Wood shaving conveying metering device and method for conveying wood shaving thereof

A technology of measuring equipment and shavings, used in conveyors, weighing equipment for materials with special properties/forms, weighing, etc., can solve problems such as poor sizing quality, achieve uniform and stable flow, high metering good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

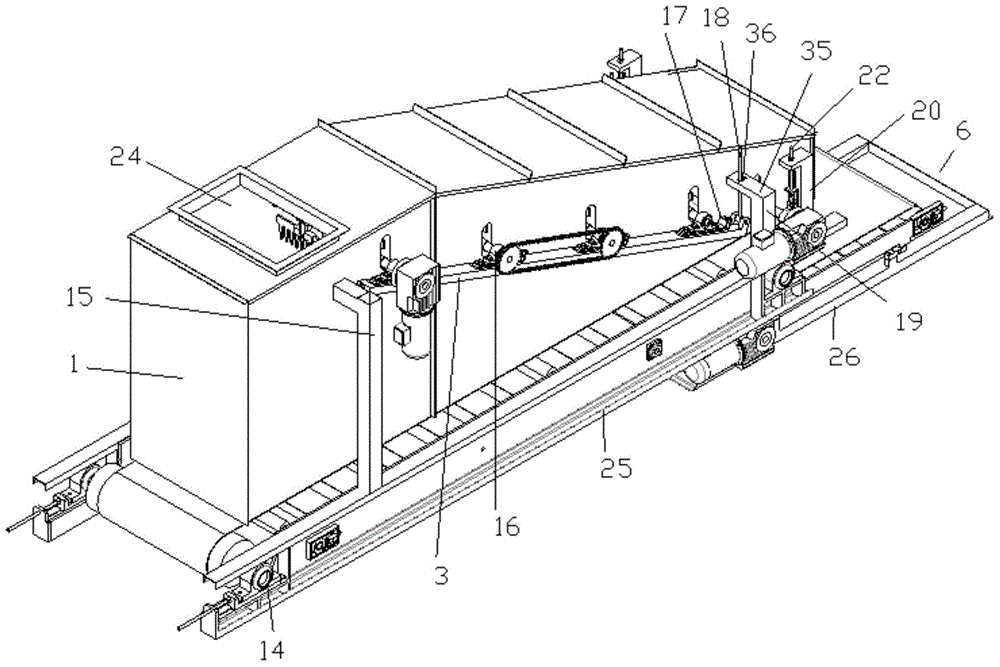

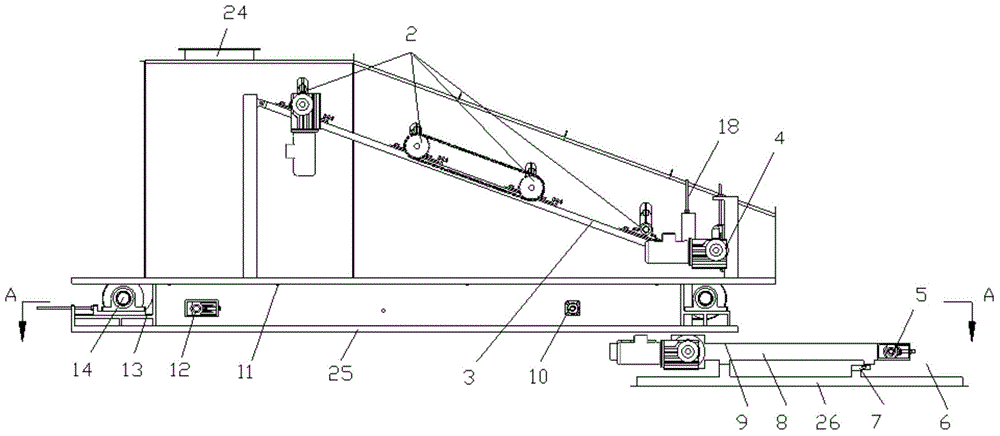

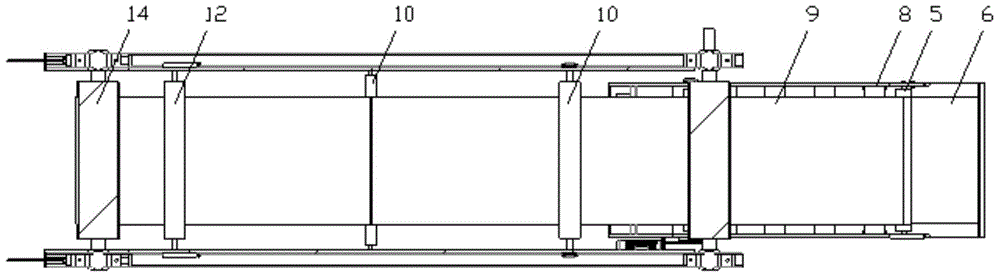

[0038] Such as figure 1 As shown, the perspective view of the shavings conveying and metering equipment provided by the present invention (not showing the part where the feed bin is located above the second conveyor belt 9), and figure 2 , image 3 , Figure 4 Shown are the front view, A-A sectional view and rear view of the shavings conveying and metering equipment in the front view, respectively.

[0039] Depend on Figure 1-Figure 3 It can be seen that the shavings conveying and metering equipment of the present invention includes: a base for placing a feed bin, which has a first base 25 and a second base 26; One end is provided with a discharge port 6; the conveying device has a first conveyor belt 13 and a second conveyor belt 9 arranged in parallel up and down along the moving direction inside the silo, and is used to relay the shavings from the feed port 24 of the silo Delivered to the discharge port 6, wherein, the feed end of the second conveyor belt 9 is positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com