Urea formaldehyde resin adhesive for moisture-proof environment-friendly medium density fiberboard and production method as well as composite additives thereof

A technology of urea-formaldehyde resin and composite additives, which is applied in adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problems of high cost, high price, and poor market acceptance, and achieve low cost , low price, and the effect of reducing the amount of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

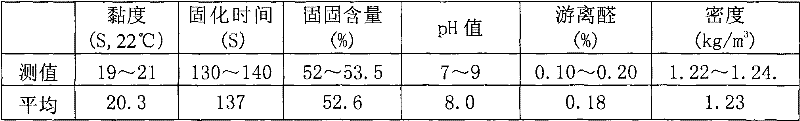

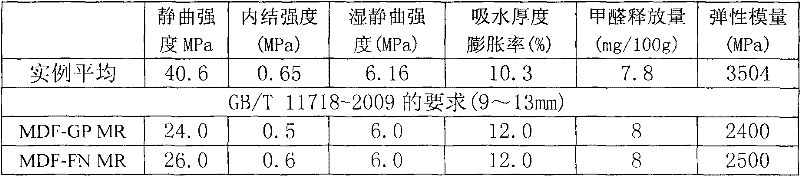

Embodiment 1

[0023] 1. Recipe composition

[0024] The molar ratio of formaldehyde to urea was F / U=1.156, 550 parts of formaldehyde (37% concentration), 354 parts of urea (98% purity), and 60 parts of compounding aids.

[0025] Percentage composition of compound auxiliary: sodium chloride 24%, esterified starch 16%, melamine 57%, dicyandiamide 3%.

[0026] 2. Glue making process

[0027] Put 480 parts of formaldehyde aqueous solution into the reaction kettle, start the stirrer, start heating and heating, stop heating when the temperature is raised to 40 ° C, and adjust the pH value with 25-30% sodium hydroxide aqueous solution to 7.5-8.0;

[0028] Add 170 parts of the first batch of urea, stop heating when the temperature rises to 70°C, then naturally heat up to 90°C, check pH (guaranteed pH=6.5~7.0), add 12 parts of compound additives after holding for 10 minutes, stir for 15 minutes minute;

[0029] Adjust pH=4.8-5.2 with 25-30% formic acid aqueous solution, and carry out polyconden...

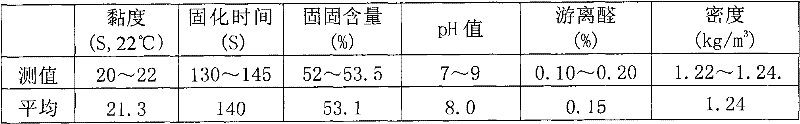

Embodiment 2

[0044] 1. Recipe composition

[0045] The molar ratio of formaldehyde to urea was F / U=1.2, 550 parts of formaldehyde (37% concentration), 346 parts of urea (98% purity), and 67 parts of compounding auxiliary.

[0046] Percentage composition of compound auxiliary: sodium chloride 24%, oxidized starch 16%, melamine 57%, dicyandiamide 2%, hexamethylenetetramine 1%.

[0047] 2. Glue making process

[0048] Put 480 parts of formaldehyde aqueous solution into the reaction kettle, start the stirrer, start heating and heating, stop heating when the temperature is raised to 40 ° C, and adjust the pH value with 25-30% sodium hydroxide aqueous solution to 7.5-8.0;

[0049] Add 165 parts of the first batch of urea, stop heating when the temperature rises to 70°C, then naturally heat up to 90°C, check the pH (guaranteed pH=6.5~7.0), add 13 parts of compound additives after holding for 10 minutes, stir for 15 minutes minute;

[0050] Adjust the pH between 5.0 and 5.2 with 25-30% formi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com