Cleaning and drying device used after silicone rubber key spraying

A drying device and silicone rubber technology, which can be applied to the arrangement of drying gas, the device for coating liquid on the surface, and the drying of solid materials, etc., which can solve the problems of long waiting time for natural air-drying, excessive water accumulation on the surface of the button layer, and increased labor costs. , to avoid wasting water resources, speed up drying rate, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

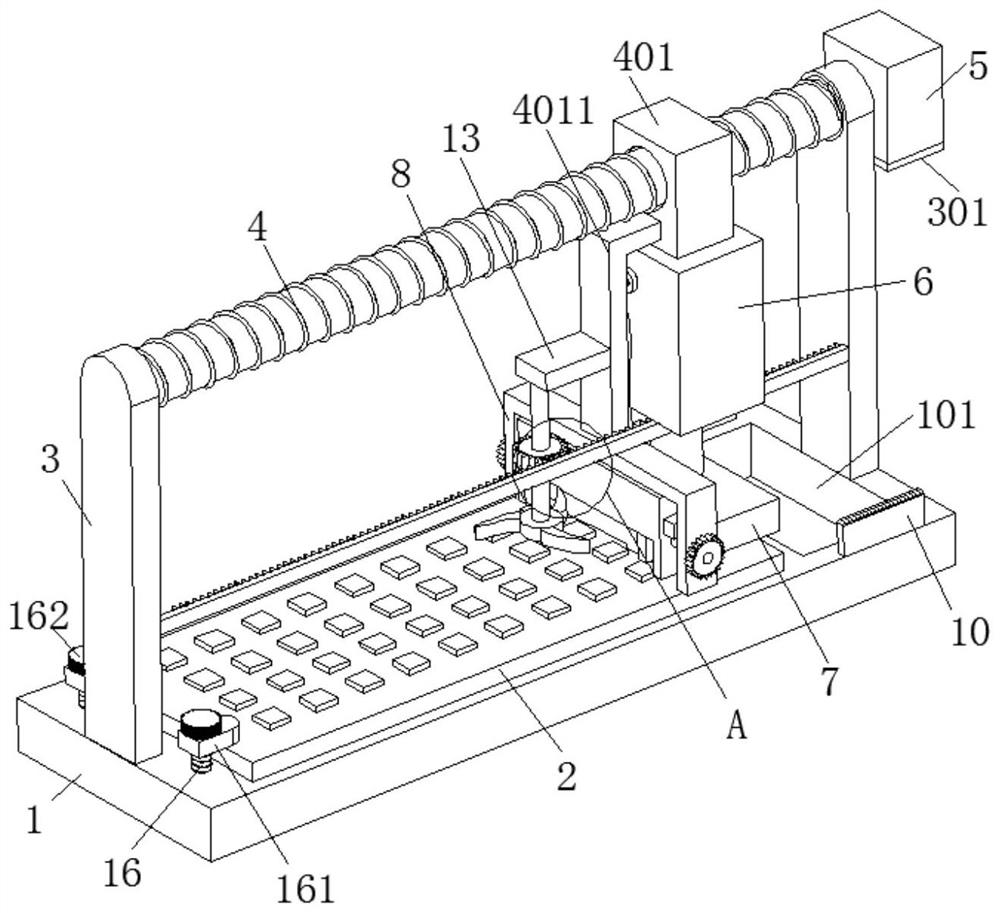

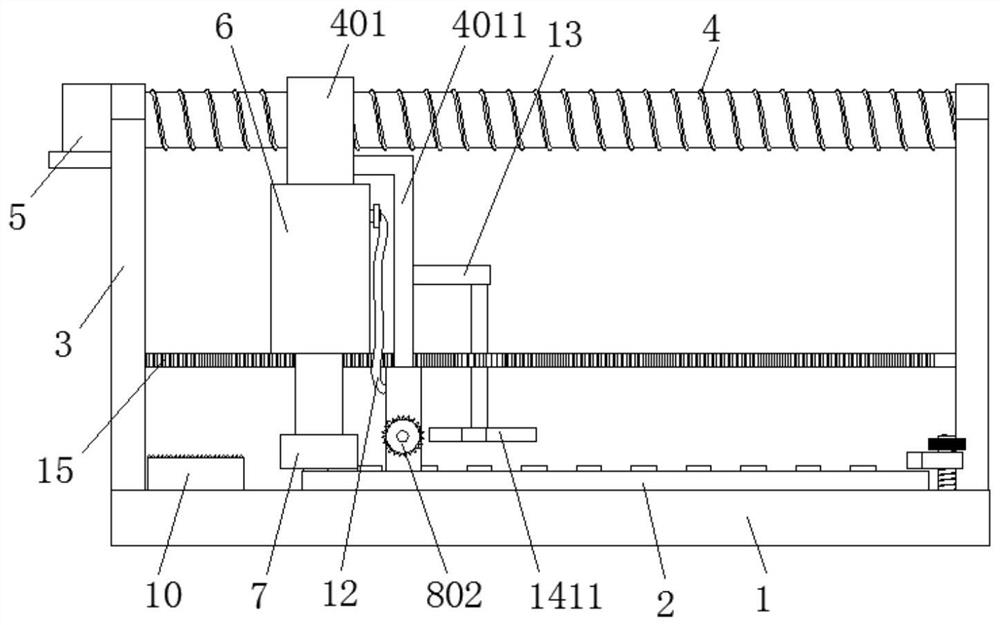

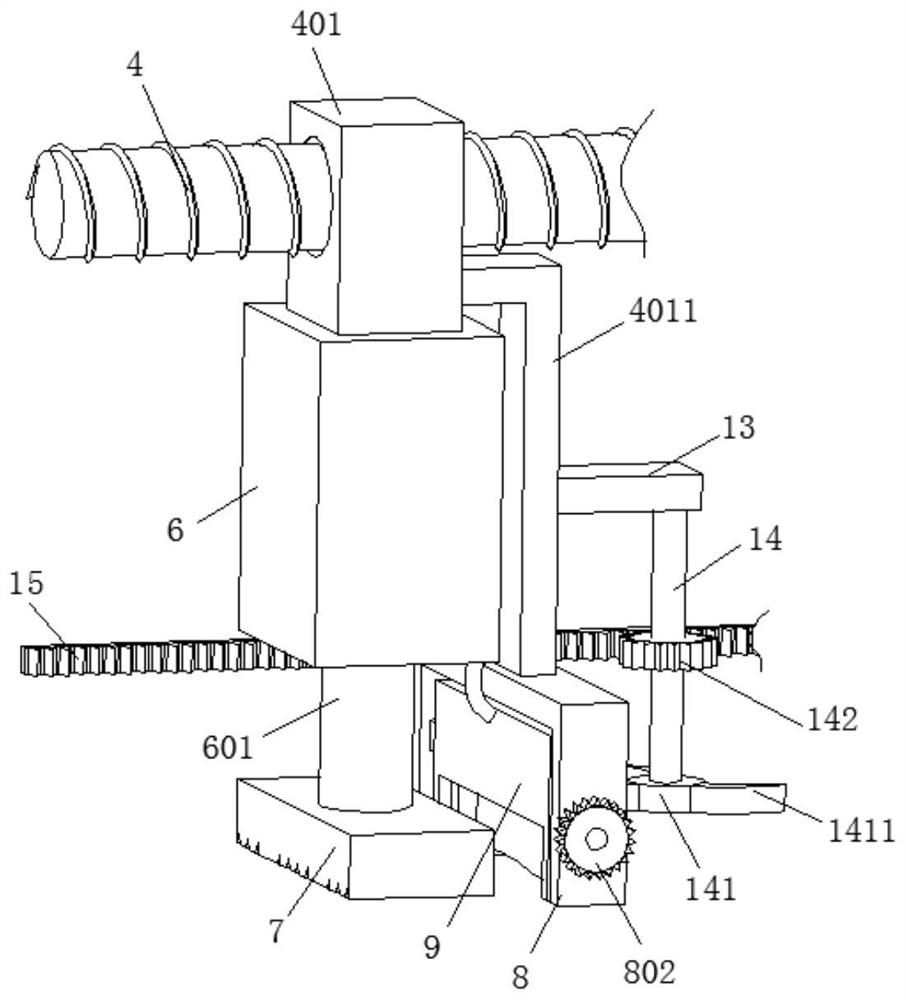

[0031] like Figure 1 to Figure 5 As shown, a cleaning and drying device for a silicone rubber button of the present invention after spraying comprises a base 1 and a silicone rubber button layer 2, the silicone rubber button layer 2 is placed on the top surface of the base 1, and both sides of the top surface of the base 1 are fixed Connected to the fixed base 3 that is vertically arranged, the first screw rod 4 is arranged between the two groups of fixed bases 3, the two ends of the first screw rod 4 are connected to the fixed base 3 through bearings, and the sides of the fixed base 3 are fixedly connected There is a support plate 301, the first motor 5 is fixedly installed on the support plate 301, the output end of the first motor 5 is fixedly connected with one end of the first screw mandrel 4, and the first sleeve 401 is screwed on the first screw mandrel 4, The bottom end of the first sleeve 401 is fixedly connected with the water tank 6, the bottom of the water tank 6 ...

Embodiment 2

[0034] like Figure 1 to Figure 6 As shown, the cleaning and drying device for a silicone rubber button of the present invention after spraying is basically the same as that of Embodiment 1, furthermore, the bottom wall of the water tank 6 is provided with a tapered hole 602, and the inner wall of the tapered hole 602 is movably connected with The piston 6021 is fixedly connected with the telescopic rod 603 between the piston 6021 and the top wall of the water tank 6, and the peripheral side of the telescopic rod 603 is provided with a spring 6031. One end of the rod 603 is fixedly connected with the hollow rod 601;

[0035] The hollow rod 601 is a circular hollow tube, the circumference of the hollow rod 601 is provided with multiple groups of water inlet holes 6011, the brush plate 7 includes a water storage chamber 701 and a brush body 702, and the brush body 702 is fixedly connected to the water storage chamber 701 The bottom wall of the water storage chamber 701 communic...

Embodiment 3

[0039] like figure 1 , figure 2 and Figure 7 As shown, a cleaning and drying device of the present invention is used after spraying a silicone rubber button, which is basically the same as that of Embodiment 1. Further, the L-shaped plate 4011 is fixedly connected with a connecting plate 13, and the bottom end face of the connecting plate 13 is rotated through the bearing. A rotating rod 14 is connected, the bottom end of the rotating rod 14 is fixedly connected with a disk 141, and the peripheral side of the disk 141 is fixedly connected with a plurality of groups of fan blades 1411 arranged in a circular array, and the body of the rotating rod 14 is also fixedly sleeved with The second gear 142, the second rack plate 15 meshing with the second gear 142 is fixedly connected between the two sets of fixed seats 3; the L-shaped plate 4011 moves with the first sleeve 401 to drive the rotating rod 14 and the second gear 142 moves, the second gear 142 meshes with the second rac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com