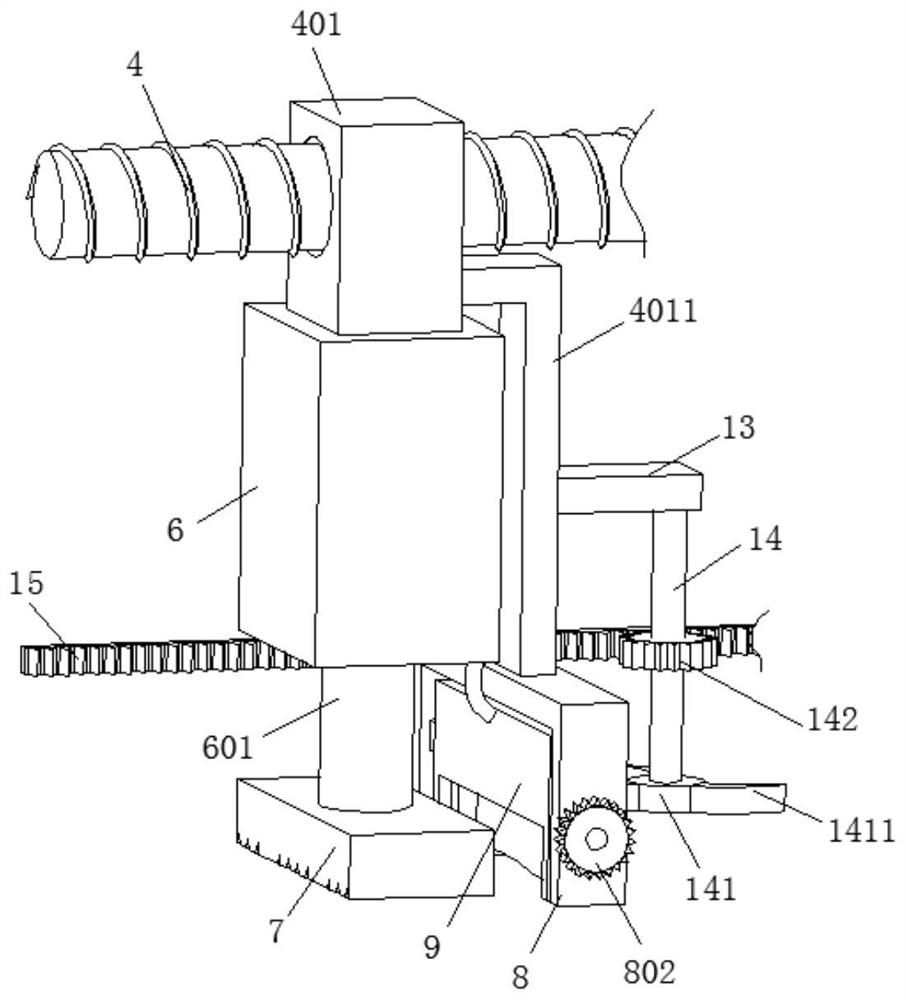

The invention discloses a cleaning and drying device used after silicone rubber key spraying. The cleaning and drying device comprises a base and a silicone rubber key layer, wherein the silicone rubber key layer is placed on the top end face of the base, vertically-arranged fixing bases are fixedly connected to the two sides of the top end face of the base, a first lead screw is arranged betweenthe two fixing bases, two ends of the first lead screw are rotationally connected with the fixing bases through bearings, a supporting plate is fixedly connected to the side face of the fixing base, afirst motor is fixedly installed on the supporting plate, the output end of the first motor is fixedly connected with one end of the first lead screw, a first sleeve is in threaded connection with the first lead screw, and the bottom end of the first sleeve is fixedly connected with a water tank. According to the device, residual accumulated water on the surface layer of a silicone rubber key isabsorbed by a water absorption cloth while the surface of the silicone rubber key layer is automatically cleaned through a brush, the production cost is conveniently reduced, the air drying speed is increased, and then the working efficiency is improved.

Owner:南京林名鑫电子有限公司

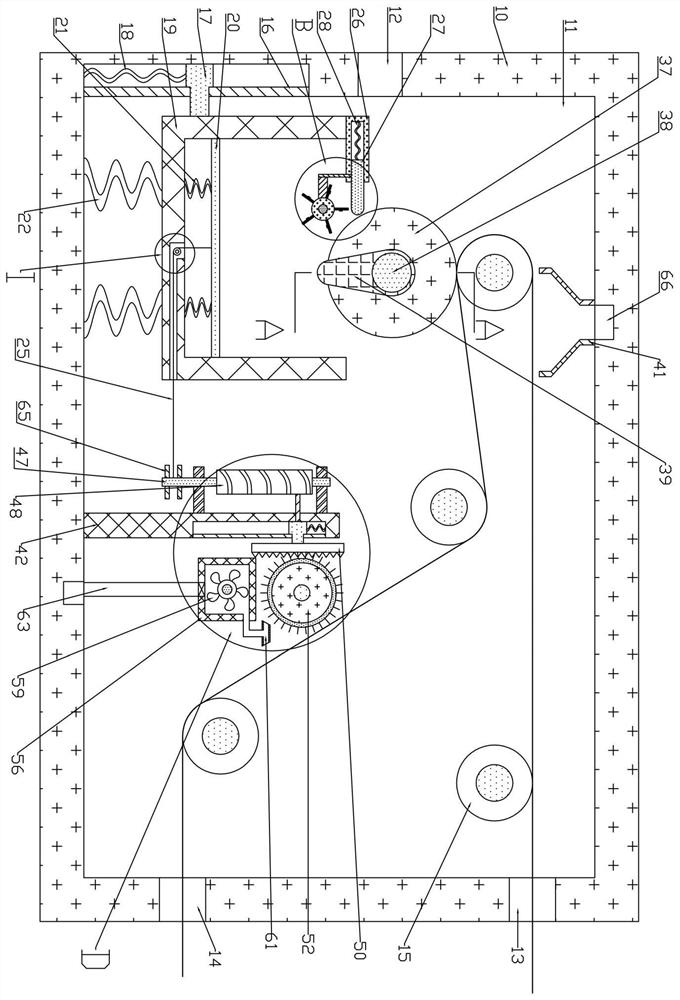

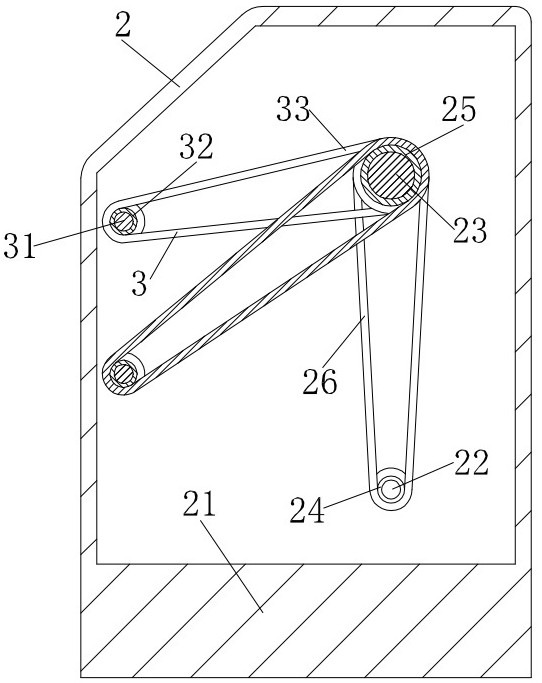

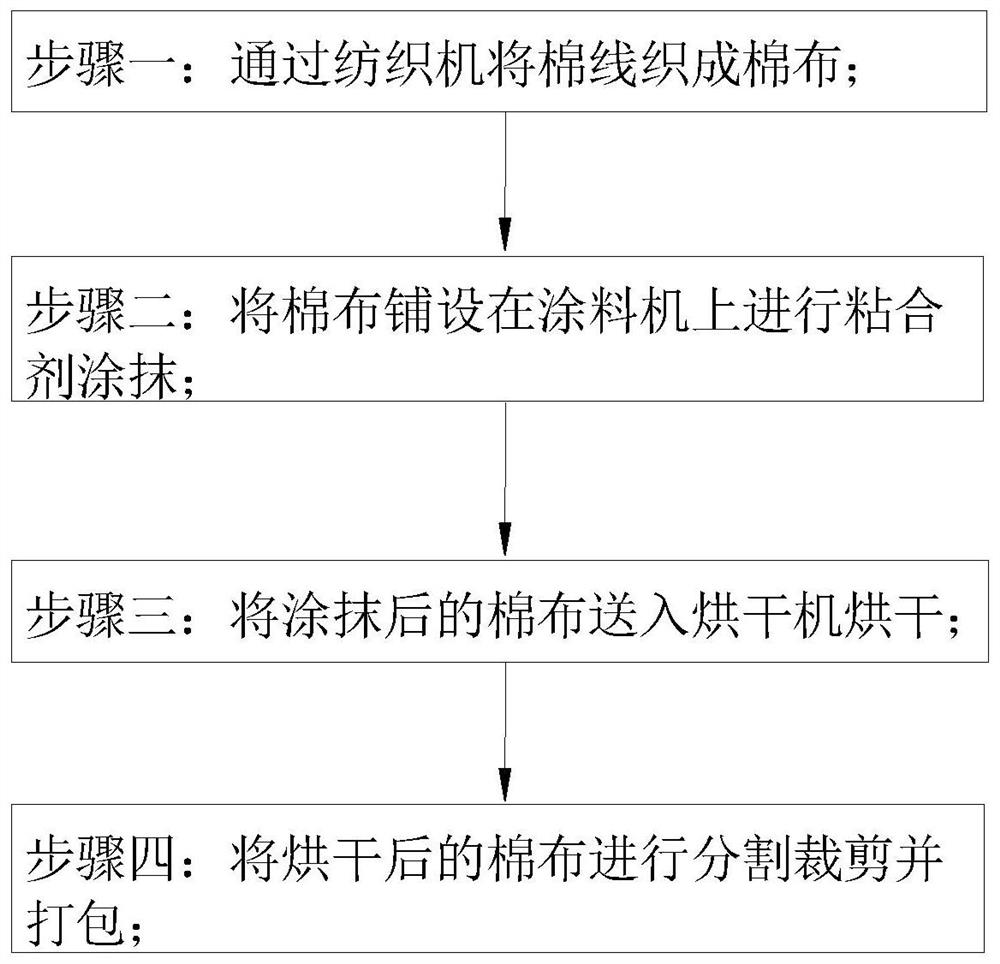

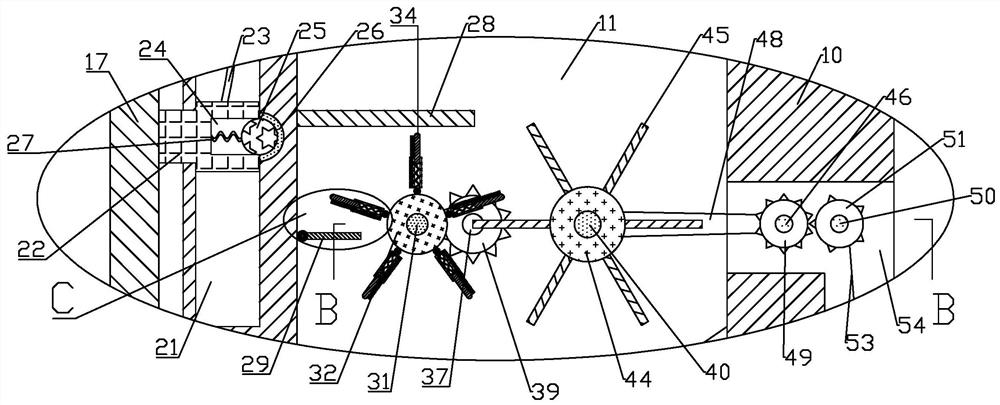

Glue spreading device for adhesive tape, and using method thereof

InactiveCN112191456AAdvantages of usingControl distanceSpraying apparatusPretreated surfacesAdhesive beltAdhesive glue

The invention provides a glue spreading device for an adhesive tape, and a using method thereof, and belongs to the technical field of adhesive tape production. According to the glue spreading device,the problems that, in the adhesive tape production process, the surface of a film to be glued is not treated, and consequently dust falls on the surface of the film; the glue spreading effect of thefilm is affected, and glue on the surface of a roller dipped with the glue is uneven; consequently, the glue on the film is unevenly spread, and the quality of the adhesive tape is reduced are solved.According to the glue spreading device for the adhesive tape, and the using method thereof, a shell, a storage mechanism, a glue spreading mechanism, a dust removal mechanism and a transmission mechanism are coordinated to complete corresponding treatment operation, and a working space is defined in the shell; four conveying wheels for conveying an adhesive tape film are rotationally connected between the inner walls of the front side and the rear side of the shell; and a glue injection port is formed in the left end wall of the shell. According to the glue spreading device for the adhesive tape, and the using method thereof, the glue spreading effect is better, and the product quality is higher.

Owner:程杰杰

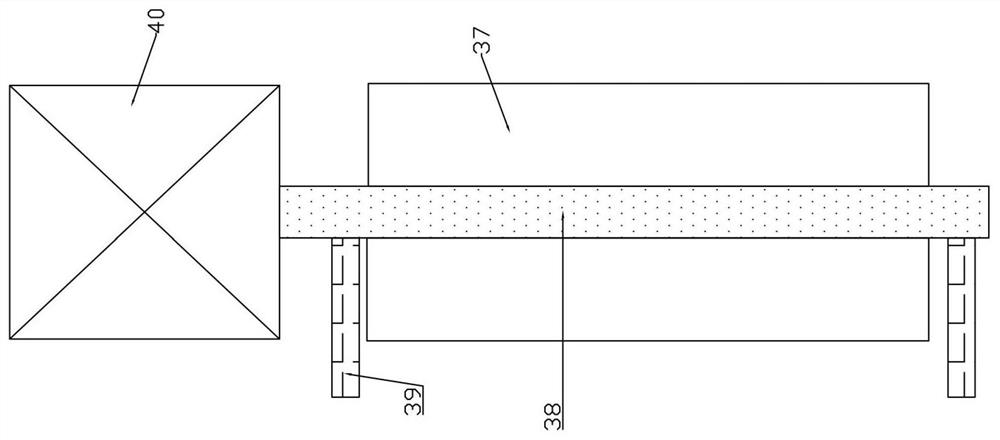

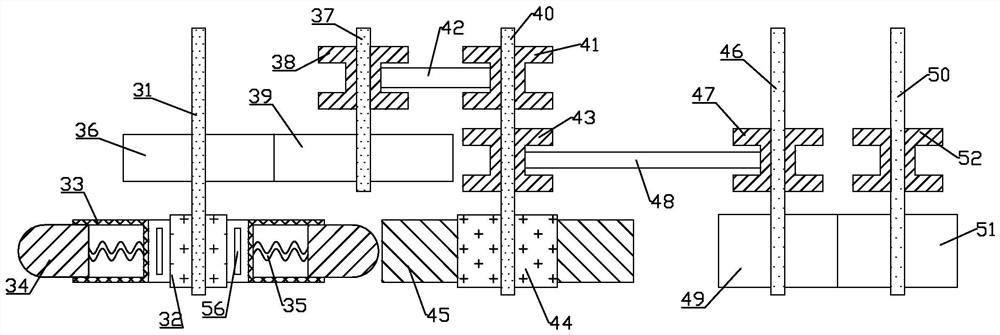

Rolling system with efficient cleaning function

PendingCN113385538ANo bendingAchieve rollingMetal rolling stand detailsRolling equipment maintainenceStructural engineeringMechanical engineering

The invention relates to a rolling system with an efficient cleaning function, and relates to the technical field of aluminium plate rolling. The rolling system comprises a machine frame, a lower roller and an upper roller, the horizontally-arranged lower roller is fixedly installed on the inner side of the machine frame, auxiliary supporting rollers parallel to the lower roller are arranged in front of and behind the lower roller, the auxiliary supporting rollers are flush with the top of the lower roller, the upper roller parallel to the lower roller and adjustable in height is arranged above the lower roller, the upper roller and the lower roller are the same in diameter, and one end of the lower roller and one end of the upper roller extend into a transmission box. Materials with different thicknesses can be rolled by adjusting the up-down position of the upper roller, the function of sweeping impurities on the upper and lower surfaces of the lower roller, the upper roller and materials in a rolling brush mode can be achieved through a cleaning mechanism, a horizontal sliding rail pair can drive a first cleaning roller to move, and position adjusting equipment can drive a second driving box to further move a second cleaning roller, so that the condition that the cleaning effect is affected after the first cleaning roller and the second cleaning roller are used and abraded is avoided.

Owner:LUOYANG WANJI ALUMINUM PROCESSING CO LTD

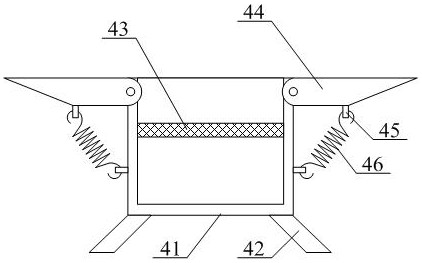

Peanut cleaning device for agriculture facilitating soil sedimentation

The invention discloses an agricultural peanut cleaning device which is convenient for soil precipitation, which comprises a cleaning box, a support frame, a mesh basket, a cylinder and a water tank; a connection bracket is fixed on one side of the support frame, and the connection bracket is fixedly connected to a horizontal cylinder; An inclined mud deflector is fixedly arranged on the inner wall of the cleaning box, a blanking plate is arranged between the mud deflectors on both sides, a horizontal rotating shaft is fixedly installed in the middle of the blanking plate, and the upper surface of the blanking plate A first wedge block is fixed, and a second wedge block is fixed on the upper supporting frame corresponding to the first wedge block. The present invention enables the washed peanuts to be quickly poured out through the set separate net basket, without consuming a lot of labor and time, and improves the efficiency of peanut cleaning; It can also drive the lower cutting plate to swing, and guide the cleaned sludge into the lower sedimentation chamber.

Owner:苏清凉

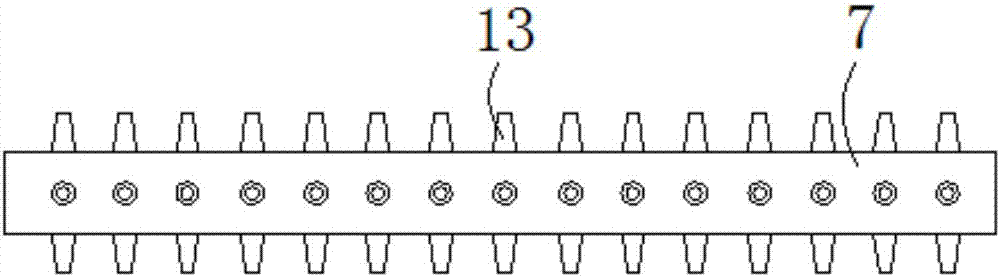

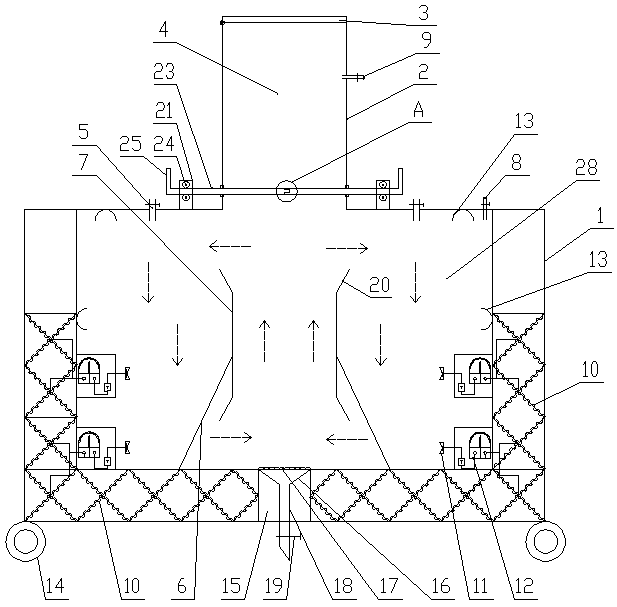

High-efficient dust removal device

InactiveCN107486427AAvoid wastingComprehensive cleaningDrying gas arrangementsPhotovoltaicsEngineeringWater pipe

The invention discloses a high-efficient dust removal device. The dust removal device comprises a photovoltaic panel; a spray head support is connected with a first edge of the photovoltaic panel, a water pipe is arranged on the spray head support, and uniformly-distributed spray heads are arranged on the lower part of the water pipe; a water collecting groove is connected behind the spray head support, one end of the water collecting groove is connected with a water pump, the water pump is connected with a rotating shaft through a hose, and the rotating shaft is connected with a first motor; the water collecting groove and the water pump are connected with a support; a first slide rail is arranged beside the side part of a second edge of the photovoltaic panel, and the first slide rail is in sliding connection with the spray head support; and the spray head support is further connected with an air cylinder. According to the dust removal device, the photovoltaic panel can be washed and dried, and most of cleaning water adopts rainwater stored in rainy days so that resources can be saved; and rust-proof coatings coat the positions of the spray head and the spray head support so that corrosion affects cleaning effect can be effectively avoided, and therefore the service life of cleaning equipment can be prolonged.

Owner:浦江县顺光科技有限公司

Batch cleaning device for bottles

The invention belongs to the technical field of a special method or special equipment for cleaning hollow objects, and particularly discloses a batch cleaning device for bottles. The batch cleaning device comprises a rack, a water pump, an air pump, a motor, a water tank and a baffle, wherein the water tank is fixed to the upper end face of the rack; the baffle is arranged above the water tank; aspace is formed between the baffle and the water tank; the water pump, the air pump and the motor all are fixed to the upper end face of the water tank; a water pipe for connecting the water tank withthe water pump is arranged between the water tank and the water pump; the water tank is provided with washing parts communicating with the water tank; each washing part is peripherally provided witha positioning part; and the washing parts and the positioning parts are correspondingly fixedly connected with rotating parts and rotate relatively under the driving of the rotating parts. The batch cleaning device disclosed by the invention aims to solve the problems that in the prior art, the bottles are unstably positioned and cannot be washed completely in a washing process.

Owner:重庆市长寿区临东酒业有限责任公司

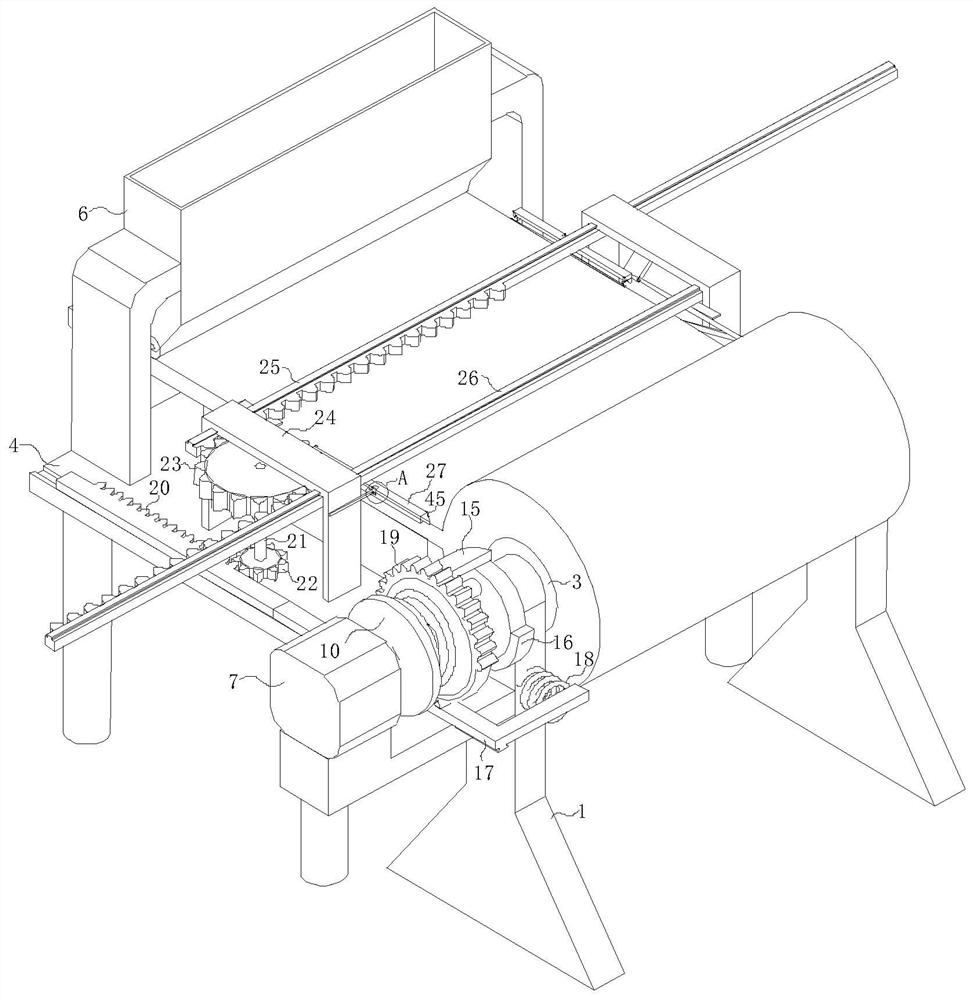

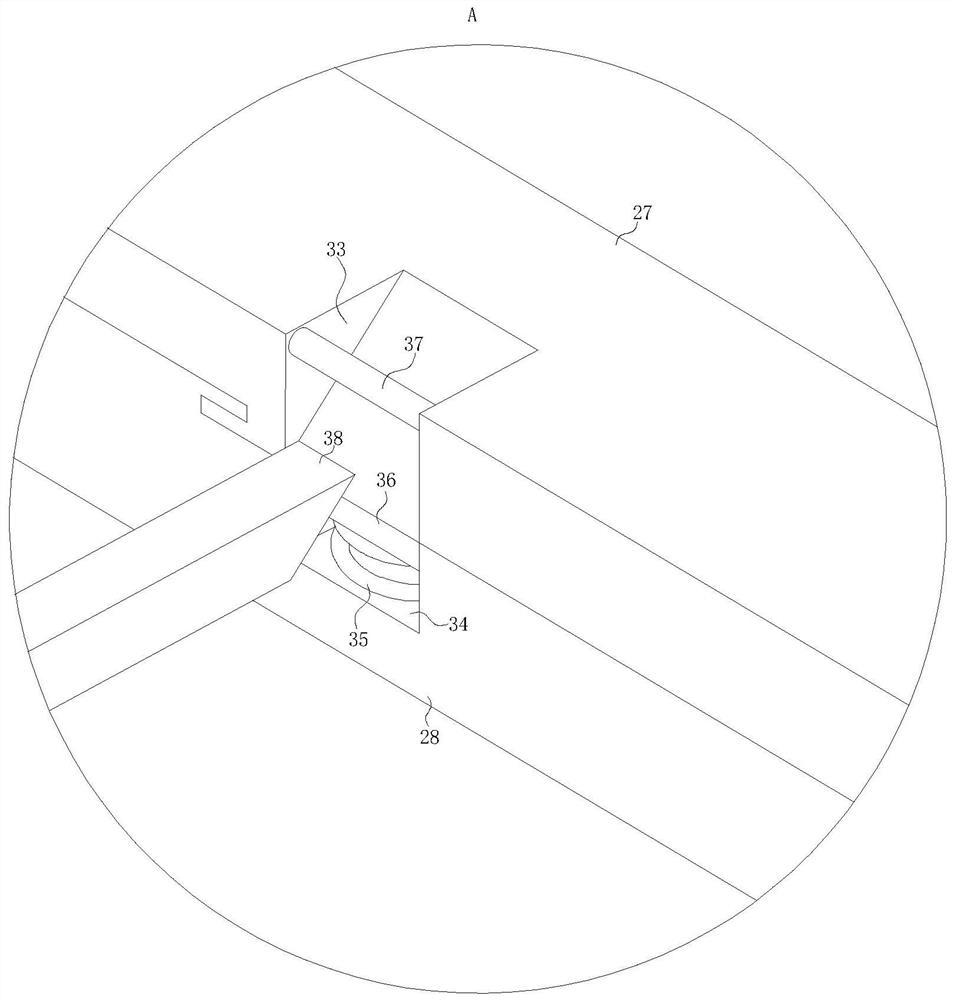

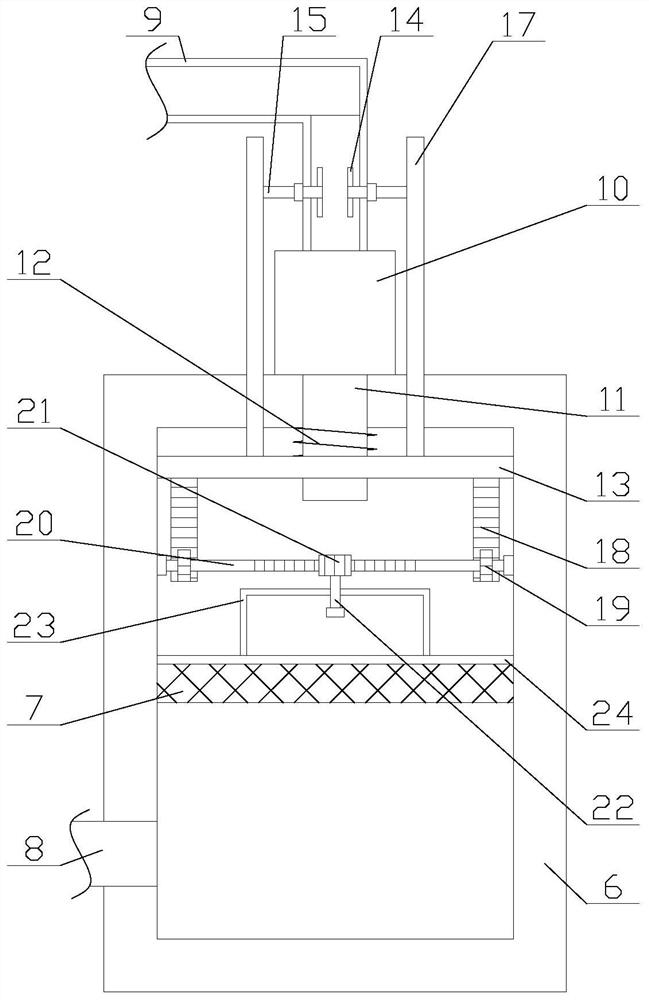

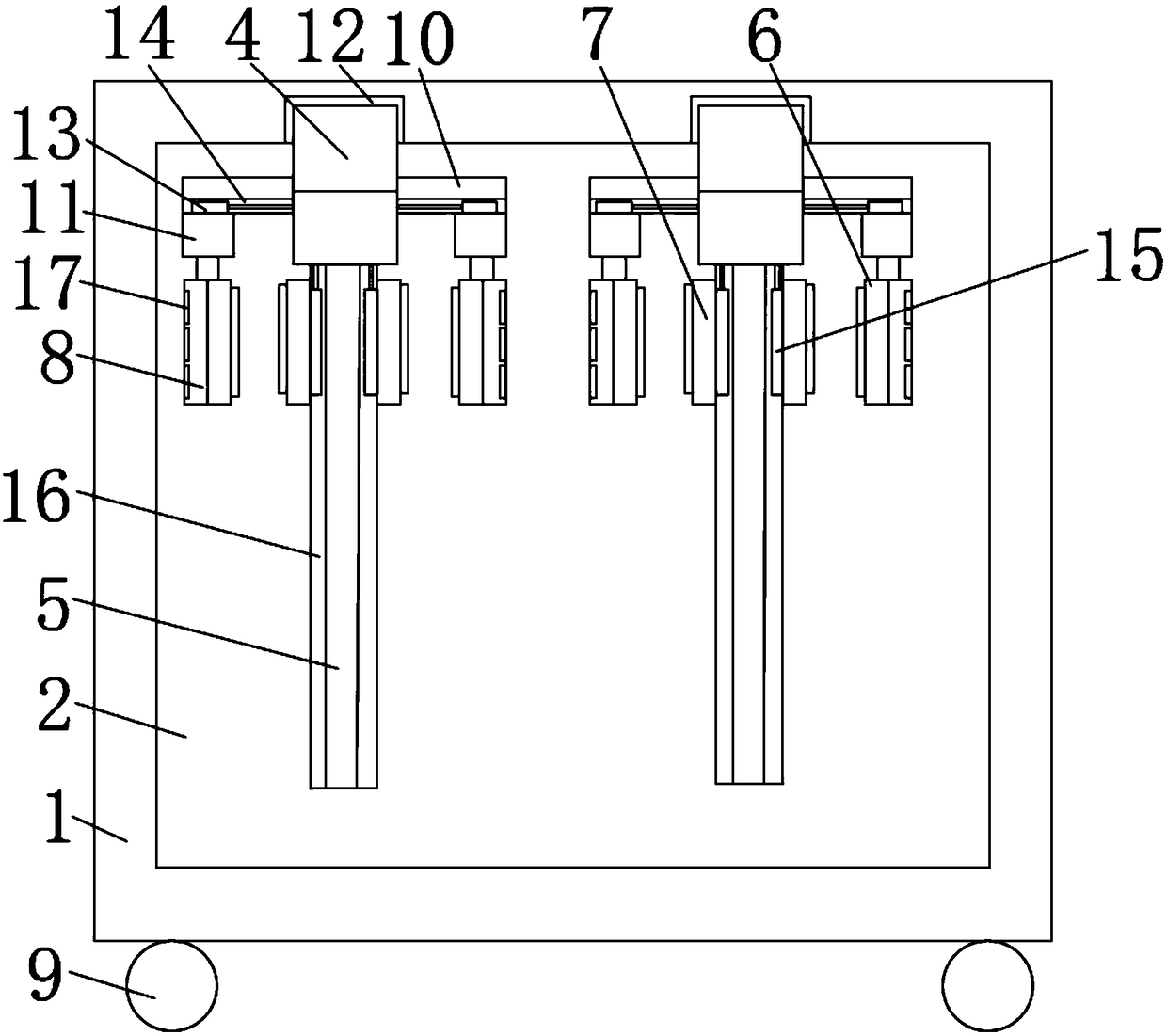

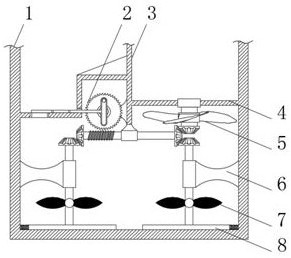

Bubble cleaning machine for processing of agricultural by-products

InactiveCN107874287APrevent the problem that the self-weight is too large and cannot be turned overAffect cleaning effectClimate change adaptationFood treatmentWater savingAgricultural engineering

The invention discloses a bubble cleaning machine for processing of agricultural by-products. The bubble cleaning machine comprises a base, wherein the top part of the base is fixedly connected with acleaning tank and a discharge groove through bolts; a stirring roller, a hairbrush, a feeding sloping plate and an air pipe are mounted in the cleaning tank; the hairbrush is positioned between the stirring roller and the feeding sloping plate; the stirring roller is positioned between the hairbrush and the stirring roller; and a soft rubber cushion is mounted on the outer wall of the stirring roller. The bubble cleaning machine is convenient for vegetables to be in contact with bubbles comprehensively to achieve the effect of sufficient cleaning, and also avoids the problem that the vegetables with excessive self-weight cannot be turned over and prevents the vegetables from plugging and affecting the cleaning effect; impurities in the cleaning tank can be effectively filtered by a filterscreen, thereby avoiding secondary pollution after the vegetables are cleaned and ensuring the cleaning quality of the vegetables; and the bubble cleaning machine is capable of saving water, avoidingwaste of water resources, flushing off impurities adhered to the surfaces of the vegetables and improving the degree of cleanness of cleaning.

Owner:LINQUAN YUCHENG MACHINERY

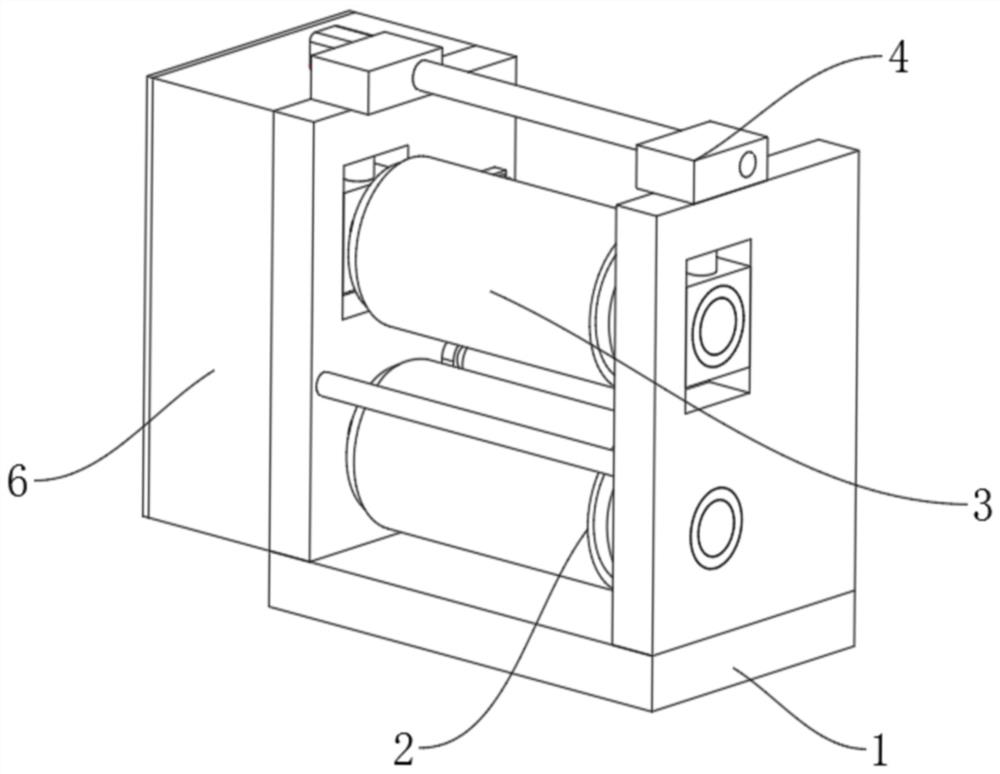

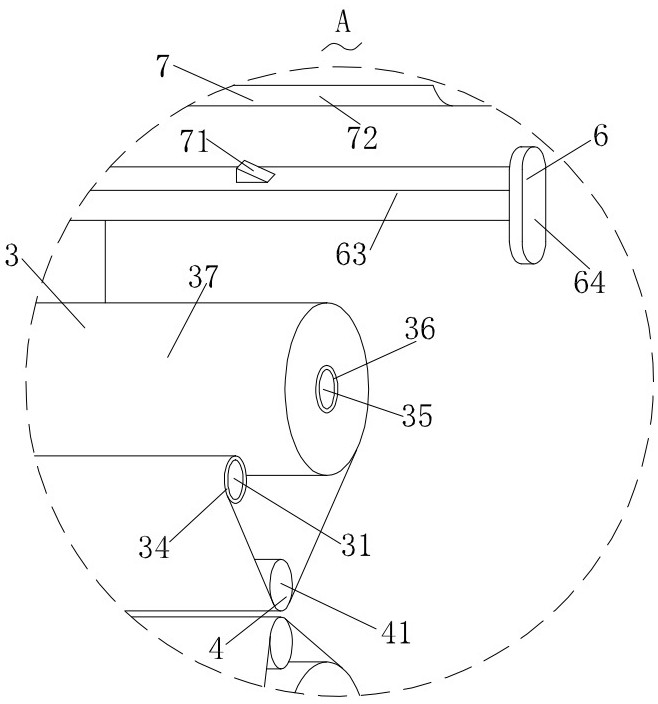

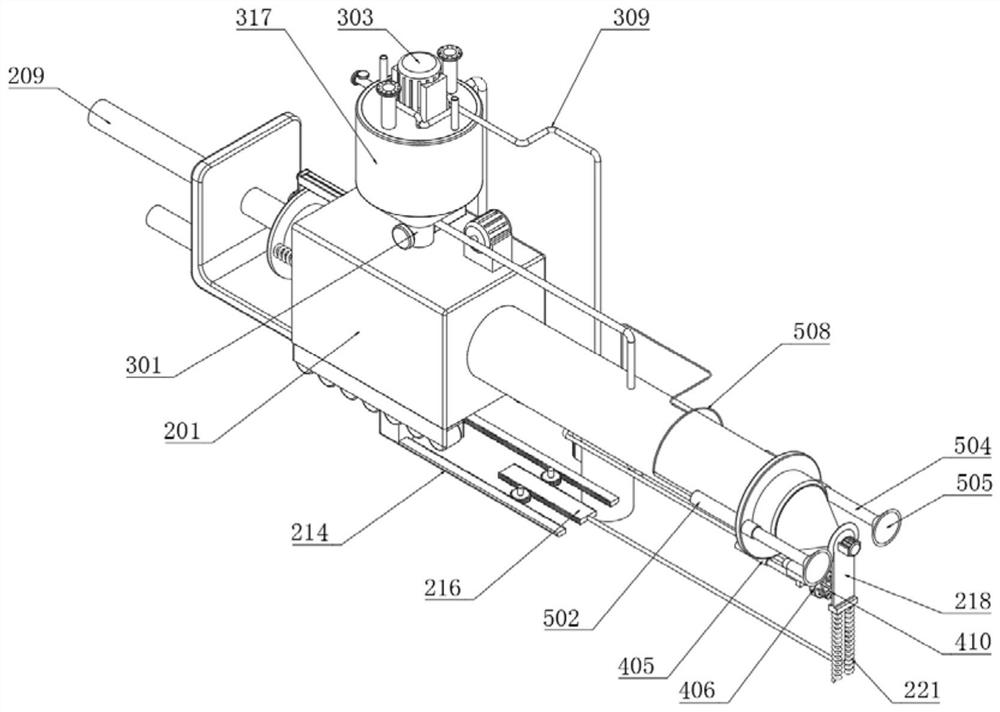

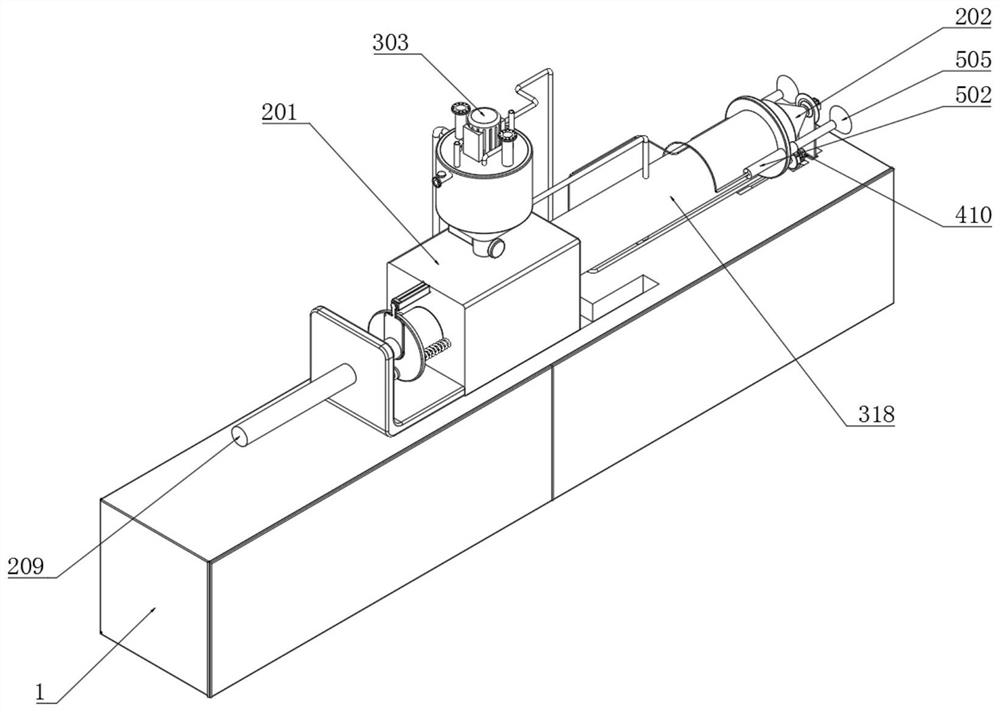

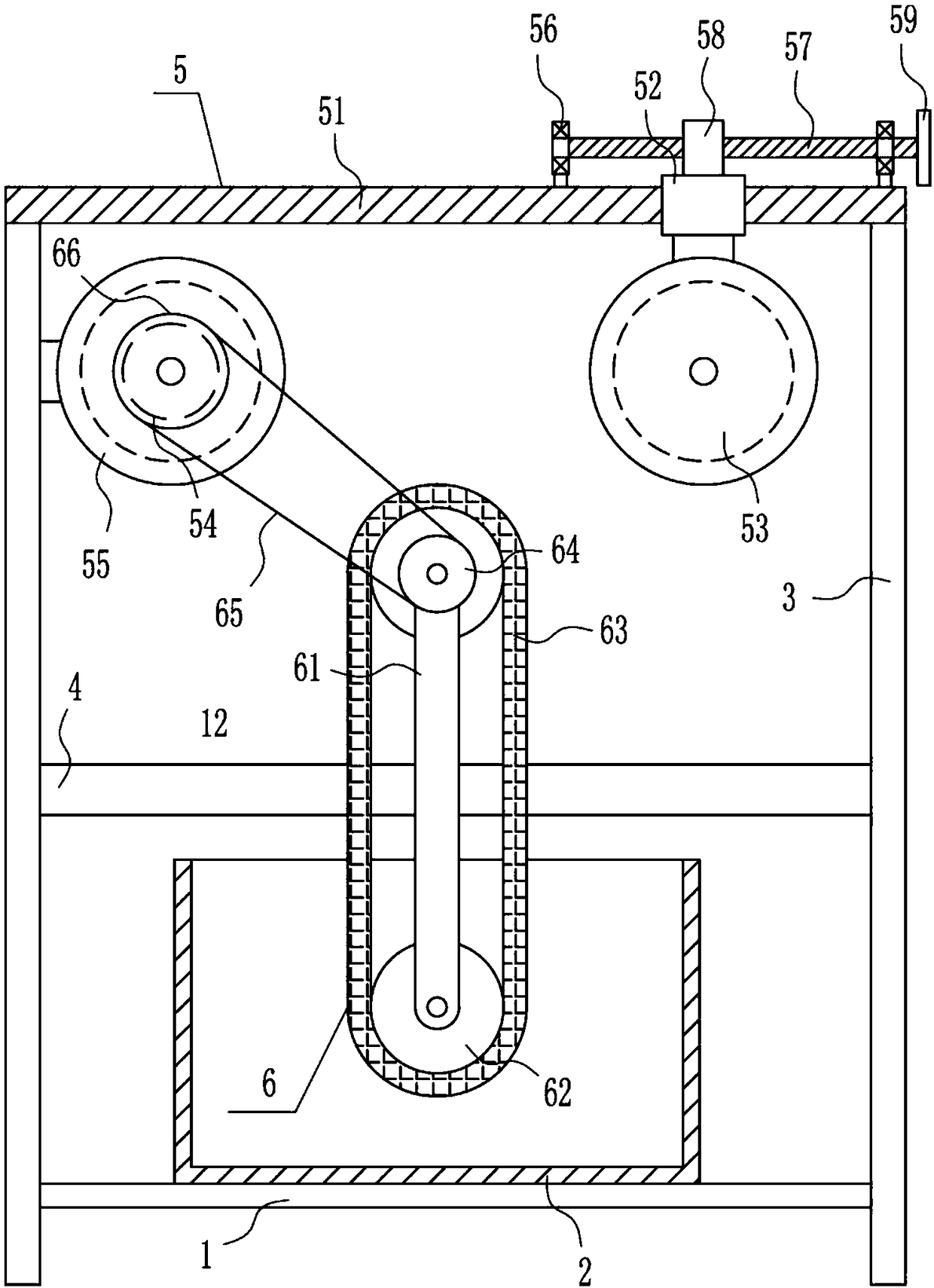

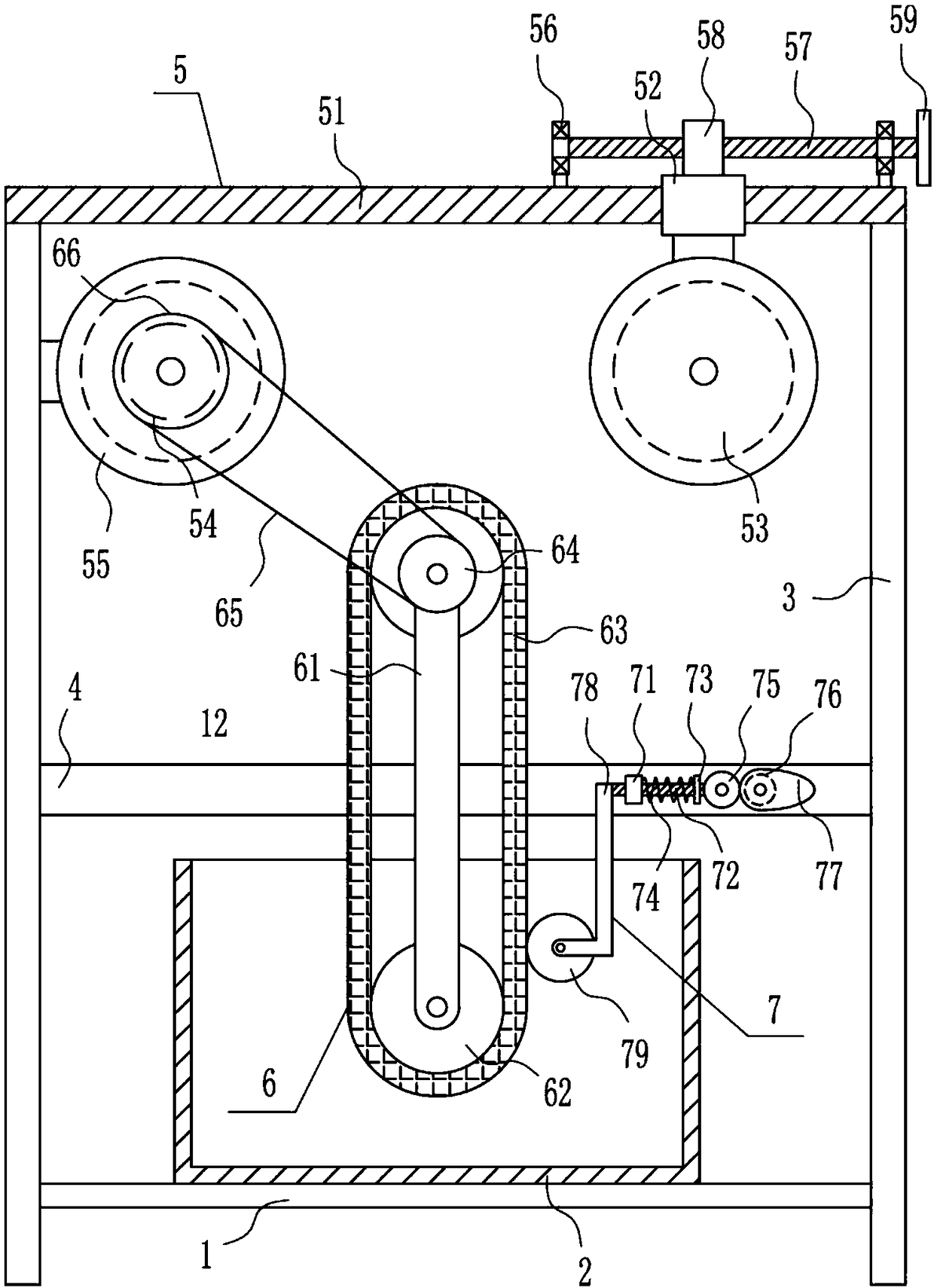

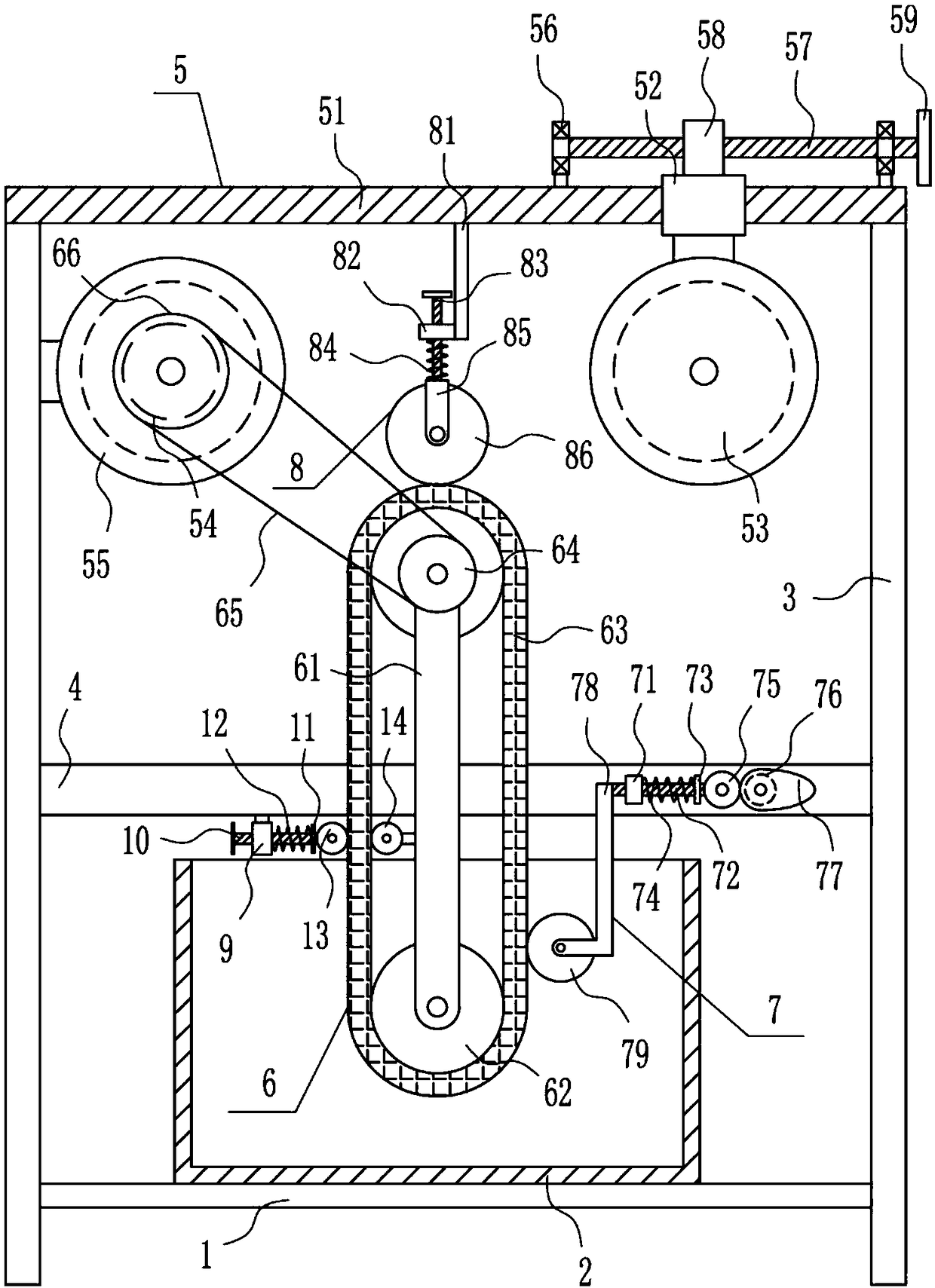

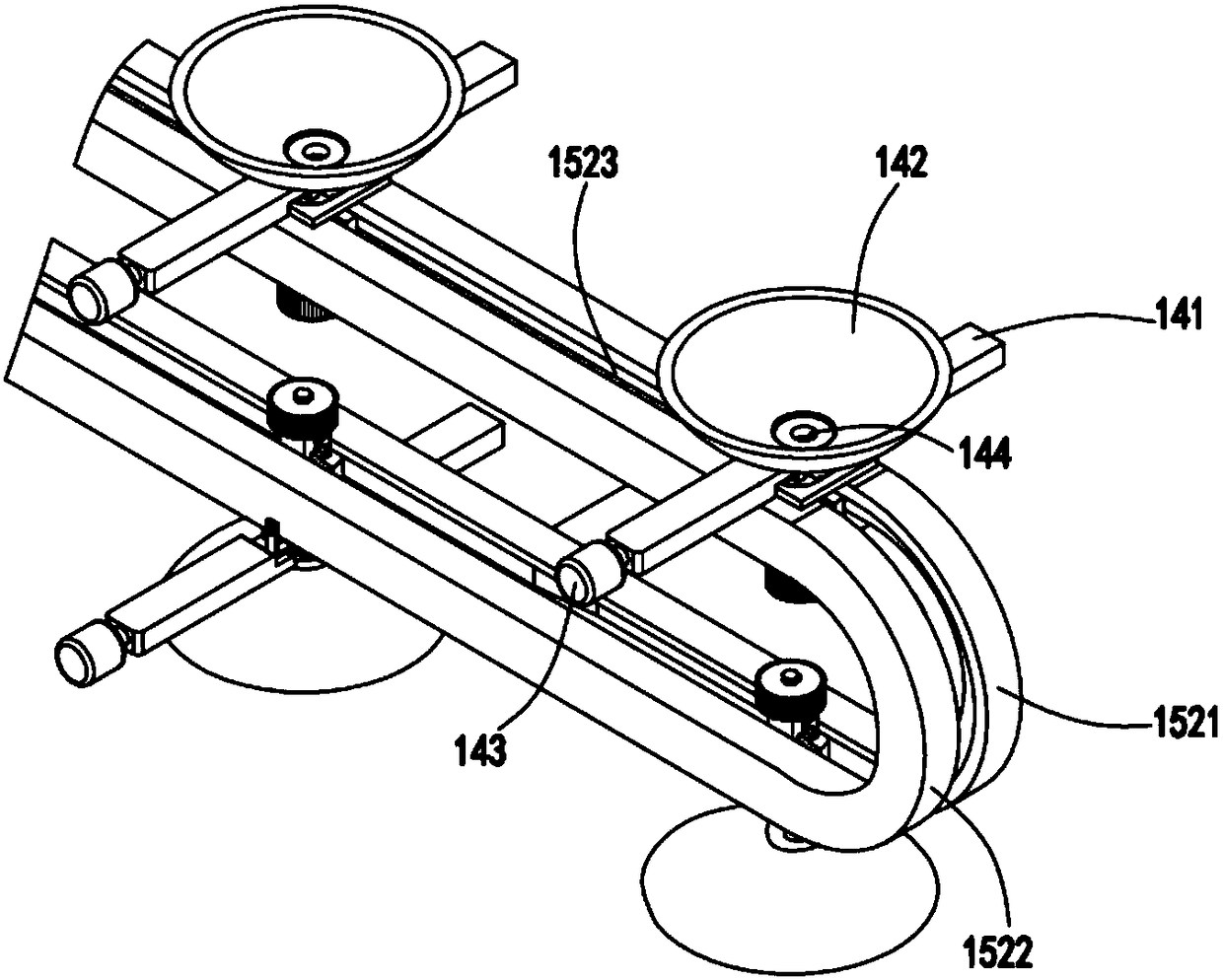

Winding equipment for electrolytic copper foil production

ActiveCN113247663AImprove cleaningGuaranteed winding qualityCleaning using toolsWebs handlingCopper foilEngineering

The invention relates to the technical field of electrolytic copper foil production and processing, in particular to winding equipment for electrolytic copper foil production. The winding equipment comprises a base, a winding structure is mounted on the base, a cleaning structure is mounted on the winding structure, an abutting structure is mounted on the winding structure, and a limiting structure is further mounted on the winding structure. A pushing structure is arranged on the winding structure, a fixing structure is arranged on the winding structure, an unloading structure is installed on the base, and a pouring structure is arranged on the unloading structure; and when the winding structure conducts winding work, the cleaning structure can be synchronously driven to work, through work of the cleaning structure, the two faces of an electrolytic copper foil can be finely wiped in the manner that wiped cloth is wound, the problem of repeated wiping does not exist, the cleaning work on the surface of the electrolytic copper foil is increased, and the winding quality of the electrolytic copper foil is ensured.

Owner:拓楚(江苏)电子科技有限公司

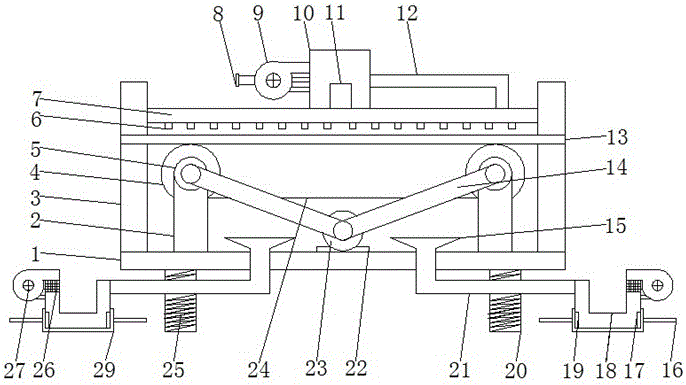

Cleaning device of surface of textile fabrics

ActiveCN106400440AImprove product qualityAffect cleaning effectMechanical cleaningPressure cleaningEngineeringTextile

The present invention discloses a cleaning device of surface of textile fabrics. The device comprises a pedestal, and the top of a supporting rod is connected with rollers through a bearing; a cleaning belt is connected between the two rollers; a motor is arranged at the middle portion of the top of the pedestal; the surface of the motor is connected with the rollers through a transmission belt; pipelines are arranged at two sides of the inner cavity of the pedestal; a positive plate and a negative plate are respectively arranged at two sides of the inner cavity of a U-type tube; one side of the top of the inner cavity of the U-type tube is provided with a filtering screen; the top of the one side of the U-type tube is connected with a suction fan; supporting columns are connected at two sides of the top of the pedestal; the inner cavities of the supporting columns penetrate cloth feeding channels; and a gas ejector pipe is arranged between the two supporting columns, the left side of a breather pipe is connected with a heating chamber, the inner cavity of the heating chamber is provided with a heater, and the left side of the heater is connected with an air blower. The cleaning device of the surface of textile fabrics can remove the fuzz on the surface of the cloth so as to solve the problem that the cloth production quality is reduced.

Owner:无锡锡东新农村投资发展有限公司

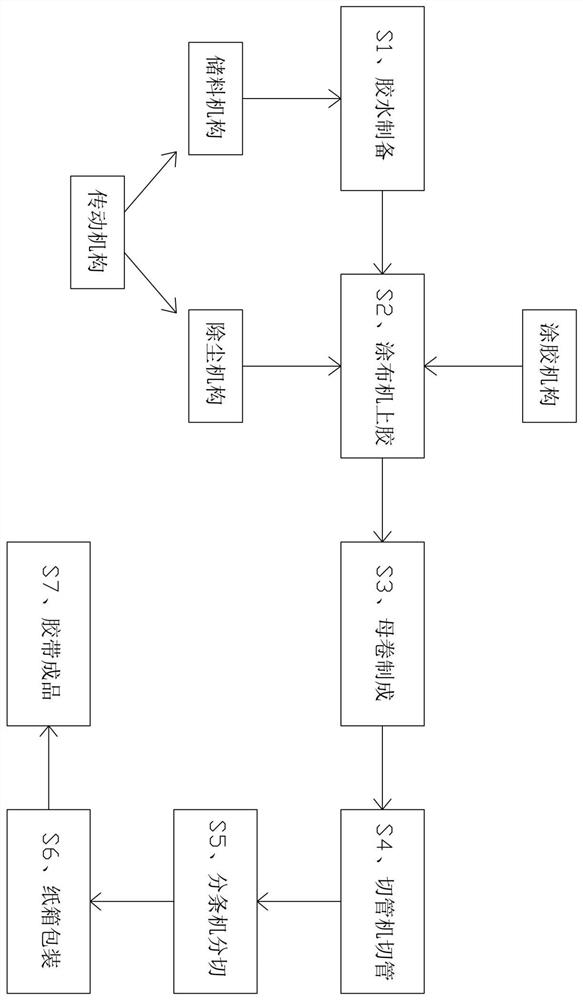

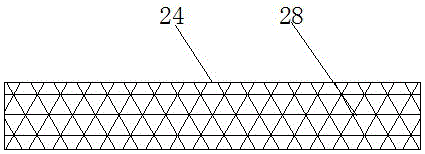

Antistatic textile material production and preparation process

InactiveCN113102190AAvoid Insufficient Antistatic PropertiesGuaranteed antistatic effectLiquid surface applicatorsCleaning using toolsCotton clothAdhesive

The invention discloses an antistatic textile material production and preparation process in the technical field of textile material production. The process comprises the following specific steps: step 1, weaving cotton threads into cotton cloth through a textile machine, step 2, laying the cotton cloth on a coating machine for coating an adhesive, step 3, feeding the coated cotton cloth into a drying machine for drying, and step 4, cutting and packaging the dried cotton cloth. An arc-shaped block is arranged and rotates along with a first transmission disc, when the highest point of the arc-shaped block does not make contact with an arc plate, a second transmission disc rotates, the cotton cloth on a workbench moves rightwards, when the highest point of the arc-shaped block makes contact with the arc plate, the second transmission disc is disengaged from a first elastic telescopic rod and does not rotate any more, and a gear ring drives an L-shaped rack to move, so that a second rack and a third rack move, the adhesive on the cotton cloth is evenly coated, and in cooperation with front-back reciprocating movement of a material pushing mechanism, the adhesive can make full contact with the cotton cloth.

Owner:北京深核智能科技有限公司

Anti-blocking injection molding machine

The invention discloses an anti-blocking injection molding machine is characterized in that an injection molding gun barrel is welded to one end of a supporting entering box, a conveying auger is welded to the side end of a movable transmission rod, a movable supporting barrel is welded to one end of a clamping sealing block, a reset spring is welded to one end of the movable supporting barrel, and an auxiliary moving block is welded to the bottom end of the supporting entering box; and a driving rack is welded to one end of the auxiliary moving block, a cleaning plate is rotationally connected to one end of a sliding moving plate, a pushing electromagnet is installed on the inner side of a sliding cavity, a pushing spring is welded to one end of the inner side of the sliding cavity, and an anti-blocking column is welded to one end of the pushing spring. The conveying auger and a reverse flow preventing threaded column drive a raw material to move and prevent the raw material from backflow, the hollow situation is avoided, and a contact switch controls the opening and closing of the pushing electromagnet, so that the anti-blocking column can be quickly reset when needing to be reset, and the discharge port is sealed while the requirement for discharging solidified raw materials at the discharge port position is met.

Owner:姚新耿

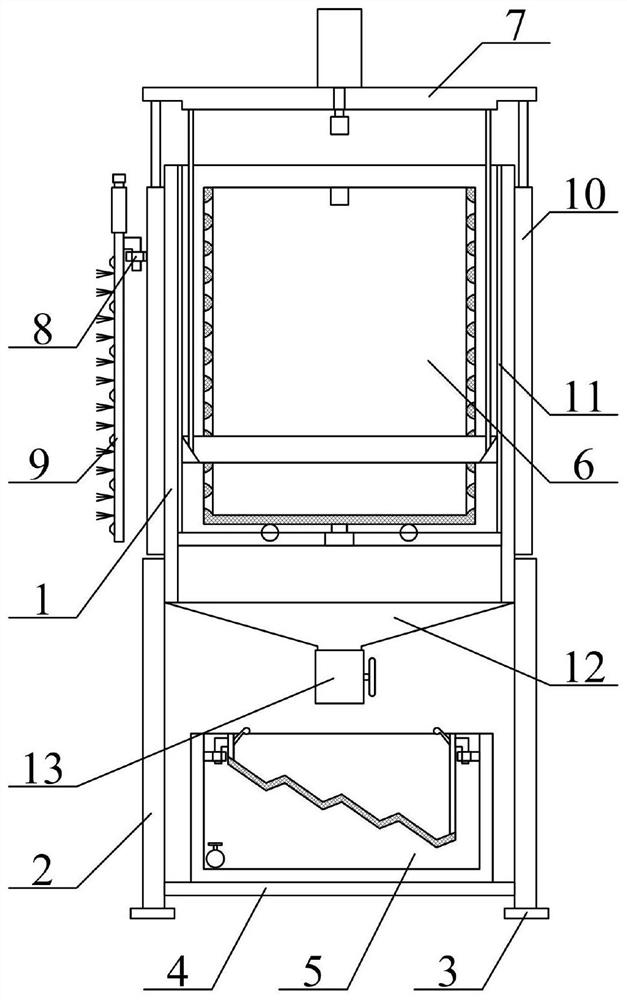

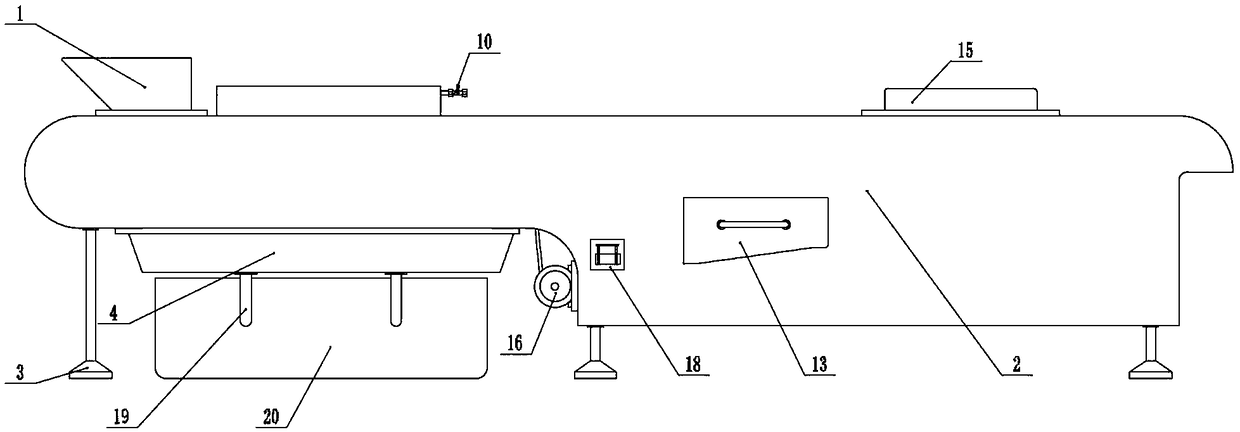

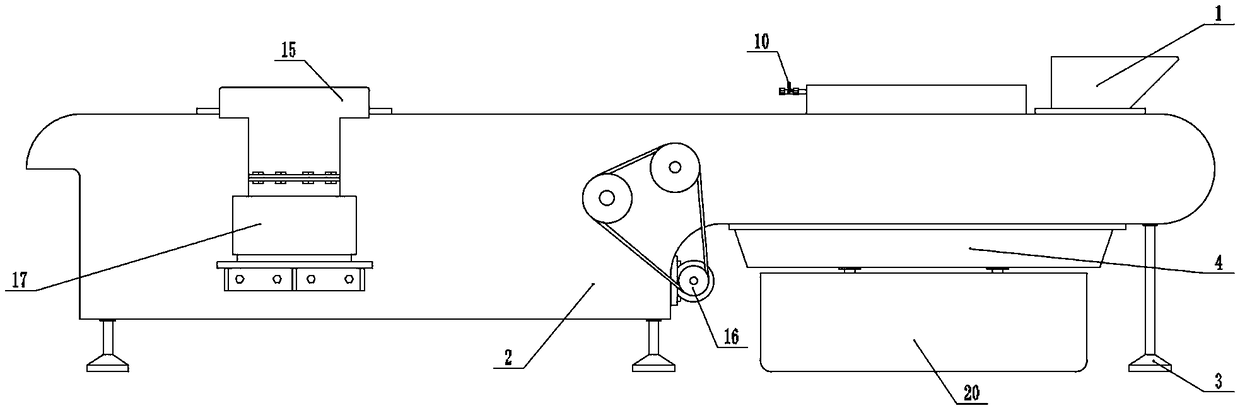

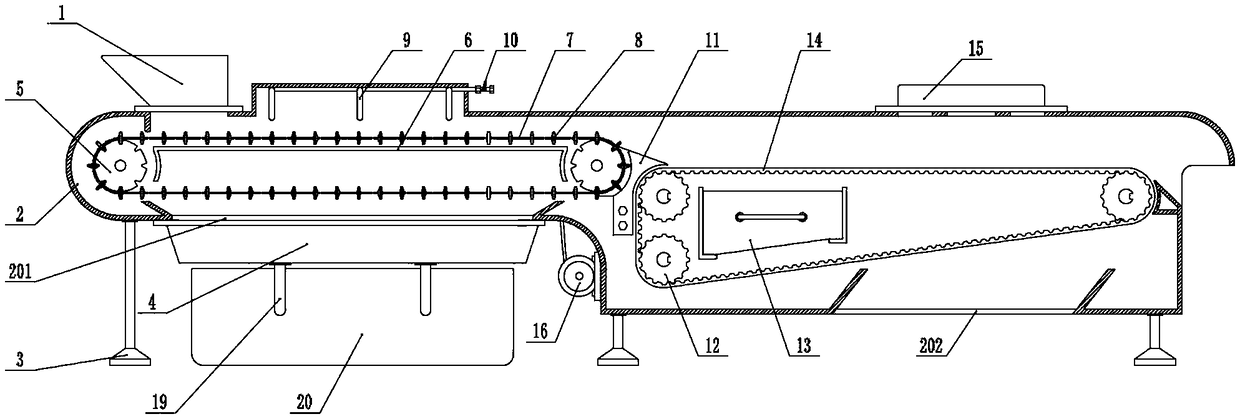

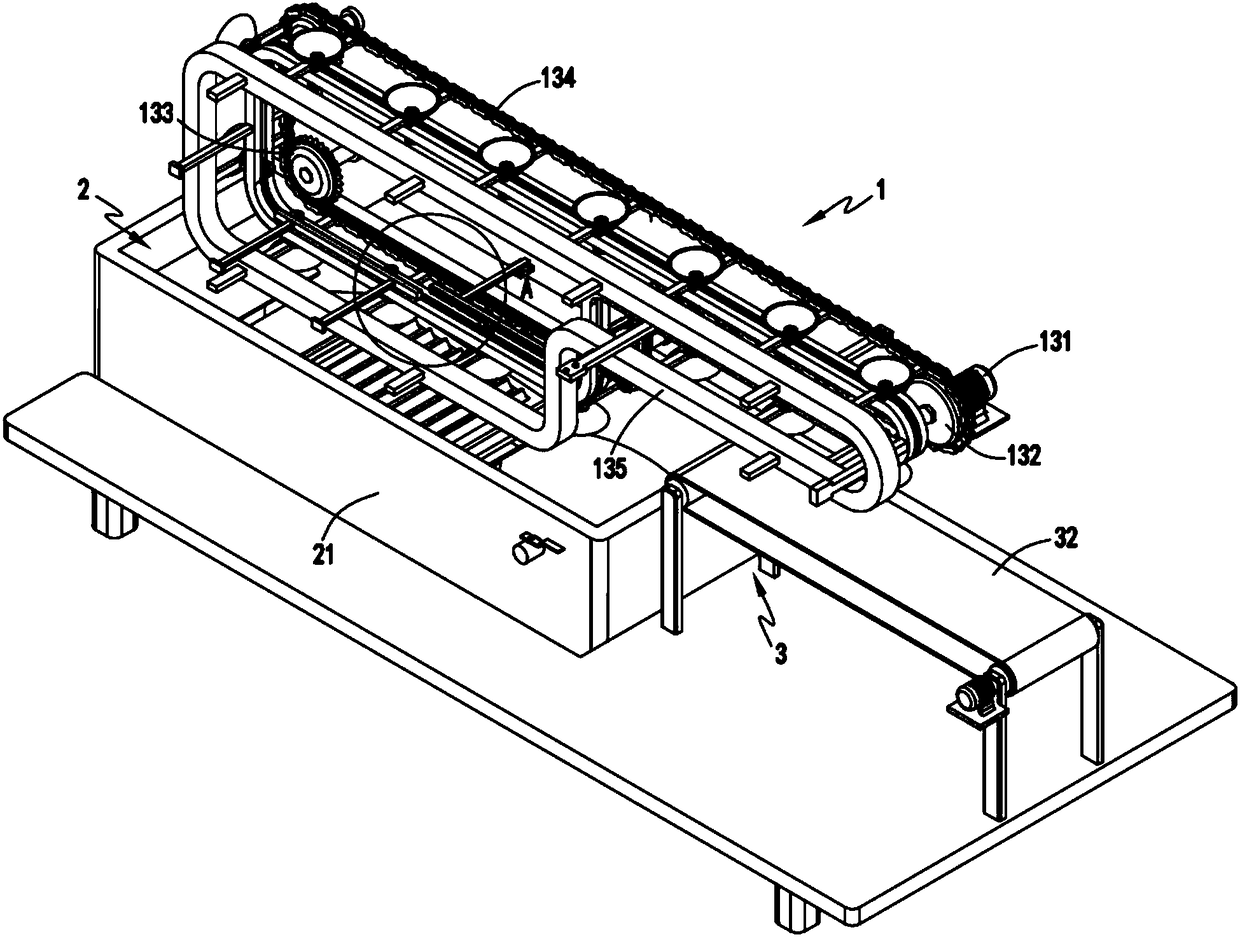

Cleaning equipment of transmission belt in construction machinery

InactiveCN108526060AAffect cleaning effectEasy to cleanCleaning using toolsTransmission beltArchitectural engineering

The invention relates to cleaning equipment, in particular to a cleaning equipment of a transmission belt in construction machinery. According to the cleaning equipment of the transmission belt in construction machinery, time and labor are saved, the cleaning effect is good, and the transmission belt is not prone to be damaged; the cleaning equipment of the transmission belt in construction machinery comprises a bottom plate and the like; a frame body is arranged in the middle of the top of the bottom plate, vertical plates are arranged on the left side face of the bottom plate and the right side face of the bottom plate correspondingly, and the vertical plates are symmetrically arranged; and cross rods are installed between the middle of the right side face of a left vertical plate and the middle of the right side face of the left vertical plate on the other side, rotating devices are arranged at the tops of the vertical plates of the two sides on the left side and the right side, andcleaning devices are arranged between the rotating devices and the middle part of the front side of the cross rod. According to the equipment, by means of a striking device, a sponge belt can be hit,so that the impurities left on the sponge belt fall off, the cleaning effect of the sponge belt is better, and time and labor are saved, cleaning effect is good and the transmission belt is not proneto be damaged.

Owner:南京六创科技发展有限公司

Spinning device and polyacrylonitrile fiber spinning machine

PendingCN112126991AReduce manufacturing costShort processSpinning head liquid feederArtificial filament washing/dryingMoulding deviceEngineering

The invention discloses a spinning device. The spinning device comprises a roller composed of first spinning rollers and a second spinning roller which are different in diameter, filaments alternatelypass through the first spinning rollers and the second spinning roller and are wound from one end of the roller to the other end of the roller, the second spinning roller comprises a washing section,a water spraying mechanism sprays water to the washing section to wash the filaments, and the quality of the filaments is further ensured. The polyacrylonitrile fiber spinning machine comprises a forming device and the spinning device, the forming device comprises a coagulating bath tank, a primary washing tank and a drafting roller arranged between the coagulating bath tank and the primary washing tank, the diameter of the drafting roller is d, the rotating speed of the drafting roller is n, the diameter of the first spinning rollers is d1, the rotating speed of the first spinning rollers isn1, and n / n1 is smaller than d1 / d. The speed of the filaments entering the primary washing tank is smaller than the speed of the filaments leaving the primary washing tank, in the whole technologicalprocess, only one-time drafting is carried out in the primary washing tank, multiple times of drafting are not needed, and production equipment is simplified.

Owner:吉林富博纤维研究院有限公司

Household sewage treatment center

InactiveCN112495016AGuaranteed cleaning effectAffect operationStationary filtering element filtersSewage treatmentSewage

The invention provides a household sewage treatment center, and belongs to the technical field of sewage treatment. The problem that although an existing washing machine, an existing vegetable washingsink and the like are provided with filtering devices, different filtering devices need to be cleaned frequently, and great trouble is caused is solved. The household sewage treatment center comprises a shell with an opening in the upper end, a filter cavity is defined in the shell, four water inlets are formed in the end walls of the left side and the right side of the shell, every two of the four water inlets form a group, the four water inlets are distributed in the side end wall of the shell, and the outer diameters of the four water inlets are different; and a water outlet is formed in the lower end wall of the shell. The household sewage treatment center is more convenient to use and better in sewage filtering effect.

Owner:杜锦超

Ultrasonic cleaner with foreign matter removal function

InactiveCN111618033AReduce impurityAvoid secondary pollutionCleaning using liquidsStationary filtering element filtersForeign matterMegasonic cleaning

The invention relates to an ultrasonic cleaner with the foreign matter removal function. The ultrasonic cleaner comprises a base, an ultrasonic wave transmitter, a transducer, a storage box and a cleaning tank and further comprises a cleaning mechanism and two filter mechanisms. Each filter mechanism comprises a fixing box, a connecting pipe, a filter screen, a water pumping assembly, a pressing plate, a first spring, a foreign matter removal assembly and two power assemblies. The cleaning mechanism comprises a rotating plate, a rotating shaft, a limiting assembly, a torsion spring, a ring andtwo connecting assemblies. According to the ultrasonic cleaner with the foreign matter removal function, by means of the filter mechanisms, the foreign matter removal work is carried out on cleaningfluid in the cleaning tank, the foreign matter content in the cleaning tank is reduced, and the problem that stains cleared off an article are dissolved in the cleaning fluid to cause secondary pollution to the article is prevented; and by means of the cleaning mechanism, the cleaning work is carried out on the bottom of the article in the storage box, and the cleaning effect is improved.

Owner:广州市欧伊若科技有限公司

Impurity separation device for cleaning chemical fiber raw materials

InactiveCN112871847AStable supportExtended service lifeHollow article cleaningCleaning using liquidsFiberEngineering

The invention provides an impurity separation device for cleaning chemical fiber raw materials. The impurity separation device comprises a shell, supporting columns, base plates, a transverse plate, an impurity filtering frame structure, a material dewatering frame structure, an impurity scraping frame structure, a hanging ring, a manual cleaning frame structure, an air cylinder, a rubber pad, a discharging hopper, a discharging valve, an anti-skid pad and a plastic shell, wherein the supporting columns are welded to the four corners of the lower portion of the shell respectively; the base plates are welded to the lower portions of the supporting columns; the transverse plate is in bolted connection with the lower portions of the inner sides of the supporting columns; and the impurity filtering frame structure is mounted on the upper portion of the transverse plate. The impurity separation device for cleaning the chemical fiber raw materials has the beneficial effects that through the arrangement of a cross beam, a spherical groove and supporting balls, the supporting balls roll on the inner side of the spherical groove along with a dewatering net barrel, the periphery of the lower portion of the dewatering net barrel can be supported, therefore, pressure borne by the bottom of the dewatering net barrel is shared, and the service life of the dewatering net barrel is prolonged.

Owner:滨州市沾化区凯棣化工有限公司

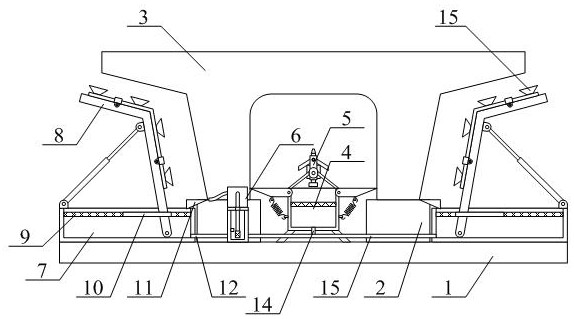

Segmental box girder spraying maintenance system

The invention provides a segmental box girder spraying maintenance system which comprises a base, supporting tables, a segmental box girder, a water source recovery frame structure, a bottom rotary spraying frame structure, a water quality detection frame structure, a collecting box, a convenient-to-disassemble side face spraying frame structure, a filter screen, a sliding groove, a guide hopper,a left side connecting pipe, a right side connecting pipe, a middle connecting pipe and a spraying head. The supporting tables are welded to the left side and the right side of the upper portion of the base correspondingly. The segmental box girder is placed at the upper part of the supporting tables. The segmental box girder spraying maintenance system has the beneficial effects that through thearrangement of a water receiving hopper, a hanging ring and an extension spring, the extension spring pulls the water receiving hopper downwards through the hanging ring, the side face of the water receiving hopper abuts against the inner side of the segment box girder, a gap between the water receiving hopper and the segment box girder can be prevented, and therefore a water source is prevented from flowing out of the gap between the water receiving hopper and the segment box girder, and the influence of cleaning effect by workers on the ground is avoided.

Owner:山东双端数字科技有限公司

Grille decontamination machine

InactiveCN111704181AEasy to operateEasy to adjustSpecific water treatment objectivesWater/sewage treatmentElectric machinerySewage

The invention relates to the technical field of dirt removers, and discloses a grille decontamination machine. A first motor is fixedly mounted on the upper surface of the pollution discharge rack body; rake teeth are rotationally mounted in the pollution discharge rack body; a fixed plate is welded on the front surface of the pollution discharge rack body; a second motor is mounted on the upper surface of the fixed plate; an adjusting assembly is fixedly connected to the central position of one side of the pollution discharge rack body; a cleaning assembly is fixedly mounted on one side, close to the fixed plate, of the front surface of the pollution discharge rack body; through the adjusting assembly, the angle of the pollution discharge rack body is adjusted; sewage can be decontaminated by adapting to different angles; the grille decontamination machine is simple in structure and easy to operate and convenient to adjust, the supporting effect can be effectively achieved through thearrangement of the supporting rod, the situation that impurities existing on the surfaces of the rake teeth cannot fully fall off, and consequently the sewage cleaning effect is affected can be avoided through the arrangement of the cleaning assembly, and a cleaning sleeve adheres to the rake teeth through the adhesive layer and is convenient to detach and replace.

Owner:YANGZHOU RENZHI INFORMATION TECH CO LTD

Combined type automatic cleaning machine for vehicle evaporation box

InactiveCN112264417AReasonable structural designPracticalHollow article cleaningCleaning using liquidsWater storage tankEvaporator

A combined type automatic cleaning machine for a vehicle evaporation box comprises two groups of supporting columns, cleaning boxes are fixedly connected to the upper ends of the supporting columns, fixing assemblies are arranged on the left wall and the right wall of a fixing seat, a linkage assembly is connected to the lower end of a rotating shaft, a cleaning brush is installed at the other endof a connecting plate, a flushing assembly is connected with the upper side of the connecting plate, a liquid storage tank and a clear water tank are arranged at the upper ends of the cleaning boxes,and a liquid inlet assembly is connected between the liquid storage tank and the clear water tank. According to the combined type automatic cleaning machine, two evaporation boxes can be fixed through the fixing assemblies, the situation that the cleaning effect of the evaporation boxes is affected due to movement of the evaporators in the cleaning process is prevented, the cleaning brush is driven by the linkage assembly to move up and down, and the cleaning brush can be driven to comprehensively and thoroughly clean the evaporators up and down; and the liquid inlet assembly and the flushingassembly are matched to spray cleaning liquid to the two side faces of the evaporation boxes to be cleaned, meanwhile, clean water cleans the evaporator again finally, the cleaning effect is improved, the evaporation boxes are pressed through pressing plates, and the fixing effect of the evaporation boxes is improved.

Owner:安徽省玉环清洗设备制造有限公司

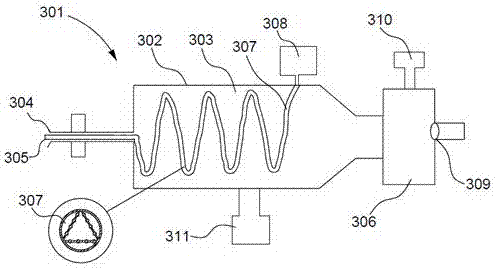

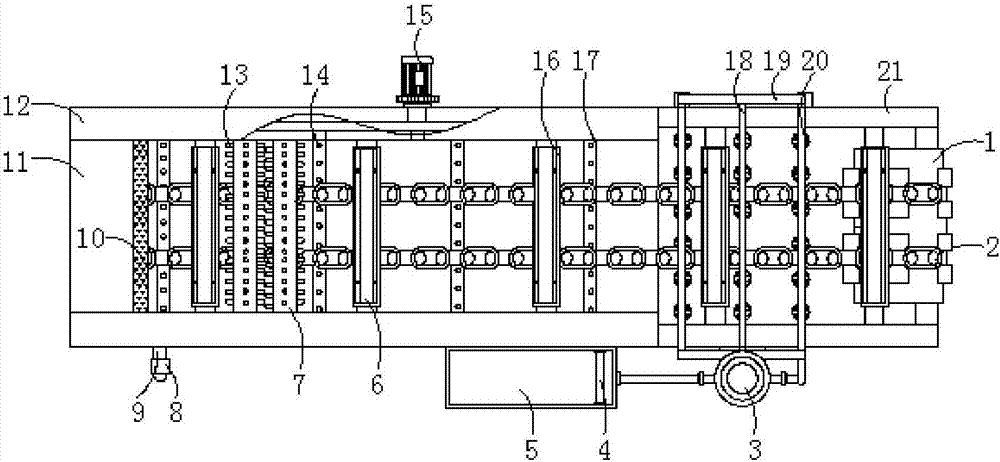

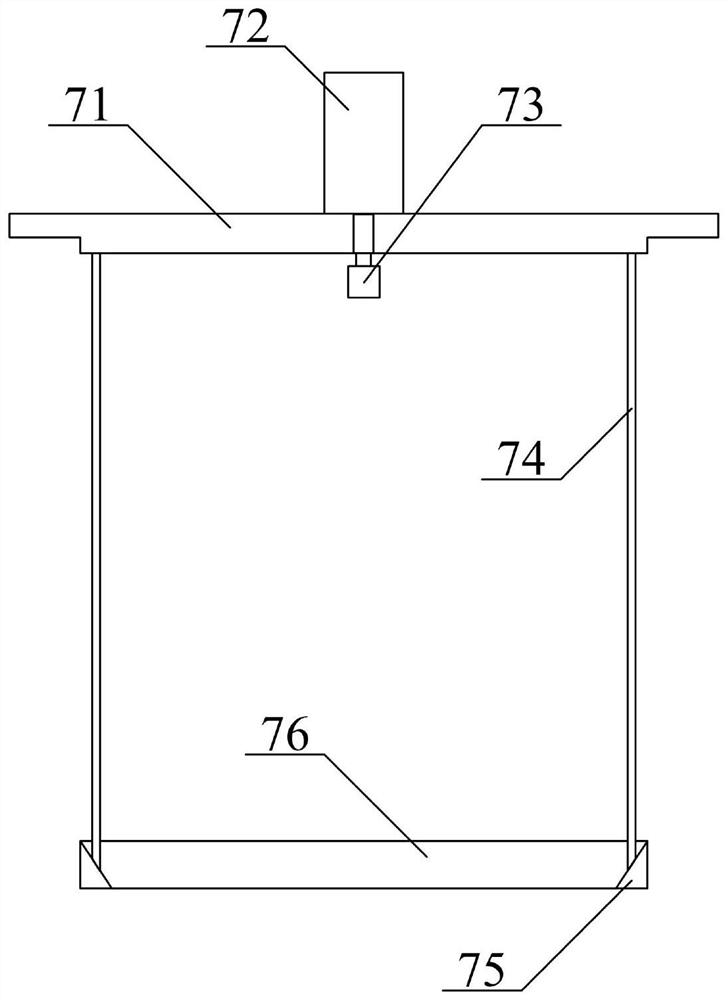

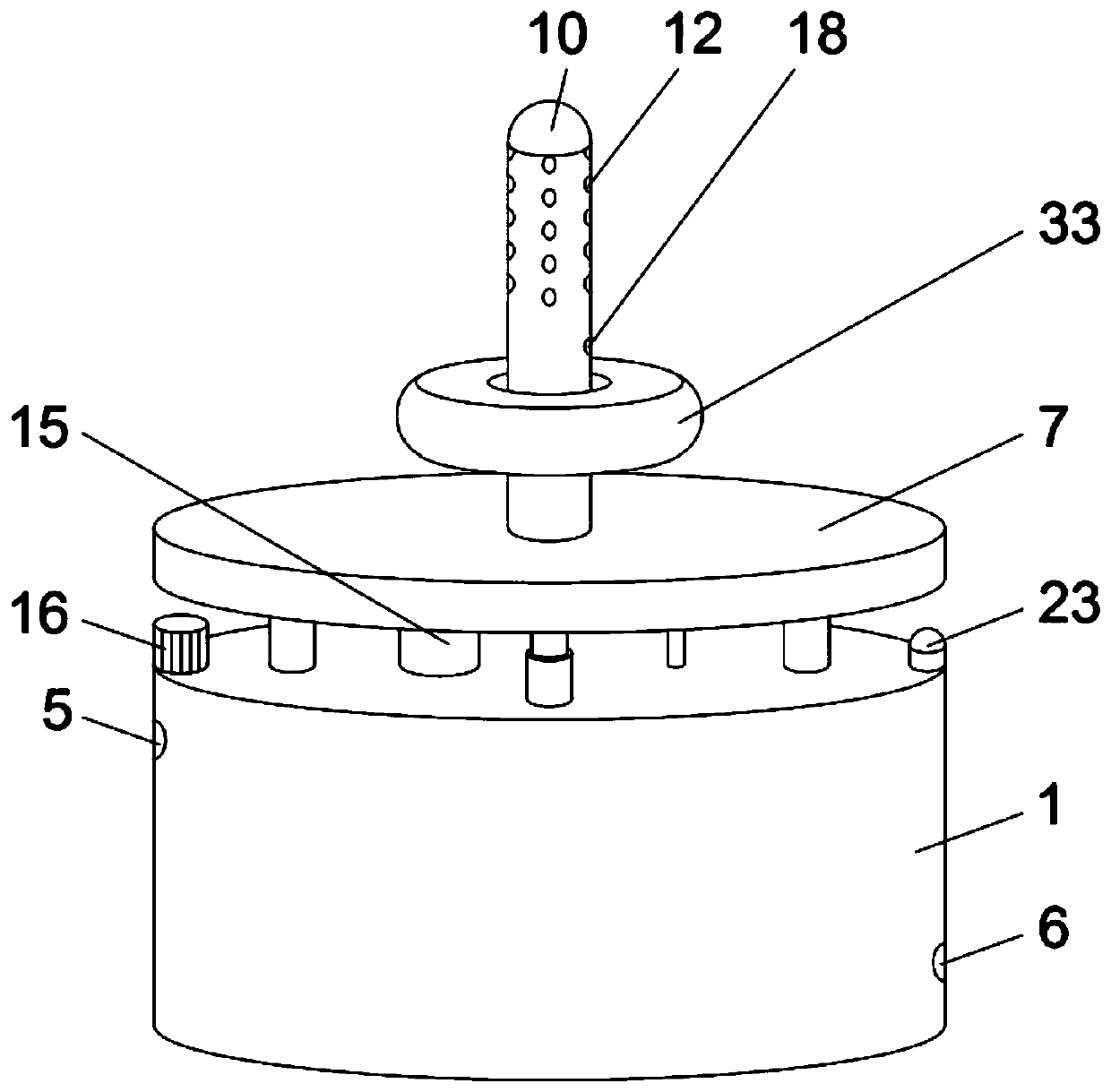

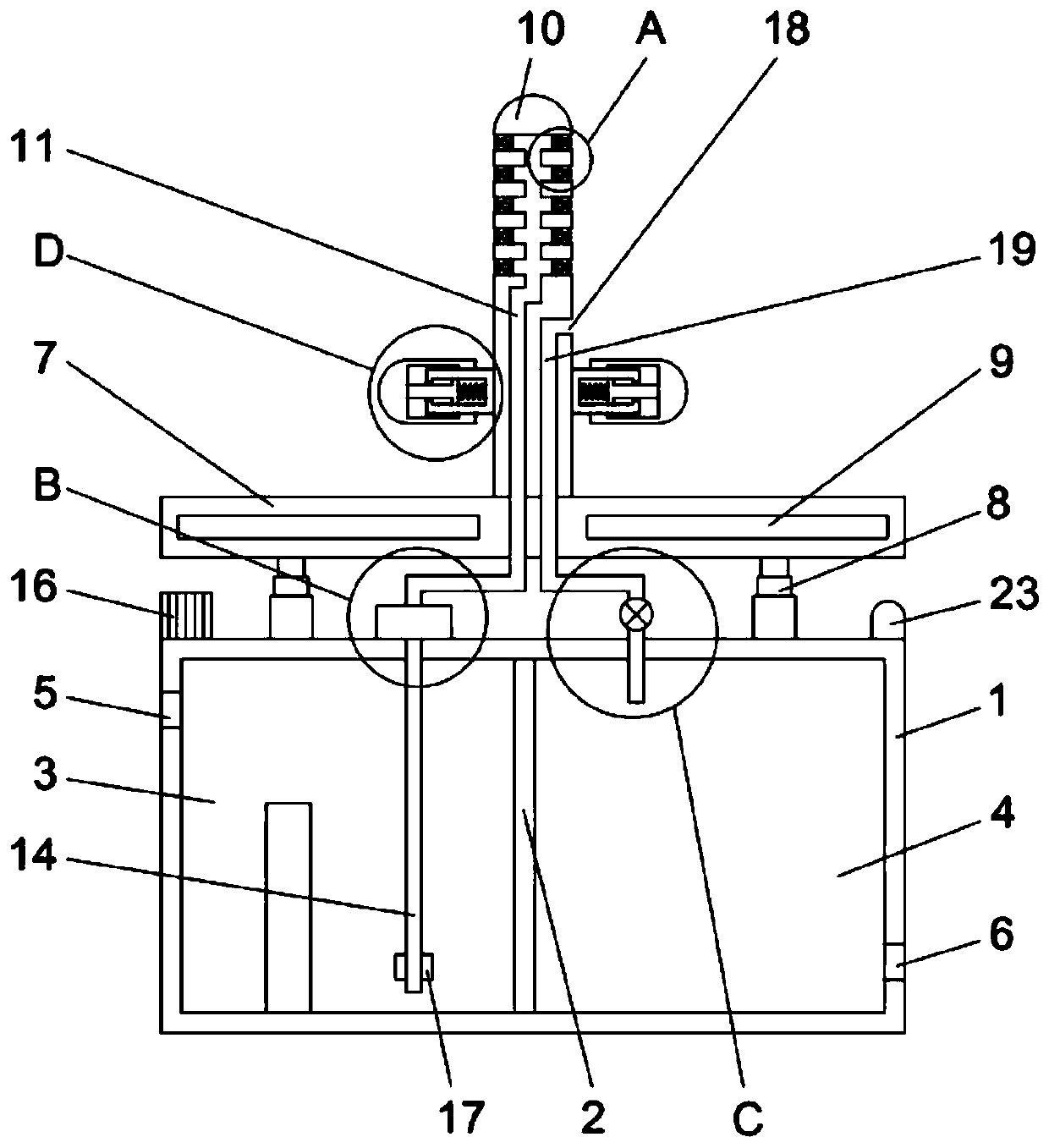

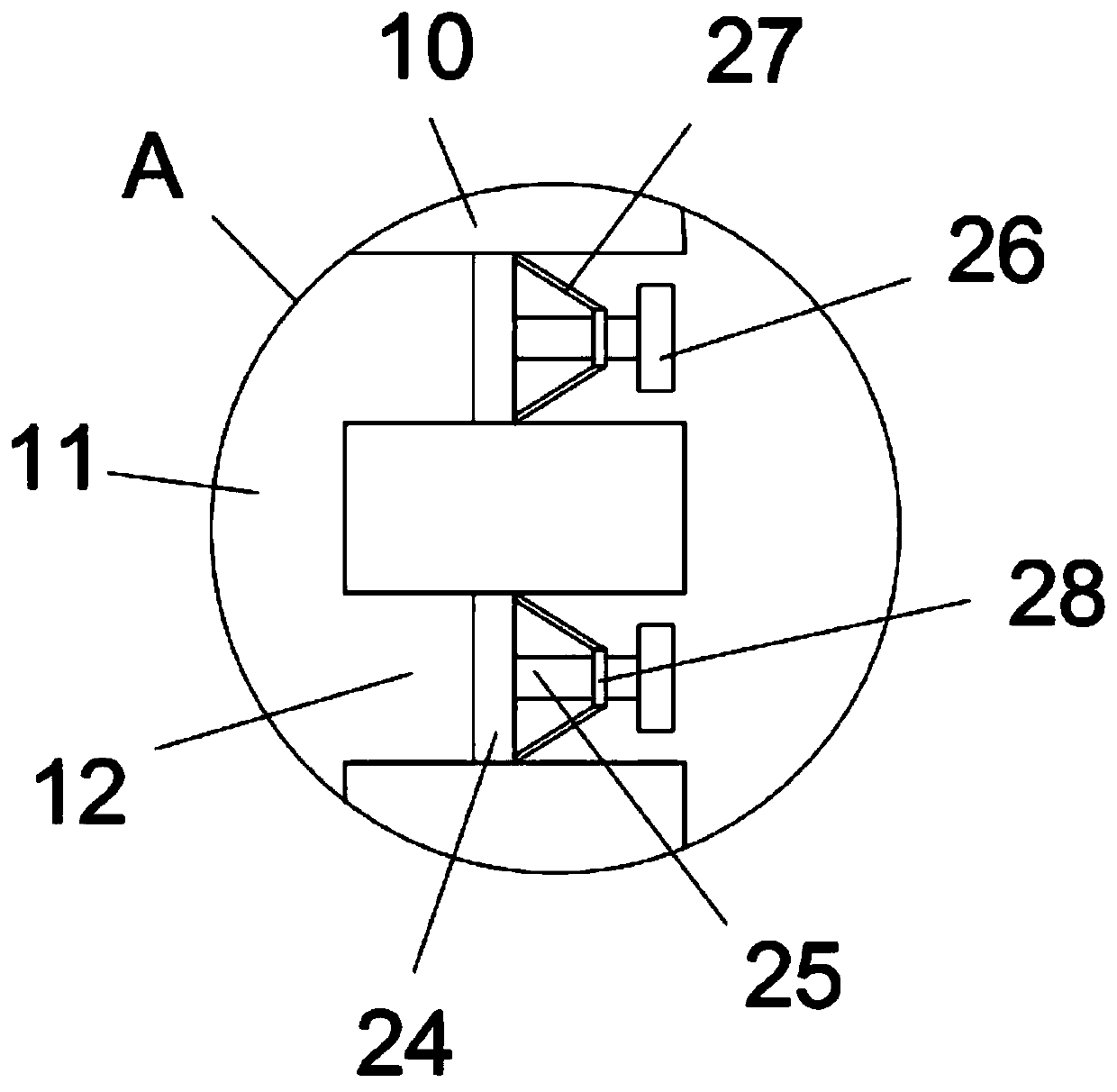

Large and medium-sized layered heating experiment device for anaerobic fermentation of coal and experiment method of layered heating experiment device

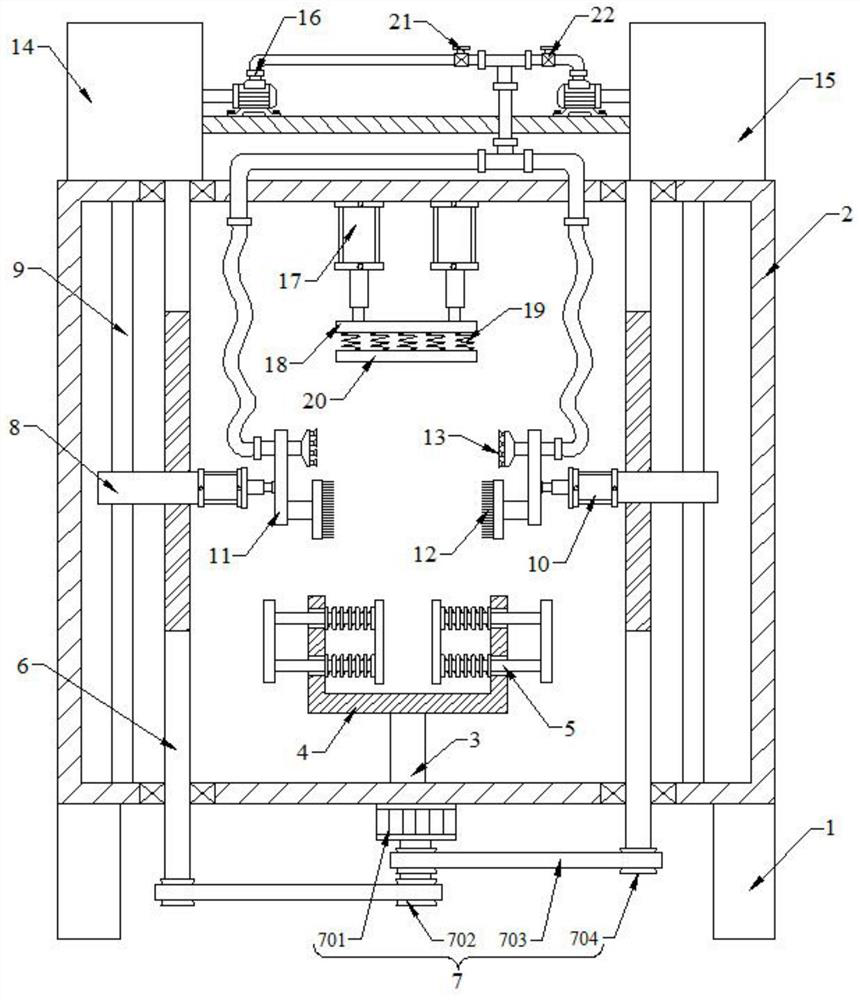

PendingCN110106068AReasonable designCompact structureBioreactor/fermenter combinationsBiological substance pretreatmentsPush pullEngineering

The invention provides a large and medium-sized layered heating experiment device for anaerobic fermentation of coal. The device comprises the tank body, a feed cylinder is arranged on the top of thetank body, the top of the feed cylinder is provided with a tank cover, a horizontal push-pull type material retention mechanism is arranged on the lower portion of the feed cylinder, and an enrichmentculture area is arranged in the feed cylinder. A plurality of gas holes are formed in the top of the tank body, a circulating flow guide cylinder coaxial with the tank body is arranged in the tank body, a mixing gas production area is arranged in the tank body, and a first gas suction opening and a second gas suction opening are formed in the edge of the top of the tank body and the upper portionof the feed cylinder respectively. The invention further discloses an experiment method of the large and medium-sized layered heating experiment device for anaerobic fermentation of the coal. The principle is scientific, the design is reasonable, and uniform heating is kept in the whole fermentation process; the mixing gas production area and the enrichment culture area are integrated into one, so that the interference of outside air is avoided to the greatest extent; by using a gas-pressurization circulating type stirring device, a secondary guarantee is provided for the uniform heating of the fermentation process.

Owner:HENAN POLYTECHNIC UNIV

Multifunctional vegetable cleaning equipment

ActiveCN108720051AAffect cleaning effectGuaranteed cleaning effectSievingScreeningWater collectionMechanical engineering

The invention provides multifunctional vegetable cleaning equipment which comprises a pipeline and a soaking barrel. A feeding hopper is mounted at the left end of the top end face of a main body through screws and communicated with the inside of the main body, a water drainage hole is formed in the bottom of the main body, a water collection tank is mounted at the water drainage hole through screws, an exhaust hole is formed in the right-end bottom of the main body and communicated with an air incoming pipe mounted at the top of the main body, six supporting columns are mounted on the bottomend face of the main body, a bead chain belt wheel is rotatably connected with a bead chain and is in transmission connection with a motor through a belt, a water incoming valve is positioned at the top of the main body and communicated with an outside water supply pipeline, and two ends of a hollow plate are mounted on the inner wall of the main body respectively. Fixing of the outside of a smalltomato is facilitated when the small tomato is cleaned, so that impact on effect of cleaning the outside of the small tomato due to the fact that the small tomato rolls around inside the equipment isavoided.

Owner:汝城县繁华食品有限公司

Shirt hanging device specialized for garment workshop

PendingCN109235006AAffect cleaning effectNo need for manual cleaningMechanical cleaningPressure cleaningEngineeringOrganic glass

The invention discloses a shirt hanging device specialized for a garment workshop, and relates to the technical field of garment production and processing. The shirt hanging device comprises a hangingdevice body which comprises a hanging box, a box door, hanging blocks, hanging plates, outer shaving machines, inner shaving machines, steam engines and moving wheels. One side of the front end of the hanging box is fixedly connected with one end of the box door through hinges. According to the shirt hanging device specialized for the garment workshop, the box door can be closed when the hangingbody is working, and dust and particulate matter from the outside can be prevented from flying in to affect the cleaning effect of shirts; besides, the box door is the transparent organic glass box door and the internal working situation of the hanging box can be observed when the box door is closed; then the outer shaving machines and the inner shaving machines can work simultaneously to clean the hairs on the inner side and the outer side of the shirts so as to be convenient and quick without manual cleaning; furthermore, there are not less than two hanging blocks and hanging plates so thatmore shirts can be hung at one time by the hanging device body.

Owner:湖州韩源进出口有限公司

Cleaning device for urological and anorectal surgical nursing

ActiveCN111420153AFreely change the areaImprove comfortCannulasEnemata/irrigatorsNursing careEngineering

The invention discloses a cleaning device for urological and anorectal surgical nursing. The device comprises a box body, a blocking mechanism and an anti-backflow mechanism; a partition plate is vertically and fixedly connected into the box body; and the box body is divided into a cleaning liquid chamber and a waste liquid chamber by the partition plate. The device is provided with the blocking mechanism, so that when the anorectum of a user is blocked, the anorectum of the user can freely stretch and retract, damage to the anorectum of the user by a hard blockage mode is avoided, and comfortfor the user is improved. Meanwhile, anorectum with different diameters can be blocked by a freely telescopic elastic rubber frame, so that applicability is improved. The device is further provided with the anti-backflow mechanism, so that waste liquid generated after anorectal cleaning is prevented from flowing back into a liquid distribution pipe to pollute the liquid distribution pipe and a cleaning catheter, a cleaning device is convenient to clean and disinfect after being used, meanwhile, outflow efficiency of cleaning liquid is improved, and the outflow time of the cleaning liquid is shortened. An electric telescopic rod is further arranged, and the height of a cushion is adjusted through the electric telescopic rod, so that a user can sit more comfortably.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Rod type automatic moving bent pipe inner wall cleaning device

ActiveCN112643418AEasy to cleanArc automatically adaptsRevolution surface grinding machinesGrinding drivesPipeMechanics

The invention relates to the technical field of steel pipe machining, and discloses a rod type automatic moving bent pipe inner wall cleaning device. The device comprises a base and four outer rods, a fixing device is arranged in the base, a water inlet pipe is fixedly connected to the bottom of the base, and extendable rods are arranged in the outer rods. According to the rod type automatic moving bent pipe inner wall cleaning device, when a bent pipe is cleaned and the cleaning device enters the bent pipe, an inner ball can rotate in an outer ball, the interior of the bent pipe can be cleaned conveniently, bending can be conducted according to the radian of the bent pipe, then the inner wall of a steel pipe can be cleaned, the situation that the interior of the bent pipe is inconvenient to clean is avoided, it is guaranteed that the device can automatically adapt to the radian of the bent pipe, then steel pipes with different bent radians can be cleaned conveniently, and when the steel pipes with the excessively-large bent radians are cleaned, the length of the extendable rod with the proper length should be changed.

Owner:杭州新元素医疗科技有限公司

Flushing device avoiding excessive cleaning liquid waste for surgical nursing

InactiveCN111803743AAvoid wastingControl amountShaking/oscillating/vibrating mixersCannulasLiquid wasteNursing care

The invention relates to the technical field of medical instruments, in particular to a flushing device avoiding excessive cleaning liquid waste for surgical nursing. The device comprises a shell, a fixing frame is fixedly connected to the interior of the shell, a worm wheel is rotatably connected to the interior of the fixing frame, a limiting column is fixedly connected to the front surface of the worm wheel, an adjusting plate is slidably connected to the outer surface of the limiting column, and the adjusting plate slides in the fixing frame. When the adjusting plate slides until the leakage hole in the adjusting plate is concentric with the through hole in the fixing frame, a cleaning agent in the fixing frame falls out through the through hole and is mixed with falling mixed water, and the mixed water and the cleaning agent are mixed together to form a cleaning liquid, so that the using amount of the cleaning liquid can be reasonably controlled according to requirements, medicalstaff can control the amount of the mixed water according to the required amount, the effect of controlling the amount of the cleaning liquid can be achieved, the medical staff do not need to blend the cleaning liquid, and the working time of the medical staff is saved.

Owner:JILIN UNIV FIRST HOSPITAL

Dehydrated vegetable pretreatment production line

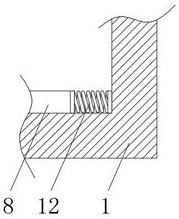

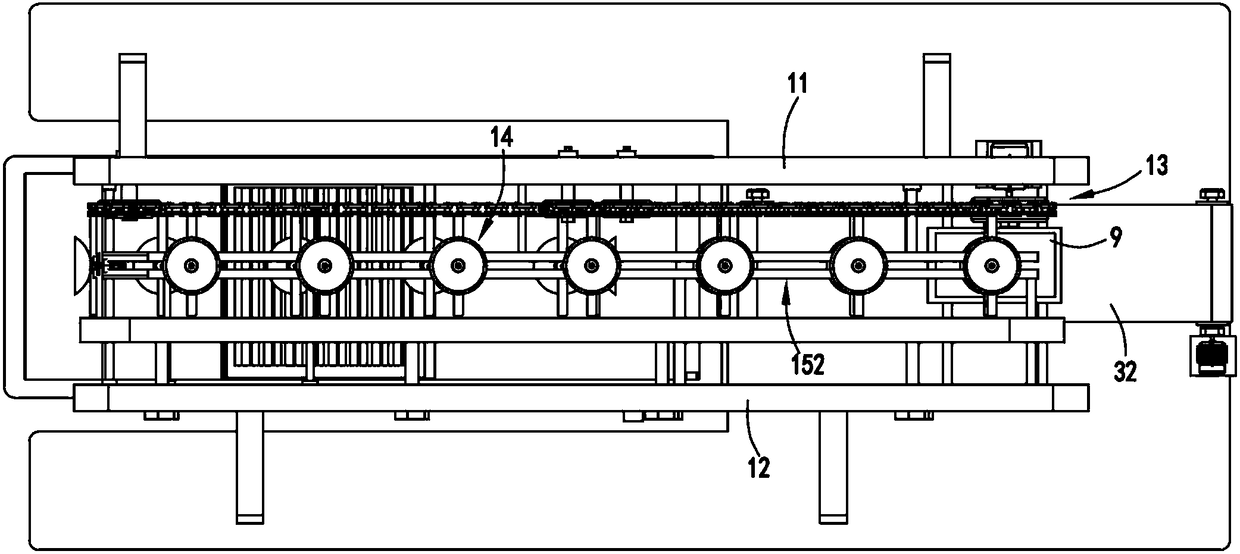

ActiveCN108576862AImprove cleaning effectImprove cleaning efficiencyFood treatmentPre treatmentWater tanks

The present invention relates to a dehydrated vegetable pretreatment production line. The dehydrated vegetable pretreatment production line comprises a vegetable rotating device, a washing device anda post-treatment device; the vegetable rotating device comprises a first bracket, a second bracket, a rotating mechanism between the first bracket and second bracket, a plurality of supporting mechanisms for carrying vegetables on the rotating mechanism and clamping mechanisms for fixing vegetable roots arranged under the supporting mechanisms; the rotating mechanisms drive the supporting mechanisms and clamping mechanisms to conduct rotation motions with the vegetables; the washing device comprises a water tank, a rotating mechanism for driving the vegetables to rotate in water arranged and arranged above the water tank, and a sludge cleaning mechanism arranged in the water tank and for enabling water to produce surge and at the same time concentrating sludge deposited at a bottom part toa place; and the post-treatment device comprises cutters for cutting off the vegetable roots and an output belt arranged under the cutters. The dehydrated vegetable pretreatment production line overcomes the following problems: in the washing processes, the vegetables are easily damaged; only unclean matters on surfaces can be washed away, while the mingled unclean matters inside cannot be washedaway; the washing efficiency is low; and the produced unclean matters in the washing cannot be cleaned up in time, which affects the subsequent washing effects.

Owner:临泉县恒达食品有限公司

Anti-winding cleaning rolling brush and cleaning robot

PendingCN112515551AReduce volumeSave spaceCarpet cleanersFloor cleanersReciprocating motionElectric machinery

The invention relates to the field of cleaning equipment, in particular to an anti-winding cleaning rolling brush and a cleaning robot, the anti-winding cleaning rolling brush is provided with a rod body, a brush body is arranged on the rod body to form a main body of the anti-winding cleaning rolling brush, the rod body is provided with a gap extending along the axis of the rod body, and a reciprocating lead screw is arranged in the rod body; one end of the reciprocating lead screw is detachably connected with the rolling brush frame in a clamped mode, the reciprocating lead screw is sleevedwith a limiting piece, the limiting piece and the reciprocating lead screw are connected to be capable of doing reciprocating motion along the reciprocating lead screw, and a cutting piece is fixedlyconnected to the limiting piece and stretches out of the gap. During use, the rod body rotates, acting force is transmitted to the cutting piece through the gap, and due to the fact that the reciprocating lead screw is connected to the rolling brush frame in a clamped mode, the cutting piece does reciprocating motion along the reciprocating lead screw through the acting force, and hair and the like wound on the rod body are cut. Compared with the structure that the reciprocating screw rod is arranged outside the rolling brush, the rolling brush has the advantages that the size is greatly reduced, and the motor loss is reduced.

Owner:SHENZHEN SILVER STAR INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com