Glue spreading device for adhesive tape, and using method thereof

A gluing device and adhesive tape technology, which are applied to the cleaning method using tools, the device for coating liquid on the surface, and the cleaning method using gas flow. inequality problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

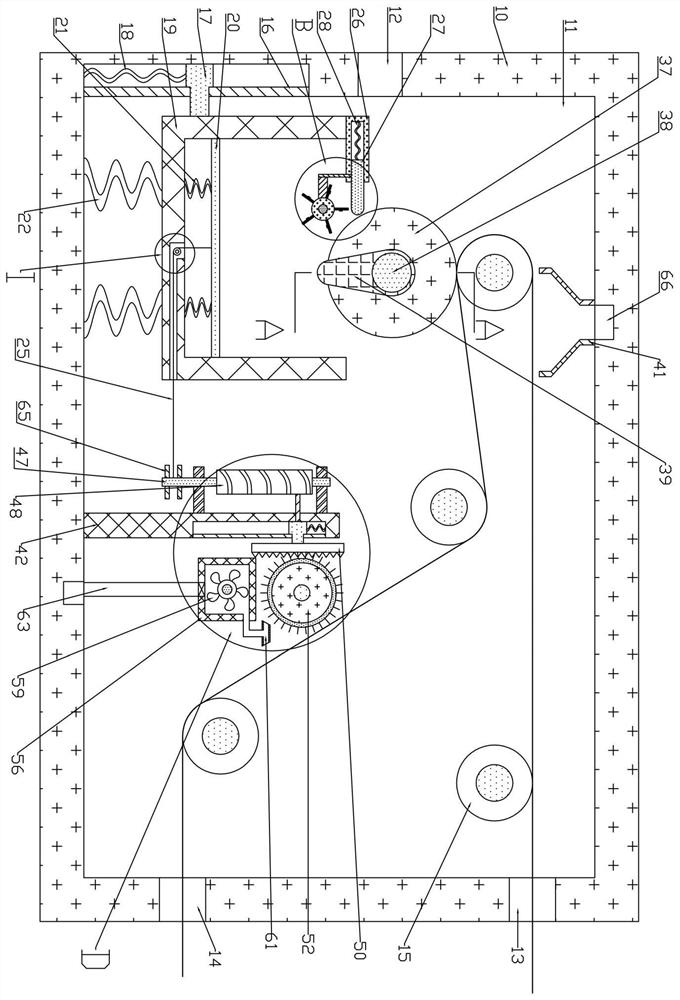

[0045] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

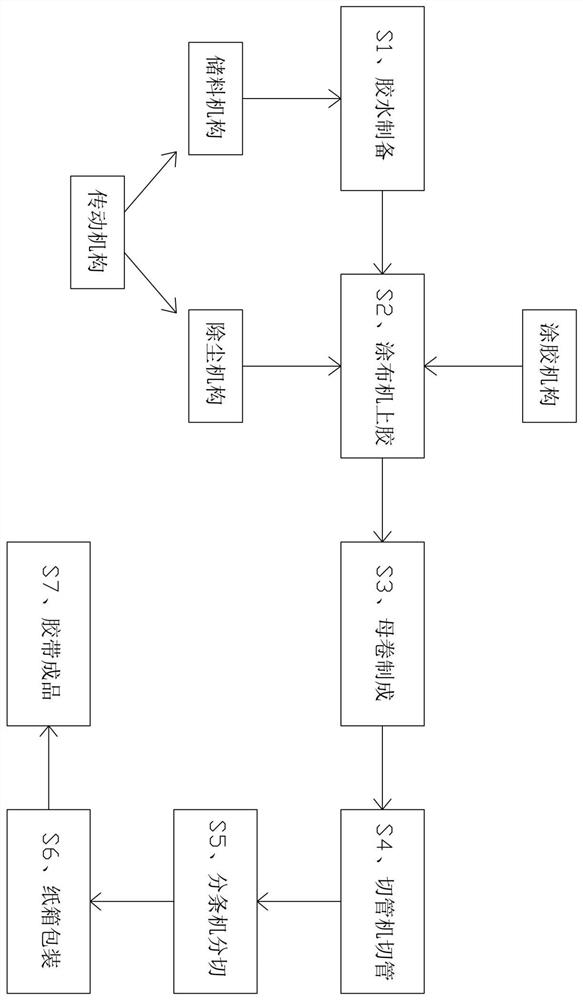

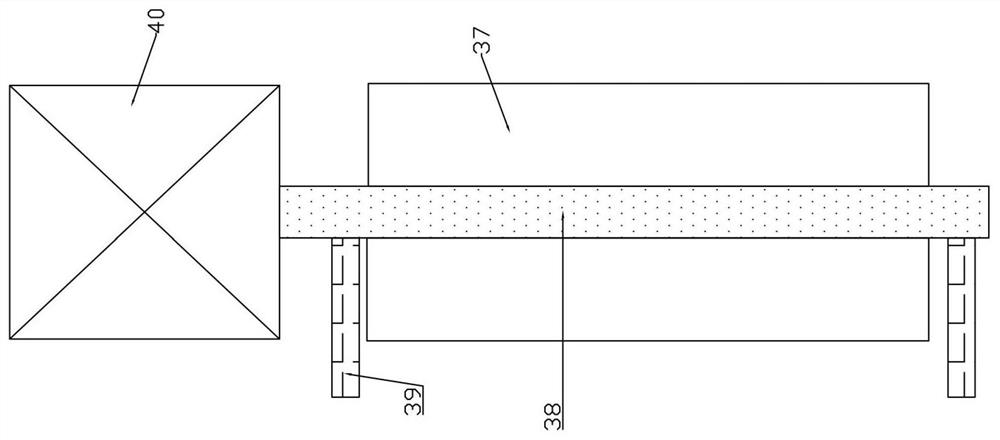

[0046] Such as figure 1 , figure 2 As shown, a tape gluing device and its use method, the specific processing method steps are as follows:

[0047] S1. Glue preparation: emulsify and heat raw materials such as acrylic acid to prepare glue;

[0048] S2. Coating machine gluing: The glue produced in step S1 is filled in the storage mechanism, and the film is glued through the gluing mechanism. While gluing, the dust removal mechanism cleans and air-dries the film, and at the same time passes through the transmission mechanism and the storage mechanism. Cooperate with the material organization;

[0049] S3, making of the parent roll: after the step S2, the semi-finished product of the adhesive tape is produced;

[0050] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com