Patents

Literature

374results about How to "Broaden sources of raw materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

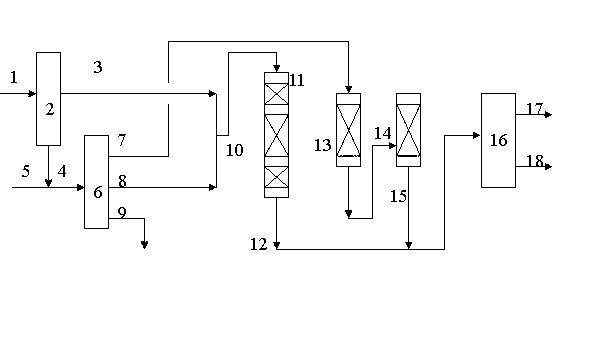

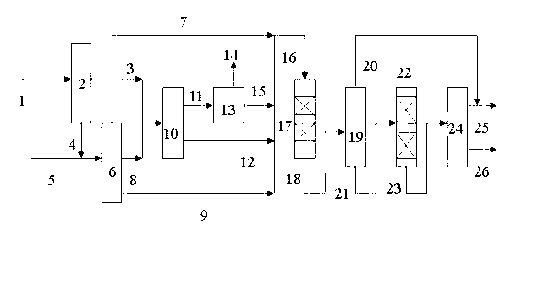

Treatment method for inferior heavy oil and residual oil

ActiveCN1766059ABroaden sources of raw materialsReduce production operating costsTreatment with hydrotreatment processesSolventChemistry

The invention discloses a process for treating inferior heavy oil and residual oil comprising the following steps: loading heavy oil and petroleum residue into a solvent extraction apparatus, charging the obtained deasphalted oil into a fixed bed for hydrotreatment, entering the obtained tail oil into a catalytic cracking device, loading part or total slurry oil and de-oiled asphalt into a floating bed hydrogenation unit, separating the outcome yield to obtain lightweight fraction and untransformed tail oil, which is circulated to the solvent extraction device.

Owner:CHINA PETROLEUM & CHEM CORP +1

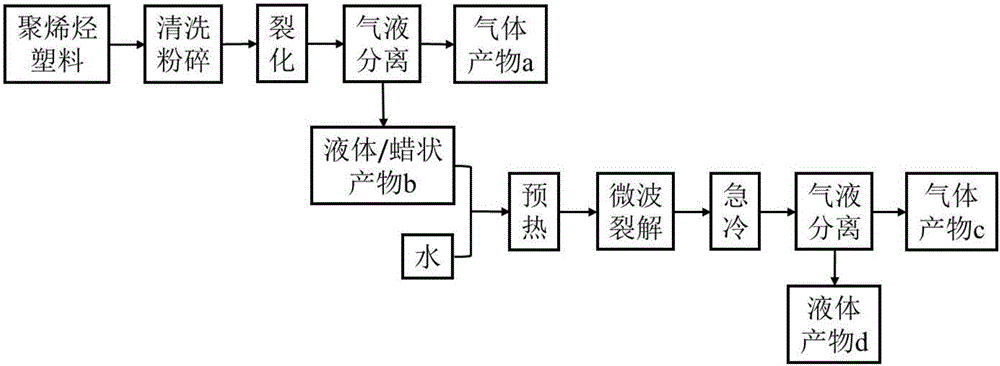

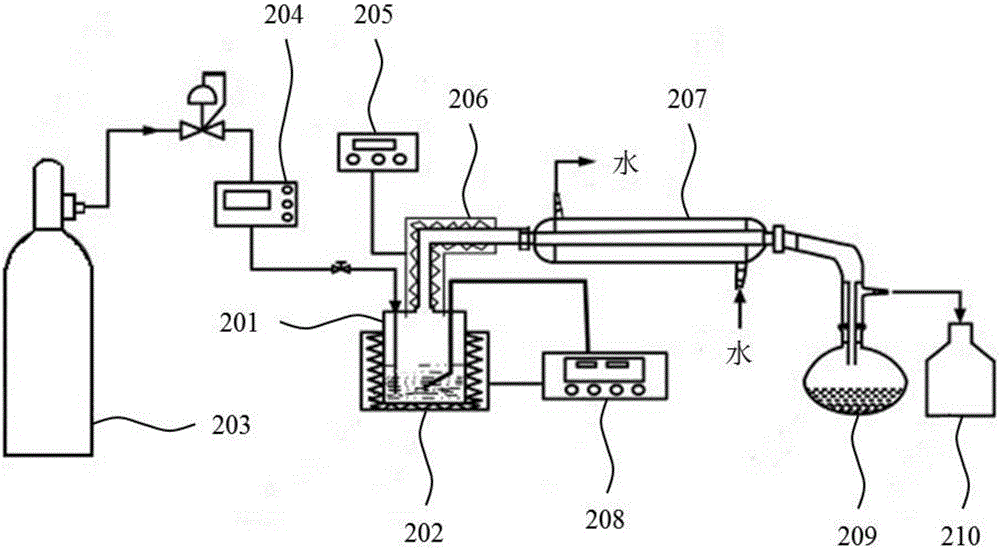

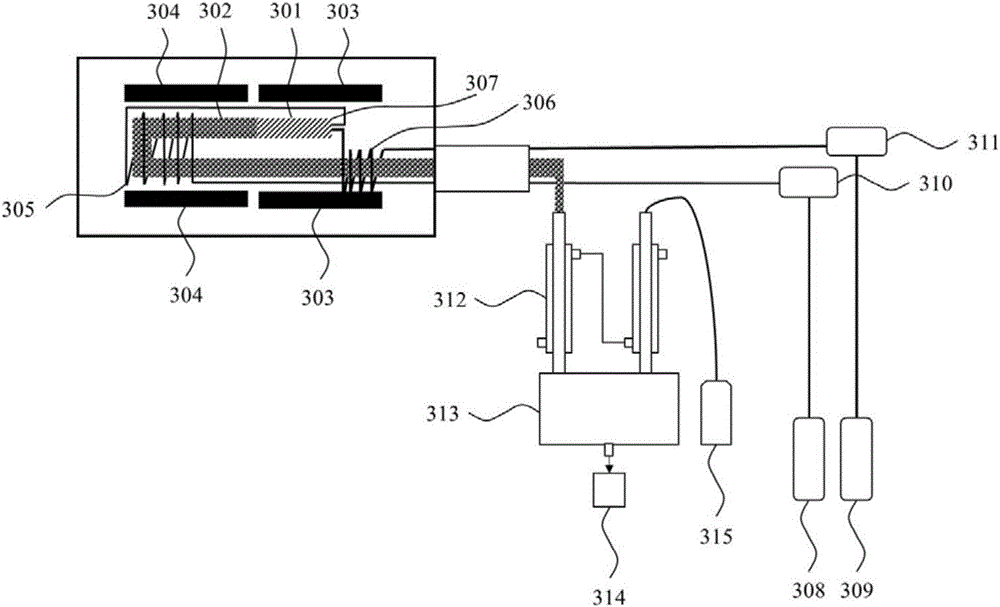

Method for using polyolefin plastic to prepare micromolecule alkene

InactiveCN106520176AImprove heating efficiencyRaise the cracking temperatureThermal non-catalytic crackingLiquid hydrocarbon mixture productionChemistryPolyolefin

The invention provides a method for using polyolefin plastic to prepare micromolecule alkene. According to the method, at first, the polyolefin plastic is cracked, then a liquid / waxy product obtained through cracking is mixed with selectable liquid petroleum hydrocarbon and water, and the mixture is subjected to microwave pyrolysis to obtain micromolecule alkene. The method specifically comprises the following steps that the polyolefin plastic is conveyed into a moderate cracking device to be cracked, and a gas product a and the liquid / waxy product b are obtained through gas-liquid separation; the product b is mixed with selectable liquid petroleum hydrocarbon and the water, and the mixture serves as a microwave pyrolysis raw material; and the microwave pyrolysis raw material is mixed with the water, the mixture is conveyed into a microwave pyrolysis device, after microwave pyrolysis is carried out, the mixture is quenched to be 500 DEG C or below, and a cracked product is obtained. According to the method, microwave heating of hydrocarbon raw materials insensitive to microwaves is achieved, the source of the raw material for preparing micromolecule alkene is expanded, by means of the inner heating characteristic of microwave heating, the cracking temperature is increased, the cracking efficiency is improved, and energy consumption is lower than that of a traditional pipe cracking furnace.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Non-sintered ceramic aggregate with stone coal vanadium extraction tailings as main raw material and preparation method thereof

InactiveCN102617097AEffective way to useExpand sourceSolid waste managementThermal insulationExpanded clay aggregate

The invention relates to a non-sintered ceramic aggregate with stone coal vanadium extraction tailings as a main raw material and a preparation method thereof. The non-sintered ceramic aggregate comprises the following raw material components in percentage by weight: 45-60 percent of stone coal vanadium extraction tailings, 10-30 percent of fly ash, 7-15 percent of solid alkali exciter, 5-10 percent of cement, 5-10 percent of quick lime, 2-5 percent of gypsum and 5-15 percent of water. The preparation method comprises the following steps of: according to the raw materials and the contents thereof, uniformly mixing the stone coal vanadium extraction tailings and the solid alkali exciter and grinding to be below 0.074 mm to prepare a prefabricated material; adding the fly ash, the cement, the quick lime, the gypsum and the water into the prefabricated material and uniformly stirring to prepare a mixture; aging the mixture for 1-3 hours; pelletizing; aging for 3-7 days; holding in an autoclave; and autoclaving under the condition of 0.8-1.2 MPa for 6-10 hours. The non-sintered ceramic aggregate has the advantages of environmental friendliness, simple process, low energy consumption and high utilization rate of tailings; and a prepared non-sintered ceramic aggregate product has high strength and good thermal insulation performance.

Owner:WUHAN UNIV OF SCI & TECH

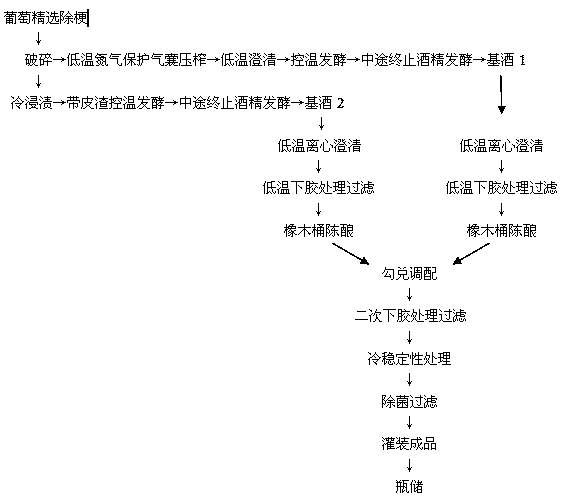

Ageing sweet-white wine and brewing process of ageing sweet-white wine

ActiveCN103911242ABroaden sources of raw materialsEnrich market product typesMicroorganism based processesWine preparationSweet white wineBottle

The invention relates to an ageing sweet-white wine and a brewing process of the ageing sweet-white wine, belonging to the technical field of brewing of wines. The physicochemical indexes of the ageing sweet-white wine disclosed by the invention are as follows: the content of reducing sugar is 80-90 g / L; the total acidity is 7.0-8.5 g / L; the alcoholic strength is 10.0-12.0%vol; the content of free sulphur dioxide is 30-45 mg / L; the total content of sulphur dioxide is less than or equal to 250 mg / L; the content of volatile acid is less than or equal to 1.0 g / L. The brewing process of the ageing sweet-white wine disclosed by the invention comprises the following steps of: (1) finely selecting grapes and removing stems; (2) crushing; (3) technically dividing; (4) centrifuging and clarifying at low temperature; (5) fining at low temperature, and filtering; (6) ageing by using an oak barrel; (7) blending and mixing; (8) fining for the second time, and filtering; (9) coldly processing stability; (10) sterilizing and filtering; (11) filling finished goods; (12) storing in a bottle. The ageing sweet-white wine disclosed by the invention is full-bodied in fragrance, graceful, lasting and plump in mouth feel; the brewing process of the ageing sweet-white wine disclosed by the invention is simple, scientific and convenient to operate; the production cost can be effectively reduced; the scale production of high-end sweet-white wines is realized.

Owner:COFCO GREAT WALL WINE YANTAI

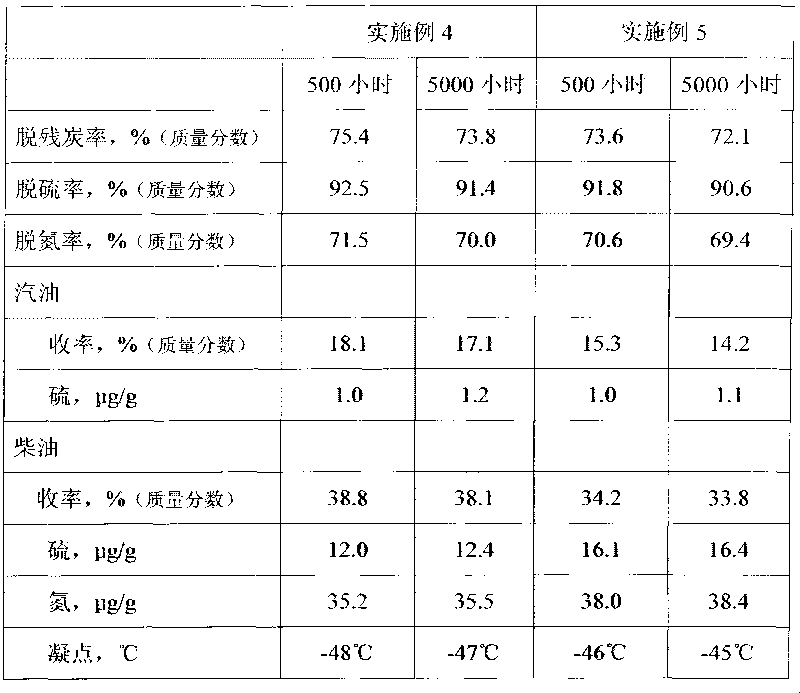

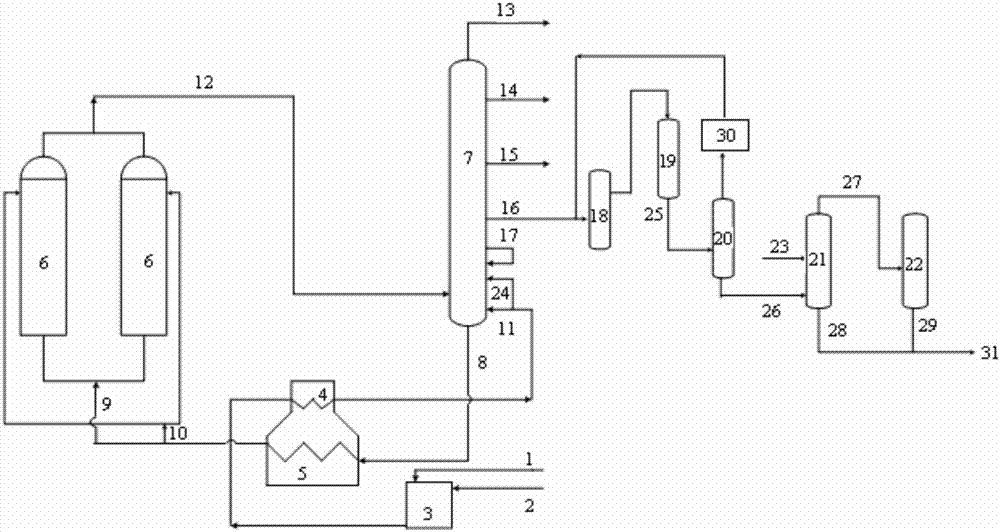

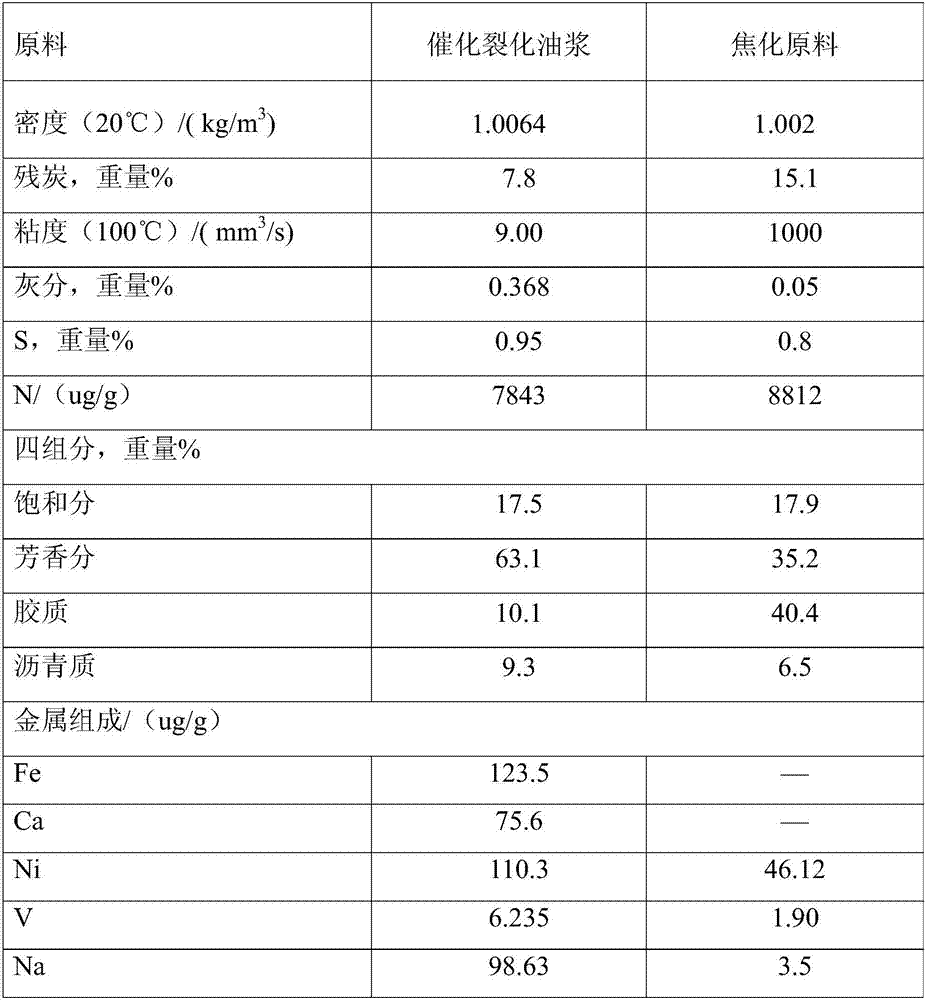

Method for hydrogenating ethylene tar

The invention discloses a method for hydrogenating ethylene tar, which selects an appropriate cutting point to fractionate the ethylene tar into a light fraction and a heavy fraction aiming at the characteristics of high content of arene, colloid, carbon residue and asphaltene in the ethylene tar. The light fraction passes through a hydrogenation protection catalyst, a hydrofining catalyst, a hydrogenation and carbon residue-removing catalyst and a hydrocracking catalyst sequentially to obtain a gasoline fraction and a diesel oil fraction; and the heavy fraction passes through the hydrogenation protection catalyst, the hydrogenation and carbon residue-removing catalyst and a hydro-conversion catalyst sequentially to obtain a gasoline fraction and a diesel oil fraction. According to the component characteristics of the light fraction and the heavy fraction of the ethylene tar, the method selects different hydrogenation schemes so as to convert the ethylene tar into fuel oil to a great extent, increase the additional value of the ethylene tar and make the device operate for a long time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cream cheese and preparation method thereof

InactiveCN101167500ABroaden sources of raw materialsStable textureCheese manufactureStaphylococcus lactisAdditive ingredient

The invention relates to a cream cheese and a preparation method thereof. The technical scheme is to use milk fat raw material: 15-85%; whole milk: 10-80%; milk protein raw material: 1-10%; carbohydrate raw material: 1-10%. The present invention expands the raw material source of the cream cheese, uses milk protein raw material, carbohydrate raw material and stabilizer as ingredients, forms a stable texture without whey precipitation, and omits the process step of removing whey. The invention uses lactic acid bacteria including diacetyl lactis streptococcus to mix and ferment the ingredients of cream cheese, so that the product can form a new flavor.

Owner:TIANJIN UNIV OF SCI & TECH

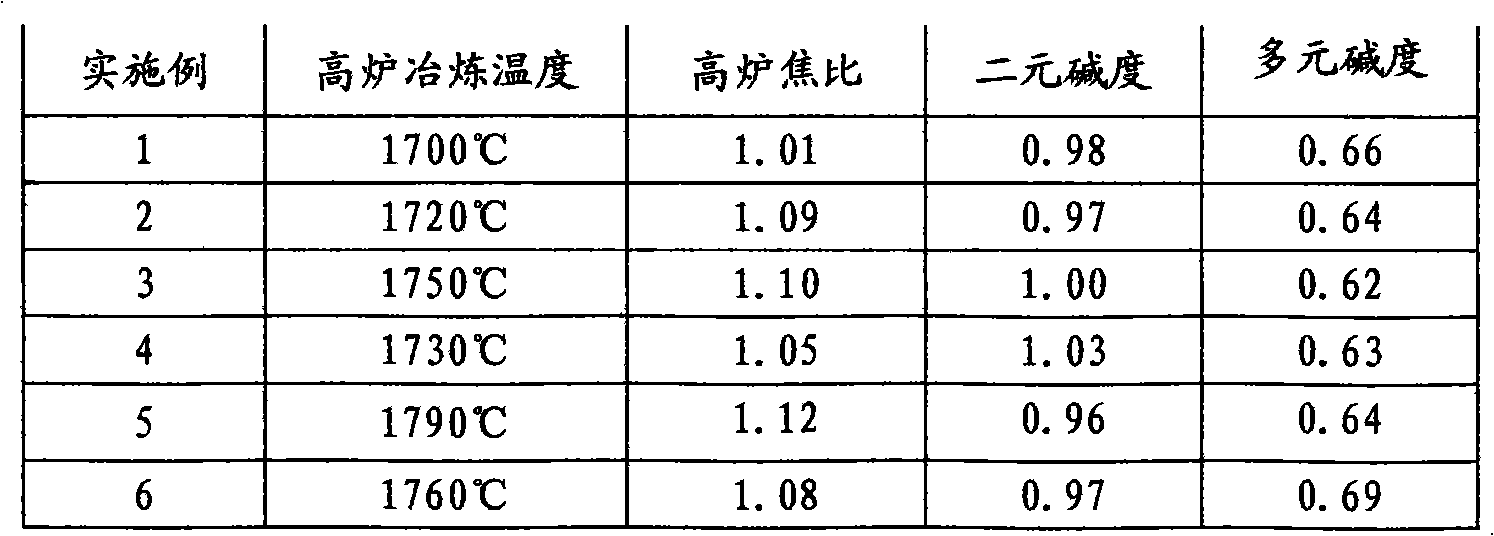

Preparation method of acanthopanax sessiliflorus berry anthocyanin with antioxidant activity

The invention relates to a method for extracting anthocyanin from plant berries and particularly relates to a preparation method of acanthopanax sessiliflorus berry anthocyanin with antioxidant activity. The preparation method comprises the following steps of (1) selecting acanthopanax sessiliflorus berries as raw materials; (2) extracting the acanthopanax sessiliflorus berry anthocyanin by using an enzyme freezing and thawing method: mixing the frozen raw materials and an extracting solution, unfreezing and breaking the frozen raw materials, and carrying out enzymolysis; (3) carrying out ultrasonic-microwave synergistic extraction on the acanthopanax sessiliflorus berry anthocyanin: carrying out ultrasonic-microwave synergistic extraction on enzymatic hydrolysate, and centrifuging to obtain a crude extracting solution; (4) purifying the crude extruding solution of the anthocyanin: absorbing the crude extruding solution by using macroporous resin, collecting an eluant, and carrying out vacuum concentration; (5) freezing and drying in vacuum; and (6) smashing the anthocyanin, and then, packaging the anthocyanin. The preparation method has the advantages of high extracting efficiency, short time, low energy consumption, small reagent dosage, stable properties of effective components and the like; and meanwhile, a vacuum freeze drying technology is adopted, so that a product has better biological activity, color, luster and solubility and the preparation method is suitable for industrial production.

Owner:JILIN UNIV

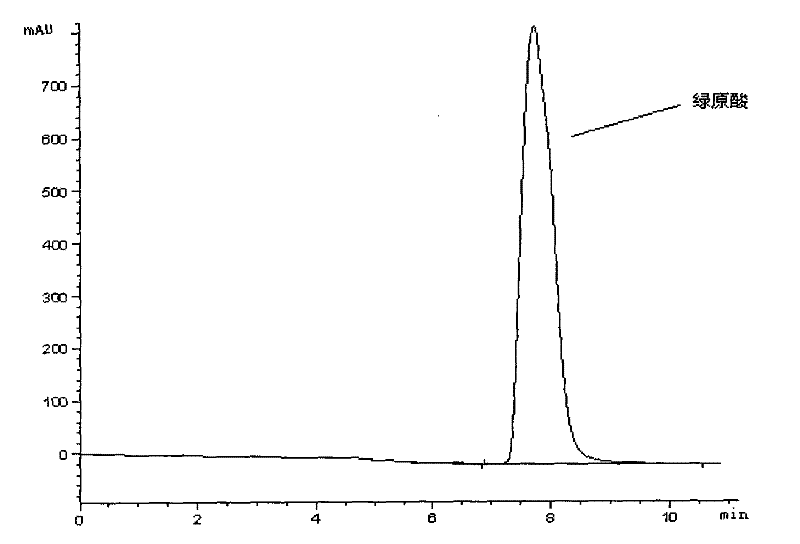

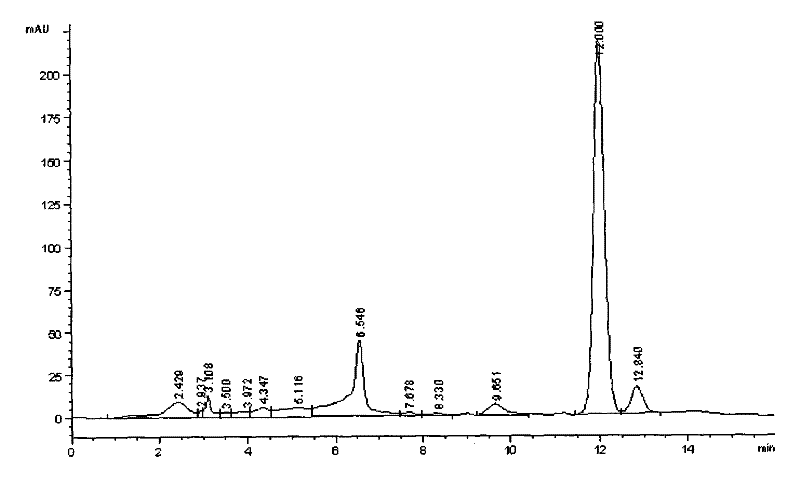

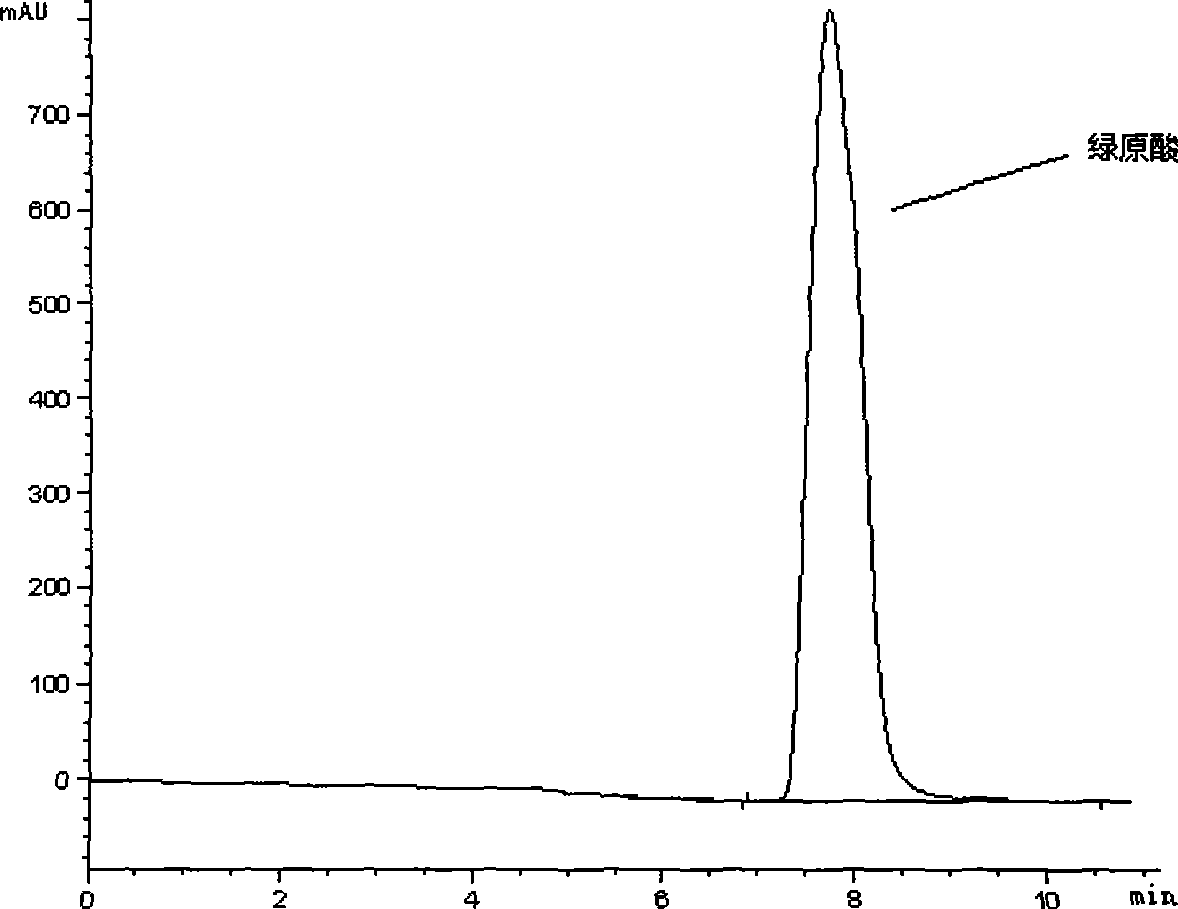

Method for preparing chlorogenic acid by using Jerusalem artichoke

InactiveCN101747196AValue development and utilizationHigh yieldOrganic compound preparationCarboxylic acid esters preparationChlorogenic acidPolyamide

The invention relates to a method for extracting chlorogenic acid from Jerusalem artichoke. The method is that, after the water of the jerusalem artichoke is removed and the enzyme is activated, the raw material is extracted by using solvent under the action of ultrasonic wave or microwave, chlorogenic acid extract liquid is obtained after solid-liquid separation, and finally pure chlorogenic acid is obtained after adsorption separation through polyamide or macroporous resin, elution and refining. The solvent can be water, organic solvent or mixed solution of organic solvent and water. Through the fixation treatment of the Jerusalem artichoke and the extraction by using the organic solvent or water under the assistance of the ultrasonic wave or the microwave, the yield of chlorogenic acid is improved and the extraction time is reduced. By using Jerusalem artichoke to extract pure chlorogenic acid, the source of raw material for preparing chlorogenic acid is widened, more valuable development and utilization of the Jerusalem artichoke are realized, and the economic benefit and the social benefit are better.

Owner:NANJING NORMAL UNIVERSITY

Cotton and wood composite cellulose pulp and method for producing same

InactiveCN1844497AShinyHigh whitenessConjugated cellulose/protein artificial filamentsVegetable materialWood fibreSlurry

This invention discloses a compound fiber new-type slurry pulp and it's making method. The compound fiber new-type pulp is composed of the materials that are two or more than two among velveteen, wood, hemp, bamboo. The making steps as follows: brewing, washing, syringing, beating, mixing up, removing impurities and washing, preparing acid, preparing chlorine, bleaching, acid dealing, removing impurities and washing. This invention can satisfy various needs of the pulp material for viscose.

Owner:YIBIN GRACE

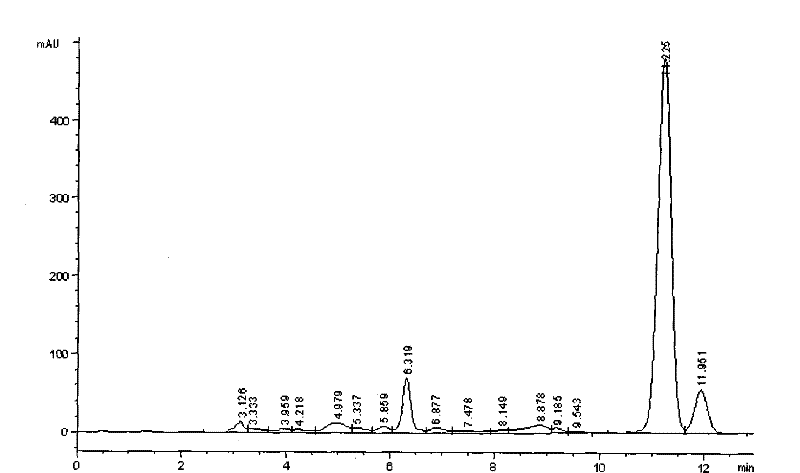

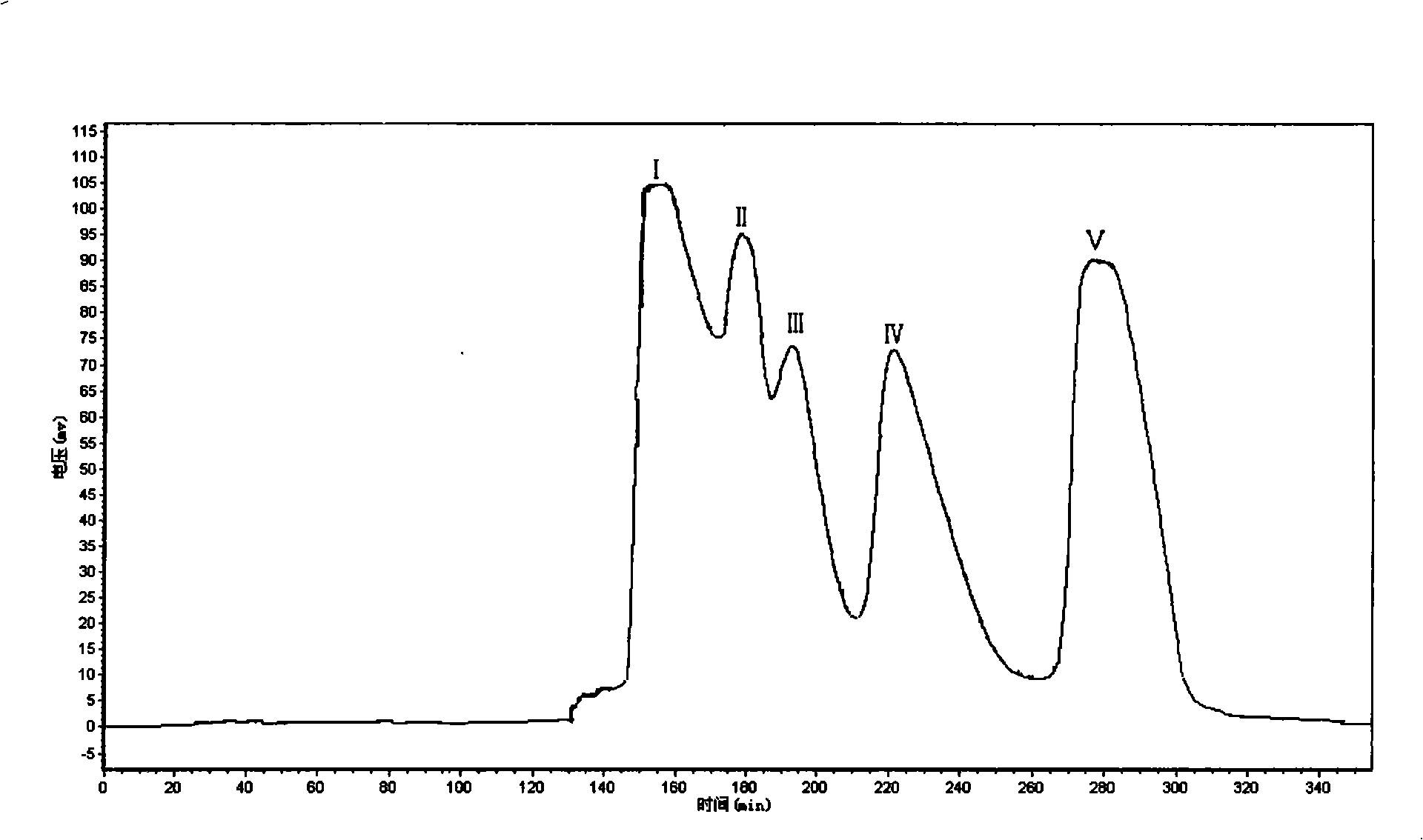

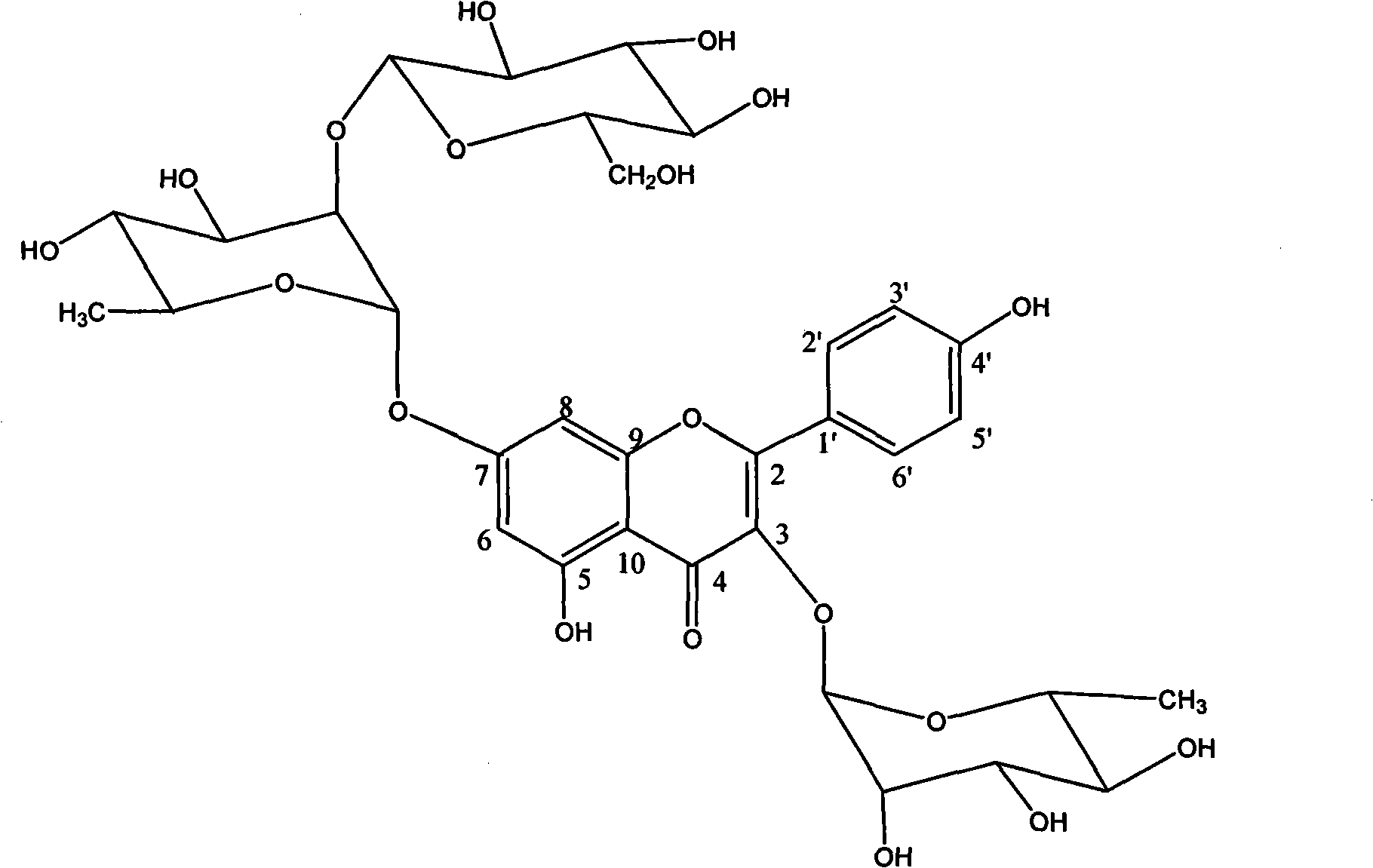

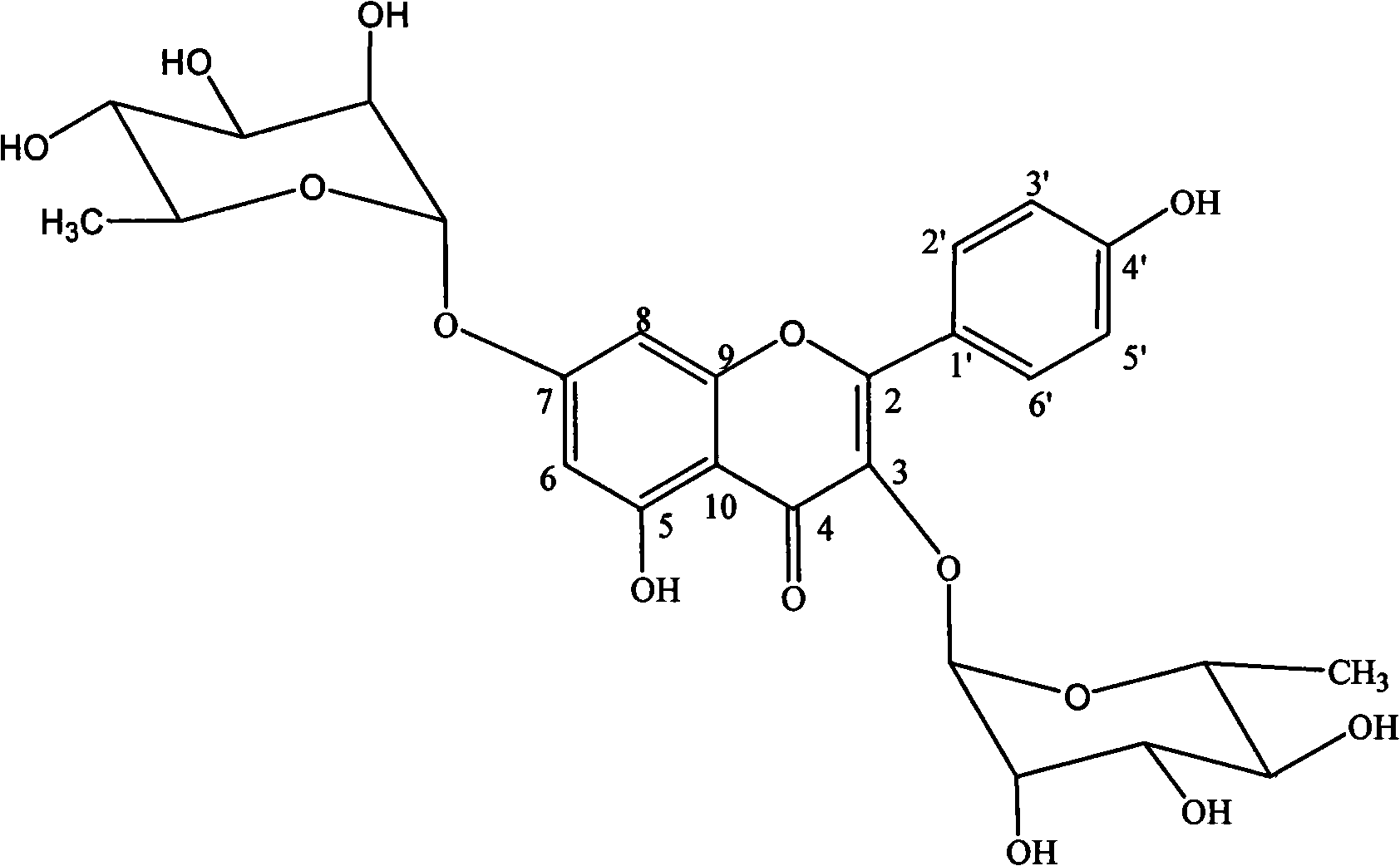

Method for separating and purifying Momordica grosvenori leaf chromocor compound by high-speed countercurrent chromatography and products thereof

InactiveCN101353363ABroaden sources of raw materialsAvoid wastingSugar derivativesSugar derivatives preparationChromatographic separationEthyl acetate

The invention discloses a method for separating and purifying a flavone compound of momordica grosvenori leaves by HSCCC and the product thereof, wherein, the method of the invention comprises the following steps: the grosvenori leaves are added with water or other polar solvents so as to carry out reflux extraction; the obtained extracts adopt the mixed solution of ethyl acetate, normal butanol and water as a solvent system and are separated and purified by a preparation-type high-speed counter current chromatograph, and then kaempferol-3-O-Alpha-L- rhamnose-7-O-[Beta-D-glucosyl group(1-2)-O-L-rhamnoside] and kaempferol-3,7-Alpha-L-2- rhamnoside. In the method, by applying the HSCCC method to separate and purify the extracts of the momordica grosvenori leaves, two flavone compounds with higher purity are successfully obtained by separation, thereby extending the source of the raw materials for flavone products; moreover, the method has simple preparation technique, easy operation and high purification efficiency, lays the solid first stone for extraction and utilization of the effective components in the momordica grosvenori leaves, and can avoid environment pollution caused by the waste and throw of a large amount of momordica grosvenori leaves.

Owner:GUANGXI NORMAL UNIV

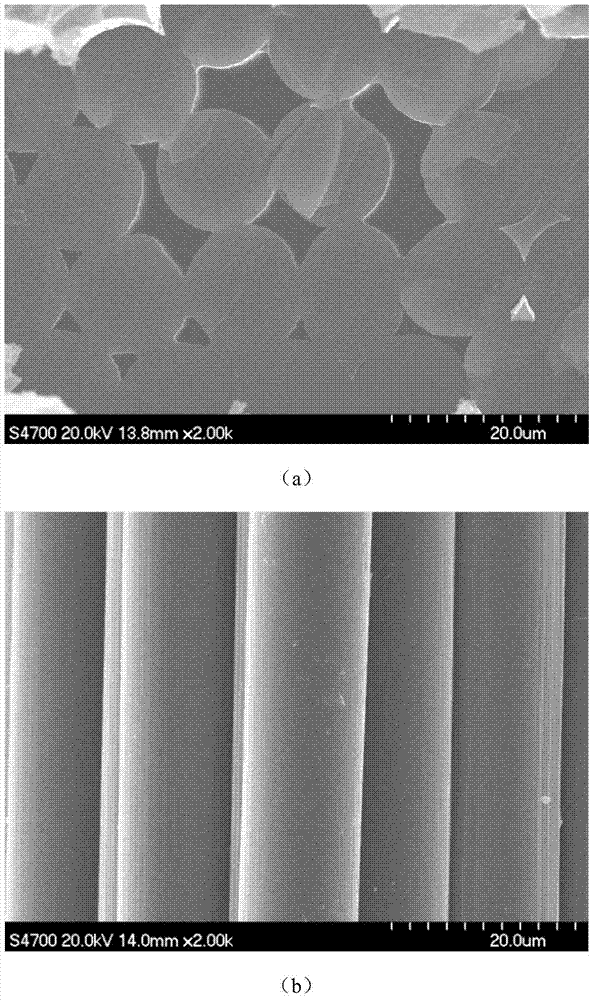

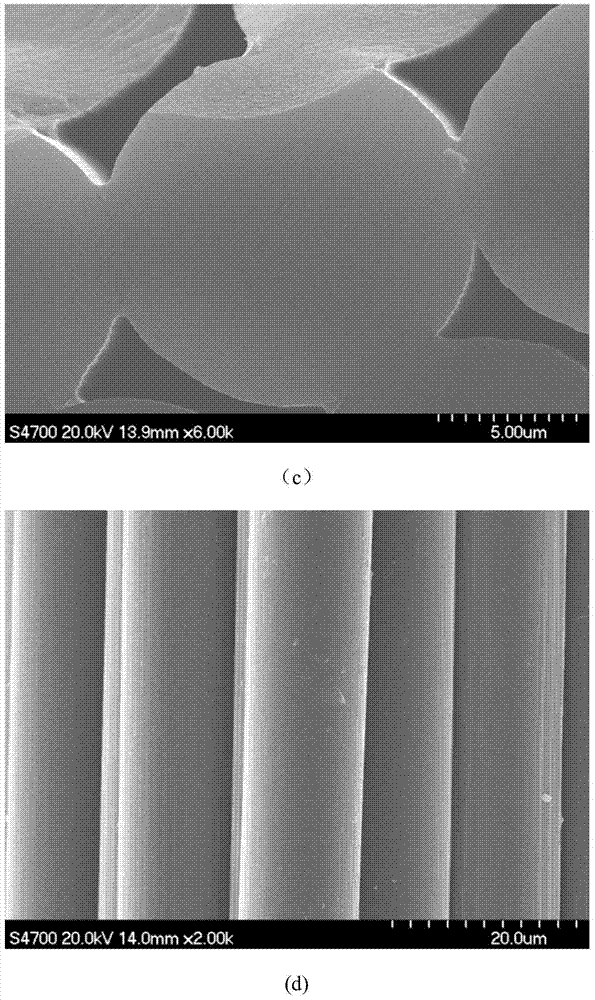

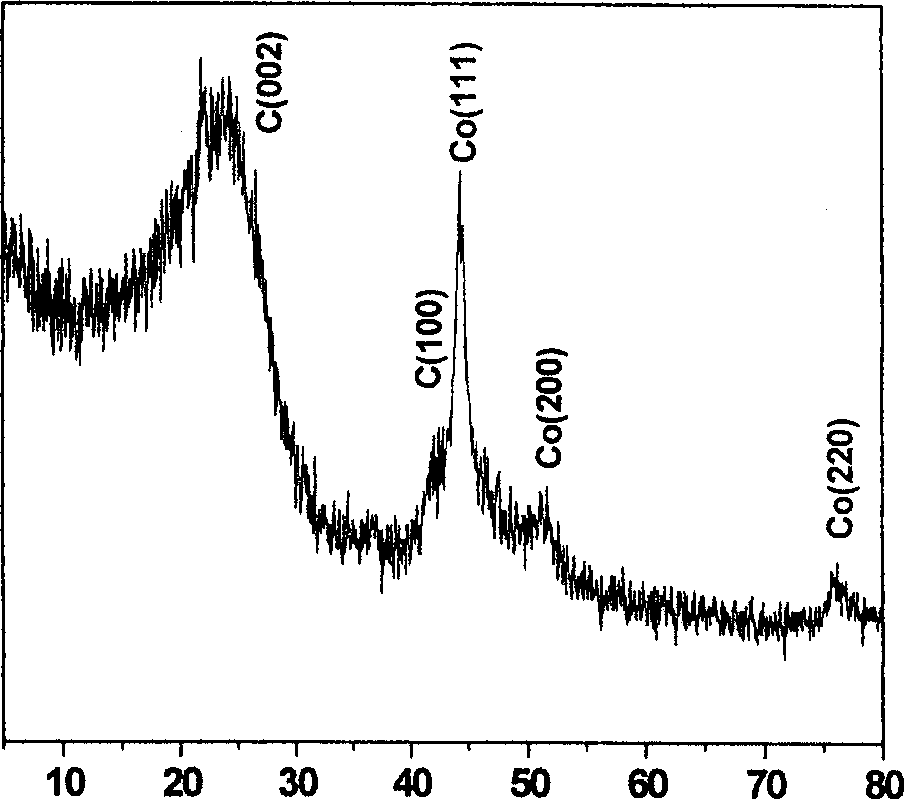

Polyamide acid/polyacrylonitrile-based carbon fiber and preparation method thereof

The invention provides a polyamide acid / polyacrylonitrile-based carbon fiber and a preparation method thereof, and belongs to the technical field of carbon fibers. The method comprises the following steps: firstly, preparing PAA / PAN primary blending fibers from a PAA / PAN blended solution by adopting a wet spinning method; heating the PAA / PAN fibers at an air atmosphere at 200-280 DEG C to cyclically transform PAA into polyimide (PI) and PAN to realize pre-oxidation so as to obtain PI / pre-oxidized PAN blended yarns; and treating at high temperature in the protection of inert gas to prepare the carbon fibers. The method is short in production cycle, the prepared carbon fibers have the advantages of high compactness, high coefficients of electric and thermal conductivities and small thermal expansion coefficient, and a novel source is provided to exploration of carbon fiber raw materials.

Owner:BEIJING UNIV OF CHEM TECH

Method for hydrotreating ethylene tar

The invention discloses a method for hydrotreating ethylene tar, which comprises the following steps of: performing fractional distillation on the ethylene tar by selecting a proper cutting point to obtain light and heavy fractions; making the light fraction contact a hydrogenation protective agent, a hydrogenation refining catalyst, a hydrogenation carbon residue catalyst and a hydrocracking catalyst in turn, reacting to obtain products, and separating the products to obtain gasoline and diesel fractions; and making the heavy fraction contact a hydrogenation protecting catalyst, a hydrogenation carbon residue removing catalyst and a hydro-conversion catalyst in turn to obtain hydro-conversion generated oil, wherein partial hydro-conversion generated oil is circulated to enter a hydrogenation reaction area, and the rest hydro-conversion generated oil is separated to form gasoline and diesel fractions. In the method, according to composition characteristics of the light and heavy fractions of the ethylene tar, different hydrotreating schemes are selected, so that the ethylene tar is converted into fuel oil to the greatest extent, the problem of high temperature rise of a hydrogenation reactor bed can be effectively solved, the running period of the device is prolonged, full fractions of the ethylene tar are fully utilized and the added value of the ethylene tar is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ceramic coating burning colorful sand and method for making same

The present invention relates to the sintering color sand with ceramic coating, the aggregates of which are basalt sand grains. The sintering color sand is coated with a color ceramic coating and the color ceramic coating is composed of pigments and adhesives. The present invention is characterized in that the adhesives are aluminium dihydric phosphates; calculated according to the mass ratio, the raw materials are composed of 1000 portion of sand grains, 7 to 20 portion of adhesives and 3 to 20 portion of pigments. The preparation method of the sintering color sand with ceramic coating is that 100 portion of phosphoric acids, 5 to 20 portion of aluminum hydroxides and 8 to 25 portion of water are mixed together and stirred so as to react with each other, thus making the adhesives by cooling the mixtures; the basalt stones are broken up into 8 to 40 order of sand grains; 1000 portion of sand grains, 7 to 20 portion of adhesives and 3 to 20 portion of pigments are stirred uniformly and sintered and the temperature ranges from 300 to 900 Celsius system; cooling is carried out after the sintering to obtain the product. The solidifying temperature of the adhesives of the present invention is low and the sintering is firm; the process is simple and the energy consumption is obviously reduced, thus reducing the cost; the defects that the surface of the products in the prior art is rough, the color difference is large, the color is not uniform, the white head comes into existence for the products, etc are eliminated. The latent solvents are added in the optimization scheme, thus further lowering the sintering temperature.

Owner:江苏欧文斯彩砂科技有限公司

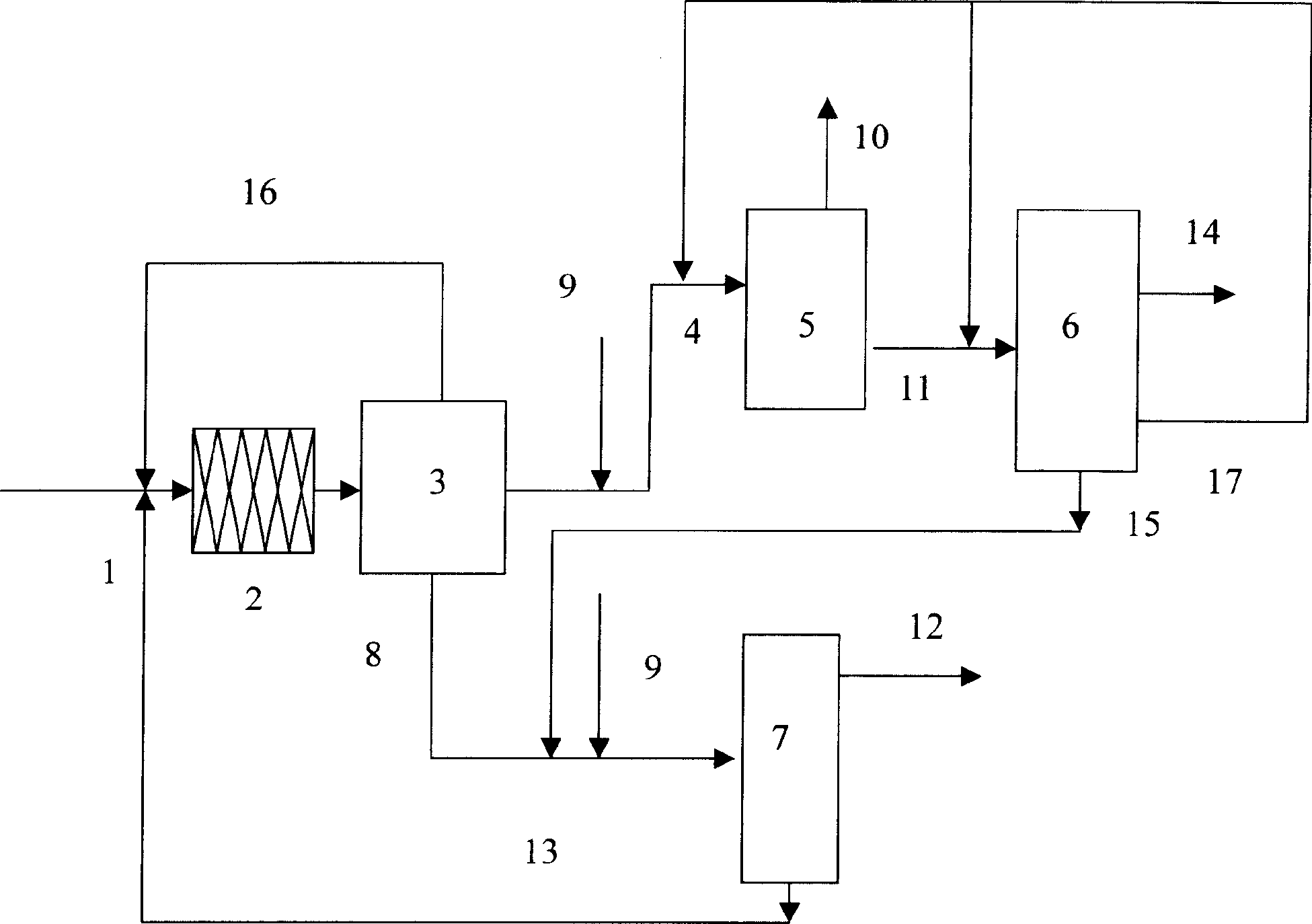

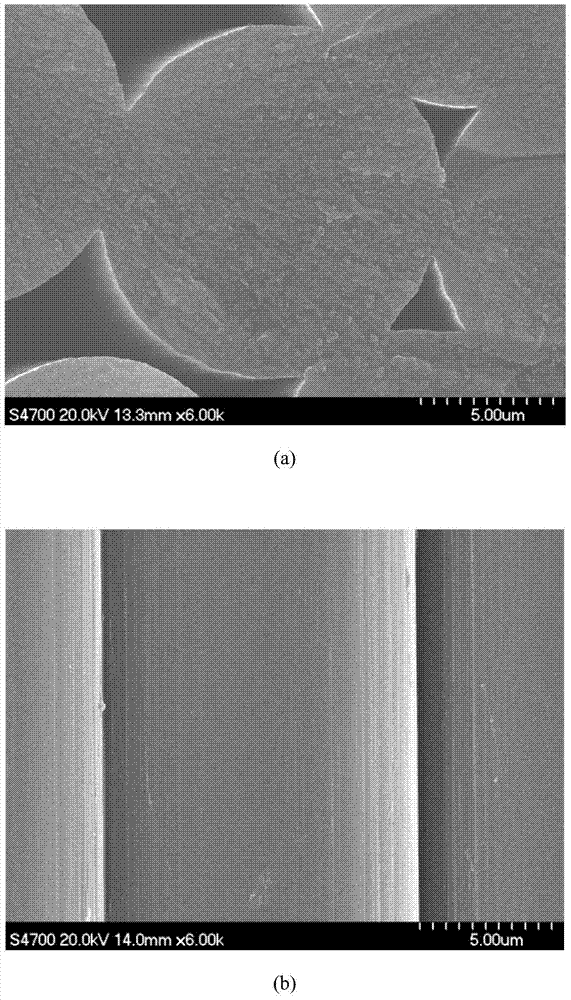

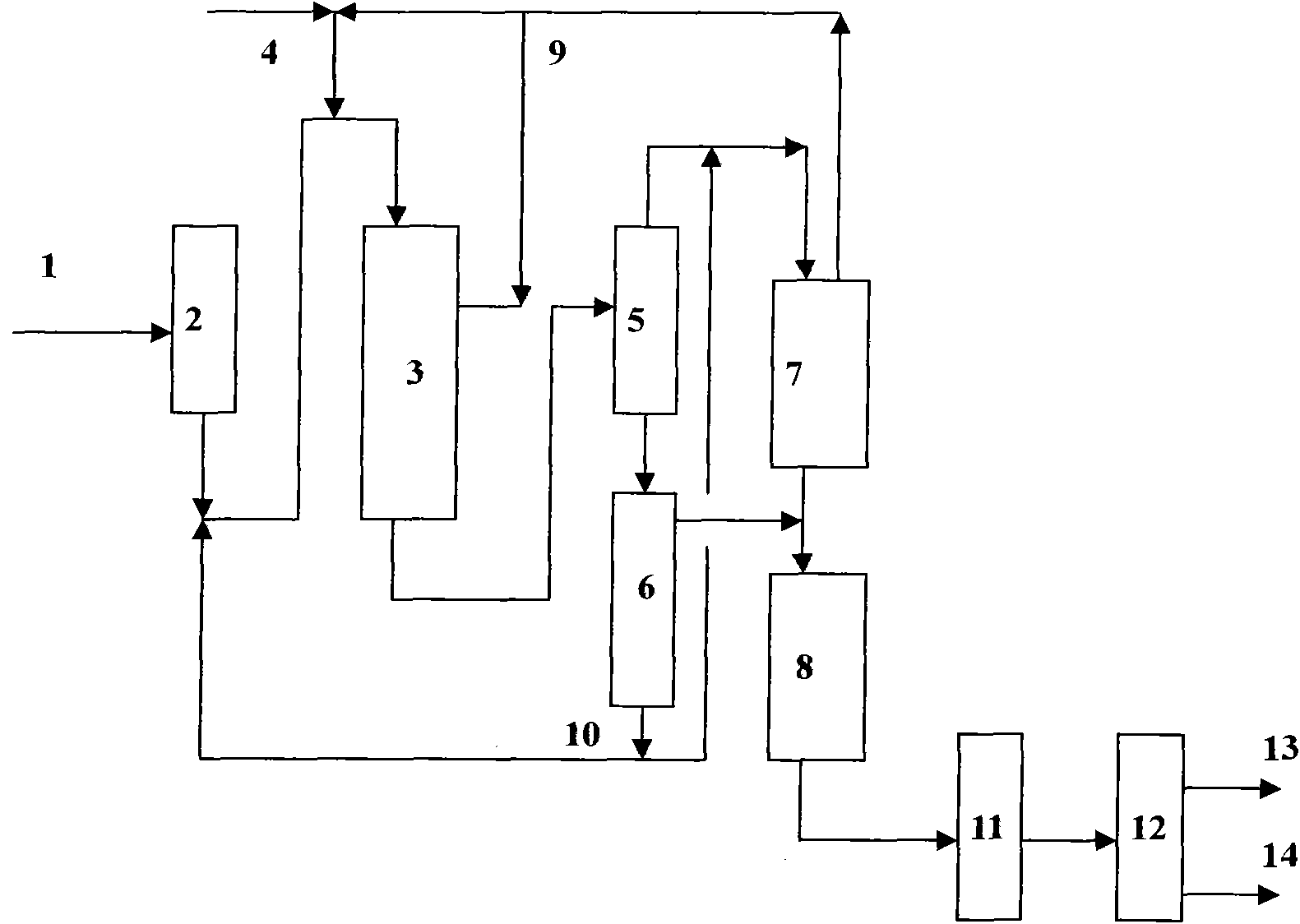

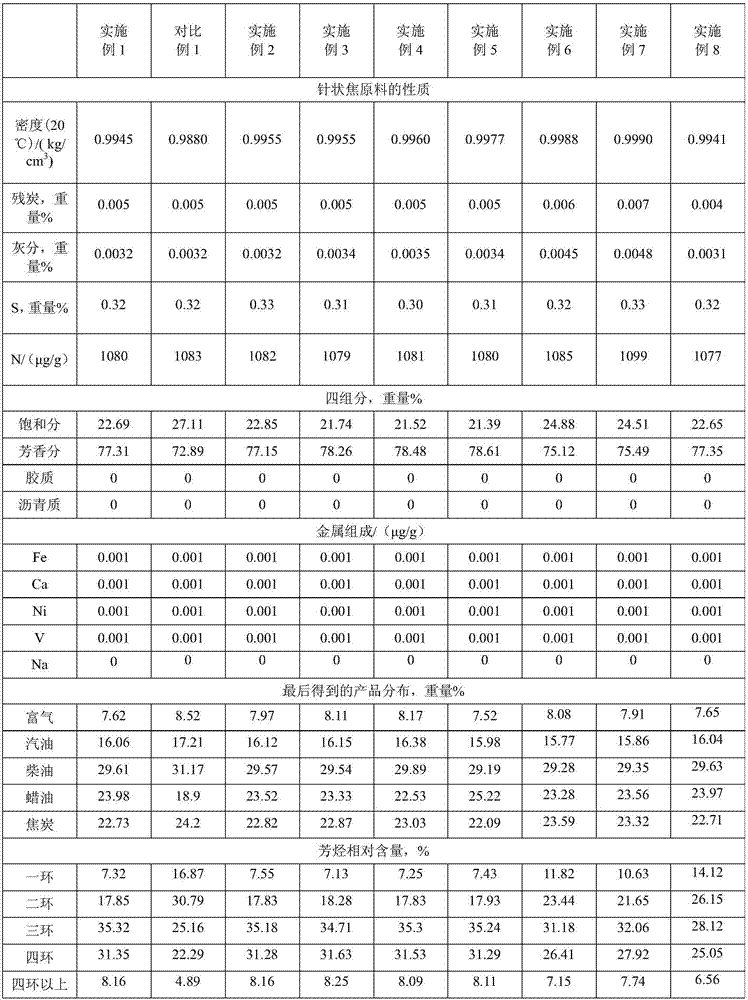

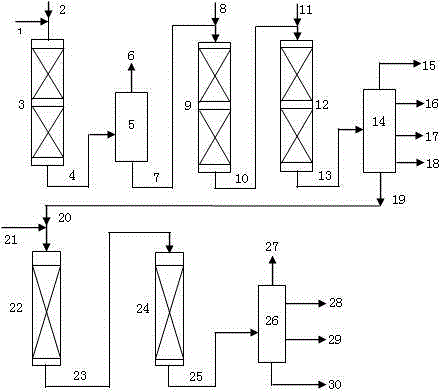

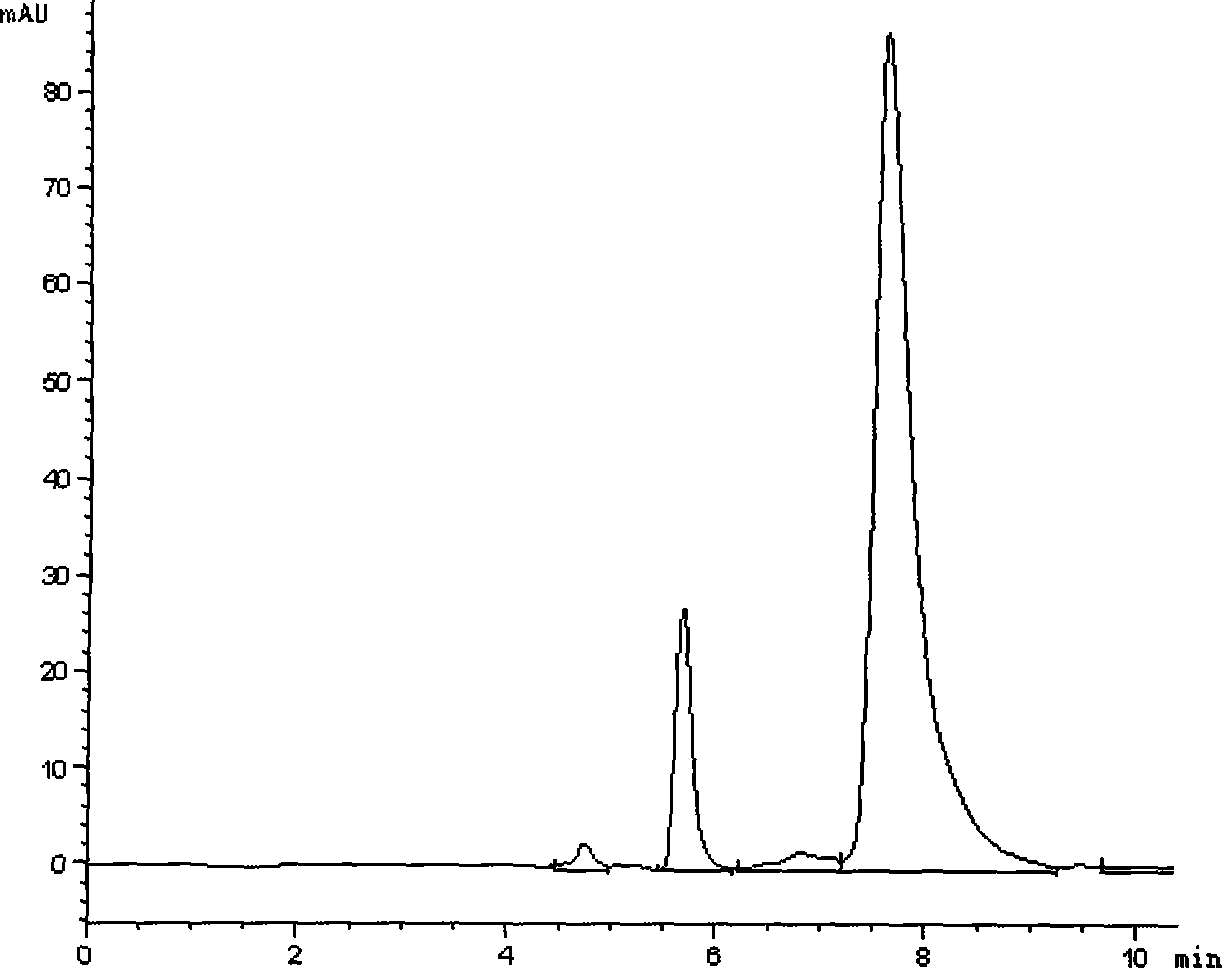

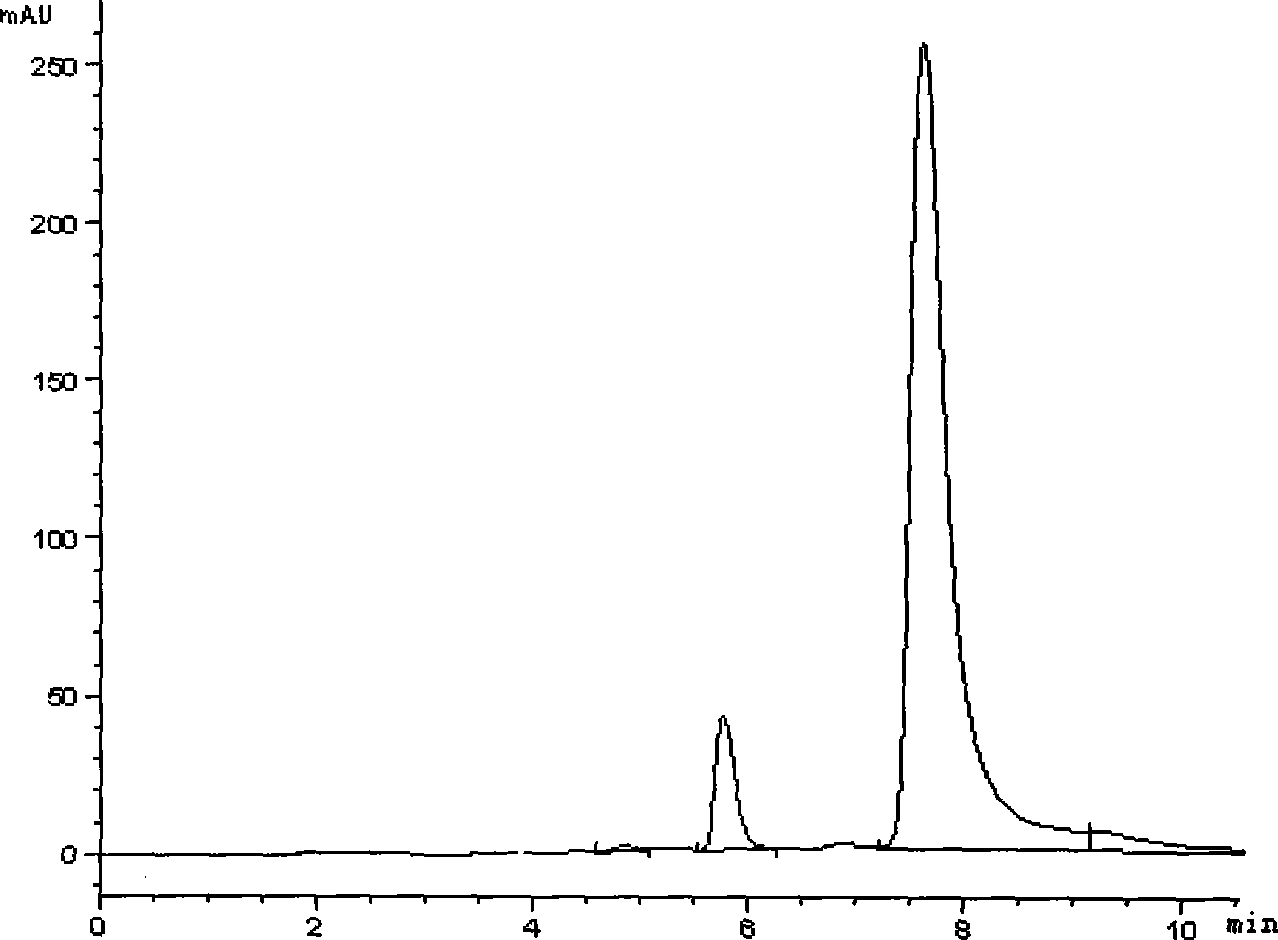

Method and equipment for preparing needle coke crude materials

ActiveCN107987880AQuality improvementExpand sourceTreatment with hydrotreatment processesFractionationSlurry

The invention relates to the field of preparation of needle coke crude materials and discloses a method and equipment for preparing the needle coke crude materials. The method comprises steps as follows: (1), a mixed crude material containing catalytic cracking slurry oil and a coking crude material is subjected to a cracking reaction, and an oil-gas mixture is obtained; (2), the oil-gas mixture is subjected to fractionation, and a gas oil component is obtained; (3), the gas oil component is subjected to hydrotreatment, and a hydrogenated product is obtained; (4), the hydrogenated product is separated into a gas oil light component rich in monocyclic and bicyclic aromatic hydrocarbons and a gas oil heavy component rich in tricyclic and tetracyclic aromatic hydrocarbons; (5), the gas oil light component is subjected to a condensation reaction, and a liquid-phase component rich in tricyclic and tetracyclic aromatic hydrocarbons is obtained. According to the method, the high-quality needle coke crude materials can be prepared through effective utilization of the catalytic cracking slurry oil, the crude material source of needle coke is widened, and quality of the needle coke crude materials is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing carboxymethyl cellulose by cotton dropped on the ground

InactiveCN101768220AReduce environmental pollutionBroaden sources of raw materialsChemistrySodium carboxymethylcellulose

The invention relates to a preparation method of carboxymethyl cellulose, in particular to a method for preparing carboxymethyl cellulose by cotton dropped on the ground, which belongs to the technical field of polymer chemistry. The preparation method comprises: taking waste cotton dropped on the ground during spinning as a raw material and refining the cotton dropped on the ground; and obtaining a product of the invention by performing carboxymethylation to cellulose through processes of activation to the cellulose as well as etherification reaction, neutralization reaction and washing to the activated cellulose. The invention can broaden raw materials of the carboxymethyl cellulose and reduce the production cost and production risks brought by shortage of raw materials; and the cotton dropped on the ground produces no poisonous and harmful substances during purification, and has no emission of waste water, waste residue and waste gas, thereby reducing the environmental pollution.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Application of decoction dregs as pulping raw material of paper making

InactiveCN101275370AReduce consumptionSolve pollutionNatural cellulose pulp/paperDigestersFiberPulp and paper industry

The inventive Chinese medicine dregs used as paper-making pulping raw material pertains to the paper-making pulping technique field, especially relates to a Chinese medicine dregs as raw material pulping. The object of the invention is to provide a paper pulp for preparing corrugated paper, wrapper paper and the like, taking the Chinese medicine dregs as raw material through a mechanical physical method pulping method and technique. The method and technique includes: boiling multiform chinese medicine dregs in pressure vessels or normal pressure steamers; pulp milling, pulp washing and pulp mixing in a mechanical method; respectively obtaining fibre pulp and powdery deposited matter. The fibre pulp can be used for preparing various paper products such as corrugated paper or wrapper paper; the deposited matter and paper making water can be used as organic inorganic fertilizer, animal fodder, or the like after a precipitating centrifuge process.

Owner:吴水生

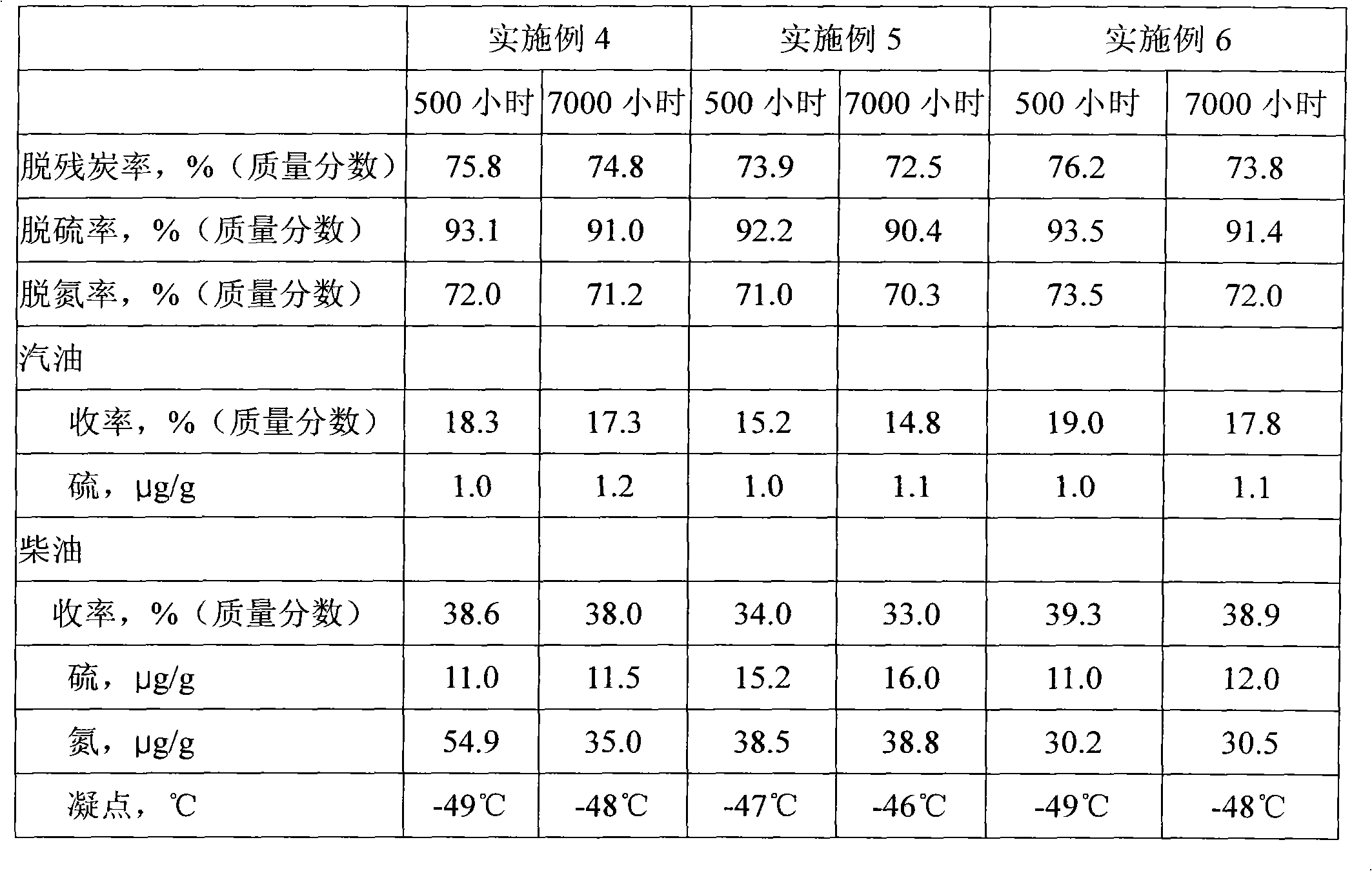

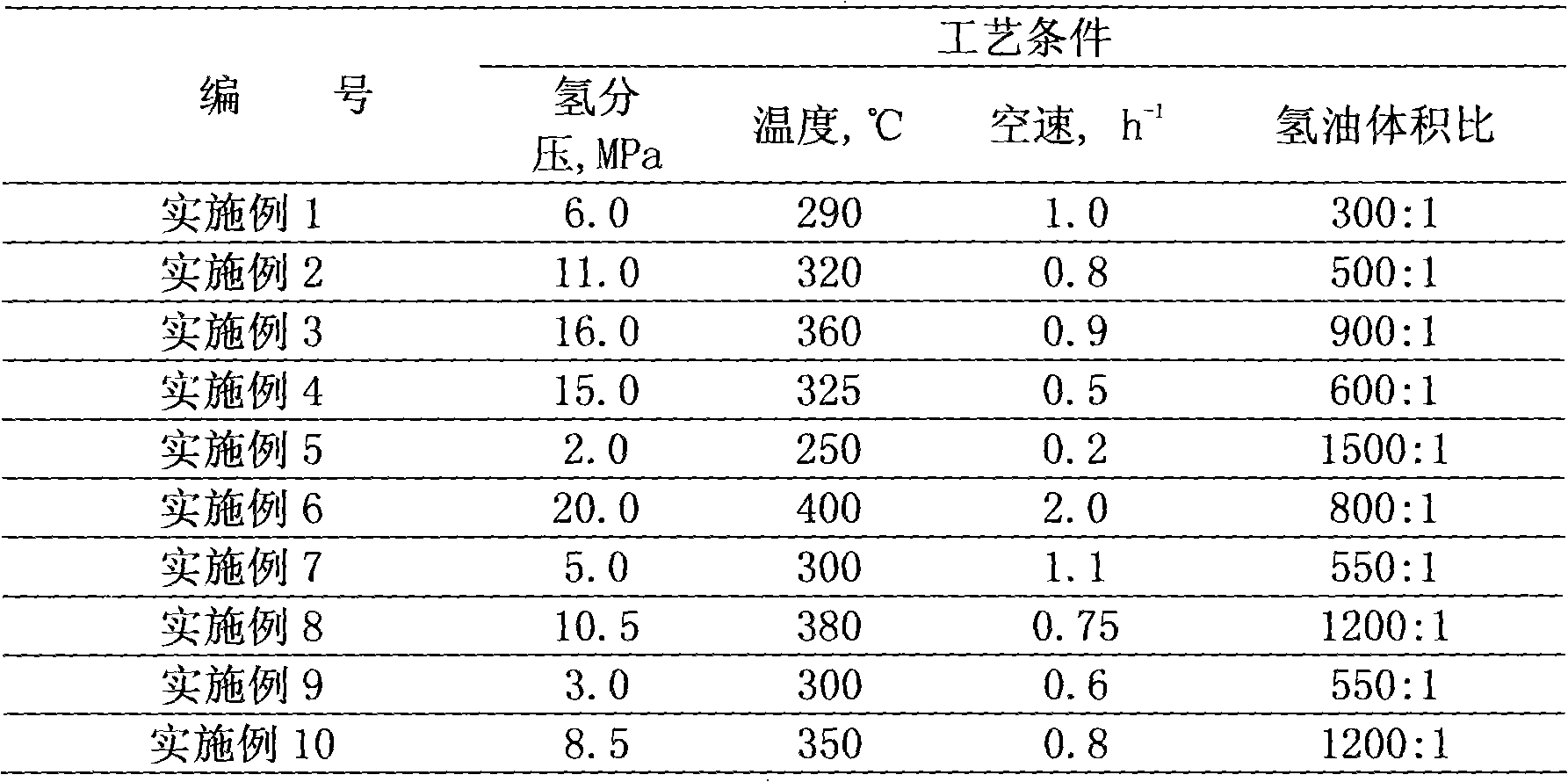

Hydrogenation method for producing lubricating oil base oil through poor-quality heavy distillate oil

ActiveCN104611037AEffectively play an active roleBroaden sources of raw materialsTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenNitrogen

The present invention discloses a hydrogenation method for producing lubricating oil base oil through poor-quality heavy distillate oil. According to the method, poor-quality heavy distillate oil and hydrogen gas enter a first-stage reaction zone to carry out a hydrorefining reaction, the reaction effluent is separated, the obtained liquid enters a second-stage reaction zone to carry out a hydrorefining reaction, the second-stage reaction effluent enters a third-stage reaction zone to carry out a hydrocracking reaction, the hydrocracking effluent is separated, and at least part of the tail oil and new hydrogen are mixed and then are subjected to an isomerizing dewaxing and finishing reaction to obtain various lubricating oil base oils. With the method of the present invention, the nitrogen-containing impurities in the poor-quality raw material can be subjected to hydrotreating under the relatively mild condition so as to make the poor-quality raw material meet the hydrocracking feeding requirement, such that the lubricating oil base oil raw material source is broadened; and the hydrorefining temperature is substantially reduced so as to increase the operation period of the device and process the poor-quality raw material, or increase the processing capacity of the device in the same operation period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for extracting and separating chlorogenic acid from chrysanthemum

InactiveCN101445456ASolve the problem of low extraction rate and inability to extract single componentsHigh yieldOrganic compound preparationCarboxylic acid esters preparationMicrowave - actionChlorogenic acid

The invention relates to a method for extracting and separating chlorogenic acid from chrysanthemum. The method comprises the following steps: after water-removing is performed to a chrysanthemum, the raw material is lixiviated with solvent under the ultrasonic or microwave action, the crude extract of the chlorogenic acid is obtained after through solid-liquid separation, and then the chlorogenic acid pure product is obtained after through resin adsorption, separation and elution. The solvent is water, organic solvent or organic solvent-water mixed liquor. The water-removing is performed to the chrysanthemum, and the chrysanthemum is lixiviated with organic solvent or water at assistance of ultrasonic sound and microwave. Therefore, the yield of the chlorogenic acid can be improved, the production cycle is reduced, the chlorogenic acid pure product is obtained not the mixture with other ingredients, and the chlorogenic acid monomer is extracted form one chrysanthemum. Therefore, the range of the raw material of the chlorogenic acid can be extended, especially for the chrysanthemum in Canada, the chrysanthemum can turn the harmful into the beneficial and waste into valuable after development and utilization, and the invention has good economic, social and environmental benefits.

Owner:NANJING NORMAL UNIVERSITY

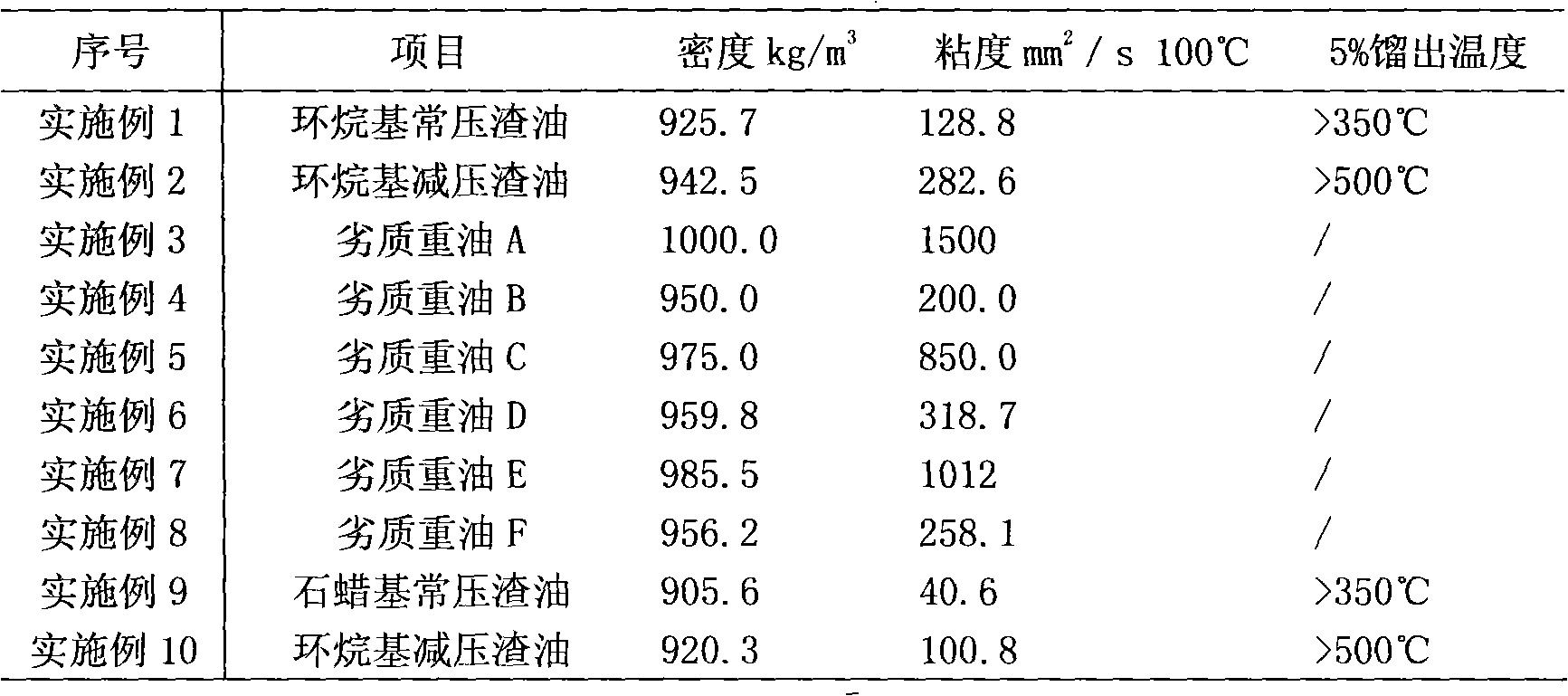

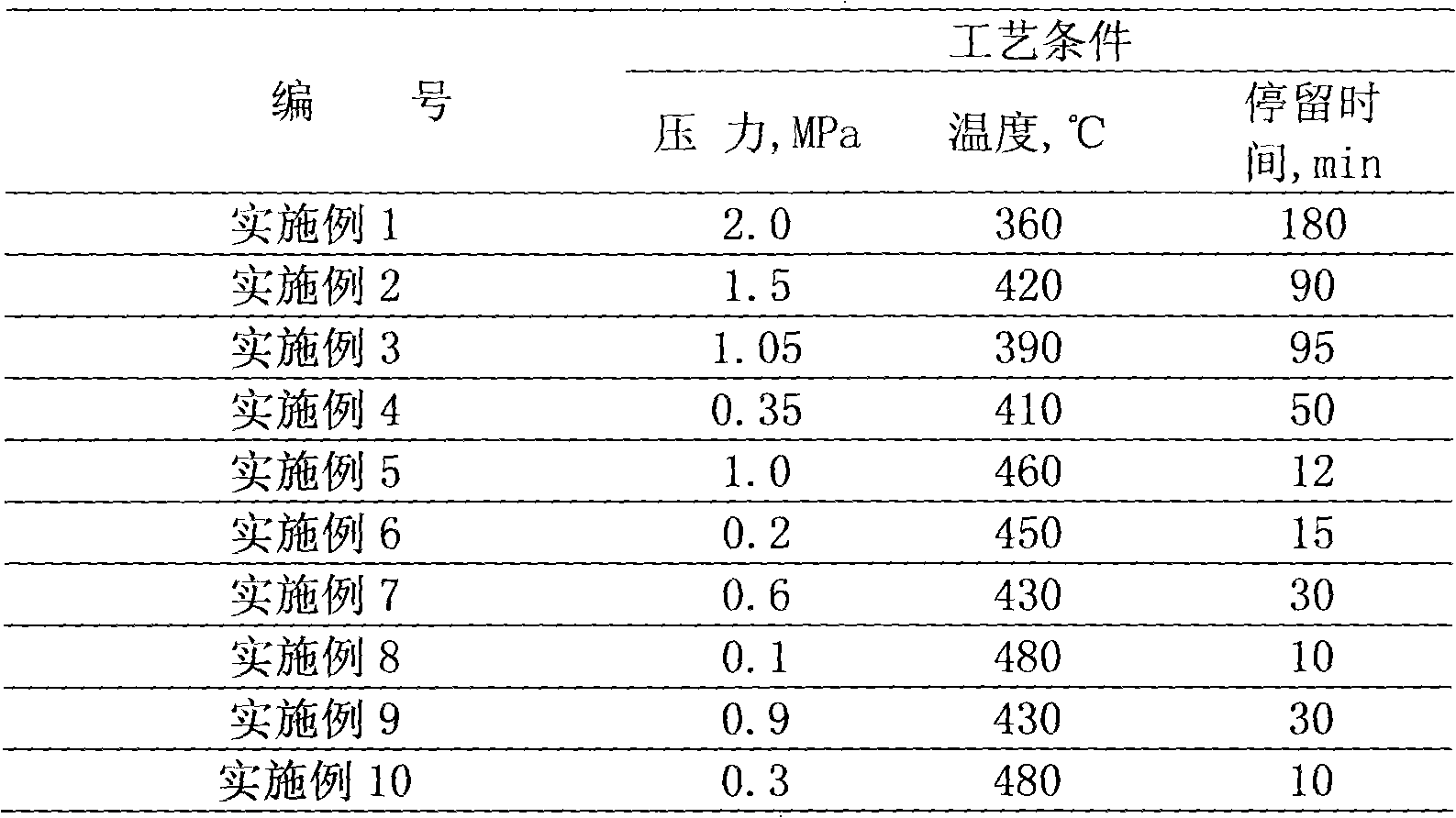

Preparation method of base oil of transformer oil

ActiveCN102485846ABroaden sources of raw materialsExpand sourceLiquid organic insulatorsTreatment with hydrotreatment processesParaffin waxSide chain

The invention relates to a preparation method of base oil of transformer oil. The preparation method utilizes inferior heavy oil and naphthenic atmospheric / reduced pressure residuum and / or paraffin-based atmospheric / reduced pressure residuum as raw materials and comprises the following steps of heating the raw materials, feeding the heated raw materials into a reactor, carrying out cooling and fractionation of the reaction products to obtain a fraction of 260 to 360, carrying out hydrofinishing of the fraction of 260 to 360 to remove S atoms, N atoms and O atoms, carrying out an olefin saturating process and an aromatic hydrocarbon hydrogenation process, carrying out solvent-based refining of the hydrofinished oil obtained by the previous step to remove polycyclic short-side chain aromatic hydrocarbons, compounds containing S, O and N, and colloid asphalt so that refined oil is obtained, carrying out hydrogenation sedimentation of the refined oil to remove a high-pour point component, and carrying out white clay-based refining of the hydrogenation sedimentation product oil obtained by the previous step to obtain white clay refined oil, wherein the white clay refined oil is the base oil of transformer oil. The preparation method provided by the invention widens raw material sources of base oil of transformer oil. Through the preparation method, the base oil of transformer oil has good viscosity-temperature characteristics and accords with standards of the IEC60296 (2003) standard, the ASTM D3487 standard, the GB 2536-90 standard and the SH0040-91 standard.

Owner:PETROCHINA CO LTD +1

Method for preparing active carbon from licorice waste residue

InactiveCN104326471ABroaden sources of raw materialsGood societySolid waste disposalActivation methodActive agent

The invention discloses a method for preparing active carbon from licorice waste residue, belonging to the field of preparation of active carbon. According to the method, the licorice waste residue is used as a raw material, and the active carbon is prepared by adopting a chemical activation method under an appropriate process condition, wherein the appropriate process condition for preparing the active carbon is determined by controlling the influence of factors including the category and concentration of an active agent, a solid-liquid ratio, the activation time, the activation temperature and the like on the yield and adsorption performance of the active carbon. The method comprises the procedures of treating the licorice waste residue and activating with potassium hydroxide or phosphoric acid to obtain a finished product. The active carbon is prepared by adopting a potassium hydroxide or phosphoric acid activation method, so that Chinese medicinal residue can be transformed from low additional value to high additional value, environmental pollution is reduced, the raw material source for producing the active carbon is widened, and a new path is developed for recycling Chinese medicinal residue.

Owner:NINGXIA MEDICAL UNIV

Method for making mushroom culture medium by using kitchen waste and grape branches as main materials

ActiveCN103708971ABroaden sources of raw materialsReduce manufacturing costBio-organic fraction processingOrganic fertiliser preparationBiotechnologyShiitake mushrooms

The invention discloses a method for making a mushroom culture medium by using kitchen waste and grape branches as main materials, and belongs to the technical field of edible fungi cultivation. The culture medium is prepared from main raw materials of treated kitchen waste and grape branches and urea and wheat bran as auxiliary materials through adding a mixed bacterium agent and a mixed enzyme and adding auxin through controlling the fermentation by stage type temperatures. According to the method for making the mushroom culture medium, provided by the invention, organic macromolecular substances and substances such as lignin, cellulose, hemicellulose and pectin in the grape branches, which are available to edible mushrooms, can be rapidly and effectively degraded, and transformed into micromolecular substances which can be utilized and absorbed by mushroom hypha, so that the source of raw materials of the mushroom culture medium is enlarged, the production cost of the mushroom is reduced, the cultured mushroom is good in shape and delicious in taste, the yield and quality of the mushroom are improved, the cyclic utilization of changing the kitchen waste and the grape branches into valuables is realized, and the pressure faced by the municipal environment is solved.

Owner:天津北洋百川生物技术有限公司

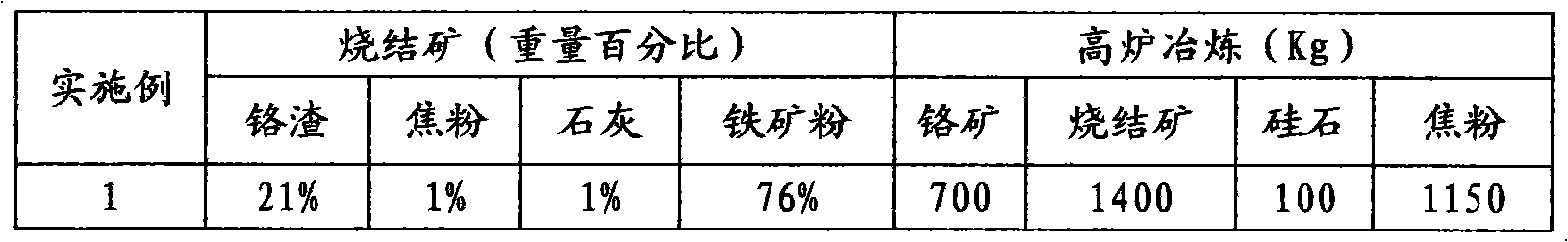

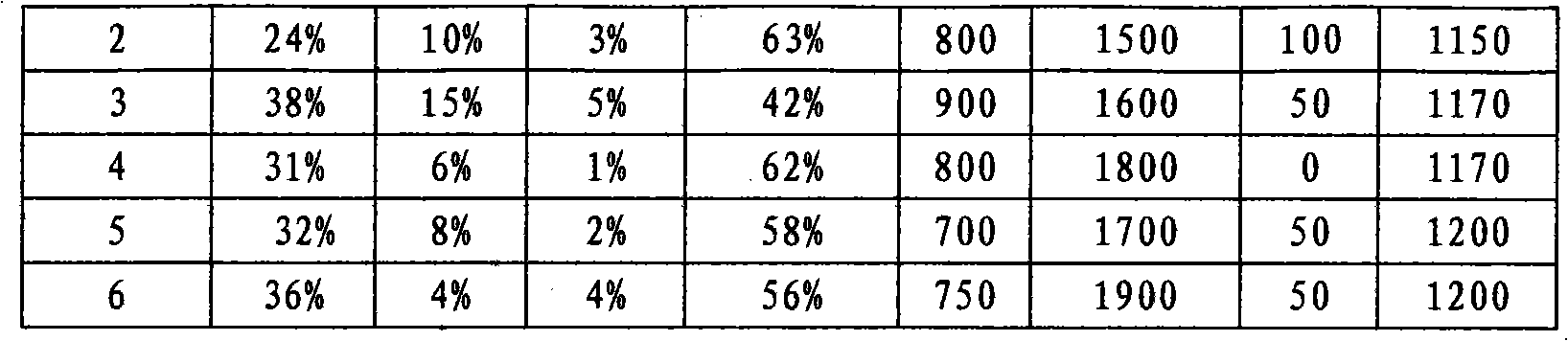

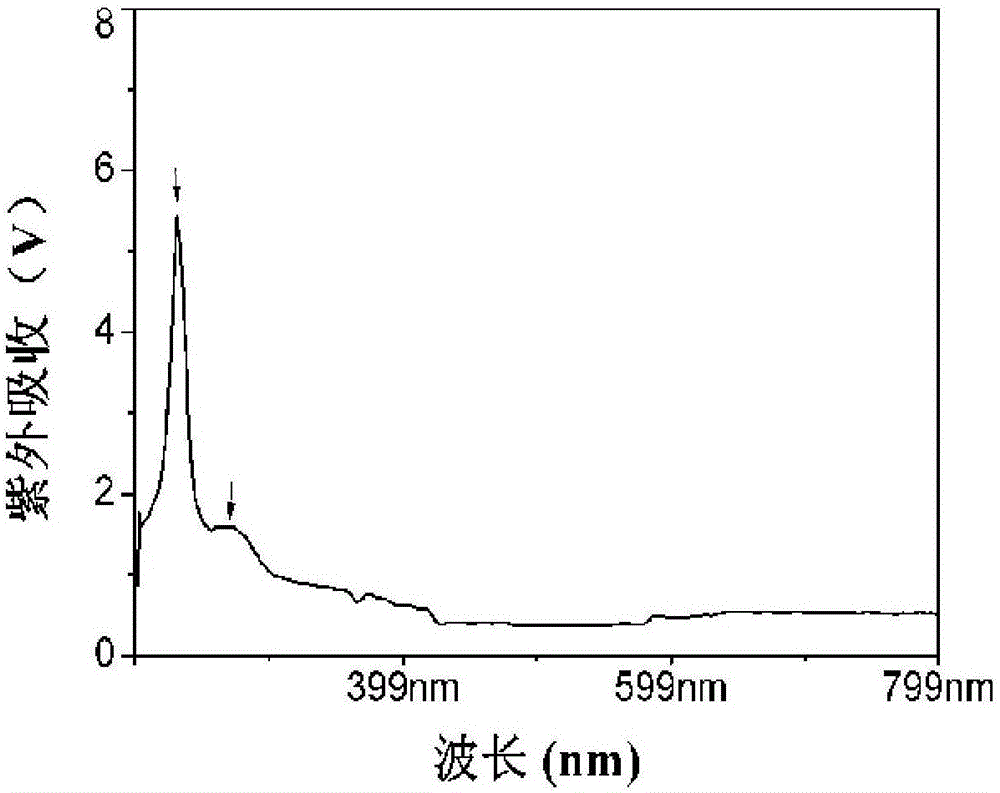

Method for smelting low chromium pig iron by utilizing chromium slag

InactiveCN101875987AExpand raw material sourcesBroaden sources of raw materialsBlast furnace detailsProcess efficiency improvementChromiumRaw material

The invention discloses a method for smelting low chromium pig iron by utilizing chromium slag, which is characterized in that low chromium pig iron is prepared by carrying out granulation after mixing the chromium slag, iron ore powder, coke powder and lime, sintering granules by a sintering machine to form sintered ores after granulation, and then sending the sintered ores into a blast furnace to smelt. The invention has the advantages that the chromium slag is adopted as raw materials and smelted to form the low chromium pig iron by utilizing the blast furnace, thereby treating the harmful waste chromium slag, also increasing the raw material source of the low chromium pig iron, providing a new economic and practical raw material source to industries of stainless steel, wear resistance cast and the like and changing waste into valuable.

Owner:TULUFAN SHENHONG METAL IND

Composite cellulose viscose filament yarn with composite cellulose pulp as raw materials made of cotton, wood, hemp and bamboo mixture, and preparation method thereof

InactiveCN1865547AShinyGood air permeabilityConjugated cellulose/protein artificial filamentsSpinning solutions preparationManufacturing efficiencyNatural fiber

The invention discloses a composite fiber viscose filament and preparing method, which adopts the following random two or more combination as raw material: cotton velvet, hemp, wood, bamboo, straw and crust. The preparing method comprises the following steps: blending pulp; immersing; squeezing; grinding; etiolating; adhering glue to grind; dissolving; grinding; filtering; ripening; debubbling; spinning; refining; drying to make cylinder. The invention reduces cost to improve manufacturing efficiency with excellent paintability, elasticity, desiccating and air permeability, which is better than kinds of synthesizing fiber.

Owner:YIBIN GRACE

Method for producing water-soluble potassium ammonium phosphate from wet-process phosphoric acid

ActiveCN103011122AHigh purityLess impurity ionsSilicon halogen compoundsPhosphorus compoundsPhosphatePhosphoric acid

The invention relates to a method for producing water-soluble potassium ammonium phosphate from wet-process phosphoric acid. According to the method, a monoammonium phosphate solution is prepared from low-cost wet-process phosphoric acid as the raw material by the steps of desulfuration and defluorination and neutralization with ammonia; then the replacement reaction of the monoammonium phosphate solution and potassium chloride and the crystallization are carried out to obtain a water-soluble fertilizer which contains potassium dihydrogen phosphate as a main component and adopts ammonium dihydrogen phosphate as an auxiliary component, wherein the content of chlorine is smaller than 2%; and excess potassium chloride and nitrogen produce a by-product such as nitrogen phosphorus and potassium chloride water soluble compound fertilizer. Meanwhile, the by-product in the production process can be directly used as a citric acid soluble phosphatic fertilizer. The method has simple processes, and the prepared water-soluble ammonium potassium dihydrogen phosphate is high in purity, nutrient and potassium content. No waste residues are discharged in the whole process, so that the method is environment-friendly and has better social and economical benefits.

Owner:KINGENTA ECOLOGICAL ENG GRP

High-sulfating chondroitin sulfate (CS) and preparing method and application thereof

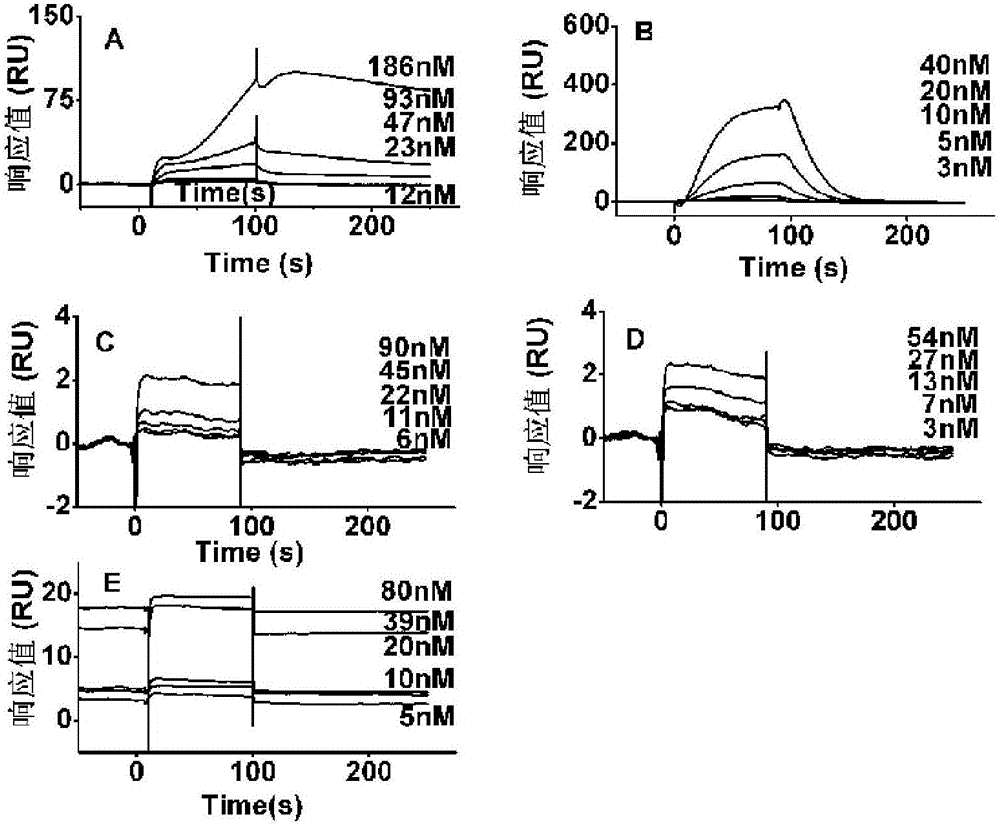

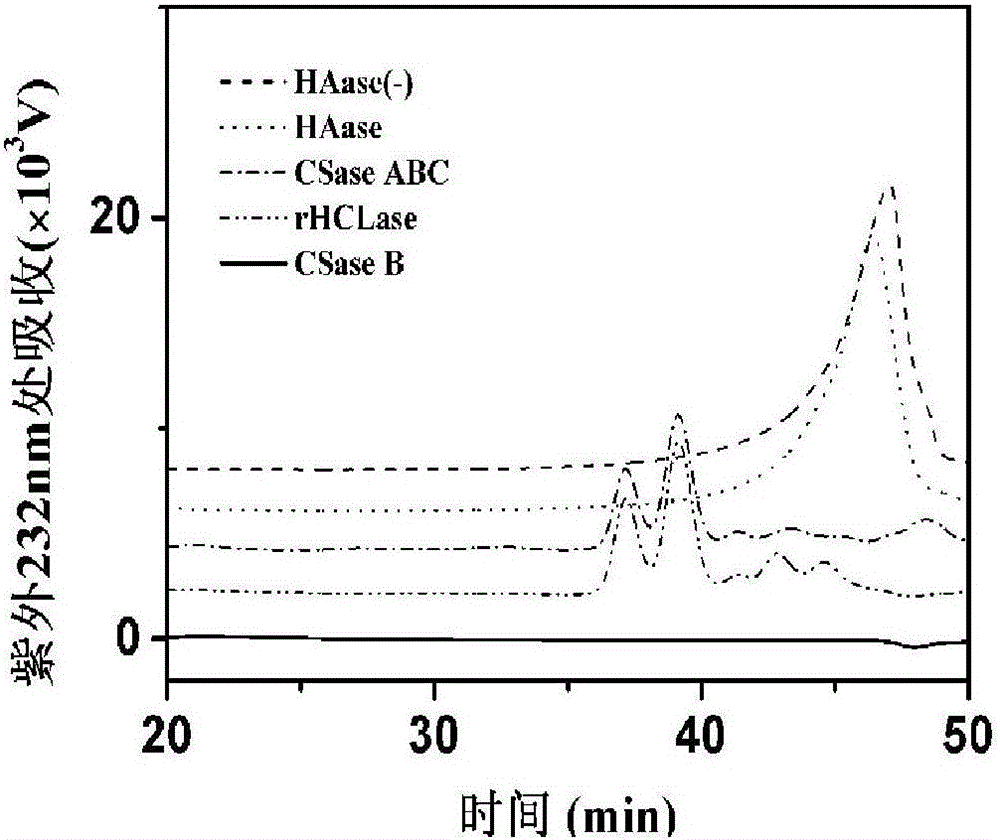

ActiveCN105924544AShorten the growth cycleIncrease productionOrganic active ingredientsAntineoplastic agentsSulfationChondroitin

The invention relates to a high-sulfating chondroitin sulfate (CS) and a preparing method and application thereof. According to the high-sulfating CS, the molecular weight is 100 KDa to 800 KDa, the sulfating degree is 0.7 to 1.43, and disaccharide compositions are O-units, C-units, A-units and E-units. The high-sulfating CS is a CS which is extracted from cartilage of dosidicus gigas and is rich in E-unit, and is a DG-CS with the specific disaccharide compositions, specific carbohydrate chain arranging and the specific molecular weight. An experiment proves that the high-sulfating CS has quite good anti-tumor metastasis activity.

Owner:SHANDONG UNIV

Limestone tailing-bricks and preparation method thereof

InactiveCN101638924AMaximize utilizationSolve the occupation of land resourcesSolid waste managementBuilding componentsBrickLand resources

The invention relates to limestone tailing-bricks and a preparation method thereof, which solves the maximization comprehensive utilization of the limestone tailings. Measures are as follows: the limestone tailing-bricks comprise components according to weight percentage: 60-92% of the limestone tailings and 8-10% of firming agent. The method is as follows: dehydrating the limestone tailings and controlling water content thereof to be less than or equal to 15%; again dehydrating and controlling water content thereof to be less than 5%; clearing lumps with grain size larger than or equal to 5;blending and controlling silt content to be 20-50% of the total weight; blending the limestone tailings with grain size less than or equal to 5 millimeter and the firming agent; watering and uniformlystirring; controlling the weight percentage of the blended raw materials thereof to be 9-11%; brick making and maintaining. The invention enlarges the raw material source of the brick making, causesthe limestone tailings to be fully used, solves the problem of stockpiling occupying land resources; and the prepared building bricks are in line with the national standard, has simple technique, stable quality control and low production cost.

Owner:武钢集团有限公司

Method for producing clean fuel oil from ethylene tar

ActiveCN103102974AIncrease profitBroaden sources of raw materialsTreatment with hydrotreatment processesTarFuel oil

The invention discloses a method for producing clean fuel oil from ethylene tar. The method consists of: fractionating ethylene tar into light fraction and heavy fraction, mixing the heavy fraction with a conventional coking raw material, conducting delayed coking to obtain coker gasoline and coker diesel oil, performing hydrofining on the coker gasoline, mixing the coker diesel oil with the ethylene tar light fraction, subjecting the mixture to hydrotreating, and leaving the reaction effluent and the coker gasoline hydrofining product together to undergo separation by a fractionating tower, thus obtaining clean gasoline and diesel oil products. Directed at the characteristics of high content of aromatic hydrocarbon, colloid, carbon residue and asphaltene in ethylene tar, the method provided in the invention fractionates the ethylene tar into light fraction and heavy fraction, and adopts different processing processes according to the composition characteristics of each fraction, thus not only enhancing the utilization rate of ethylene tar, increasing the yield of light fuel oil, but also improving the product quality of light fuel oil, and enabling the equipment to run smoothly for a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

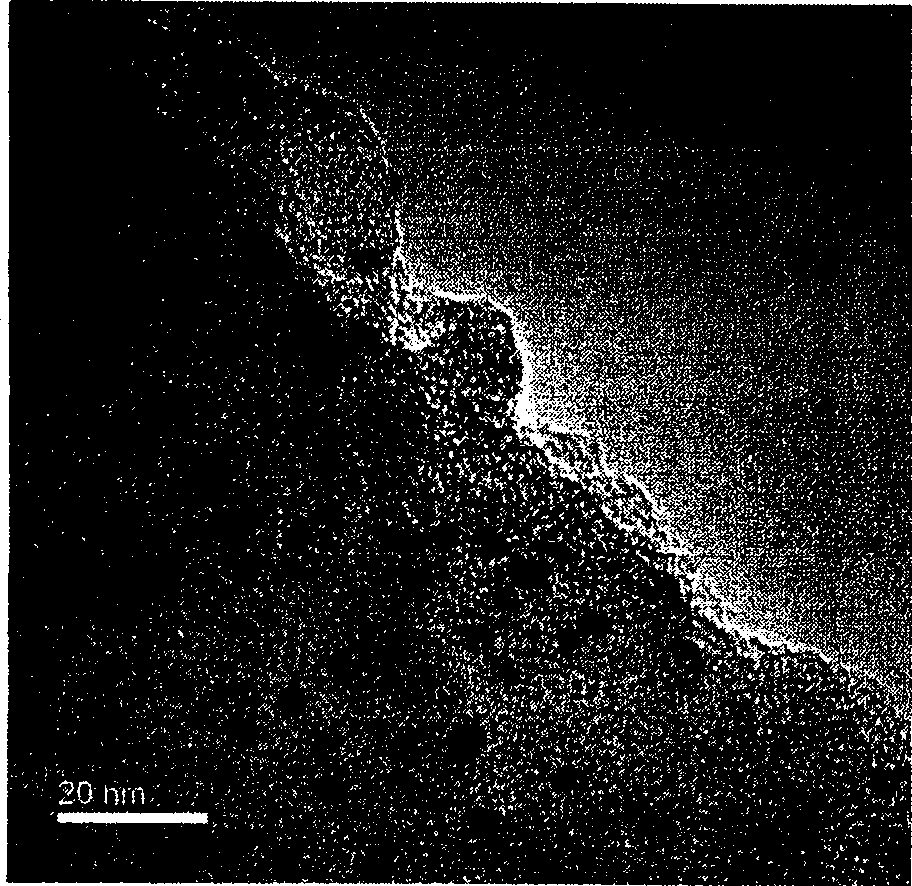

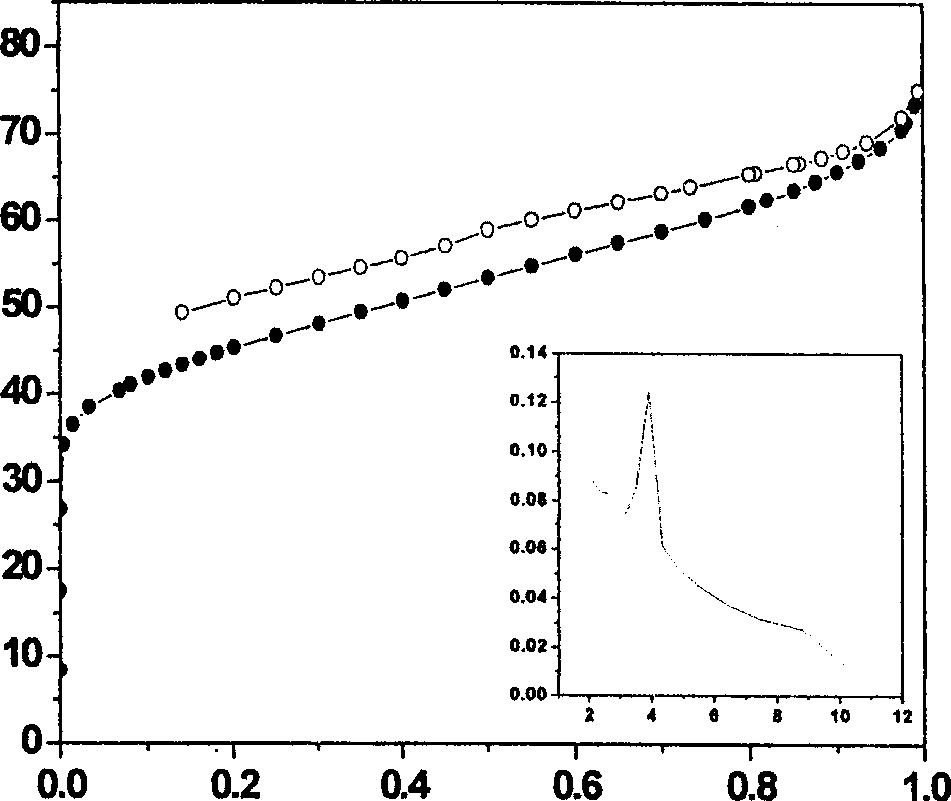

Method for preparing metal or metallic oxide/carbon composite material

InactiveCN101376114AEasy to implementSimple process routeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsCarbon compositesCarbon source

The invention belongs to the scientific and technical field of carbon materials, and provides a method for preparing metal or metal oxide / carbon composite materials by asphaltine. The method takes the by-product asphaltine in the coal liquefaction process as a carbon source, takes a pyrolytic polymer as a pore-forming agent, and takes easily-pyrolytic metal salt as a metal precursor; and then the metal or the metal oxide / carbon composite materials are prepared by one step after the physical blending and carbonizing reductive treatment. The metal or the metal oxide / carbon composite materials prepared by the method have the controllable appearance that the metal or the metal oxide is uniformly dispersed in a carbon carrier with the grain diameter of 3-50nm. The preparation process has simple routes, mild conditions, conventional equipment, low cost, and controllable output of products, and is suitable for mass production. The prepared metal or the prepared metal oxide / carbon composite materials can be used as a highly-active catalyst, an adsorbent, a magnetic separation material, an electrode material and the like.

Owner:DALIAN UNIV OF TECH

Colored photoelastic polyester fine denier carpet yarn and preparation method thereof

ActiveCN102286819AIncrease productionLow priceYarnPigment addition to spinning solutionWeather resistanceEngineering

The invention relates to a colored glossy elastic polyester fine-denier carpet yarn and a preparation method. The carpet yarn is a plied yarn of 1,200 to 3,600dtex formed by at least two twisted polyester single yarns of 600 to 1,800dtex; and the twisted polyester single yarn is formed by multifilaments of a colored, glossy, fine-denier, profiled and three dimensional crimped polyester filament yarn. The preparation method comprises the steps: firstly, carrying out fibrous colored spinning procedures comprising spinning, false twist deformation and yarn doubling in the field of garment; secondly, obtaining three dimensional crimped polyester filament yarns with colors, fine-deniers and heteromorphous sections; and thirdly, obtaining colored, glossy and elastic polyester fine-denier carpetyarns through the post processing procedures comprising strand combing and sizing in the field of carpet yarns. The colored glossy elastic polyester fine-denier carpet yarn solves the problems of poor handfeel, resilience and dyeing property of the polyester fiber, not only can meet the requirements on the characteristics of carpet products, such as coverage, bulkiness, resilience, lodging resistance and foot-feel comfort, but also has the characteristics of high weather resistance, good color fastness, and energy-saving high-temperature high-pressure dyeing prevention.

Owner:CHANGZHOU LINGDA SPECIAL FIBER

Treatment method of ethylene tar

ActiveCN103102976AImprove economic efficiencyAvoid concentrated heatDistillation purification/separationTreatment with hydrotreatment processesCrystallization PurificationGasoline

The invention discloses a treatment method of ethylene tar. The method consists of: fractionating ethylene tar into light fraction and heavy fraction, mixing the heavy fraction with a conventional coking raw material, conducting delayed coking to obtain coker gasoline, coker diesel oil and coker gas oil, mixing the coker diesel oil with the ethylene tar light fraction, performing rectification / crystallization purification to obtain naphthalene, mixing the naphthalene removed oil, naphthalene after-cut oil, with the coker gasoline and the coker gas oil, taking the obtained mixture as a hydrotreating raw material, leaving the material to undergo a hydrofining reaction, separating gasoline fraction I, subjecting the obtained fraction heavier than gasoline to hydrocracking so as to obtain gasoline fraction II and a diesel oil product, and mixing the gasoline fraction II with the gasoline fraction I so as to obtain a final gasoline product. Directed at the characteristics of high content of aromatic hydrocarbon, colloid, carbon residue and asphaltene in ethylene tar, the method provided in the invention fractionates the ethylene tar into light fraction and heavy fraction, and adopts different processing processes, thus increasing the added value of ethylene tar. While generating the chemical raw material naphthalene, the method also improves the product quality of light fuel oil, and also enables the equipment to run smoothly for a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com