Degradable liquid mulching film and production method thereof

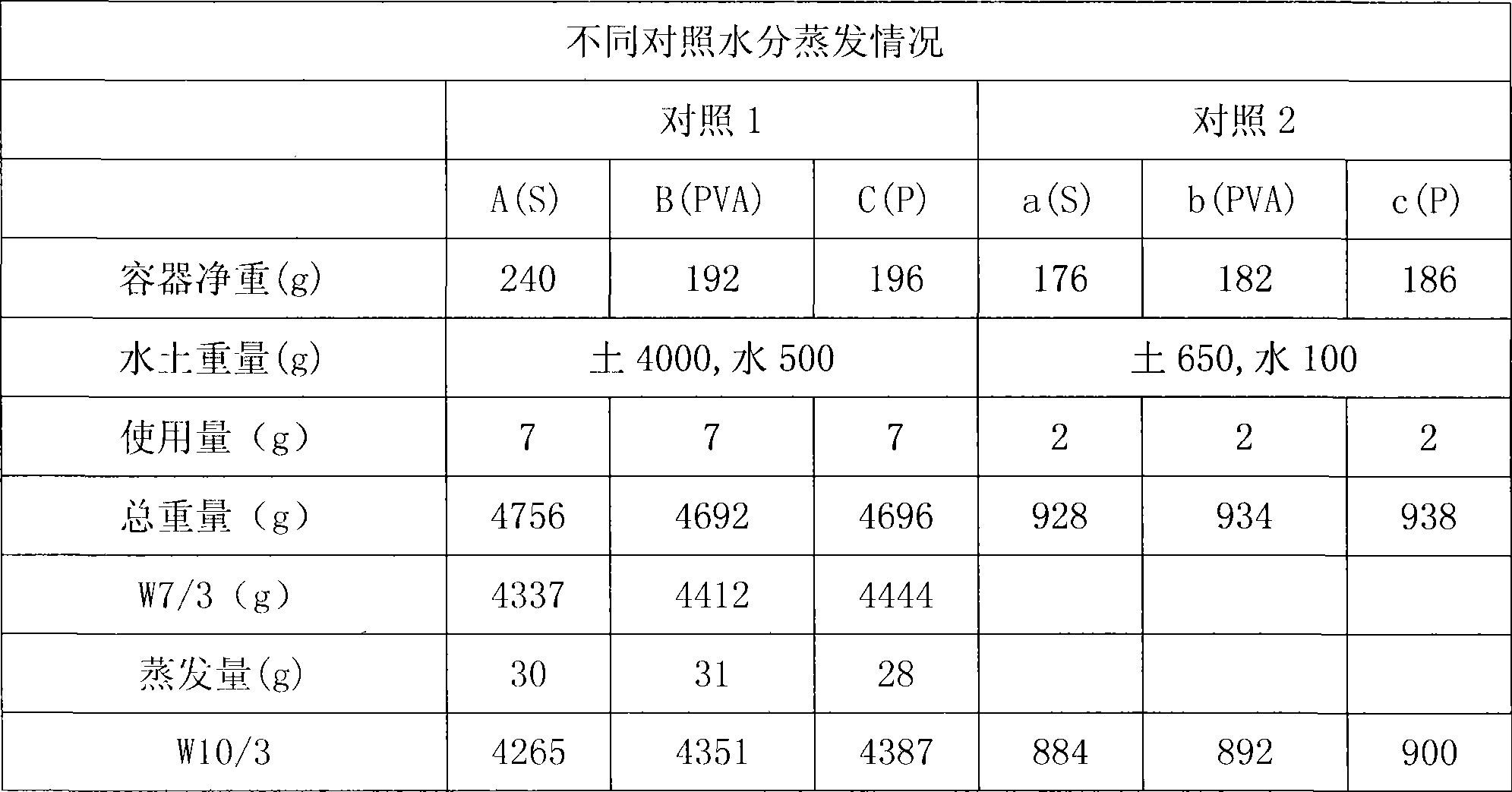

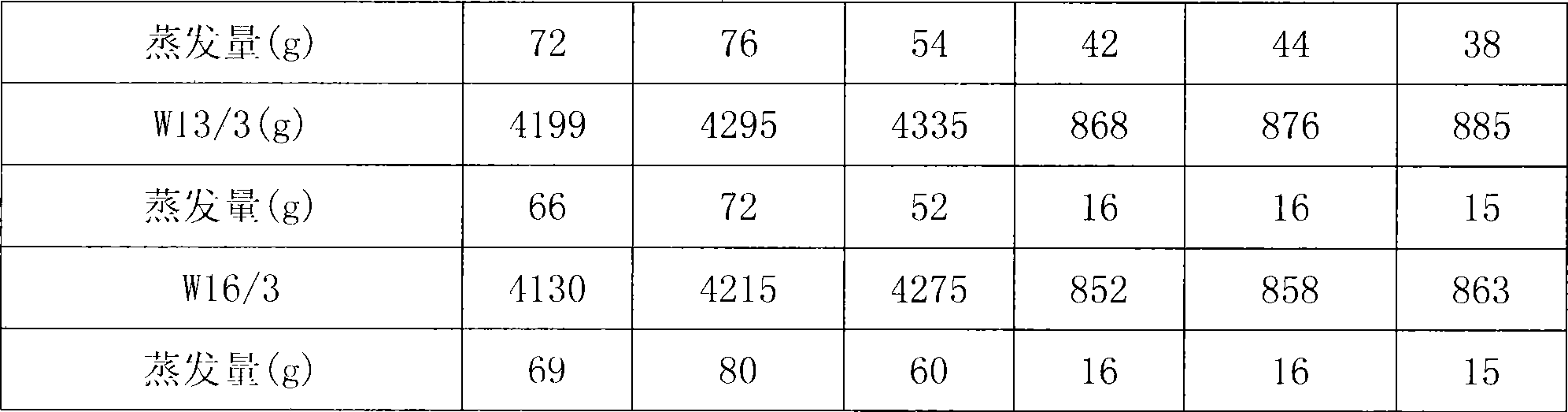

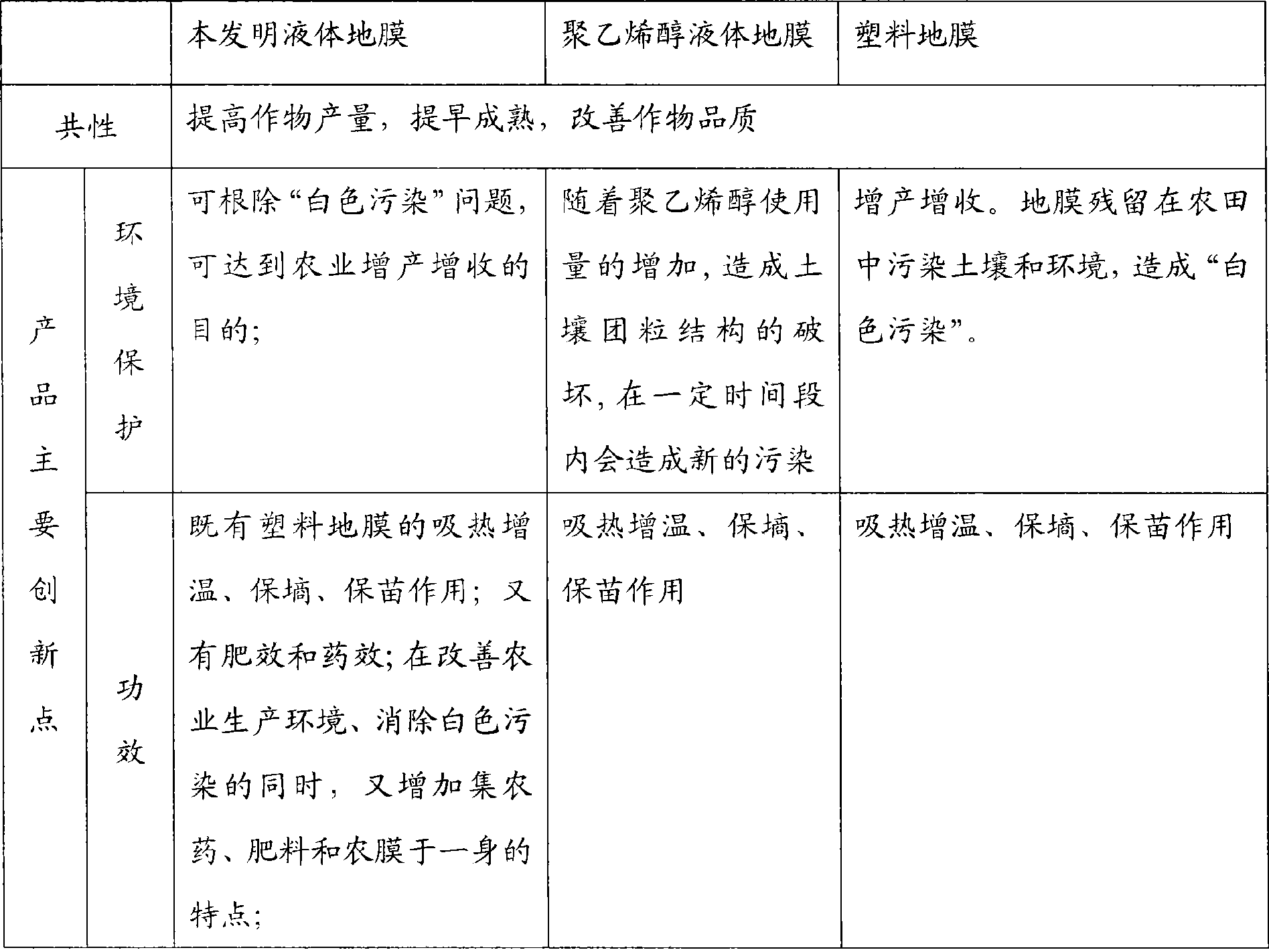

A liquid mulch and aqueous solution technology, applied in chemical instruments and methods, organic fertilizers, fertilizer mixtures, etc., can solve the problems of low cross-linking degree, large usage amount, and reduced yield, etc., to solve white pollution, inhibit water evaporation, The effect of increasing the effective accumulated temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Liquid mulch raw material composition:

[0070] Papermaking black liquor (100% dry basis) 100 parts

[0071] Lignite (100% humic acid) 5 parts

[0072] Sodium sulfite (100%) 0.5 parts

[0073] Urea (100%) 2 parts

[0074] Melamine (100%) 1.5 parts

[0075] 1% FeSO 4 1 part aqueous solution

[0076] 30%H 2 o 2 0.5 parts of aqueous solution

[0077] Liquid mulch manufacturing method:

[0078] (1) Get 100 parts of straw papermaking black liquor (calculated on a 100% dry basis), and react with 5 parts of humic acid (calculated by 100%) under stirring for 40 minutes at a temperature of 90° C. and normal pressure. Neutralize the residual alkaline substances in papermaking black liquor, and simultaneously produce crosslinking and copolymerization reactions;

[0079] (2) Add Na to the above reaction solution 2 SO 3 0.5 parts (100% calculation), at a temperature of 90°C, stirred and reacted for 30 minutes to carry out sulfonation reaction;

[0080] (3) At a tempera...

Embodiment 2

[0083] Liquid mulch raw material composition:

[0084] Straw cooking slurry (100% dry basis) 100 parts

[0085] Weathered coal (100% humic acid) 10 parts

[0086] Sodium sulfite (100%) 1 part

[0087] Urea (100%) 2 parts

[0088] Herotropine (100% discount) 1 part

[0089] 1% FeSO 4 1.5 parts of aqueous solution

[0090] 30%H 2 o 2 0.8 parts of aqueous solution

[0091] Liquid mulch manufacturing method:

[0092] (1) Take 100 parts of straw cooking slurry (calculated on a 100% dry basis), and react with 10 parts of humic acid (calculated by 100%) at a temperature of 80°C and normal pressure for 50 minutes under stirring, Neutralize the residual alkaline substances in papermaking black liquor, and simultaneously produce crosslinking and copolymerization reactions;

[0093] (2) Add Na to the above reaction solution 2 SO 3 1 part (100% calculation), stirred and reacted at a temperature of 80° C. for 30 minutes, and carried out sulfonation reaction;

[0094] (3) Add ...

Embodiment 3

[0097] Liquid mulch raw material composition:

[0098] Papermaking black liquor (100% dry basis) 100 parts

[0099] Fulvic acid (100% humic acid) 15 parts

[0100] Sodium sulfite (100%) 2 parts

[0101] Urea (100%) 4 parts

[0102] Herotropine (100% discount) 2 parts

[0103] Melamine (100%) 3 parts

[0104] 1%FeSO 4 2 parts aqueous solution

[0105] 30%H 2 o 2 1 part aqueous solution

[0106] Liquid mulch manufacturing method:

[0107] (1) Get 100 parts of straw papermaking black liquor (calculated on a 100% dry basis), and react with 15 parts of humic acid (calculated by 100%) under stirring for 60 minutes at a temperature of 100° C. and normal pressure. Neutralize the residual alkaline substances in papermaking black liquor, and simultaneously produce crosslinking and copolymerization reactions;

[0108] (2) Add Na to the above reaction solution2 SO 3 2 parts (100% calculation), stirred and reacted at a temperature of 80° C. for 30 minutes, and carried out sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com