Segmental box girder spraying maintenance system

A maintenance system and box girder technology, applied in the field of segment box girder spray curing system, can solve the problems of water source outflow, small spray range, and laborious maintenance of side spray racks, etc., to reduce maintenance costs, save energy consumption, The effect of increasing the spray range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

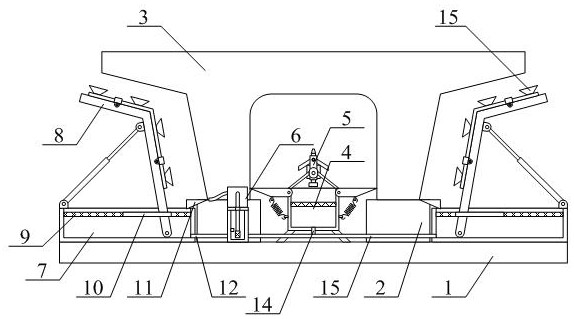

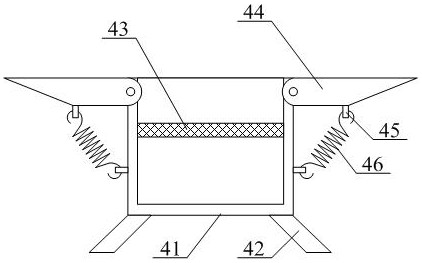

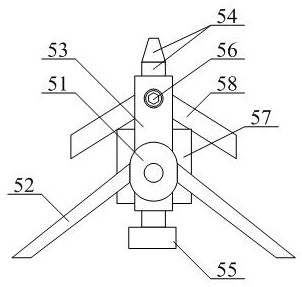

[0035] as attached figure 1 And attached figure 2As shown, a segmental box girder spray maintenance system includes a base 1, a support platform 2, a segmental box girder 3, a water source recovery frame structure 4, a bottom rotating spray frame structure 5, a water quality detection frame structure 6, and a collection box 7. Disassemble the side spray frame structure 8, the filter screen 9, the chute 10, the guide bucket 11, the left connecting pipe 12, the right connecting pipe 13, the middle connecting pipe 14 and the sprinkler head 15, the support platform 2 are respectively welded on the left and right sides of the upper part of the base 1; the section box girder 3 is placed on the upper part of the support platform 2; the water source recovery frame structure 4 is installed at the upper middle position of the base 1; the bottom rotation The spray frame structure 5 is arranged on the upper part of the water source recovery frame structure 4; the water quality detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com