Patents

Literature

1036 results about "Wood shavings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood Shavings. a general term for the waste materials obtained in working wood by cutting it with woodworking machine tools and for certain semifinished products (singleply veneer, lath, thin paneling), made by the woodworking industry.

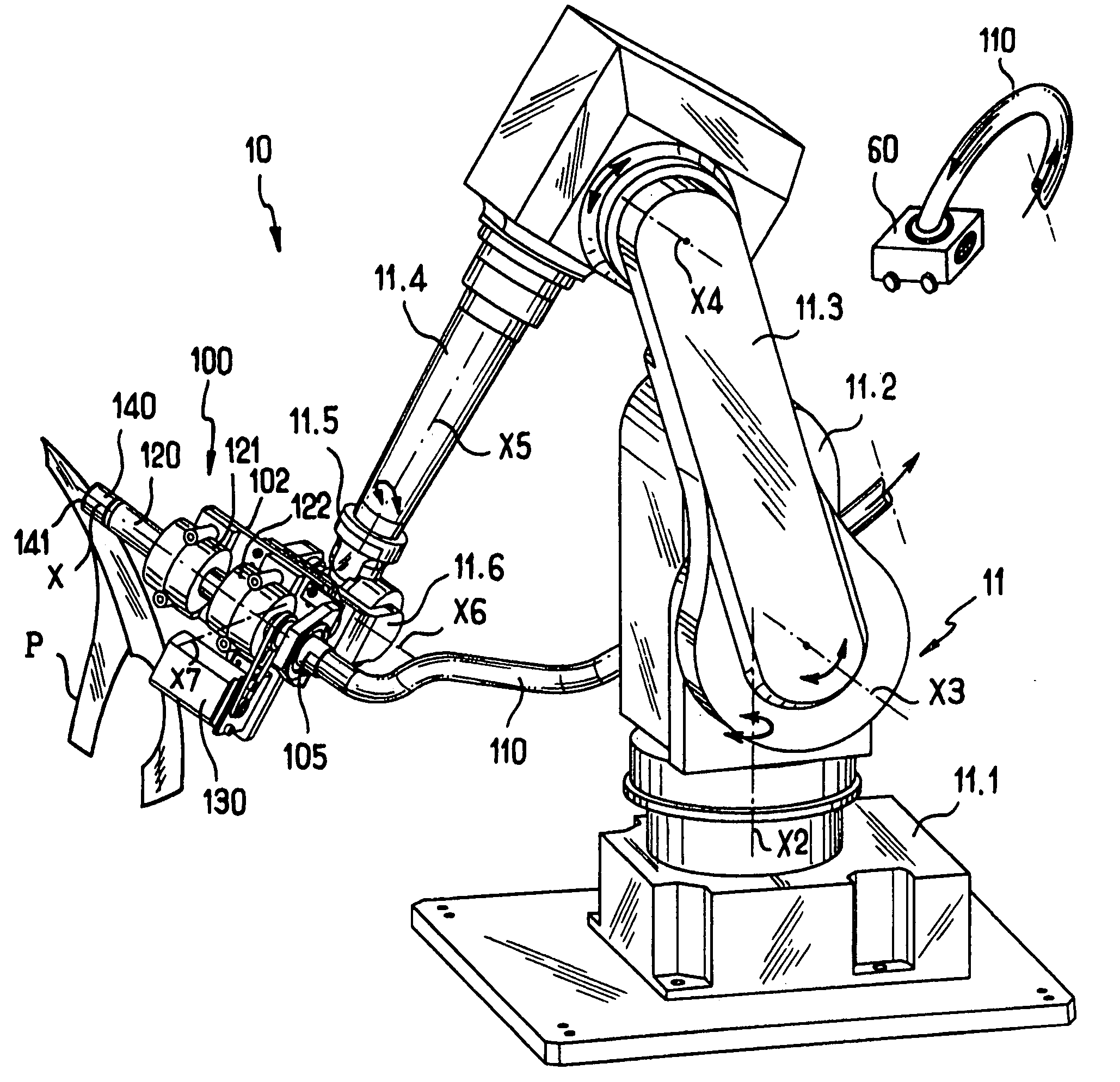

Optical subassembly having insertable cylindrical sleeve

An optical subassembly (“OSA”) for use in optical communications modules is disclosed. The OSA solves various issues related to the insertion and removal of an optical fiber connector into and from the OSA receptacle, including hard plug, wiggle performance, and shavings production. In one embodiment, an optical communications module is disclosed and includes a housing and an optical subassembly of the present invention partially contained within the housing. The optical subassembly includes various components, including a body composed of a first material, and a plug receptacle formed with the body. The plug receptacle includes an inner surface on which surface features, such as threads, are formed. A hollow cylindrical sleeve composed of a second material is received in the plug receptacle such that the outer sleeve surface engages the surface features of the plug receptacle inner surface and such that an optical fiber connector can be received by the sleeve.

Owner:II VI DELAWARE INC

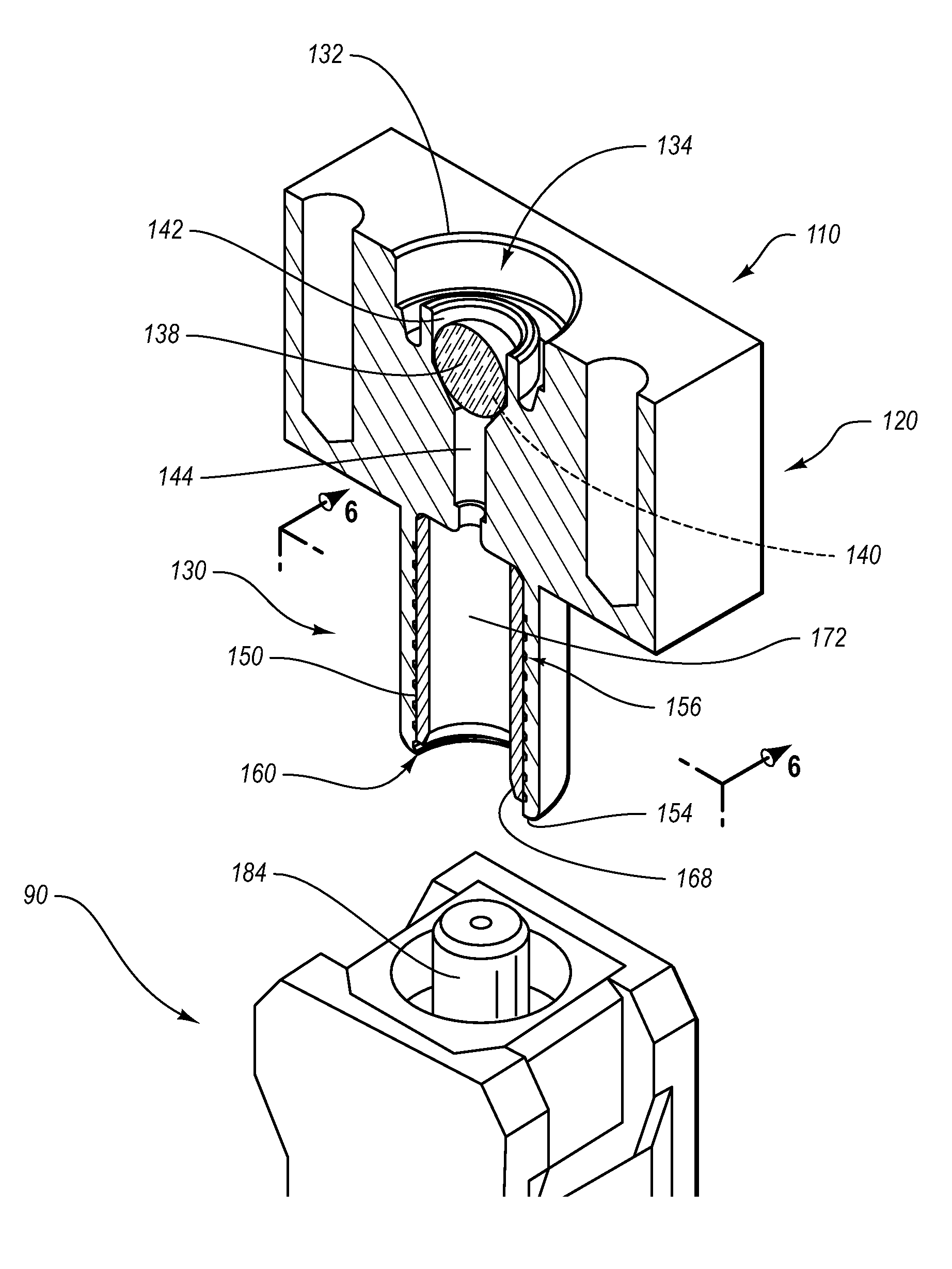

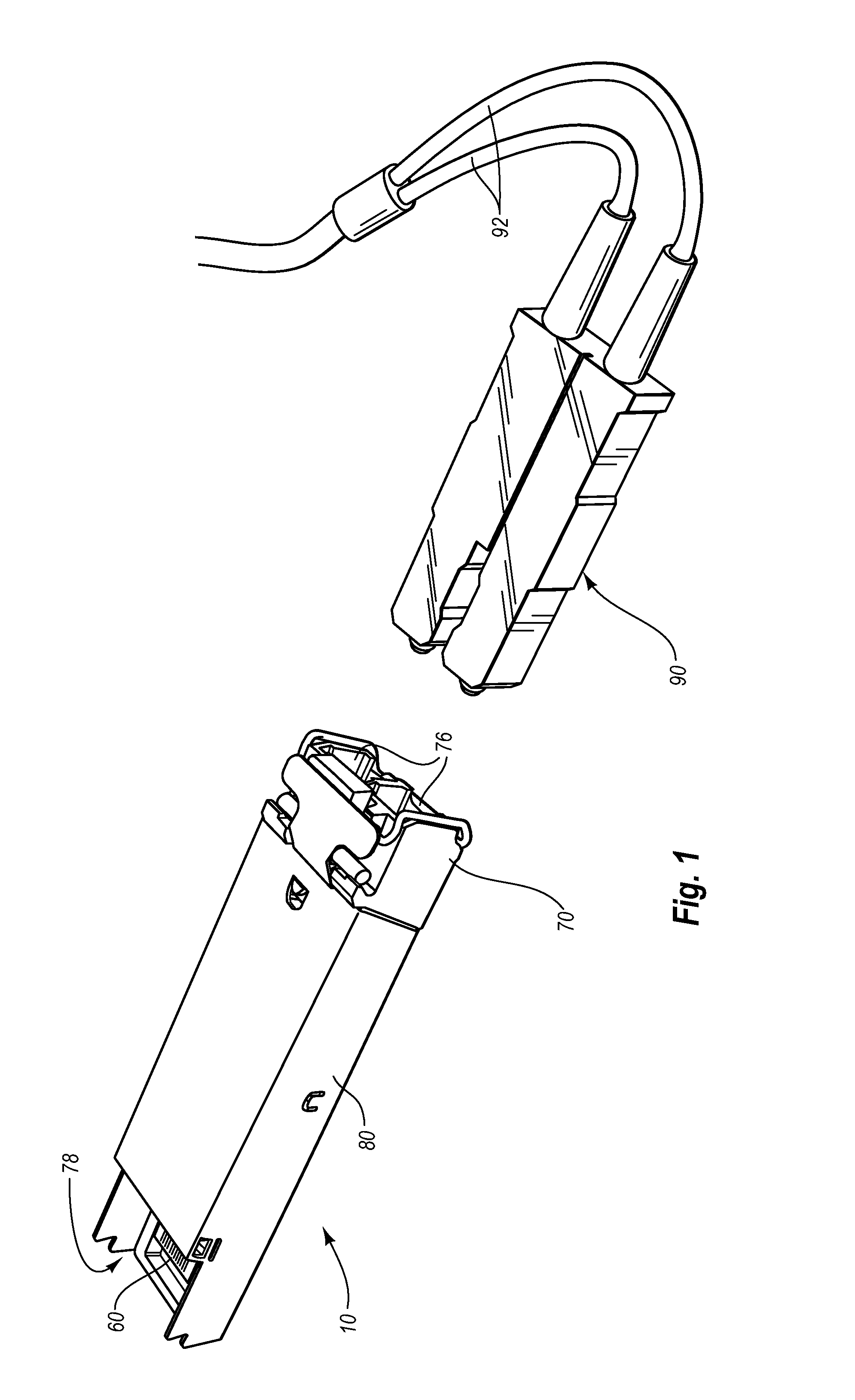

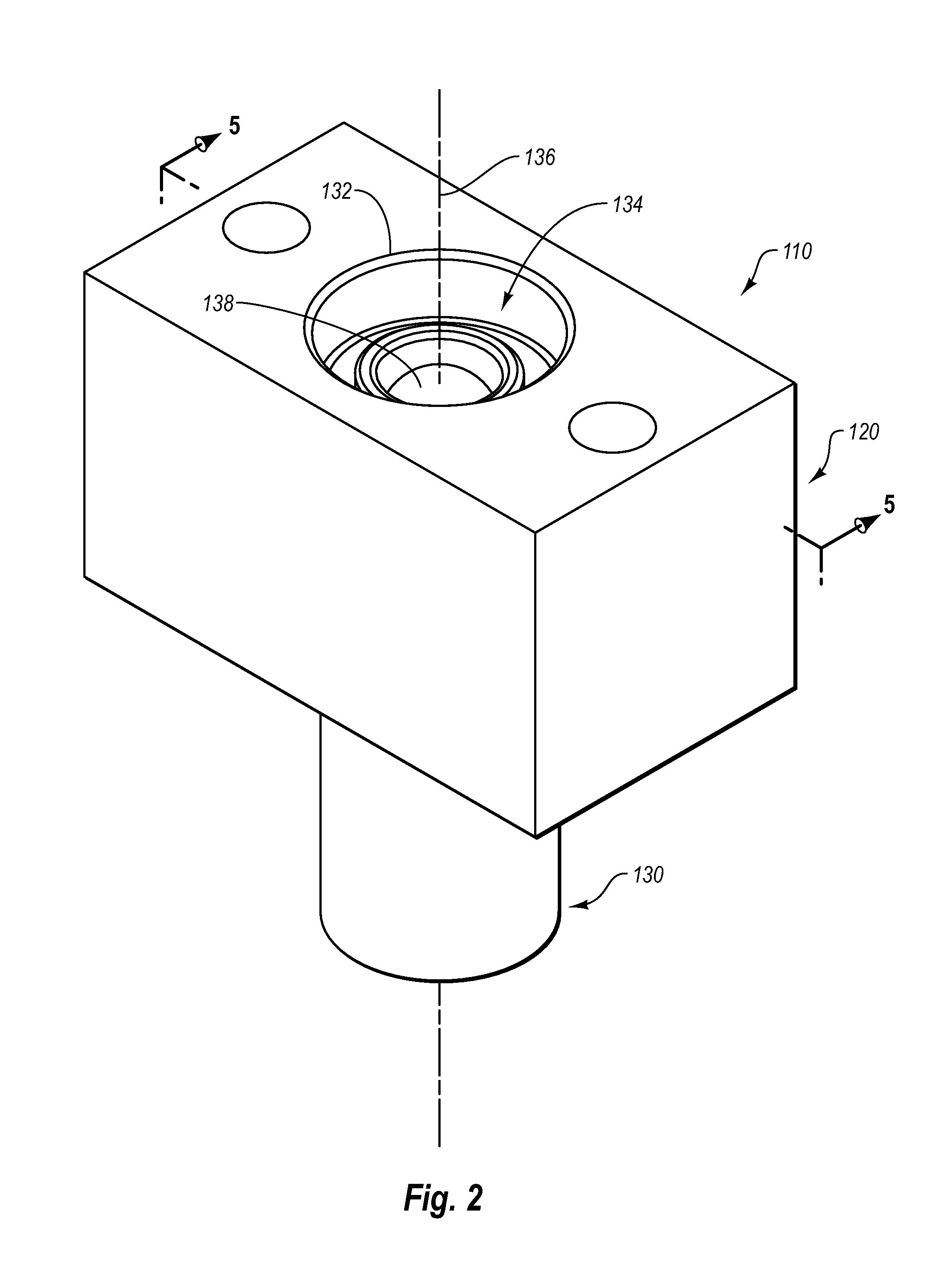

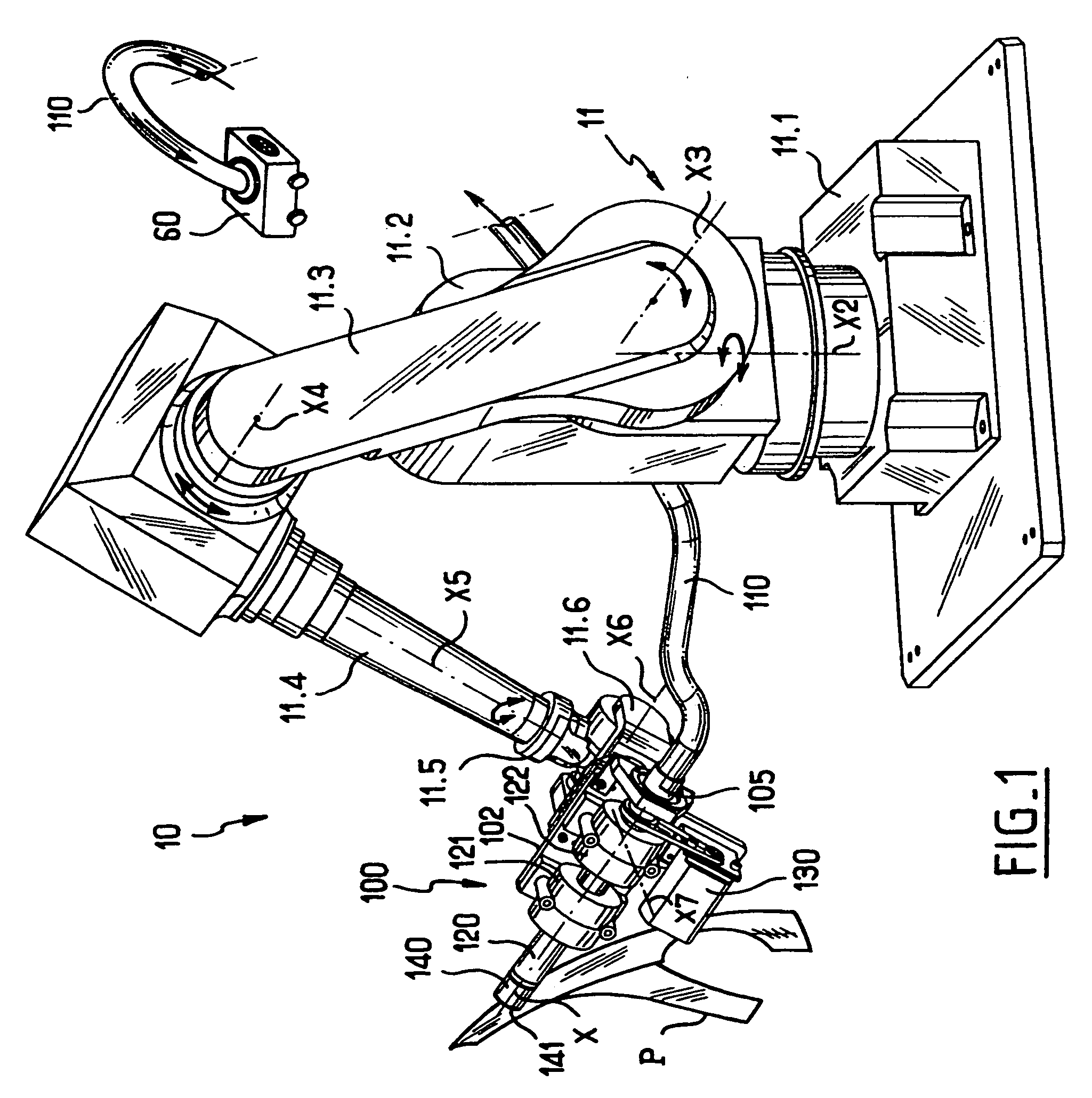

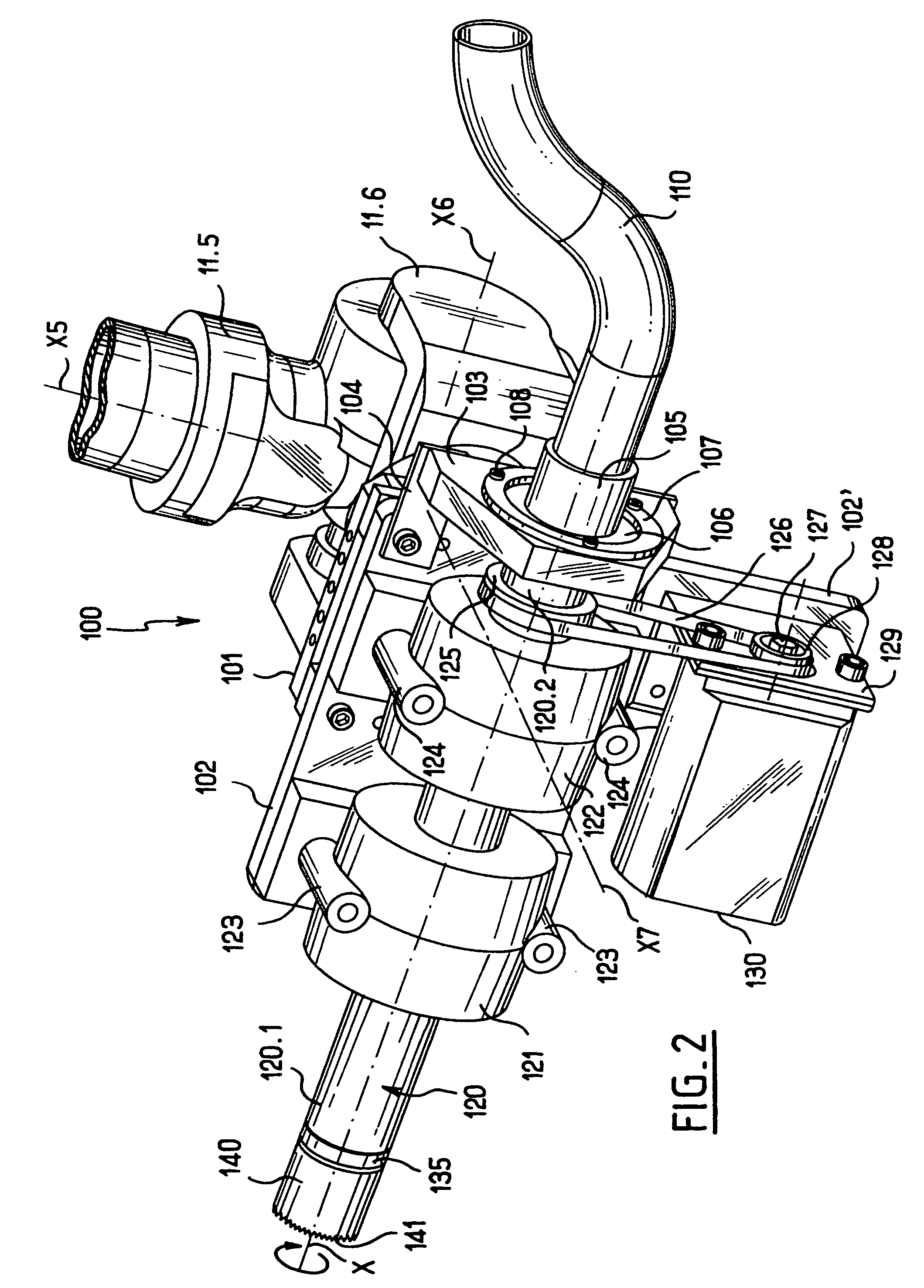

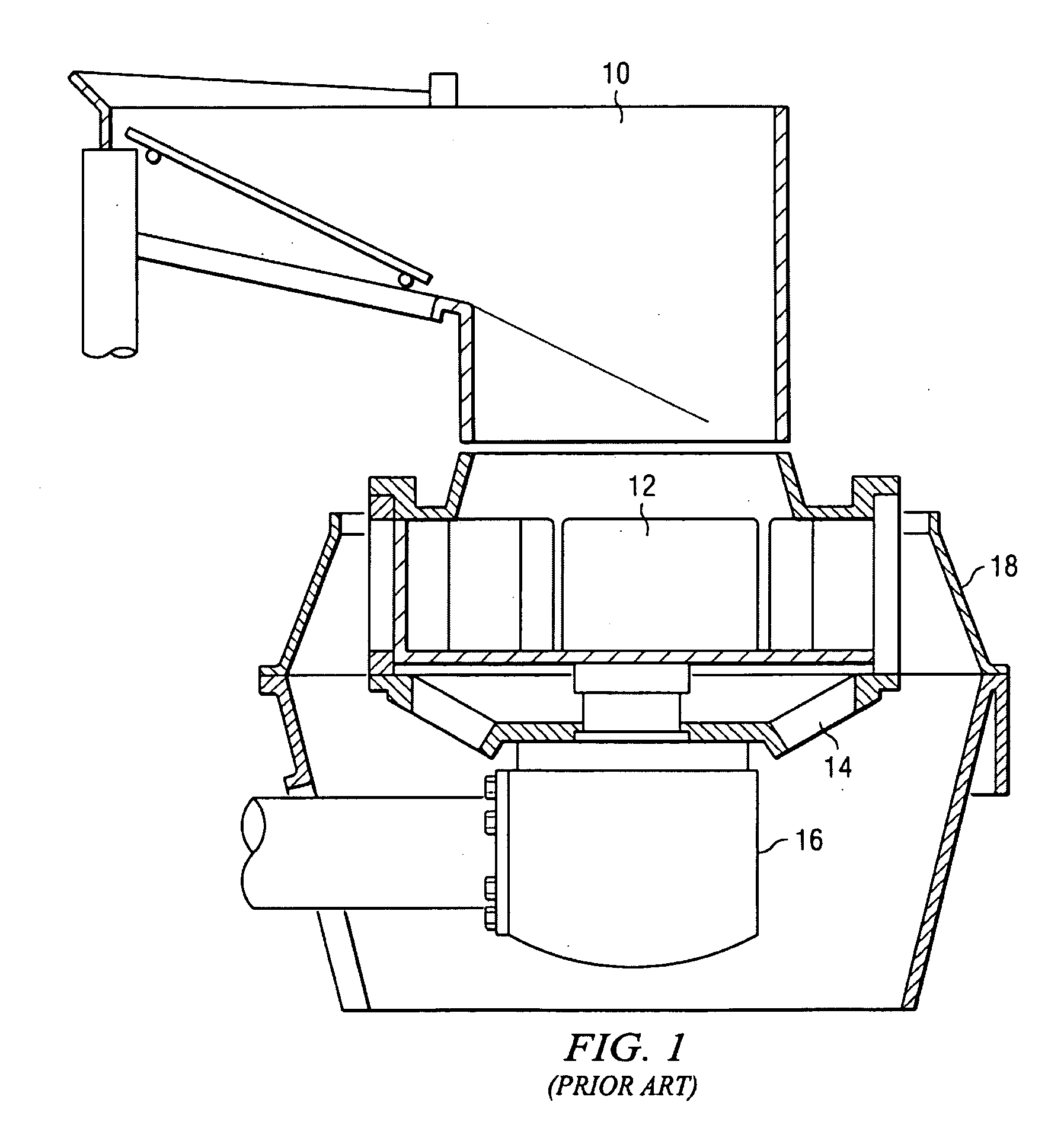

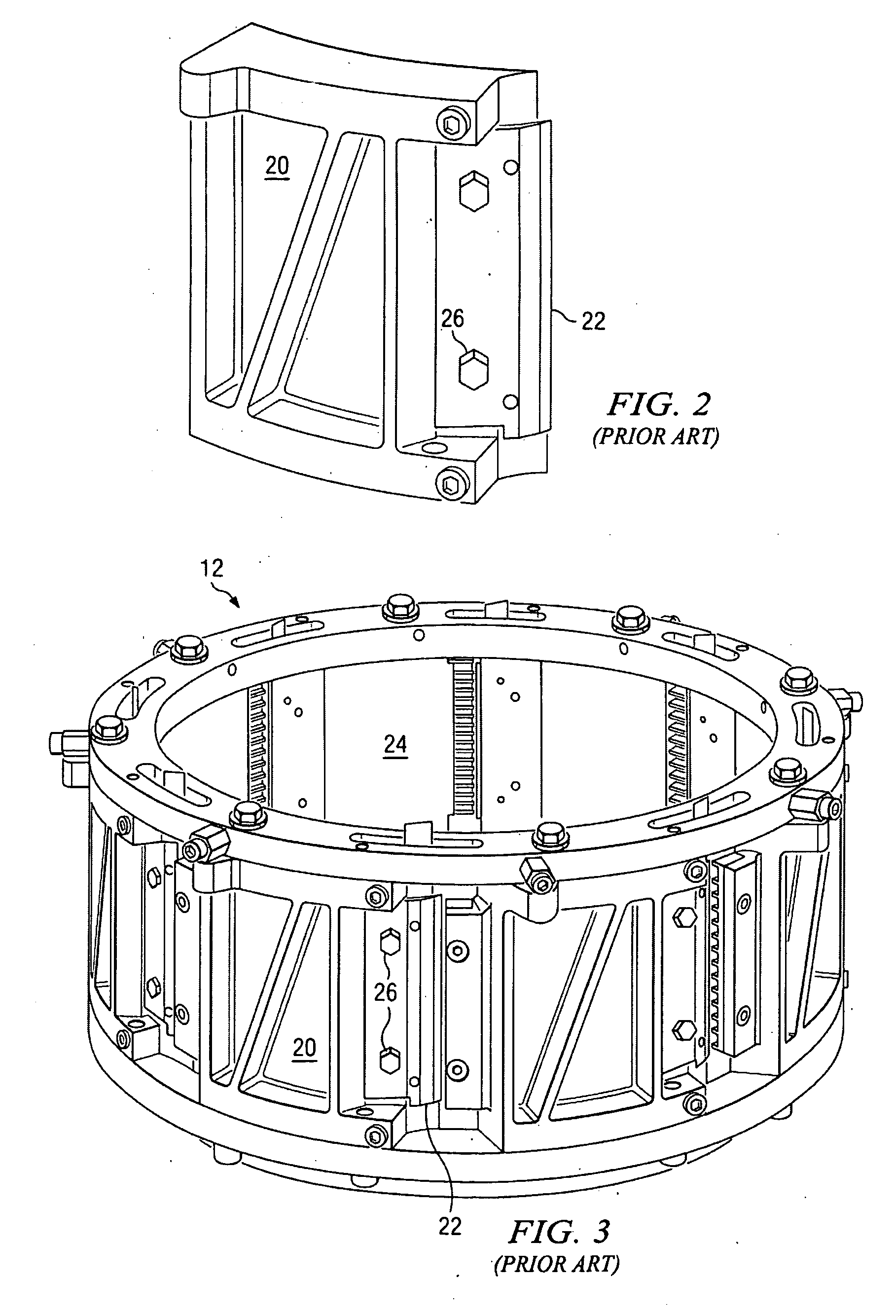

Machining mechanical parts with a hollow cylindrical tool

ActiveUS20060291970A1Simple processAvoid high frequency noiseThread cutting feeding devicesDrilling rodsWood shavingsMechanical components

The present invention relates to a device for machining mechanical parts by means of a hollow cylindrical tool presenting a distal end with a free edge that is shaped to perform machining when said tool is rotated about its axis. In accordance with the invention, the hollow cylindrical tool is fitted internally with a transverse member forming a shaving-breaker, and said hollow cylindrical tool is secured axially to a distal end of a hollow cylindrical spindle, said hollow cylindrical spindle being mounted to rotate about its own axis on a support plate, and being driven externally by rotary drive means mounted on said support plate, and said hollow cylindrical spindle having a proximal end facing and directly adjacent to a hollow cylindrical endpiece secured to said support plate and connected to a suction hose, such that the machining shavings can be evacuated internally by passing successively through the hollow cylindrical tool going round the transverse member forming a shaving-breaker, through the hollow cylindrical spindle, through the hollow cylindrical endpiece, and through the suction hose.

Owner:ROMER INC

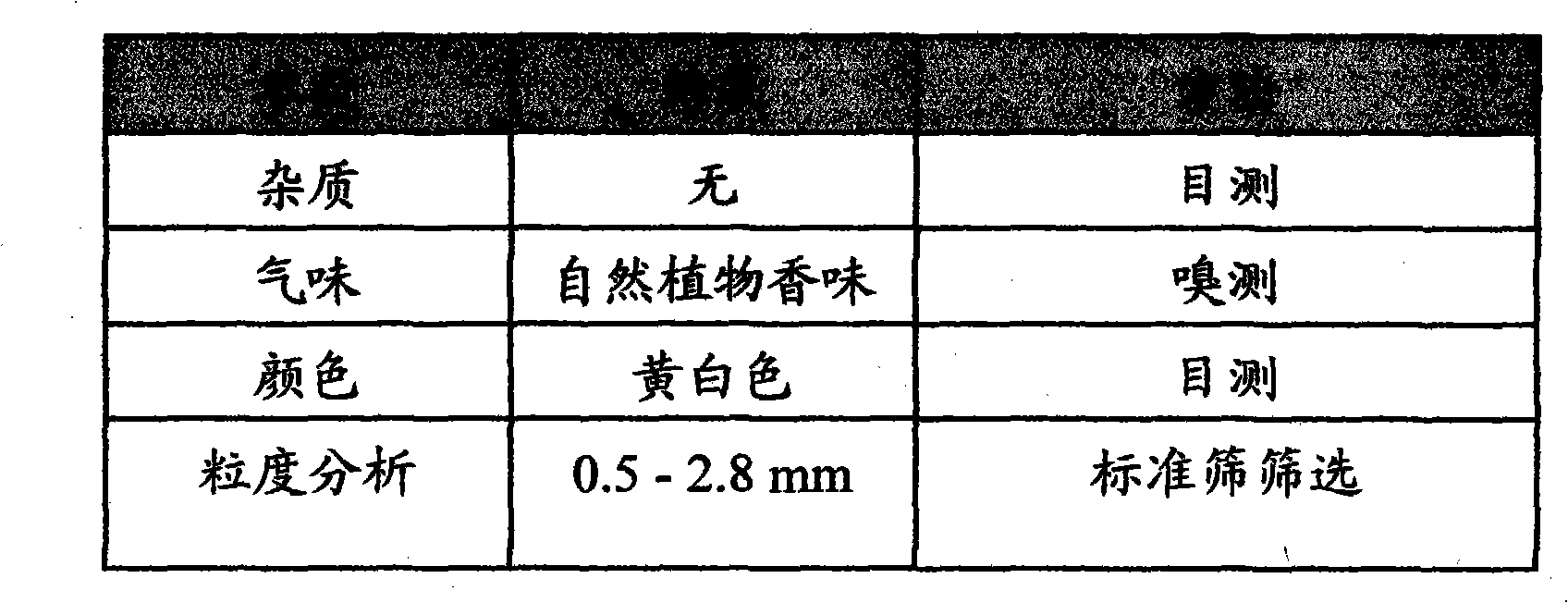

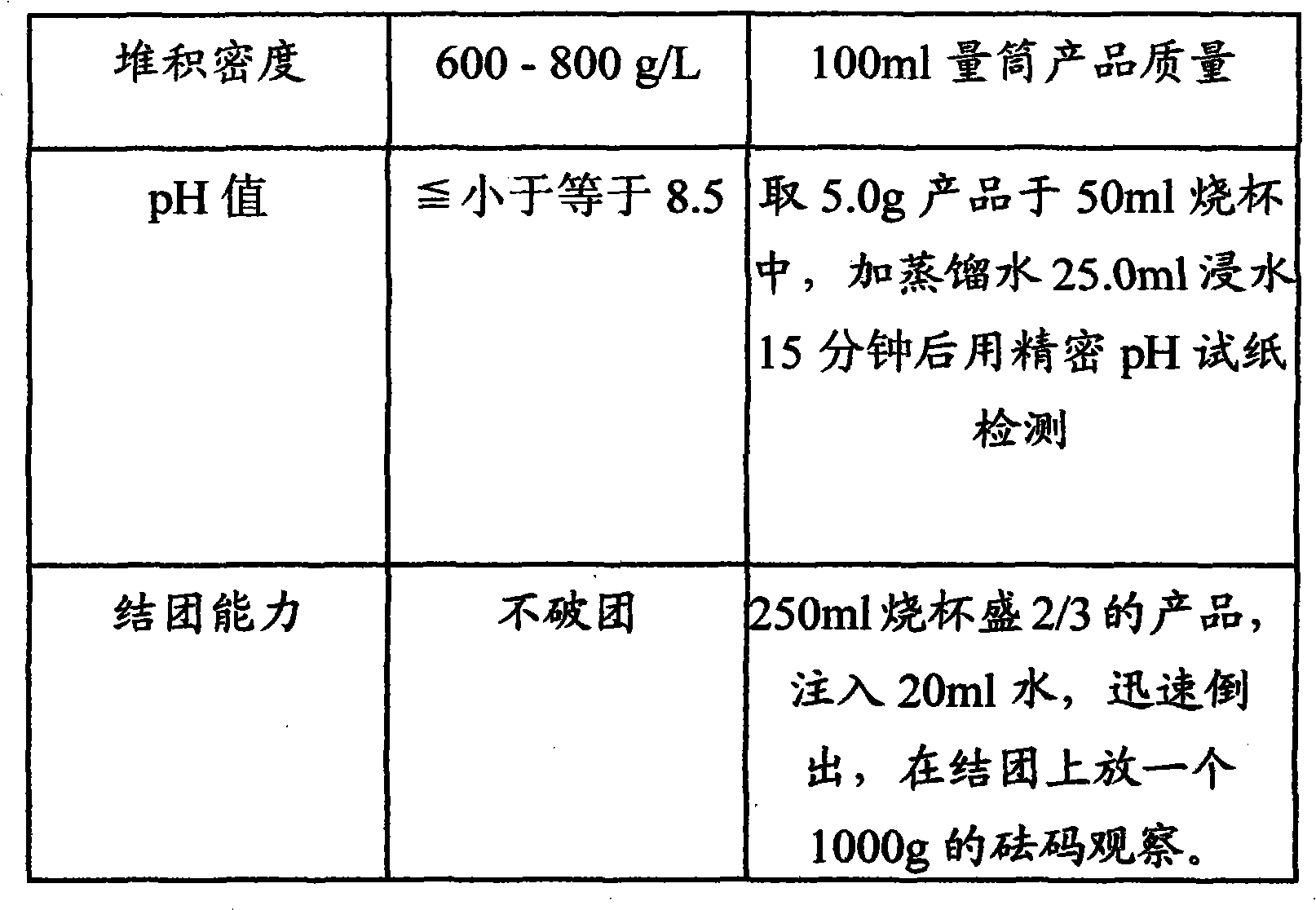

Cat litter and making method thereof

InactiveCN102150627AEnhanced adsorption and deodorization abilityImprove deodorization abilityAnimal housingSodium BentoniteSilica gel

The invention discloses cat litter comprising a composition prepared from the following components in percent by weight: 50-80% of inorganic clay, 5-15% of silica gel, 5-20% of organic substrate and 8-20% of mineral matter, wherein the inorganic clay is selected from one or a mixture of attapulgite, bentonite, kaolinite and sepiolite; the organic substrate is selected from one or a mixture of corncob, corn, wheat, clover, peanut hull, walnut shell, pine wood shavings and broadleaved tree wood shavings; and the mineral matter is selected from one or a mixture of perlite, diatomite, pumice and other low-density mineral matters. The cat litter disclosed by the invention has the following advantages of largely strengthened adsorption deodorization capacity due to the addition of the silica gel component, stronger deodorization capacity by utilizing the adsorbability of natural materials, natural fragrance, small weight and strong caking capability, in particular no dust and easiness for treatment; and the cat litter disclosed by the invention is 40% lighter than the traditional bentonite cat litter.

Owner:QINGDAO FRANK FINE CHEM

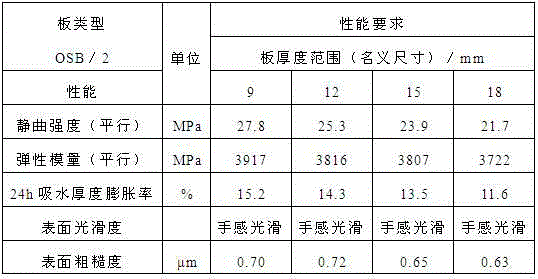

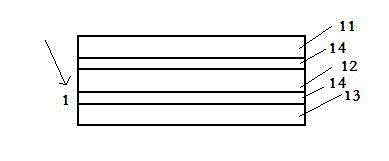

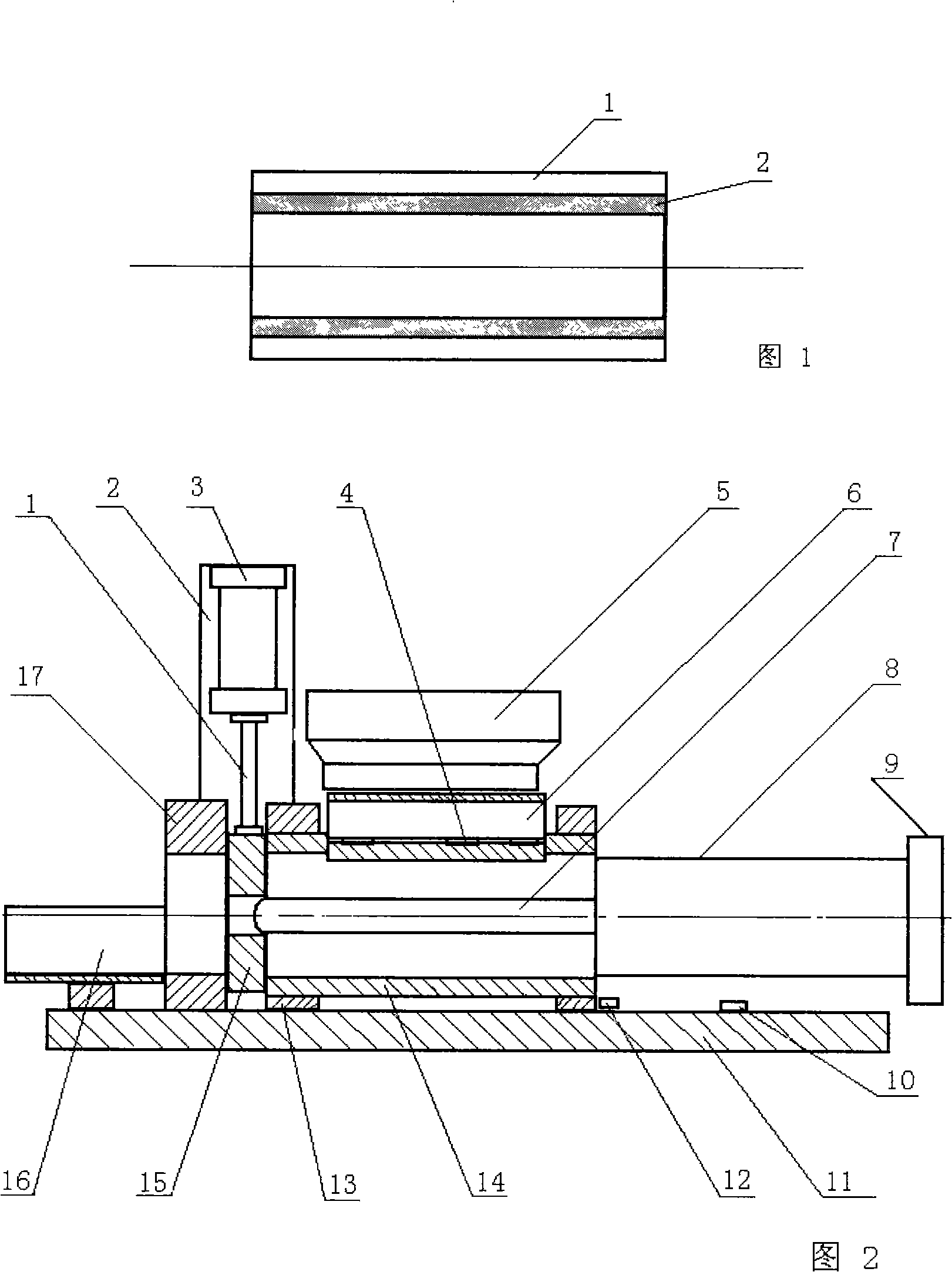

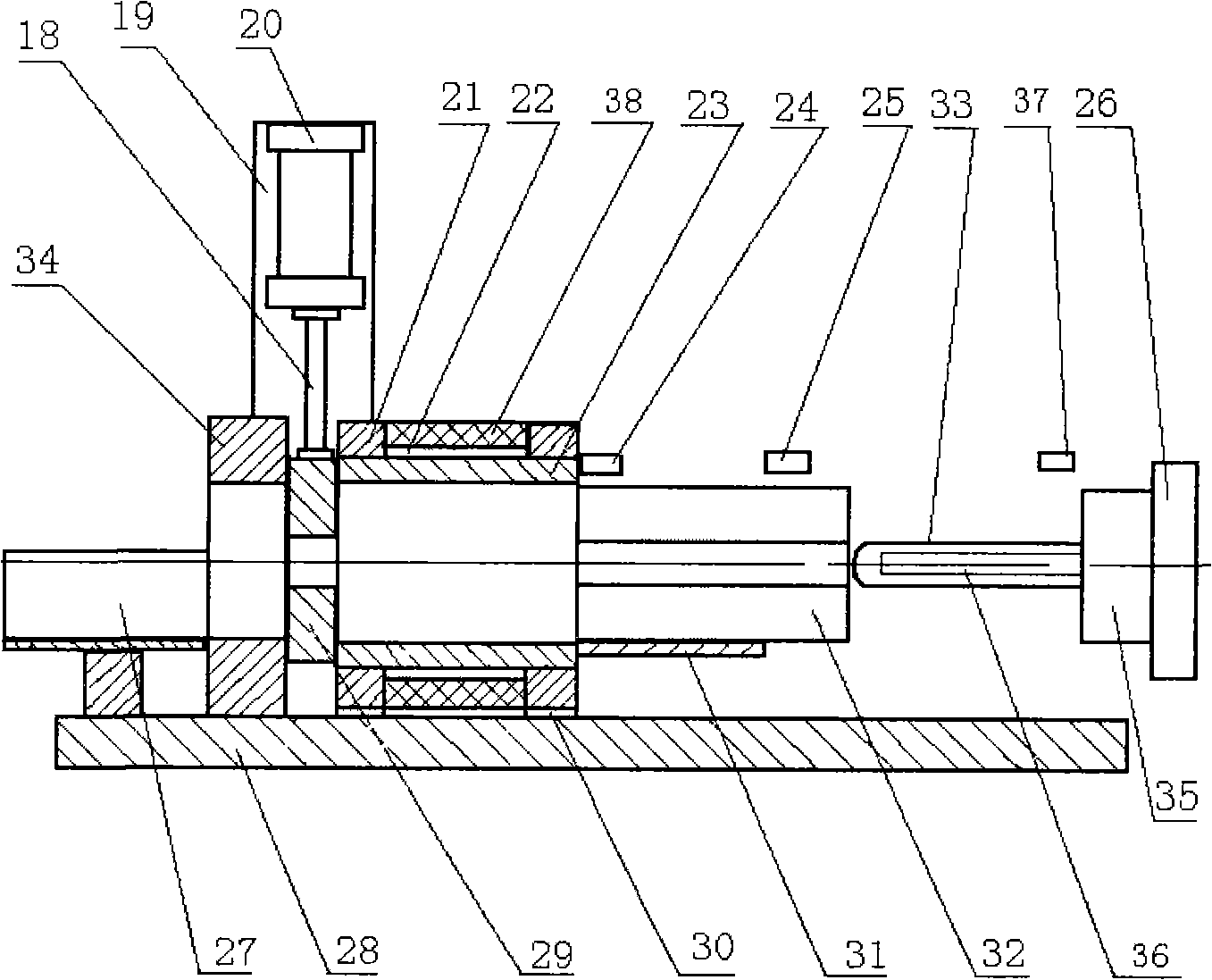

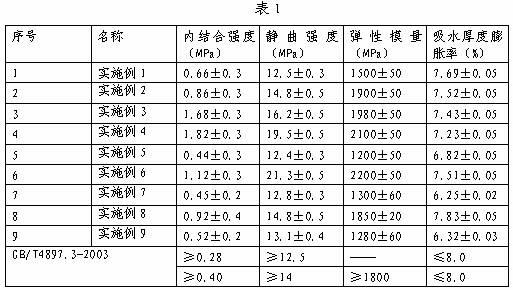

Oriented chipboard and processing technology

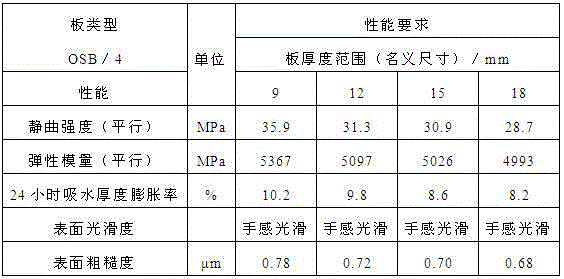

ActiveCN102198684ASave resourcesReduce consumptionWood working apparatusDomestic articlesWood shavingsSurface layer

The invention discloses an oriented chipboard and a processing technology. The chipboard is composed of three layers including two surface layers and one intermediate core layer, which are adhered together by adhesives; the processing technology uses rotary cut veneer wastes remained in a plywood production process as raw materials to substitute small-diameter standard materials, so that a large volume of wood is saved, and production cost is saved; and simultaneously, the length of the oriented chipboard can be increased by using the method, consequently, inherent mechanical property indexes of the oriented chipboard can be improved, and the oriented chipboard has higher carrying capacity; the oriented chipboard and the processing technology provided by the invention have the advantages that the rotary cut veneer wastes can be used as the raw materials, so that the large volume of wood is saved, the production cost is saved, the static bending strength and the elastic modulus of the produced oriented chipboard are synchronously increased, and the carrying capacity of the oriented chipboard is greatly improved.

Owner:寿光市鲁丽木业股份有限公司

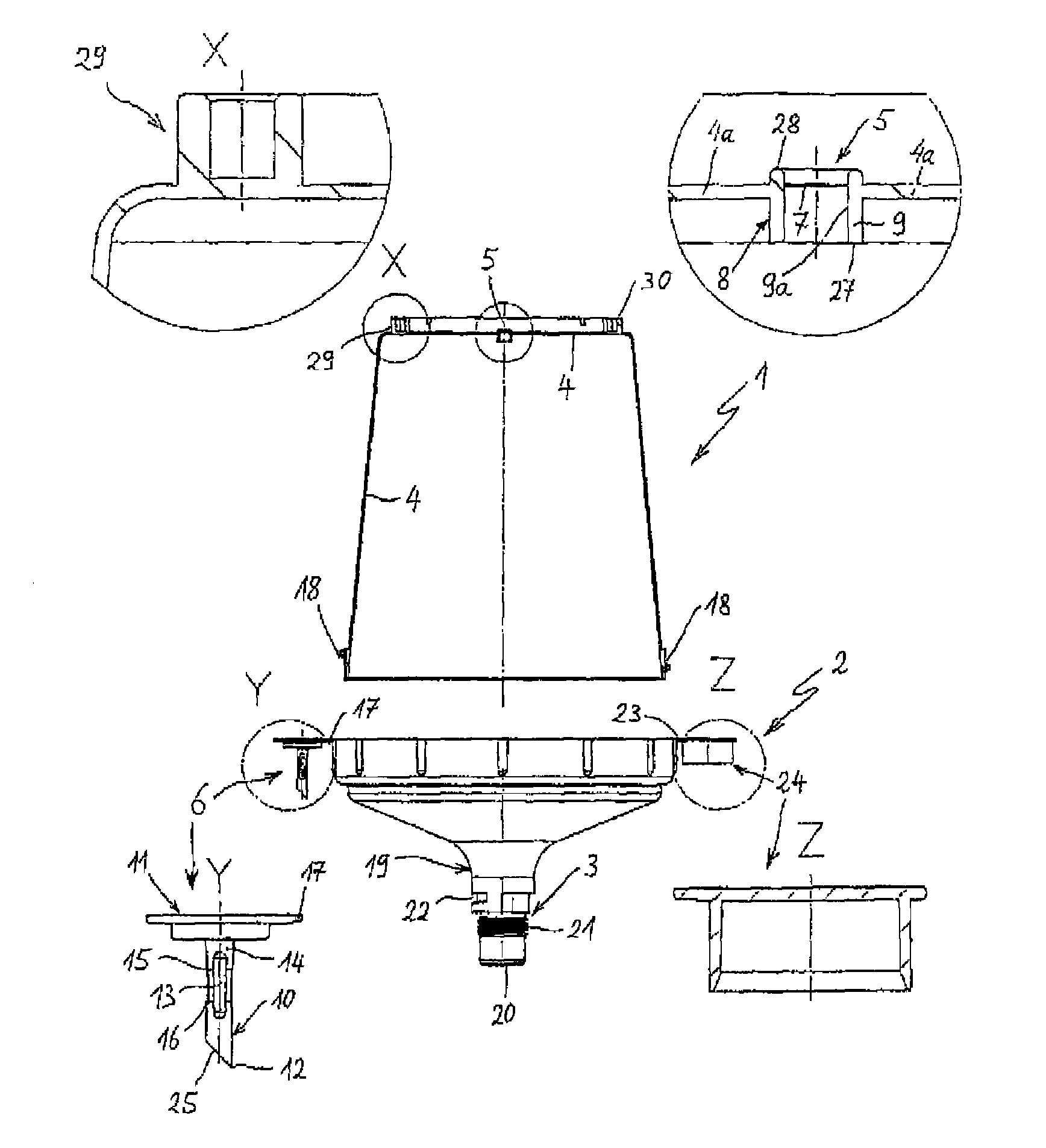

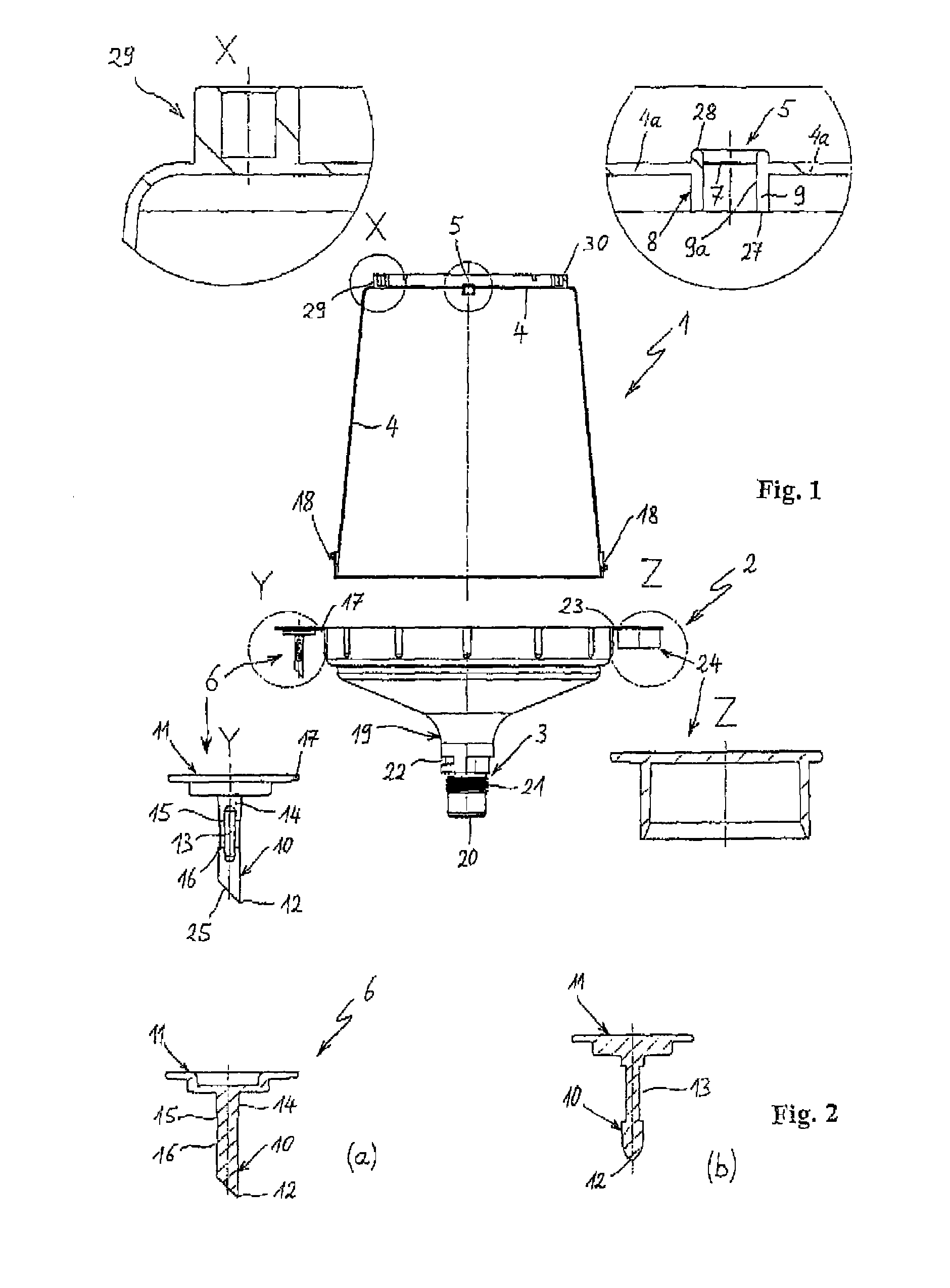

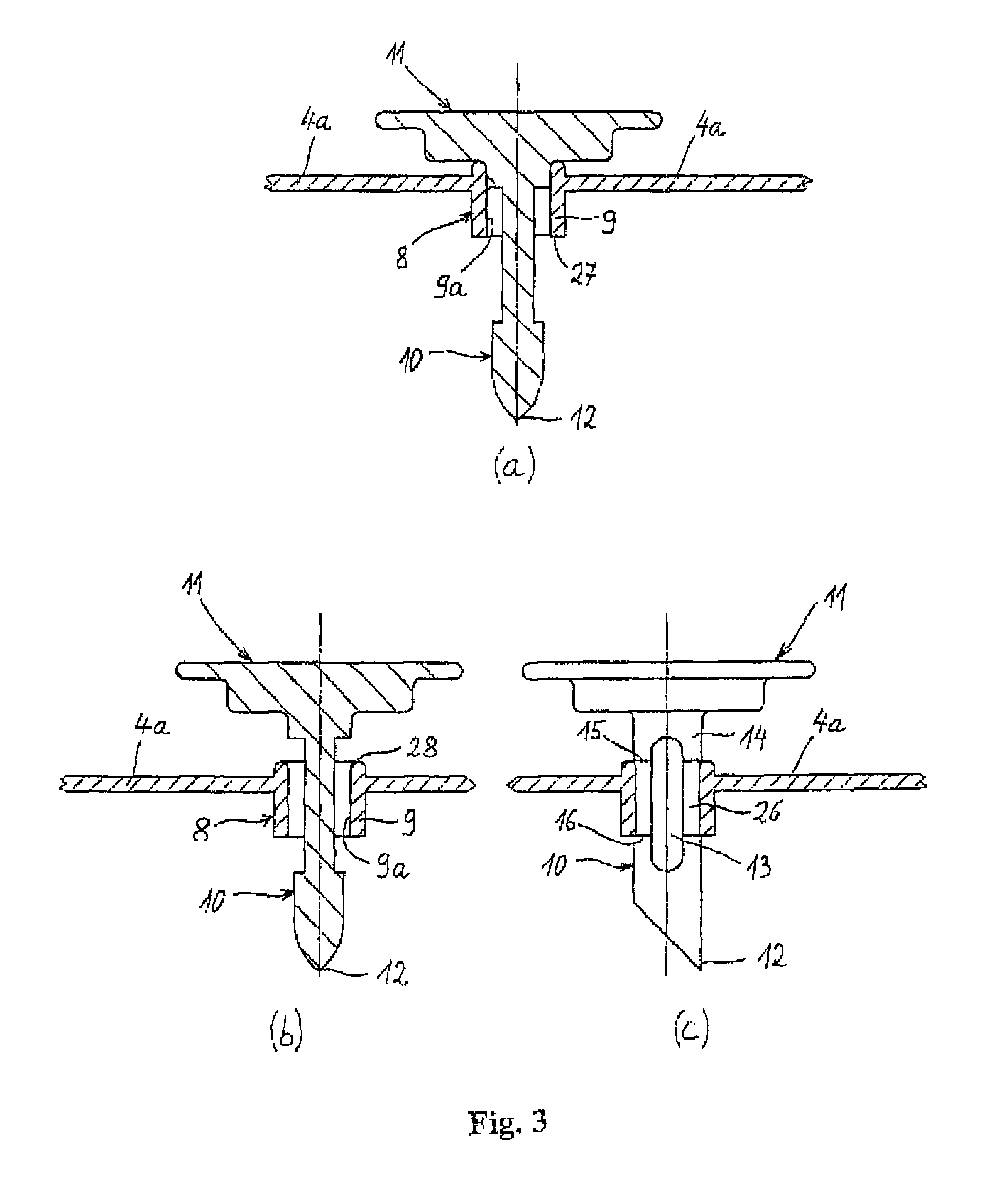

Paint reservoir system for a paint spray gun

ActiveUS7819341B2Simple and fast and uncomplicated formationLiquid flow controllersFire rescueWood shavingsThermodynamics

Owner:SATA GMBH & CO KG

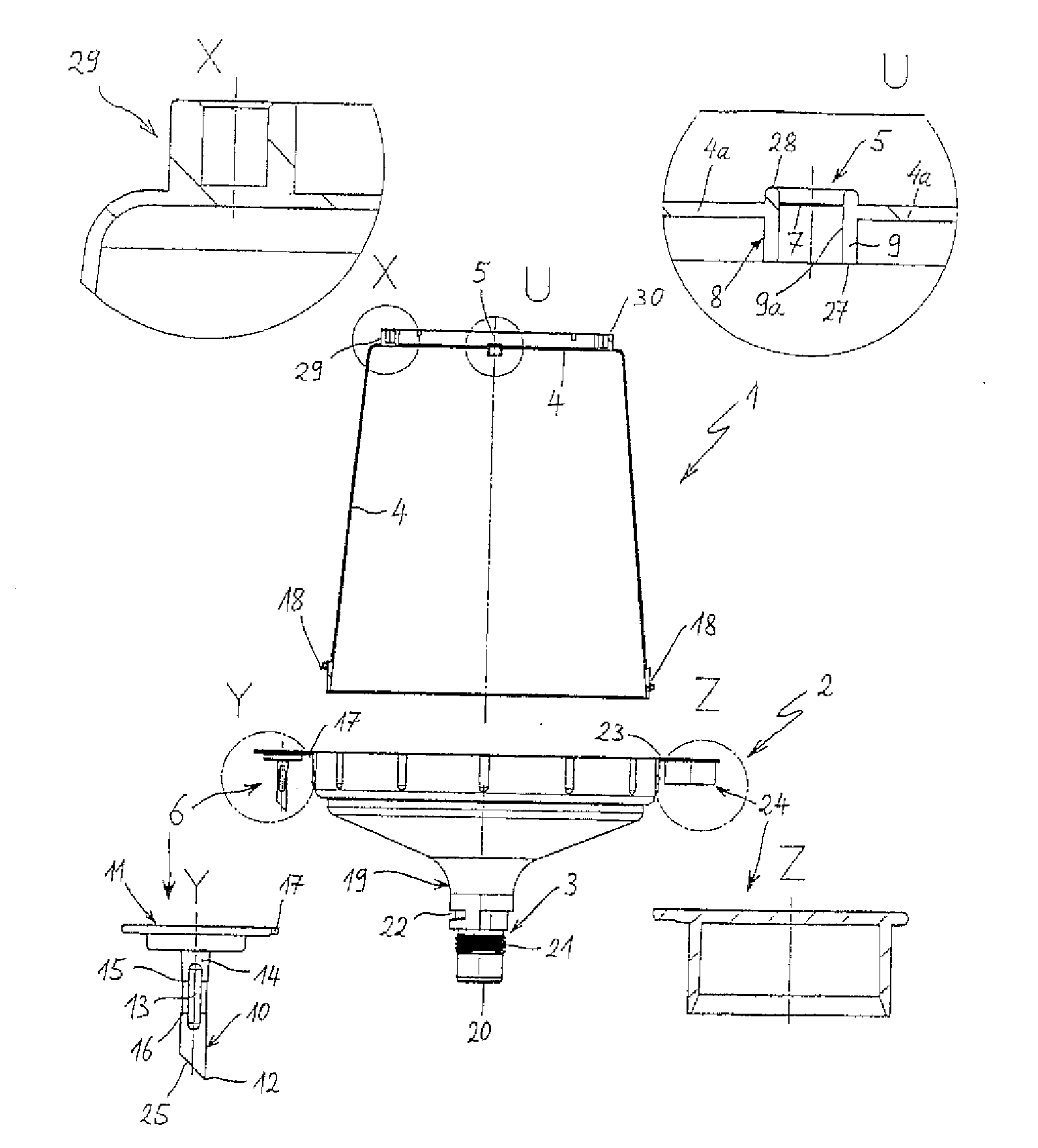

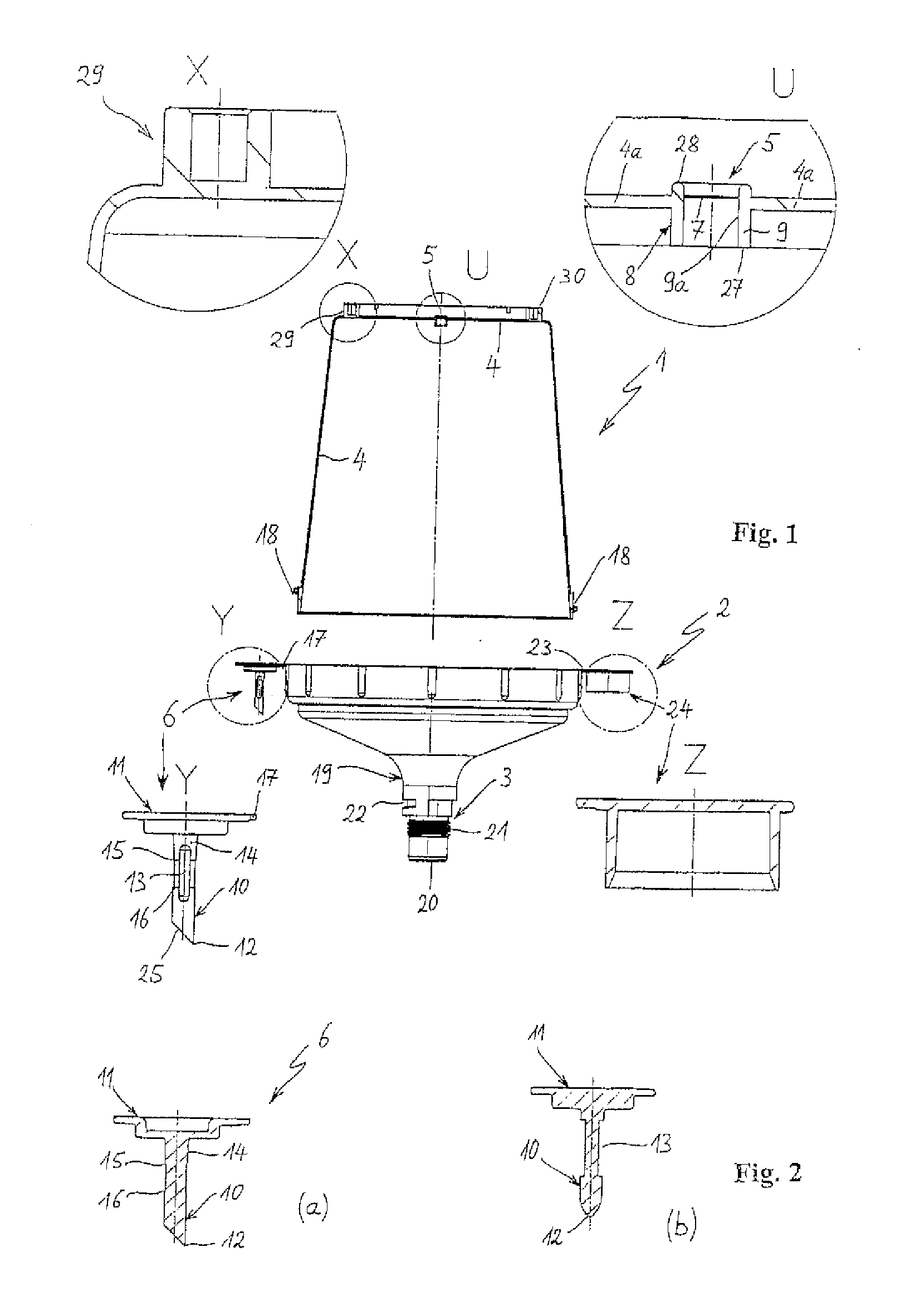

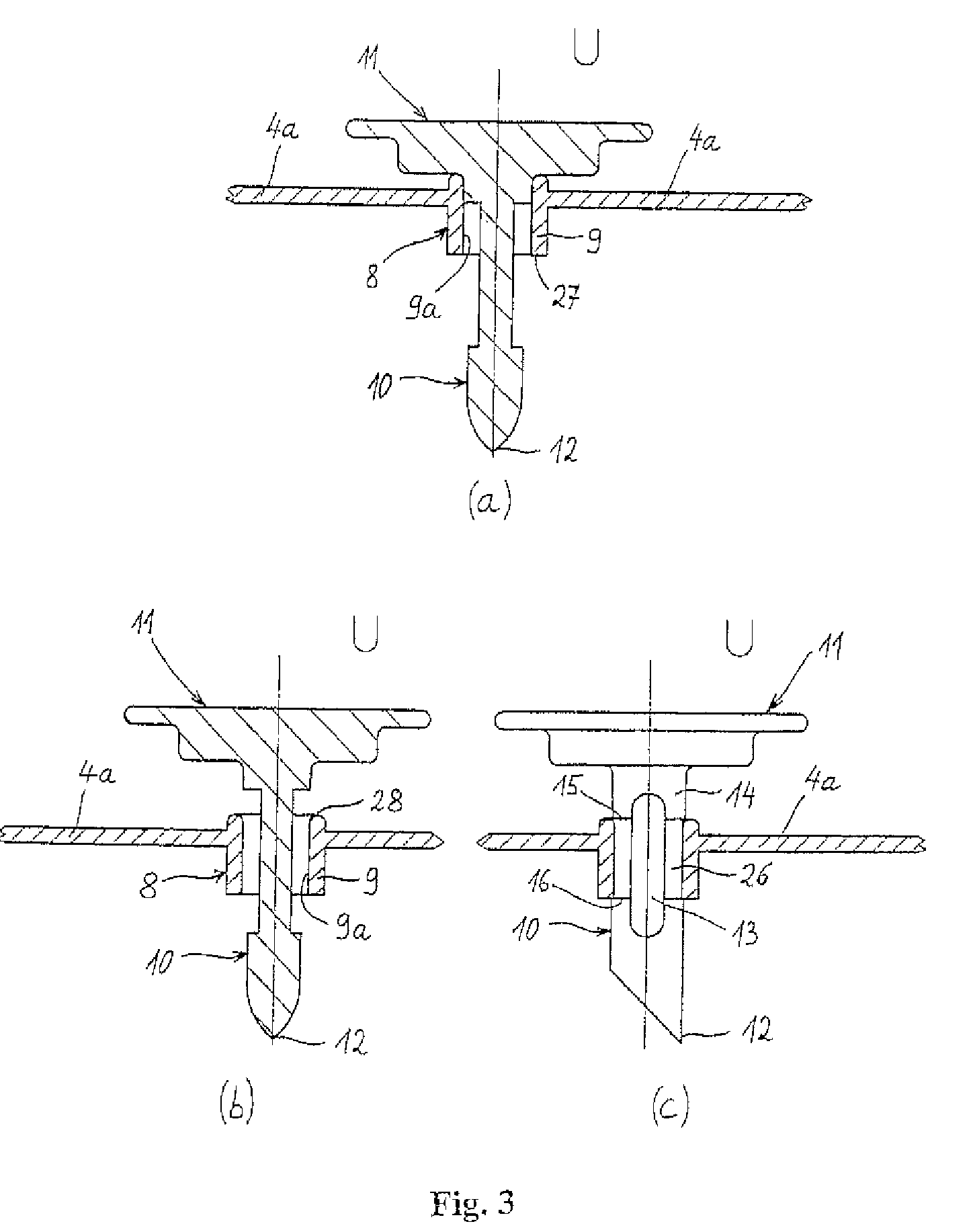

Paint Reservoir System For A Paint Spray Gun

ActiveUS20080179763A1Simple and fast and uncomplicated formationLighting and heating apparatusUsing liquid separation agentWater reservoirEngineering

The invention relates to a gravity flow reservoir for a paint spraying gun having a container and a cover, which can be placed thereon and which has a connecting part in order to place the gravity flow reservoir onto the paint spraying gun or onto an adapter. Prior art reservoirs require a separate pointed tool, which serves to make a vent hole, is often unavailable and can lead to operating errors. The aim of the invention is to provide a paint reservoir system that enables a simple, rapid and uncomplicated insertion of a vent hole into the container wall of the gravity flow reservoir while preventing shavings or plastic parts from entering the gravity flow reservoir. To this end, a delimited area is provided in the wall of the container and can be penetrated by the pointed tool in order to make a vent hole.

Owner:SATA GMBH & CO KG

Surface-decorated oriented strand board and preparation process thereof

ActiveCN104626292AHigh strengthGood dimensional stabilityLaminationLamination apparatusFiberParticle board

The invention relates to a surface-decorated oriented strand board and a preparation process of the surface-decorated oriented strand board. The surface-decorated oriented strand board comprises a core layer and a surface layer. Rotary cut veneer leftovers left in the plywood production process are selected as raw materials of the core layer. Sawdust, wood shavings, waste fibers and sanding powder produced in the production process of glued-laminated timber, core-boards, particle boards or medium-density fiberboards are selected as raw materials of the surface layer. The raw materials are subjected to drying, screening, gluing, laying, plate blank sawing and cutting and hot-pressing, and then the surface-decorated oriented strand board can be manufactured. The static bending strength of the oriented strand board in the parallel direction can reach 22-30 MPa, the elasticity modulus of the oriented strand board can reach 3500-4800 MPa, and the surface roughness of the oriented strand board is less than 0.8 micron. The surface-decorated oriented strand board can be directly processed into a decorative surface and can also be widely used for replacing artificial boards such as plywood, the core-boards, the particle boards and the medium-density fiberboards.

Owner:寿光市鲁丽木业股份有限公司

Multifunctional environment protection type artificial board and method of producing the same

ActiveCN101269513AIncrease the use of functionsMeet the requirements of pursuing a healthy and quality lifeWood working apparatusDomestic articlesAntibiosisWood shavings

The invention discloses a multifunctional and environmental protective hard board composed of fibre or paring, and a preparation method thereof. In the production process of the hard board, appropriate quantity of functional material is mixed in the plant fibre or in the paring; the functional material contains tourmaline powders; wherein, proportioning by weight of the plant fibre or the plant paring and the tourmaline powder is 100:0.5 to 10; thereby the prepared hard board has manifold environmental protective functions such as anion releasing, far infrared ray emission, antibiosis, room air purifying, degradation of noxious gas (like formaldehyde, toluene nitrogen oxide, etc.), etc.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

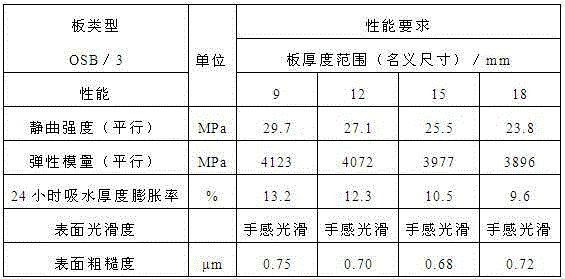

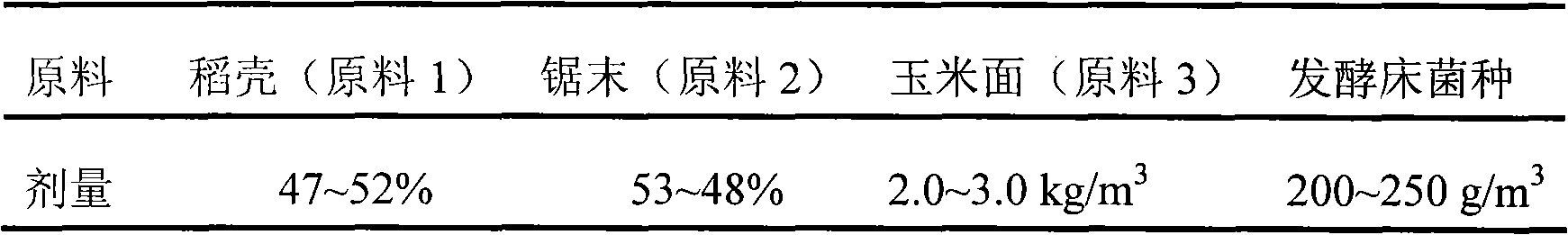

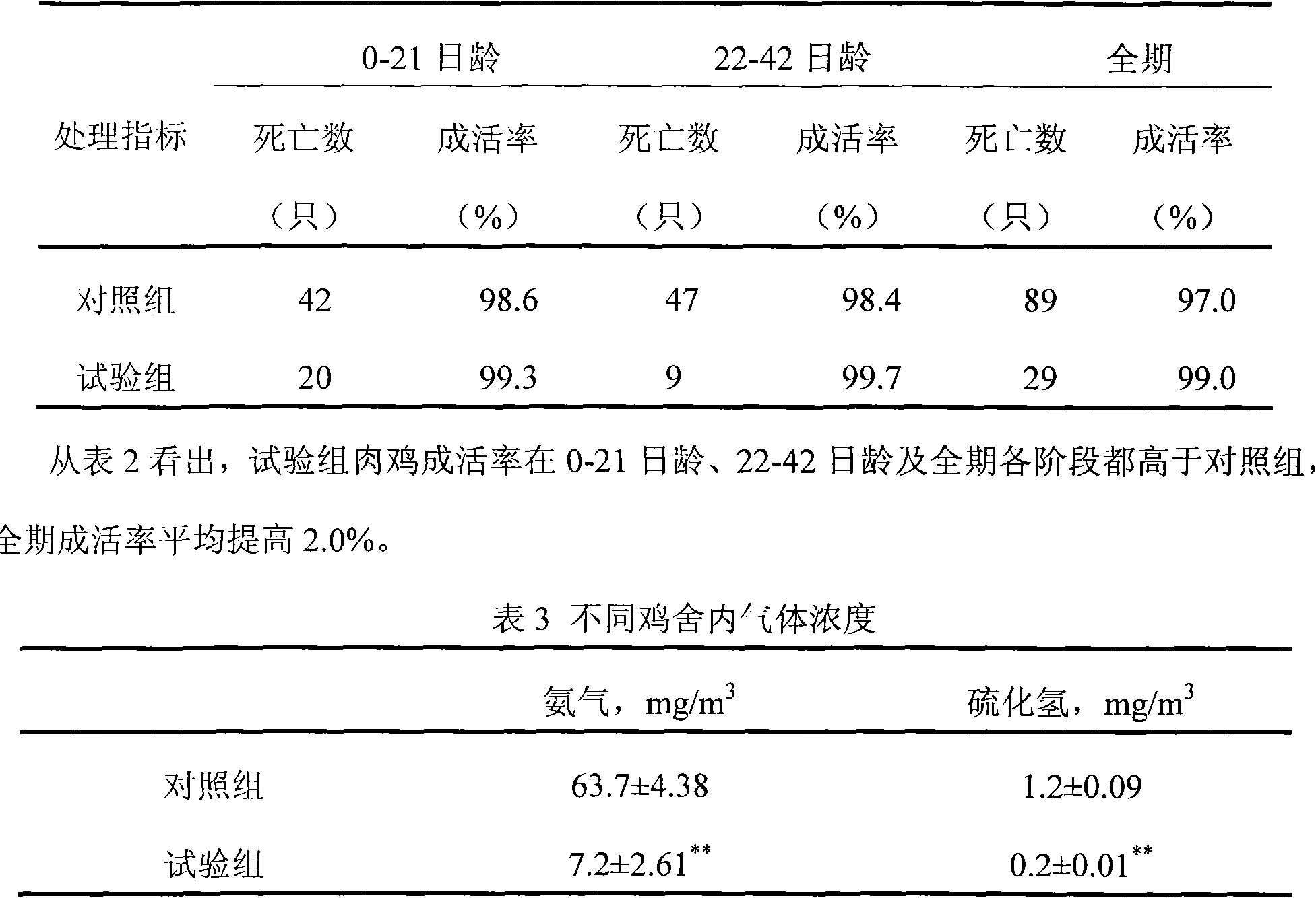

Water and energy saving domestic animal fermentation bed and preparation method thereof

The invention discloses a water and energy saving domestic animal fermentation bed and a preparation method thereof. The fermentation bed is prepared from the following materials; material 1: rice husk or peanut shell or the like; material 2: sawdust or wood shavings or the like; and material 3: corn flour or rice bran or the like and fermentation bed strains. The method is as follows: firstly mixing the material 3 with the fermentation bed strains, laying the material 2 on the ground, laying the mixture of the material 3 and the fermentation bed strains on the material 1, then laying the material 1 on the mixture of the material 3 and the fermentation bed strains, and finally mixing the materials. The thickness of the padding of the fermentation bed is 20-40cm. The invention takes the physiological habits of poulards, meat ducks, broiler breeders, egg breeders, meat type breeding ducks and pigs into full consideration, reduces the thickness of the padding of the conventional fermentation bed and the cost of the padding of the fermentation bed and relieves the heat stress in summer; the padding is thoroughly mixed with the fermentation bed strains; the fermentation bed improves the dung degradation effect; the dung of the domestic animals is unnecessary to be added and pre-accumulated for fermentation, thus saving water and energy; and the operation is simple. The fermentation bed and the preparation method thereof are suitable for chickens, ducks and pigs and the application range is expanded.

Owner:INST OF ANIMAL SCI & VETERINARY MEDICINE SHANDONG ACADEMY OF AGRI SCI

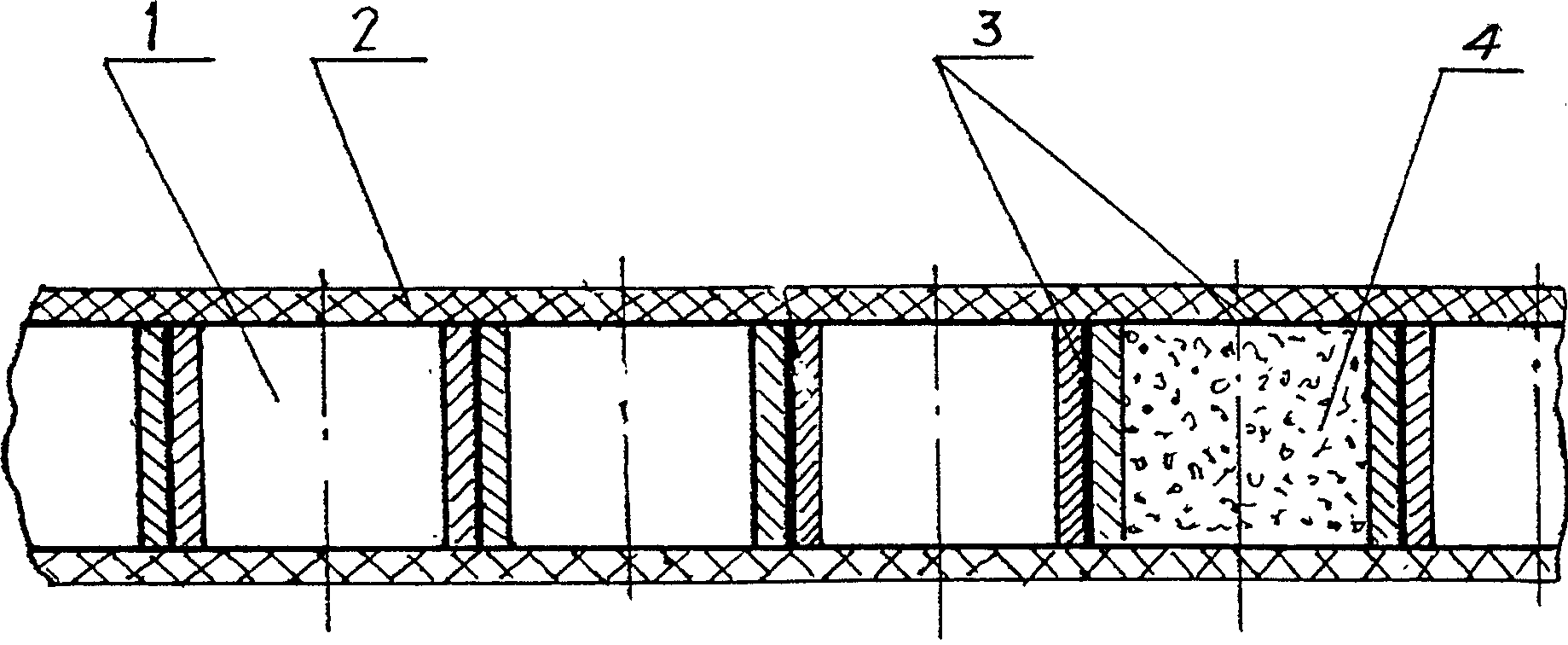

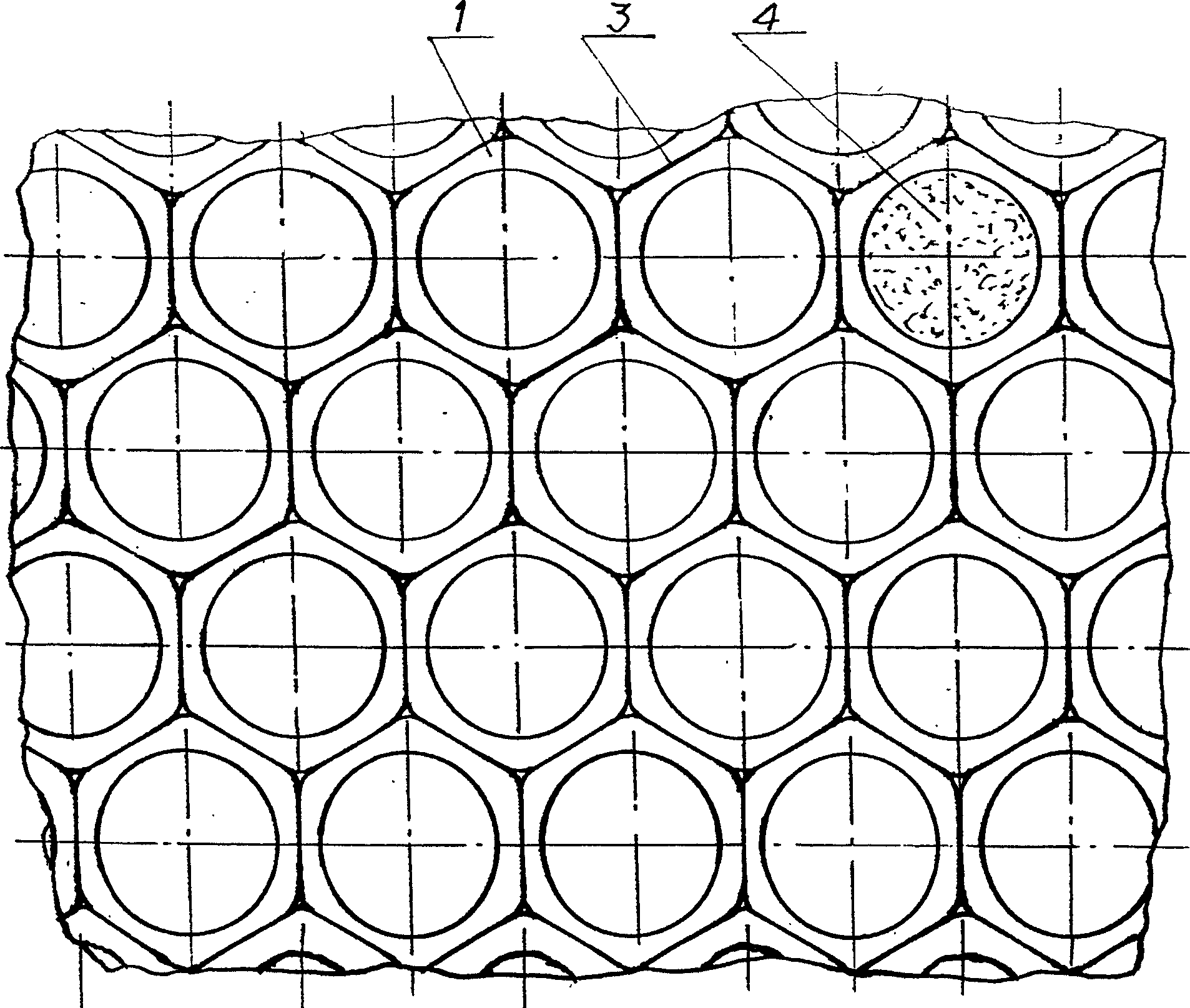

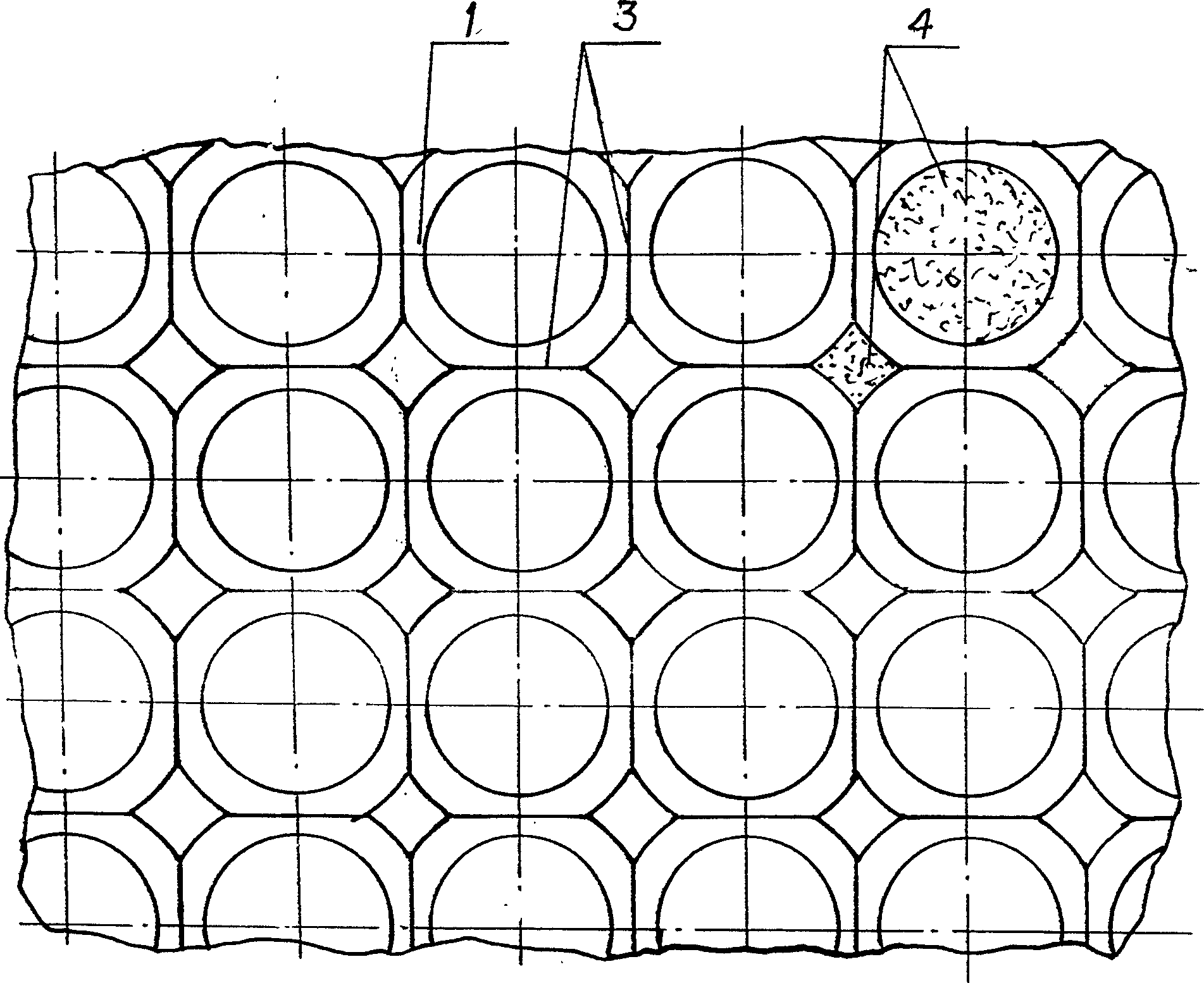

Bamboo-made wallboard

InactiveCN1743598AReduce weightEasy constructionConstruction materialLayered productsFiberWood shavings

A bamboo wall board is composed of bamboo tubes with adhesive peripheral faces, in which, the outer shapes of multiple bamboo tubes are the same, they are orthohexagonal post, die-square or cylindrical and an adhesive agent for connecting bamboo tubes is set at the contact places of the peripheral faces, the tubes are filled with fillers of bamboo bits, wood flour, wood shavings, fibers, crushed plant stovers, cement slurry, gypsum powder or foamed plastics, all of which are doped with adhesives. The bamboo wallboard is adhered with coats of bamboo boards, wood plywood, fiberboard, plastics, metallic board, gypsum boards or asbestos boards.

Owner:天津市朗明通信科技有限公司

Process of producing bamboo chipboard

InactiveCN101066606ASolve the problem of full stalk utilizationGood removal effectDomestic articlesFlat articlesWood shavingsEngineering

The process of producing bamboo flake chipboard includes the steps of resolving bamboo longitudinally into large bamboo flakes, drying, gluing, pre-pressing and hot pressing to obtain bamboo flake chipboard in required cross section shape. The bamboo flake chipboard may be used widely in replacing wooden board for building, packing, vehicle, ship, decoration and other fields. The present invention has high bamboo utilizing rate, and lowered material cost and production cost.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Isocyanate strengthened agricultural residue fiber/plastic composite material and its preparation method

This invention relates to a agricultural remainder / plastic composite enhanced by isocyanate. The weight percentage of its components is that agricultural remainder fabric material 10-60%, plastic 10-60%, couplant 0.3-10% which is percentage weighed by bone dry weight of agricultural remainder fabric material. It is complex made by the technology of wood based panel. Its preparation is that at first agricultural remainder fabric material is pretreated into paring, fiber or powder and dried with water content 0-25%, and then thermoplastic is classified and shattered into lamellar or granular; At last, two kinds of materials, together with 0.3-10% couplant, are mixed for pretreatment in ordinary temperature, then a mixed powder is made. Pavement and thermocompression are conducted at 130-223DEG C and 1-20MPa about 1-20min, then the plate is received by cutting-edge at ordinary temperature.

Owner:LANGFANG HUARI FURNITURE CO LTD

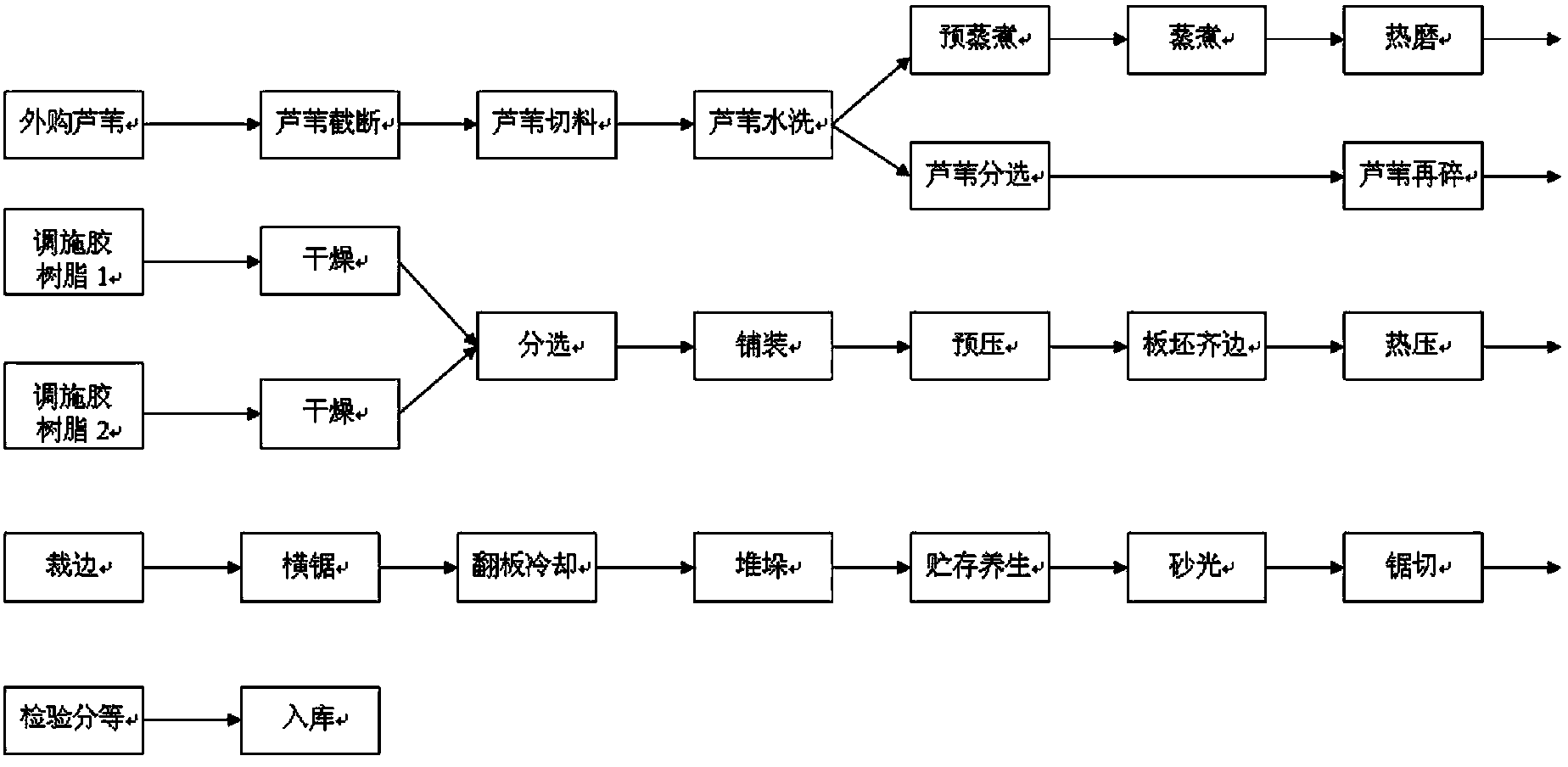

Preparation method for reed fiber particle board

ActiveCN104227819AReduce the effects of gluingReduce releaseLaminationLamination apparatusFiberWood shavings

The invention discloses a preparation method for reed fiber particle board. The preparation method comprises the following steps: cutting a reed raw material by using a circular sawing machine to prepare stem-shaped reeds with certain sizes; cutting the material by using a reed cutting machine, wherein one part of the cut material is cooked and softened to obtain the reed fibers, and the other part of the cut material crushed again to obtain fine reed shavings; respectively applying different resin adhesives to the reed fibers and the shavings, and drying, air-sorting and paving to form three-layer or multi-layer structural board blank; pre-pressing the three-layer or multi-layer structural board blank into a continuous flat-pressing hot press to press and produce the environment-friendly reed fiber particle board. The preparation method has the advantages that the influence of a wax layer on the surface of a reed on gluing performance is reduced to the greatest extent by graded pavement treatment; the production cost of the reed fiber particle board prepared by the process is moderate; both the physical and chemical properties of the reed fiber particle board meet related national standard requirements; the free formaldehyde release amount reaches the level-E1 standard requirement. According to the preparation method, reed resources of a wet land are fully utilized; the source of production raw materials of artificial boards is enlarged; the requirements on building resource-saving and environment-friendly society of China are met.

Owner:DONGYING ZHENGHE WOOD IND

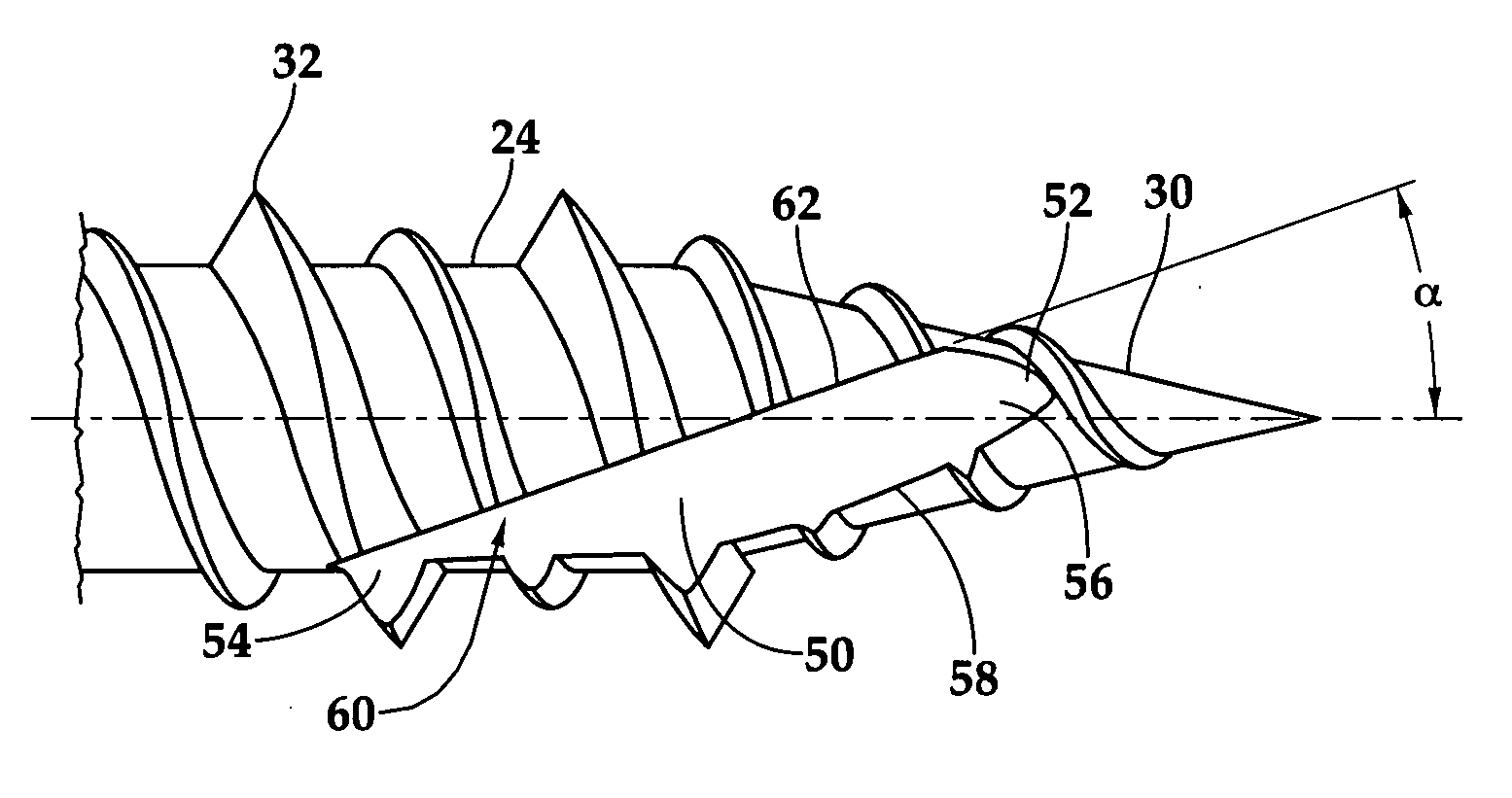

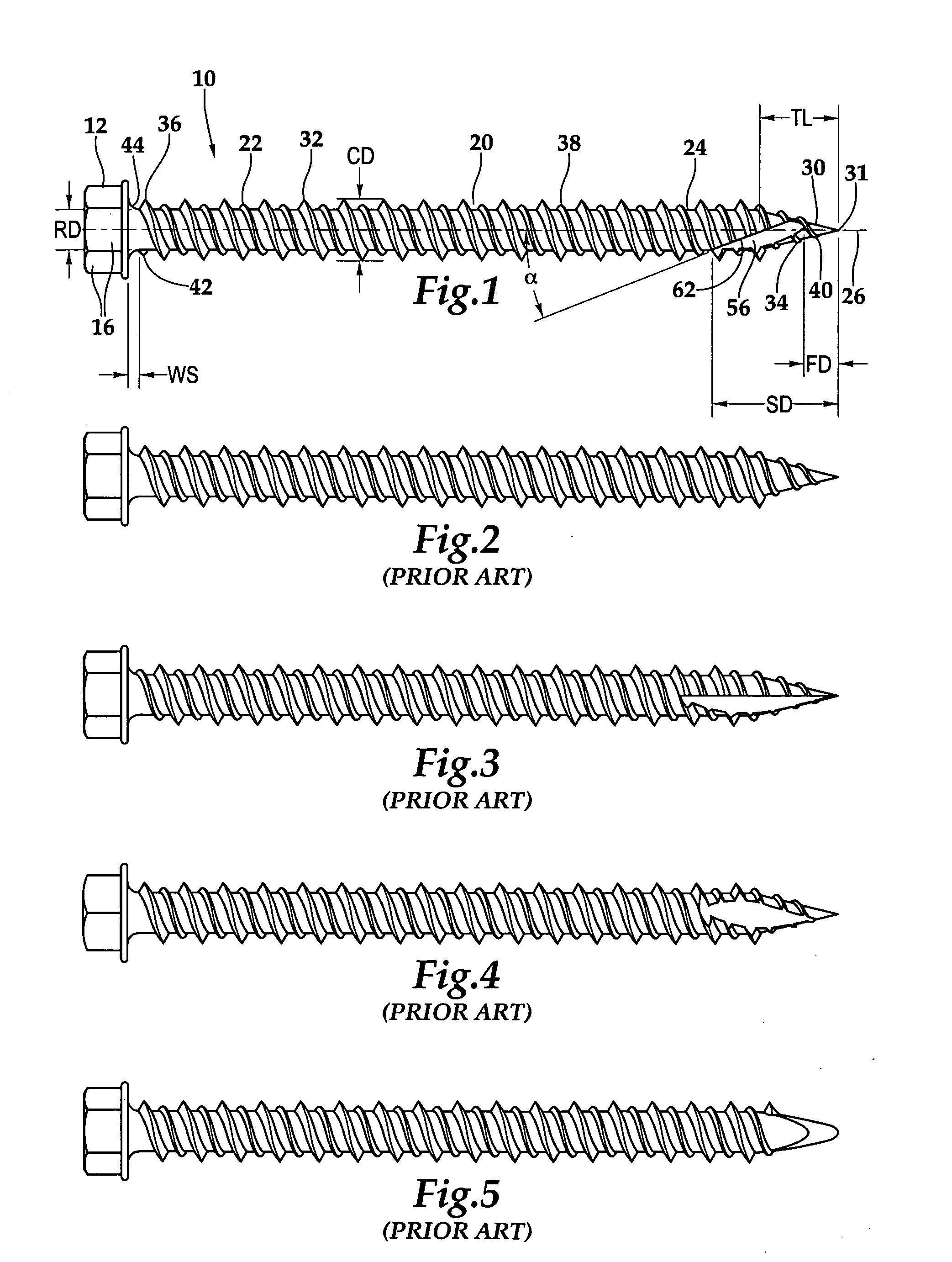

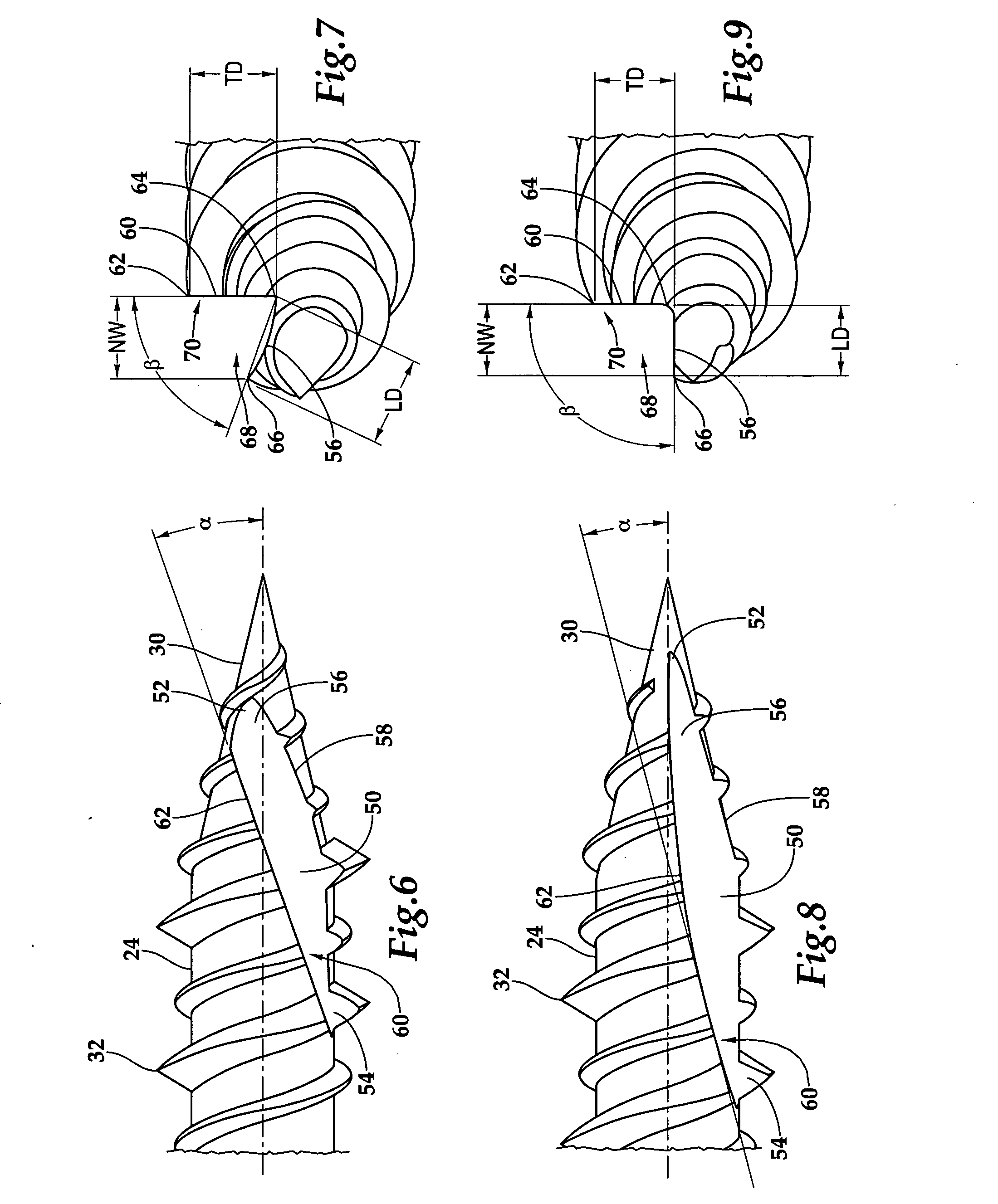

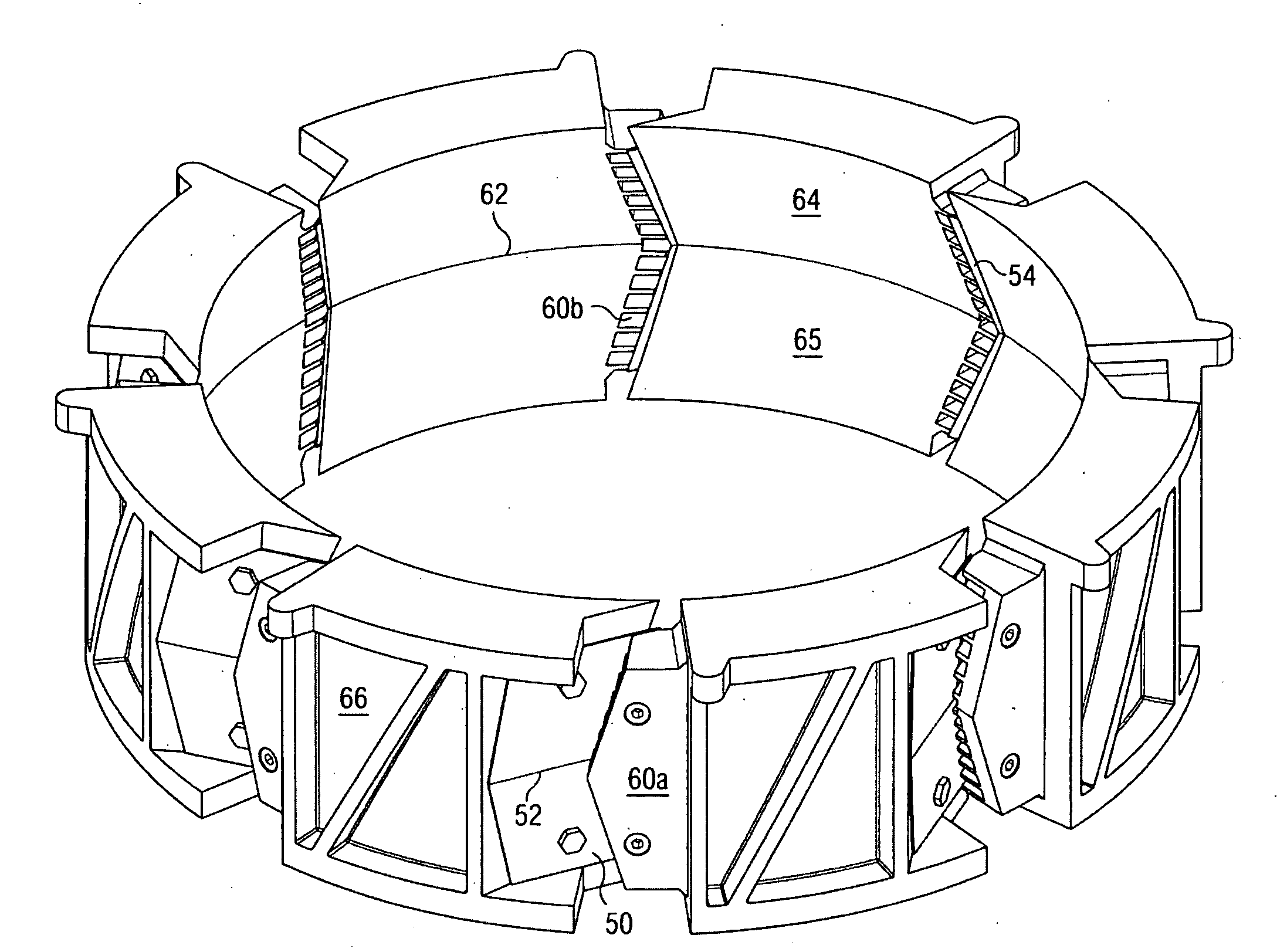

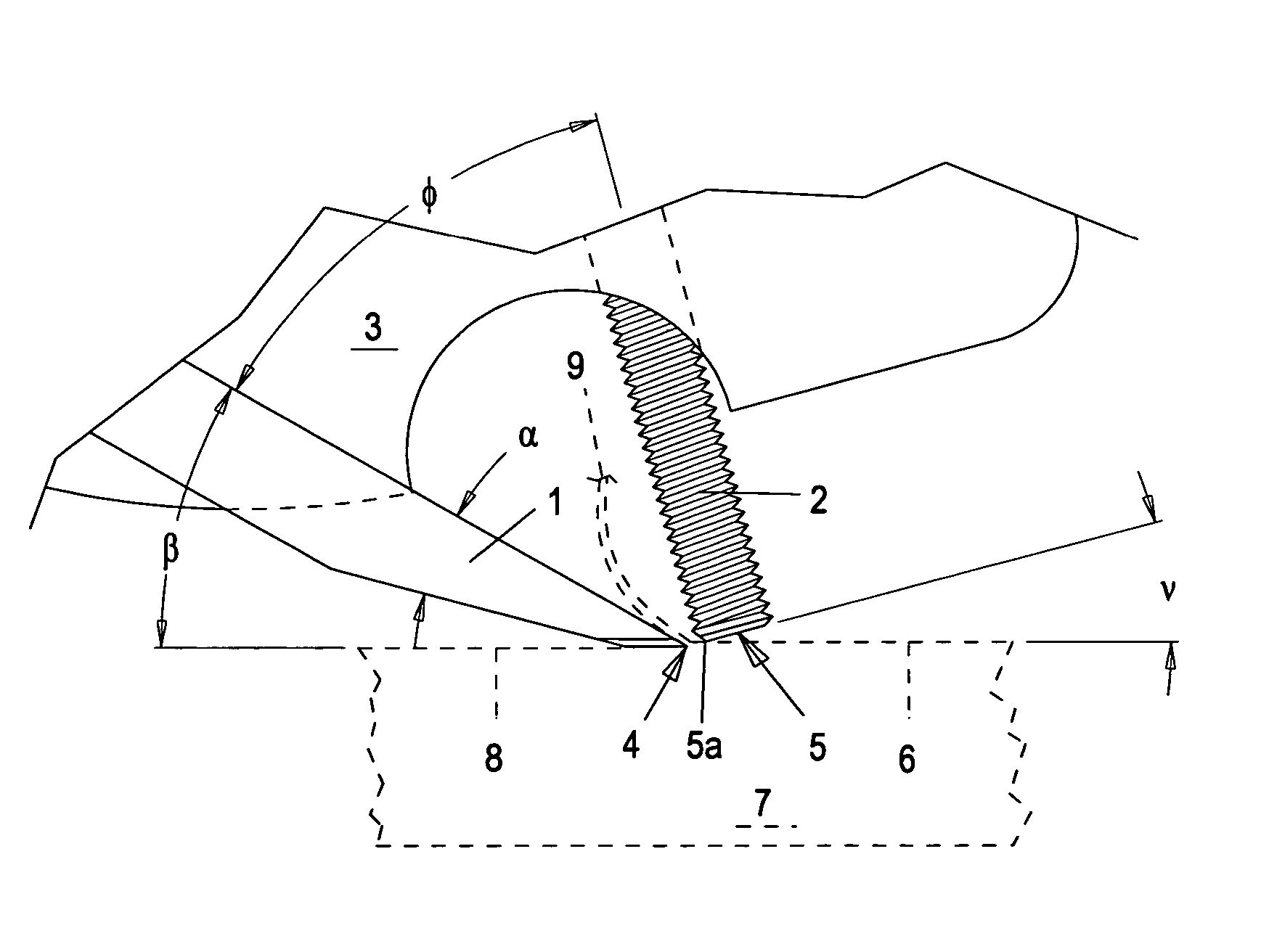

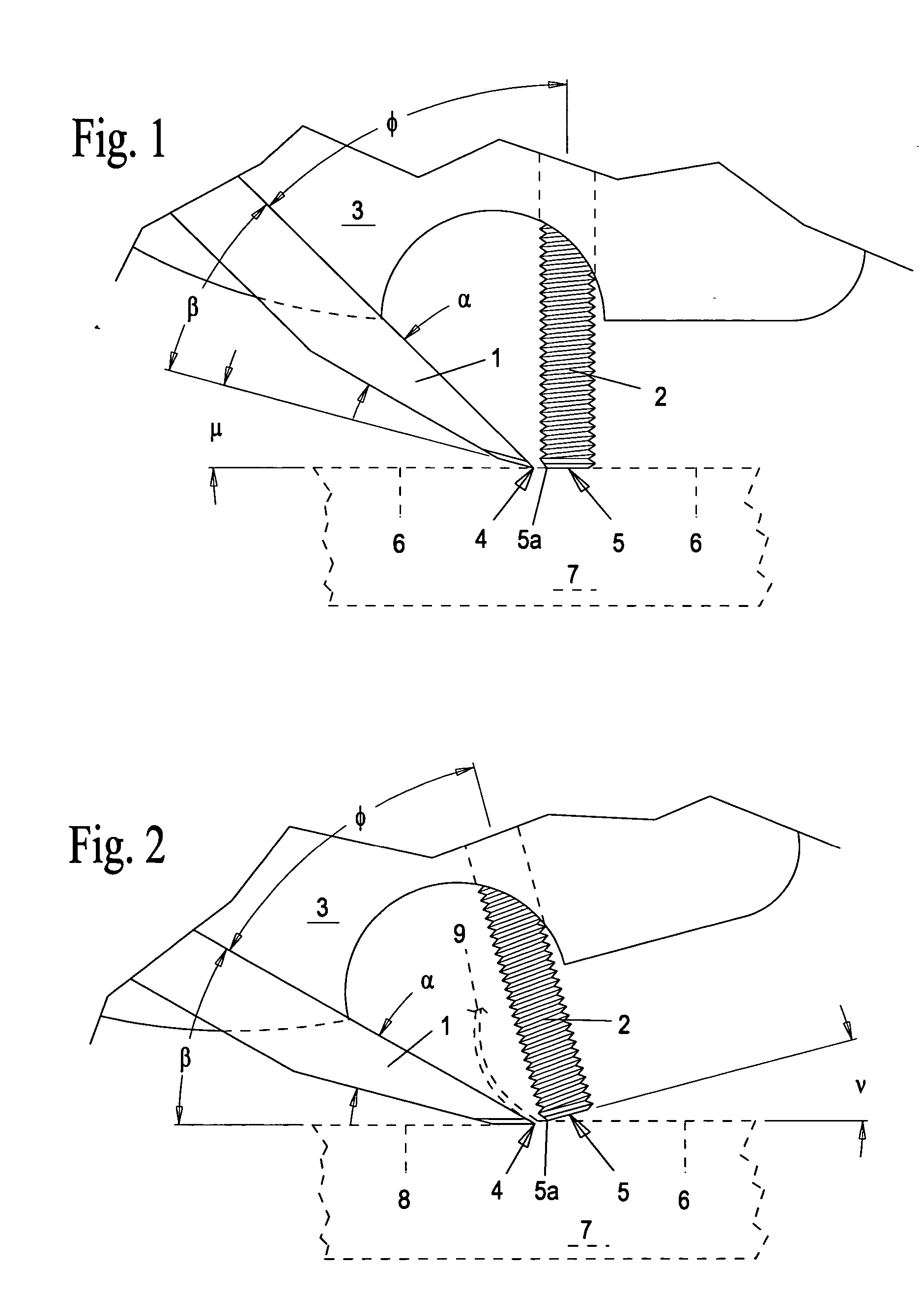

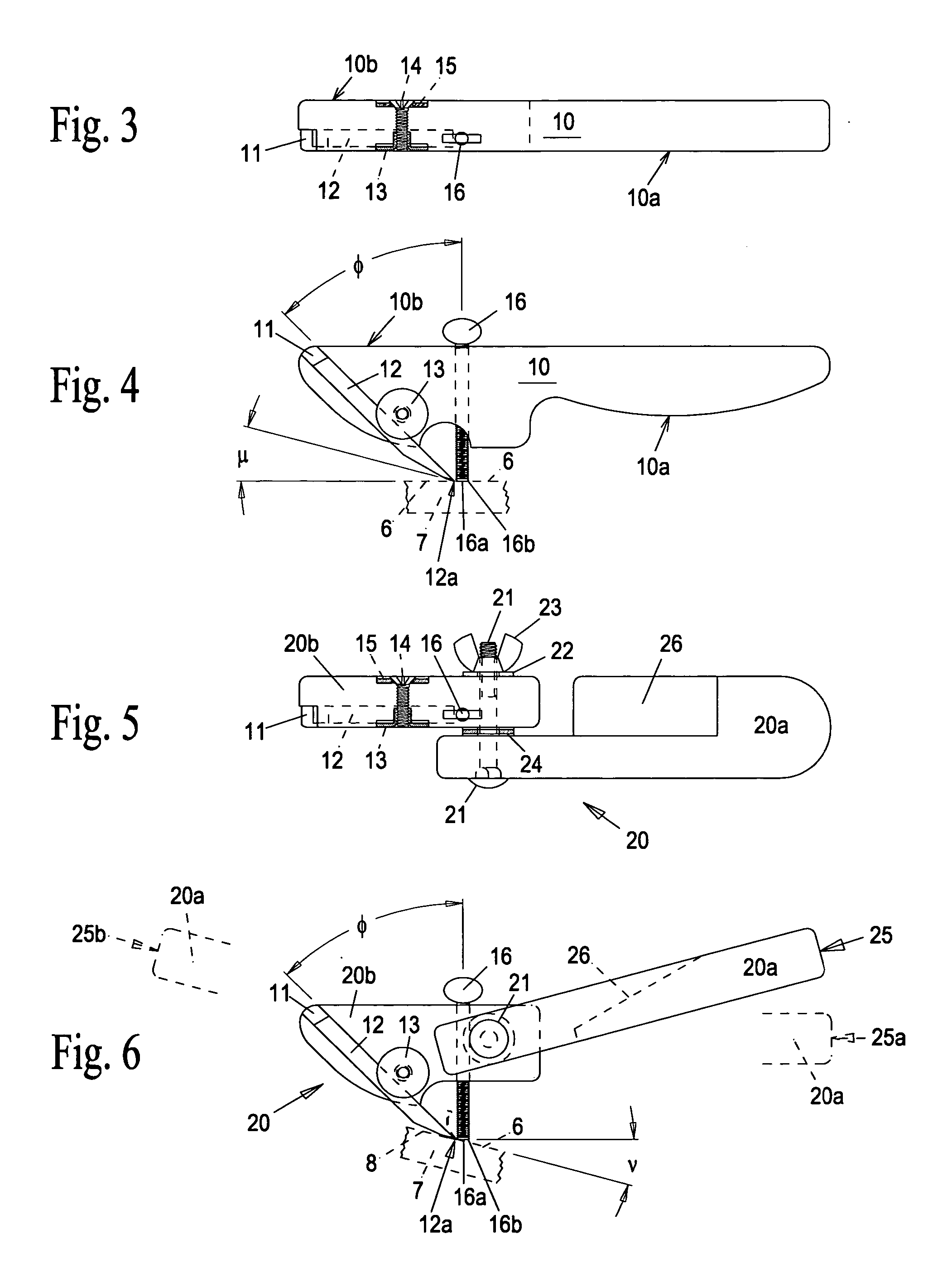

Fastener with Shaving Inhibitor

A fastener with shaving inhibitor for fastening a material such as a metal sheeting panel to a substrate such as metal or wood. The fastener has a notch angled leftwardly with respect to an axis of the fastener, the notch having a first end and a second end, a leading face and a trailing face, each face having outer edges and a common edge at their intersection. At least one of the leading and trailing faces may be substantially planar but may have other shapes, such as concave. Leftwardly angled notch with faces having outer edges may attract and then cut shavings formed from material being installed, thereby reducing the quantity and / or length of shavings, prolonging the life of the material or the structure to which the material is fastened.

Owner:ILLINOIS TOOL WORKS INC

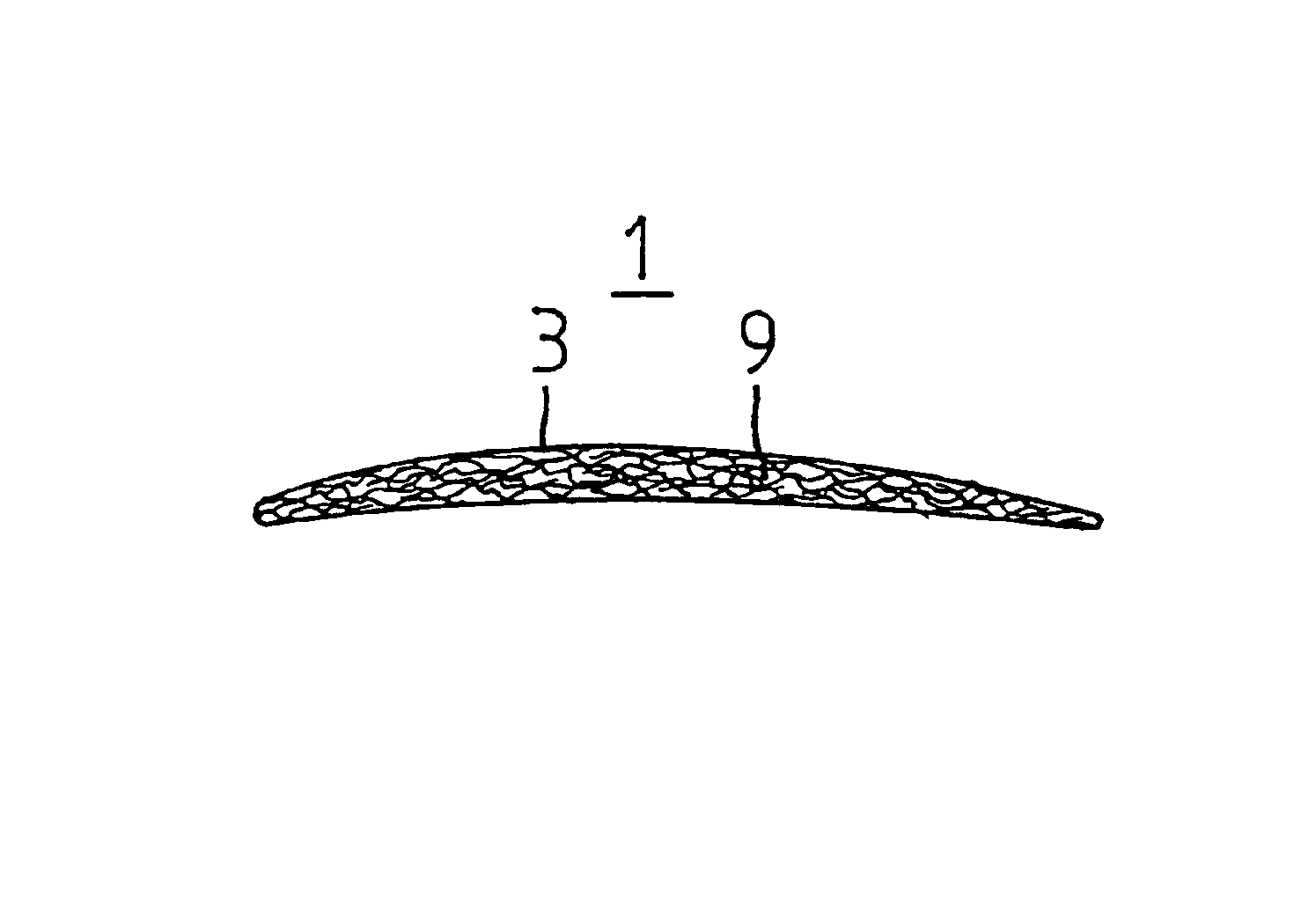

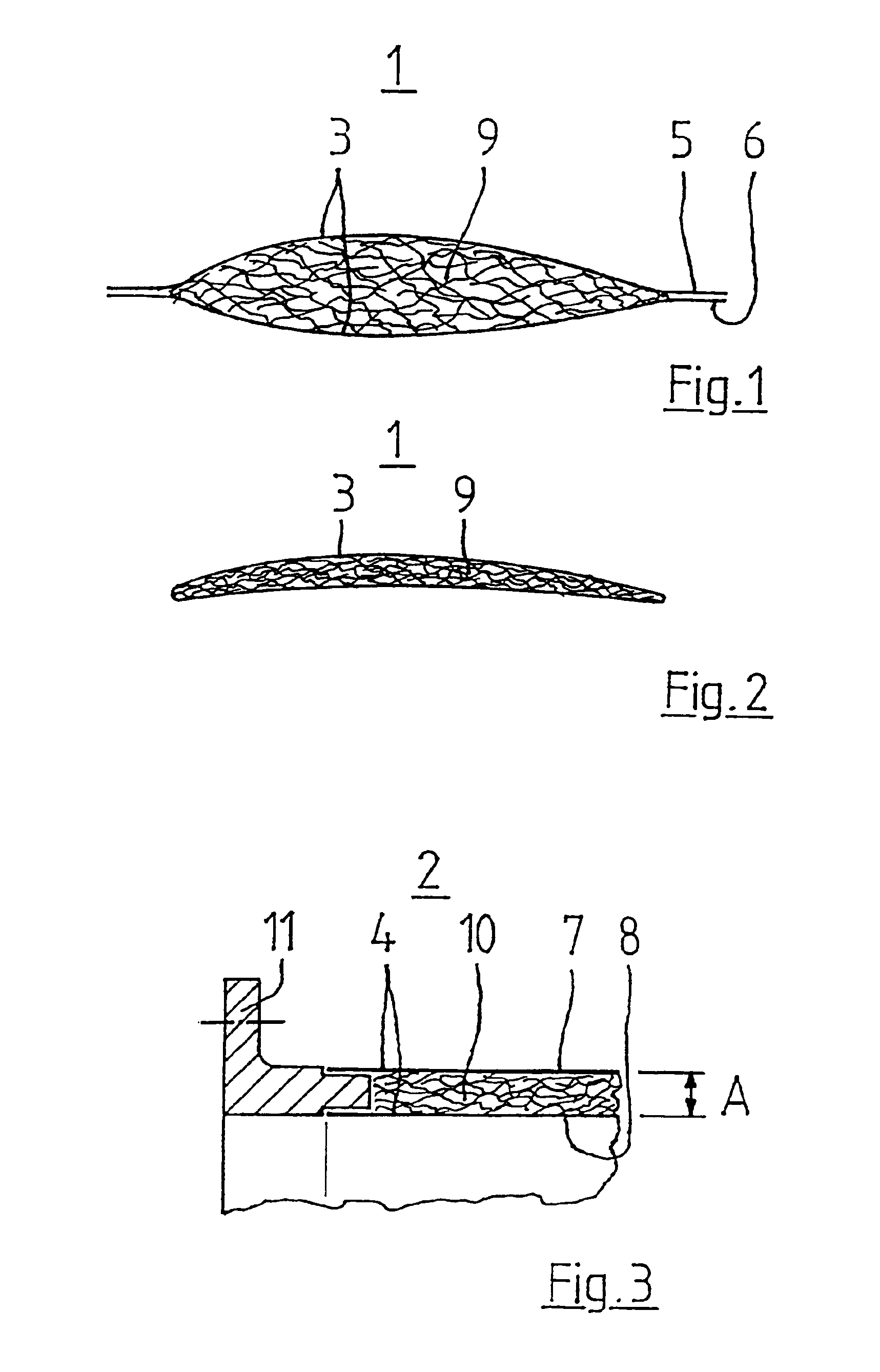

Lightweight structural component having a sandwich structure

A lightweight, composite structural element for turbo engines, includes a thin metallic shell and a metallic core structure, of which a large proportion of the volume is empty space, the shell and the core structure being rigidly connected to each other. The core structure has a spatial, felt-like and / or mesh-like construction and is made of one or more wires, strips, shavings, or comparable elements. The core structure is sintered together, and sintered to the shell.

Owner:MTU AERO ENGINES GMBH

A kind of attapulgite soil-based nano-wood flame retardant

ActiveCN102294718ANo costNo pollution in the processWood impregnation detailsSolid woodWood shavings

The invention discloses an attapulgite-based nano-scale wood fire retardant. A preparation method of the attapulgite-based nano-scale wood fire retardant comprises the following steps of weighing respectively raw materials by weight part, pouring an acid solution into attapulgite, carrying out stirring, supersonic treatment, standing and decantation of upper suspension at a normal temperature, washing solids by deionized water, wherein the solids are obtained by repeated centrifugation, drying attapulgite modified by an acid, grinding into powder, dividing the powder into two parts, preserving the two parts in a sealed environment, mixing water-soluble flame-retardant ingredients and one of the two parts, treating the other one of the two parts by an aluminate coupling agent aqueous solution with stirring at a normal temperature for 8 hours, mixing flame-retardant suspension and the attapulgite aqueous solution obtained by the previous step, and stirring the mixture for 20 minutes to obtain a attapulgite-based nano-scale wood fire retardant solution. Through vacuum pressurization, the attapulgite-based nano-scale wood fire retardant can be injected into solid wood, wood single boards, wooden fibers or wood shavings without changes of other production processes so that flame-retardant artificial boards or solid wood with efficient flame retardance are obtained.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Modified slicing shoes and method for making food product shavings

InactiveUS20100015312A1Reduce moistureImprove the level ofGang saw millsFood shapingWood shavingsEngineering

Modified slicing shoes and method for making food product shavings. A conventional slicing shoe for insertion into a slicing head assembly used in conjunction with a centrifugal type slicing machine is modified. The modified slicing shoes comprise a cutting edge having top and bottom ends that protrude towards the interior of a slicing head assembly as a vertex protrudes away from the interior such that the blade is not confined to one plane. In one embodiment, the slicing shoe blade cutting edge and its components comprise a V-shape having an angle that ranges from between about 90° to about 140°. In a second embodiment, the slicing shoe and its components are curvilinear having a curvature ranging from about 1.5 cm to about 2.0 cm. The shape of the blade and its corresponding components allow for the production of snack chips having folded or curled shapes.

Owner:FRITO LAY TRADING CO GMBH

Animal litter

InactiveUS6837181B2Simple preparation processHighly absorbent of both liquids and odorsAnimal housingOther apparatusWood shavingsAnimal science

An animal litter consists of wood particles and wood shavings and baking soda. The wood particles and wood shavings are selected from the group consisting of pine and aspen, to thereby provide a litter with optimal absorbency and odor control characteristics.

Owner:AMERICAN WOOD FIBERS INC

Formaldehyde purification inflaming retarding oriented strand board and manufacturing method thereof

The invention relates to a paint-free decorative overlay fitment board, in particular to a formaldehyde purification inflaming retarding oriented strand board and a manufacturing method thereof, and belongs to the wood processing industry. The formaldehyde purification inflaming retarding oriented strand board comprises a base material layer, an upper surface layer decorative film adhesive layer and a lower surface layer decorative film adhesive layer. The upper surface layer decorative film adhesive layer and / or the lower surface layer decorative film adhesive layer are immersed with an amino resin adhesive solution and a formaldehyde decomposition adhesive solution, the base material layer is an oriented strand board layer, the oriented strand board layer comprises an upper surface layer, a lower surface layer and a core layer shaving layer, wherein the glue mixing wood shavings on the upper and lower surface layers are longitudinally arranged in the fiber direction, the glue mixing wood shavings on the core layer shaving layer are transversely arranged in the fiber direction, an inflaming retarding layer is arranged between the lower surface shaving layer and the core layer shaving layer, and an inflaming retarding layer is arranged between the upper surface shaving layer and the core layer shaving layer. The manufacturing method of the paint-free decorative overlay fitment board comprises the steps of base material sanding, formaldehyde decomposition adhesive solution preparation, decorative film adhesive manufacturing, assembling and pressing and sticking. The formaldehyde purification inflaming retarding oriented strand board is realistic in effect, low in cost and good in formaldehyde purification effect.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

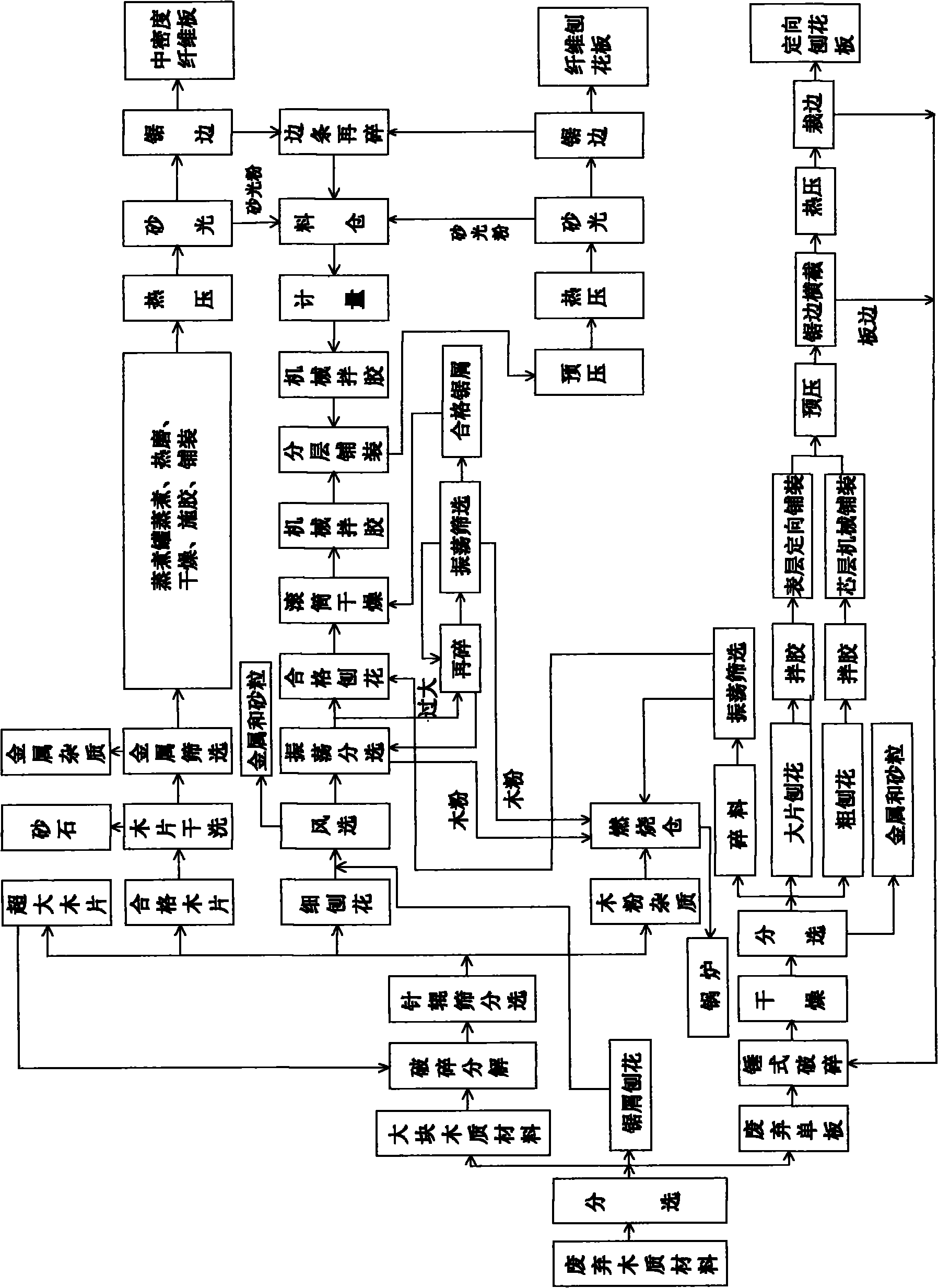

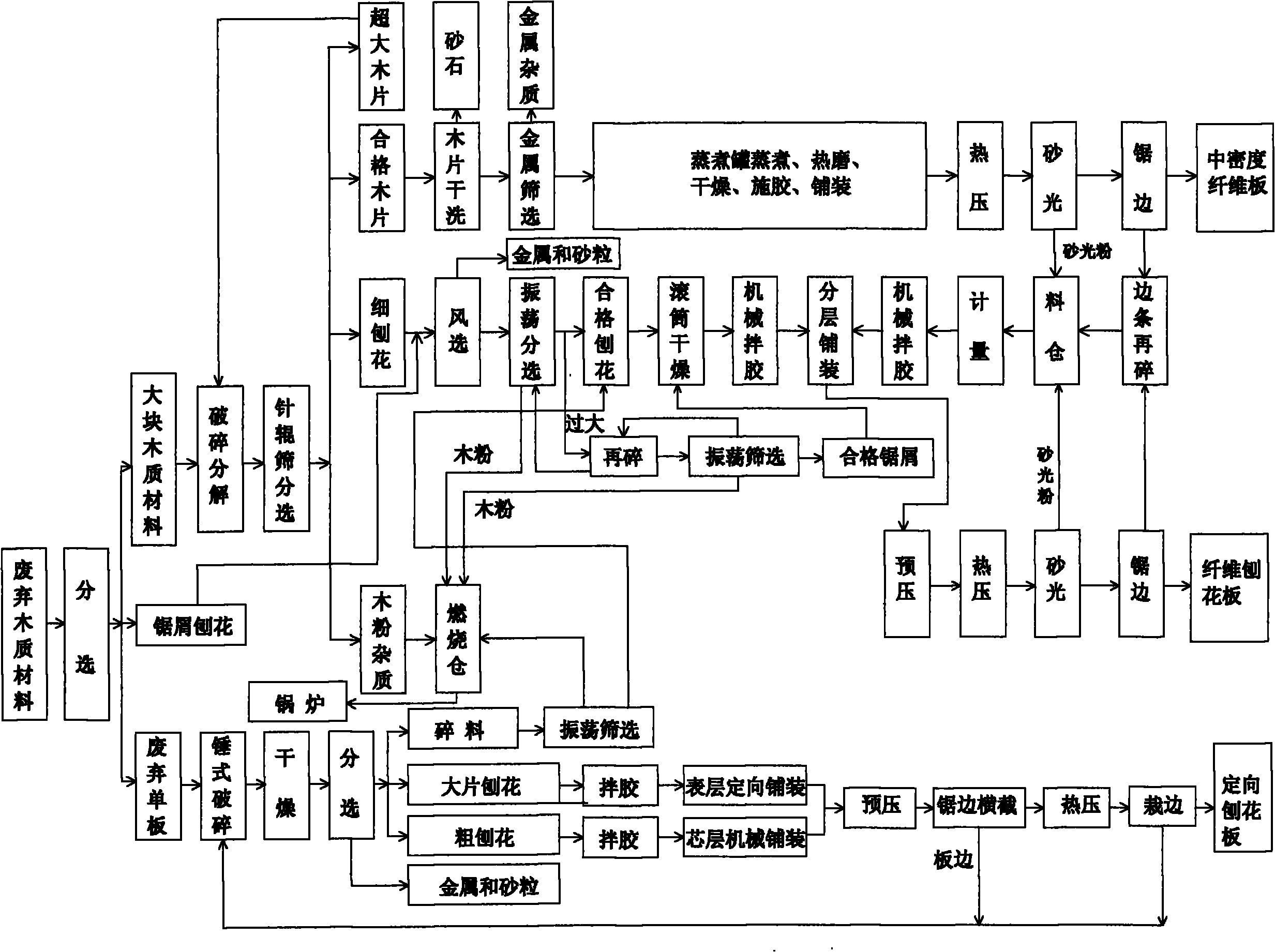

Method for manufacturing regenerated composite boards by using waste wood

InactiveCN102310453AReasonable useMaximize utilizationWood working apparatusDomestic articlesFiberWood shavings

The invention discloses a method for manufacturing regenerated composite boards by using waste wood. The method comprises the following steps of: a, sorting waste wood materials into a massive wood material, sawdust wood shavings and waste veneers; b, crushing and decomposing the massive wood material; c, sorting with a needle roll screen, and obtaining extra large wood chips, qualified wood chips, thin wood shavings and wood meal impurities; d, treating the extra large wood chips according to the step b; e, processing the qualified wood chips into medium density fiber boards by a medium density fiber board manufacturing process; f, removing metal and sand from the thin wood shavings by winnowing, removing powder, gravel and metal impurities from the thin wood shavings by oscillation sorting to form qualified wood shavings, and manufacturing fiber shaving boards by a fiber shaving board production process; g, conveying the wood meal impurities to a fuel bin; h, treating the sawdust wood shavings according to the winnowing process of the step f; i, removing metal and sand from the waste veneers by hammer-type crushing, drying and sorting, and forming crushed materials, big wood shavings and thick wood shavings; and j, producing oriented shaving boards by an oriented shaving board production process.

Owner:JUYE WODESEN PLATE IND

Composite paper reel and manufacturing method thereof

InactiveCN101348201AAvoid damageImprove protectionPaper/cardboard wound articlesWood working apparatusWood shavingsResin-Based Composite

The invention provides a composite paper reel and a manufacturing method thereof. The composite paper reel consists of a molded fiber drum and a paper winding drum, wherein the molded fiber drum is arranged inside the paper winding drum; the paper winding drum is sleeved outside the molded fiber drum; the molded fiber drum is formed by composite resin fiber which is heated, pressurized and molded; and the composite resin fiber which is heated, pressurized and molded is formed by mixed resin fiber bagasse fiber, or the composite resin fiber which is heated, pressurized and molded is formed by mixed resin wood shavings. The manufacturing method comprises the following steps of using a mold and a press machine to produce the molded fiber drum and then using a paper winder to wind sized paper on the molded fiber drum. The composite paper reel is manufactured by use of reused waste bagasse, cornstalks and waste scrap, which reduces destruction to forest resources and is beneficial to environmental protection; meanwhile, as the cost of composite resin bamboo fiber is lower than that of high fiber paper, the cost can be saved.

Owner:林智勇

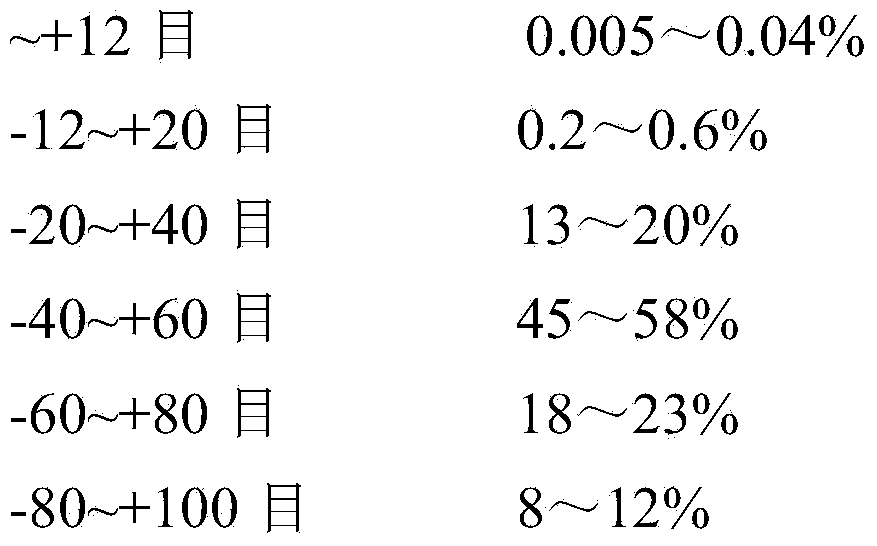

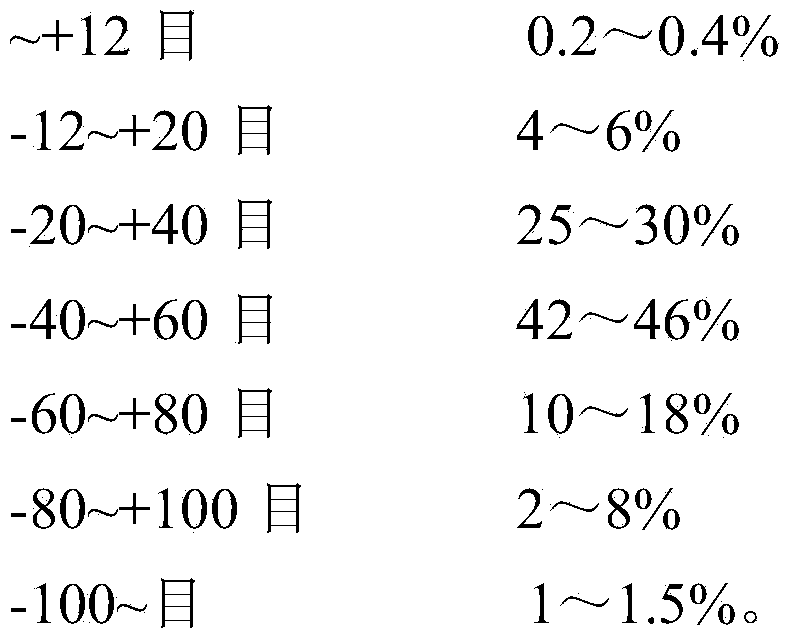

Low-density wood-plastic composite shaving board and manufacture method thereof

ActiveCN102504557ALow densityHigh strengthFlat articlesDomestic articlesWood shavingsProduction line

The invention discloses a low-density wood-plastic composite shaving board and a manufacture method thereof. The shaving board comprises the following components in parts by weight: 5 to 200 parts of expandable polystyrene, 200 to 600 parts of wood shavings (50 to 100 parts of surface shavings, 150 to 500 parts of core shavings), 1.5 to 5 parts of coupling agent, and 4 to 10 parts of adhesive. The manufacture process comprises the following steps of: drying the wood shavings until the water content is between 2 and 5 percent; separating the wood shavings into surface shavings and core shavings by virtue of separation equipment, wherein the surface shavings are glued to serve as a surface material, and the core shavings are subjected to surface treatment by using the coupling agent and mixed with EPS (expandable polystyrene) to serve as a core material; and producing the low-density wood-plastic composite shaving board by virtue of assembling, pre-pressing and thermal-press molding. Compared with a common shaving board, the product has the advantages of low density, excellent physical and mechanical performances, good water repellency and environmental friendliness and simple production process, can be produced on an existing shaving board production line, and can be widely used as furniture materials, package materials and wall materials.

Owner:FUJIAN AGRI & FORESTRY UNIV

Manufacturing method of bamboo-Chinese fir composite plate

InactiveCN101664952AHigh strengthIncrease profitNon-macromolecular adhesive additivesWood treatment detailsWood shavingsComposite plate

The invention relates to a manufacturing method of a bamboo-Chinese fir composite plate, in particular to solving the technical problem of providing a manufacturing method of a bamboo-Chinese fir composite plate by comprehensively and efficiently utilizing Chinese fir slabs and bamboo processing residues. The method aims at improving the utilization rate of the bamboos and wood and the composite plate has the characteristics of flat plate surface, high strength, little glue mount and good dimensional stability. The technical scheme for solving the problem is as follows: the method comprises the following steps: (1) splicing; (2) flaking and first sorting; (3) Chinese fir flaking and steam-injecting; (4) bamboo flaking and poaching; (5) drying; (6) flaking and sorting; (7) glue blending; (8) paving; (9) prepressing; (10) hot pressing; and (11) post treatment. The method is suitable for such fields as furniture manufacturing, indoor decoration and the like.

Owner:ZHEJIANG FORESTRY UNIVERSITY

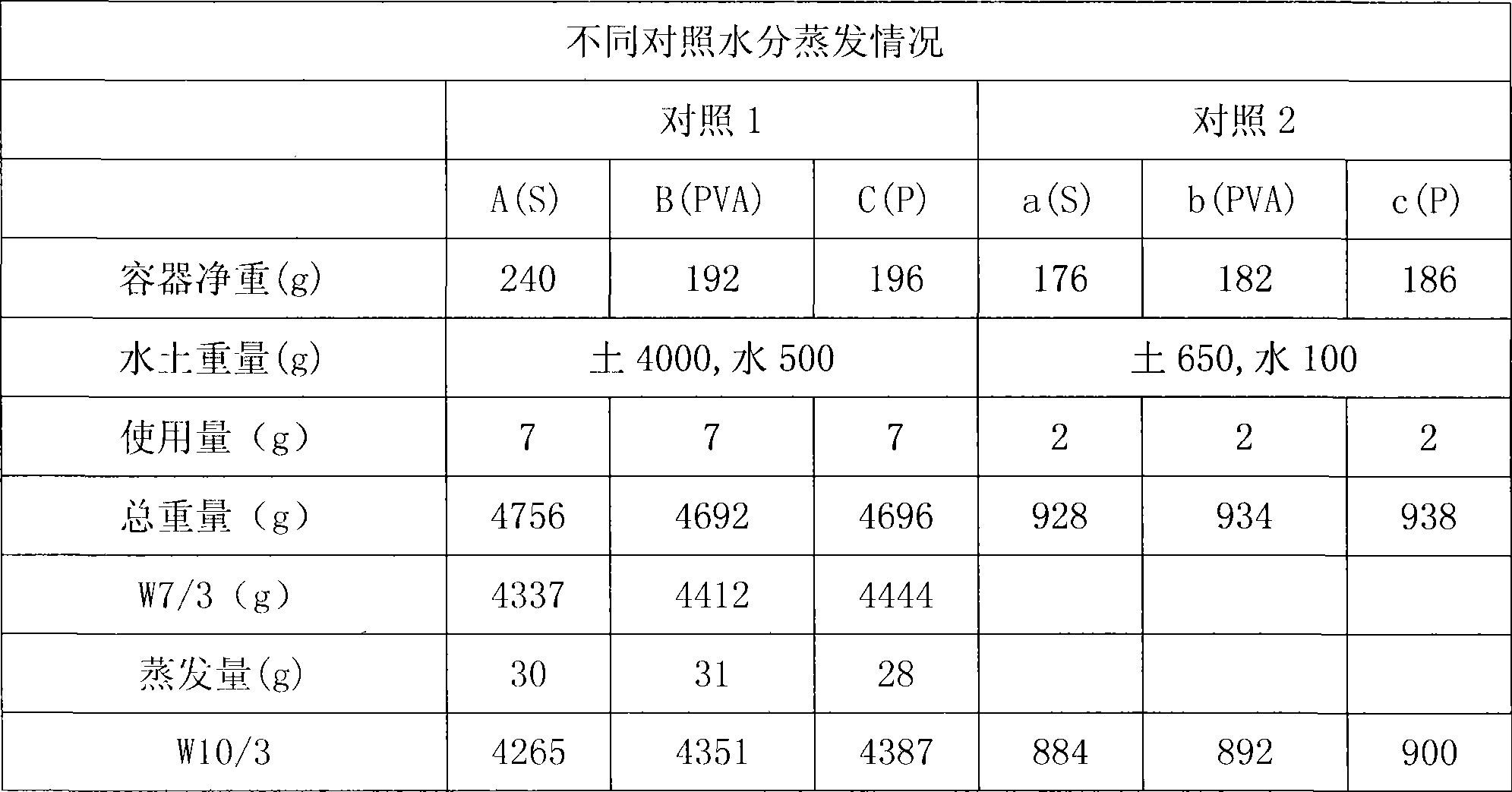

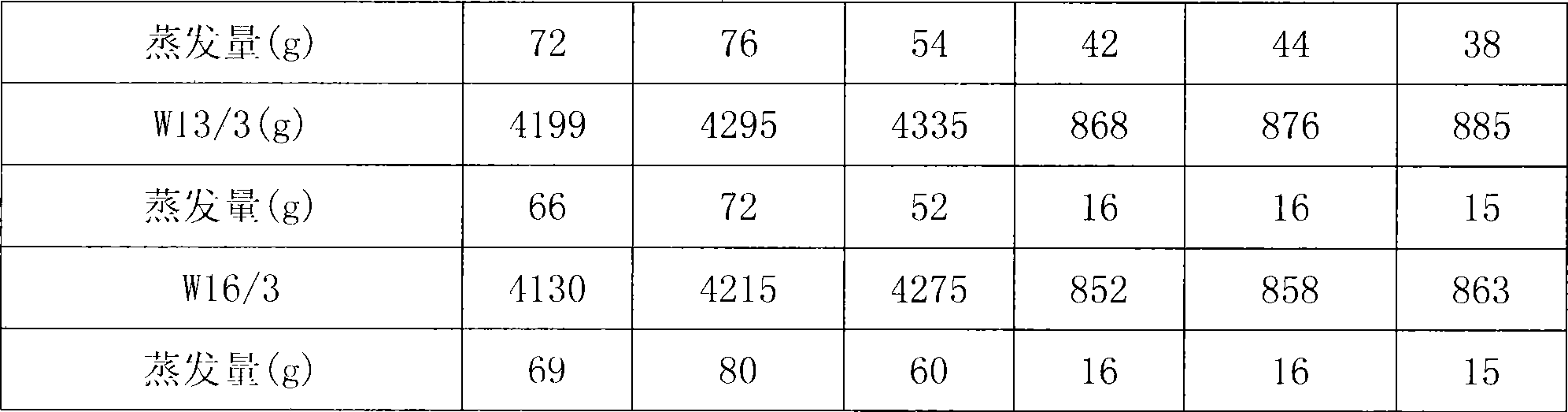

Degradable liquid mulching film and production method thereof

InactiveCN101445731AEfficient captureInhibition lossAgriculture tools and machinesOrganic fertilisersCelluloseEvaporation

The invention relates to a degradable liquid mulching film and a production method thereof, particularly to an environment-friendly degradable liquid mulching film with straws as a basic raw material and a production method thereof. The degradable liquid mulching film is prepared from steaming slurry of crop straws (such as wheat straws, rice straws, cotton straws, wood shavings, and the like) or straws paper-making black liquor as a main raw material by a series of reactions, such as sulfonation, crosslinking and copolymerization, of macromolecules in the slurry or the black liquor, such as lignin, cellulose and polysaccharides, under the action of a film formation additive. The macromolecules in the degradable liquid mulching film have a large amount of hydrophilic groups which can effectively catch the water molecules evaporated and diffused from soil to the air, so as to prevent water evaporation and heat loss arising therefrom, thereby increasing the temperature and preserving soil moisture. The degradable liquid mulching film is helpful for increasing crop yield and improving crop quality; and the yield is higher than that by use of a plastic mulching film, and the per mu yield is increased by more than 5%. The degradable liquid mulching film can replace the conventionally used plastic mulching film.

Owner:SHANDONG SI DA KE BIODEGRADABLE TECH CO LTD

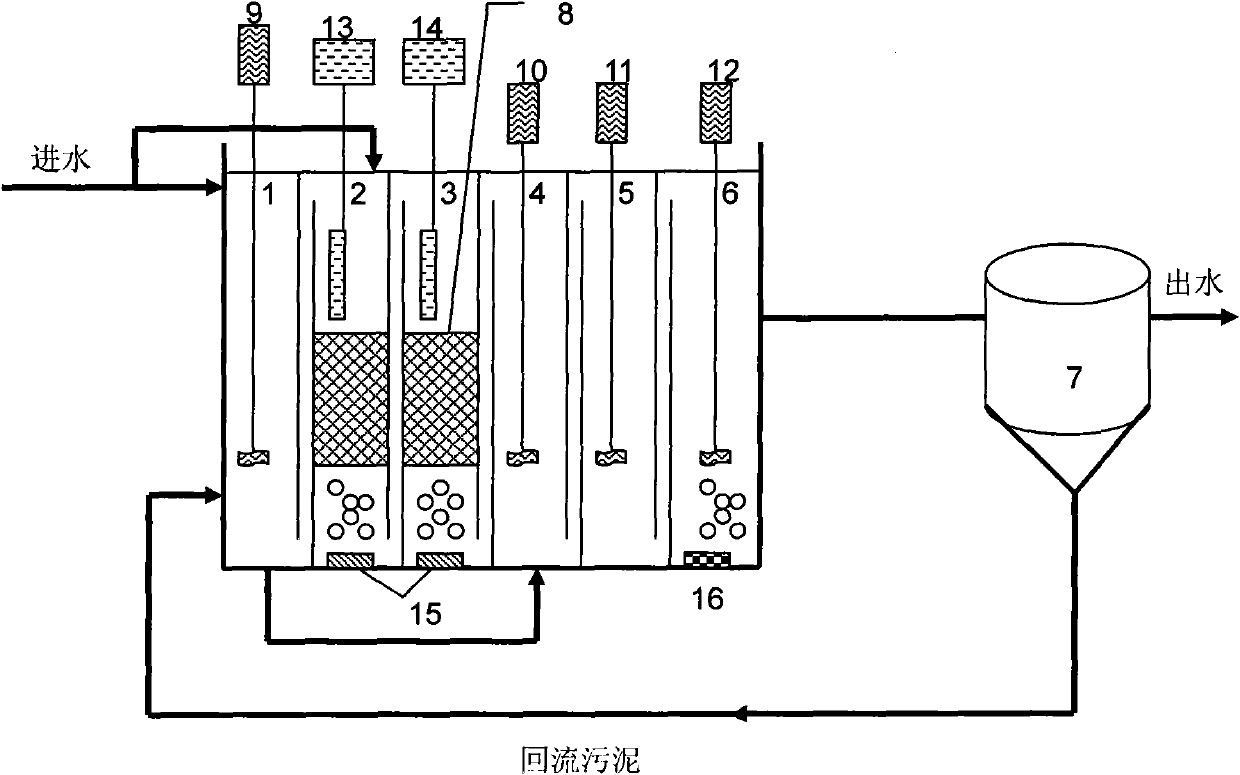

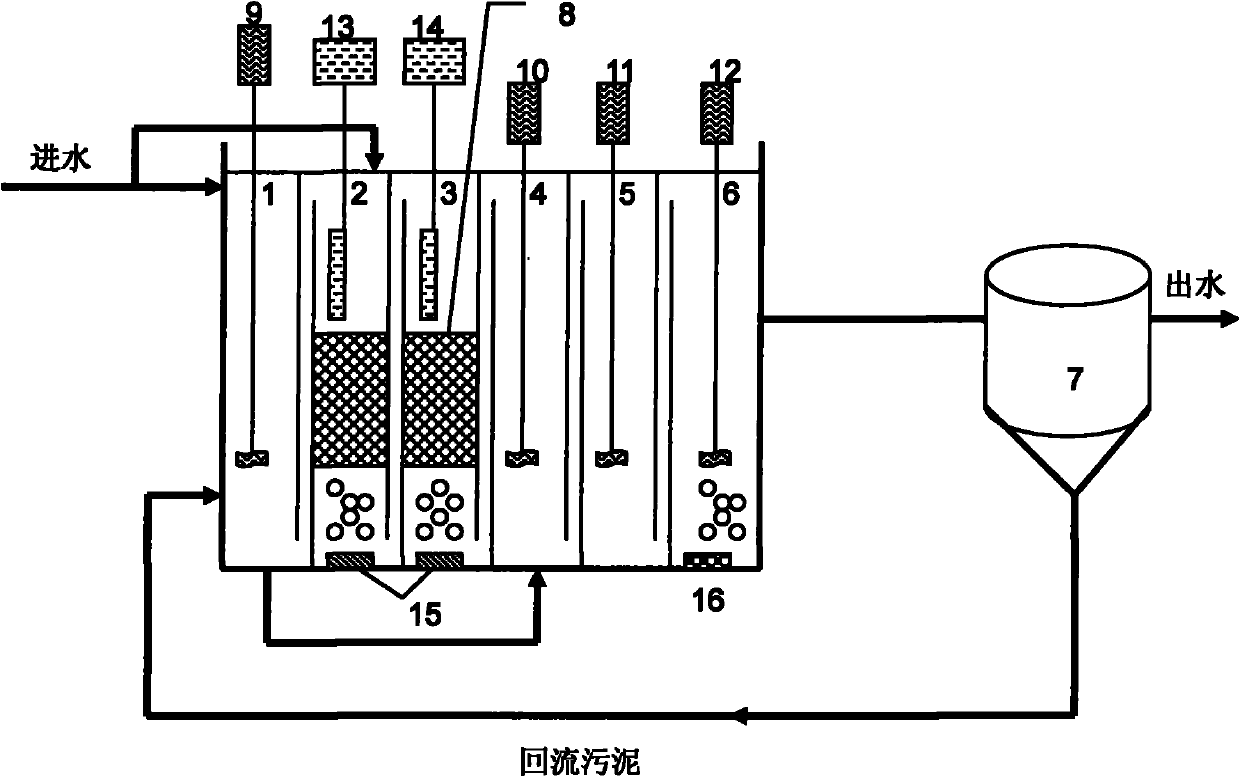

Energy-saving consumption-reducing short-range nitration dephosphorizing coupling technique with synchronous denitrification and device thereof

ActiveCN101792233AAccumulation and stabilityRealize energy saving and consumption reductionWater contaminantsMultistage water/sewage treatmentElectron donorNitration

The invention discloses an energy-saving consumption-reducing short-range nitration dephosphorizing coupling technique with synchronous denitrification and a device thereof, belonging to technical field of domestic and industrial sewage treatment. A metal carrier bed is installed in an aerobic section with integrated reaction, and is made of iron wood shaving washed through acid cleaning; and the outer part of the iron wood shaving is covered by wire netting. Under conditions of normal temperature and low dissolved oxygen, the aims of short-range nitration and synchronous denitrification can be realized; an anaerobic section is used for finishing phosphorous releasing; the aerobic section is used for finishing short-range nitration, an anoxic section is used for finishing denitrification for removing phosphorous, a fast aerobic section is used for removing remaining ammonia and nitrogen and phosphorous. The invention uses iron wood shaving with low cost to realize stable accumulation of nitrite; the aerating amount is small, the carbon source is saved, and denitrification for phosphorous removing is carried out by taking the nitrite produced via short-range nitration as electron donor, thus the nitrogen and phosphorous can be removed synchronously; and the problem that the nitrite in water could damage the environment and has toxicity is solved. The invention can realize the aims of saving energy and reducing consumption to the largest extent, and is suitable for purifying and treating domestic sewage continuously for a long time.

Owner:TSINGHUA UNIV

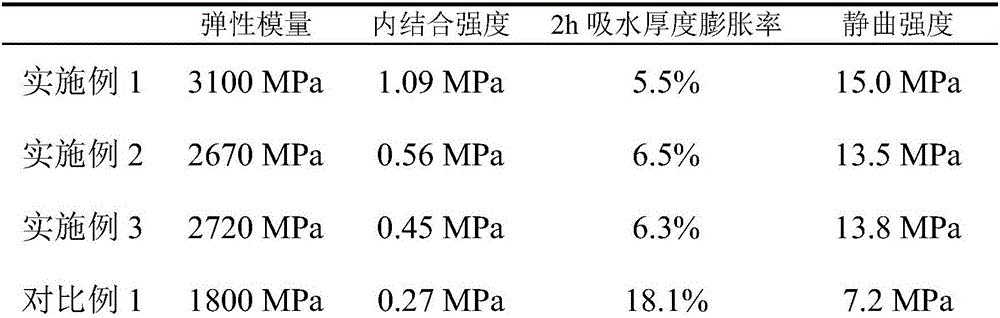

Soybean-based formaldehydeless adhesive used for chipboards, and application method thereof

ActiveCN105838304ASolve for uniformitySolve the problem of excessive moisture content of wood shavings after sizingNon-macromolecular adhesive additivesProtein adhesivesWood shavingsCross-link

The invention discloses a soybean-based formaldehydeless adhesive used for chipboards, and an application method thereof. The soybean-based formaldehydeless adhesive is prepared from, by weight, 10-30 parts of a soybean derivative, 0.1-1 part of an acidity-alkalinity adjusting agent, 1-30 parts of a cross-linking agent, 0.1-1 part of a mildew inhibitor, 0.1-1 part of a leveling agent, 10-100 parts of water and 5-50 parts of a tackifier. Multi-component adhesive application is adopted to solve the problems of unable adhesive application of commercial soybean adhesives and too high water content of wood shavings after adhesive application, and the tackifier is used to solve the problems of poor initial viscosity of chipboards made by using the soybean adhesives, poor pre-forming property after adhesive application of wood shavings, and low static bending strength and large water absorption thickness swelling rate of boards.

Owner:宁波朝露新材料科技有限公司

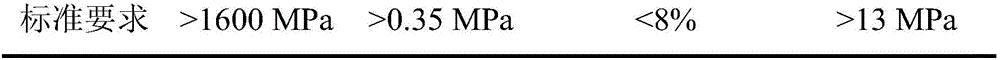

High-intensity shaving board and manufacturing method thereof

InactiveCN102179856ASave resourcesHigh strengthWood working apparatusFlat articlesWood shavingsEcological environment

The invention discloses a high-intensity shaving board and a manufacturing method thereof. The manufacturing method comprises the following steps of: smashing industrial hemp rods into wood shavings; adding 2 to 14 percent of adhesive; and performing hot pressing to obtain the shaving board. A hemp rod / wood composite shaving board can be prepared by further blending common wood shavings. In the invention, the shaving board is manufactured by the industrial hemp rods which have the characteristics of high intensity, a large number of holes and low density for the first time; and compared with a similar wood shaving board product, the shaving board product has the characteristics of low density, high intensity and high load bearing property. By the implementation of the technology, wood resources can be obviously saved, an ecological environment is protected, wastes are made profitable, and a new path is provided for the application of industrial hemp; and further development of an industrial hemp industry is facilitated, and good social and economic benefits are achieved.

Owner:云南工业大麻股份有限公司 +1

Straw particle board employing bark powder modified phenolic resins as adhesives

ActiveCN101693380ALow costImprove performanceFlat articlesDomestic articlesWood shavingsWood machining

A straw particle board employing bark powder modified phenolic resins as adhesives adopts straws as main raw materials and woodworking fragment wood shavings as secondary materials. The particle board is characterized in that the adhesives of the pressed straw particle board employ the bark powder modified phenolic resins, a large amount of renewable wood processing remained bark powders are adopted to replace parts of petrochemical phenols, the phenols are employed to directly activate the bark powders, the bark powders are applied to preparation of phenolic resin adhesives, and operation is simple. In a gluing process, CH3Si (OH) 3 organic silicon liquor with low cost is adopted to modify the adhesives so as to enable the adhesives to easily moisten, penetrate and diffuse on the surfaces of the straws, thereby being favorable for glue joint of the straws. Simultaneously, interfaces of the straws are modified so as to enable the bark powder adhesives to be applied to production of the straw particle board. The straw particle board produced by adopting the adhesives has the advantages of attaching importance to effective usage of biological materials, having low product manufacturing cost, fine performance, strong operability and bringing remarkable ecological benefits and environmental benefits after being popularized.

Owner:BEIHUA UNIV

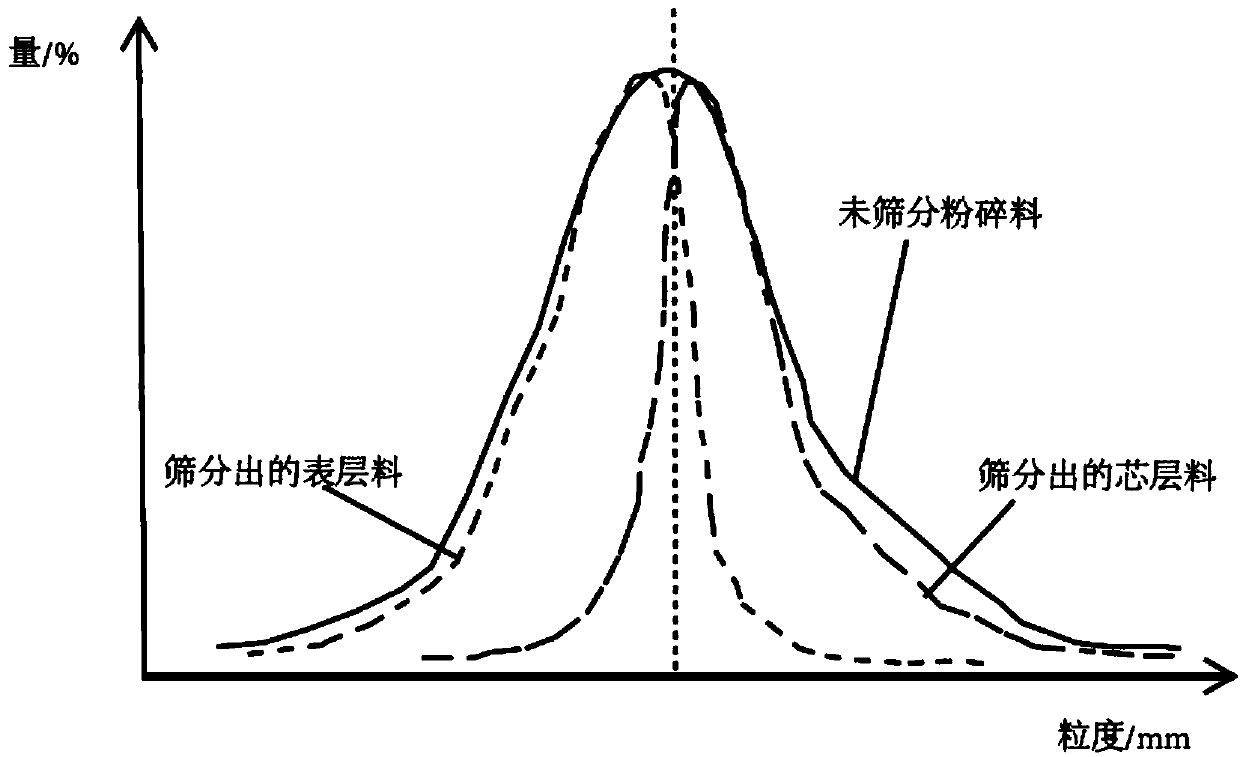

Artificial board made of crop straw and method for manufacturing artificial board made of crop straw

ActiveCN104070591AIncrease productivityMorphological distribution is reasonableWood working apparatusFlat articlesWood shavingsFiber

The invention discloses a method for manufacturing an artificial board made of crop straw. The method for manufacturing the artificial board made of crop straw comprises the steps that (1) the straw is cut into straw sections with the lengths ranging from 20 mm to 40 mm, wherein the water content of the straw sections ranges from 12% to 20%; (2) the straw sections are pulverized by means of a pulverizer, wherein the mesh size of the pulverizer ranges from 5 mm to 10 mm, the sizes of fiber particles obtained after pulverization are in normal distribution, the value of mu ranges from 0.2 mm to 1.0 mm, and the value of sigma ranges from 0.2 mm to 0.6 mm; (3) coarse materials and fine materials are obtained by screening the fibers obtained after pulverization through a screening device, wherein the ratio of mass of the coarse materials to the mass of the fine materials is 1-2:1-2; (4) the coarse materials and the fine materials are dried respectively, the water content of the coarse materials is controlled between 8% and 14%, and the water content of the fine materials is controlled between 10% and 14%. According to the method for manufacturing the artificial board made of crop straw, materials, obtained after screening, of a surface core layer of the artificial board made of crop straw can meet different form distribution requirements, namely, thick wood shavings do not exist in the surface layer, and superfine fibers do not exist in the core layer.

Owner:WANHUA CHEM GRP CO LTD

Contouring shave

The invention is directed to a hand tool for cutting shavings from the surface of a workpiece of wood (or other workable material) to shape and make smooth any three-dimensional surface having concave, flat, and / or convex contours. The thickness of the shavings is modulated by the angular relationship and distance between a blade and a regulating post. An embodiment comprises a combination body and handle holding a protruding cutting blade at an angle of about 30° to the surface of the workpiece, and an adjustable protruding post in front of the cutting edge to limit the effective exposure of the cutting edge as the tool is moved into contact with the workpiece. The embodiments provide a full view of the cutting zone and unrestricted one-hand use on surfaces of any contour.

Owner:DENKER JAMES M

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com