Method for manufacturing regenerated composite boards by using waste wood

A production method and composite board technology are applied in the production field of using waste wood to manufacture recycled composite boards, which can solve the problems of incapability of recycling and application of waste wood, the overall integration of production lines, and the reduction of raw material quality of recycled composite boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

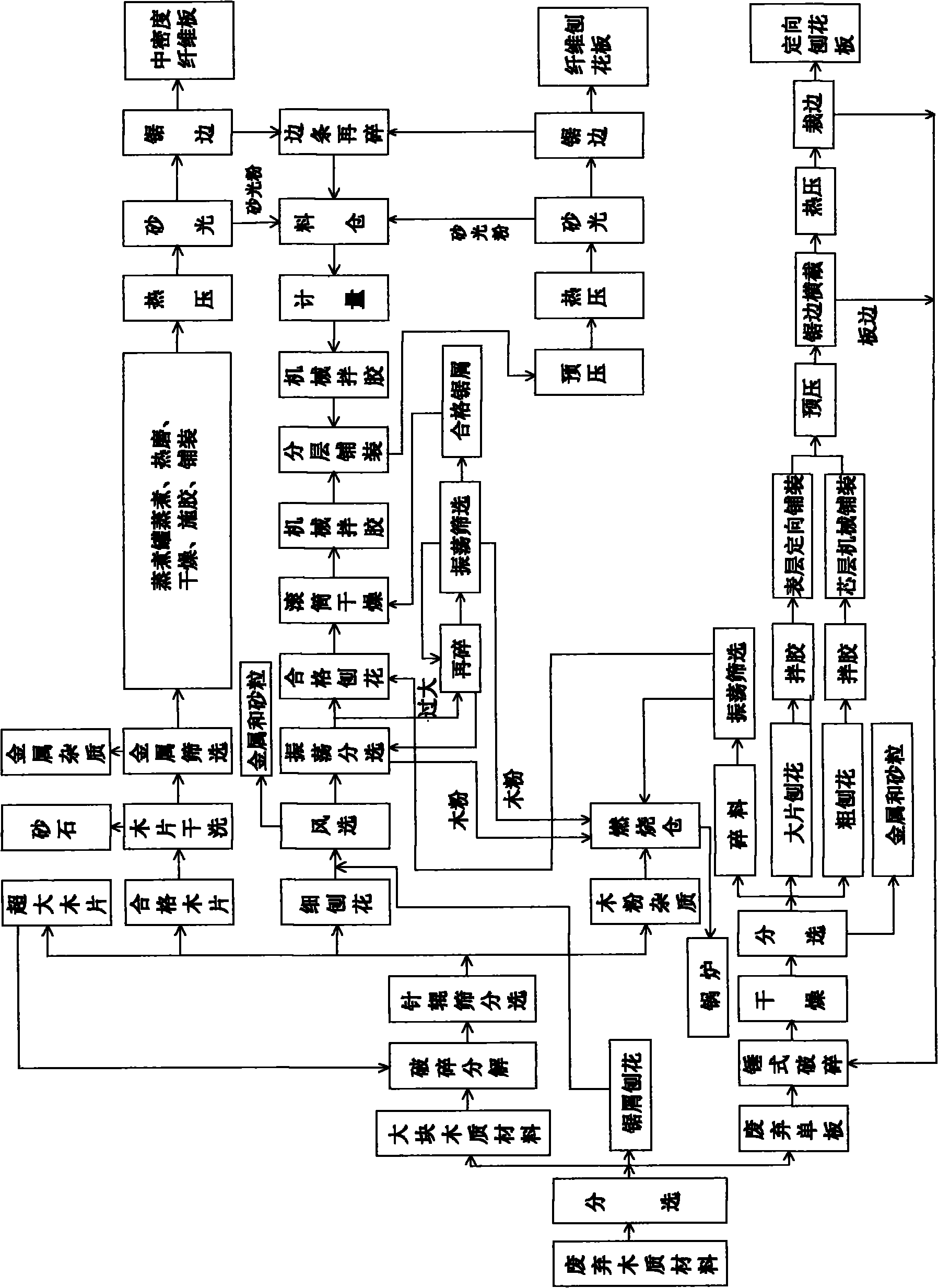

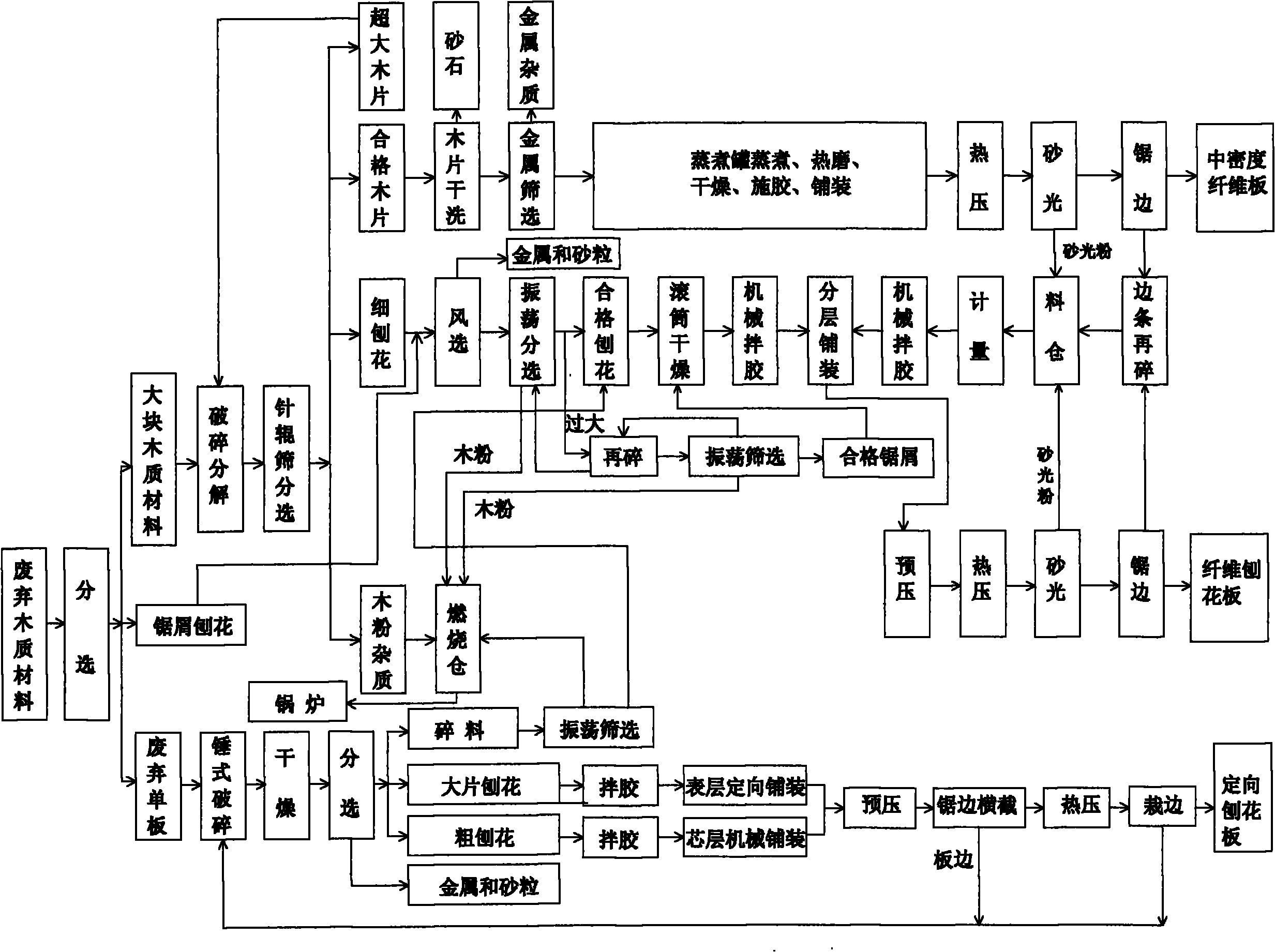

[0026] The production method of the present invention using waste wood to produce recycled composite boards will be further described in detail in conjunction with the accompanying drawings.

[0027] Such as figure 1 As shown, the production method of utilizing waste wood to manufacture recycled composite boards of the present invention comprises the following process steps:

[0028] a. Sorting waste wood materials into three categories: bulk wood materials, sawdust and shavings, and waste veneers;

[0029] b. Crushing and decomposing large pieces of wood materials;

[0030] c. Needle rolling screening to form four categories of oversized wood chips, qualified wood chips, fine shavings, and wood powder impurities;

[0031] d, oversized wood chips re-enter step b;

[0032] e. Qualified wood chips form medium density fiberboards after dry cleaning of wood chips - metal screening - cooking in a cooking tank - hot grinding - drying - sizing - hot pressing - sanding - sawing. Am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com