Method and equipment for preparing needle coke crude materials

A needle coke raw material and coking raw material technology, applied in the petroleum industry, hydroprocessing process, hydrocarbon oil treatment, etc., can solve the problems of difficulty in producing high-grade needle coke products, large investment, and affecting the quality of needle coke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

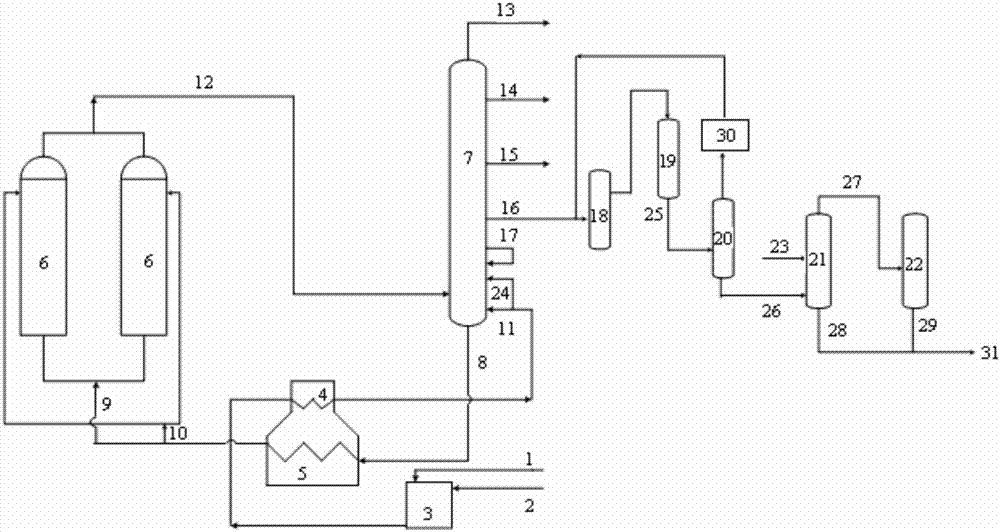

Image

Examples

preparation example Construction

[0051] Preferably, the condensation reaction is carried out in a wax oil reactor in the presence of a catalyst comprising an active component and a carrier, the active component containing at least one of iron, copper and nickel (such as iron, copper, nickel , iron-copper, iron-nickel, copper-nickel or iron-copper-nickel and other active components), the carrier contains at least one of alumina and molecular sieve (such as alumina carrier, molecular sieve or alumina-molecular sieve) , and based on the weight of the catalyst, the content of the active component in terms of elements is 5-35% by weight, and the content of the carrier is 65-95% by weight. When the active component contains multiple components, there is no special requirement for the ratio of the aforementioned multiple components, and it can be any ratio, as long as the total content of the active component in terms of elements can be satisfied as 5-35% by weight. ; When the carrier contains multiple components, t...

Embodiment 1

[0071] This example is used to illustrate the method for preparing needle coke raw material of the present invention.

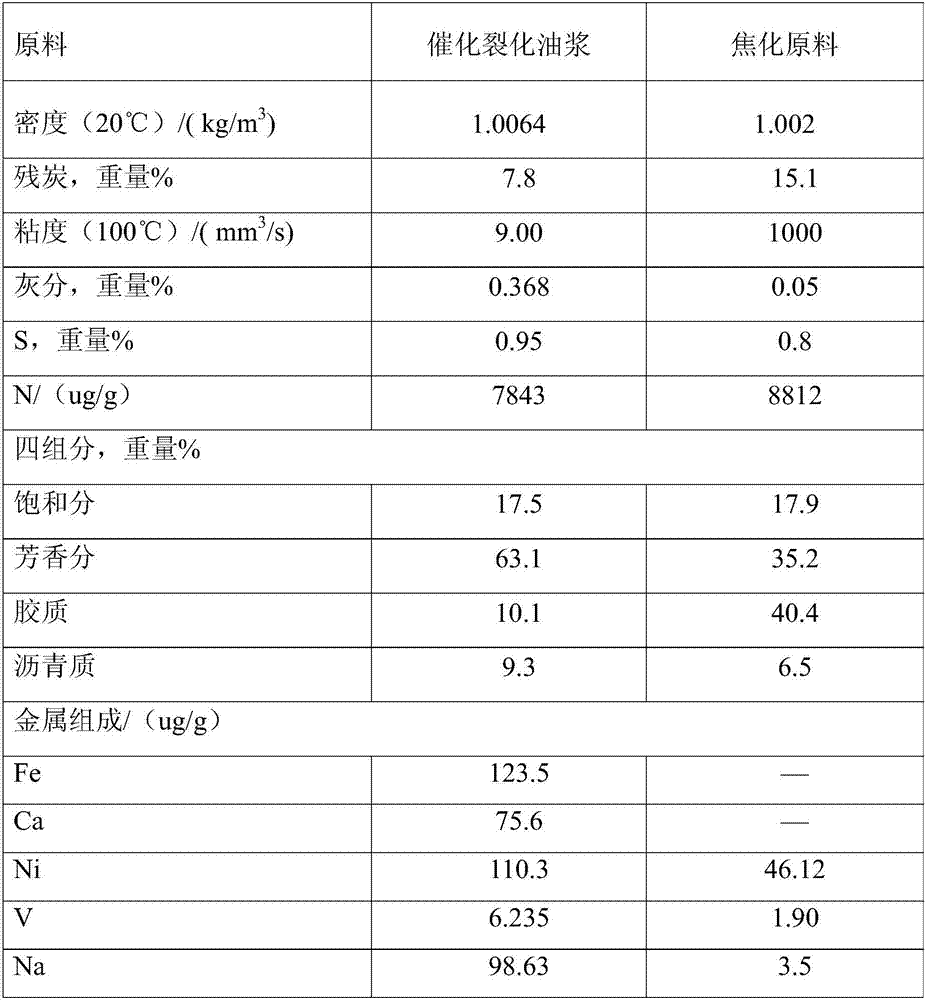

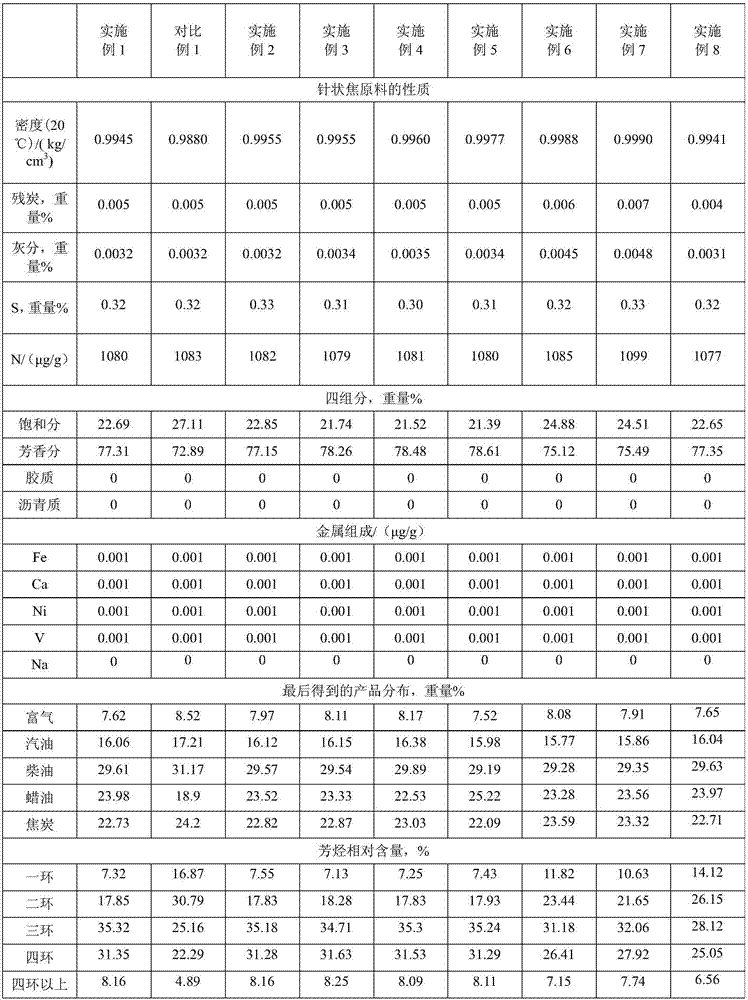

[0072] Such as figure 1 As shown, coking raw material 1 vacuum residue (related parameters are shown in Table 1) and catalytic cracking oil slurry 2 (related parameters are shown in Table 1) are mixed in mixer 3 at a weight ratio of 75:25, and extracted After heat exchange with coking gasoline 14, coking diesel oil 15, coking wax oil 16, coking heavy wax oil 17 ( figure 1 The heat exchange is not marked in ) enters the convection section 4 of the delayed coking heating furnace to preheat to 320 ° C, and then divides into two feeds, the upper feed 24 and the lower feed 11, and enters the lower part of the delayed coking fractionation tower 7, and in the delayed coking fractionation tower 7 The liquid phase stream formed after heat exchange between the high-temperature oil gas 12 from the delayed coking coke tower 6 in the lower part and the upper feed 24 and ...

Embodiment 2

[0076] This example is used to illustrate the method for preparing needle coke raw material of the present invention.

[0077] Adopt the method of embodiment 1 to carry out, difference is that vacuum residue and catalytic cracking oil slurry are mixed according to the weight ratio of 70:30 in mixer;

[0078] The conditions for the delayed coking reaction include: the temperature at the outlet of the heating furnace is 496°C, the pressure of the coke tower is 0.16MPa, the coking period is 28h, the proportion of the feed weight of the upper part of the coke tower to the total feed weight is 85%, and the cycle weight ratio 0.25:1, the length from the upper feeding position of the coke tower to the lower end of the cylinder accounts for 7 / 10 of the entire cylinder length;

[0079] The conditions of fractionation include: the temperature at the top of the fractionation tower is 115°C, the pressure at the top of the fractionation tower is 0.13MPa, and the temperature at the bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com