Patents

Literature

589 results about "Medium density fiberboard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medium-density fibreboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming panels by applying high temperature and pressure. MDF is generally denser than plywood.

Wood adhesive and method of preparing thereof

InactiveUS20100258033A1Drying rate of adhesiveLow pour pointProtein waste adhesivesStarch adhesivesHigh densityAdhesive

A wood adhesive having a) 100 weight parts of water; b) between 3 and 45 weight parts of a proteinaceous material; c) between 0.01 and 15 weight parts of an acidity regulator; d) between 0.01 and 15 weight parts of an aromatic compound; e) between 0.01 and 15 weight parts of a curing agent; f) between 0.01 and 15 weight parts of a preservative; g) between 0 and 15 weight parts of a viscosity modifier; h) between 0 and 10 weight parts of a filler; and i) between 0 and 15 weight parts of a drier. The wood adhesive can be used for preparation of plywood, blockboard, oriented strand board (OSB), flakeboard, fiberboard, veneer plywood, middle density fibreboard, high density fibreboard, hardboard, flooring substrate, LVL, and so on. A method for preparing the wood adhesive is also provided.

Owner:YANG GUANG +1

Method of manufacturing composite board

InactiveUS20060145384A1Improve flow characteristicsIncreased flexural modulusMouldsFrozen sweetsFiberThermoplastic

A composite board is made from waste medium density fiber (MDF) board or waste particle board that includes solid urea formaldehyde. The waste board is chopped and milled into particles having a size between 20 mesh and 150 mesh, creating a waste flour. After removing moisture from the waste flour, the dried waste flour is mixed with a thermoplastic to bind and encapsulate the waste flour. Internal lubricants are added to improve the flow characteristics of the blended material, and external lubricants are added to present sticking of the mixture to an extruder or mold. Mineral fillers are added to improve the flexural modules of the composite board, and a plasticizer can be added to improve the physical properties or mechanical characteristics of the mixture. An ultraviolet absorber, a biocide, and a pigment can also be added. The blended material is extruded or molded into a desired shape. When cooled, the thermoplastic hardens to form a solid composite board.

Owner:MASCO CABINETRY

Making process of E1/E0 level green artificial plate

InactiveCN1526528AThe effect of free formaldehyde content is obviousGuarantee market supplyWood veneer joiningFlat articlesFiberHigh density

The present invention discloses one kind of making process of E1 / E0 level environment protection artificial plate. After plain plate with free formaldehyde releasing amount greater than or equal to E2 level is made with common urea resin adhesive, the plain plate is processed through ammonia vacuum process to lower the free formaldehyde releasing amount to E1 / E0 level. According to the density and initial formaldehyde releasing amount of the plain plate, the ammonia consumption and formaldehyde lowering time are regulated to control the processing effect. The said process has stable product quality and low cost, and is suitable for various artificial plates, including plywood, medium density fiber plate, high density fiber plate and shaving board.

Owner:NANJING FORESTRY UNIV

Method for producing wood fibre composite products

A process for producing a thermoformable fibre-plastics composite product comprising lignolcellulosic or natural fibres, particularly but not exclusively useful as an intermediate product in subsequent manufacture, comprises conveying the fibres in a dry or wet air stream and applying to the fibres a thermoplastic binding agent, and forming the fibres into a solid or semi-solid product such as a panel, which is thermoformable. In at least a preferred embodiment the process may be carried out in known plant for manufacture of medium density fibre board.

Owner:NEW ZEALAND FOREST RES INST

Agronomic crop stalk medium density fiberboard using natural rubber and manufacturing method therefor

InactiveCN101367227AIncrease profitInhibition releaseFlat articlesDomestic articlesFiberStearic acid

The invention provides a crop straw medium density fiberboard by natural gum. Raw materials of the medium density fiberboard comprise crop straw fiber, a bonding agent, a waterproof and lubricating agent and a flame retardant, wherein the bonding agent is natural gum and comprises plant gum and animal gum; the waterproof and lubricating agent is natural wax, stearic acid or stearate; and the flame retardant is non-toxic and harmless flame retardant. The mixture ratio for all the raw materials by weight percent is: 75 to 93 percent of the crop straw fiber, 1 to 8 percent of the bonding agent (dried), 0.5 to 8 percent of the waterproof and lubricating agent, and 5.5 to 23.5 percent of the flame retardant. All the raw materials are produced into a finished product through mixing, sizing, spreading, prepressing, hot pressing and edge cutting; and microwave is used for auxiliary heating in the hot pressing phase. The crop straw medium density fiberboard by the natural gum can realize complete degradation under natural condition after the medium density fiberboard is abandoned or destroyed without any nonreversible destruction to the environment, so the production and application of the crop straw medium density fiberboard realize complete sustainability and recyclability, and have significant realistic and historic significance.

Owner:张东旭

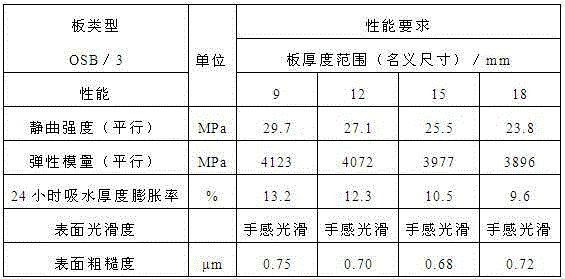

Surface-decorated oriented strand board and preparation process thereof

ActiveCN104626292AHigh strengthGood dimensional stabilityLaminationLamination apparatusFiberParticle board

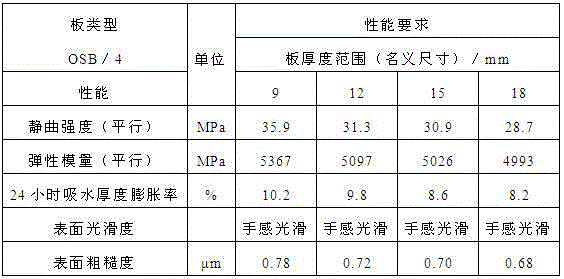

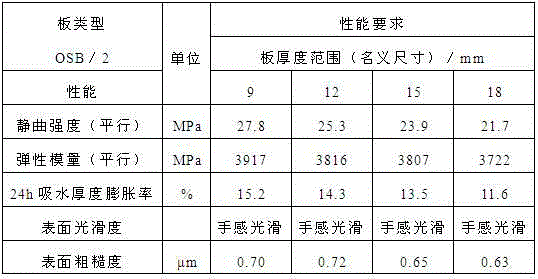

The invention relates to a surface-decorated oriented strand board and a preparation process of the surface-decorated oriented strand board. The surface-decorated oriented strand board comprises a core layer and a surface layer. Rotary cut veneer leftovers left in the plywood production process are selected as raw materials of the core layer. Sawdust, wood shavings, waste fibers and sanding powder produced in the production process of glued-laminated timber, core-boards, particle boards or medium-density fiberboards are selected as raw materials of the surface layer. The raw materials are subjected to drying, screening, gluing, laying, plate blank sawing and cutting and hot-pressing, and then the surface-decorated oriented strand board can be manufactured. The static bending strength of the oriented strand board in the parallel direction can reach 22-30 MPa, the elasticity modulus of the oriented strand board can reach 3500-4800 MPa, and the surface roughness of the oriented strand board is less than 0.8 micron. The surface-decorated oriented strand board can be directly processed into a decorative surface and can also be widely used for replacing artificial boards such as plywood, the core-boards, the particle boards and the medium-density fiberboards.

Owner:寿光市鲁丽木业股份有限公司

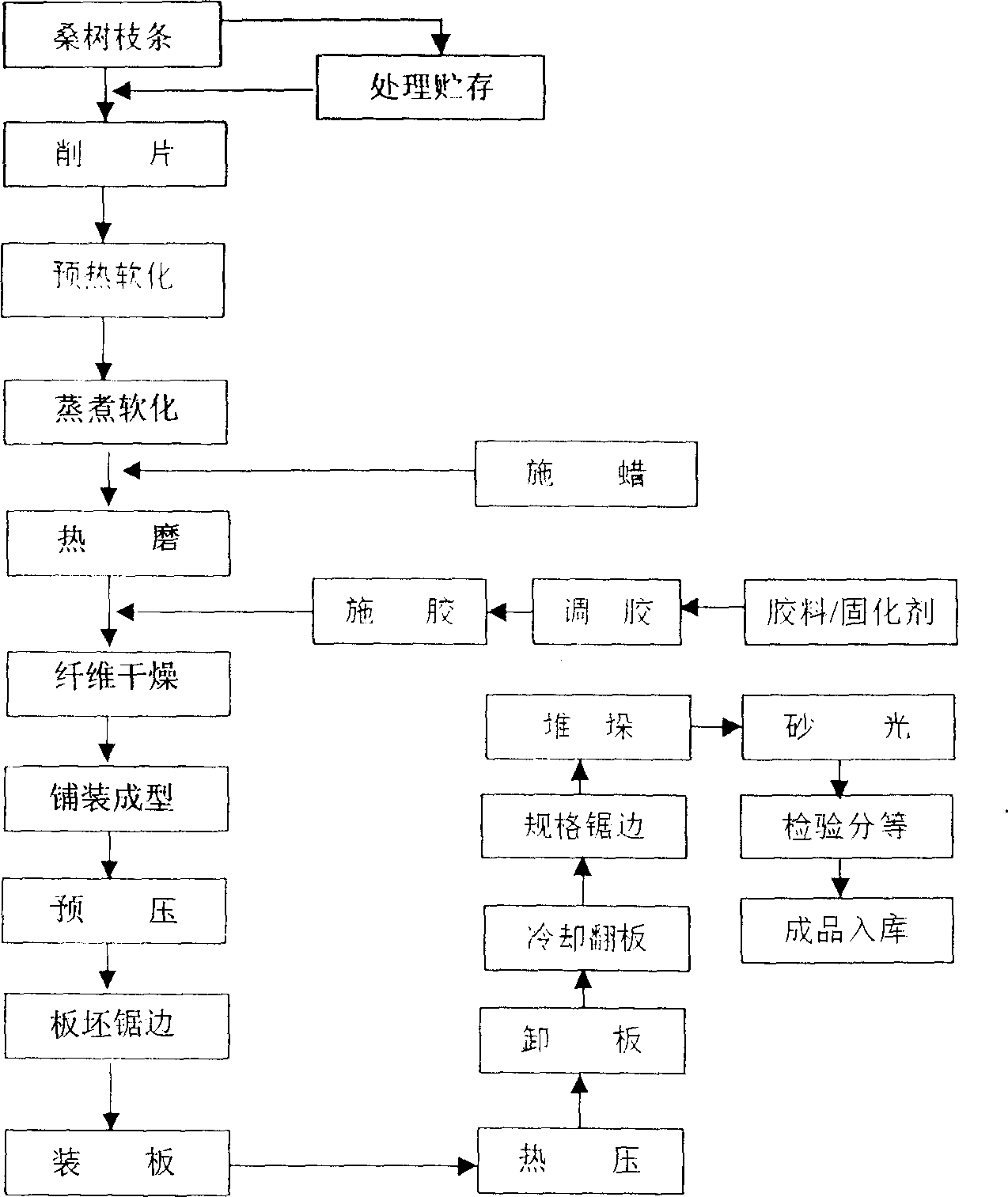

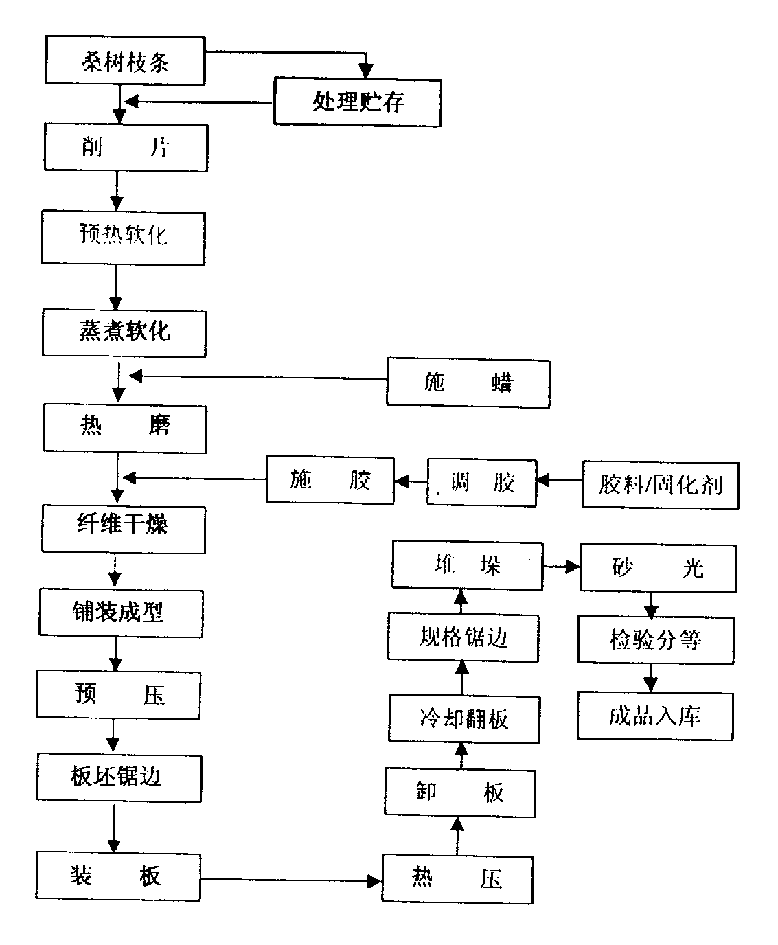

Middle-density fibre board and its production method

InactiveCN1334181ASave resourcesImprove protectionWood working apparatusDomestic articlesFiberAdhesive

A middle-density fibre board is made from mulberry fibres, water-proofing agent and adhesive through cutting mulberry twigs into piece, steaming for softening, adding water-proofing agent, hot grinding, adding adhesive, drying, spreading, pre-pressing, removing edges by sawing and hot pressing. Its advantage is use of cheap mulberry twigs as raw material for low cost.

Owner:蒋贵华

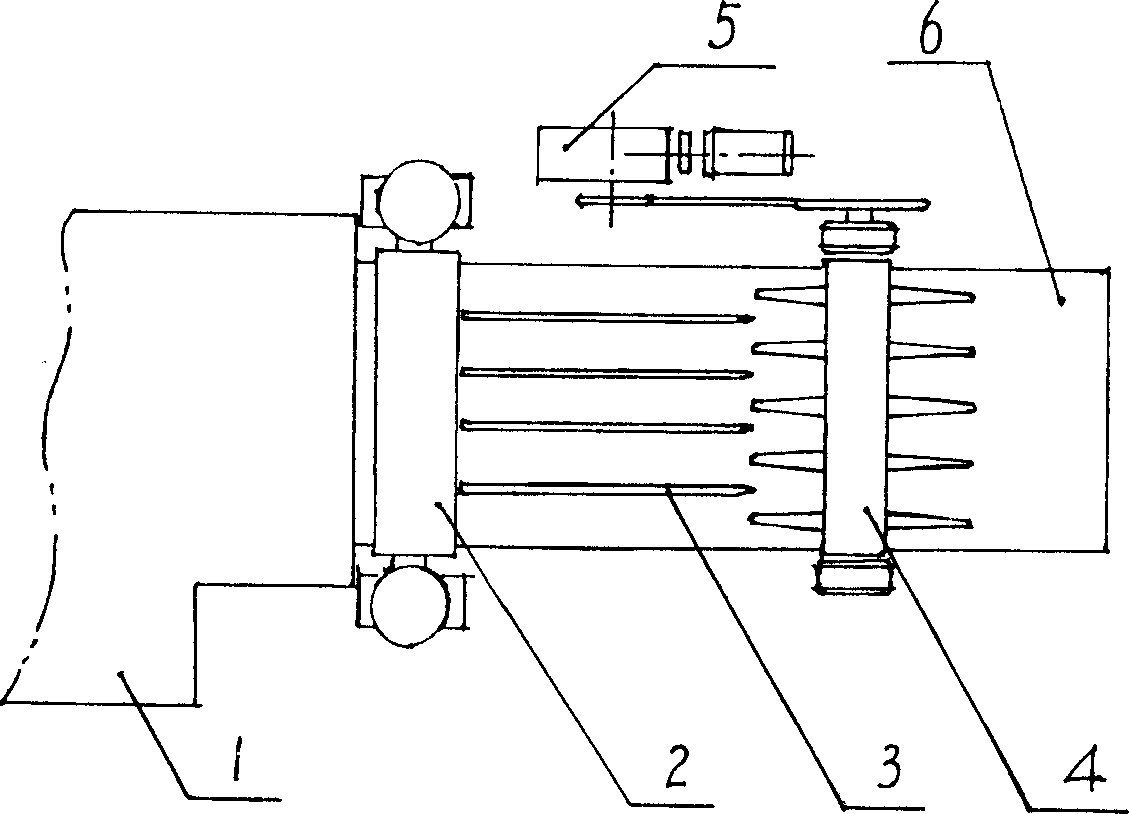

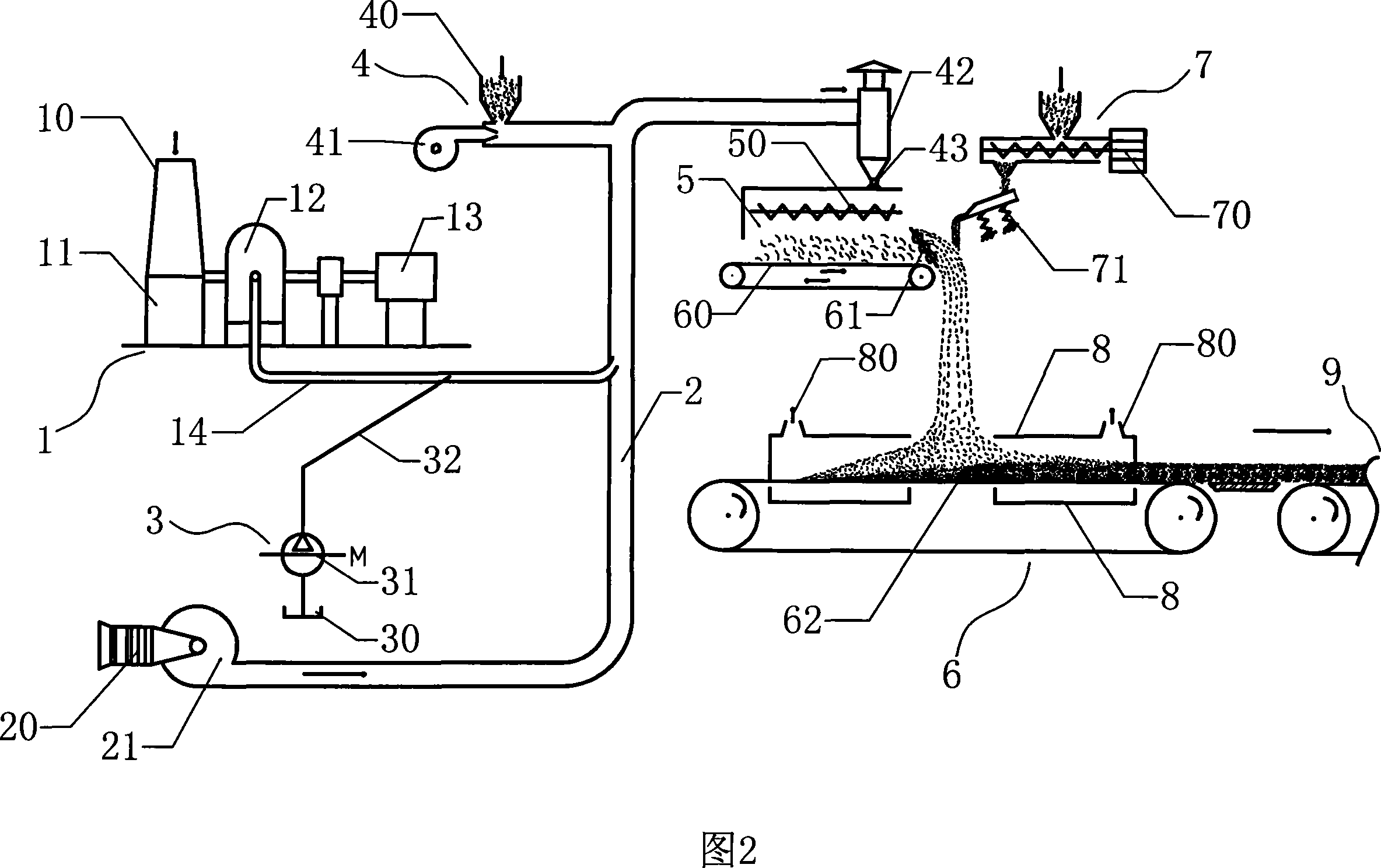

Low glue consumption method for making medium density fiberboard

InactiveCN102514071AGuaranteed mechanical propertiesReduce the amount of sizingWood working apparatusFlat articlesFiberFiberboard

The invention relates to a low glue consumption method for making a medium density fiberboard, which comprises the following steps of: material preparation, i.e. processing the raw materials of small dimension wood, brush wood and the like into wood chips by adopting a drum chipper; fiber preparation, i.e. sending qualified wood chips to a wood chip cooking pot through a belt conveyor, introducing papermaking waste liquid into a boiler to carry out cooking softening treatment after filtering the papermaking waste liquid, sending the wood chips which are cooked and preheated into a thermofiner to carry out mechanical separation through a feeding screw, and filling molten wax before the wood chips enter a grinding chamber body of the thermofiner, so that after the wood chips are separated into the fibers, the wax is uniformly distributed on the surfaces of the fibers; sizing and drying of the fibers, wherein a production process of firstly sizing and then drying is adopted; pavement and formation of a board blank; hot-press forming, i.e. sending the single board blank into a hot press to carry out hot pressing through a loader, so that under the combined action of heat and pressure, moisture in the board blank is gasified and evaporated, the density of the board blank is improved, glue is cured and a waterproof agent is redistributed; and post-processing, i.e. finally, sending the obtained product into a sanding machine to carry out surface processing. The low glue consumption method for making the medium density fiberboard is simple and convenient.

Owner:广西新凯骅实业集团股份有限公司

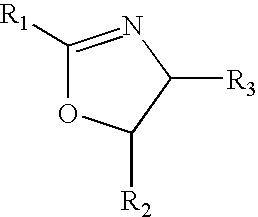

Wood Adhesives Comprising Protein and Oxazoline Polymer or Resin

InactiveUS20100069533A1Improve curing speedEasy curingProtein adhesivesPaper coatingLignosulfonatesMedium density fiberboard

The present invention provides wood adhesive binder compositions comprising a naturally occurring protein component, e.g. soy flour, and an oxazoline-functional group containing polymer or resin component, the two components in a solids weight ratio of from 60:40 to 98:2. As formulated, the compositions may comprise from 40 to 98 wt. % of the naturally occurring protein component, preferably, 50 wt. % or more. Preferably, the wood adhesive binder further comprises lignins or lignosulfonate. Where the wood adhesive binder compositions comprise lignins or lignosulfonates, they remain more fluid and workable at a higher pH such as, for example, 4.5 or more. Any of the compositions may be formulated with one or more in situ acid generator compound to insure more rapid cure on heating or pressing. The binder enables the provision of mechanically sound, low cost and biodegradable composites, such as, medium density fiberboard (MDF).

Owner:BRADY JEAN M +4

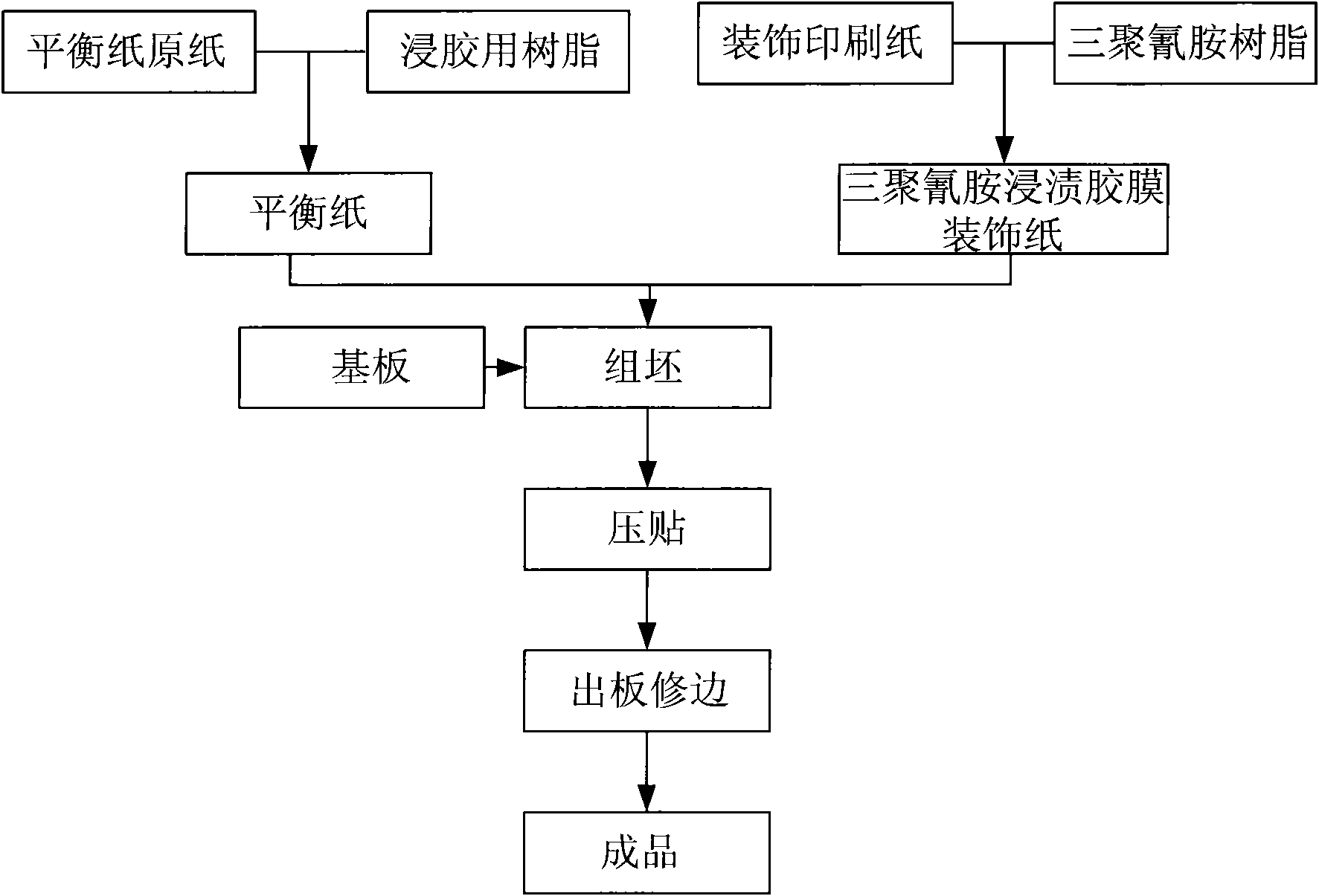

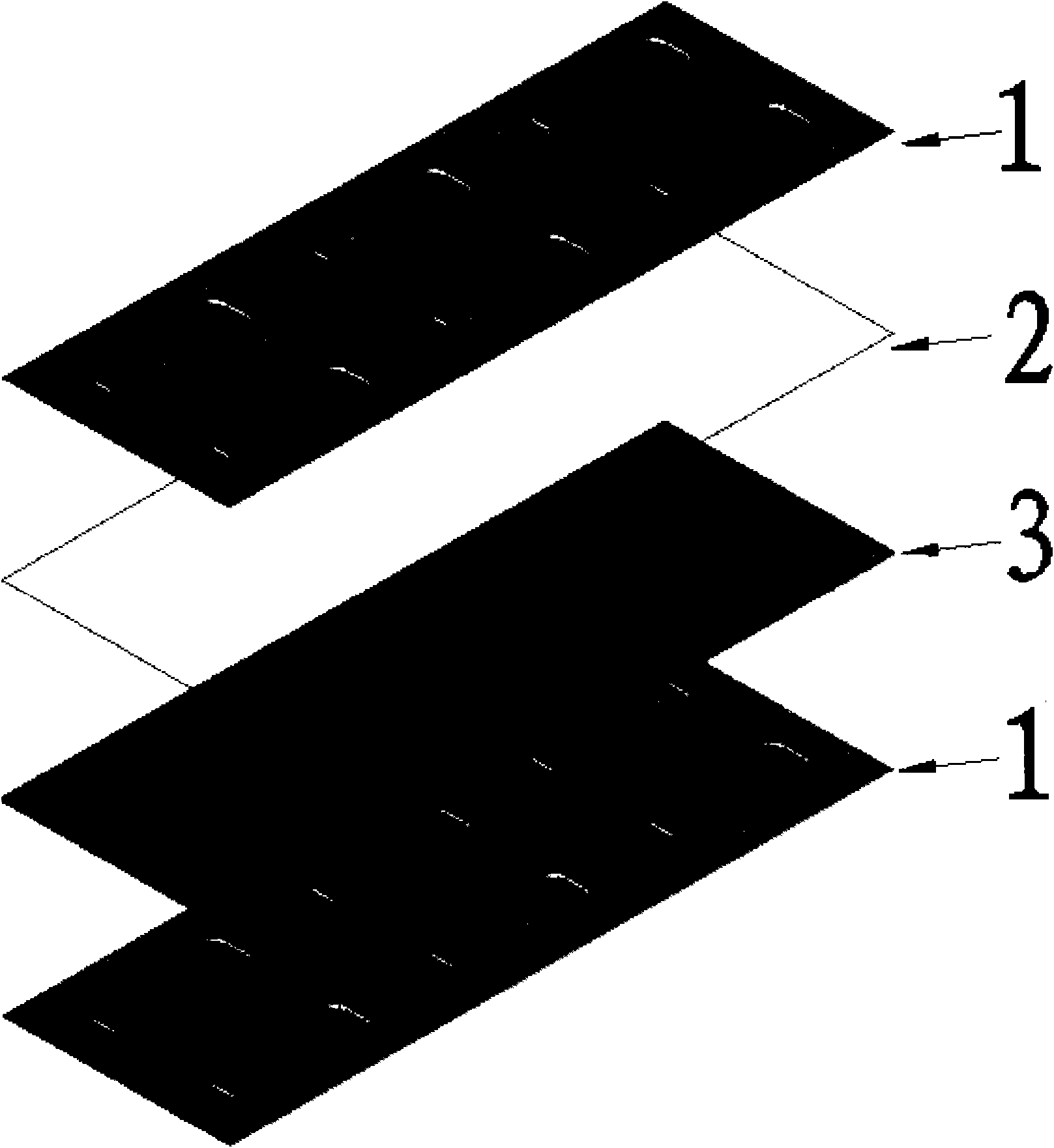

Novel solid wood multilayer veneer panel and production method thereof

InactiveCN101648393AImprove impact resistanceLow costWood veneer joiningWood layered productsSolid woodMedium density fiberboard

The invention provides a novel solid wood multilayer veneer panel and a production method thereof. A substrate adopts a medium density fiberboard, a flakeboard, a wood board with a single layer structure or a plywood board with a laminated structure having more than three layers; a panel comprises balance paper and melamine-impregnated adhesive film decorative paper; and the substrate is attachedwith the balance paper and the melamine-impregnated adhesive film decorative paper in sequence. The production process comprises the following steps of: selection, gluing, hot pressing, natural drying, trimming, inspection and the like. After the substrate is covered with the balance paper and the melamine-impregnated adhesive film decorative paper, the hot pressing is carried out between an uppertemplate and a lower template of a hydraulic machine. The temperature of the upper template and the lower template is between 90 and 150 DEG C, the pressure is between 200 and 600kg / cm <2>, and the pressing time is between 1 and 20 minutes. A layer of the balance paper is additionally arranged between the substrate and the decorative paper to ensure that the surface of the substrate does not needa whole piece of high-quality veneer, which not only reduces cost and defective rate, but also greatly improves impact resistance of the veneer panel.

Owner:吴根水

Novel high sealing property unsaturated polyester white primer, and preparation method thereof

The present invention discloses a novel high sealing property unsaturated polyester white primer, and a preparation method thereof. The unsaturated polyester white primer provided by the present invention comprises, by weight, 40-45% of unsaturated polyester PE resin, 0.2-0.3% of an antifoaming agent, 0.3-0.5% of a wetting dispersant, 0.2-0.3% of a polyacrylate leveling agent, 0.1-0.2% of an anti-green agent, 4-6% of organic bentonite pre-clotting slurry, 0.2-0.8% of fumed silica, 3-7% of zinc stearate, 3-9% of 1250 mesh pulvistalci, 7-11% of 800 mesh pulvistalci, 13-21% of ground calcium carbonate, 11-17% of rutile titanium dioxide, 2-5% of a nitrocellulose solution and 1-3% of n-butyl acetate. The unsaturated polyester PE primer provides especially good sealing property for the low density medium density fiberboard, wherein the low density medium density fiberboard is not subjected to a sealing treatment or is treated bad. In addition, the unsaturated polyester PE primer has characteristics of excellent caving resistance, excellent sagging resistance, short polishing time, good polishing property, strong interlayer adhesion, and can be applicable for the comprehensive primer solution schemes for different environments, various processes and plates.

Owner:恒昌涂料(惠阳)有限公司

Wood adhesive and method of preparing thereof

InactiveUS8057892B2Improve waterproof performanceAccelerate the drying rate of an adhesive coatingProtein waste adhesivesLayered productsHigh densityPreservative

A wood adhesive having a) 100 weight parts of water; b) between 3 and 45 weight parts of a proteinaceous material; c) between 0.01 and 15 weight parts of an acidity regulator; d) between 0.01 and 15 weight parts of an aromatic compound; e) between 0.01 and 15 weight parts of a curing agent; f) between 0.01 and 15 weight parts of a preservative; g) between 0 and 15 weight parts of a viscosity modifier; h) between 0 and 10 weight parts of a filler; and i) between 0 and 15 weight parts of a drier. The wood adhesive can be used for preparation of plywood, blockboard, oriented strand board (OSB), flakeboard, fiberboard, veneer plywood, middle density fiberboard, high density fiberboard, hardboard, flooring substrate, LVL, and so on. A method for preparing the wood adhesive is also provided.

Owner:YANG GUANG +1

Ultraviolet light solidifying powdery paints, producing method and applying method thereof

InactiveCN101186780AImprove flatnessMeet the protection requirementsPretreated surfacesPowdery paintsFiberUltraviolet lights

Provided are an ultraviolet-curing powder coating and processes for manufacture and painting, which relate to a manufacturing technique of the powder coating and an operation method. Unsaturated polyester resin, photoinitiators and flatting agents are put into an extrusion machine to be melted and mixed, after being frozen and broken, the unsaturated polyester resin, the photoinitiators and flatting agents are cribrated and classified, finally being packed, wherein the unsaturated polyester resin is provided with (methyl) acrylic acid of double bonds. The ultraviolet-curing powder coating manufactured through the process resolves the problem of the products of the existing technique that the products are not high-temperature resistant and the powder-painting problem of thick substrates. The ultraviolet-curing powder coating increases the curing speed of the powder coating, the leveling property of paint film is good, and chemical resistance and other mechanical properties are also good. The ultraviolet-curing powder coating can be widely used in the painting of wood, plastic, paper, preassembled elements, truck evaporators and the like, in particular to thermosensitive base materials of medium density fiber board (MDF), plastic, paper, soldering elements, assembly parts of electronic components and the like.

Owner:扬州三川实业有限公司

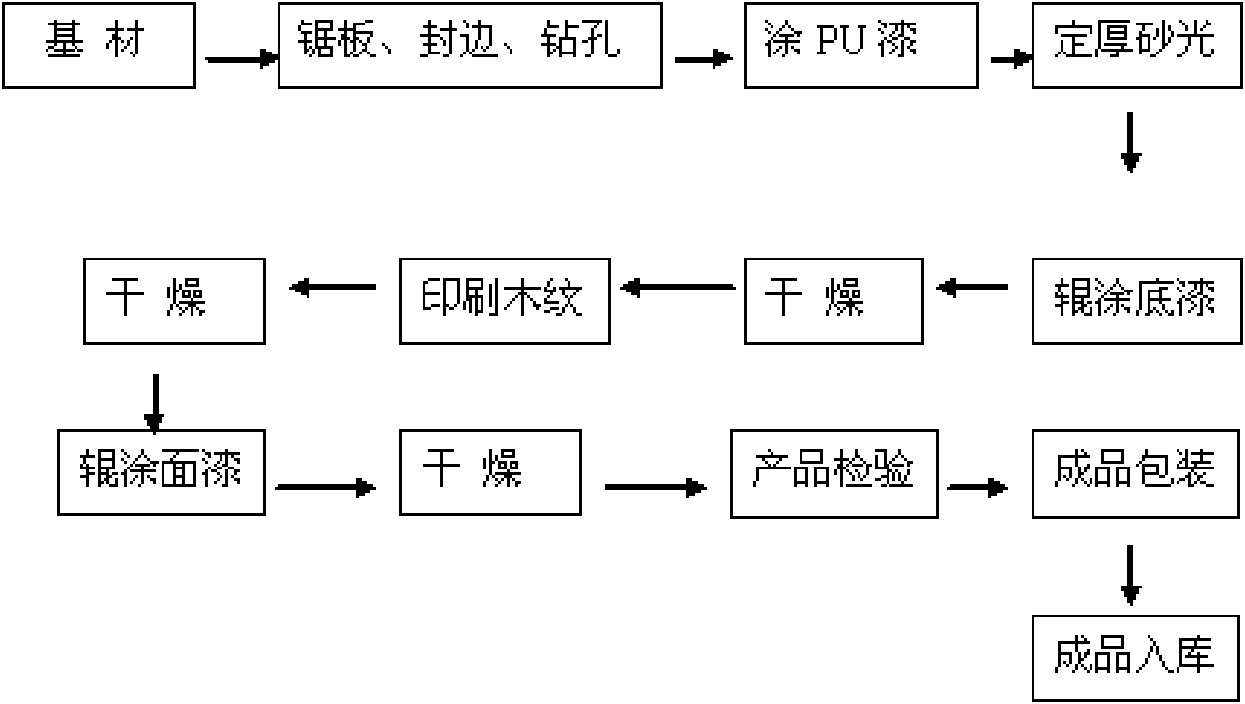

A graining roll-coating production-line method for waterborne coating material of wooden furniture

The invention relates to a graining roll-coating production-line method for carpentry waterborne coating material on medium density fiber board. The invention is characterized by the following steps: (1) processing raw material; (2) roll coating waterborne white primer; (3) roll coating middle-coating primer; (4) roll printing to color; (5) roll coating fining varnish. The invention is advantageous in that the environment-friendly waterborne carpentry material and the novel coating method are applied on low-priced heavy density fiberboards to produce high-quality furniture boards with graining coating effect, provided with low coating consumption, high coating effectiveness and low coating cost]

Owner:上海展辰涂料有限公司

Medium density fiberboard with low burst size of methanal and producing method thereof

InactiveCN101214679AReduce releaseRelease reduction effectWood working apparatusAldehyde/ketone condensation polymer adhesivesWood fibreTrapping

The present invention discloses a medium-density fibreboard with low formaldehyde-discharging quantity and a production method thereof. The dosage of E2 grade urea-formaldehyde resin is 165 kg / m<3> to 175 kg / m<3>, and the dosage of high-efficiency formaldehyde trapping glue is 5 percent to 20 percent of the dosage of the E2 grade urea-formaldehyde resin and is mixed with the E2 grade urea-formaldehyde resin with a molar ratio of 1.05 to 1.15 in order to form adhesive, which is then applied into wood fibres. Without changing the hot-pressing and hot-grinding techniques in the production of E2 grade medium-density fibreboards, the applied adhesive dosage of the urea-formaldehyde resin of the E2 grade medium-density fibreboards and the dosage of waterproof agent, the discharging quantity of medium-density fibre formaldehyde can be reduced by 50 percent to 80 percent, thus realizing the standard requirement of environment-friendly E1 grade and E0 grade artificial boards. Compared with the E2 grade medium-density fibreboards produced with the same equipment and production technique, the physical mechanical property of the E1 grade and E0 grade medium-density fibreboards is notably improved, the production cost is low, the product quality is stable, the antiaging property is excellent, and the product quality measures up to and is better than standard high-class products and E1 grade requirements.

Owner:GUANGXI FENGLIN WOOD IND GRP CO LTD

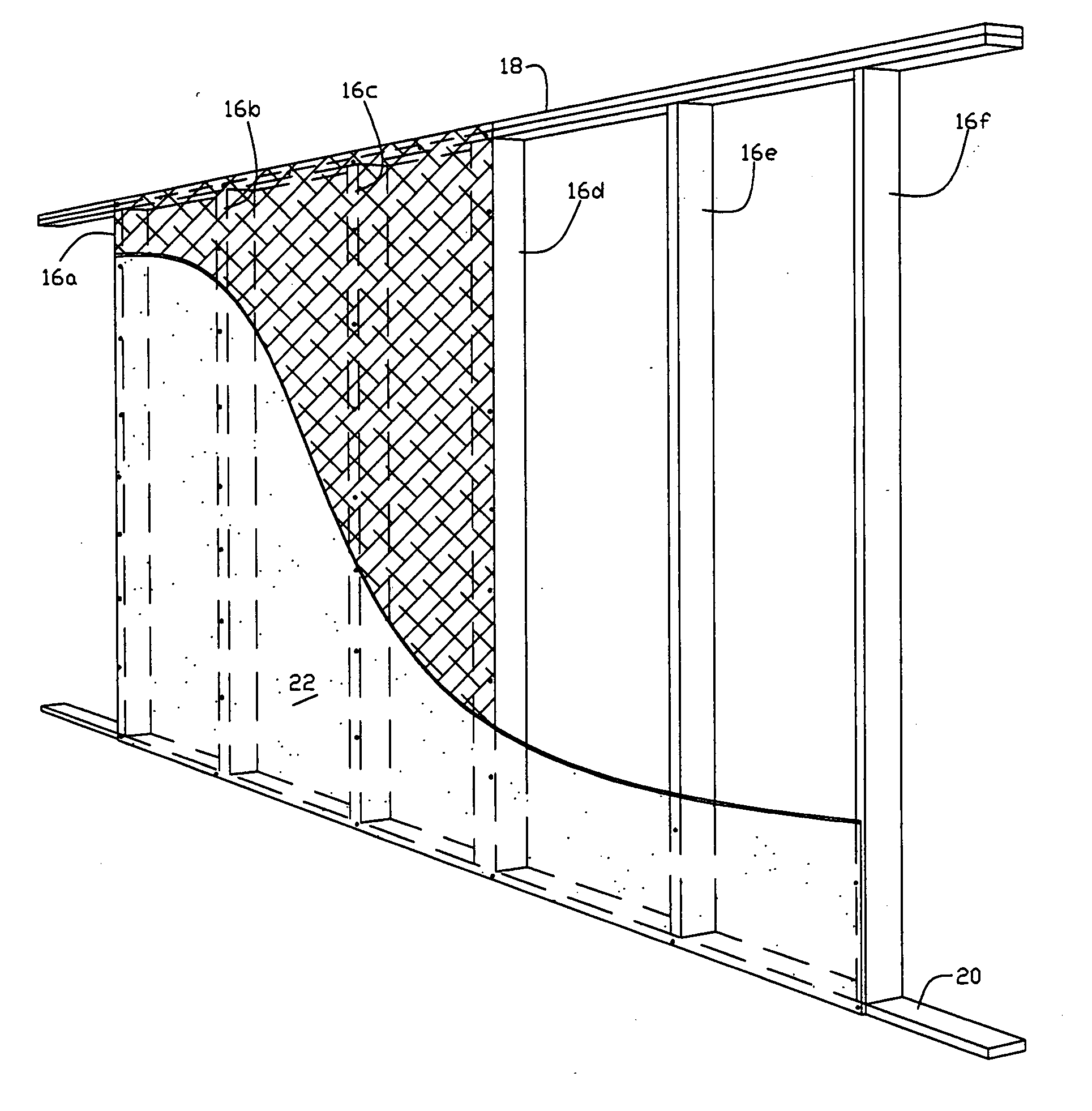

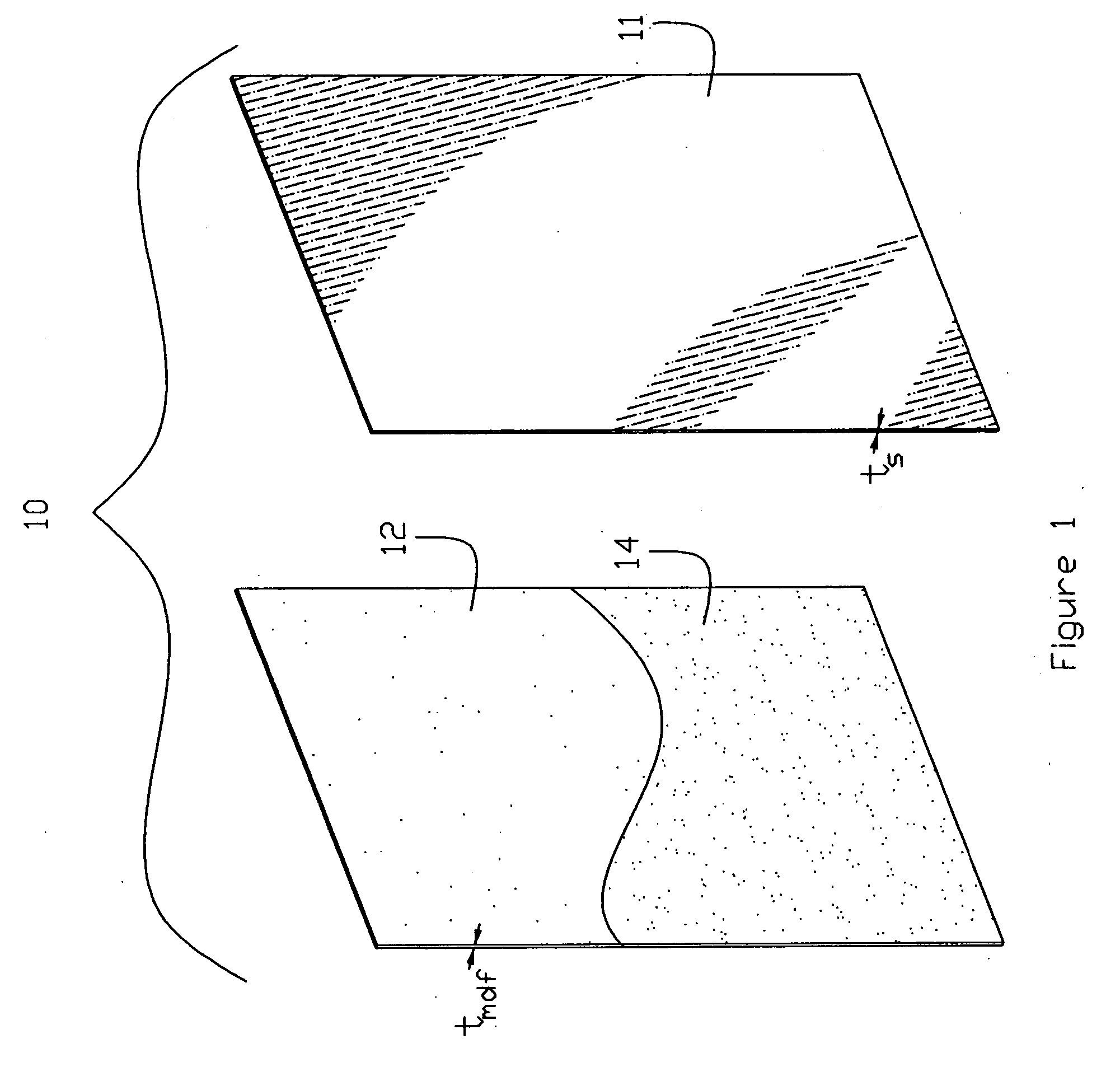

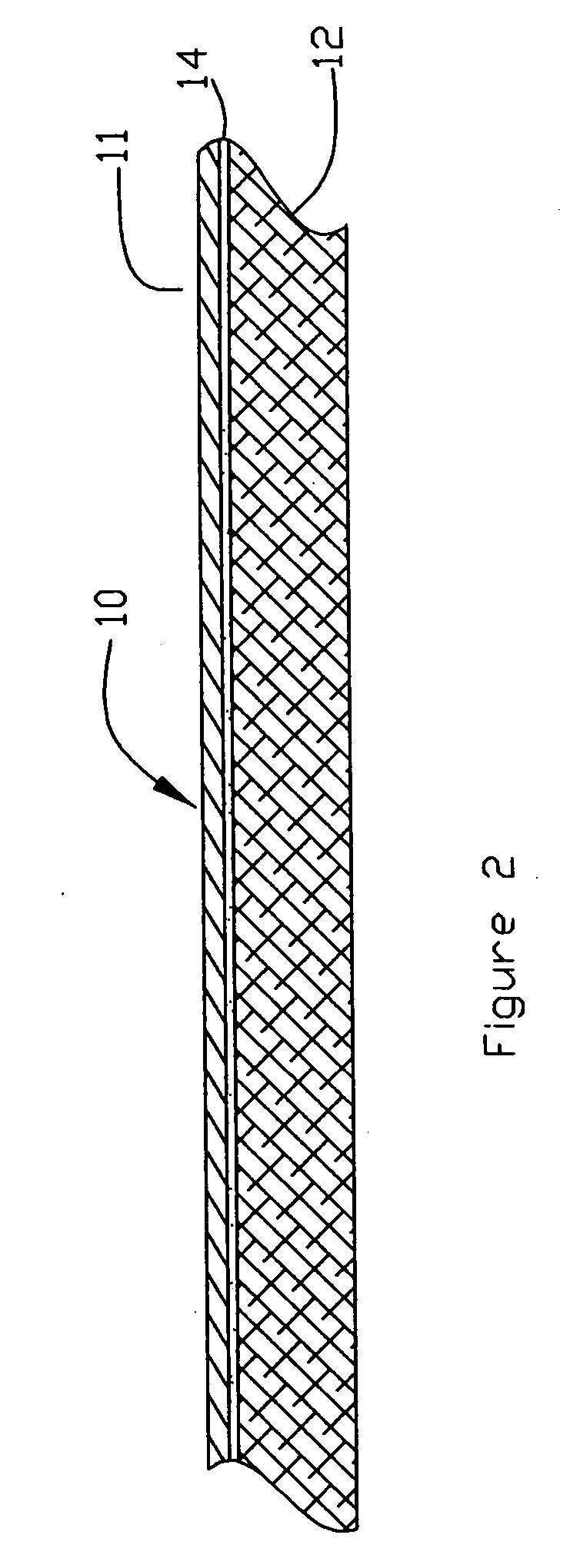

Method of framing a building shear wall structure compatible with conventional interior or exterior finishing materials and subsurface panel for use therewith

A shear wall structure is formed on a building wall or section thereof designed to accommodate anticipated wind or seismic shear loads by initially securing one or more subsurface shear panels on the interior or exterior sides of the wood or steel framing studs. Each shear panel consists of a thin steel sheet (0.015″ to 0.060″ thick) laminated to a thin rigid sheet material such as medium density fiberboard ( 1 / 16″ to ¼″ thick). Subsequently, the shear panels are covered with a conventional interior (e.g., drywall panels) or exterior (e.g., plaster) finishing materials.

Owner:SPECIALTY HARDWARE LLC

Method for preparing adhesive for grade-E0 medium density fiberboards

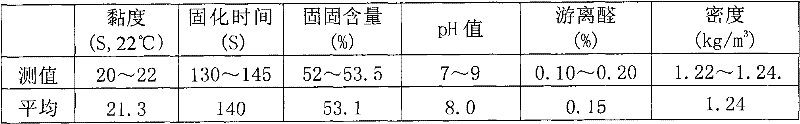

InactiveCN102134468ALow free formaldehyde contentModerate curing timeAldehyde/ketone condensation polymer adhesivesAdhesivePolyvinyl alcohol

The invention provides an adhesive for grade-E0 medium density fiberboards. The raw materials of the adhesive include formaldehyde, polyvinyl alcohol, urea and tripolycyanamide. The production process of the adhesive comprises: firstly, adding all formaldehyde into a reaction kettle, regulating the pH value of formaldehyde solution to 7.5 to 8.5 by using sodium hydroxide solution, adding the 40 to 50 percent of polyvinyl alcohol and urea and adding 80 to 90 percent of tripolycyanamide and adding the 10 to 20 percent of urea; secondly, adjusting the pH value to 5 to 6 by using formic acid, reacting for 20 to 30 minutes till a cloud point, regulating the pH value to 705 to 8.5 with caustic soda solution, and adding the 10 to 20 percent of tripolycyanamide and 20 to 30 percent of urea; and finally, adding 10 to 20 percent of urea, regulating the pH value of the adhesive to 6.6 to 7.5, and discharging. The adhesive has the advantages that: the free formaldehyde content is very low, and the manufactured medium density board is of grade E0; the curing time is proper, the storage stability is high, and the normal-temperature storage period is about 1 month; and the manufactured medium density board has high internal combining strength and high waterproof and dampproof performance.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

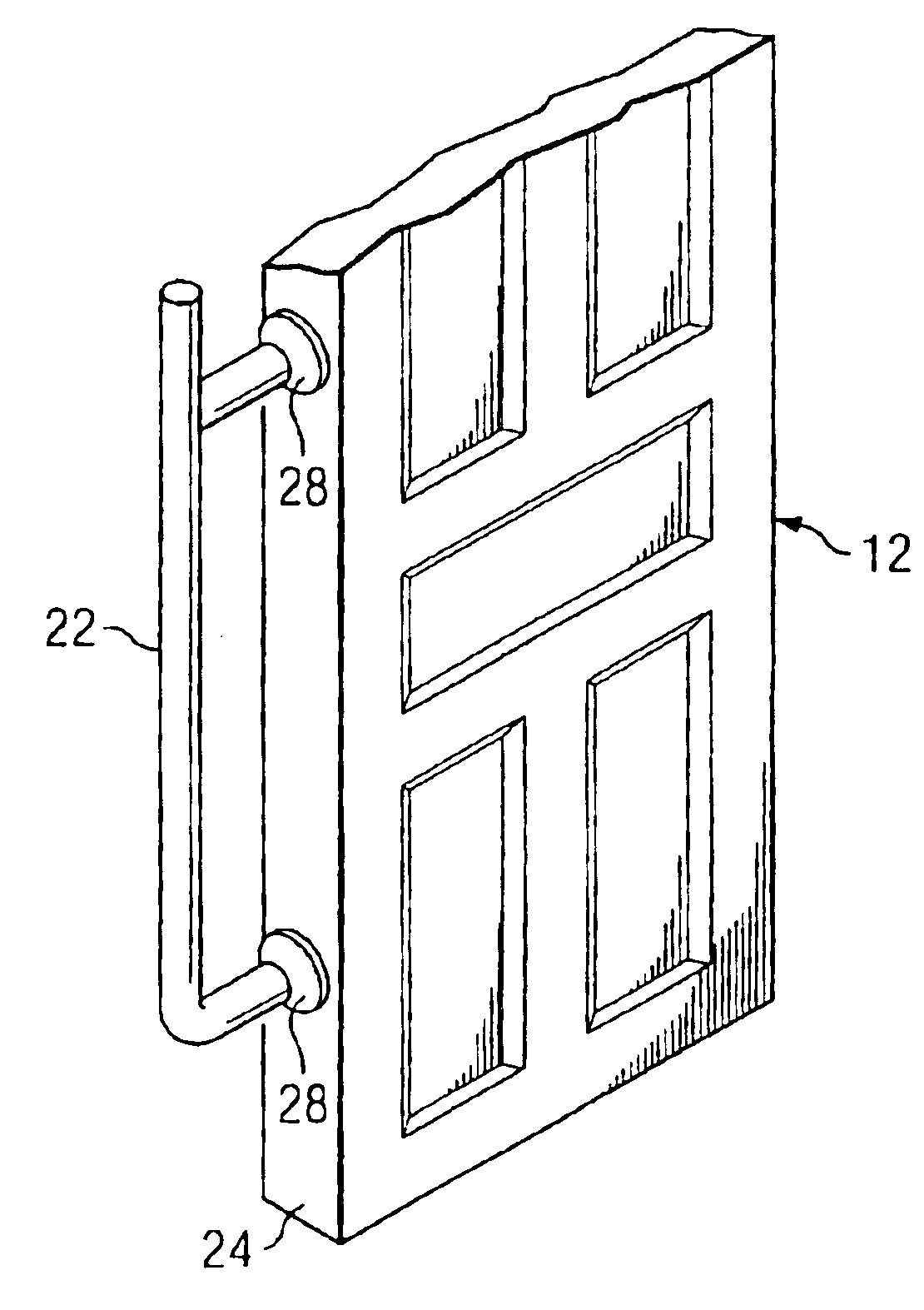

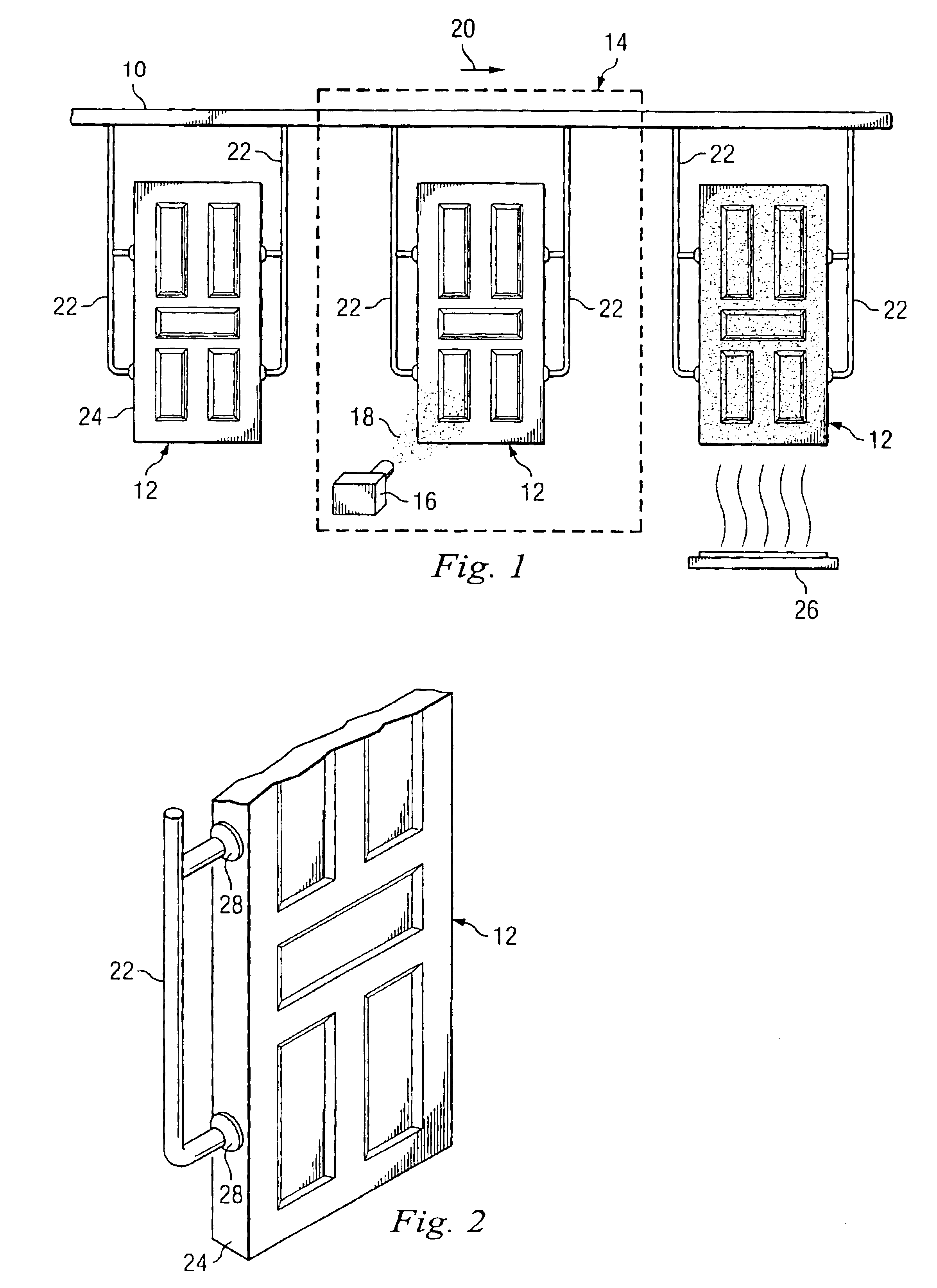

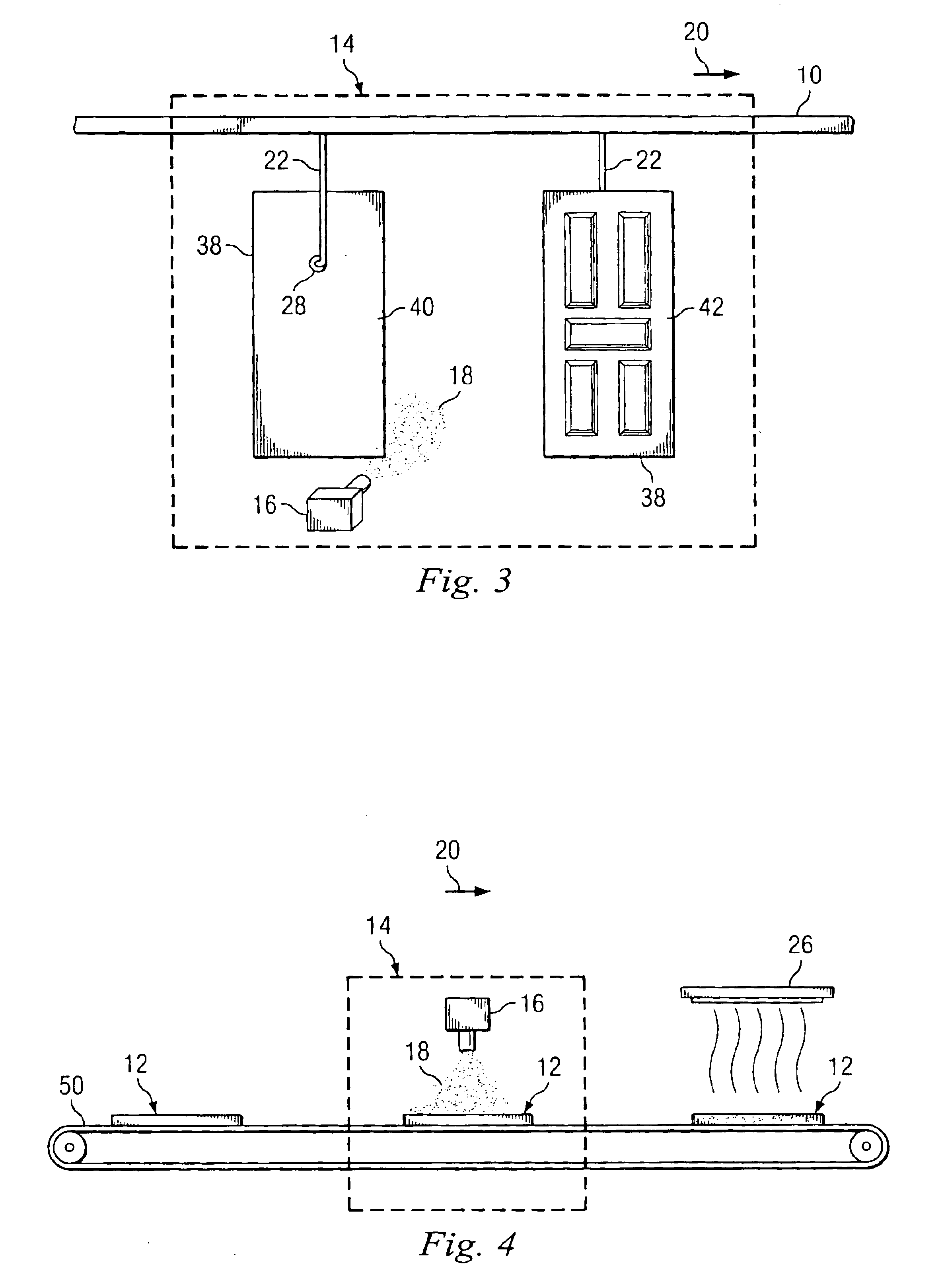

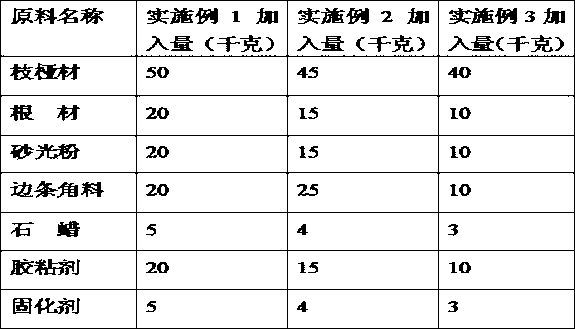

Method and system for powder coating passage doors

A method of applying a powder coating to a medium density fiberboard (MDF) or particleboard door includes attaching a first hanger to the door, providing an electrical source to the door through the first hanger, and conveying the door, via the first hanger, into a coating booth. The door is then powder-coated in the coating booth while being electrostatically charged. The powder-coated door is then cured to cause the powder to adhere to the door.

Owner:POLYMER WOOD TECH

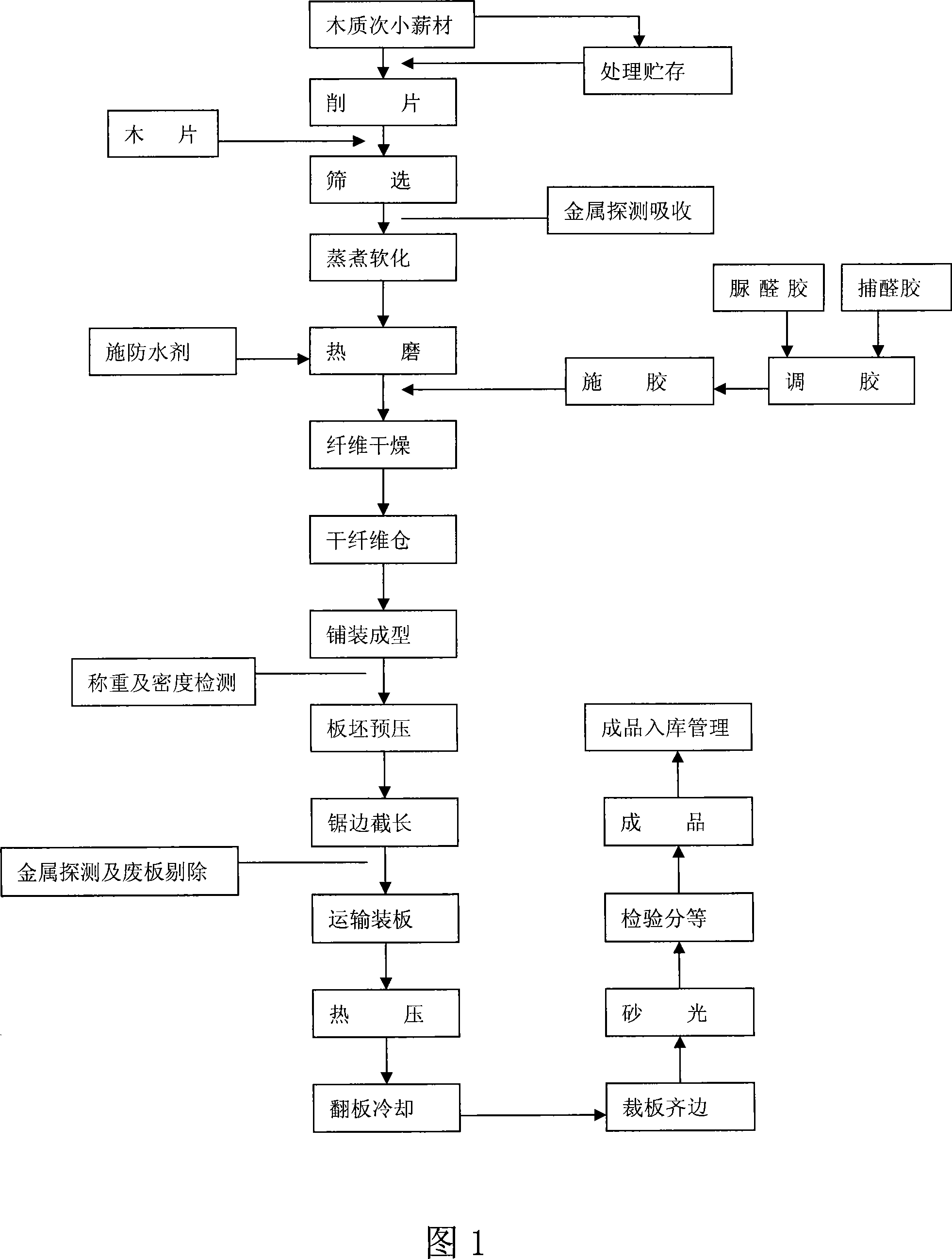

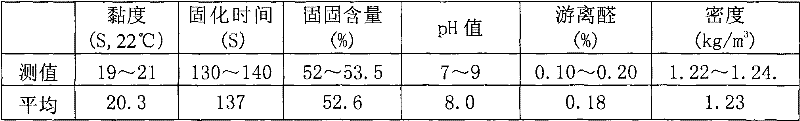

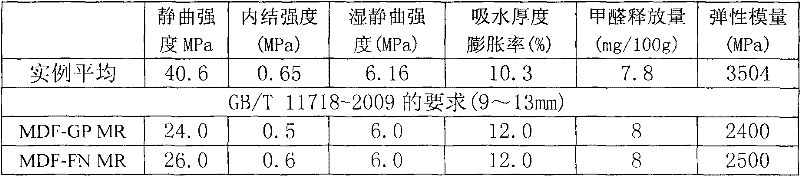

Method for manufacturing medium-density fiberboards

InactiveCN103192442AReduce manufacturing costStable internal structureWood working apparatusFlat articlesFiberManufacturing technology

The invention relates to a method for manufacturing medium-density fiberboards, and belongs to the technical field of manufacture of fiberboards. The method includes proportionally cutting root-wood and brushwood to obtain 60X30X5mm wood chips; carrying out cleaning, cooking, hot-grinding and drying procedures for the wood chips to obtain fibers; proportionally and sufficiently mixing the fibers with sanding powder and sawdust-shaped edge strip and corner materials to obtain mixtures; and carrying out gluing, paving and hot-pressing procedures for the mixtures to manufacture finished medium-density fiberboard products. The method has the advantages that the manufacturing cost of the medium-density fiberboards is reduced to a certain extent; problems that sanding dust which is generated in existing fiberboard manufacturing procedures and edge strip and corner materials which are generated during blank plate cutting are discarded as rejected materials, environments are polluted, the manufacturing cost is increased and limited forest resources are wasted are solved; and the fiberboards manufactured by the method are stable in internal structure, low in deformation and good in physical and mechanical performance.

Owner:FOJON GRP

Urea formaldehyde resin adhesive for moisture-proof environment-friendly medium density fiberboard and production method as well as composite additives thereof

ActiveCN102408855AReduce releaseLow costStarch derivtive adhesivesAldehyde/ketone condensation polymer adhesivesAccelerantMoisture

The invention discloses a urea formaldehyde resin adhesive for a moisture-proof environment-friendly medium density fiberboard and composite additives thereof. The adhesive is mainly prepared from the following raw materials in parts by weight: 50-60 parts of formaldehyde of which the mass concentration is 37%, 35-40 parts of urea of which the purity is 98%, and 4.5-7.5 parts of composite additives, wherein the composite additives comprise the following components in parts by weight: 40-90 parts of melamine, 1-30 parts of modified starch, 1-30 parts of anti-swelling agent and 1-5 parts of accelerant. By utilizing the renewable low-cost modified starch, the water resistance and bonding strength of the urea formaldehyde resin adhesive can be improved, the release amount of formaldehyde is reduced, the consumption of melamine is reduced, the product quality is stable, and the cost is lower. The invention also discloses a production method of the adhesive, which is characterized in that: the formaldehyde is fed for two times, the composite additives are fed for three times and are in end point control for three times, and the urea is fed for four times. Thus, few additives are used for playing a greater role, and the problems of higher reaction speed, longer adhesive curing time and the like caused by the melamine are avoided.

Owner:GUANGXI UNIV

White waterborne wood base coat for medium density fiberboard and preparation technology thereof

Owner:ZHEJIANG FEIDA ZHONGKE FINE CHEM

Polymer-aldehyde binding system for manufacture of wood products

InactiveUS20070167561A1Colloidal chemistry detailsUnsaturated alcohol polymer adhesivesFiberCellulose

A formaldehyde-free curable aqueous composition containing a hydroxy-containing polymer, a multi-functional crosslinking agent, and, optionally, a catalyst. The composition is used as a binder for lignocellulosic materials such as plywood, fiber particleboard, medium density fiberboard and oriented strand board.

Owner:DYNEA AUSTRIA

Wood adhesive prepared by degrading soybean protein by utilizing strong basicity and preparation method thereof

InactiveCN101724376AHigh viscosityImprove adsorption capacityProtein adhesivesGlue/gelatin preparationMedium densityAdhesive

The invention discloses a wood adhesive prepared by degrading soybean protein by utilizing strong basicity and a preparation method thereof, and relates to a soybean protein-based wood adhesive and a preparation method thereof. The invention solves the problems of low content of the soybean protein, high moisture content and large viscosity existing in conventional soybean adhesives or soybean protein adhesives. The product is prepared by performing a degradation reaction of defatted soybean protein powder or soybean protein isolate, strong base and water, then using strong phosphoric acid to adjust the pH value of the obtained solution, and then adding dialdehyde into the obtained solution to mix the solution evenly. The method comprises the steps of: 1, weighing; 2, preparing strong base solution, heating the strong base solution, adding the defatted soybean protein powder or the soybean protein isolate into the strong base solution under stirring, and then cooling the strong base solution to a room temperature after heating reflux; and 3, using the strong phosphoric acid to adjust the pH value, adding the dialdehyde into the solution, and stirring the solution evenly. The adhesive has the advantages of high content of the soybean protein, low moisture content and low viscosity, and can be used for preparing plywood, flakeboards and medium-density fiberboards.

Owner:NORTHEAST FORESTRY UNIVERSITY

Method for manufacturing regenerated composite boards by using waste wood

InactiveCN102310453AReasonable useMaximize utilizationWood working apparatusDomestic articlesFiberWood shavings

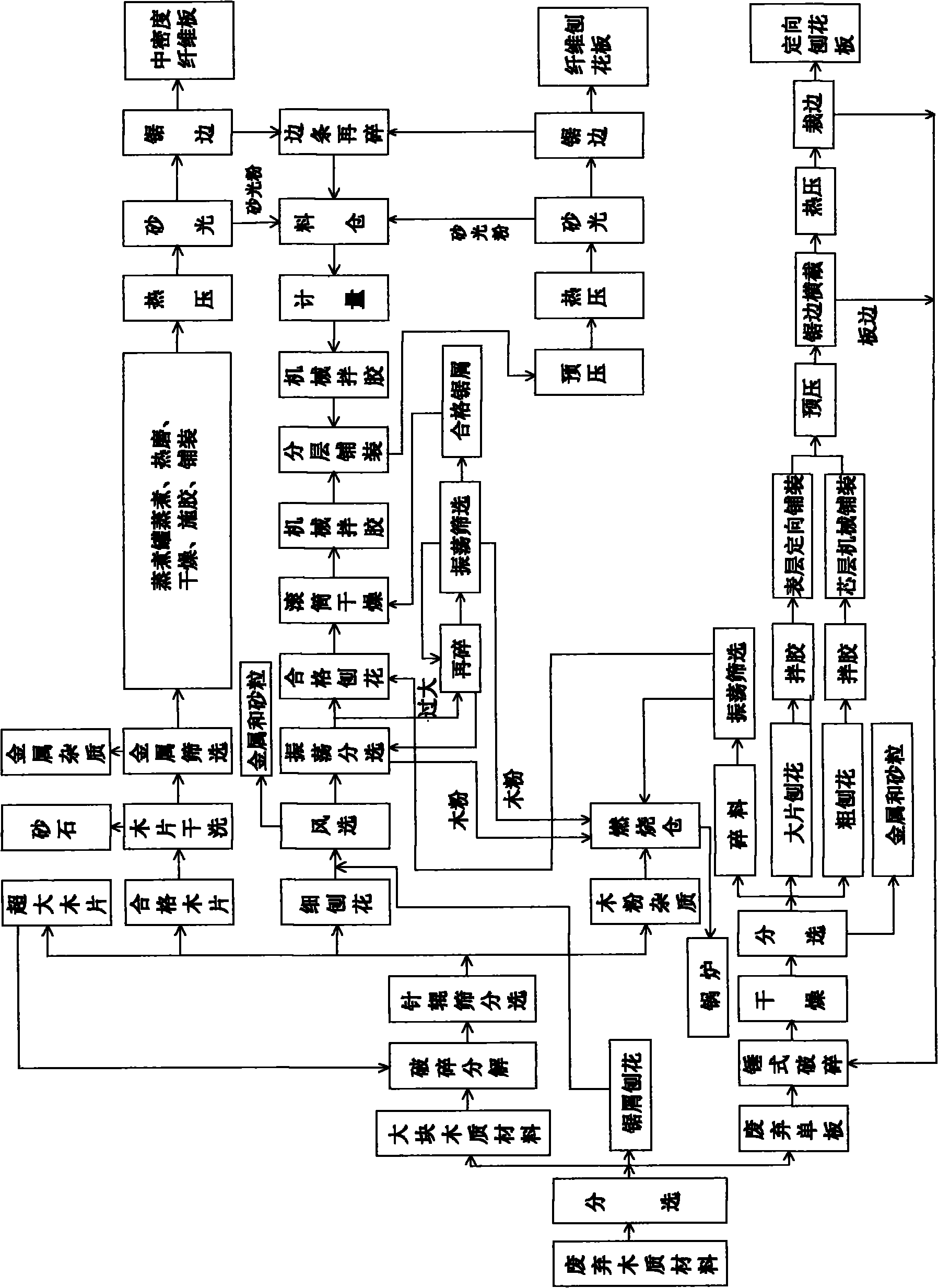

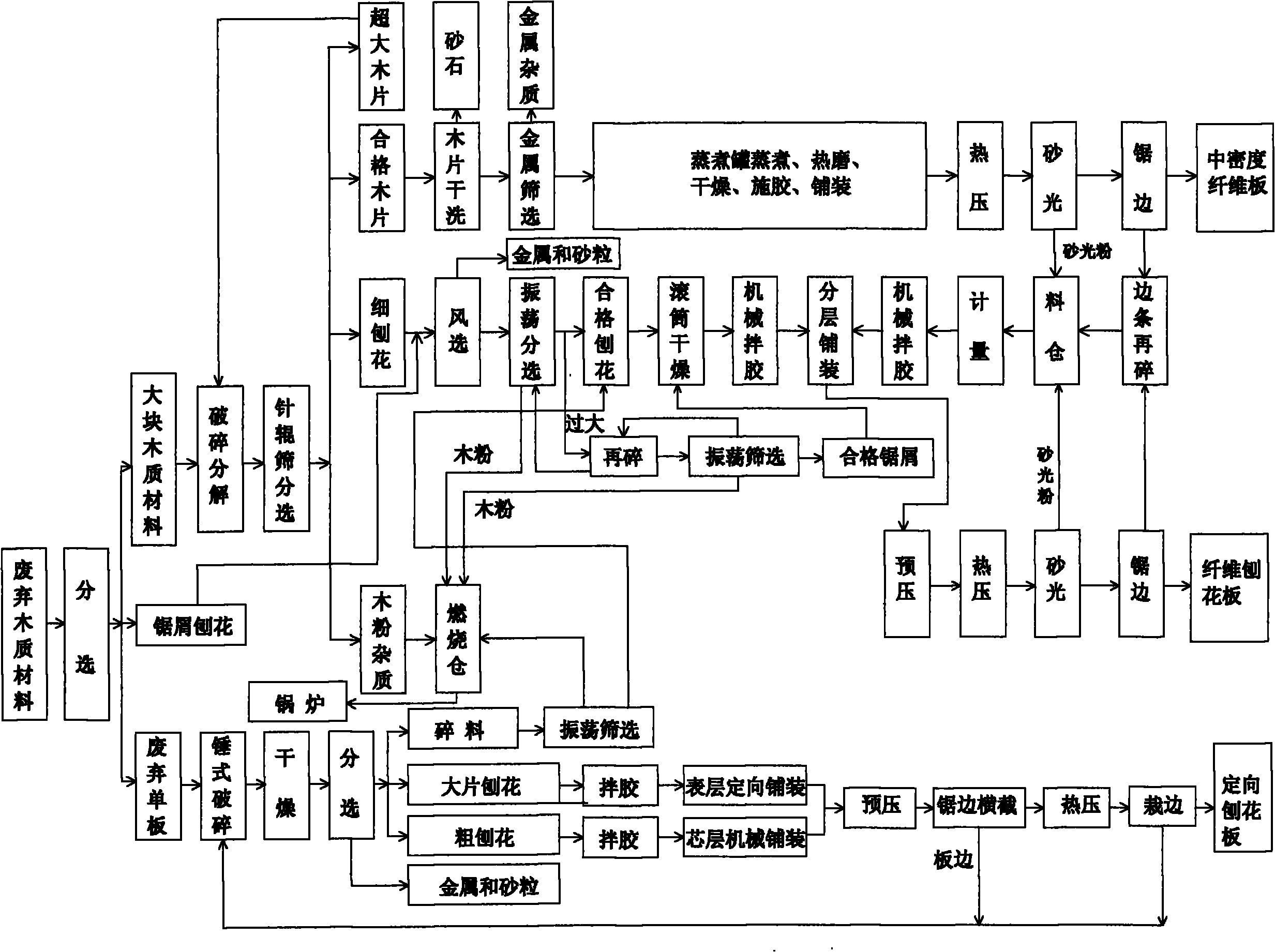

The invention discloses a method for manufacturing regenerated composite boards by using waste wood. The method comprises the following steps of: a, sorting waste wood materials into a massive wood material, sawdust wood shavings and waste veneers; b, crushing and decomposing the massive wood material; c, sorting with a needle roll screen, and obtaining extra large wood chips, qualified wood chips, thin wood shavings and wood meal impurities; d, treating the extra large wood chips according to the step b; e, processing the qualified wood chips into medium density fiber boards by a medium density fiber board manufacturing process; f, removing metal and sand from the thin wood shavings by winnowing, removing powder, gravel and metal impurities from the thin wood shavings by oscillation sorting to form qualified wood shavings, and manufacturing fiber shaving boards by a fiber shaving board production process; g, conveying the wood meal impurities to a fuel bin; h, treating the sawdust wood shavings according to the winnowing process of the step f; i, removing metal and sand from the waste veneers by hammer-type crushing, drying and sorting, and forming crushed materials, big wood shavings and thick wood shavings; and j, producing oriented shaving boards by an oriented shaving board production process.

Owner:JUYE WODESEN PLATE IND

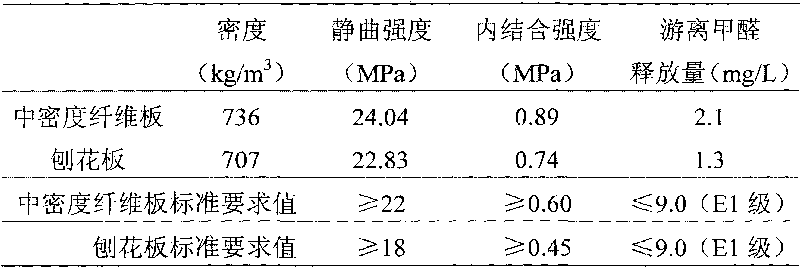

Urea formaldehyde resin adhesive medium density fiber board utilizing castor bean stalk as raw material

The invention relates to a urea formaldehyde resin adhesive medium density fiber board utilizing a castor bean stalk as a raw material, which is characterized in that the weight proportion of the solid additive amount of castor bean stalk fiber or castor bean stalk with 8 percent of water content and urea formaldehyde resin adhesive is 86-90 to 14-10. The preparation process comprises the following steps: preparing raw materials; mixing the fiber with adhesive and drying; laying and prepressing; hot pressing; and post processing. The invention has the advantages of low manufacture cost, wood resources saving, ecological environment protection and industrialized production. After urea formaldehyde resin is used as the adhesive and 1.0-1.6 percent of paraffin is added on the basis of the mass of the absolutely dry fiber, all technical indexes of the produced medium density fiber board are as follows: density 0.55-0.85kg / cm3, static bending strength 25-37MPa, elastic modulus 2950-3210MPa,plane tensile strength 0.68-1.0MPa and absorbing water thickness expansion rate 7.32 percent-9.25 percent, and reach the standard of a Chinese fiber board.

Owner:苏州伍得人造板设备有限公司

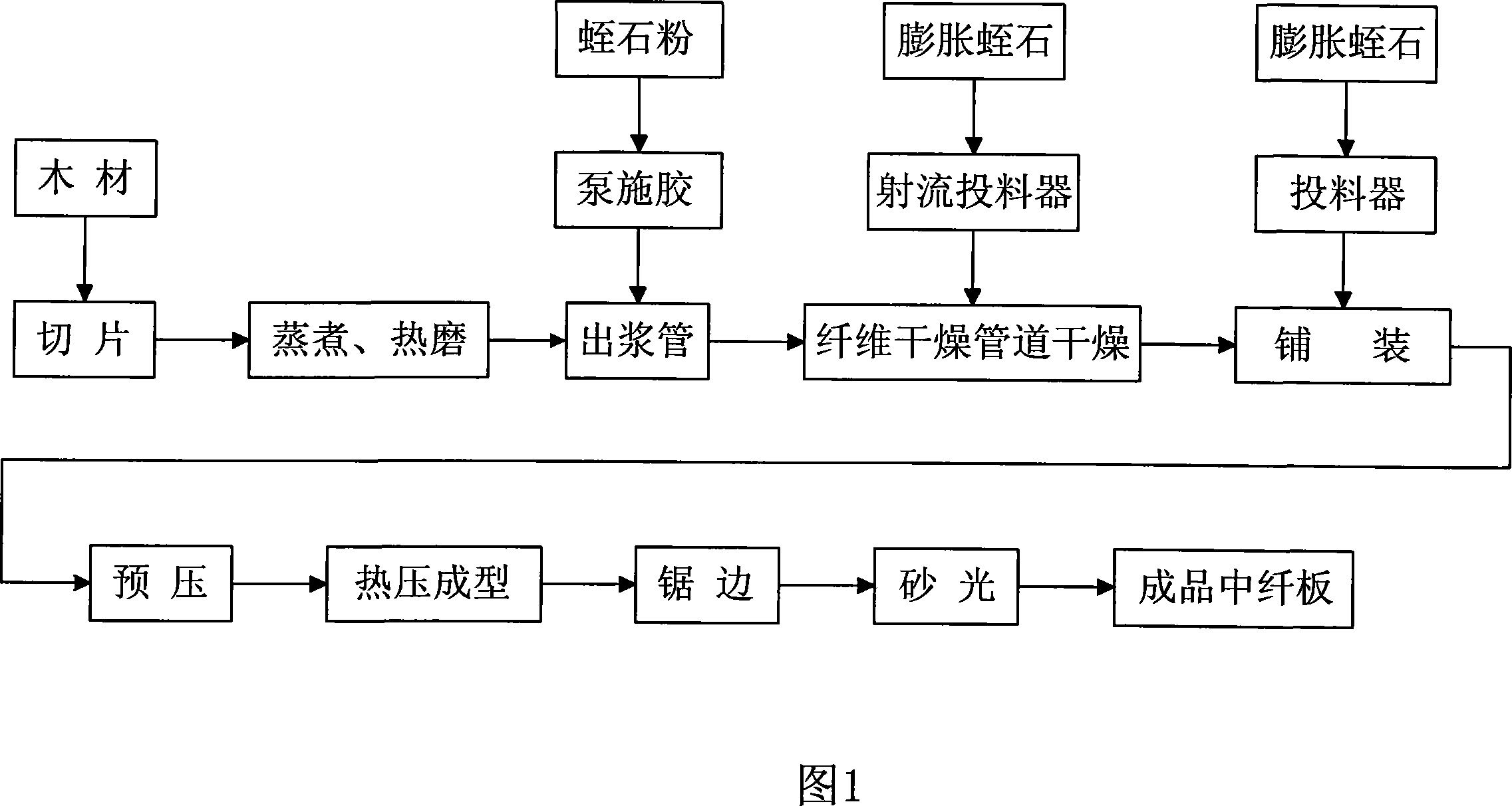

Flame retardant medium density fiberboard and manufacturing method therefor

InactiveCN101108503AReduce pollutionReduce manufacturing costDomestic articlesFlat articlesFiberMedium density fiberboard

The invention relates to a middle intensity fiber board with fire resistance performance, which comprises a wood fiber material, glue agent and fire resistance material. The fire resistance material is swelled vermiculite grain, the adding volume of the swelled vermiculite grain is 20 to 80 per cent of the absolute dry fiber material, the adding volume of the glue agent is 15 to 20 per cent of the absolute dry fiber material. Vermiculite powder is added in the fire resistance material. The method of producing the invention is that: cut the wood material into plate; the breakage material is dissolved into wood pulp by steaming and boiling and heat milling in the heat milling machine; proceed adding and mixing glue to the wood pulp; dry in a fiber drying tube; adopt a performing machine to proceed pressing into board adobe after pavement on a paving machine; the board adobe is pressed rough adobe board; the rough adobe board forms a intensity fiber board after sawing edge and sanding, before the wood fiber enters the pavement procedure, add swelled vermiculite grain or swelled vermiculite grain, vermiculite powder fire resistance material. The invention has the advantages of lightness, little pollution to environment and low manufacturing cost.

Owner:吉发

Technique for producing medium density fiberboard by using modified bulrush

InactiveCN101138856ASolve process problemsBroaden sources of raw materialsFlat articlesDomestic articlesFiberFlute

The present invention relates to a process method for manufacturing a medium density fiberboard from modified reeds. A whole reed plant is cracked and cut, reed leaves, reed paintings, reed ears, reed flowers and flute diaphragms are all selected out by winnowing and the rest reed stalk which is called reed chipping serves as a raw material. Dry fibers are produced after the modification, defibration and drying by hot air (smoke) of the reed chipping. The dry fiber is metered and quantitative powder adhesives and assistant agents are added. Then the dry fiber is spread on a spreading machine as a prepressed slab of the medium density fiberboard. A rough medium density fiberboard is produced after the pressing and hot pressing of the slab and becomes a qualified medium density fiberboard after a final treatment processing. The present invention is characterized in that the technique method solves the problem of making medium density fiberboard from reeds and powder adhesives and enlarges the raw material resource of medium density fiberboards.

Owner:TIANJIN SHENGYUN NEW MATERIAL TECH

Special veneering pressing and sticking method of melamine impregnated paper

ActiveCN101954657AAccurate angleEasy to processSurface covering paperWood treatment detailsCompression moldingWear resistant

The invention discloses a special veneering pressing and sticking method of melamine impregnated paper, which comprises the steps of: softening medium density polyethylene fibreboards, improving the formula of the melamine impregnated paper, and compression-molding by adopting a concave and convex matching mould. The method avoids the deficiencies that a traditional door sheet is not wear-resistant, is not stain-resistant, is easy to deform, crack, delaminate, burn, and mildew, and the surface of a traditional door sheet needs cumbersome processing procedures, such as many times of painting or spray painting, and the like.

Owner:JIANGSHAN OUPAI DOOR IND

Method for making environment-friendly type composite vegetation high and medium density fiber board

InactiveCN1570275AReduce consumptionExpand sourceFibreboardWater-repelling agents additionTextile fiberCellulose

This invention discloses one environmental protection vegetation compound high school density fiberboard manufacture method. This method use straw stalk processing smashing,grinding paste, defibering, exerts urea resin rubber,preparation straw stalk executes the rubber textile fiber;then uses lumber grinding paste,defibering, exerts the urea resin rubber, preparation lumber executes rubber textile fiber, executes lumber rubber textile fiber and straw stalk executes rubber textile fiber according to the proportion mix; Executes rubber textile fiber paving to take shape, the thermo-compression becomes the high school density cellulose board; Is spatial airtight the element board through the center falls the aldehyde processing room, this processing room separated in two parts; falls aldehyde processing room to pass over the ammonia, causes the element board two sides to have the pressure difference, ammonia penetrates element board under the pressure difference function, the adjustment falls aldehyde processing room controlled variable, may prepare the E1 / E0 level environmental protection high and middle density fiberboard through the physical chemistry function. This invention reduced lumber consumption, protected the environment, and reduced the production cost, this product formaldehyde content has been low, guarantee product environmental protection target.

Owner:NANJING FORESTRY UNIV

Method for surface directly coating plate fitment

ActiveCN101549513AFinishing speedFinishing high efficiencyPretreated surfacesWood working apparatusLacquerVolumetric Mass Density

The invention relates to the field of architectural decoration material and its post-contour machining technology, concretely a method for surface directly coating the plate fitment made with beaverboard of middle density as basic materials. The invention is indicated constructing continuous coating lines of priming lacquer, emulation grain and top-coat, taking the plate fitment made with beaverboard of middle density as basic materials on the continuous coating lines, and continuously coating the basic materials to form into coating of the priming lacquer, emulation grain and top-coat. With employing this method, the aforementioned coatings can dry and form film in 0.5-2 seconds, the coating speed is quickly, and the quality is excellent without environment pollution.

Owner:QUANYOU FURNITURE +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com