Patents

Literature

154results about How to "Affect uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

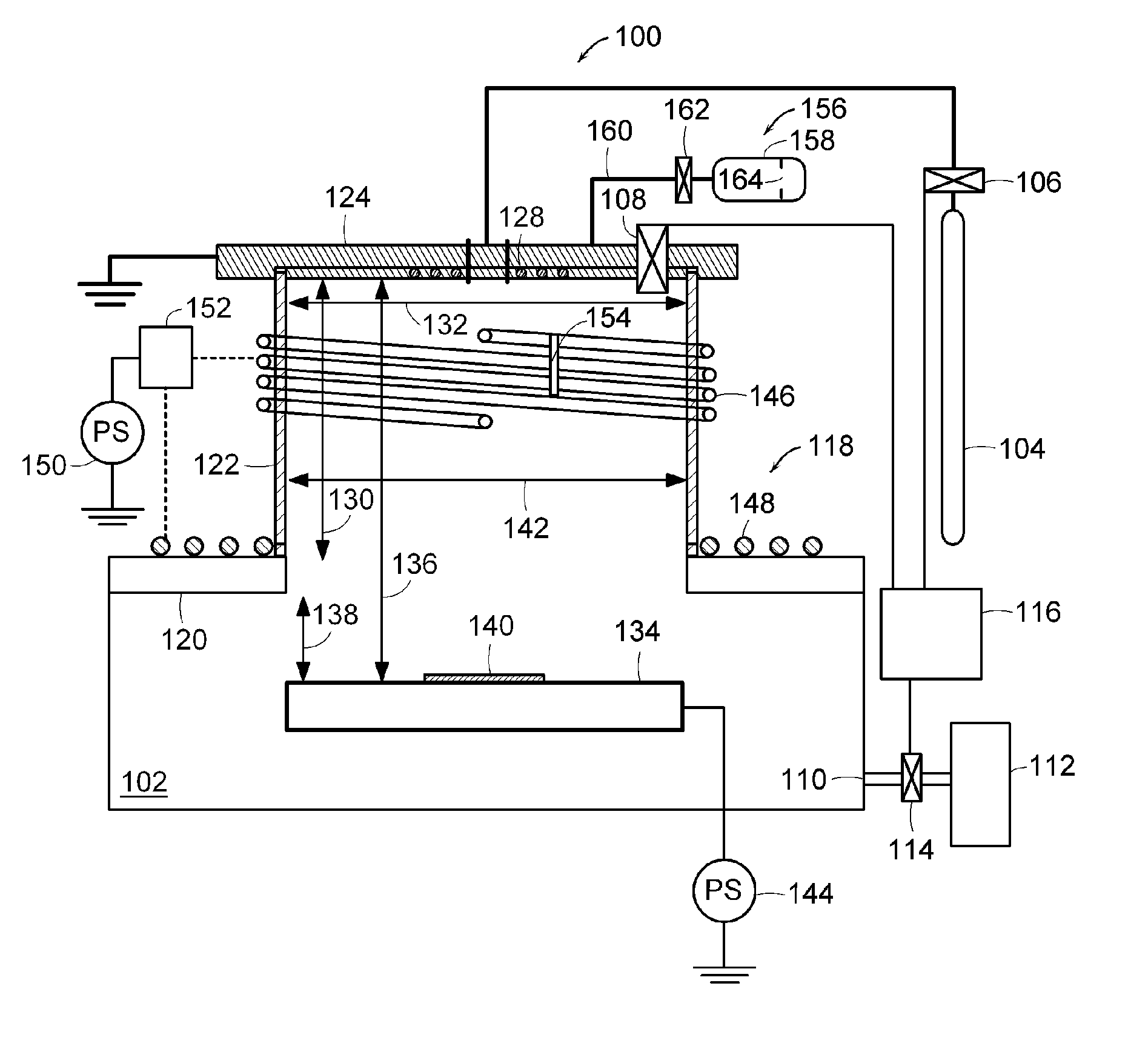

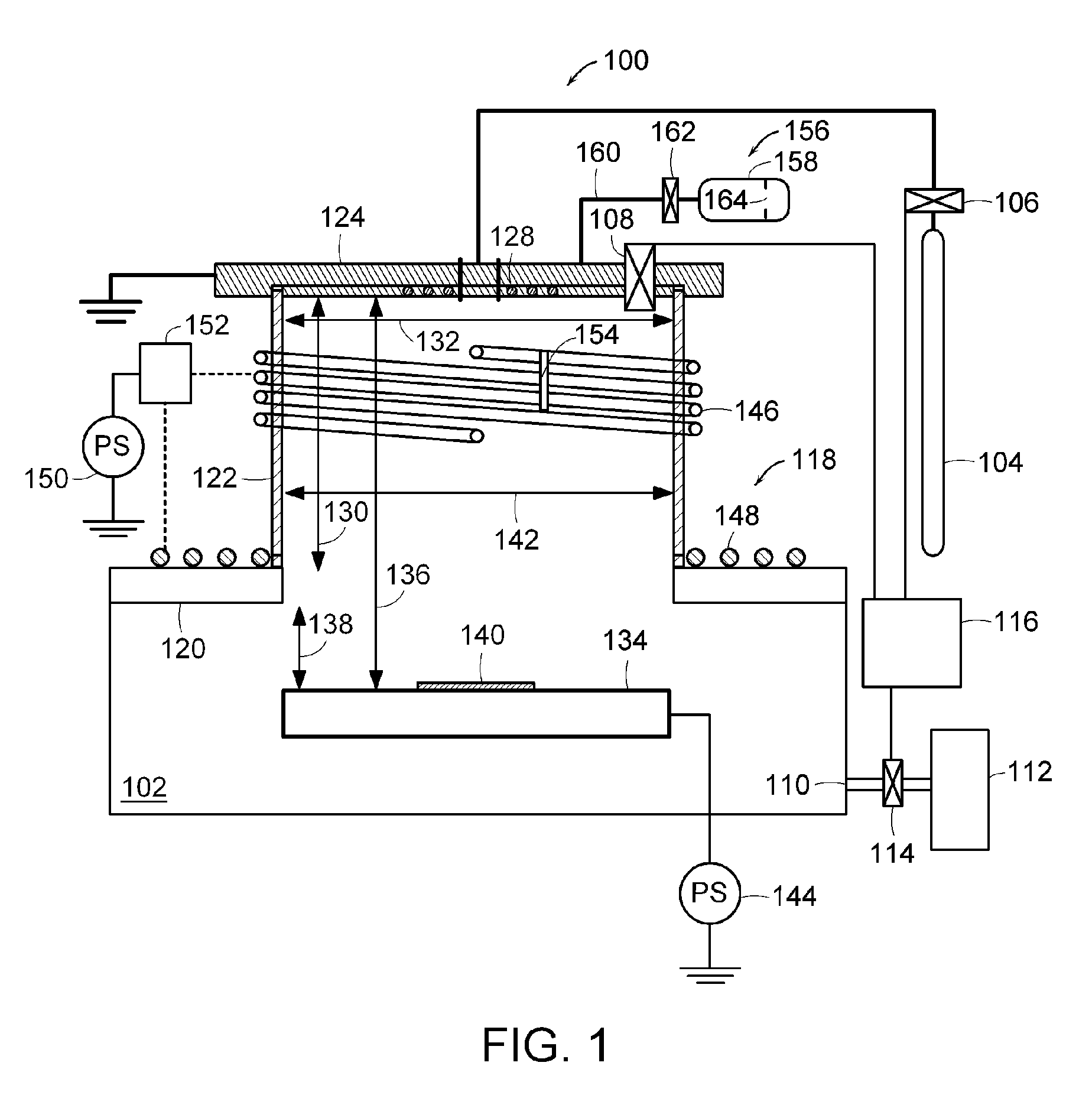

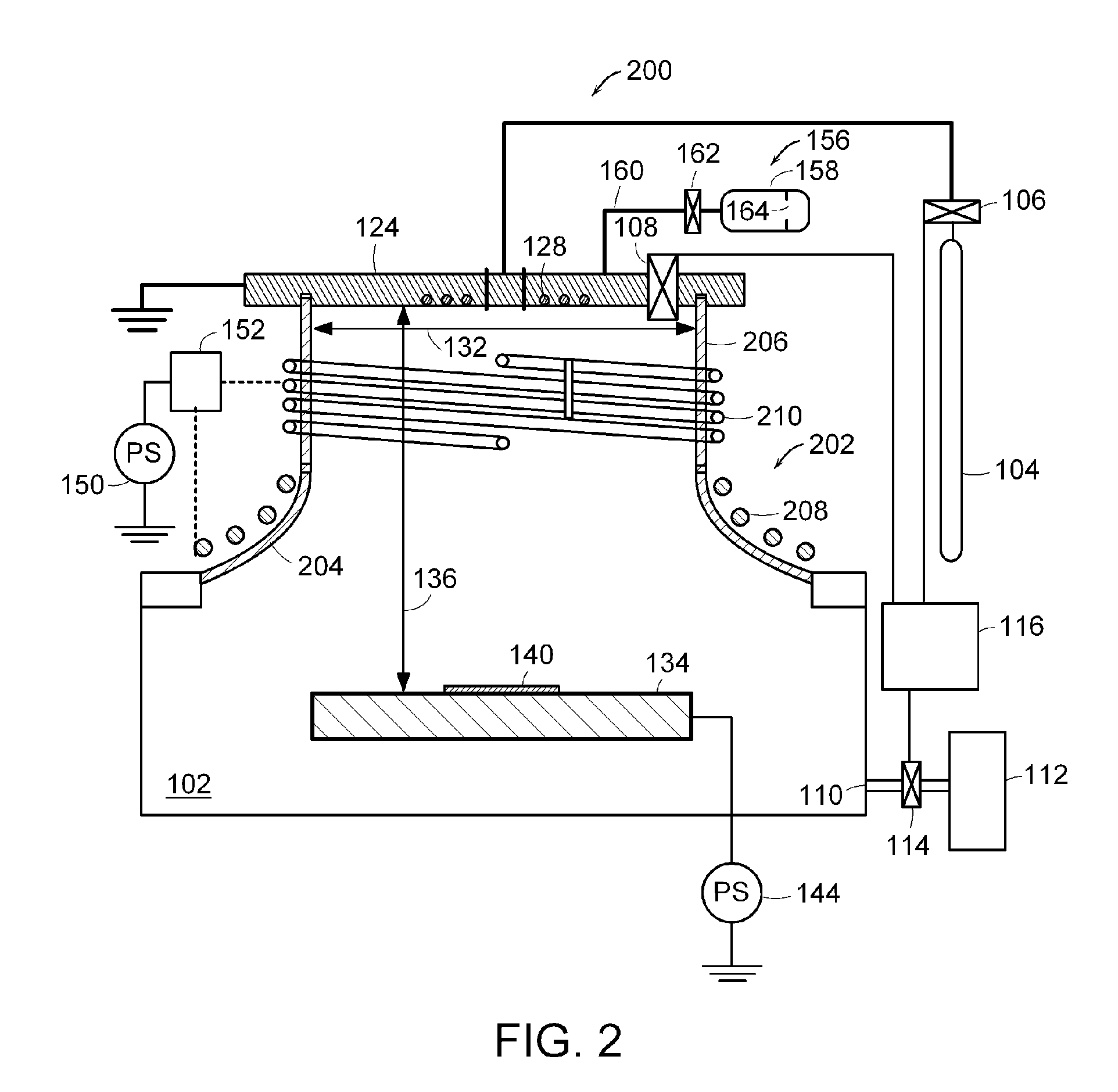

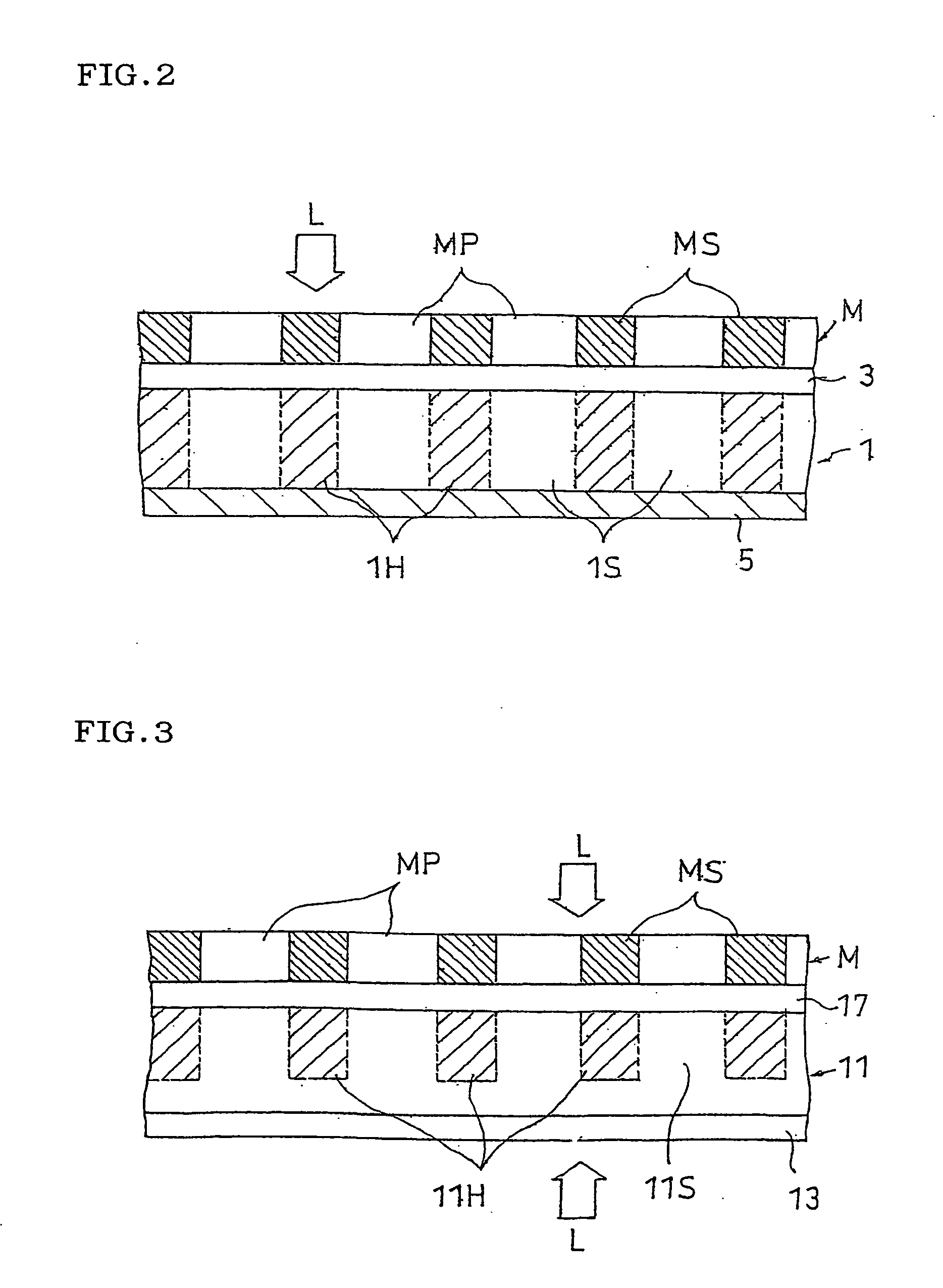

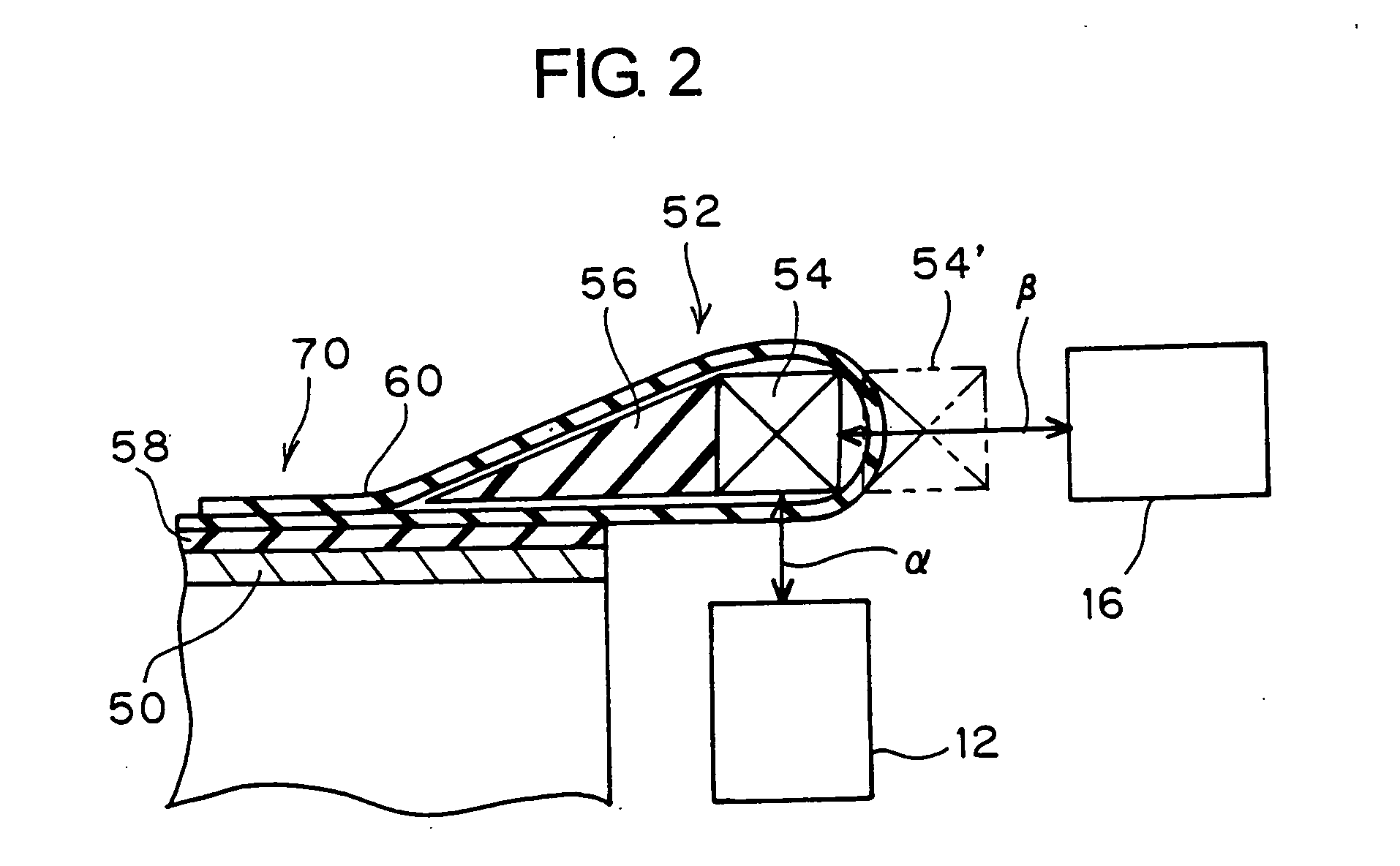

RF Plasma Source With Conductive Top Section

InactiveUS20050205212A1Heat loadMinimize charging effectElectric discharge tubesDecorative surface effectsRadio frequencyConductive materials

A plasma source includes a chamber that contains a process gas. The chamber has a chamber top comprising a first section formed of a dielectric material that extends in a horizontal direction. A second section of the chamber top is formed of a dielectric material that extends a height from the first section in a vertical direction. A top section of the chamber top is formed of a conductive material that extends a length across the second section in the horizontal direction. A radio frequency antenna is positioned proximate to at least one of the first section and the second section. The radio frequency antenna induces radio frequency currents into the chamber that excite and ionize the process gas so as to generate a plasma in the chamber.

Owner:VARIAN SEMICON EQUIP ASSOC INC

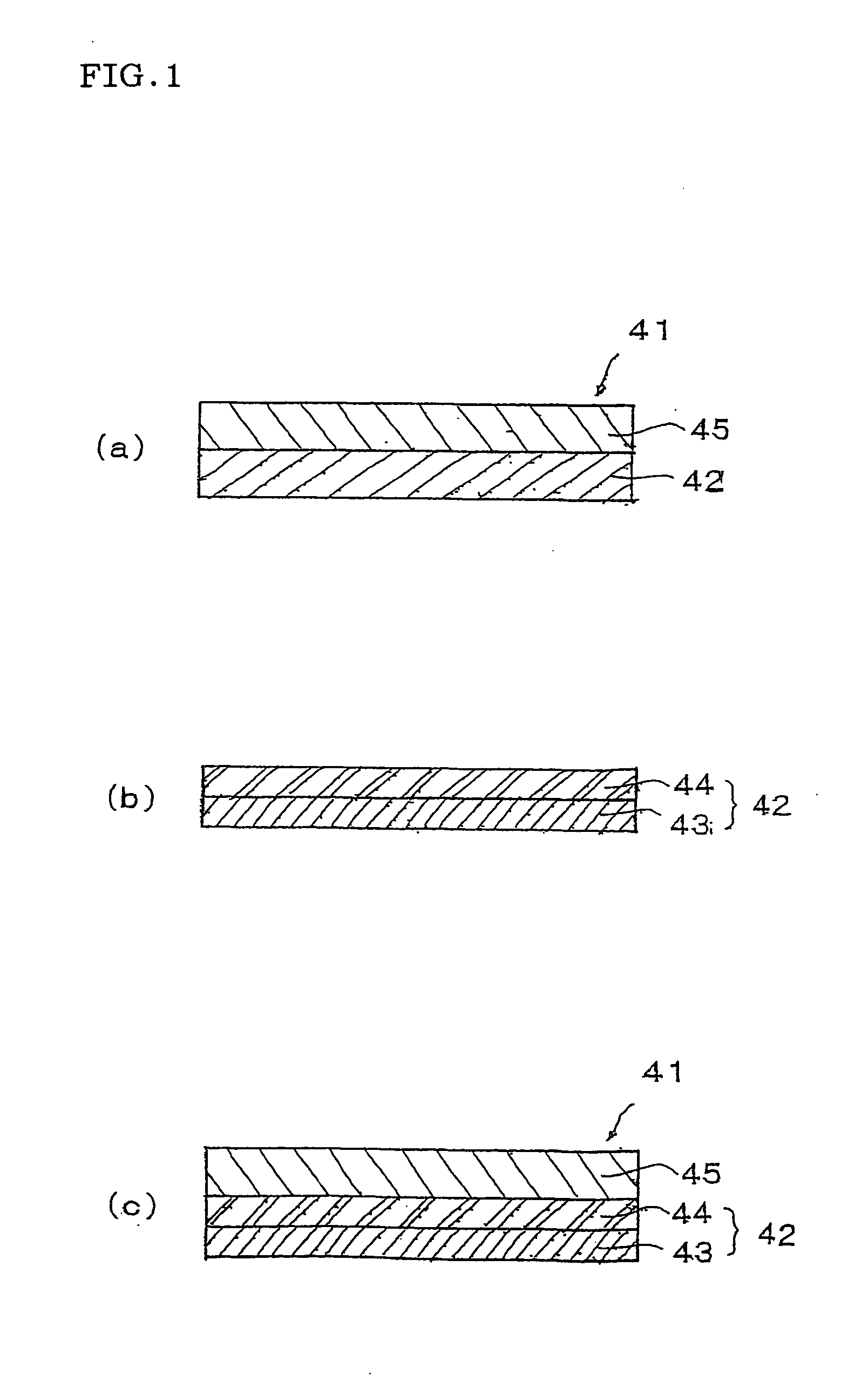

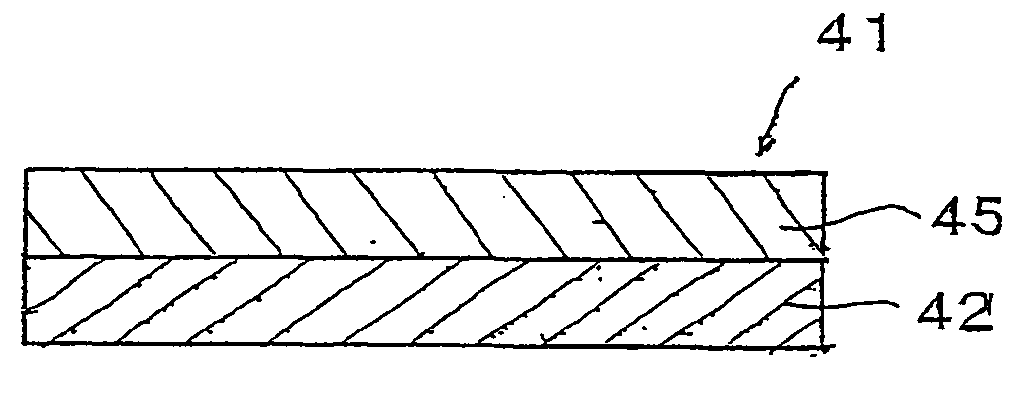

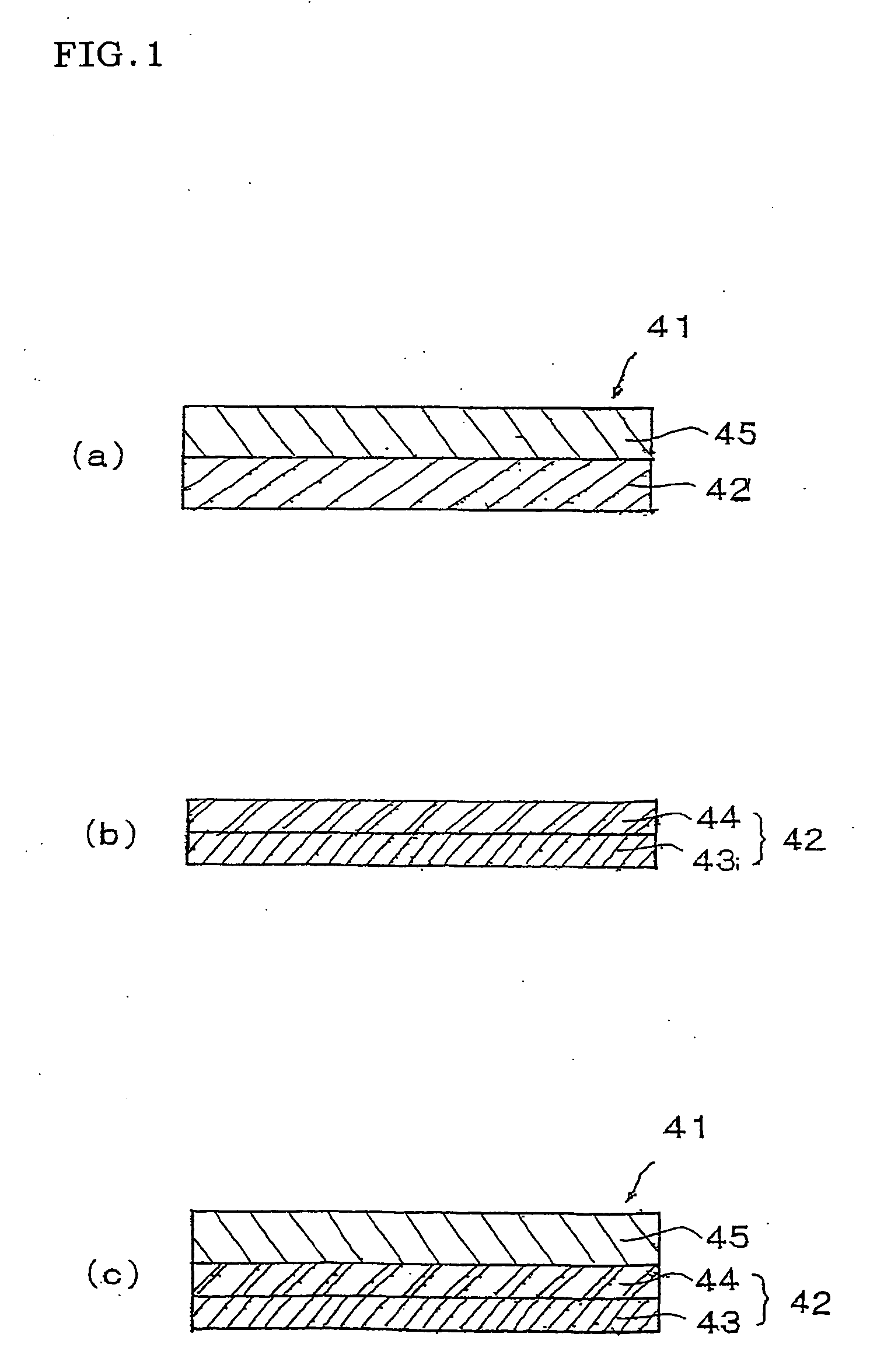

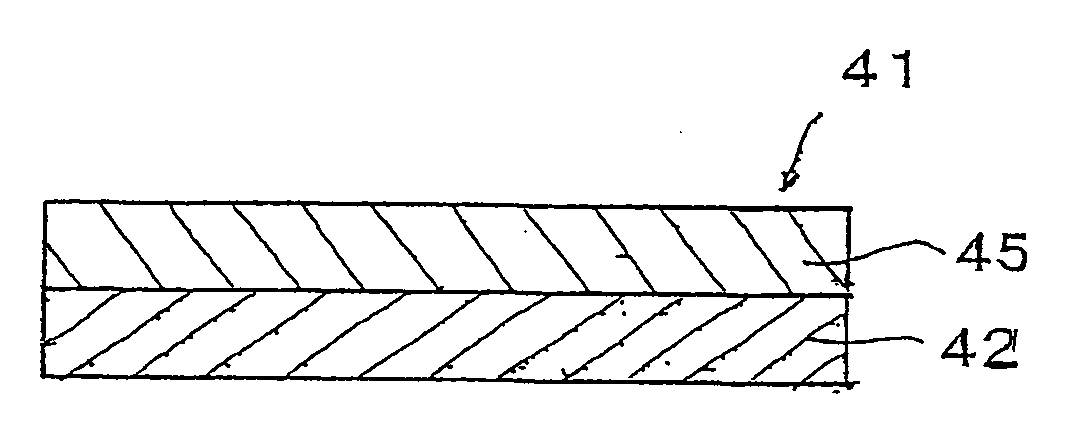

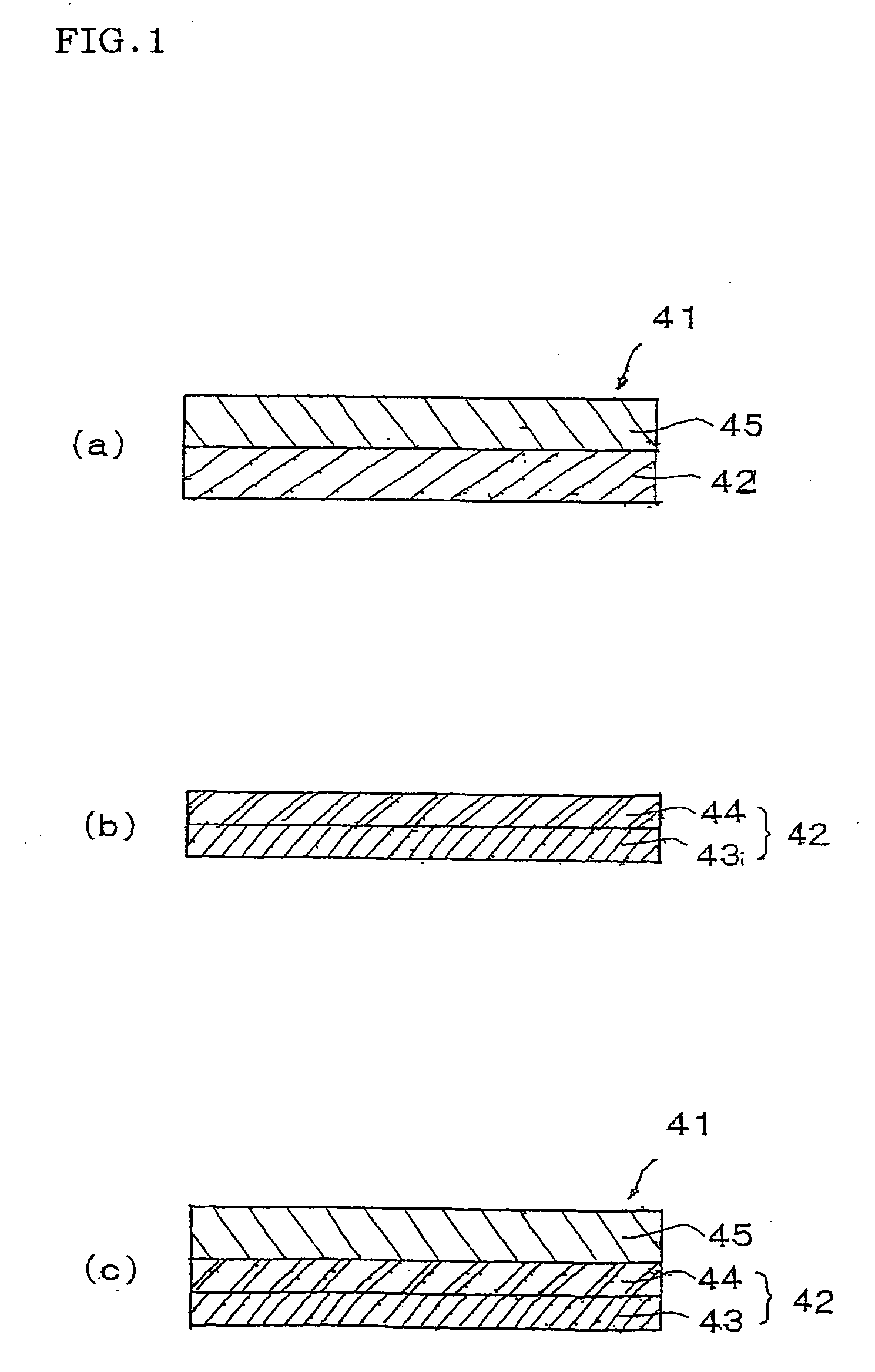

Polishing pad and cushion layer for polishing pad

InactiveUS20060148391A1Easy to processHigh thickness accuracyBelt grinding machinesAbrasion apparatusEngineeringHardness

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

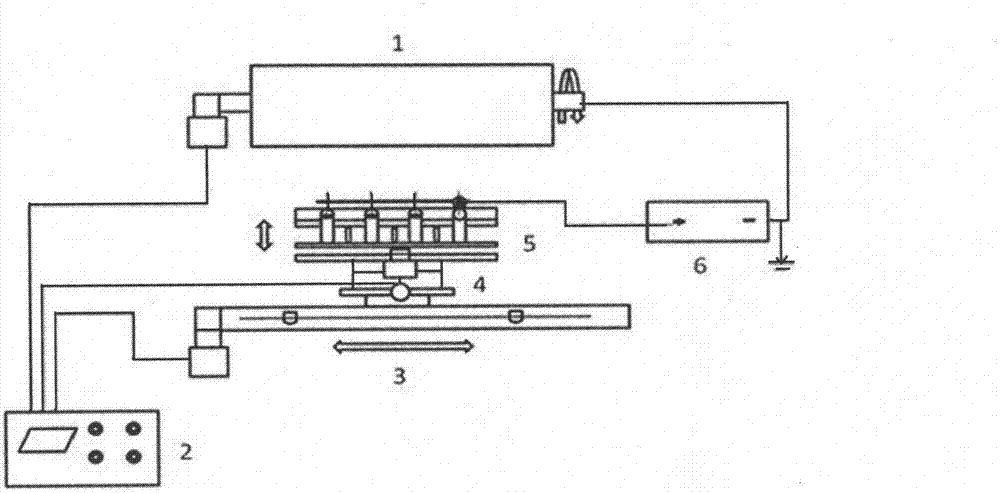

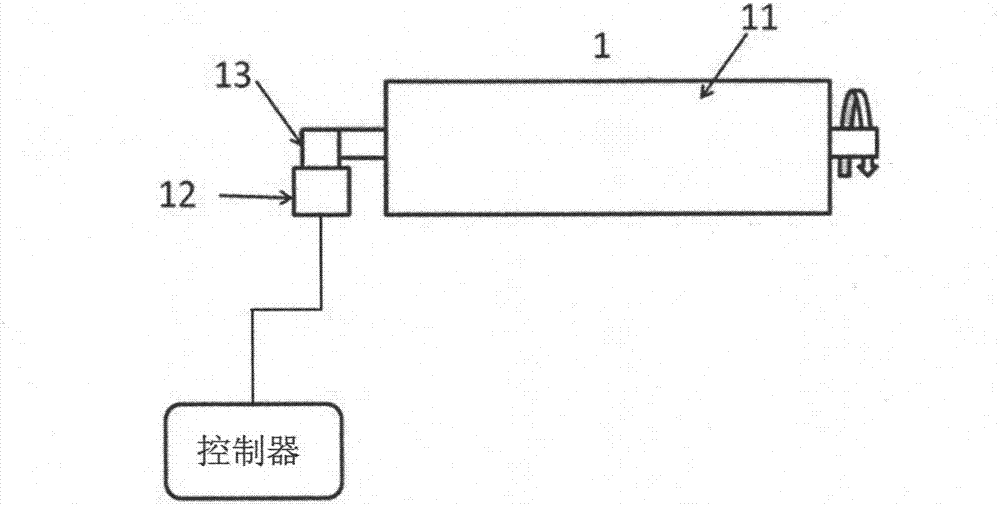

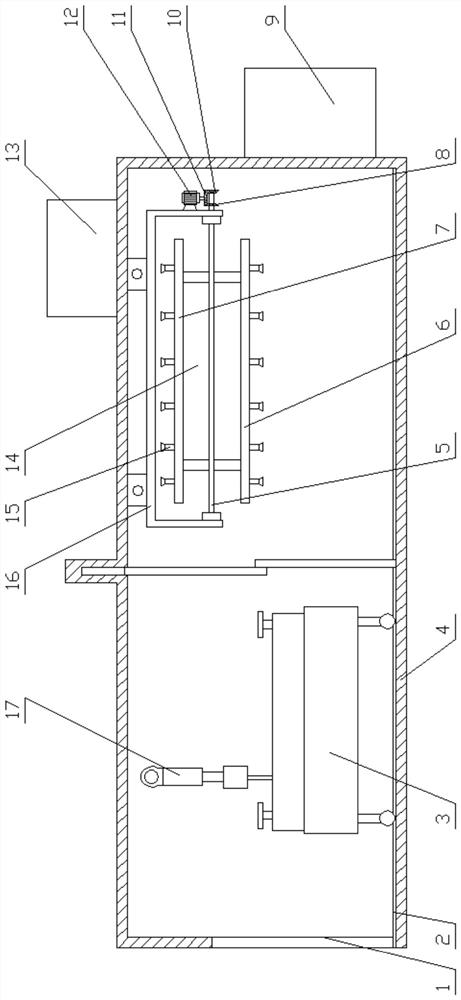

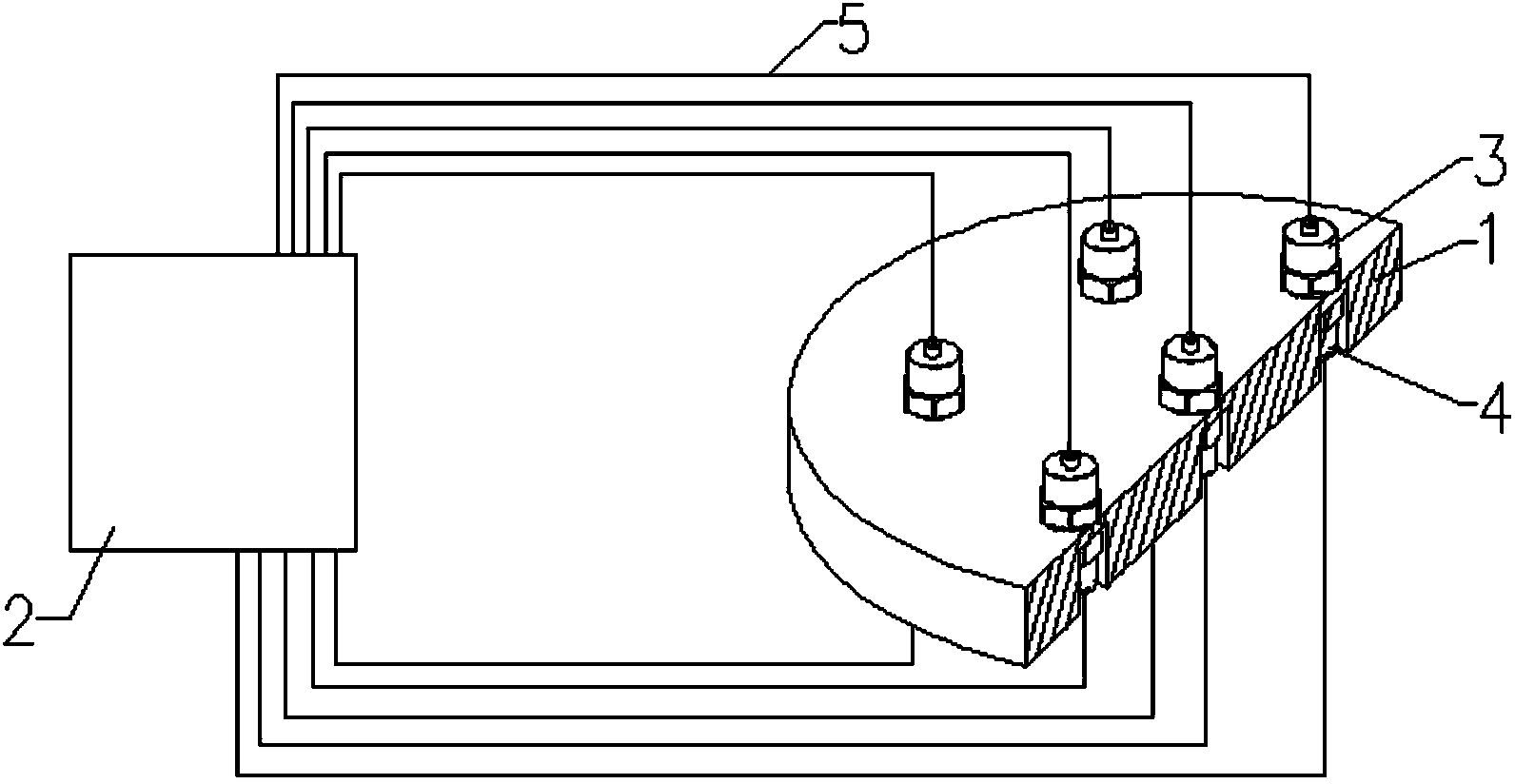

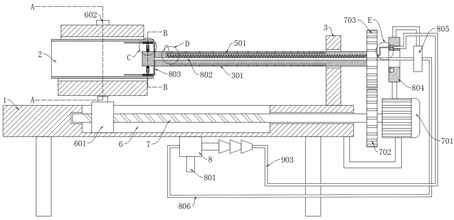

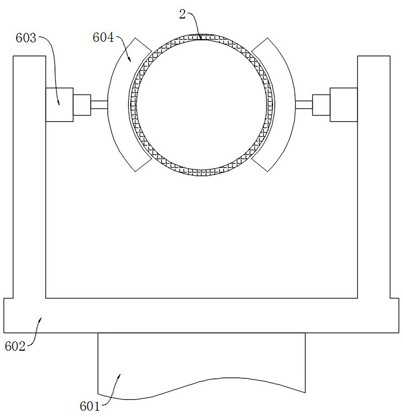

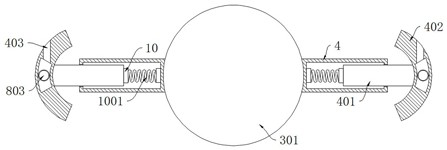

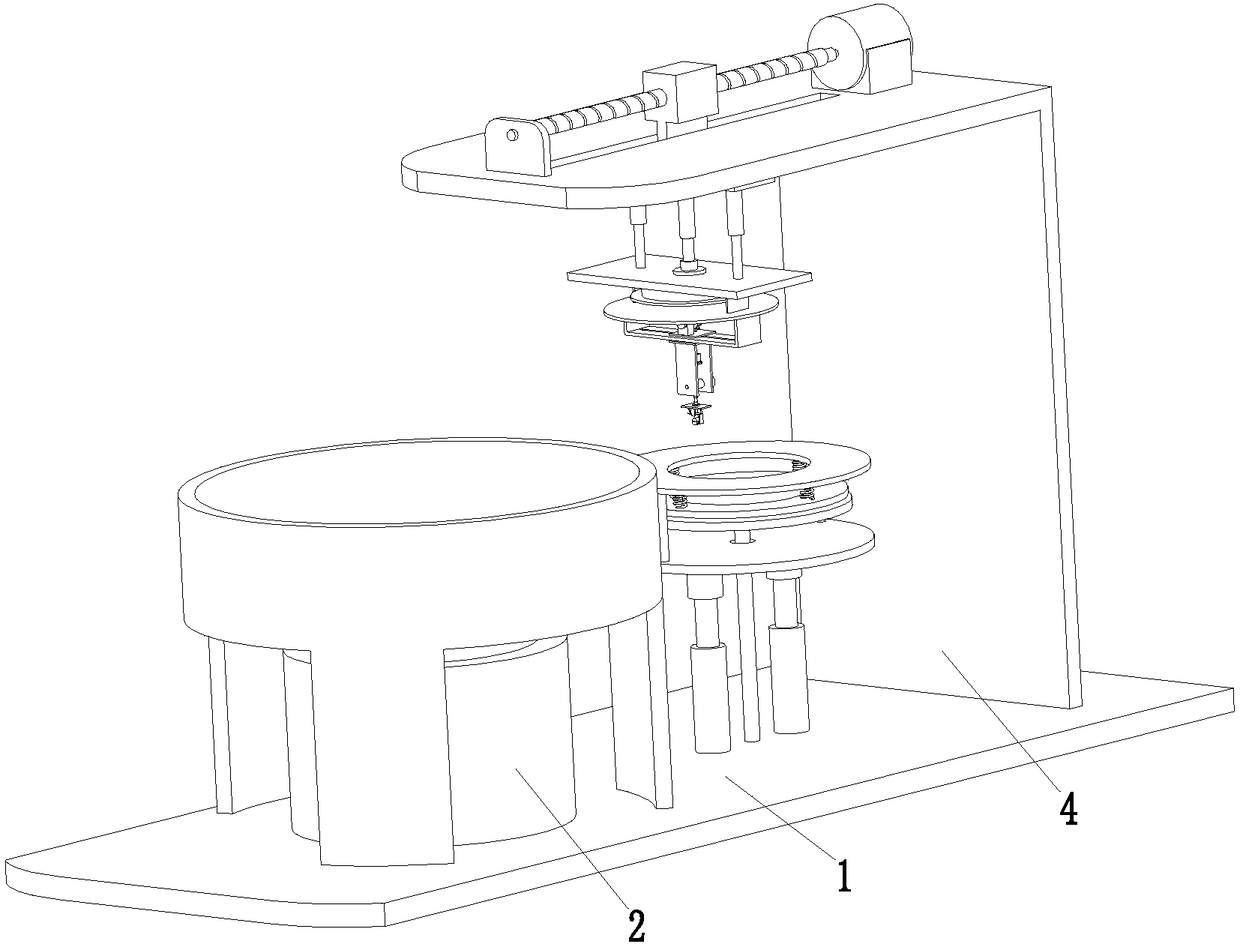

Automatic control multi-spray-head electrostatic spinning equipment

InactiveCN102776582AEasy to adjustAffect qualitySpinnerette packsFilament/thread formingFiberAutomatic control

The invention provides automatic control multi-spray-head electrostatic spinning equipment, which comprises a high-voltage electrostatic generator, a receiving device and a lifting device and is characterized by also comprising an automatic control box, a dustproof transverse moving slide table, a multi-passage precise liquid supply pump and a self-cleaning type multi-spray-head device, wherein data interfaces of multi-passage precise liquid supply pump, the dustproof transverse moving slide table and the receiving device are respectively connected with the automatic control box, an injector is fixedly arranged at the multi-passage precise liquid supply pump, the self-cleaning type multi-spray-head device is connected with the front end of the injector, a bakelite plate covered with a conducting wire is fixedly arranged on a spinning head, a conducting clamp post is fixedly arranged on the bakelite plate covered with the conducting wire, and the high-voltage electrostatic generator is connected with the conducting clamp post. The automatic control multi-spray-head electrostatic spinning equipment has the advantages that the precision, integration and automation degree is high, the operation is simple, convenient, safe and fast, the production efficiency is high, and wide application prospects are realized in the industrial aspect of nanometer fibers.

Owner:DONGHUA UNIV

Polishing pad and cushion layer for polishing pad

InactiveUS20060148393A1Easy to processHigh thickness accuracyAbrasion apparatusSemiconductor/solid-state device manufacturingCushionChemistry

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

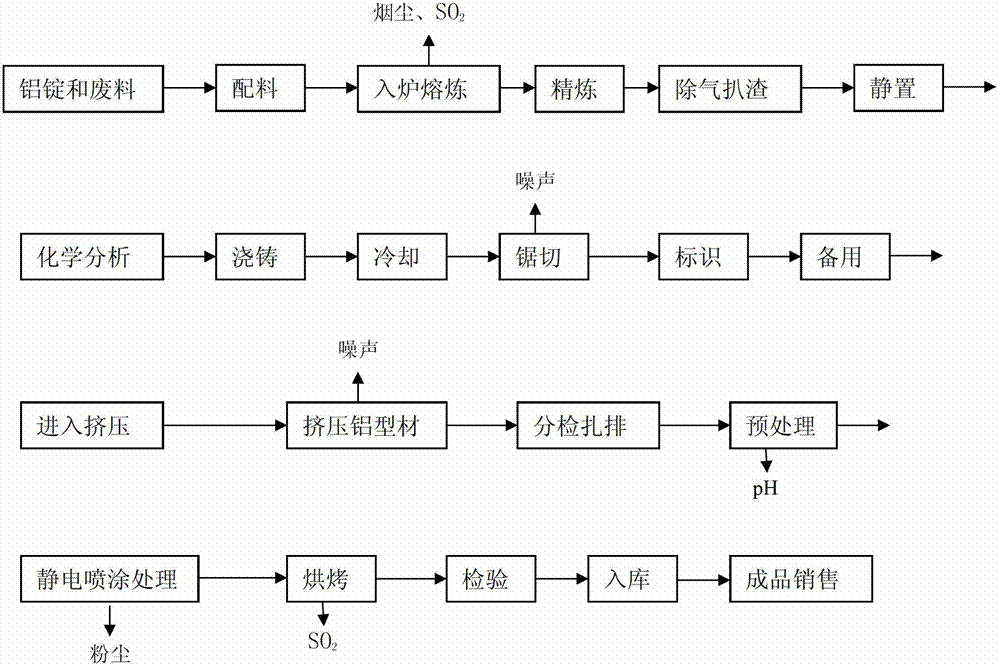

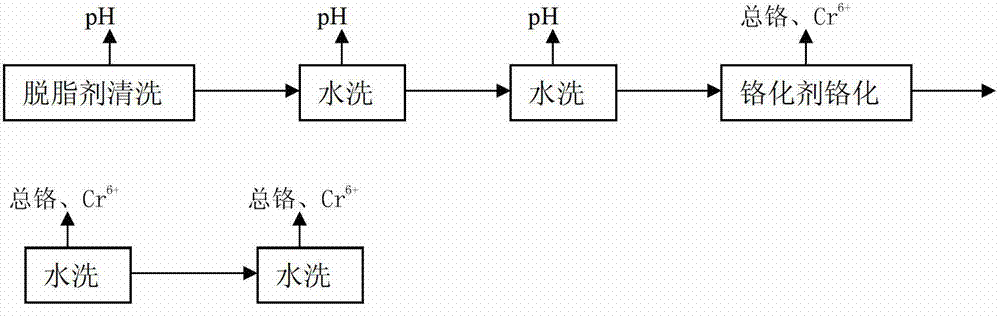

Method for producing powder-coated aluminum alloy section

ActiveCN102828073AImprove performanceAffect qualityLiquid surface applicatorsElectrophoretic coatingsAdditive ingredientIngot

The invention discloses a method for producing a powder-coated aluminum alloy section. The method includes steps of preparing an aluminum ingot and other raw materials; smelting and casting an aluminum alloy round ingot; pouring and sawing; annealing; carrying out extrusion forming; carrying out electrostatic powder coating; baking and the like. Waste aluminum materials are added into raw material ingredients, stability of performance of the aluminum alloy section is facilitated, and possibility that undetected materials are generated during smelting of molten aluminum and affect the quality of the aluminum alloy section is reduced. Besides, surfaces of the aluminum alloy section are subjected to chromation, so that corrosion resistance of oxide films on the surfaces of the aluminum alloy section is improved, and binding force of the aluminum alloy section and coatings is increased.

Owner:安徽家园铝业有限公司

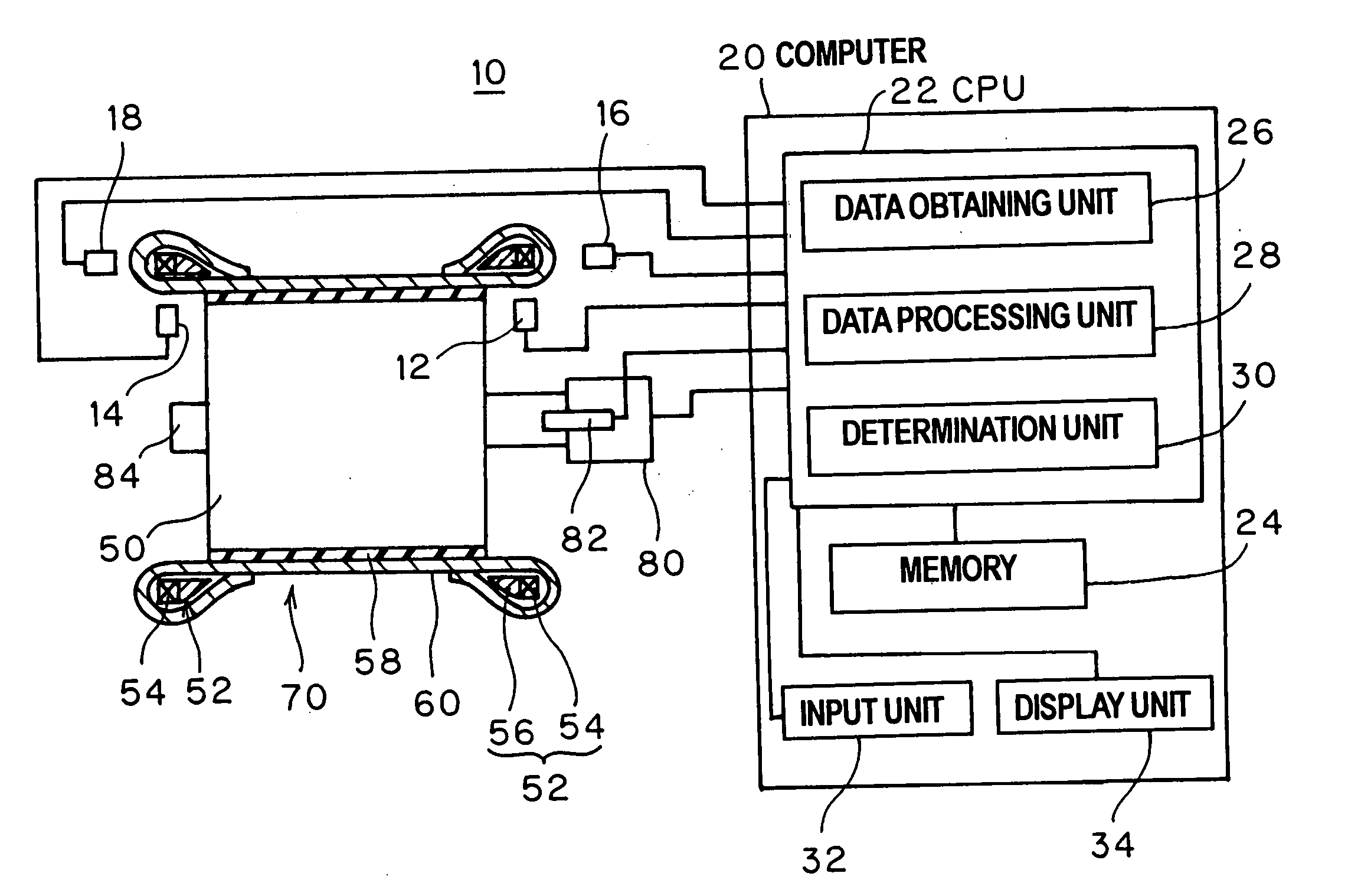

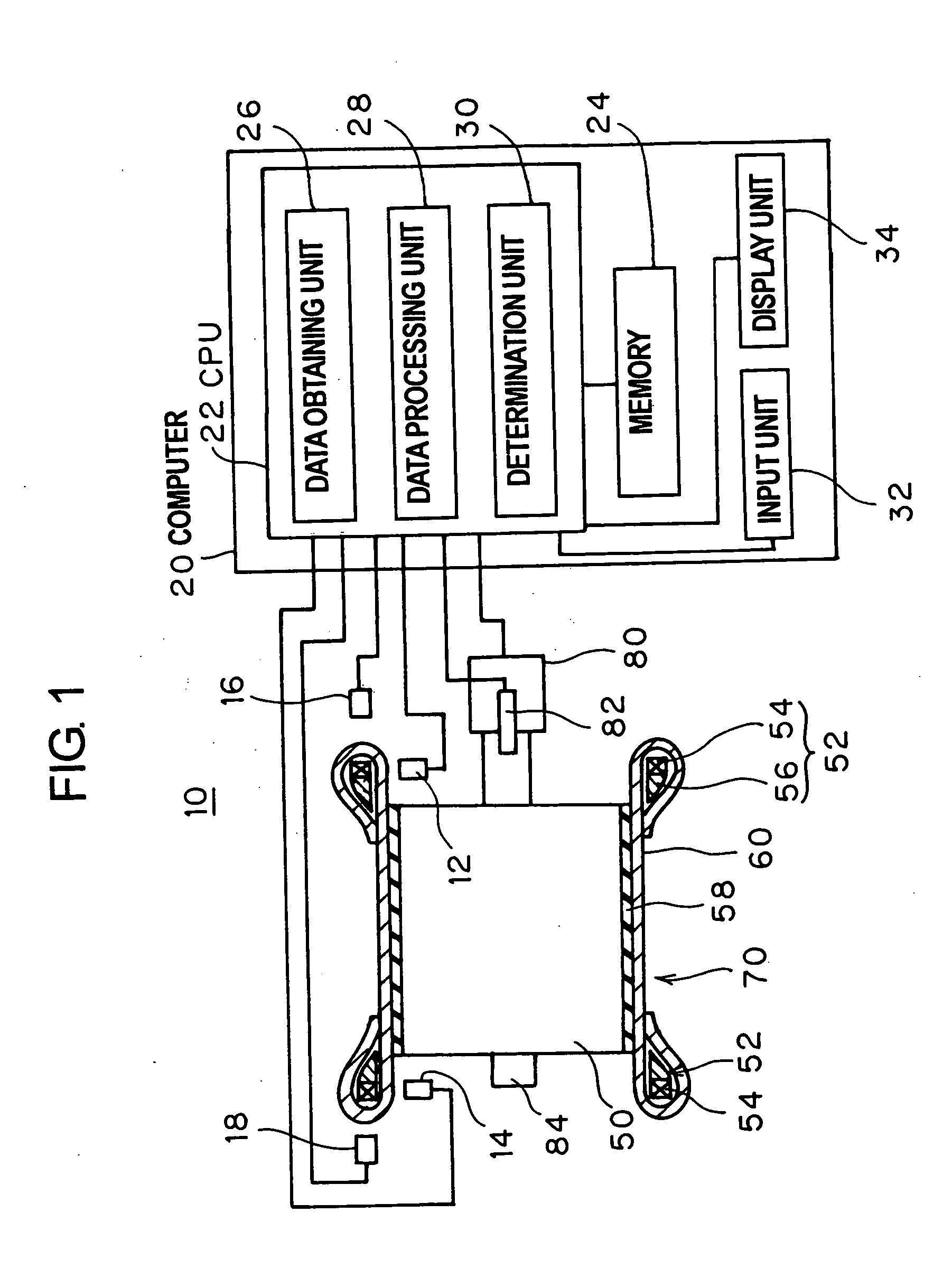

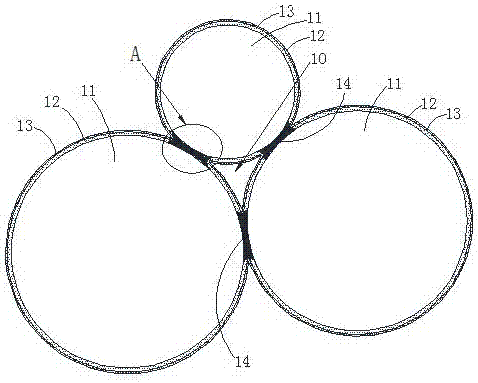

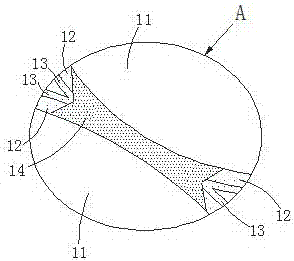

Method and apparatus for inspecting pneumatic tire during production

InactiveUS20070023122A1Reduce defectsReduce material costsLamination ancillary operationsLaminationHarmonic analysisEngineering

An inspection method for inspecting beads provided on a tire building drum in process of production a pneumatic tire includes measuring a displacement amount in a radial direction on each of the beads lying axially on both sides of the drum with a distance sensor such as an eddy current sensor while rotating the drum, synthesizing displacement amounts so obtained on the beads on both the sides, calculating a harmonic of the displacement amounts in the radial direction of the beads by performing harmonic analysis on a resultant synthesized displacement amount, and determining whether the magnitude of the harmonic so calculated falls within a predetermined range.

Owner:TOYO TIRE & RUBBER CO LTD

Double wire automatic submerged arc welding process

InactiveCN101564785AChange transition propertiesChanging the crystallization conditionsArc welding apparatusExcitation currentWeld seam

The invention provides a double wire automatic submerged arc welding process. The process comprises the following steps of: cleaning and fixing weldments; setting a weld groove; setting parameters of the welding process; and adjusting the position of a welding gun to weld a welding connector. The improvements of the process include: the set parameters of the welding process comprise a pre-heating magnetic field exciting current, a pre-heating magnetic field exciting frequency, an electromagnetic stirring magnetic field exciting current, an electromagnetic stirring magnetic field exciting frequency, a thermal treatment magnetic field exciting current and a thermal treatment magnetic field exciting frequency; after the position of the welding gun is changed on the welding connector, a pre-heating exciting coil is started first to generate pre-heating magnetic fields to pre-heat the welding wire and the groove; when a double wire submerged arc welding gun makes arc strike weld on a run-on plate in front of the weld seam, the electromagnetic stirring exciting coil and the electromagnetic thermal treatment exciting coil are started to generate electromagnetic stirring magnetic fields and electromagnetic thermal treatment external magnetic fields; and when the double wire submerged arc welding gun reaches a run-off plate at the tail end of the weld seam, the welding gun extinguishes arc and is lifted, and at the same time, the power supply of the electromagnetic stirring exciting coil and the electromagnetic thermal treatment exciting coil is cut off, so that the weld is completed. The comprehensive mechanical properties of the welding connector are improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Saline-alkali soil fruit tree planting method

ActiveCN104620928AImprove salt and alkali resistanceEnhanced ability to resist salt ion poisoningClimate change adaptationCultivating equipmentsFruit treeAlkali soil

The invention relates to a saline-alkali soil fruit tree planting method. The saline-alkali soil fruit tree planting method includes steps of taking common annual branchless fruit saplings for on-ridge root-limiting secondary culturing on land with soil property approximate to that of an orchard to be built or with the salt and alkali content lower by 0-30% than that of the common land, and applying nutrient soil to control salt by mixing in a sapling growing zone; preparing fulvic acid and naphthylacetic acid soluble powder into slurry which is used for wrapping the saplings before planting; increasing nutrient using microbial nutrition fertilizer in a sapling stage and improving resistance; performing measures like salt leaching, pressing and accumulating to improve sapling salt-alkali resistance at any time by controlling water, greatly improving salt and alkali resistance of saplings by a series of salt and alkali training, lifting the saplings and planting in the orchard to be built, dipping the saplings in the fulvic acid and naphthylacetic slurry again and broadcasting super-fine calcium carbonate in sapling holes. Various measure effects are outstanding, the survival rate of the saplings is remarkably increased in the salt and alkali area, the orchard is even, and the high yield can be realized in the second to third year and the quality is high.

Owner:SHANDONG WEIFANG ACADEMY OF AGRICULTURAL SCIENCES

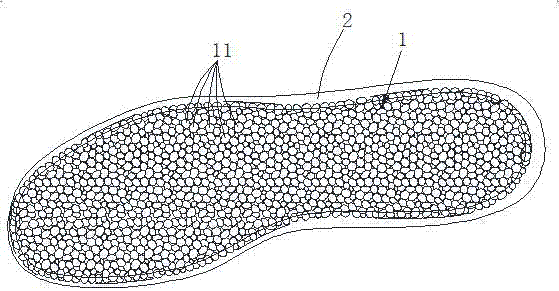

Production process of E-TPU (expanded thermoplastic polyurethane) shoe material

InactiveCN107353428APromote environmental protectionReduce usage requirementsSolesDevices for pressing relfex pointsMaterials preparationThermoplastic polyurethane

The invention relates to a production process of an E-TPU (expanded thermoplastic polyurethane) shoe material. The production process of the E-TPU shoe material comprises the steps implemented in sequence as follows: a, material preparation: 75-92 parts of TPU foamed particles, 5.9-19 parts of glue A, 0.9-4.8 parts of glue B and 0.38-1.5 parts of an accelerator are prepared by weight; b, addition of the glue A: the TPU foamed particles and the glue A are stirred uniformly; c, addition of the glue B: the glue B is added after the materials in the step b are mixed uniformly, and the materials are stirred uniformly; d, addition of the accelerator: the accelerator is added after the materials in the step c are mixed uniformly, the materials are mixed uniformly, and the mixture is injected into a die cavity; e, foaming: the die cavity is moved into an oven, foaming molding is performed at 50-70 DEG C for 2-3 min, and the molded shoe material can be obtained. The TPU particles can account for 90%-92% by weight of the shoe material, the weight reduction limit of the current shoe material is reached, and the E-TPU shoe material has the characteristics of being ultralight, ultrahigh in elasticity, more environment-friendly, low in cost and capable of performing massaging.

Owner:陈茂双

Method of producing polishing pad

InactiveUS20060148392A1Easy to processHigh thickness accuracyAbrasion apparatusSemiconductor/solid-state device manufacturingSolubilitySolvent

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

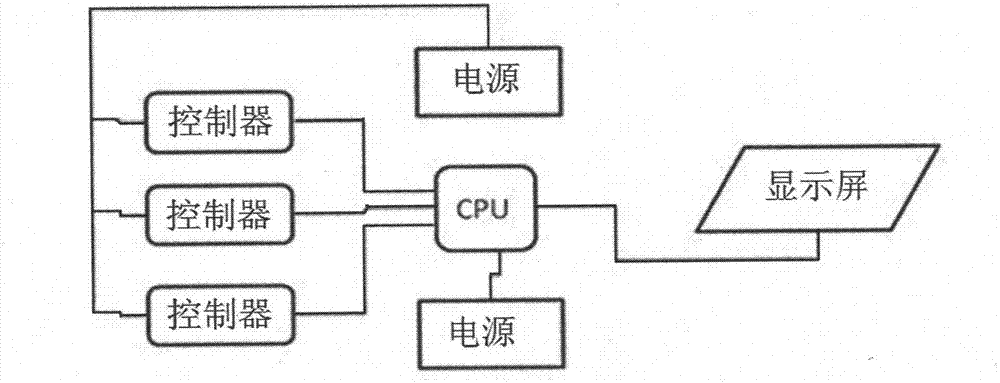

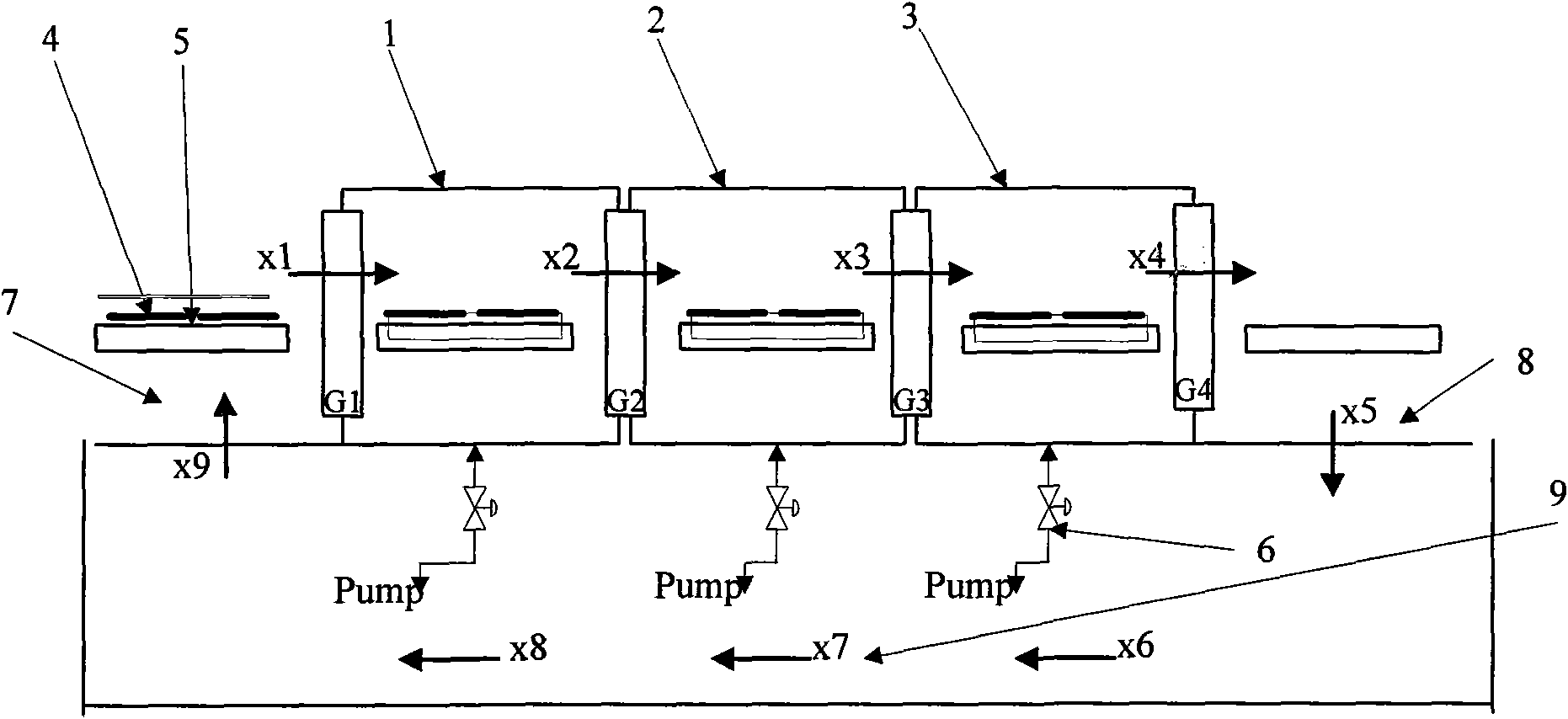

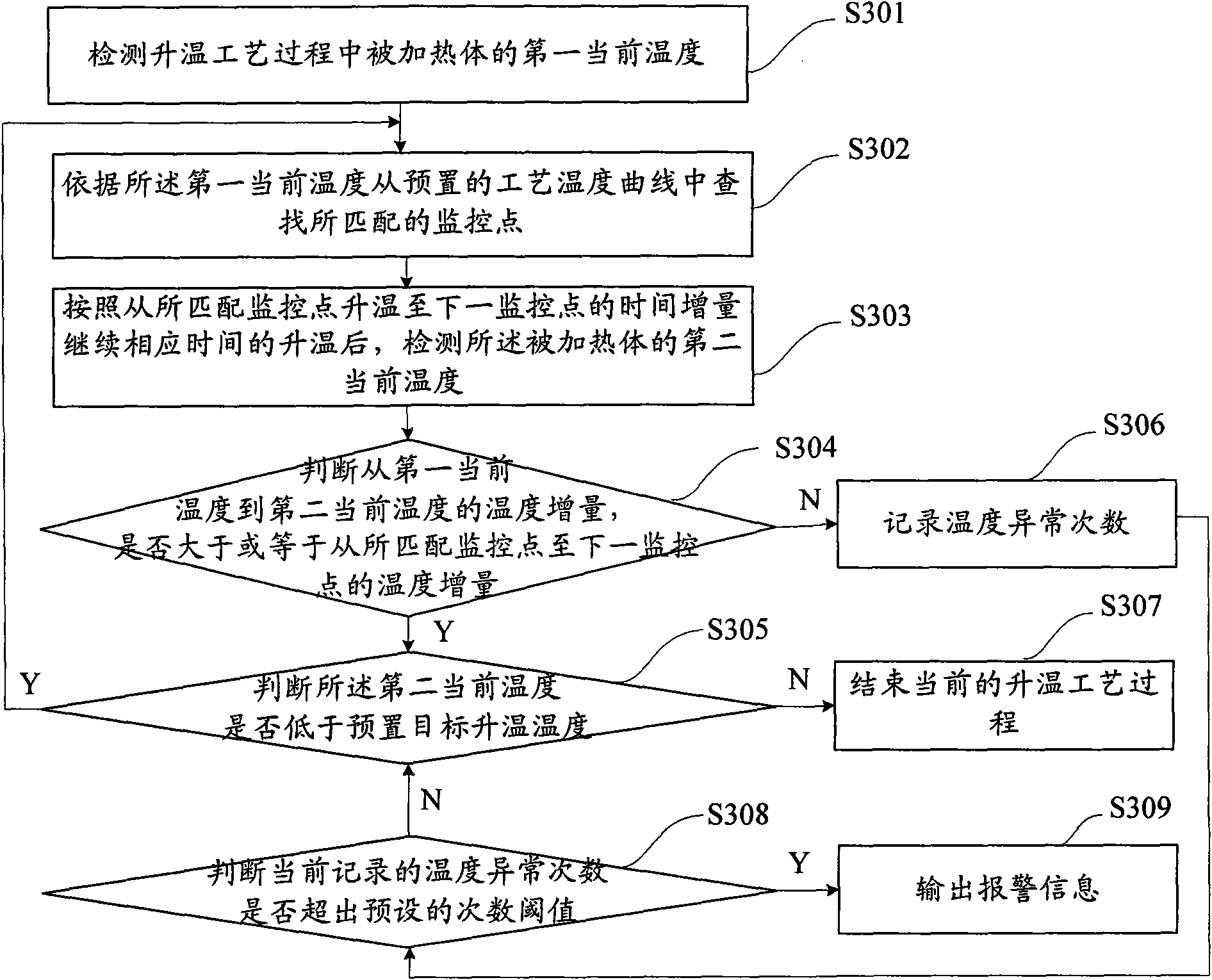

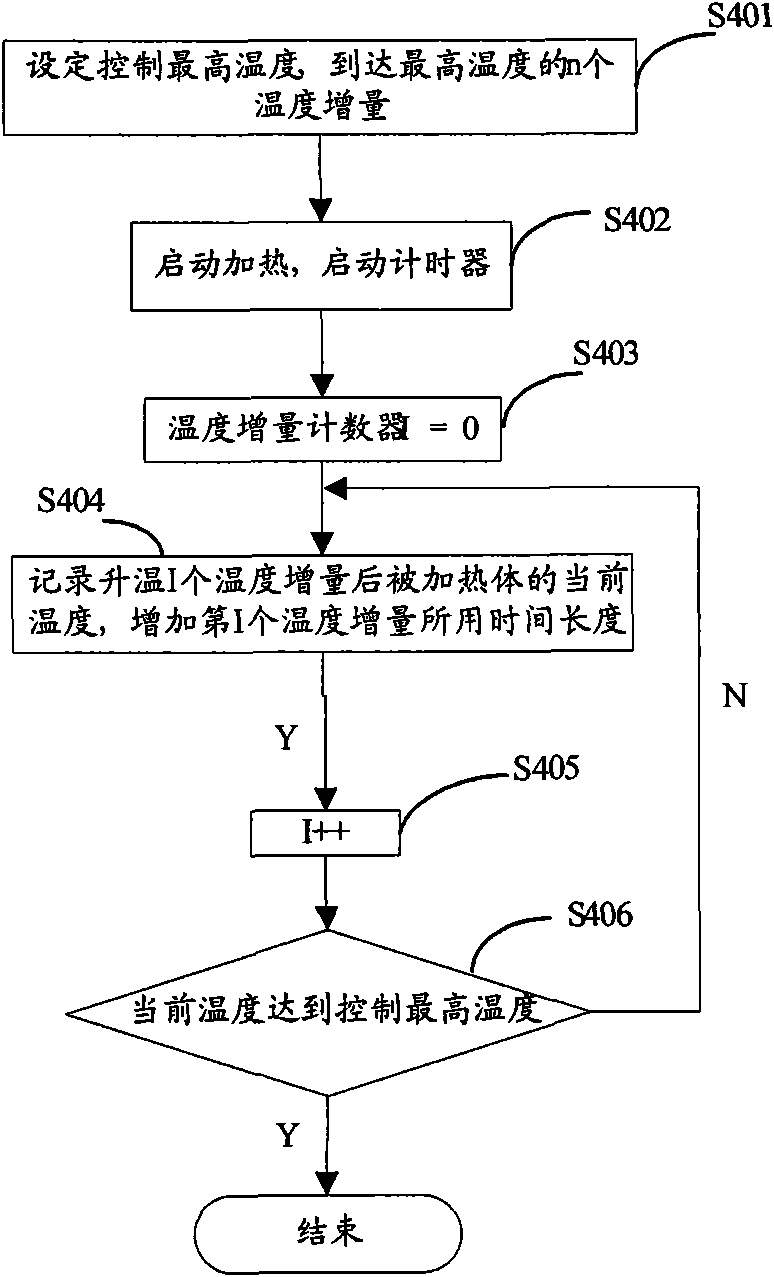

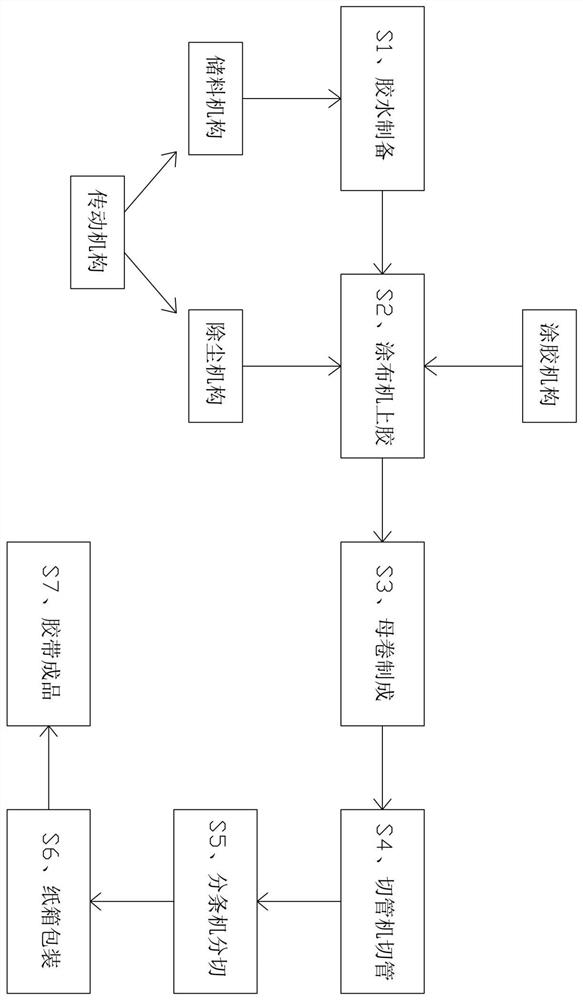

Temperature monitoring method and device of production line device

ActiveCN101620448AAffect uniformityReduce damage rateTemperature control using electric meansAlarmsTemperature curveMatched control

The invention discloses a temperature-rise monitoring method of a production line device, which comprising steps as follow: S11, detecting a first current temperature of a heated object; S12, searching out a matched control point from a preset process temperature curve according to the first current temperature; S13, detecting a second current temperature of the heated object after keeping risingtemperature according to the time increment generated when the temperature rises from the matched monitoring point to the next monitoring point; S14, judging whether the temperature increment generated when temperature rises from the first current temperature to the second current temperature is larger than or equal to the temperature increment generated when the temperature rises from the matched monitoring point to next monitoring point; if so, executing S15; if not, recording the abnormal information of temperature; S15, judging whether the second current temperature is lower than the preset objective temperature-rise temperature or not; if so, taking the second current temperature as the first current temperature and going back to S12; if not, finishing the operation. The invention can monitor temperature in real time during the temperature adjustment of the production line device on the bases of improving product percent of pass and lowing cost.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Moisture permeation and water proofing fabric, and preparation process thereof

InactiveCN102619092ASolve the weakness that it is easy to expand when exposed to waterGood moisture permeabilityFibre treatmentCoated surfaceMoisture permeation

The present invention discloses a moisture permeation and water proofing fabric, and a preparation process thereof. According to the fabric, a prime coat comprises: a polyurethane resin, butanone, toluene, water, 1,6-diisocyanatohexane and N-methylethanolamine; a first surface coating and a second surface coating comprise a polyurethane resin, butanone, toluene, water and N-methylethanolamine. The preparation process comprises: mixing 1,6-diisocyanatohexane and a main resin; mixing water and butanone to form a solvent; adding the solvent to the main resin mixing solution in at least 6 times; filtering the resulting mixed solution with a nylon net to obtain a filtered main resin solution; carrying out a deaeration treatment to form a prime coat slurry; blending a surface coating slurry with a matching solution viscosity of 3500-6000 mpas; coating the prime coat slurry on the surface of the base cloth to form the prime coat, and drying; coating the surface coating slurry on the surface of the prime coat in 2 times to form the surface coatings, and drying. In the prior art, micropores in the hydrophilic moisture permeation processing coating fabric are not uniform, and are easily expanded when contacting the water. With the present invention, the disadvantages in the prior art are solved, and the moisture permeation performance of the fabric is improved.

Owner:KUNSHAN HUAYANG NEW MATERIAL

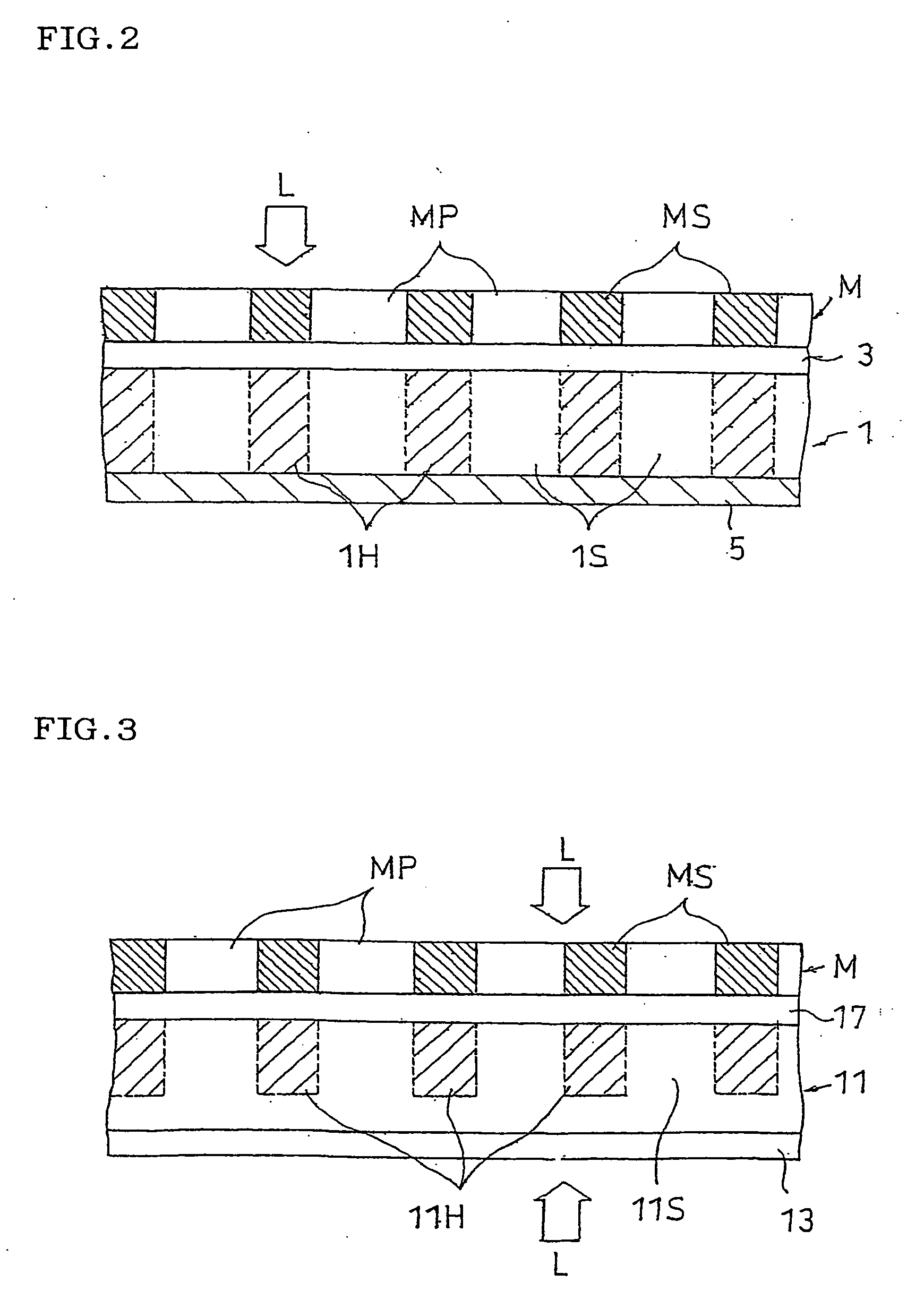

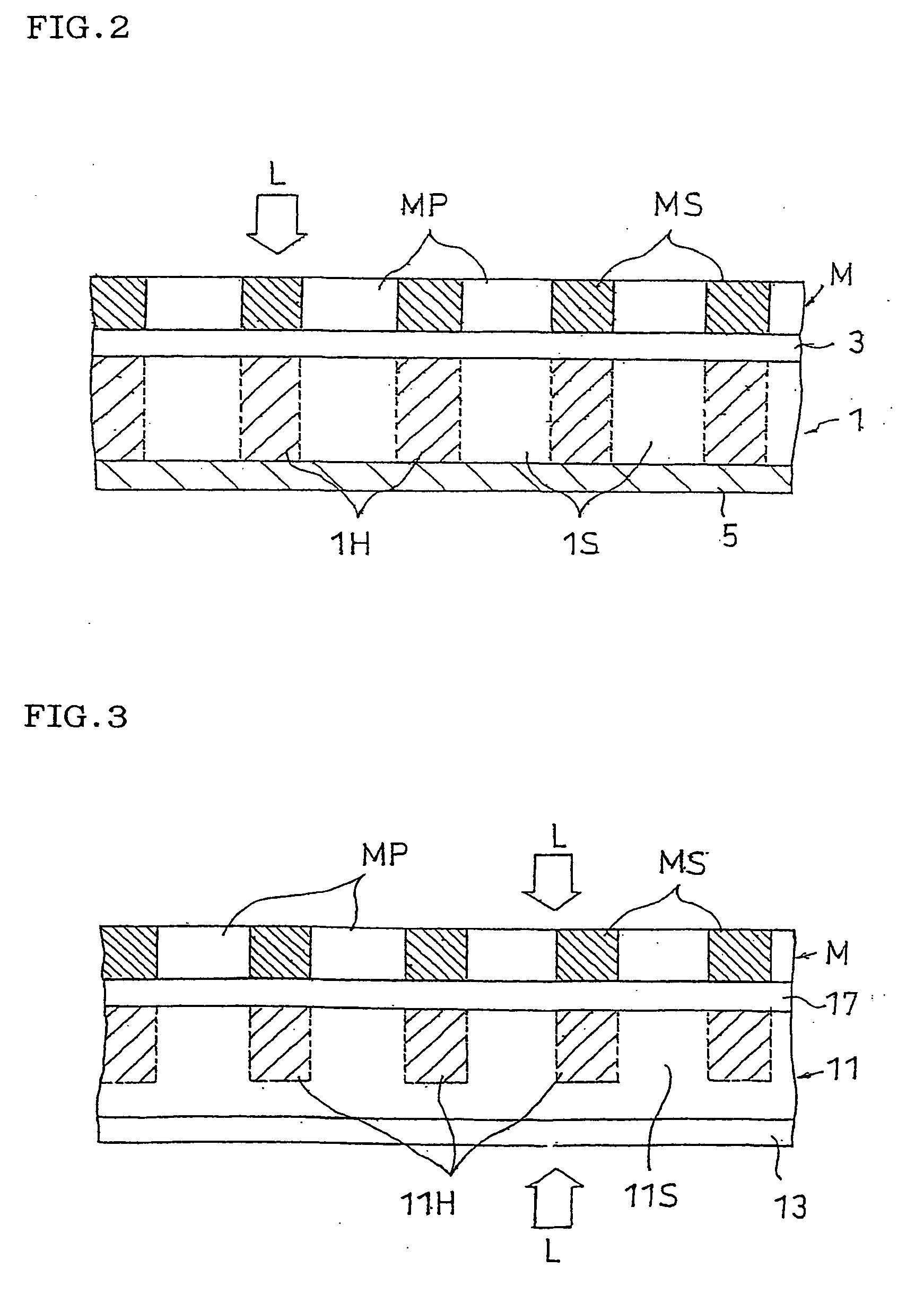

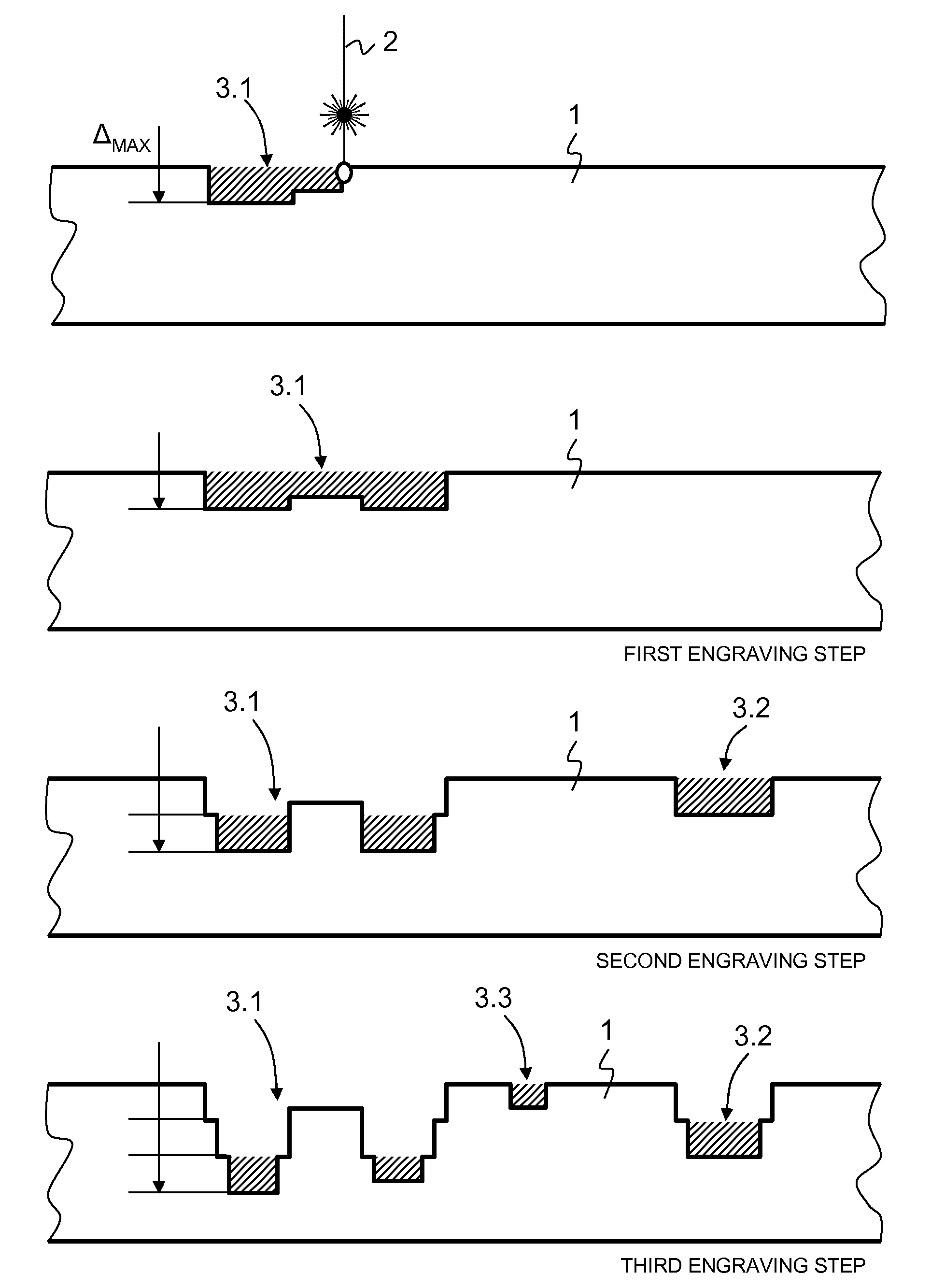

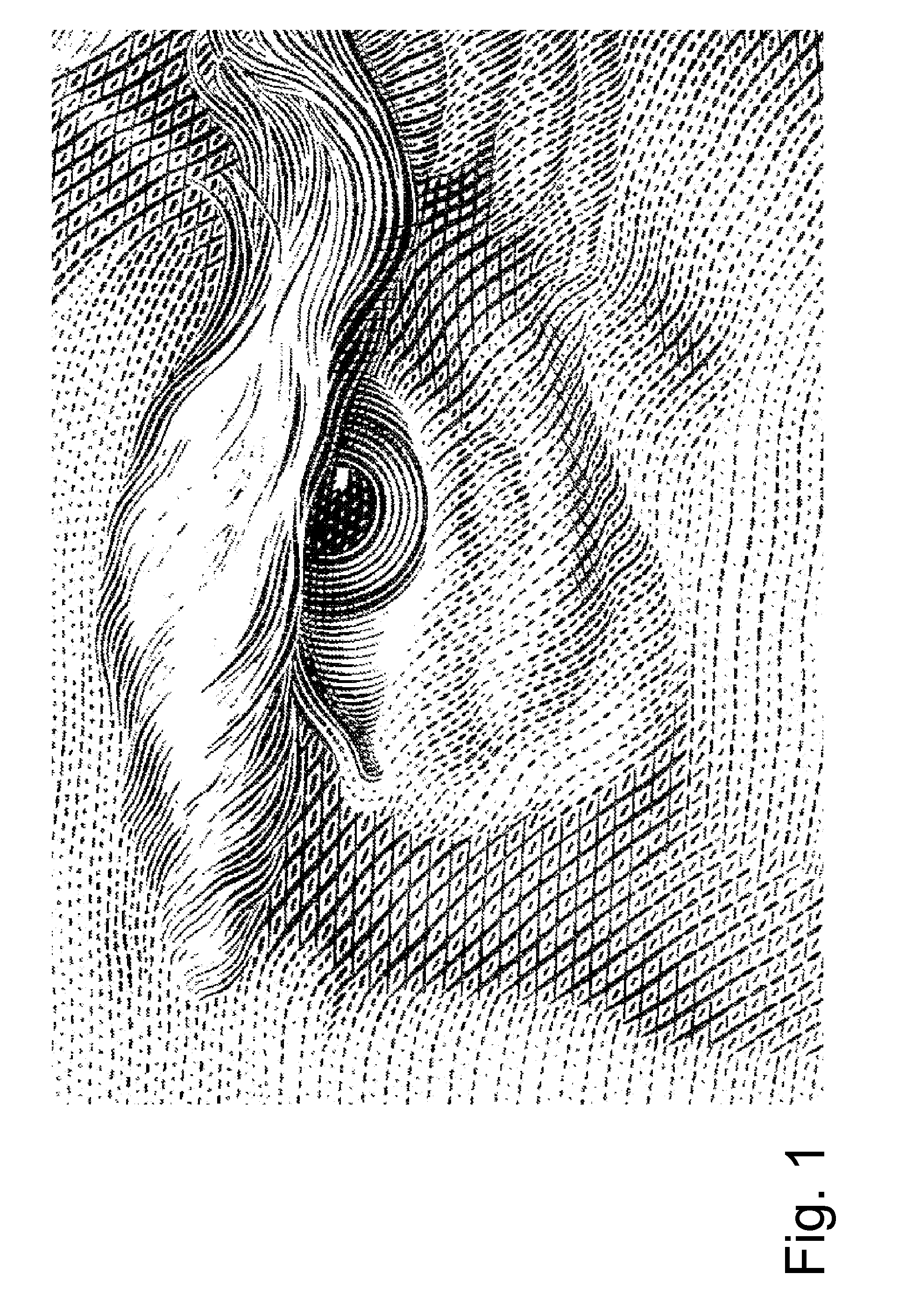

Method and System for Manufacturing Intaglio Printing Plates for the Production of Security Papers

ActiveUS20110068509A1Improve abilitiesResist formationPattern printingAuxillary shaping apparatusLaser engravingEngineering

There is described a method for manufacturing intaglio printing plates for the production of security papers, wherein a laser beam (2) is used to engrave intaglio printing patterns (3, 3.1, 3.2, 3.3) directly into the surface of a laser-engravable, especially metallic, printing plate medium (1), wherein laser engraving of the printing plate medium (1) is carried out layer by layer in several individual engraving steps performed one after the other in register so that the intaglio printing patterns (3, 3.1, 3.2, 3.3) are gradually engraved into the surface of the printing plate medium (1) up to desired engraving depths, the surface of the engraved printing plate medium (1) being cleaned from residues of the laser engraving process following and between each individual engraving step.

Owner:KBA NOTASYS SA

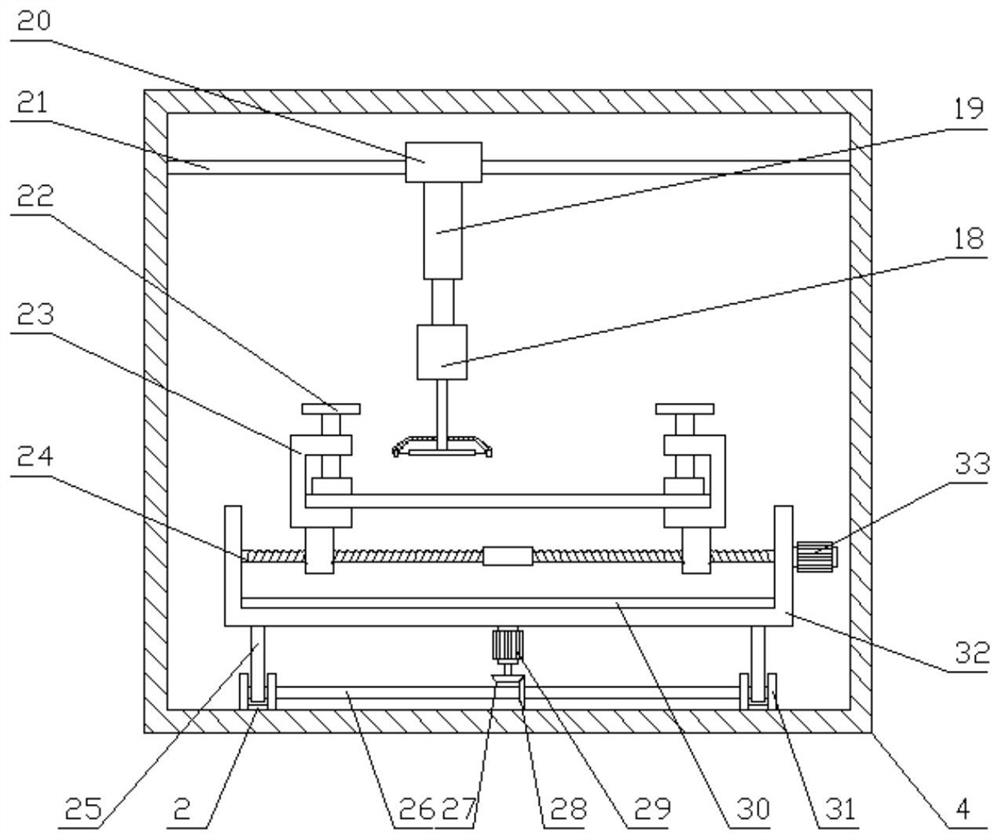

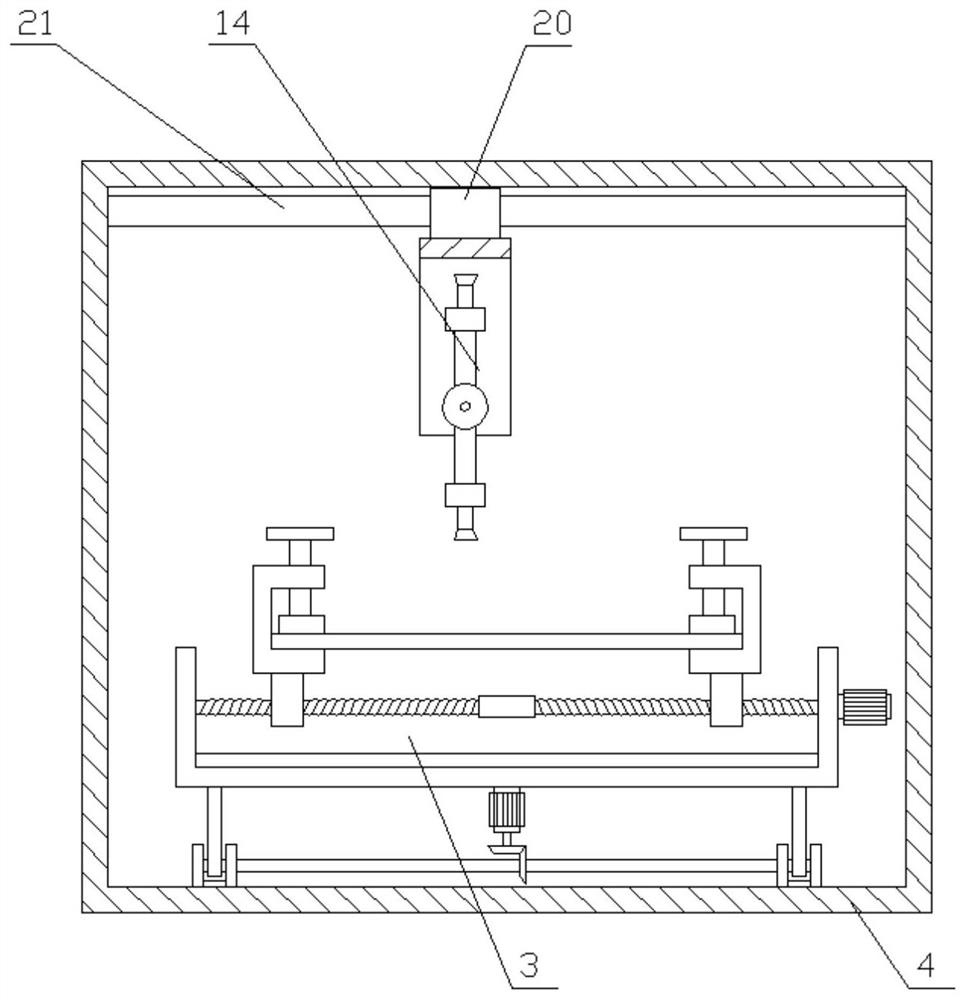

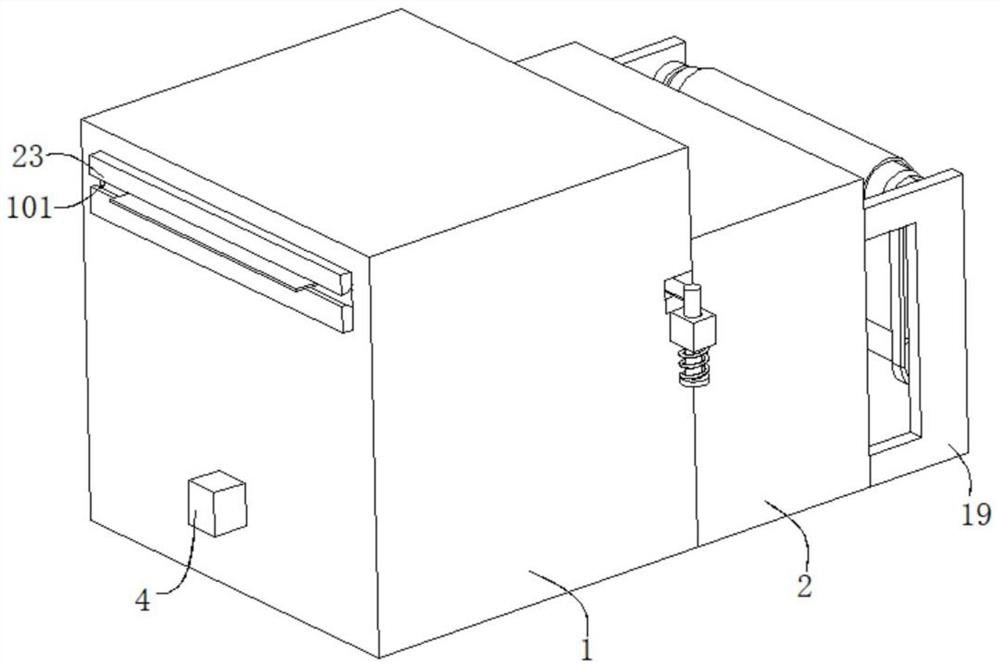

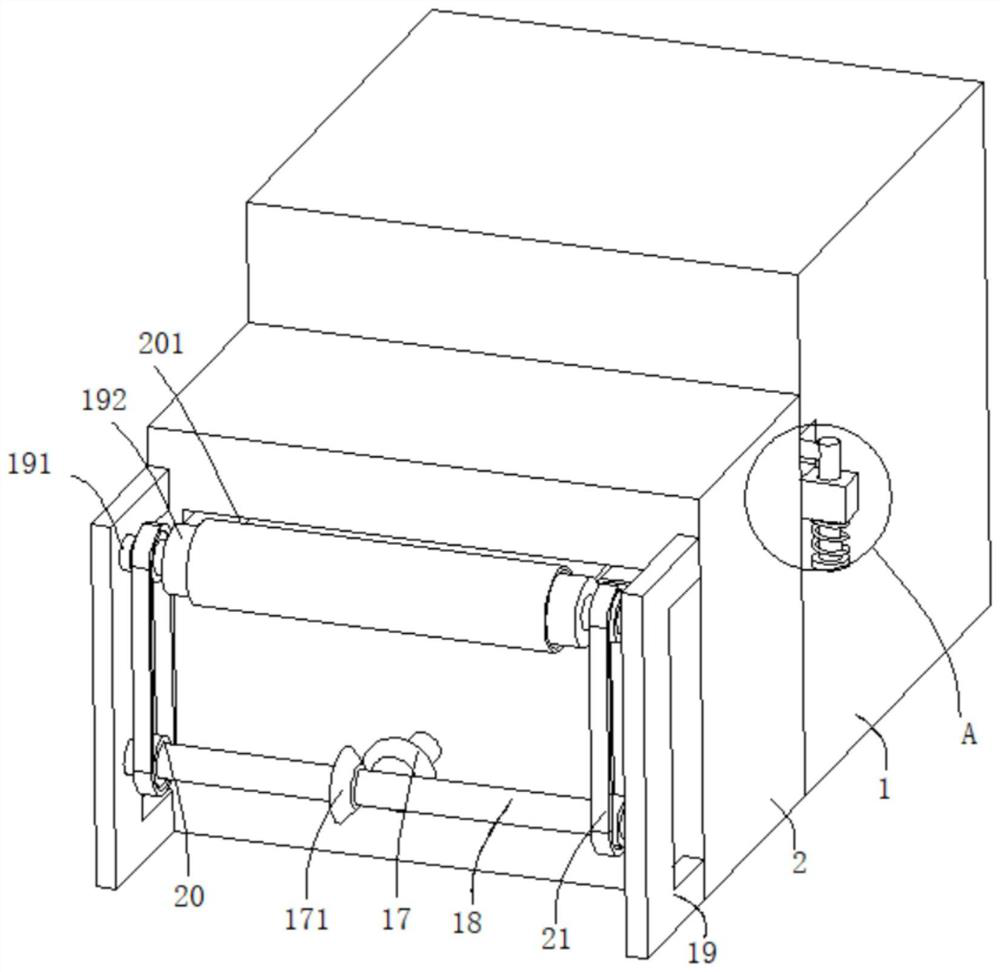

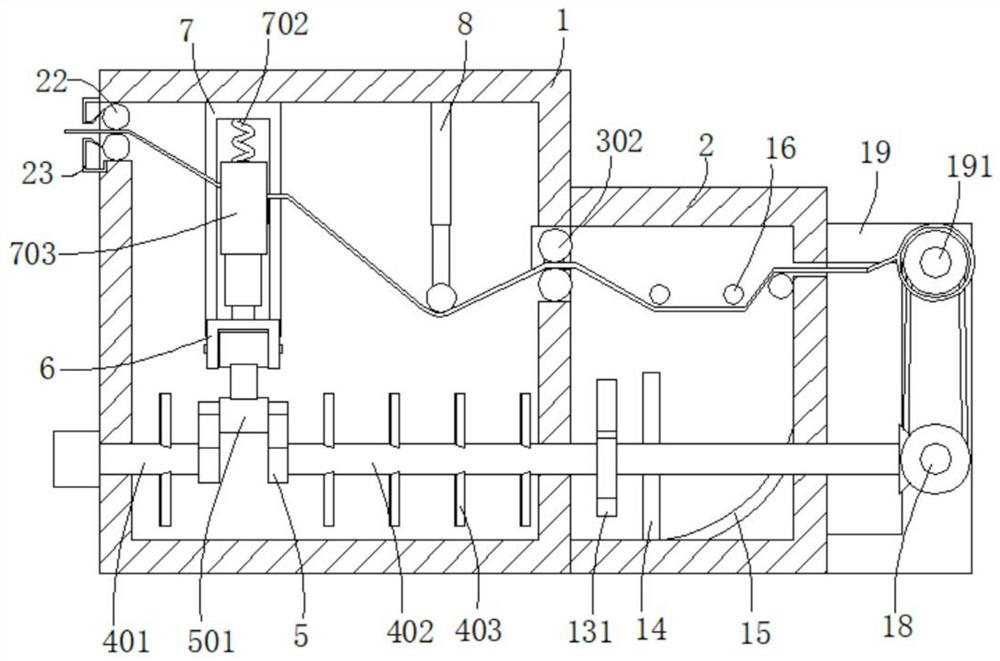

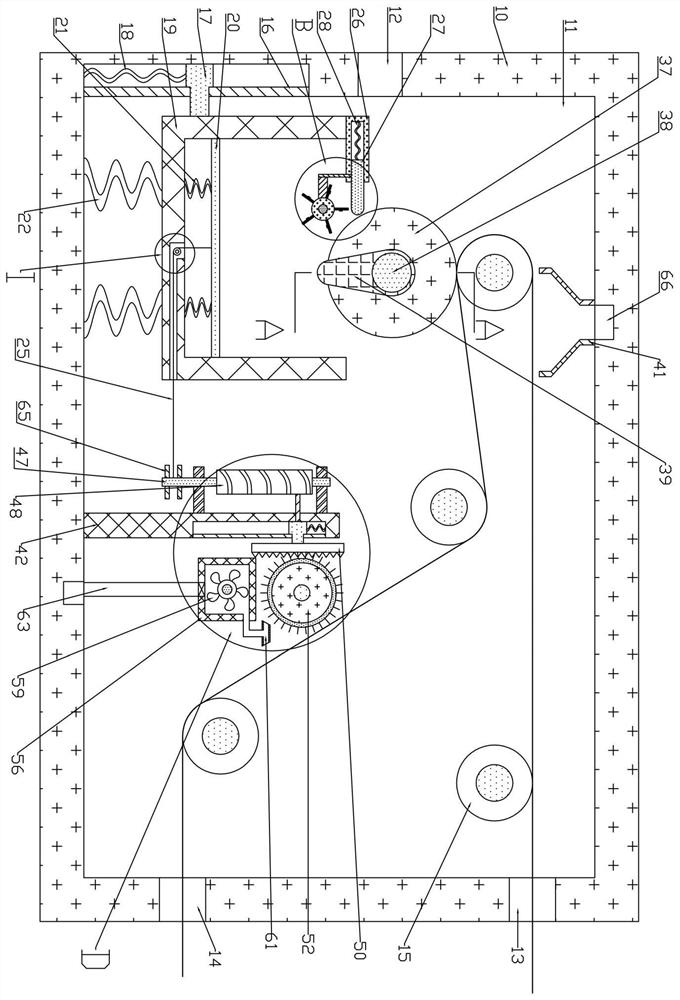

Plate polishing paint spraying device for machining

InactiveCN111760702AGuaranteed surface cleanlinessGuaranteed smoothnessPretreated surfacesGrinding machinesPolishingElectric machinery

The invention relates to the technical field of machining, and discloses a plate polishing paint spraying device for machining. The plate polishing paint spraying device comprises a first motor, a second motor, a third motor, a telescopic cylinder, a polishing machine, an air heater and a box body, wherein the output end of the second motor is fixedly connected with a third bevel gear, the third bevel gear is meshed with a fourth bevel gear, a plurality of rails are arranged on the lower side of the box body, a plate conveying mechanism is arranged on each rail, each plate conveying mechanismcomprises a supporting plate frame, a threaded shaft is rotatably connected with the upper side of each supporting plate frame, the threaded shafts are in threaded connection with a plurality of supporting frames, threads of the threaded shafts are symmetrically distributed about the center of the supporting frames, pressing bolts are arranged on the upper sides of the supporting frames, and a plurality of sliding rails are arranged on the upper side of the interior of the box body. The plate polishing paint spraying device is simple in structure, can realize polishing, paint spraying and paint drying processes of the plate, is high in automation degree, and high in grinding, paint spraying and paint drying efficiency, short in use time, capable of saving working time, and low in manufacturing cost, and has the usable value in the technical field of machining.

Owner:范翠英

Cloth soaking, printing and dyeing device and using method thereof

InactiveCN111826854AFast realization of printing and dyeingAvoid uneven printing and dyeingMechanical cleaningLiquid/gas/vapor treatment machines driving mechanismsMechanical engineeringDyeing

The invention discloses a cloth soaking, printing and dyeing device and a using method of the cloth soaking, printing and dyeing device, and belongs to the technical field of printing and dyeing. Thecloth soaking, printing and dyeing device comprises a dye box and a drying box, a through hole is connected between the dye box and the drying box, the dye box communicates with the drying box, a feeding hole is formed in the outer wall of the dye box, a discharge hole is formed in the outer wall of the drying box, the outer wall of the dye box is connected with a motor, the output end of the motor is connected with a first rotating shaft, the first rotating shaft is rotationally connected to the inner wall of the dye box, a second rotating shaft is rotationally connected to the inner wall ofthe dye box through a bearing, stirring blades are connected to the outer walls of the first rotating shaft and the second rotating shaft, cams are connected to the ends, away from the inner wall of the dye box, of the first rotating shaft and the second rotating shaft, and a connecting piece is fixedly connected between the two cams. With the technical scheme, the dye immersion into cloth can beaccelerated, so that the printing and dyeing efficiency is improved, meanwhile, the cloth can be rapidly dried, thus the situation that printing and dyeing are uneven after the cloth is rolled up is avoided, and the printing and dyeing effect of the cloth can be guaranteed.

Owner:浙江七色彩虹科技有限公司

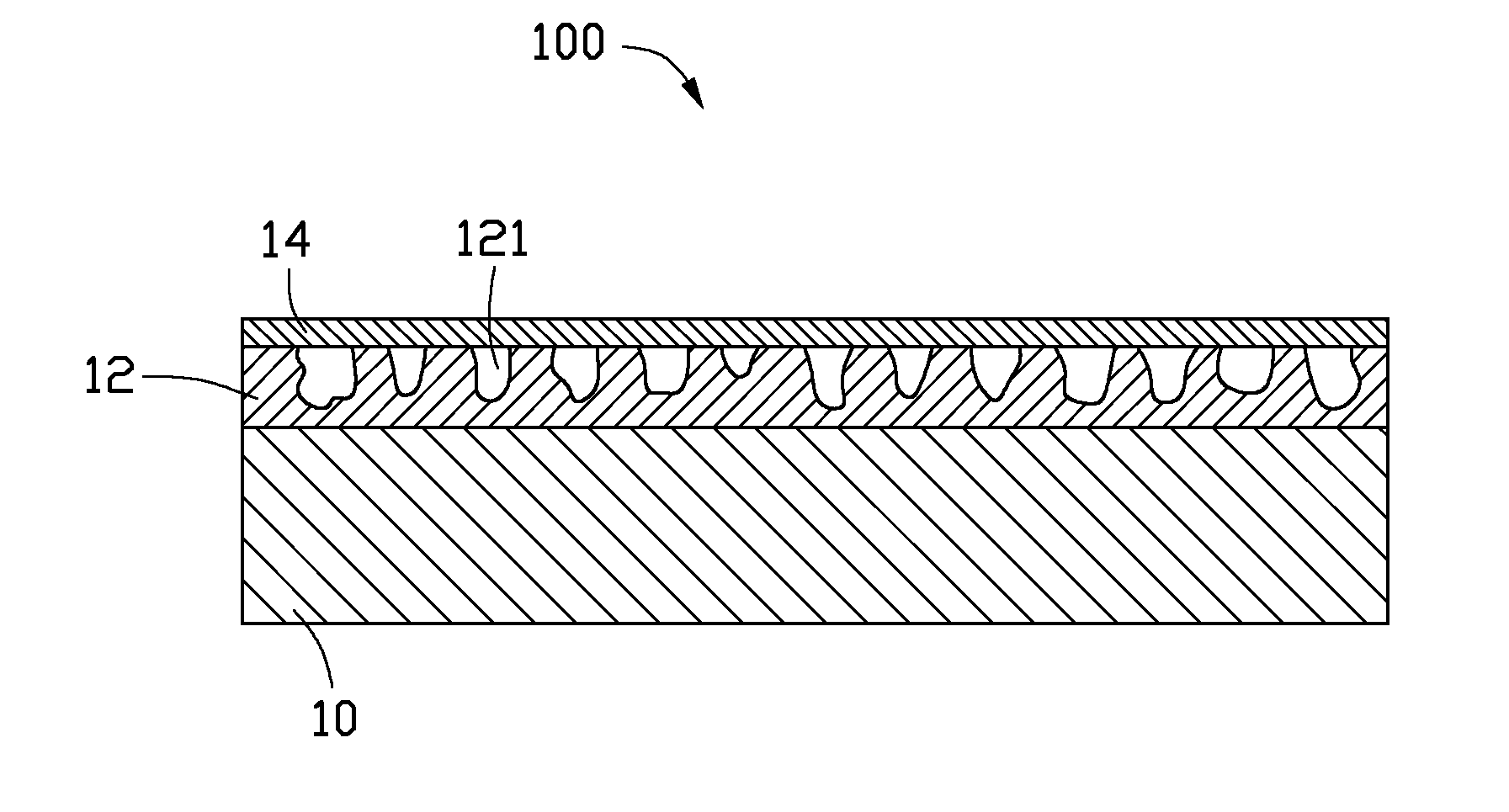

Surface treatment process for aluminum alloy and aluminum alloy article thereof

InactiveUS20140116883A1Affect uniformityAnodisationDuplicating/marking methodsAlloy substrateSilicon

A surface treatment process for aluminum alloy includes the steps of: providing an aluminum alloy substrate containing silicon element; evenly distributing the silicon element in the substrate by solution treating the substrate; removing the silicon element at / near the surface of the substrate by acid treating the substrate; forming a porous aluminum oxide film on the substrate by anodizing the substrate; and staining the aluminum oxide film. An aluminum alloy article treated by the process is also described.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

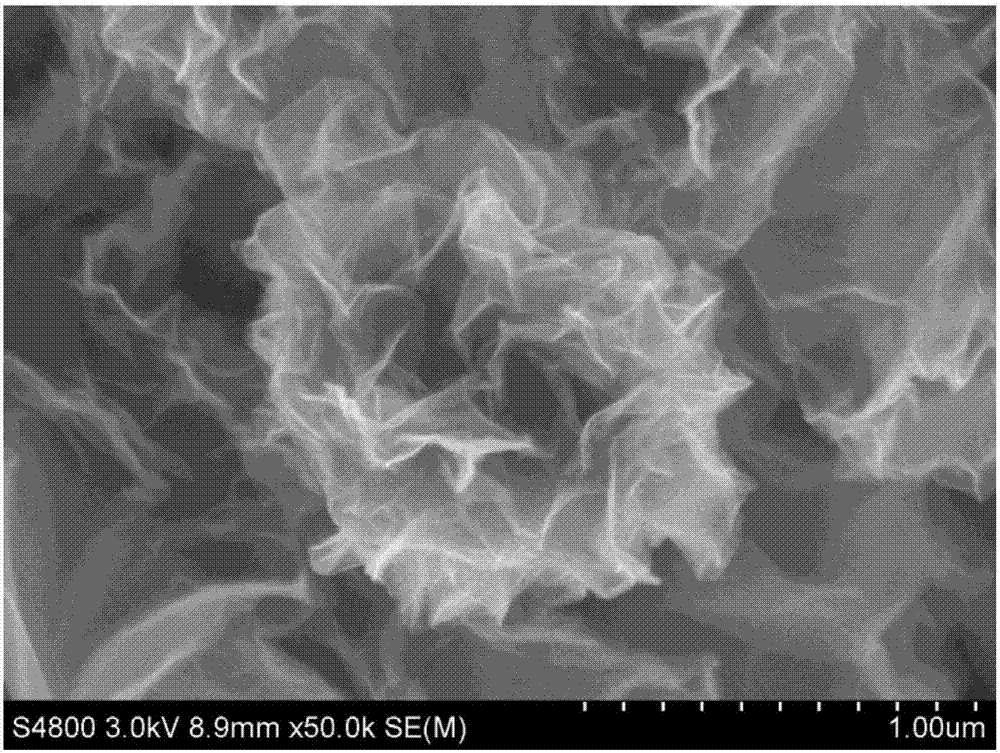

Multifunctional graphene/PET composite film, and preparation method thereof

The invention discloses a multifunctional graphene / PET composite film, and a preparation method thereof. The multifunctional graphene / PET composite film is prepared via melting film casting of a graphene / PET composite material; and the graphene / PET composite material is obtained via adding plicated ball shaped oxidized graphene and a catalyst into PET precursor and in-situ polycondensation. The preparation method is capable of avoiding stacking of oxidized graphane in esterification, reducing cost greatly, and increasing production efficiency. The obtained graphene is excellent in dispersibility in polymer matrix; adding of a small amount of graphene, the ultraviolet resistance, the static resistance, the oxygen isolation performance, and the steam isolation performance of the obtained multifunctional graphene / PET composite film are improved obviously. The preparation method is simple and effective; the obtained multifunctional graphene / PET composite film is excellent in performance, and can be used for preparing ultraviolet resistant film, food package, and protective coiled materials.

Owner:HANGZHOU GAOXI TECH CO LTD

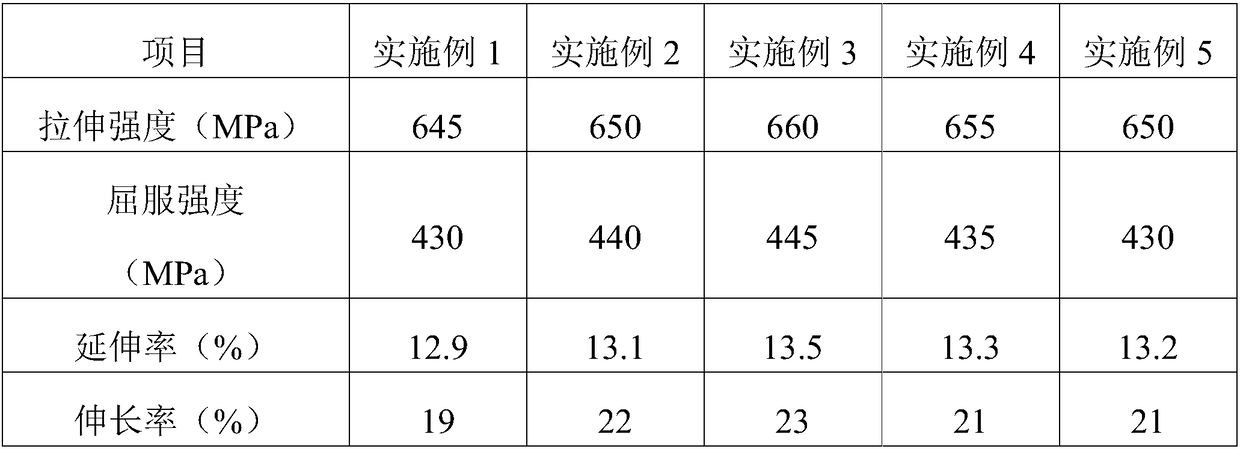

High-nitrogen composite alloy and preparation method thereof

ActiveCN109365806AImproves tensile and flexural strengthGood impact resistanceTransportation and packagingMetal-working apparatusLanthanumFlexural strength

The invention belongs to the technical field of metallurgy, and provides a high-nitrogen composite alloy which is prepared from the following components in percentage by weight: 5 to 20 percent of nitrogen, 15 to 40 percent of titanium, 15 to 40 percent of niobium, 10 to 20 percent of chromium, 10 to 20 percent of silicon, 2 to 10 percent of manganese, 1 to 5 percent of rare earth lanthanum, lessthan or equal to 1.0 percent of carbon, less than or equal to 0.06 percent of sulfur, and less than or equal to 0.1 percent of phosphorus. A preparation method comprises the steps of premixing raw material, then mixing, rising temperature, pretreating, then rising temperature for three times under the vacuum condition, preserving heat, pressing and firing. According to the prepared high-nitrogen composite alloy, the nitrogen content is remarkably improved, and a reinforcing steel bar using the high-nitrogen composite alloy has high tensile strength and bending strength, good shock resistance,good toughness and excellent mechanical property. The high-nitrogen composite alloy provided by the invention solves the problems of instable quality and low nitrogen content of the high-nitrogen reinforcing steel bar in the prior art.

Owner:河北诺凡新材料科技有限公司

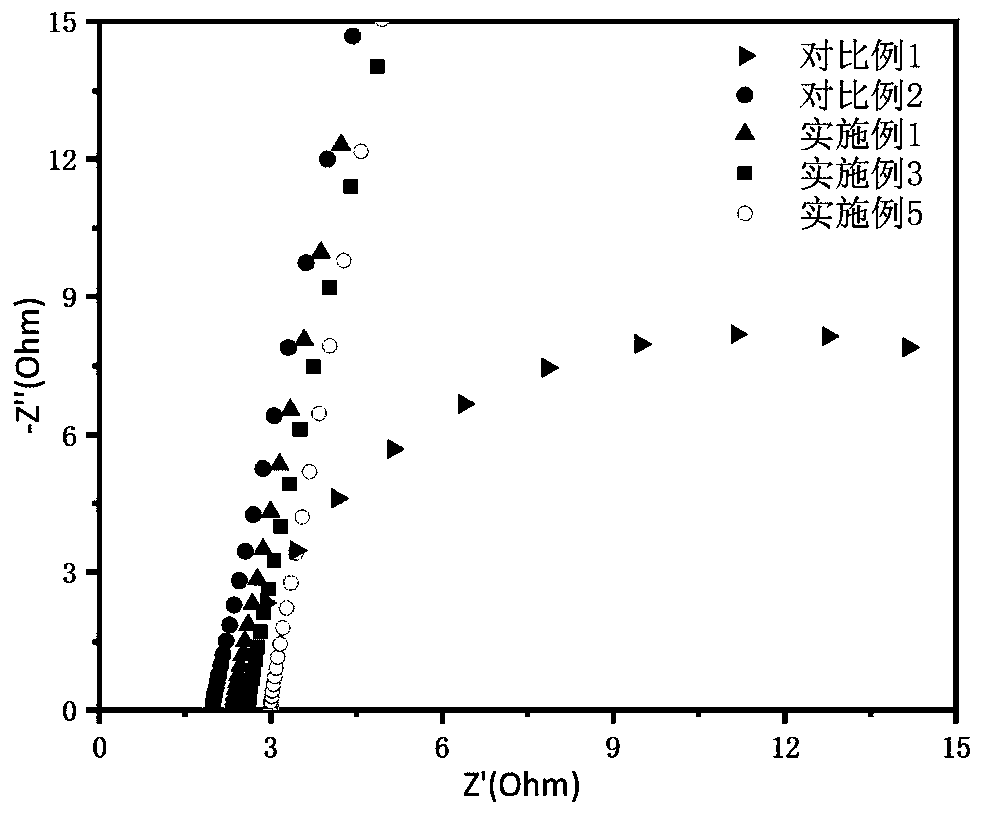

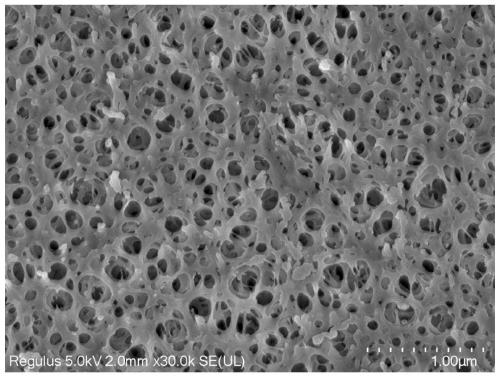

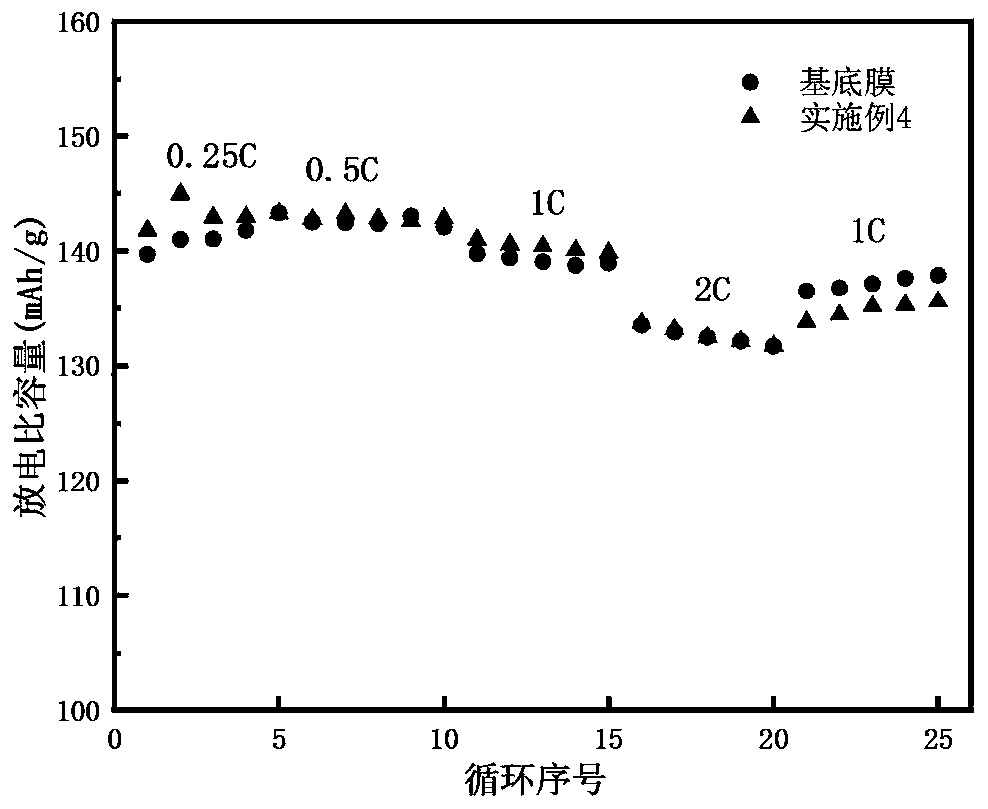

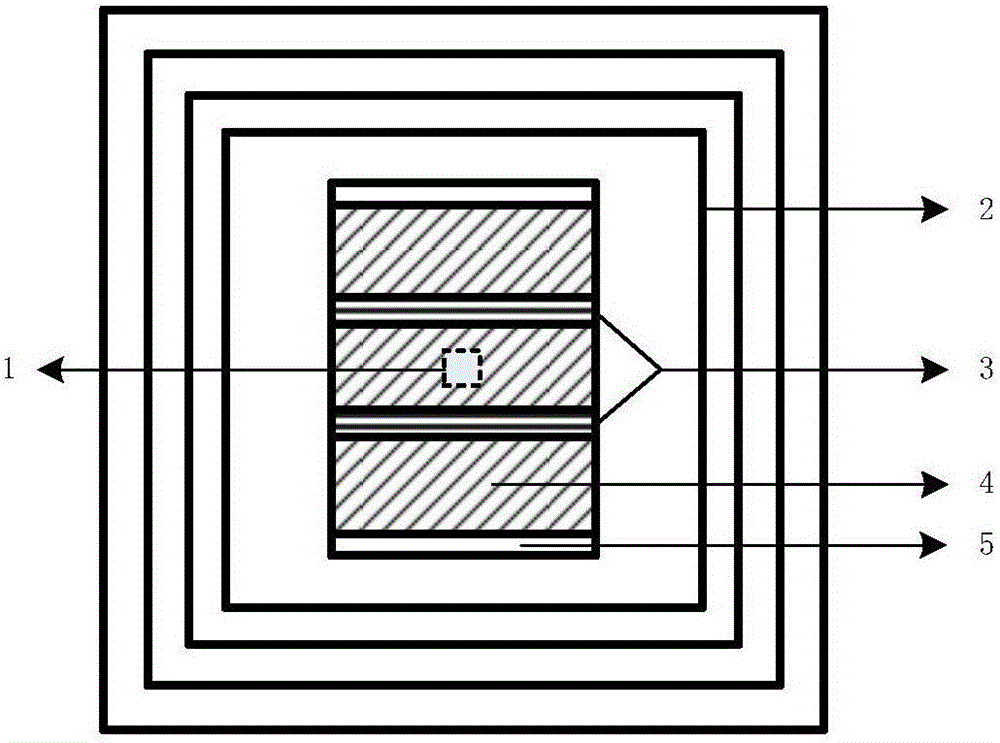

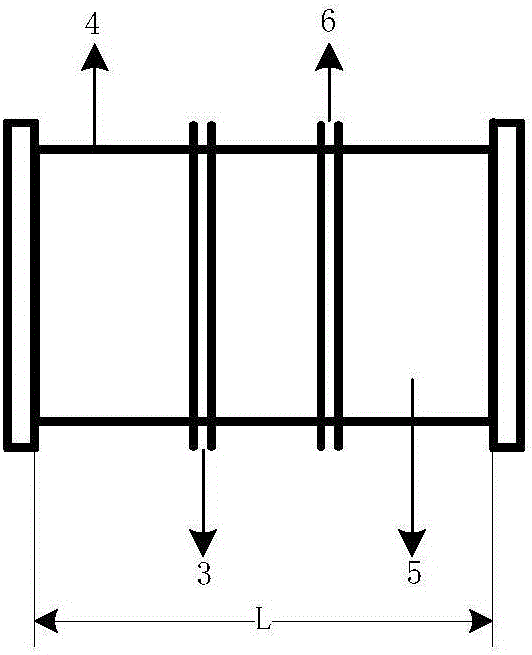

Aramid fiber phase-inversion coating lithium ion battery diaphragm and preparation method thereof

InactiveCN111370625AImprove thermal stabilityUniform hole formationSecondary cellsCell component detailsInterface impedancePhysical chemistry

The invention relates to a preparation method of an aramid fiber phase-inversion coating lithium ion battery diaphragm, which is characterized by comprising the following steps: (1) dissolving aramidfiber, a cosolvent, an oily assistant and a pore-forming agent in a first solvent at 60-100 DEG C to prepare a uniformly mixed coating solution; (2) coating one side or two sides of a diaphragm base material with the coating liquid, immersing the mixture into a coagulating bath consisting of a second solvent and water for phase inversion for 1-3 minutes, then immersing the mixture into pure waterto remove the redundant solvent, and drying to obtain a finished product of the lithium ion battery diaphragm; the surface of the diaphragm is coated with the high-temperature-resistant polymer, so that the thermal stability and the mechanical strength of the diaphragm are improved; a water-soluble pore-forming agent is used in the coating liquid, and pores are uniformly formed after phase inversion of a coating layer; and the used oily auxiliary agent reduces the interface impedance on the basis of maintaining the main body skeleton structure of the aramid fiber, improves the conductivity oflithium ions, and improves the hole plugging effect caused by oily coating.

Owner:SOUTH CHINA UNIV OF TECH

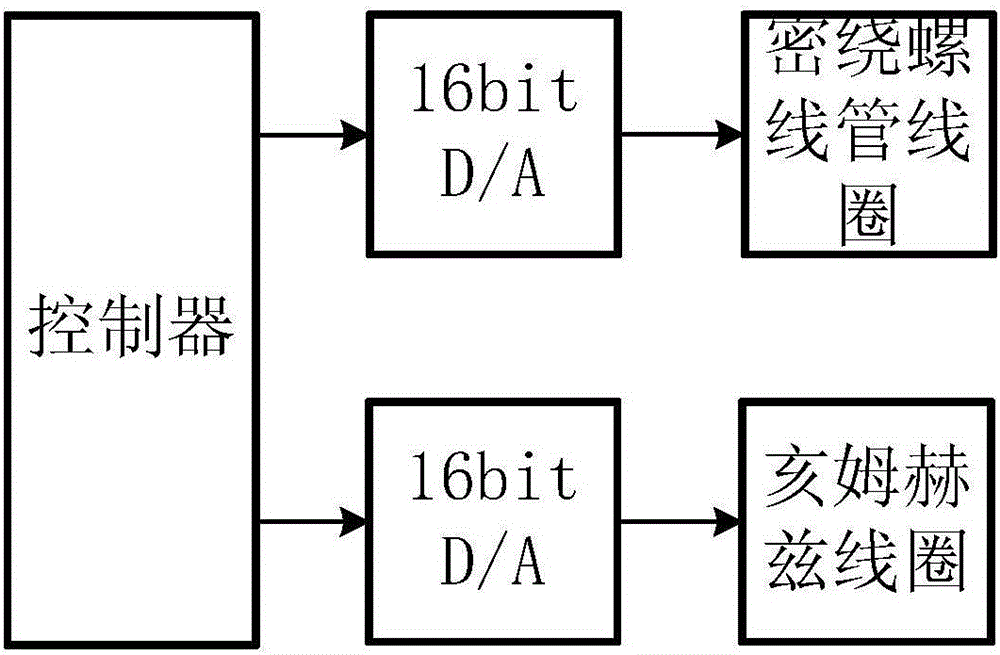

Double-coil structure for nuclear magnetic resonance gyroscope high-precision magnetic field control

ActiveCN106024260ASolve the problem of insufficient control precisionStable controlTurn-sensitive devicesCoilsNumerical controlNMR - Nuclear magnetic resonance

The invention relates to a double-coil structure for nuclear magnetic resonance gyroscope high-precision magnetic field control. According to the structure, a framework is used for fixing a close-wound solenoid coil and a Helmholtz coil. The static magnetic field is generated by the close-wound solenoid coil and Helmholtz coil together. The complete structure is arranged in a multilayer magnetic shielding cylinder, and the multilayer magnetic shielding cylinder can shield part of the magnetic field. The close-wound solenoid coil is used for generating a stable intense magnetic field, which has higher magnetic field uniformity and is suitable for roughly regulating the static magnetic field. The Helmholtz coil is used for compensating the remanent field in the magnetic shielding cylinder, and the generated magnetic field has lower intensity, poor uniformity and higher regulation precision. The two coils are matched, thereby reducing the device volume, and solving the problem of insufficient control precision in the numerical control electronic system. By adopting the double-coil structure, the control precision can be enhanced by 75 times.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Glue spreading device for adhesive tape, and using method thereof

InactiveCN112191456AAdvantages of usingControl distanceSpraying apparatusPretreated surfacesAdhesive beltAdhesive glue

The invention provides a glue spreading device for an adhesive tape, and a using method thereof, and belongs to the technical field of adhesive tape production. According to the glue spreading device,the problems that, in the adhesive tape production process, the surface of a film to be glued is not treated, and consequently dust falls on the surface of the film; the glue spreading effect of thefilm is affected, and glue on the surface of a roller dipped with the glue is uneven; consequently, the glue on the film is unevenly spread, and the quality of the adhesive tape is reduced are solved.According to the glue spreading device for the adhesive tape, and the using method thereof, a shell, a storage mechanism, a glue spreading mechanism, a dust removal mechanism and a transmission mechanism are coordinated to complete corresponding treatment operation, and a working space is defined in the shell; four conveying wheels for conveying an adhesive tape film are rotationally connected between the inner walls of the front side and the rear side of the shell; and a glue injection port is formed in the left end wall of the shell. According to the glue spreading device for the adhesive tape, and the using method thereof, the glue spreading effect is better, and the product quality is higher.

Owner:程杰杰

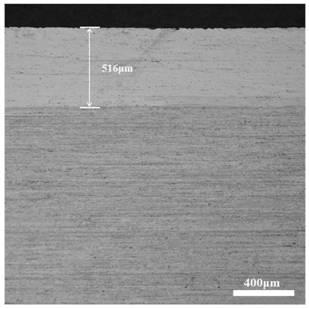

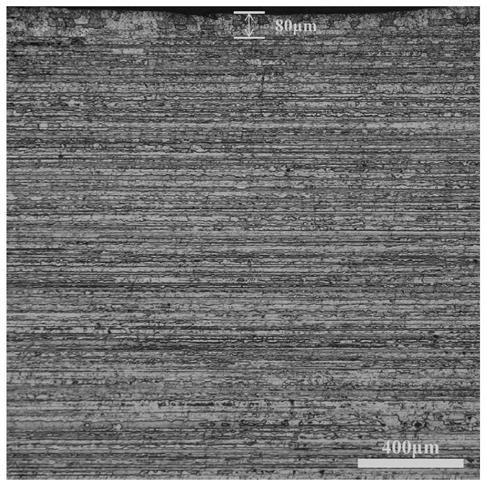

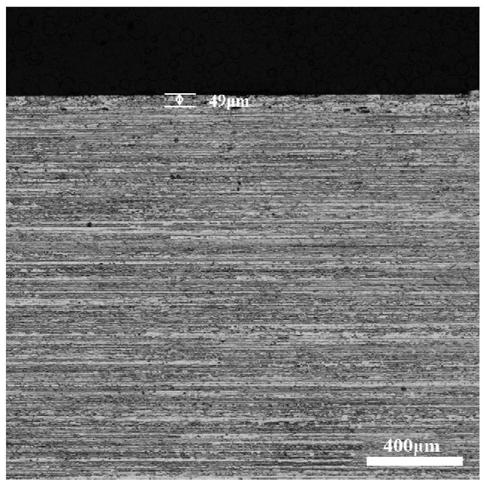

Preparation method for Al-Cu-Li series aluminum-lithium alloy plate

The invention discloses a preparation method for an Al-Cu-Li series aluminum-lithium alloy plate. The preparation method comprises the steps that an aluminum-lithium alloy ingot is firstly subjected to heat preservation at 95 DEG C-121 DEG C for 6 h-24 h, is heated to 320 DEG C-400 DEG C for heat preservation for 3 h-16 h, then is heated to 420 DEG C-450 DEG C for heat preservation for 4 h-12 h and is finally heated to 480 DEG C-510 DEG C for heat preservation for 8 h-24 h so that homogenization treatment can be carried out; then the head and the tail are sawed, face milling is carried out, ahot rolled billet is machined, preheating is carried out to 480 DEG C-520 DEG C, rolling is carried out to form the plate with the thickness being 0.8 mm-25 mm, the surface temperature of the plate inthe rolling process is not lower than 330 DEG C, and the gate pressing rate in the rolling process is 10%-30%; and the rolled plate is subjected to heat preservation at 505 DEG C-525 DEG C for 2 h-6h for solid solution and quenching treatment, pre-stretching deformation with the deformation amount being 1%-5% is carried out, and finally artificial aging treatment is carried out to the T8 state.The preparation method can effectively eliminate a coarse-grain layer on the surface layer of the aluminum-lithium alloy plate, the performance loss in the preparation process of the plate is controlled, and the uniformity of the performance of the plate is improved.

Owner:CENT SOUTH UNIV

Method for calibrating sensitivity of multiple sensors

InactiveCN104316728ANo errorsAffect flatnessTesting/calibration of speed/acceleration/shock measurement devicesMultiple sensorClassical mechanics

The invention discloses a method for calibrating the sensitivity of multiple sensors. The method comprises the following steps that a plurality of acceleration sensors to be calibrated and a plurality of standard acceleration sensors are fixed above the work surface of a vibrating table and below the work surface of the vibrating table respectively in a back-to-back mode, and the multiple sets of acceleration sensors to be calibrated and the standard acceleration sensors are electrically connected with detection equipment. According to the calibrating method, the acceleration sensors to be calibrated and the standard acceleration sensors are fixed above the work surface and below the work surface respectively in back-to-back and one-to-one correspondence modes, so that when the acceleration sensors to be calibrated are calibrated, the influence of the flatness and the evenness of the work surface is avoided, and the errors of the calibration results of all the acceleration sensors to be calibrated can not happen in the batch calibration process. Accordingly, the calibrating method saves time and labor, and improves working efficiency.

Owner:SUZHOU DONGLING VIBRATION TEST INSTR

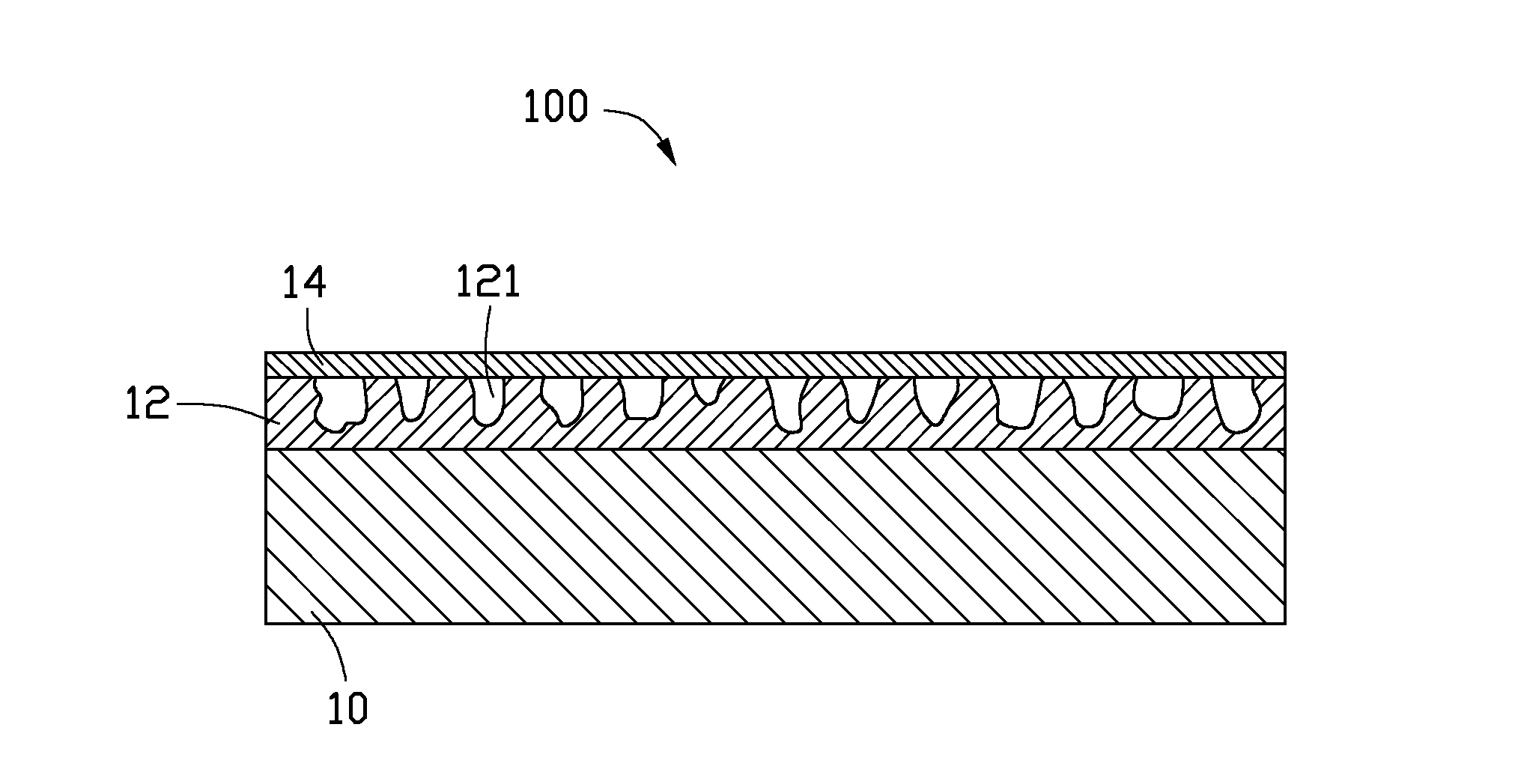

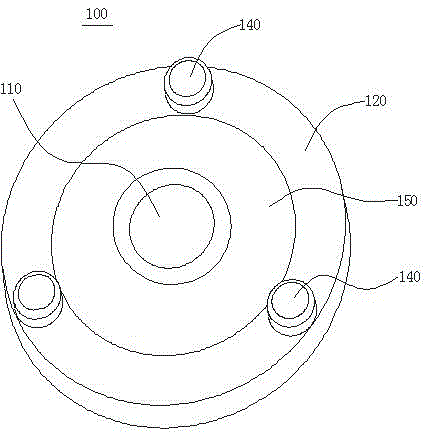

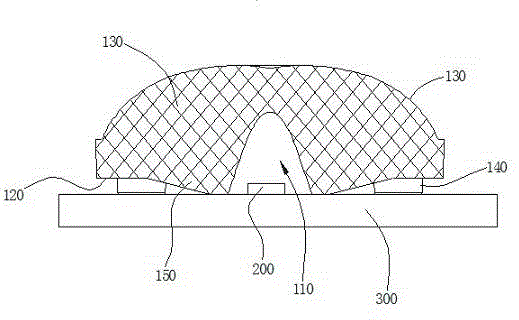

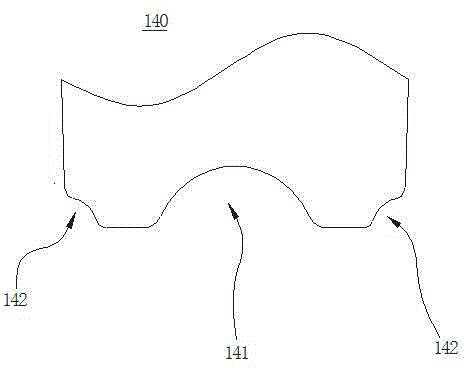

Flip chip unpackaged light source lens

InactiveCN104566213AIncrease profitPrevent intrusionPoint-like light sourceRefractorsDiffuse reflectionLight-emitting diode

The invention discloses a flip chip unpackaged light source lens. The lens comprises a lens body, wherein the bottom projection is circular; a light entrance hole is formed in the center of the bottom; the bottom surface of the lens body is symmetrically provided with a plurality of downwardly protruding mounting columns; the part at the periphery of an opening of the light entrance hole sinks to form an inverted frustum-shaped sunken part; the sinking height of the sunken part does not exceed the length of the mounting columns; the surface of the sunken part and the bottom surface of the lens body are both provided with non-planar microscopic structures for light diffuse reflection; the mounting columns are fixedly glued on a base band, an LED (Light Emitting Diode) light source is accommodated in the light entrance hole, and the sunken part is covered at the periphery of the LED light source, so the lens can completely act on light emitted by the LED light source to improve the utilization rate of the light source; glue is prevented from introducing into the bottom surface of the lens body so as not to corrode the non-planar microscopic structure because of a gap existing between the mounting columns and the sunken part; the assembly reliability is high and the structure is concise.

Owner:DONGGUAN NUOSI OPTOELECTRONICS TECH

Paint spraying device for inner wall of ventilating duct

ActiveCN113578639AGood adhesionAffect uniformityHollow article cleaningPretreated surfacesCold airEngineering

The invention discloses a paint spraying device for the inner wall of a ventilating duct. The device comprises a workbench and the ventilating duct, the upper end of the workbench is fixedly connected with a vertical rod, the side wall of the vertical rod is rotatably connected with a rotating rod, the side wall of the rotating rod is fixedly connected with a nozzle, and the rotating rod is provided with a cleaning mechanism. The cleaning mechanism comprises two hollow rods symmetrically and fixedly connected to the side wall of the rotating rod, the inner walls of the hollow rods are slidably connected with sliding rods, the upper ends of the sliding rods are fixedly connected with arc-shaped scraping plates, dust suction grooves are formed in the arc-shaped scraping plates, dust suction holes are formed in the side walls of the dust suction grooves, and impurity discharging pipes are fixedly connected to the side walls of the arc-shaped scraping plates. Dust and rust on the inner wall of the ventilating duct are scraped away through the arc-shaped scraping plates, cold air generated by a vortex tube can rapidly flow in the dust suction grooves, negative pressure can be generated in the dust suction grooves, then the dust and rust scraped away by the arc-shaped scraping plates are sucked into the dust suction grooves to be discharged, the scraped dust and rust are prevented from falling on the inner wall of the ventilating duct, and the adhesion of the paint is prevented from being affected.

Owner:南通苏瑞冷暖科技发展有限公司

Plaster manufacturing device for orthopedics department

InactiveCN108498332AFull effectDecrease productivityPharmaceutical product form changeExternal applicationOrthopedic department

The invention relates to a plaster manufacturing device for the orthopedics department. The plaster manufacturing device comprises a bottom board, wherein a heating furnace is mounted at the front endof the bottom board, a spreading and covering support rack is mounted at the rear end of the bottom board, a spreading and covering movable groove is arranged in the spreading and covering support rack, a spreading and covering adjusting mechanism is arranged in the spreading and covering movable groove, a spreading and covering operating mechanism is arranged at the lower end of the spreading and covering adjusting mechanism, a spreading and covering positioning mechanism is mounted on the bottom board, and the spreading and covering positioning mechanism is positioned just below the spreading and covering support rack. With the plaster manufacturing device for the orthopedics department, the problems that in the existing artificial manufacturing process of traditional Chinese medicinesfor external application, the raw materials of plasters need to be artificially spread to carriers of the plasters by virtue of tools, the slurry of the plasters is thick, the artificial spreading and covering for the slurry of the plasters are nonuniform, so that the efficacies of the slurry of the plasters can not be fully exerted, meanwhile, the artificial operation of spreading and covering the slurry of the plasters by virtue of the tools is complicated, as the carriers of the plasters need to be fixed so that the wrinkling of the carriers of the plasters can be prevented and the spreading and covering effects of the slurry of the plasters are not influenced, are solved.

Owner:洪娇娇

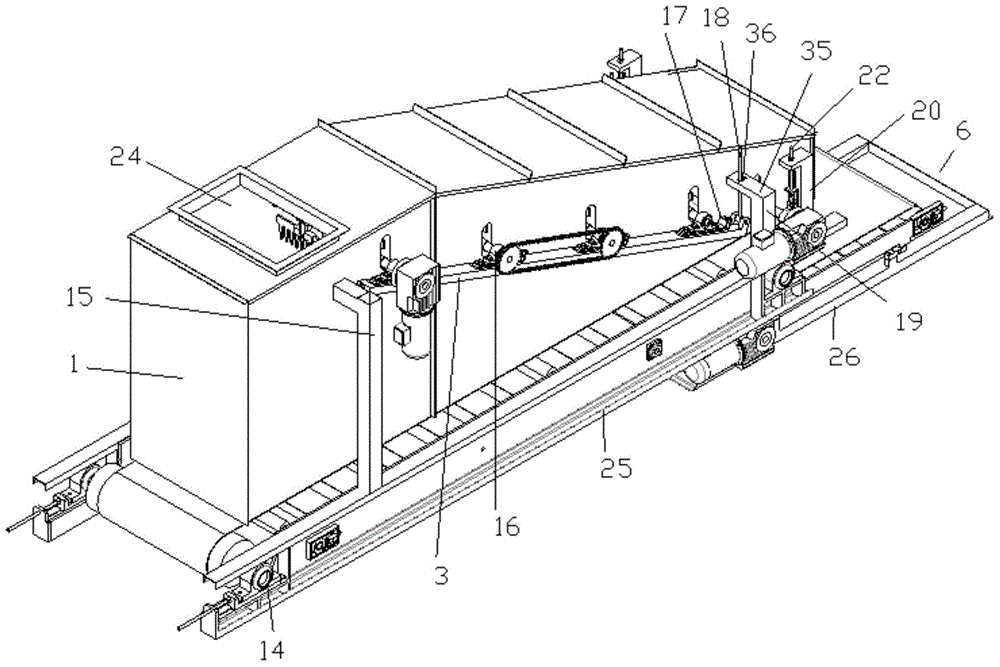

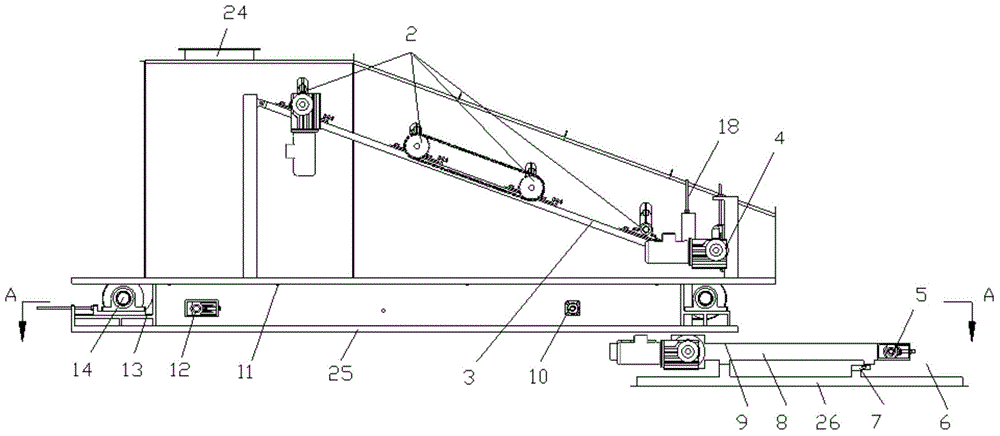

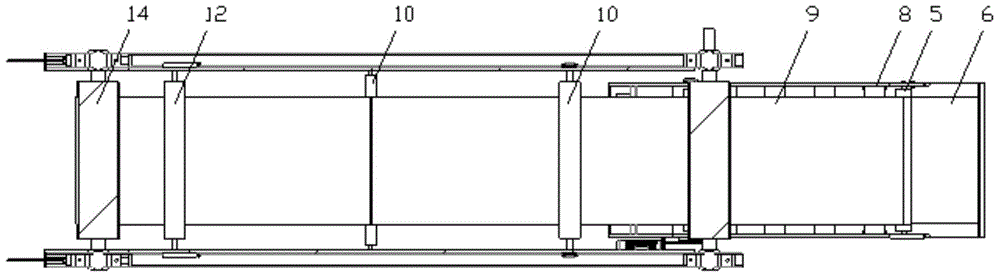

Wood shaving conveying metering device and method for conveying wood shaving thereof

InactiveCN105858263AIncrease the areaGood spread effectConveyorsWood working apparatusWood shavingsEngineering

The invention discloses a wood shaving conveying metering device, comprising a base, a stock bin, a conveying device which has a first conveyer belt and a second conveyer belt, a blanking roller device, and a self-balancing metering device. The blanking roller device is provided with a brush blanking roller. The gap between the brush blanking roller and the first conveyer belt can be adjusted. The self-balancing metering device is installed under the second conveyer belt, and is provided with a scale body structure used to realize self-balance. The brush blanking roller is used to absorb and sow wood shavings, so as to uniformly sow the wood shavings conveyed by the first conveyer belt on the second conveyer belt. The scale body structure comprises a scale rack and balance weight connected with one end of the scale rack. The scale rack and the balance weight are in a balance state. The device is simple in structure, and conveyed wood shavings are uniform in thickness, and wood shaving sowing effect is good. The device provides convenience for calculating conveying flow of the wood shavings. The device solves problems of poor sizing quality caused by errors of the wood shaving conveying flow in a subsequent sizing procedure. In addition, the invention also discloses a method for conveying wood shavings by using the above device.

Owner:BEIJING FORESTRY MACHINERY RES INST OF STATE FORESTRY ADMINISTRATION

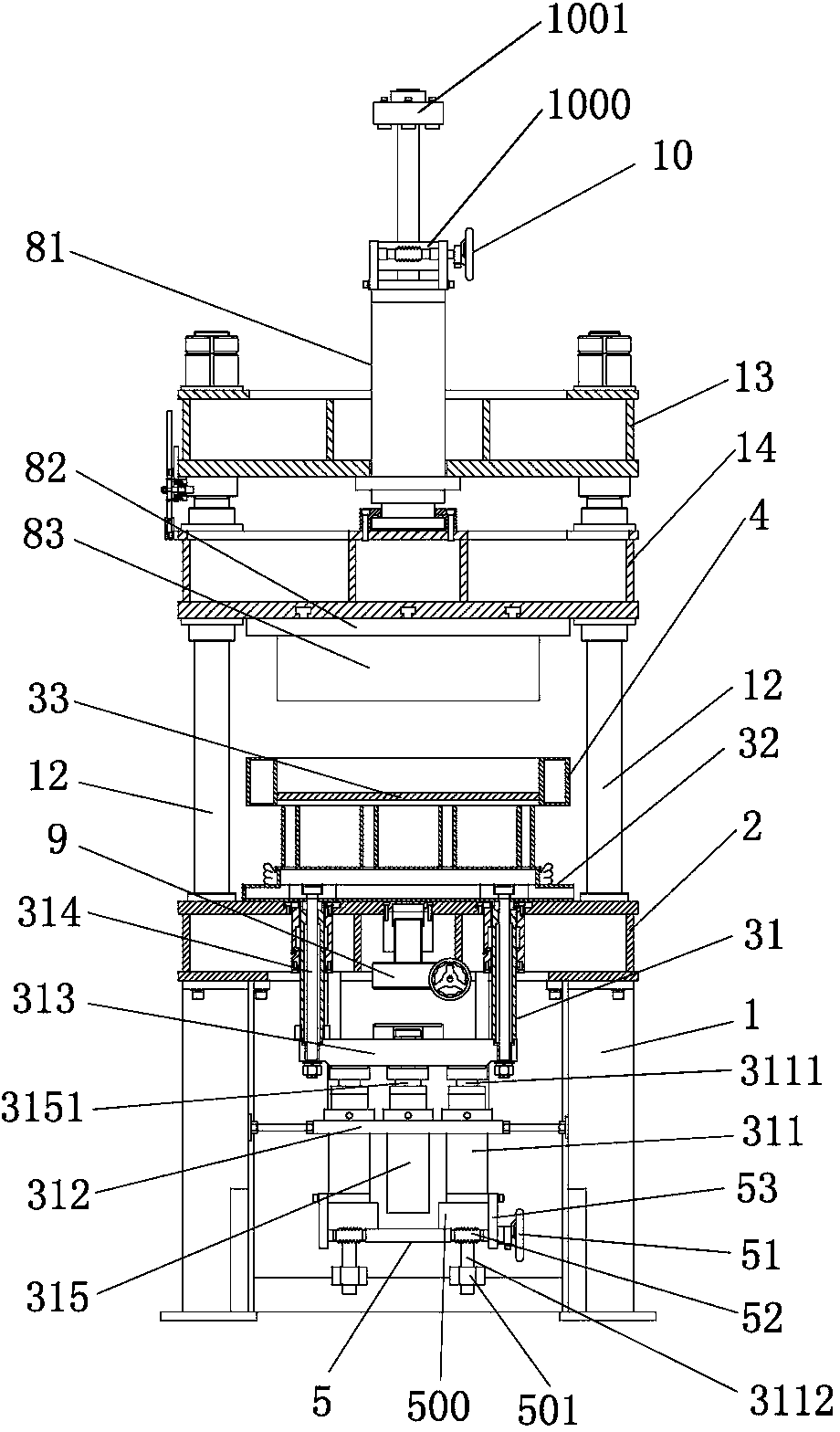

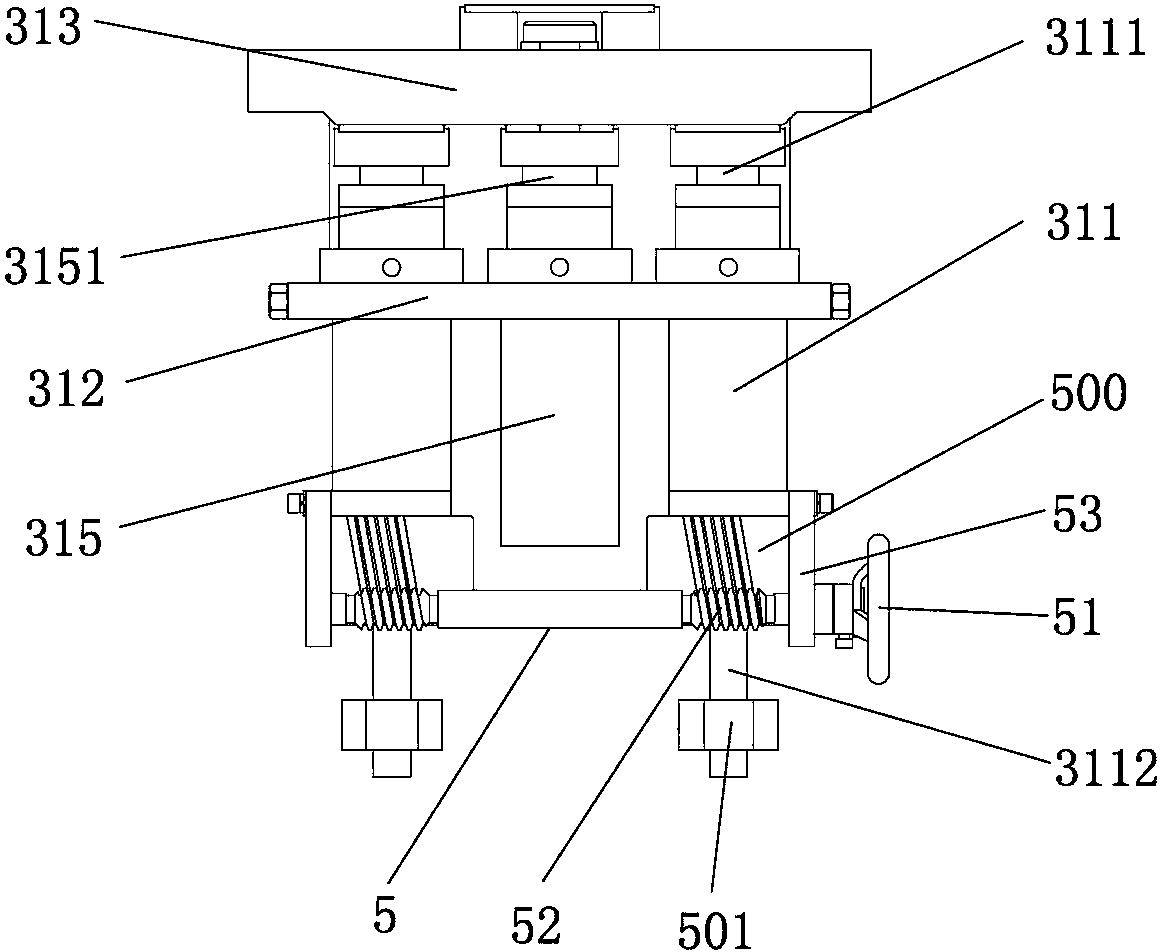

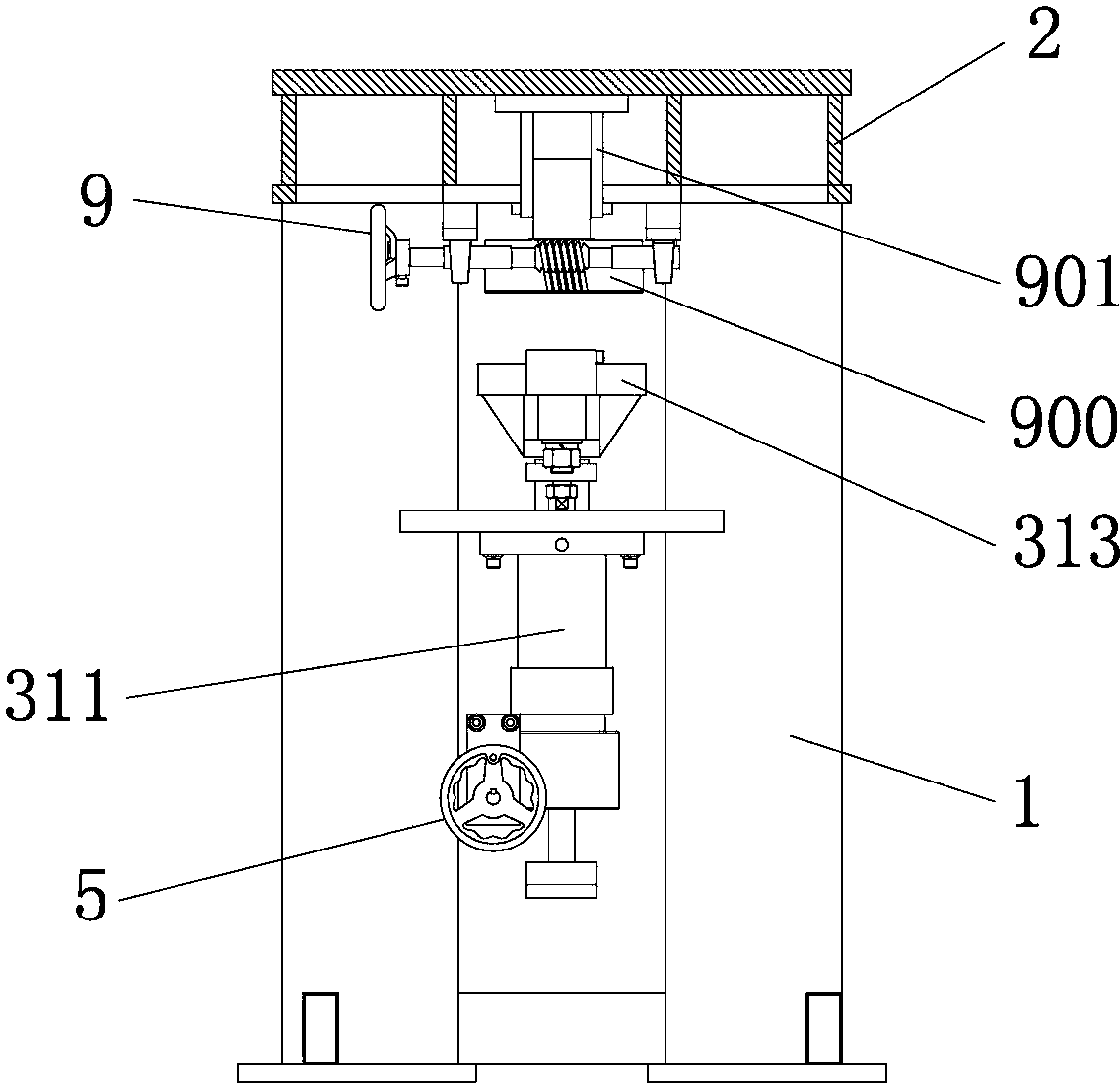

Forming machine for vacuum insulated panel

ActiveCN103522579AAvoid deformationIncrease the exhaust areaPressesEngineeringVacuum insulated panel

The invention provides a forming machine for a vacuum insulated panel. The forming machine for the vacuum insulated panel comprises a machine frame, a lower supporting device is arranged on the machine frame in an erecting mode, a lower die base is arranged on the lower supporting device in a lifting and erecting mode, and a lower die core is installed on the lower die base. An upper die core, a middle die frame, the lower die core and the lower die base are hollow. A bottom plate of the upper die core, an inner side plate of the middle die frame and a top plate of the lower die core are respectively provided with a communicated first exhaust passage, and a venting plug is inserted into the first exhaust passage close to the outer side and is fully provided with second exhaust passages. The lower die base is communicated with the lower die core. The outer side wall of the upper die core, the outer side wall of the middle die frame and the outer side wall of the lower die base are provided with third exhaust passages communicated with the outside. The forming machine is good in supporting stability, high in exhaust efficiency, capable of bearing large pressing force, suitable for pressing the vacuum insulated panel and high in safety coefficient, and the venting plug is convenient to dismount and replace.

Owner:QUANZHOU SANJIA MACHINERY

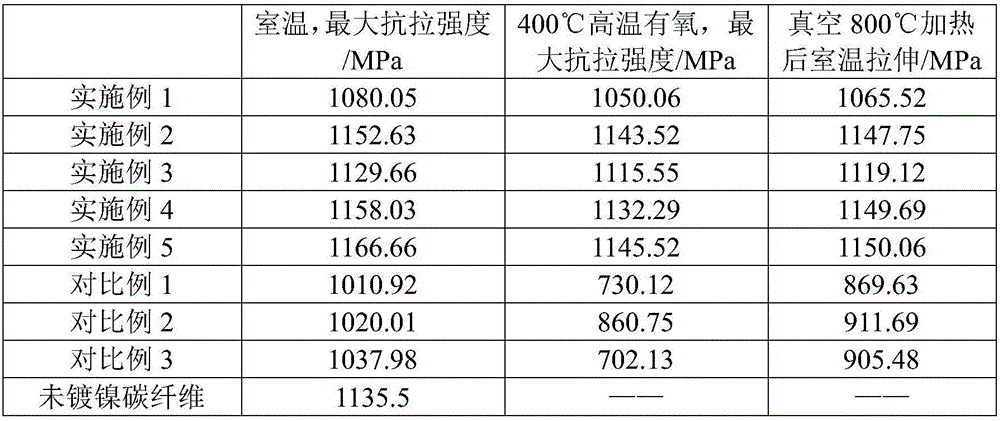

Preparation method of high-performance nickel-plated carbon fibers

InactiveCN106801335AAffect uniformityAffect bindingCarbon fibresLiquid/solution decomposition chemical coatingFiberCarbon fibers

The invention discloses a preparation method of high-performance nickel-plated carbon fibers. The method comprises the following steps: carrying out high-temperature calcination on carbon fibers to remove the surface gum, and carrying out neutralizing treatment; soaking the treated carbon fibers in concentrated nitric acid to perform coarsening treatment; soaking the coarsened carbon fibers in an activation solution composed of palladium chloride, ammonium chloride, sodium thiocyanate and deionized water to perform activating treatment; uniformly mixing nickel sulfate, sodium hypophosphite, ammonium acetate, thiocarbamide, citric acid, tartaric acid, ammonia water and deionized water to prepare a chemical plating solution, and carrying out nickel plating treatment on the activated carbon fiber surface; and collecting the waste liquid in the chemical plating process, and treating the waste liquid to recover nickel. The nickel-plated carbon fibers prepared by the method have the advantages of favorable electric conductivity, excellent mechanical properties, favorable corrosion resistance, favorable binding power between the coating and carbon fiber surface, and no environment pollution.

Owner:DONGGUAN JIAQIAN NEW MATERIAL TECH CO LTD

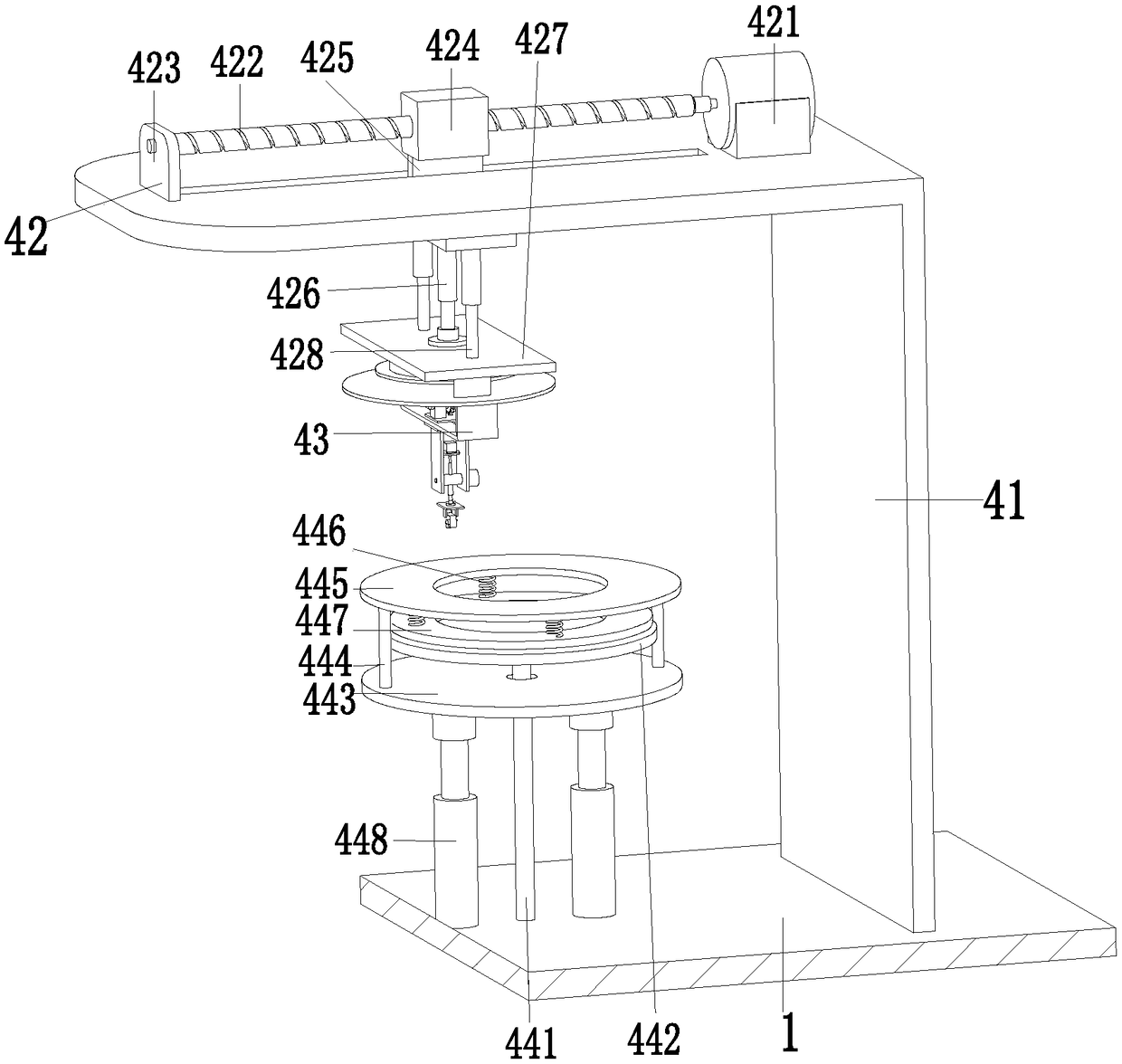

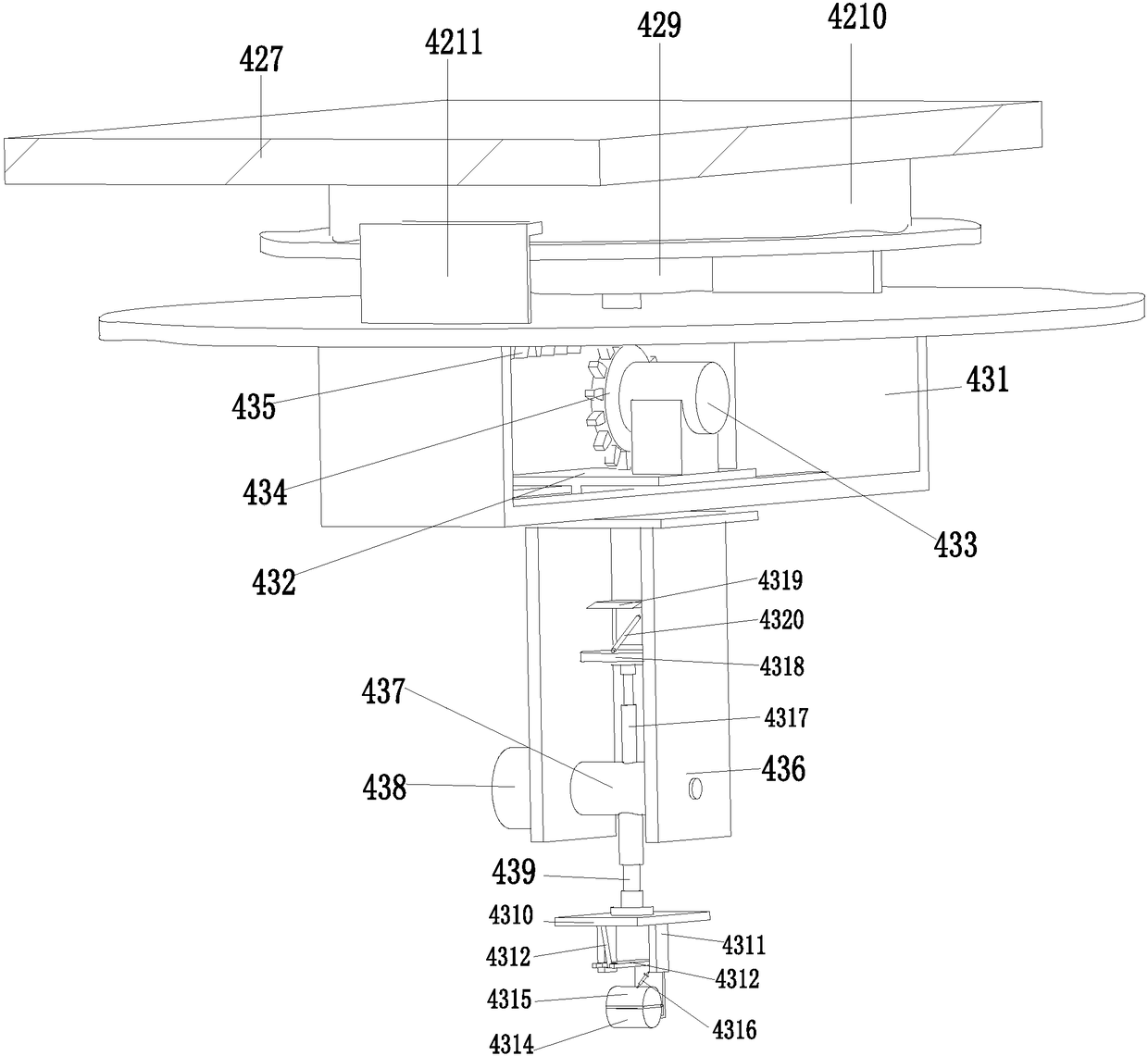

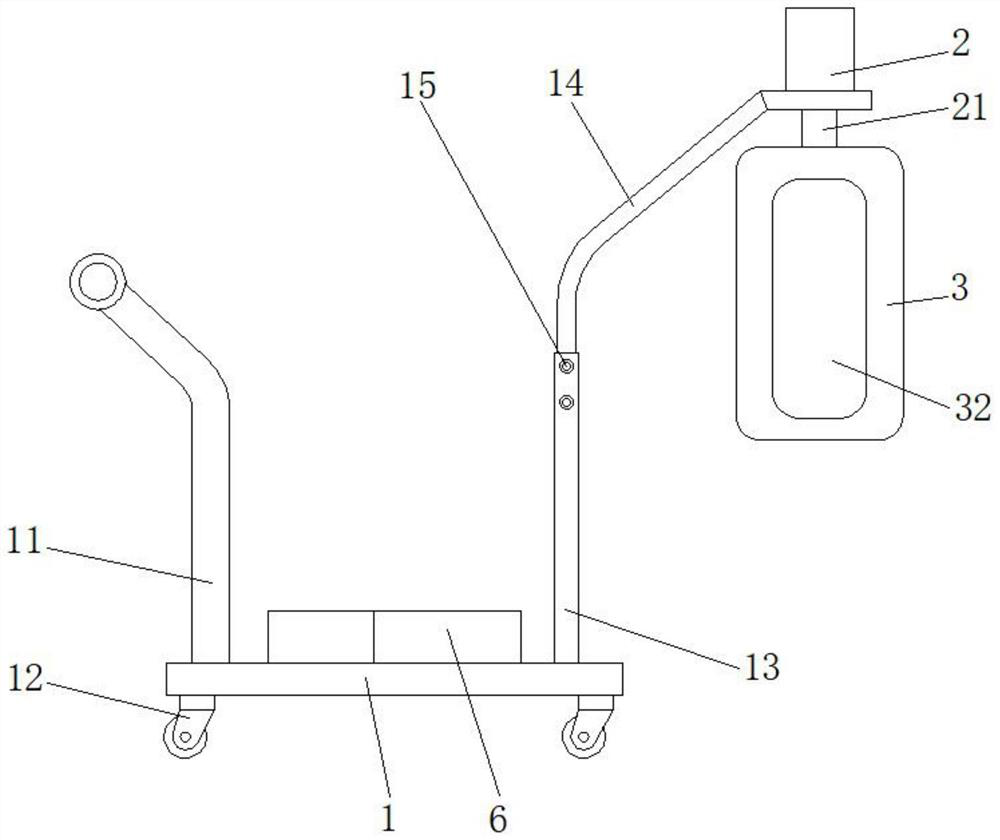

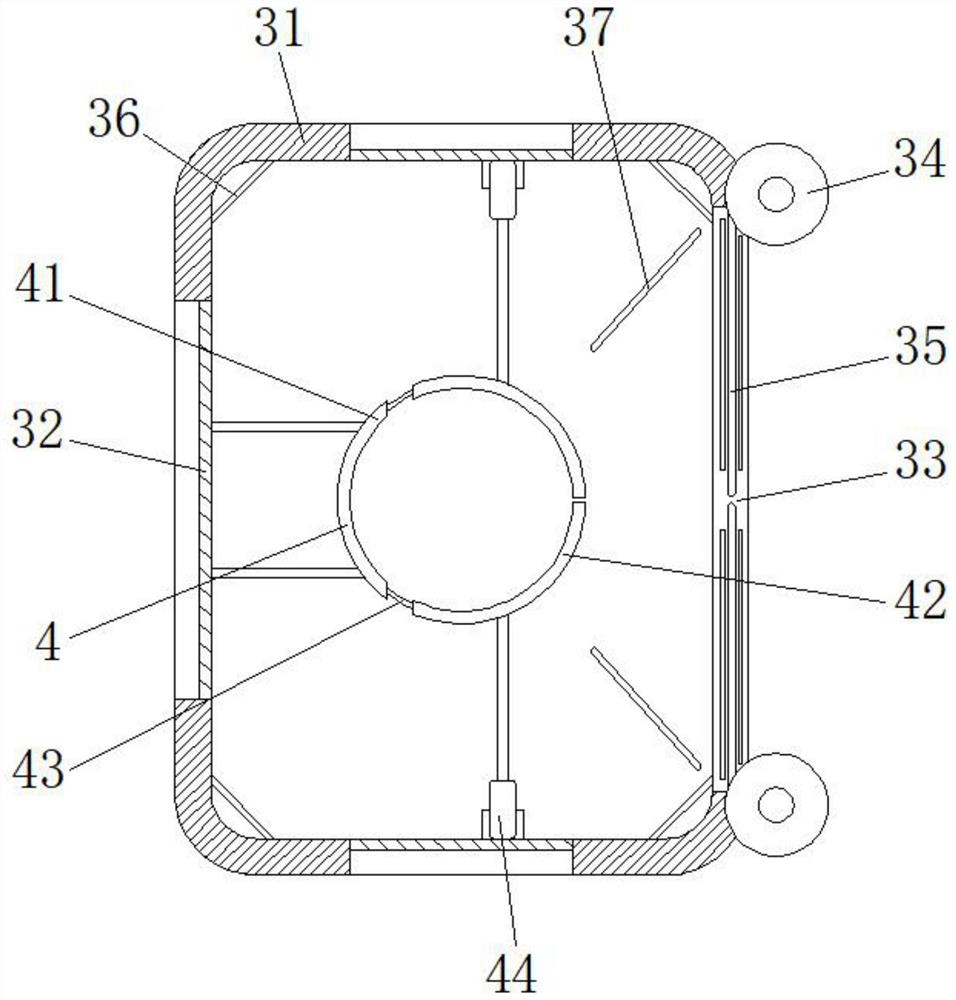

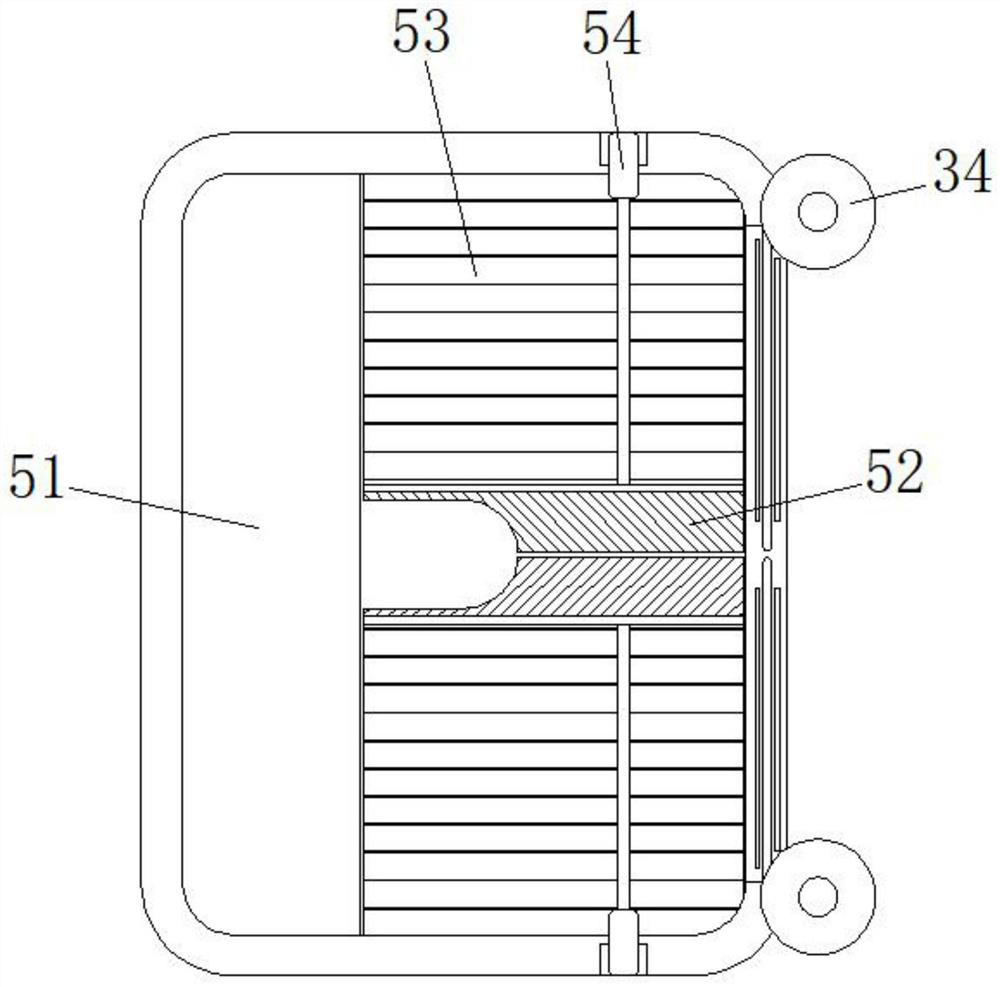

Portable rice castration device

ActiveCN113273491AAffect uniformityPrecise emasculationPlant genotype modificationElectric machineControl theory

The invention provides a portable rice castration device. The portable rice castration device comprises a bottom frame with four universal wheels arranged at the bottom end, wherein a supporting rod is sleeved with a sleeve rod on the bottom frame, an adjusting motor is fixed to the position, close to the top end, of the supporting rod, a castration cylinder is fixed to the bottom end of a rotating shaft of the adjusting motor and is particularly a rectangular cylinder, the bottom end of the castration cylinder is through, an opening is formed in the side face of the castration cylinder, observation windows are formed in the remaining three vertical sides of the rectangular cylinder, electric heating plates are fixed to the four folded corners in the rectangular cylinder respectively, and a castration limiting cylinder is arranged in the middle of the rectangular cylinder. According to the portable rice castration device, the castration cylinder is connected to the bottom frame through the supporting rod, the castration limiting cylinder is further arranged in the castration cylinder, during using, when a to-be-castrated part of rice is clamped in the castration limiting cylinder, the electric heating plates are started, so that the temperature value in the castration limiting cylinder reaches the castration temperature, after castration is finished, the bottom and the side face of the rectangular cylinder are sequentially opened, then the castration limiting cylinder is opened, and the bottom frame is pushed to retreat, so that the portable rice castration device is convenient and practical.

Owner:益阳市农业科学研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com