Medium density fiberboard with low burst size of methanal and producing method thereof

A technology with low formaldehyde release and production method, applied in other household appliances, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problem of yellowish and unsightly boards, decreased bonding performance, and molecular structure changes. and other problems, to achieve the effects of improved physical and mechanical properties, low production costs, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

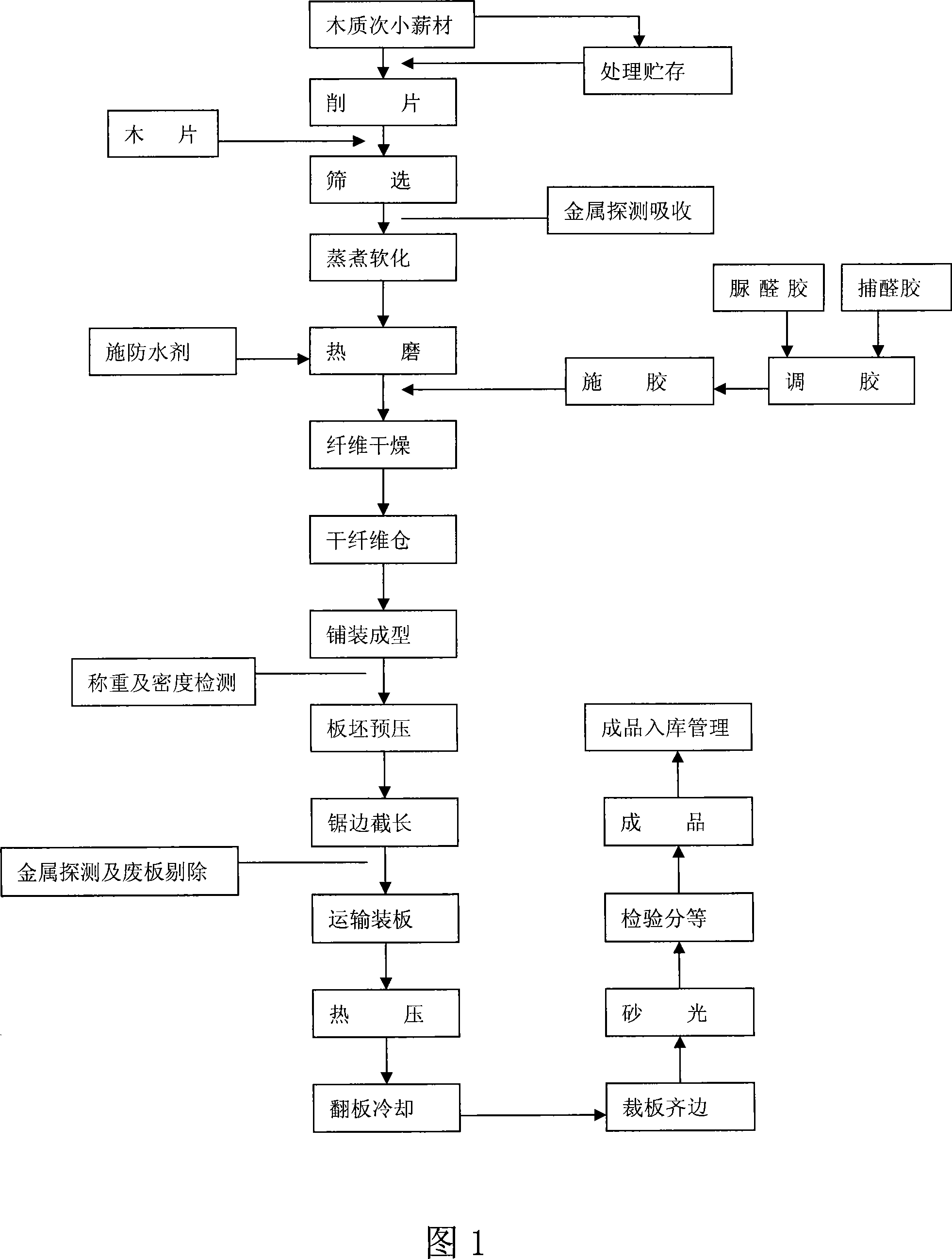

Method used

Image

Examples

Embodiment 1

[0034] ① Raw materials are classified and stored, and the moisture content is controlled at 45% to 55%.

[0035] ② Cut various wood raw materials (such as small-diameter wood, wood processing residues, etc.), tree raw materials, etc., into wood chips of certain specifications by mechanical external force. The size and size are: length 16-30mm, width 15-25mm, thickness 3-5mm , the incision is smooth and uniform in size. For the purchased wood chips, the quality inspection shall be carried out according to the above wood chip quality and raw material moisture content requirements.

[0036] ③ Screening of flake raw materials. Remove oversized chips and undersized debris. An oil-immersed iron remover is installed on the belt conveyor to detect and absorb iron and other metals that may exist in the raw materials.

[0037] ④The screened wood chips enter the steam buffer silo with a pressure of 0.7-1.0 MPa and a temperature of 172-178°C for cooking and softening, and the cooking t...

Embodiment 2

[0047] ① Raw materials are classified and stored, and the moisture content is controlled at 45% to 55%.

[0048] ② Cut various wood raw materials (such as small-diameter wood, wood processing residues, etc.), tree raw materials, etc., into wood chips of certain specifications by mechanical external force. The size and size are: length 16-30mm, width 15-25mm, thickness 3-5mm , the incision is smooth and uniform in size. For the purchased wood chips, the quality inspection shall be carried out according to the above wood chip quality and raw material moisture content requirements.

[0049] ③ Screening of flake raw materials. Remove oversized chips and undersized debris. An oil-immersed iron remover is installed on the belt conveyor to detect and absorb iron and other metals that may exist in the raw materials.

[0050] ④The screened wood chips enter the steam buffer silo with a pressure of 0.8-1.0 MPa and a temperature of 174-178°C for cooking and softening, and the cooking t...

Embodiment 3

[0060] ① Raw materials are classified and stored, and the moisture content is controlled at 45% to 55%.

[0061] ② Cut various wood raw materials (such as small-diameter wood, wood processing residues, etc.), tree raw materials, etc., into wood chips of certain specifications by mechanical external force. The size and size are: length 16-30mm, width 15-25mm, thickness 3-5mm , the incision is smooth and uniform in size. For the purchased wood chips, the quality inspection shall be carried out according to the above wood chip quality and raw material moisture content requirements.

[0062] ③ Screening of flake raw materials. Remove oversized chips and undersized debris. An oil-immersed iron remover is installed on the belt conveyor to detect and absorb iron and other metals that may exist in the raw materials.

[0063] ④The screened wood chips enter the steam buffer silo with a pressure of 0.8-1.0 MPa and a temperature of 174-178°C for cooking and softening, and the cooking t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com