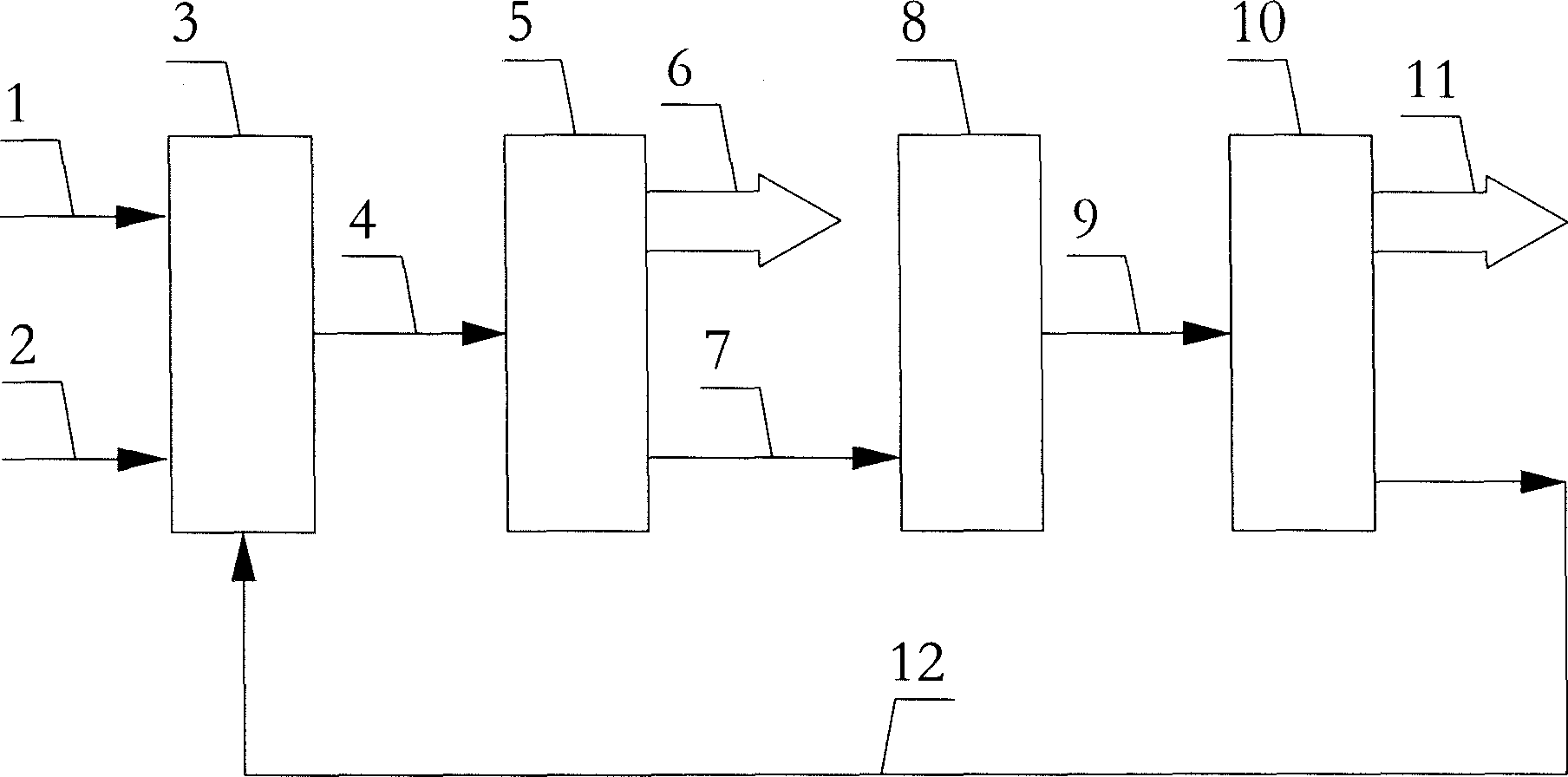

Shale oil producing process

A processing method and shale oil technology, applied in the petroleum industry, the preparation of liquid hydrocarbon mixtures, etc., can solve the problems of low product yield, immature ebullated bed process, and acid slag generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] The properties of the raw material full distillate shale oil are shown in Table 2. After mixing shale oil and hydrogen, it enters the hydrotreating reactor of the hydrotreating unit, and contacts with the hydrotreating agent and the hydrotreating catalyst. The hydrogen partial pressure is 7.0MPa, the reaction temperature is 370°C, and the total volume space velocity is 0.4h. -1 Under the operating conditions of hydrogen oil volume ratio of 1200:1, hydrotreating is carried out, and the obtained hydrogenation reaction product is separated to obtain impurity gas (H 2 S, NH 3 ), dry gas (C 1 、C 2 ), liquefied petroleum gas (C 3 、C 4 ), gasoline fraction (C 5 -160°C), diesel fraction (160-350°C) and hydrogenated heavy oil >350°C. The distribution of hydrotreated products and the main properties of the products are shown in Table 3.

[0079] The preparation method of the above-mentioned hydrogenation protecting agent and hydrogenation treatment catalyst can be found in...

Embodiment 2

[0087] Shale oil full distillate oil (same as Example 1) enters the hydroprocessing reactor after being mixed with hydrogen, contacts (same as Example 1) with hydrogenation protecting agent and hydroprocessing catalyst, is 7.0MPa, reacts at hydrogen partial pressure The temperature is 370°C and the volumetric space velocity is 0.4h -1 Under the operating condition of 1200:1 volume ratio to hydrogen oil, hydrogenation treatment is carried out, and the obtained hydrogenation reaction product is separated to obtain miscellaneous gas, dry gas, liquefied gas, gasoline fraction, diesel fraction and hydrogenated heavy oil of >350 °C. The distribution of hydrotreated products and the main properties of the products are shown in Table 5.

[0088] Hydrogenated heavy oil at >350°C is used as raw material oil for the catalytic conversion MIP-CGP process (see patents CN1232069A, CN1237477A and CN11245202A, etc.), using CGP-1 catalyst (MA is 64), the reaction temperature in the first reacti...

Embodiment 3

[0094] Shale oil full distillate oil (same as Example 1) enters the hydroprocessing reactor after being mixed with hydrogen, contacts (same as Example 1) with hydrogenation protection agent and hydroprocessing catalyst, is 15.0MPa, reacts at hydrogen partial pressure Temperature 370℃, volumetric space velocity 0.4h -1 Under the operating conditions of 1200:1 volume ratio of hydrogen and oil, hydrotreating is carried out, and the reaction products are separated to obtain products such as gasoline fraction, diesel fraction, and hydrogenated heavy oil >350°C. The distribution of hydrotreated products and the main properties of the products are shown in Table 7.

[0095] The hydrogenated heavy oil at >350°C is used as feed oil for catalytic conversion of DCC-I (patent same as Example 1) + auxiliary riser ARFCC process (see patents CN1219032C and CN1258581C), using CRP-1 catalyst (MA is 62). The heavy oil pipe reactor (DCC-I technology) has a reaction bed temperature of 545°C and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com