Spinning device and polyacrylonitrile fiber spinning machine

A technology of polyacrylonitrile fiber and spinning device, which is applied in wet spinning method, drawing spinning method, feeding solution to spinneret, etc., can solve the problems of complex equipment structure, large space occupation and high production cost, and achieve shortened time. Process flow, high production efficiency, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

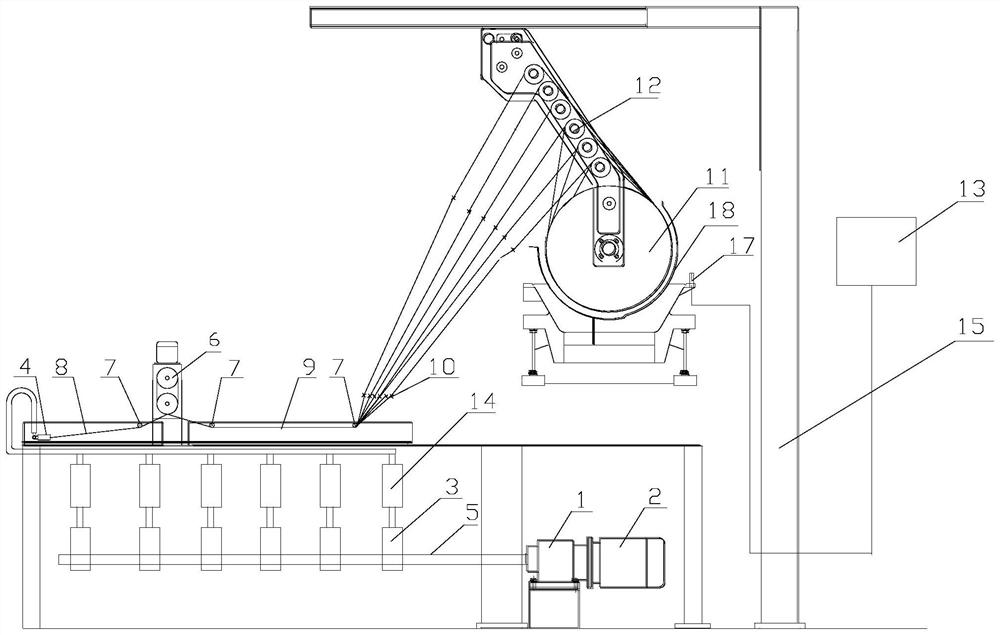

[0049] This embodiment provides a spinning device and a polyacrylonitrile fiber spinning machine with the spinning device:

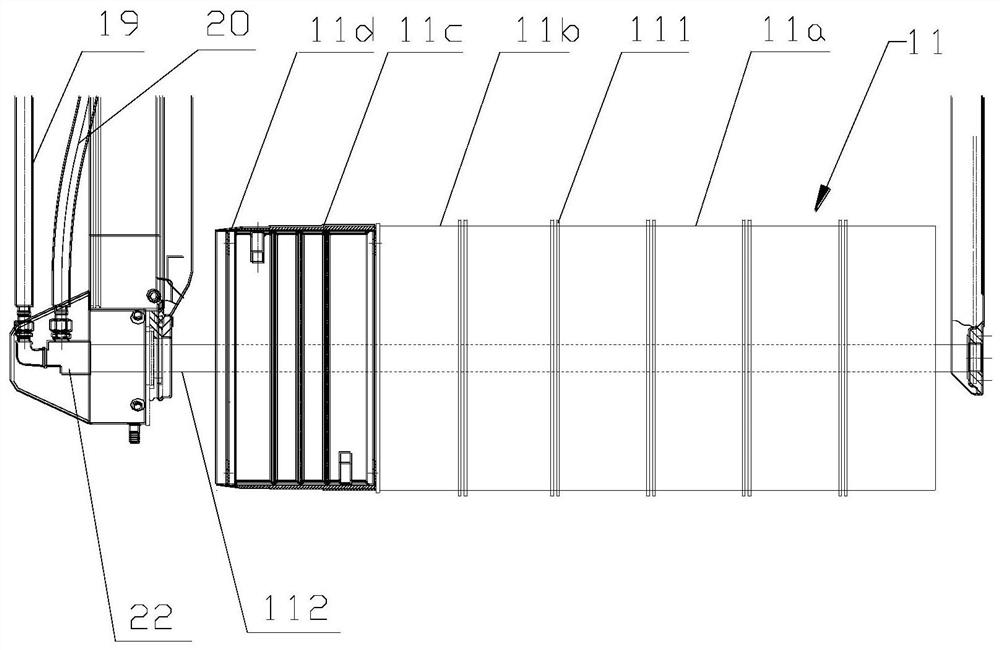

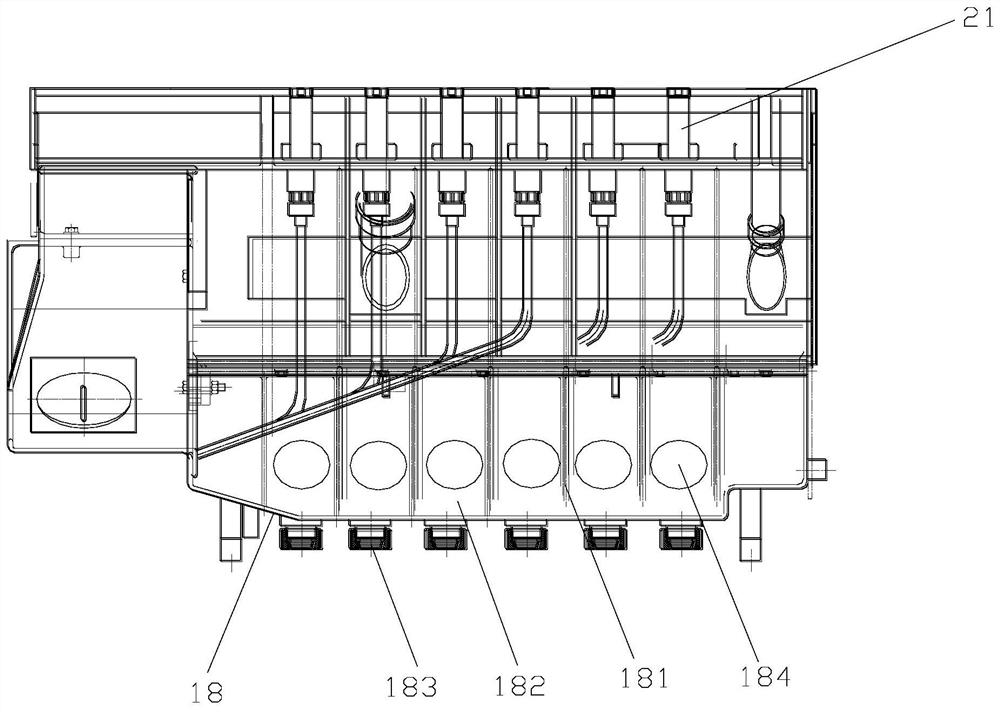

[0050] Such as Figure 1 to Figure 7 As shown, the present embodiment provides a spinning device, and the spinning device includes a pair of rollers consisting of a first spinning roll 12 and a second spinning roll 11 with different diameters, wherein the second spinning roll 11 The diameter is greater than the diameter of the first spinning roll 12, and the filaments alternately pass through the first spinning roll 12 and the second spinning roll 11 in turn, and the filaments are wound from one end of the pair of rolls to the other end, and the second spinning The roller 11 includes a water washing section 11a, and water is sprayed on the water washing section 11a by a water spraying mechanism to realize water washing of the filaments.

[0051] Preferably, in this embodiment, multiple first spinning rolls 12 correspond to one second spinning roll 11 , ...

Embodiment 2

[0112] On the basis of the first embodiment, this embodiment provides a process for preparing polyacrylonitrile fibers using the polyacrylonitrile fiber spinning machine in the first embodiment.

[0113] A preparation process for polyacrylonitrile fibers, comprising:

[0114] Spinning the spinning dope through a spinning device;

[0115] The sprayed spinning stock solution is shaped by a forming device to obtain filaments;

[0116] The formed filaments are washed with water and dried to obtain polyacrylonitrile fibers.

[0117] In order to realize the preparation technology of polyacrylonitrile fiber in the present embodiment, adopt such as Figure 1 to Figure 3 The spinning machine shown carries out the production of polyacrylonitrile fibers. Described spinning machine comprises frame 15, is used for the spinneret device that spinning dope is carried out spinning, makes the spinning dope of spraying form the molding device that forms filament, and carries out follow-up tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com