Patents

Literature

34results about How to "Effective way to use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-sintered ceramic aggregate with stone coal vanadium extraction tailings as main raw material and preparation method thereof

InactiveCN102617097AEffective way to useExpand sourceSolid waste managementThermal insulationExpanded clay aggregate

The invention relates to a non-sintered ceramic aggregate with stone coal vanadium extraction tailings as a main raw material and a preparation method thereof. The non-sintered ceramic aggregate comprises the following raw material components in percentage by weight: 45-60 percent of stone coal vanadium extraction tailings, 10-30 percent of fly ash, 7-15 percent of solid alkali exciter, 5-10 percent of cement, 5-10 percent of quick lime, 2-5 percent of gypsum and 5-15 percent of water. The preparation method comprises the following steps of: according to the raw materials and the contents thereof, uniformly mixing the stone coal vanadium extraction tailings and the solid alkali exciter and grinding to be below 0.074 mm to prepare a prefabricated material; adding the fly ash, the cement, the quick lime, the gypsum and the water into the prefabricated material and uniformly stirring to prepare a mixture; aging the mixture for 1-3 hours; pelletizing; aging for 3-7 days; holding in an autoclave; and autoclaving under the condition of 0.8-1.2 MPa for 6-10 hours. The non-sintered ceramic aggregate has the advantages of environmental friendliness, simple process, low energy consumption and high utilization rate of tailings; and a prepared non-sintered ceramic aggregate product has high strength and good thermal insulation performance.

Owner:WUHAN UNIV OF SCI & TECH

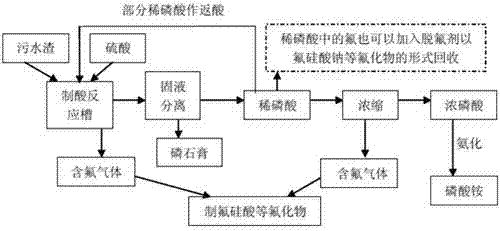

Method for recycling phosphorus and fluoride in sewage residue of phosphorus fertilizer plant

InactiveCN102502552AImprove use valueEffective way to usePhosphatesAlkali orthophosphate fertiliserO-Phosphoric AcidAgricultural engineering

The invention discloses a method for recycling phosphorus and fluoride in the sewage residue of a phosphorus fertilizer plant. According to the method, the sewage residue is decomposed by using sulfuric acid, the phosphorus and the fluoride in the sewage residue are extracted, calcium sulfate dihydrate crystal or calcium sulfate hemihydrate crystal and diluted phosphoric acid solution are generated, diluted phosphoric acid and phosphogypsum which is the by-product are obtained through solid-liquid separation, the diluted phosphoric acid is concentrated into concentrated phosphoric acid, the escaped fluorine containing gas is recycled in the process of concentrating the phosphoric acid and making acid and produced into the fluoride such as the fluosilicic acid and the like, or defluorination agent is added into the diluted phosphoric acid to recycle fluoride resources in the form of the fluoride such as the sodium fluosilicate and the like, and the obtained concentrated phosphoric acid can be used to prepare other phosphate products such as the ammonium phosphate and the like by using the traditional method. The method can be used to effectively recycle the phosphorus and fluoride resources in the sewage residue of the phosphorus fertilizer plant so that the waste materials can be changed into the valuable materials and the recycling value of the phosphorus and fluoride resources in the sewage residue of the phosphorus fertilizer plant can be improved. The method has good economic benefit and environment protection significance.

Owner:WENGFU (GRP) CO LTD

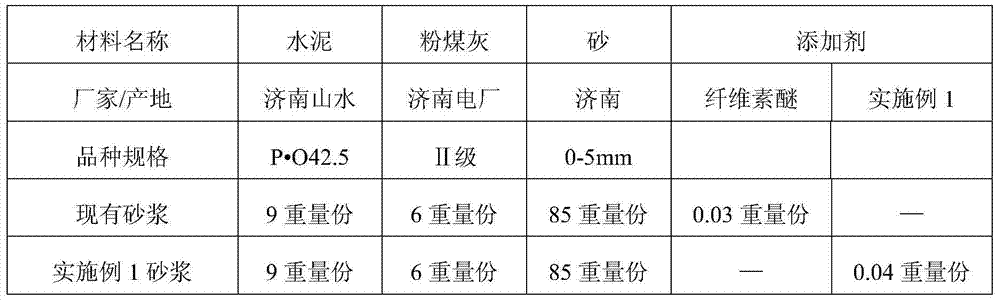

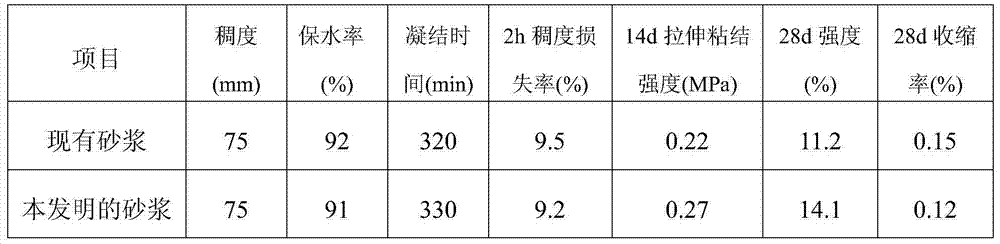

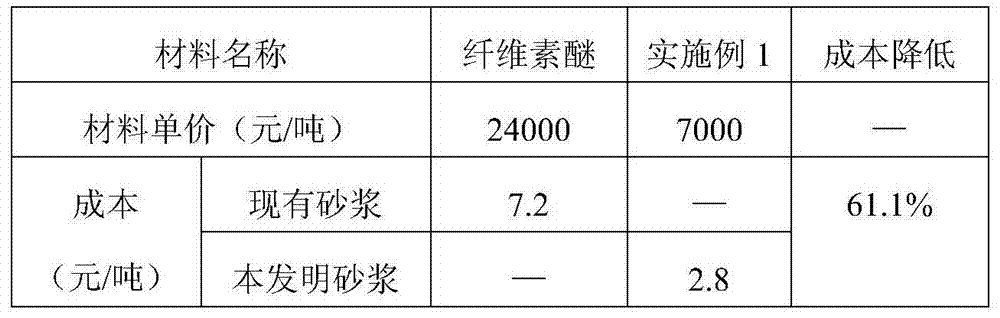

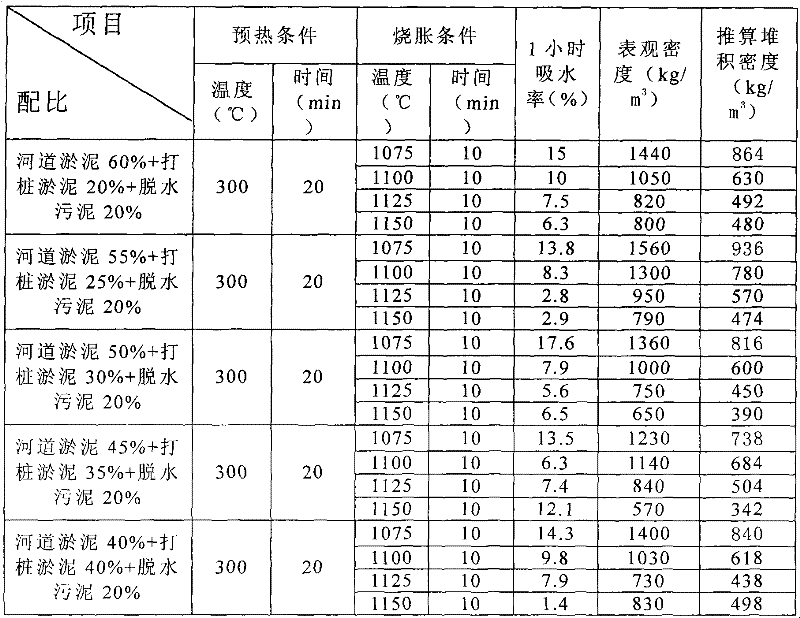

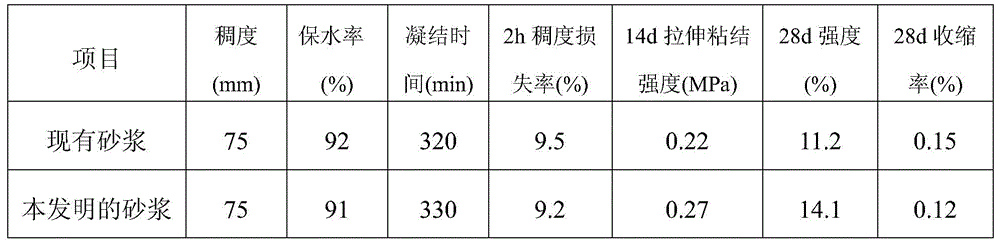

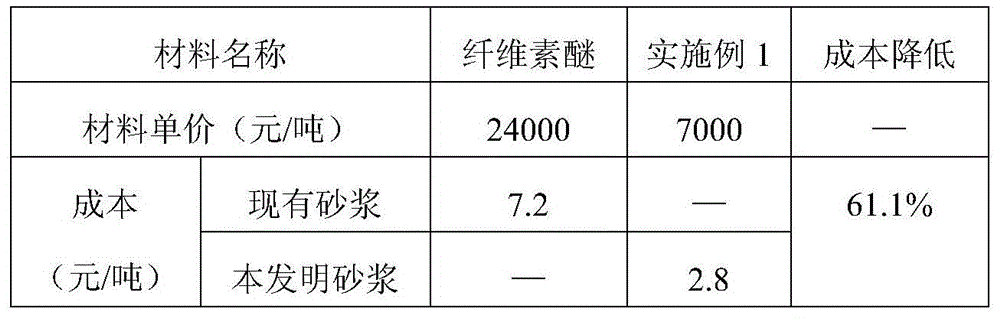

Water-retaining, thickening and reinforcing additive for cement mortar and cement mortar containing additive

The invention discloses a water-retaining, thickening and reinforcing additive for cement mortar and cement mortar containing the additive, wherein the additive is corn straw cellulose or / and modified corn straw cellulose. The water-retaining, thickening and reinforcing additive for cement mortar and the cement mortar containing the additive, disclosed by the invention, have the beneficial effects that the water-retaining, thickening and reinforcing additive for cement mortar is a green environment-friendly product which is free from toxicity, peculiar smell, pollution and corrosivity; if the water-retaining, thickening and reinforcing additive for cement mortar, disclosed by the invention, is doped into cement mortar, the water-retaining property of mortar can be effectively improved; the water-retaining property of freshly mixed mortar is more than 90% and meets standard requirements; simultaneously, the intensity of mortar is obviously increased; the use amount of cement is effectively reduced; the intensity of mortar is increased by above 25%; the 14d tensile adhesive intensity is increased by above 13%; the cost of the water-retaining and thickening material is reduced by above 16%; a utilization way of the industrial by-product, namely cellulose, separated from corn straws, is effectively provided; furthermore, the utilization value is higher. The cost of the water-retaining, thickening and reinforcing additive for cement mortar, disclosed by the invention, is 4000-8000 yuan / ton, and the water-retaining, thickening and reinforcing additive for cement mortar, disclosed by the invention, is wide in source of used raw materials, proper in cost, convenient to use, high in operability and beneficial to popularization.

Owner:SHANDONG HUASEN CONCRETE

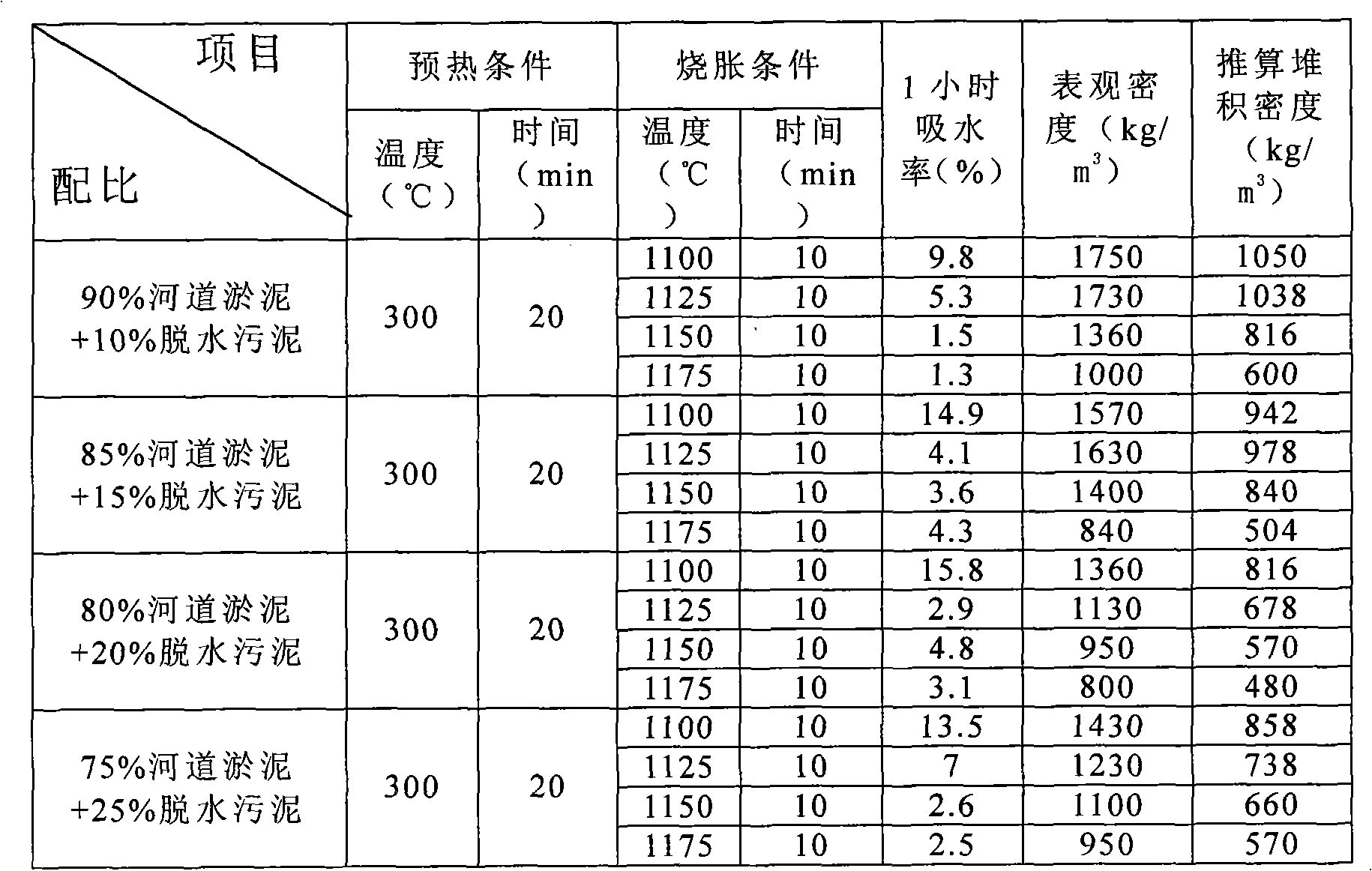

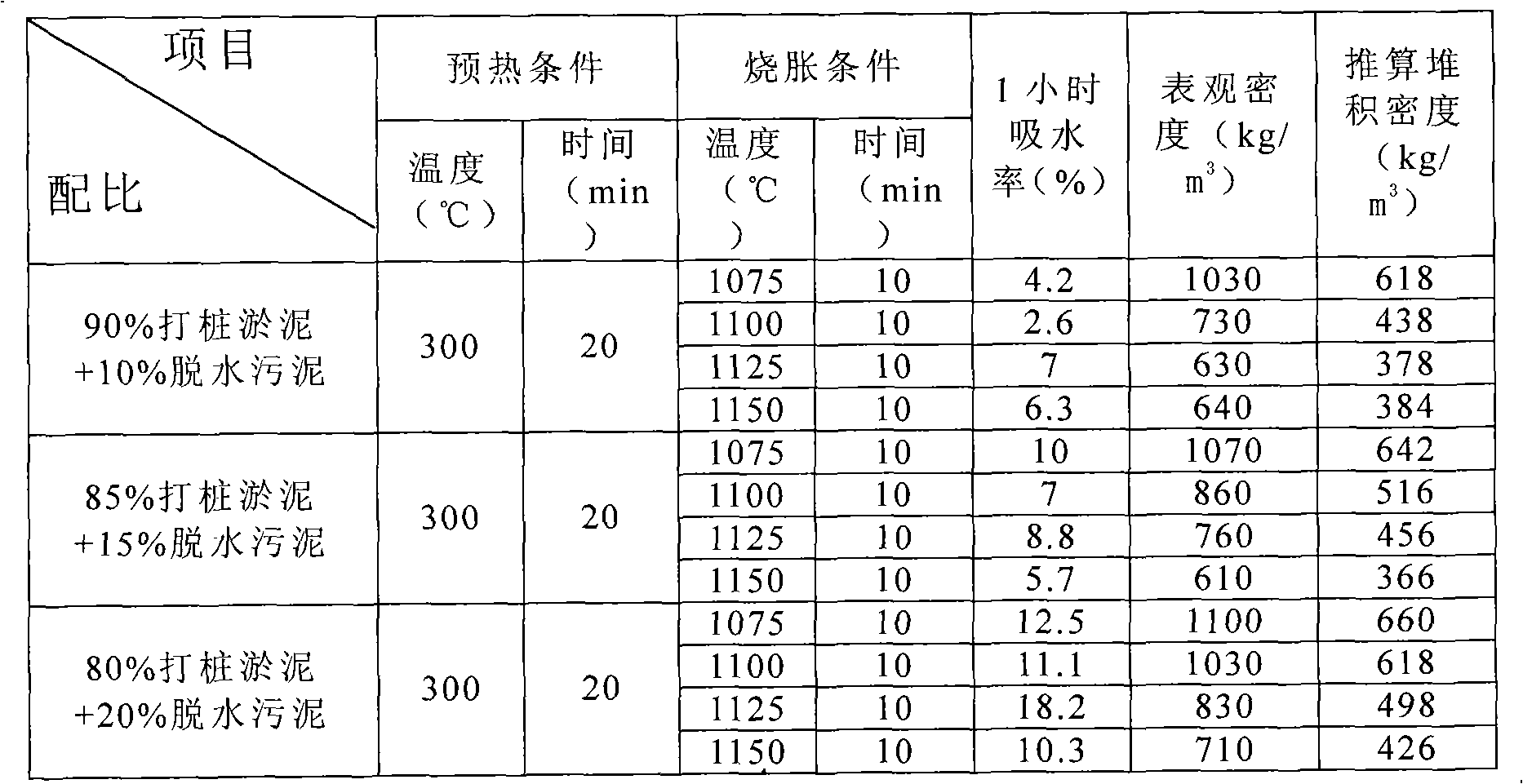

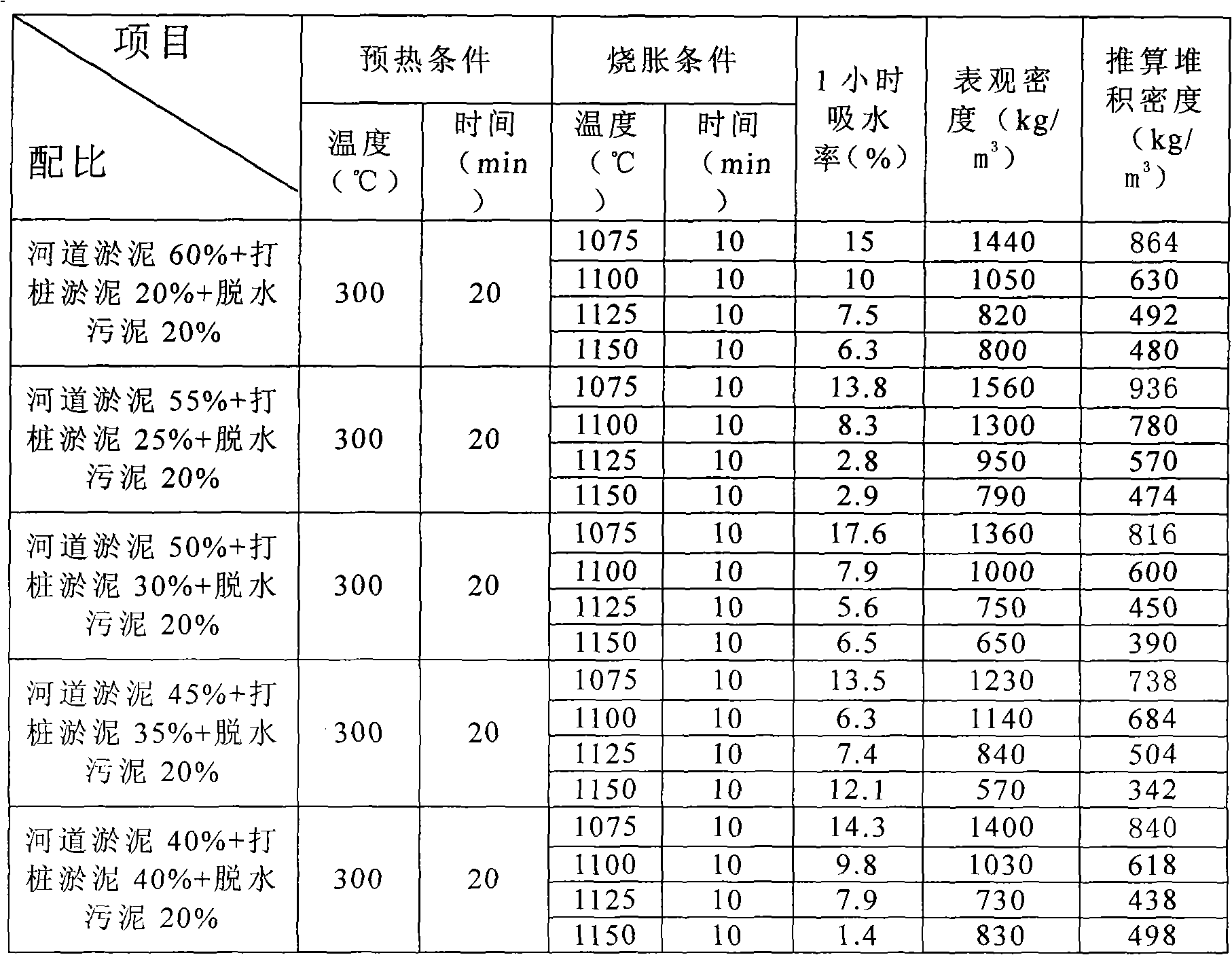

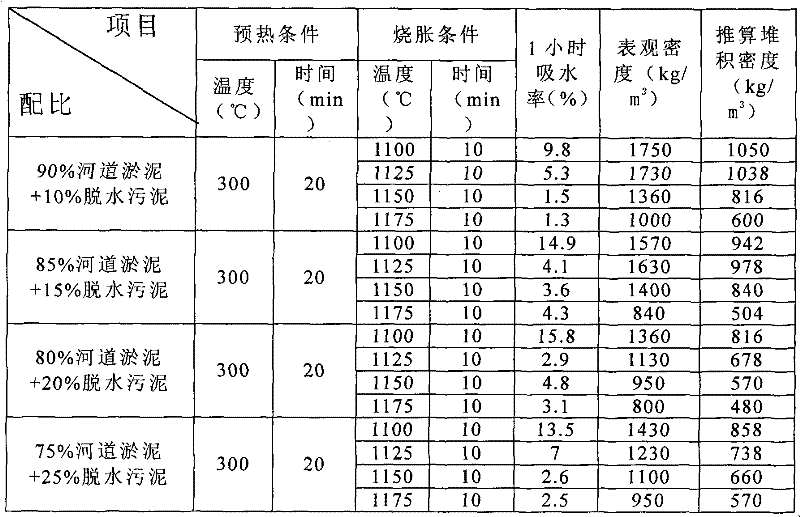

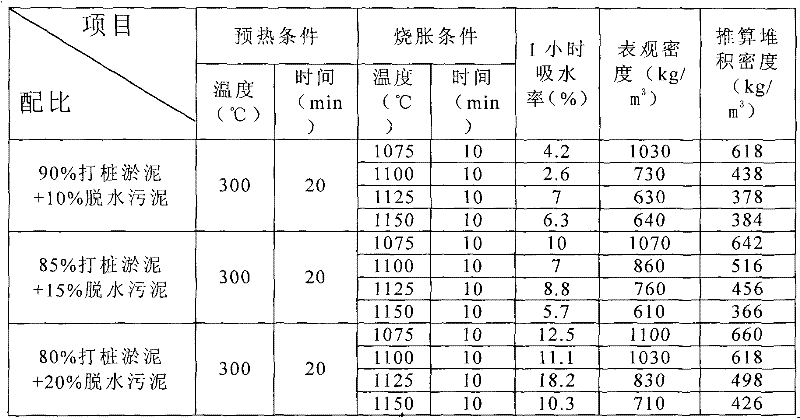

Biosolid-sludge mixed ceram site

ActiveCN101585672AImprove protectionEfficient use ofSolid waste disposalSludgeToxic industrial waste

This invention discloses biosolid-sludge mixed ceram site, belonging to the technical field of light materials. The biosolid-sludge mixed ceram site is prepared using raw materials as follows: biosolid of 10-30 parts by weight, and sludge of 70-90 parts by weight, wherein the biosolid is dehydrated mud and the sludge is river sludge and / or piling sludge. Accordingly, the mixed ceram site makes effective use of urban mud, and changes industrial waste solid into valuable; further, this utility model is wide in raw material source and is relatively low in cost.

Owner:ZHEJIANG FANGYUAN BUILDING MATERIALS TECH

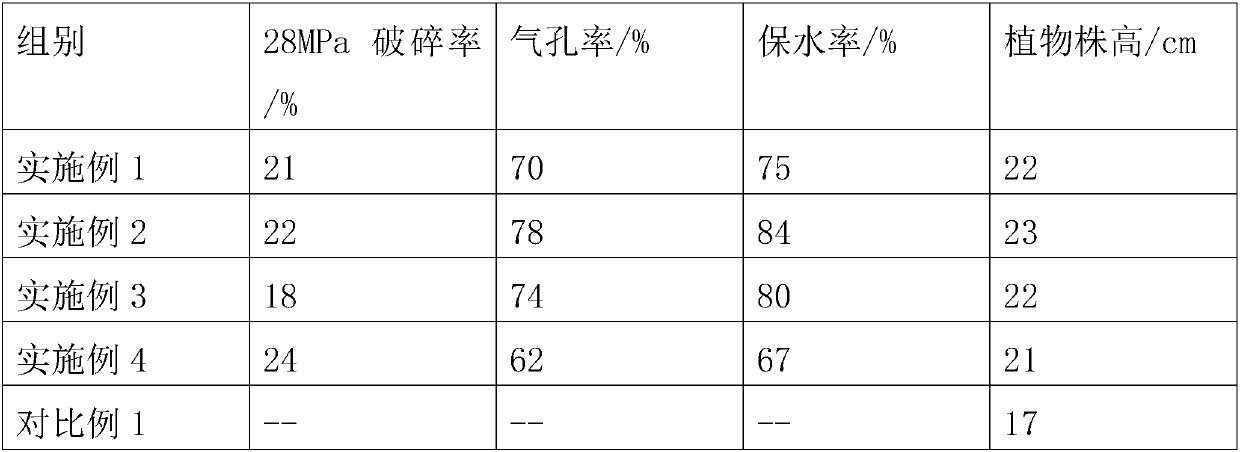

Planting sand and its preparation method

InactiveCN107484647ALow costEffective way to useGrowth substratesCulture mediaPlasticizerMaterials science

The invention provides planting sand and its preparation method. The planting sand is prepared from, by mass, 100 parts of solid waste, 0-30 parts of pore forming agents, 5-15 parts of plasticizer, 0.5-2 parts of water reducing agent and 15-30 parts of water. The planting sand is prepared by using the solid waste as raw materials, the solid waste is effectively used, the cost of raw materials is reduced, the planting sand has a porous structure and has the functions of water and fertilizer conservation, and loss of water and fertilizer can be prevented.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD +1

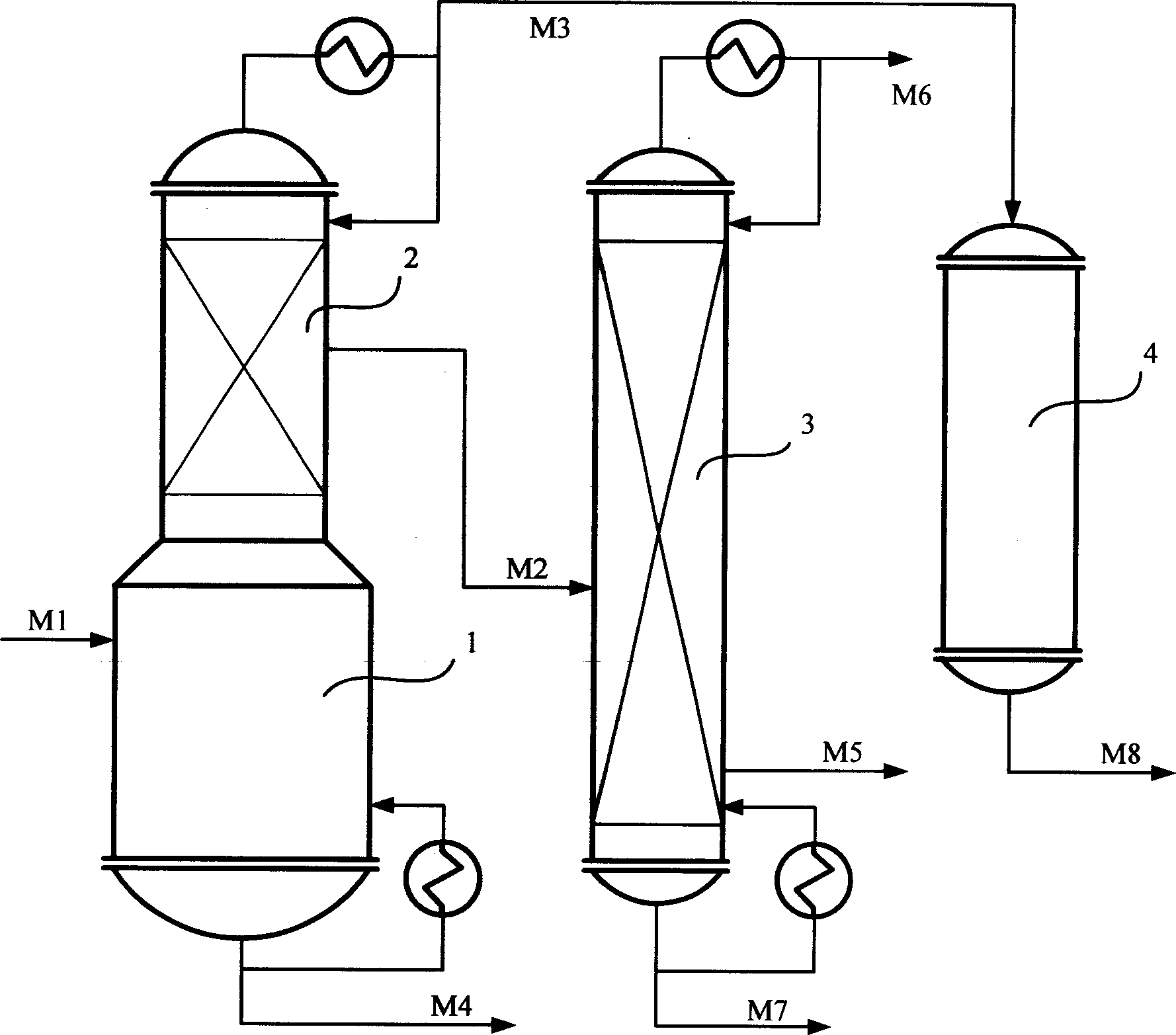

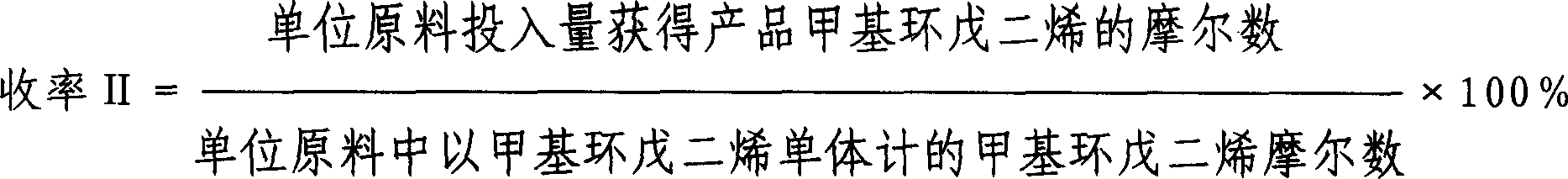

Method for preparing cyclo pentadiene and methyl cyclopentadiene by carbon 9 and carbon 10 distillation

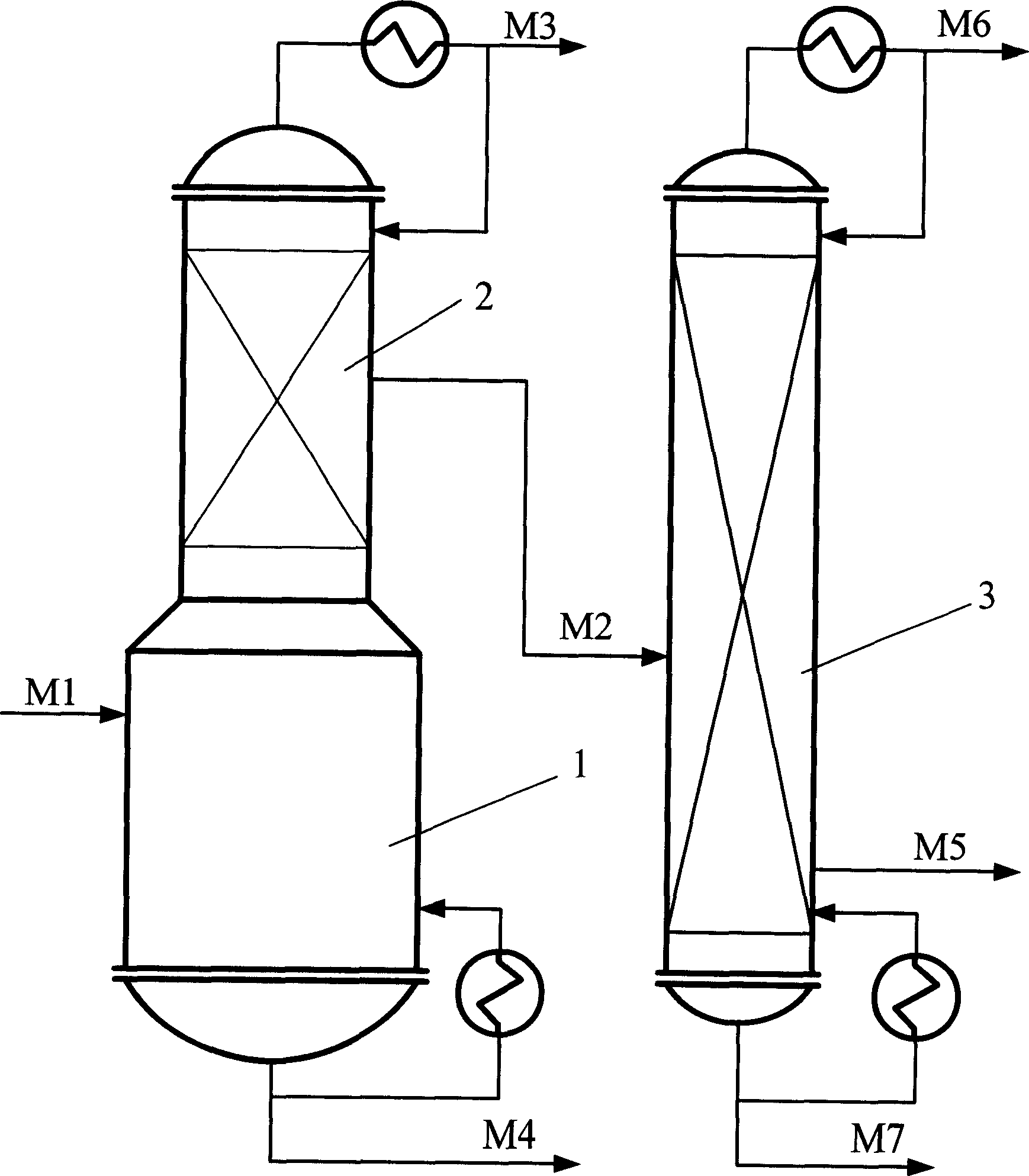

InactiveCN1850747AEffective way to useReduce manufacturing costHydrocarbon by hydrocarbon crackingDistillationGas phase

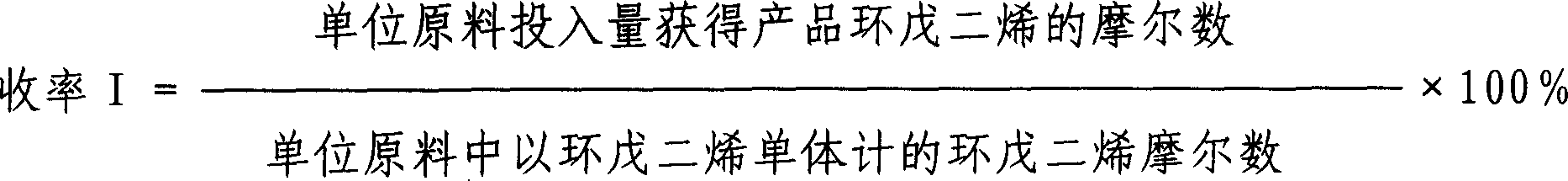

This invention relates to use carbon nine and carbon ten cut fraction making cyclopentadiene and methyl cyclopentadiene method. It includes 1) material cracking, cracking temperature is 160-230 degrees centigrade, system pressure is 0-0.3MPa, materials stay time is 1-5 hours. 2) Gas phase material generated in cracking process is directly refined, rectification tower roof temperature is 38-60 degrees centigrade, system pressure is 0-0.3MPa, reflux ratio is 0-4. Fine cyclopentadiene product is got at tower roof; crude methyl cyclopentadiene material is got at lateral line at temperature 60-80 degrees centigrade, tower tank material backs to cracking system. 3) The crude methyl cyclopentadiene material is refined, rectification tower roof temperature is 40-55 degrees centigrade, tower tank temperature is 90-120 degrees centigrade, system pressure is 0-0.2MPa, and reflux ratio is 4-10. Fine methyl cyclopentadiene product is got at tower bottom, and light component substance is discharged from tower roof.

Owner:CHINA PETROLEUM & CHEM CORP +1

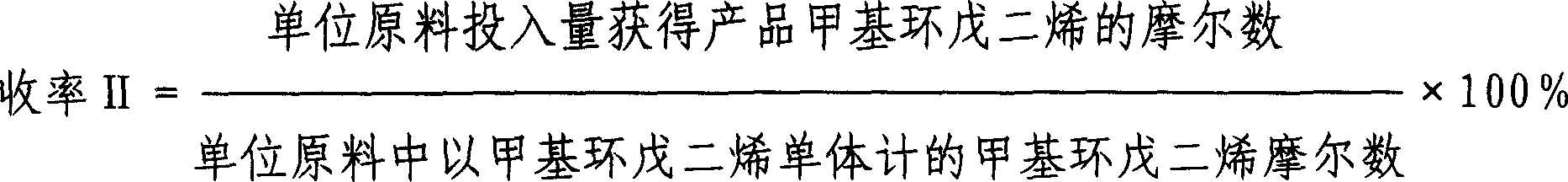

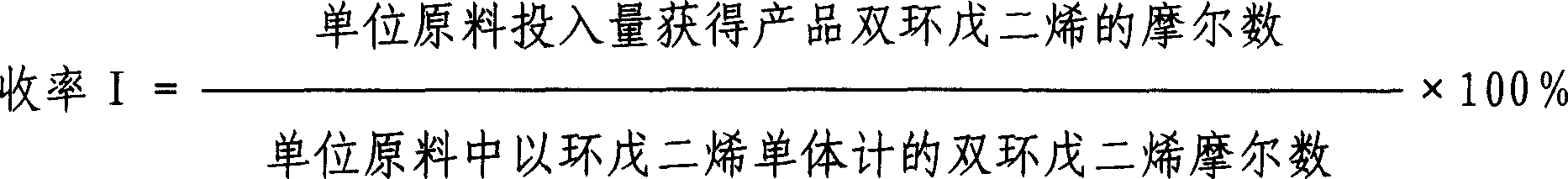

Method for preparing di-cyclopentadione and methyl cyclopentadiene by carbon 10, carbon 10 distillation

InactiveCN1850748AEffective way to useReduce manufacturing costDistillation purification/separationHydrocarbons from unsaturated hydrocarbon additionGas phaseDistillation

This invention relates to use carbon nine and carbon ten cut fraction making dicyclopentadiene and methyl cyclopentadiene method. It includes material cracking, cracking temperature is 160-230 degrees centigrade, system pressure is 0-0.4MPa, and stay time of materials is 1-5 hours. Gas phase material generated in cracking process is directly refined, rectification tower roof temperature is 40-70 degrees centigrade, system pressure is 0-0.4MPa, Fine cyclopentadiene product is got at tower roof, crude methyl cyclopentadiene material is got at lateral line at temperature 60-80 degrees centigrade, dicyclopentadiene is got by dimerization reaction of cyclopentadiene made in process 2, reaction temperature is 45-130 degrees centigrade, pressure is 0-0.2MPa. The crude methyl cyclopentadiene material is refined, rectification tower roof temperature is 40-56 degrees centigrade, tower tank temperature is 90-120 degrees centigrade, system pressure is 0-0.2MPa, and reflux ratio is 4-10. Fine methyl cyclopentadiene product is got at tower bottom, and light component substance is discharged from tower roof.

Owner:CHINA PETROLEUM & CHEM CORP +1

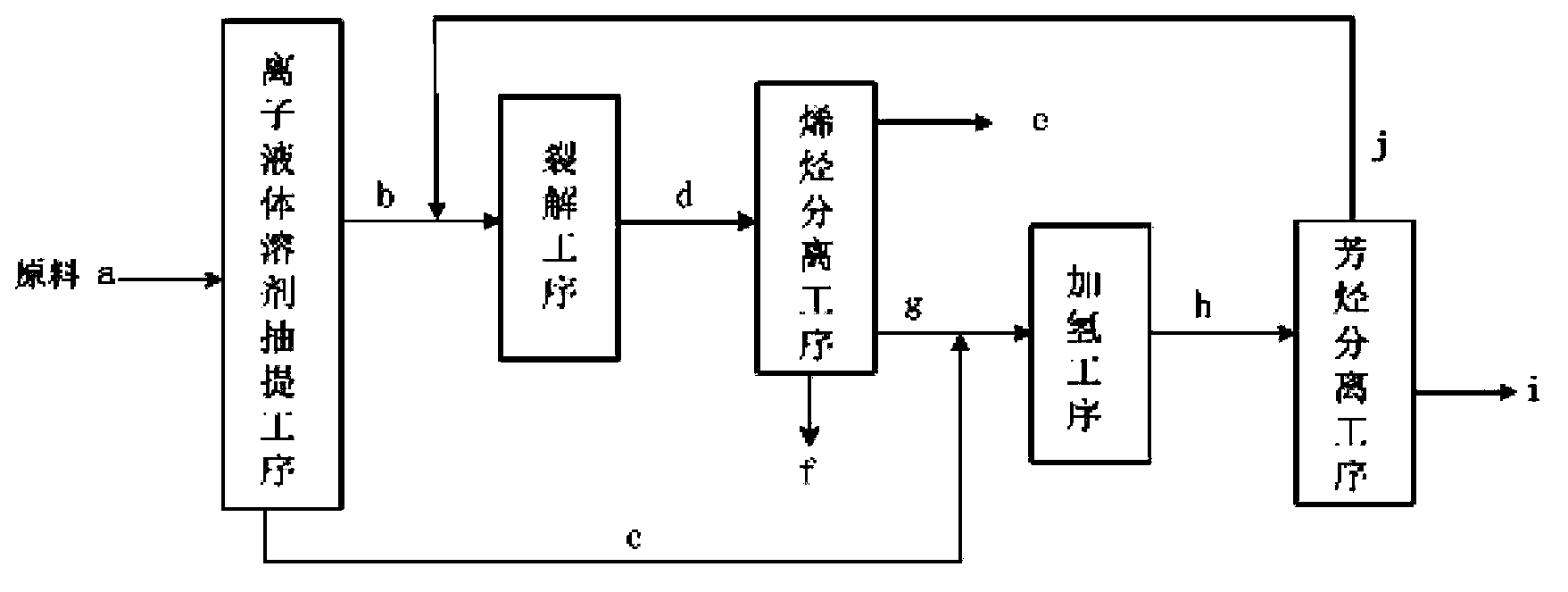

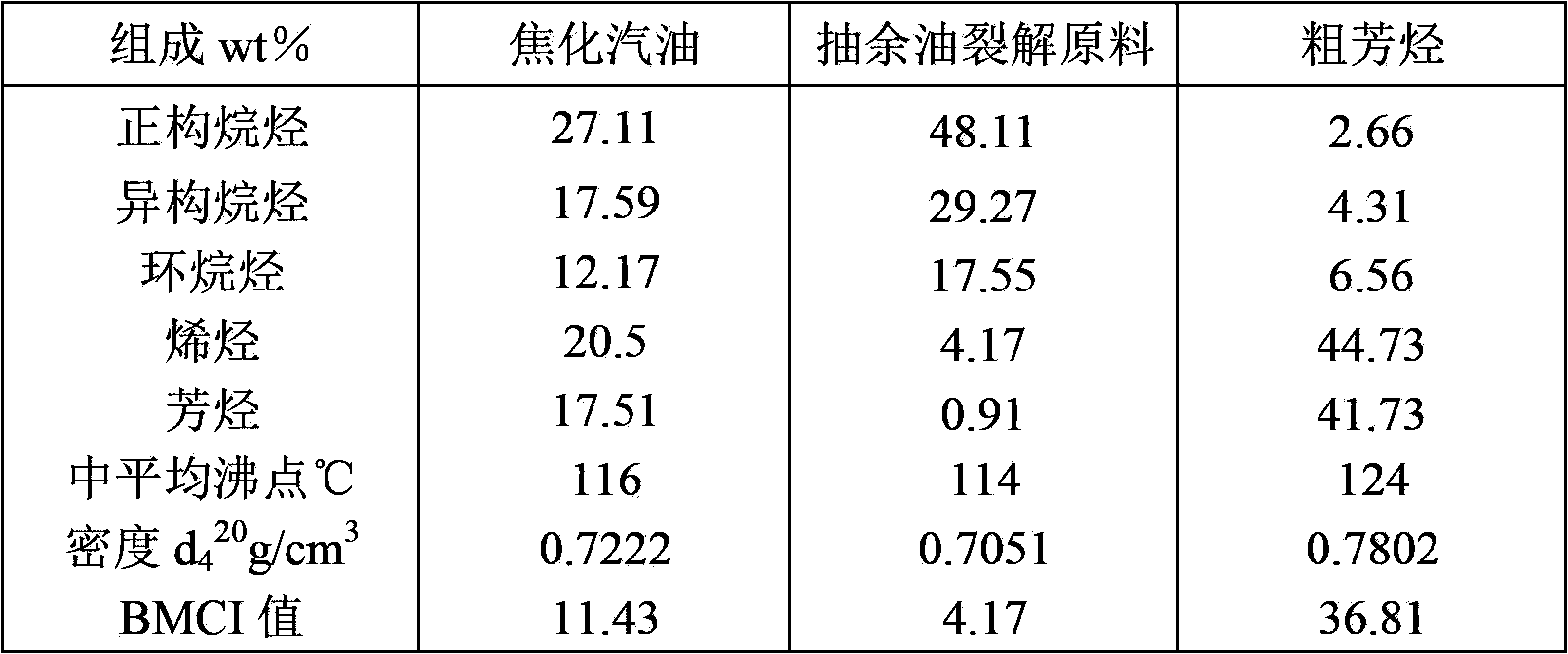

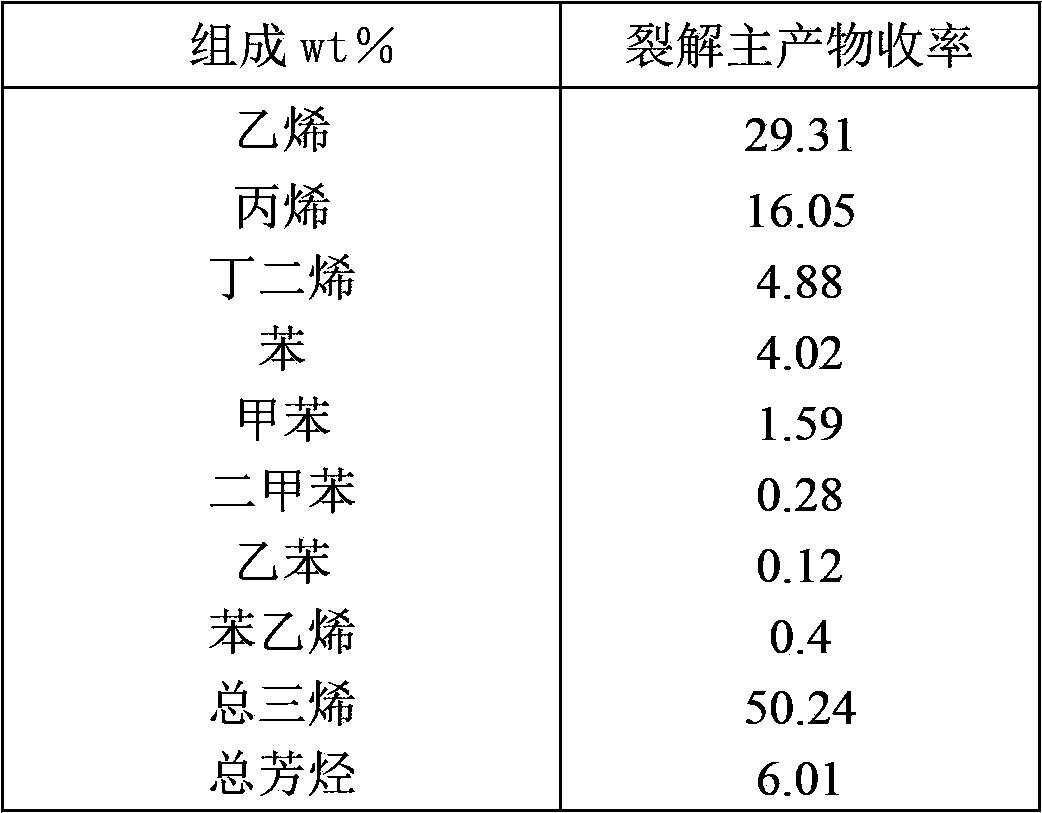

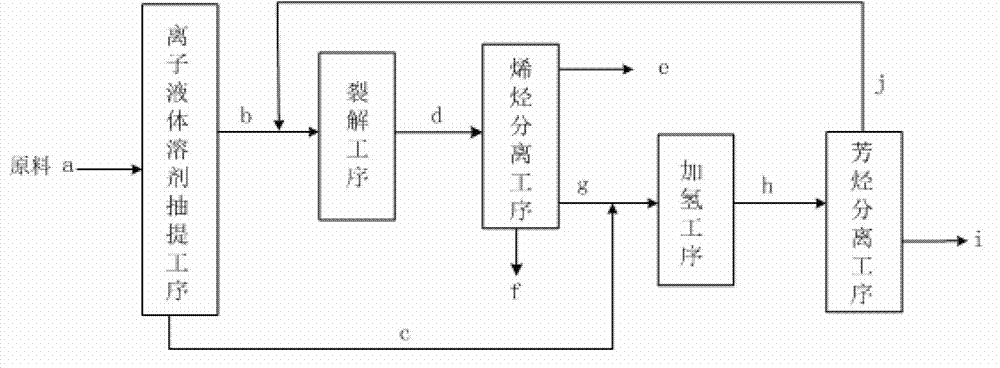

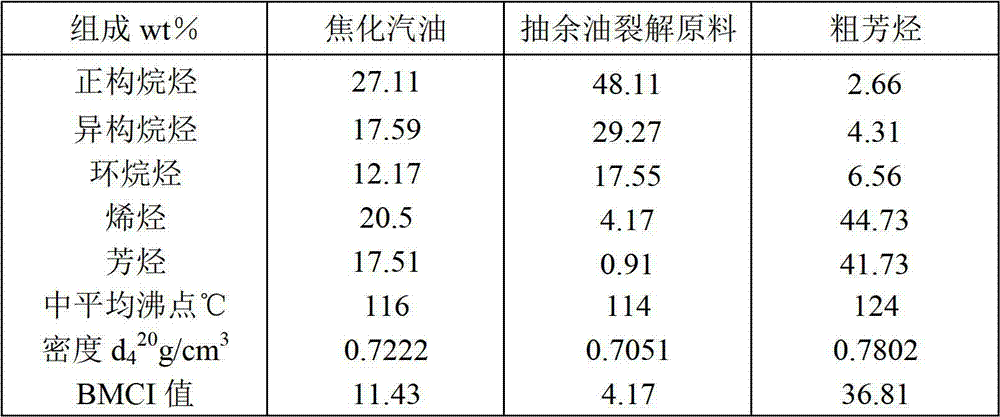

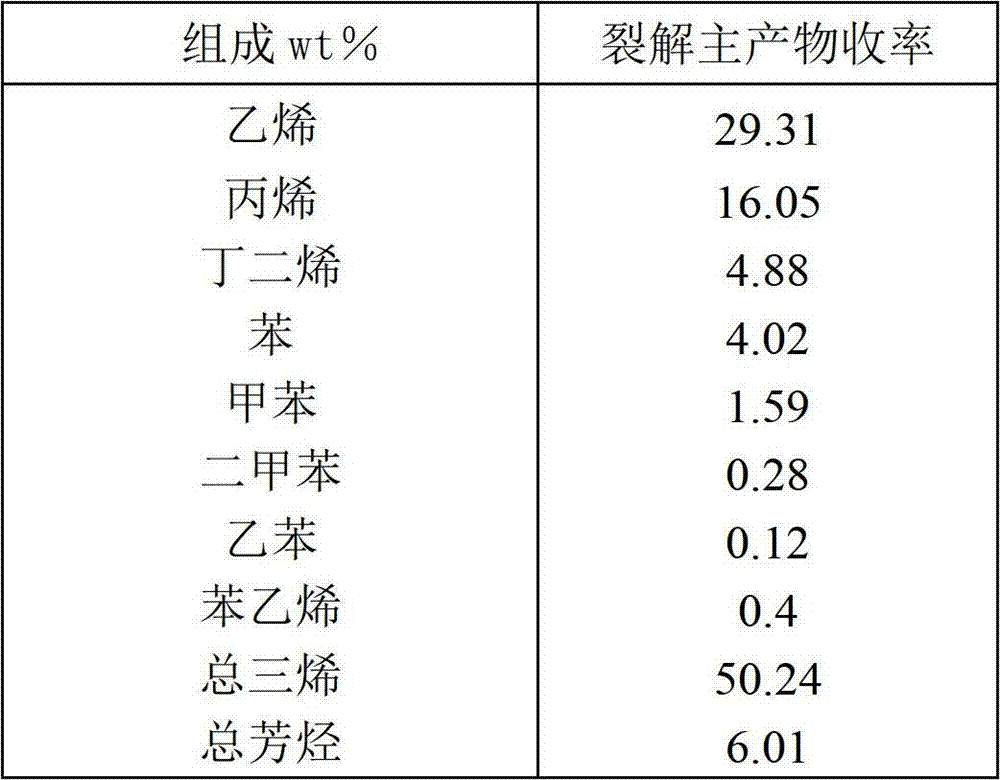

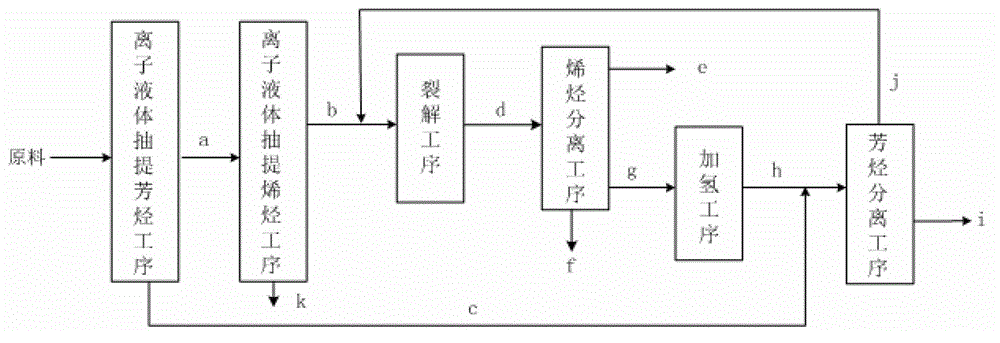

Method for increasing yields of low-carbon olefins and aromatics by coker gasoline steam cracking

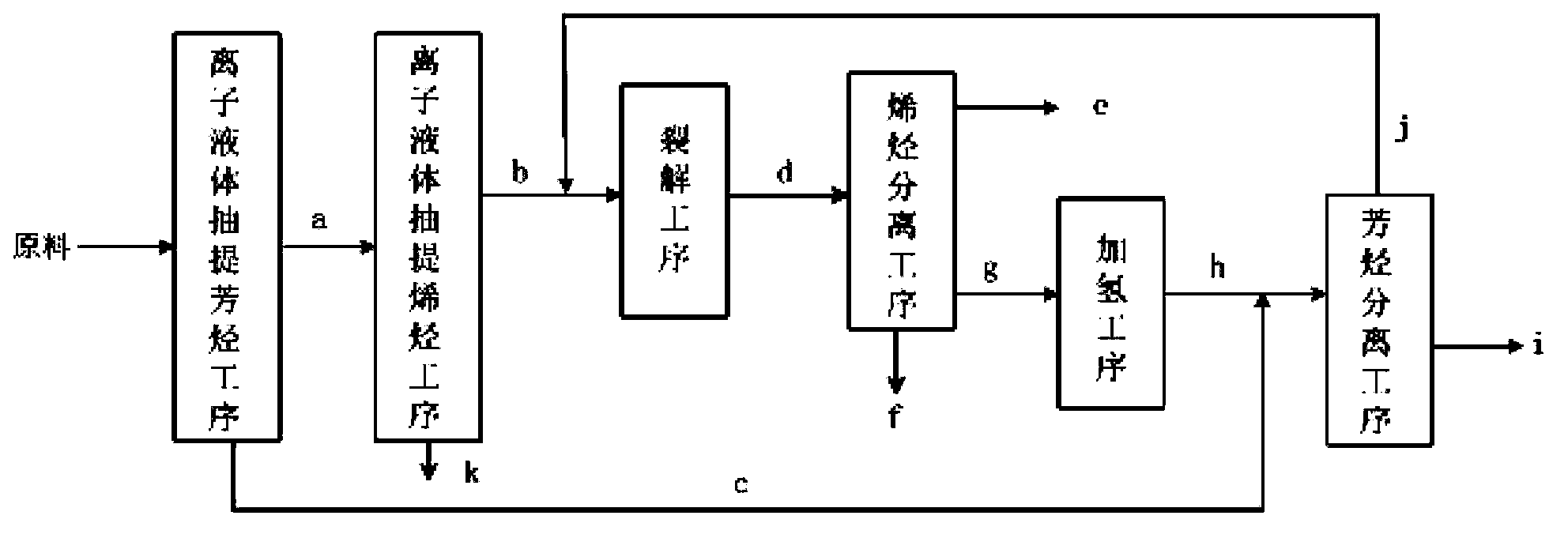

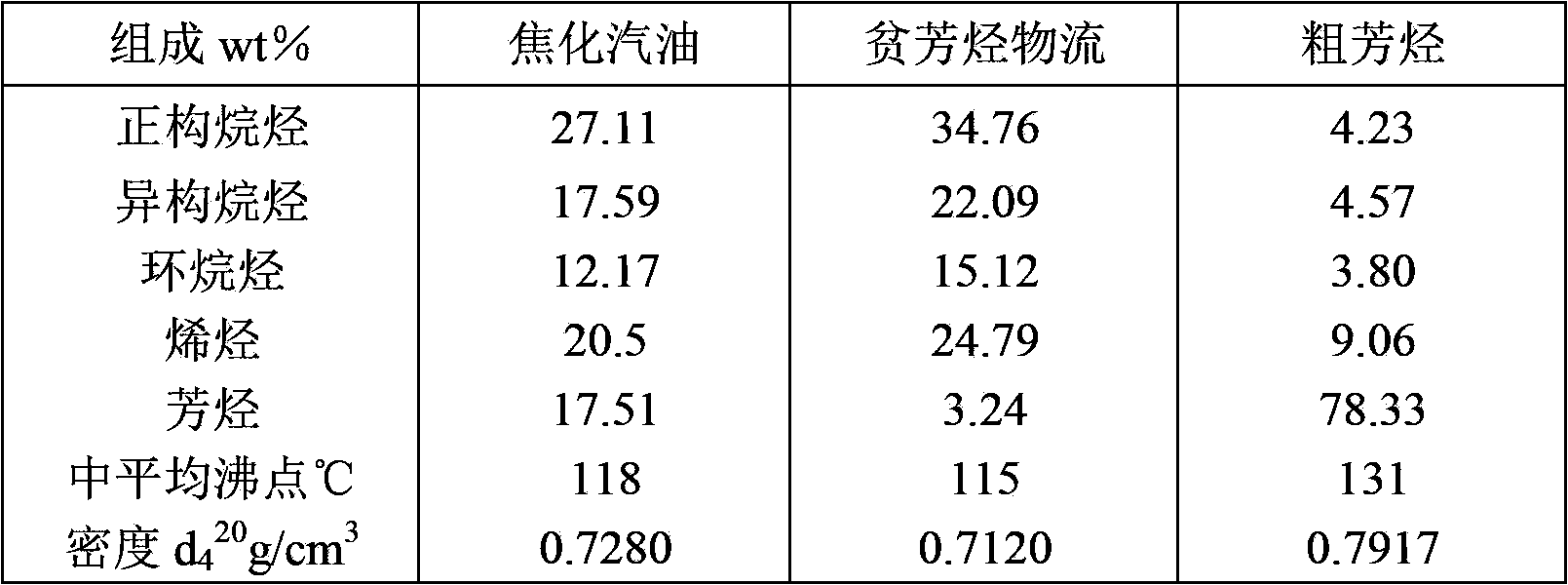

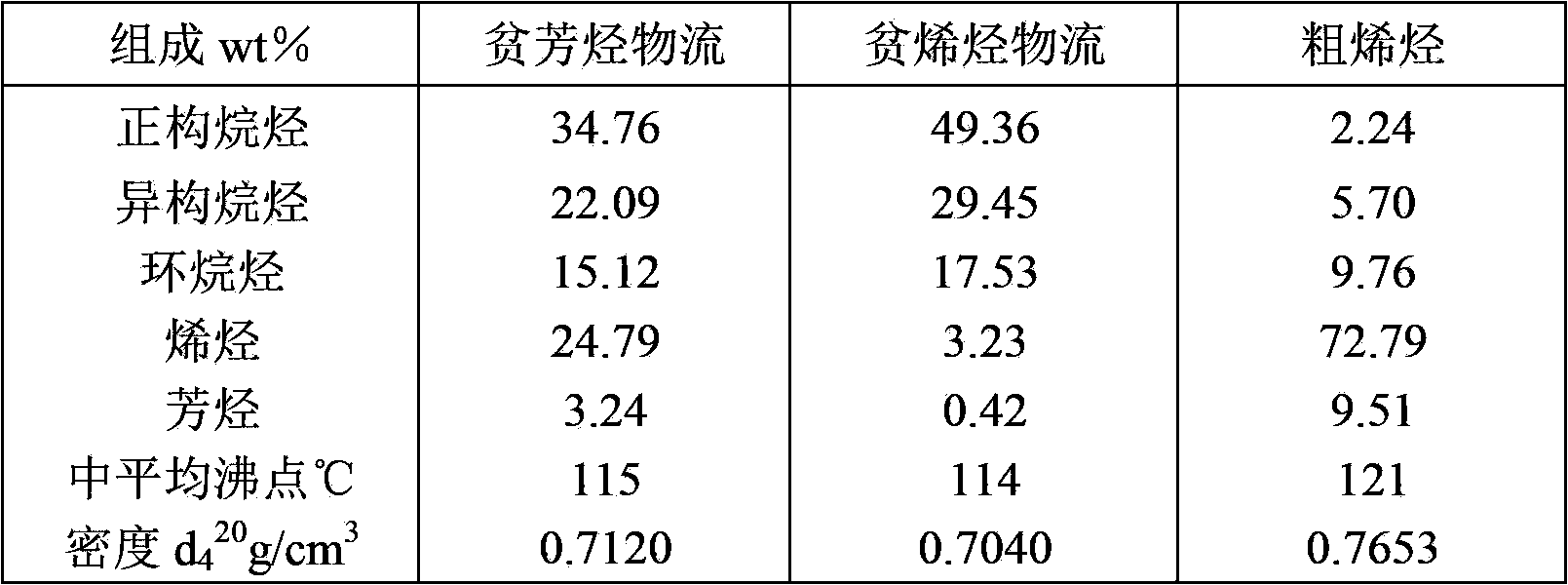

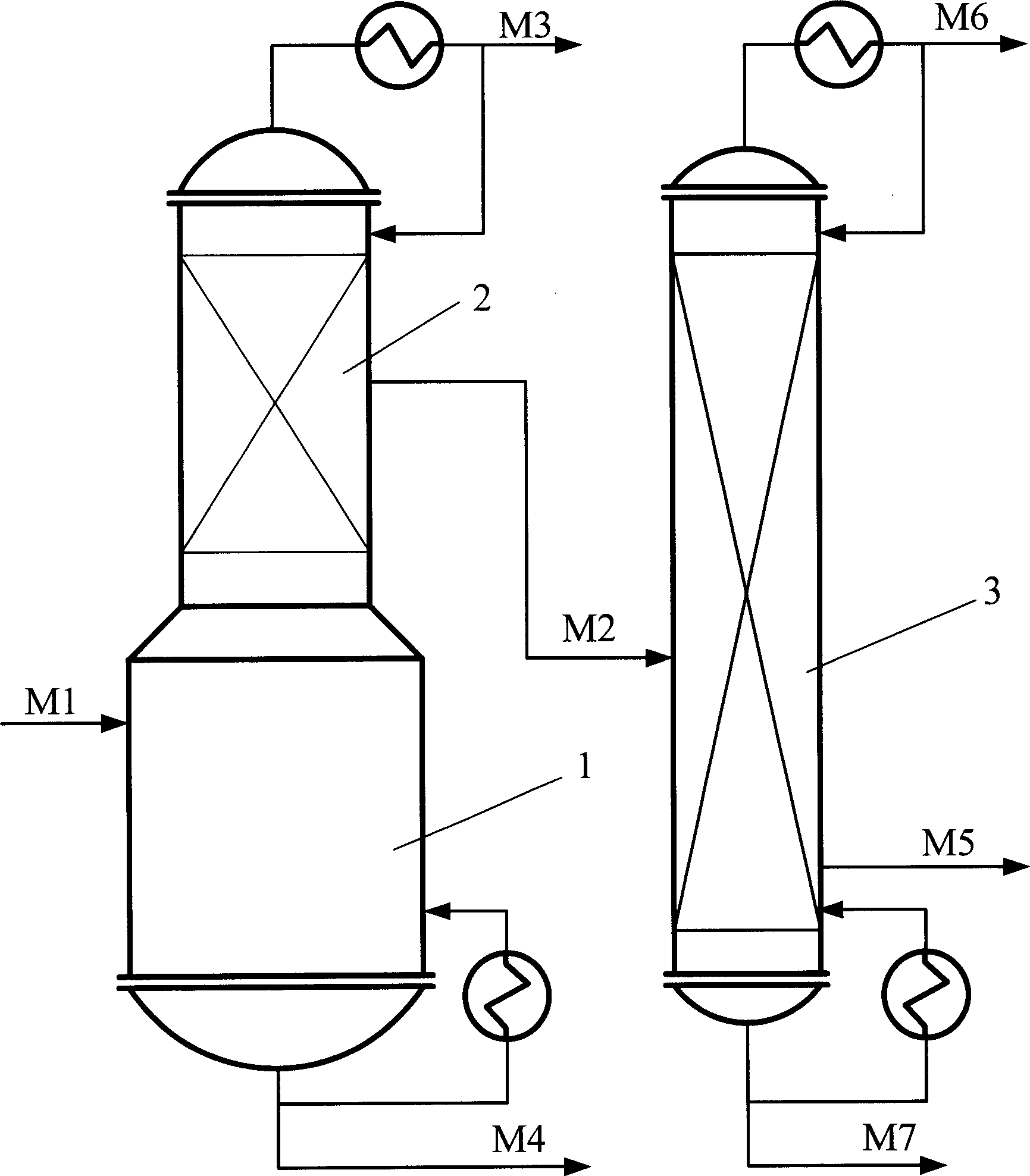

ActiveCN103666550AExpand sourceEffective way to useHydrocarbon purification/separationTreatment with plural serial stages onlyGasolineSolvent

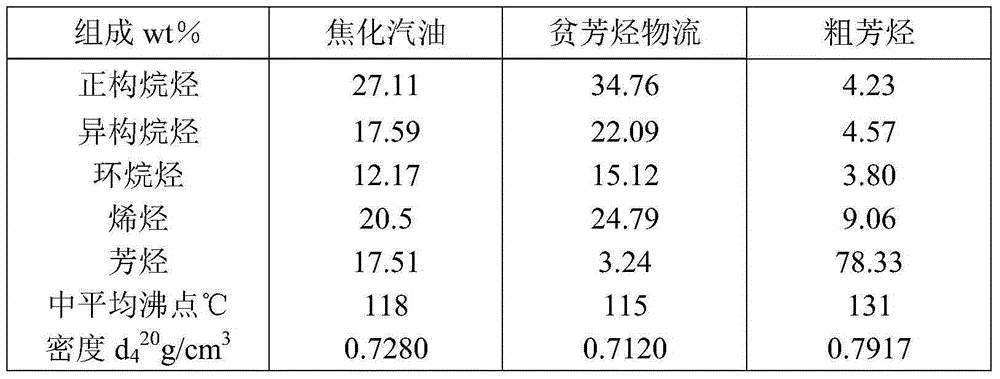

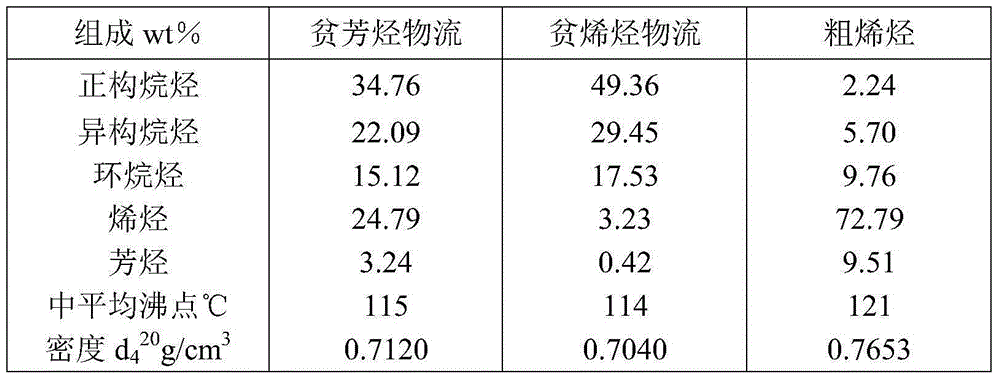

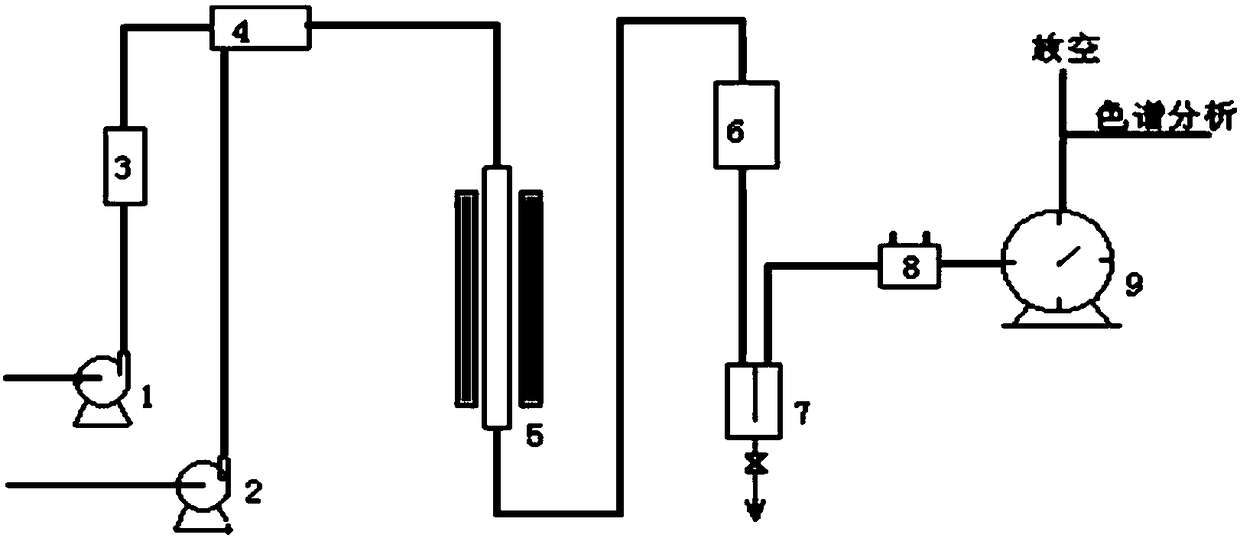

The invention relates to a method for increasing yields of low-carbon olefins and aromatics by coker gasoline steam cracking, which comprises the following steps: aromatic extraction by an ionic liquid solvent and olefin extraction by an ionic liquid solvent are respectively performed to pretreat raw oil so as to remove aromatics and olefins, thereby obtaining a hydrocarbon stream in which the aromatic content is lower than 2 wt% and the olefin content is lower than 4 wt%; the hydrocarbon stream enters a steam cracking procedure to be subjected to cracking and separation; the crude aromatic stream is sent into a hydrocracking gasoline aromatic extraction unit to separate the aromatic product; and the obtained stream containing rich saturated hydrocarbons is returned and introduced into the cracking procedure together with a petroleum hydrocarbon stream containing less aromatics to react and produce the low-carbon olefins. The method provides a proper application way for coker gasoline, widens the cracking raw material sources, recycles the non-aromatic components by using the original cracking hydrogasoline aromatic extraction system, and increases the yields of the low-carbon olefins and aromatics in the cracking process.

Owner:CHINA PETROLEUM & CHEM CORP +1

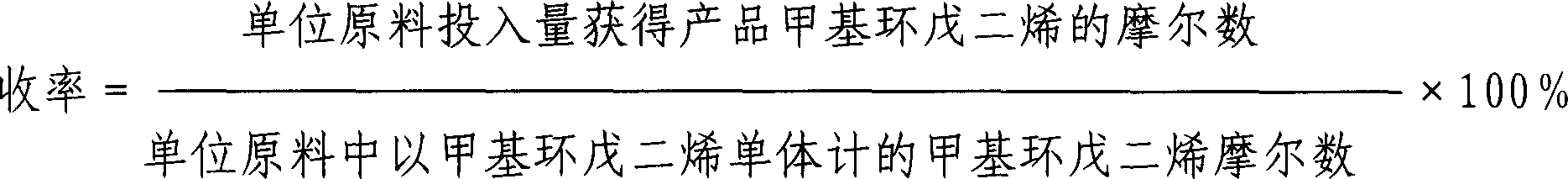

Method for preparing methyl cyclopentadiene by carbon 9, carbon 10 distillation

InactiveCN1850749AEffective way to useReduce manufacturing costHydrocarbon by hydrocarbon crackingDistillationGas phase

This invention relates to use carbon nine and carbon ten cut fraction making methyl cyclopentadiene method. The carbon nine and ten is by-product of oil cracking.It includes 1) material cracking, cracking temperature is 170-220 degrees centigrade, system pressure is 0-0.3MPa, materials stay time is 1-5 hours. 2) Gas phase material generated in cracking process is directly refined, rectification tower roof temperature is 40-65 degrees centigrade, system pressure is 0-0.3MPa, reflux ratio is 1-5. Light component material is discharged at tower roof; crude methyl cyclopentadiene material is got at lateral line at temperature 60-80 degrees centigrade, tower tank material backs to cracking system. 3) The crude methyl cyclopentadiene material is refined, rectification tower roof temperature is 40-62 degrees centigrade, tower tank temperature is 90-120 degrees centigrade, system pressure is 0-0.2MPa, and reflux ratio is 3-8. Fine methyl cyclopentadiene product is got at tower bottom, and light component substance is discharged from tower roof.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD +1

Method for increasing yields of low-carbon olefins and aromatics by coker gasoline steam cracking

ActiveCN103664479AExpand sourceEffective way to useHydrocarbon purification/separationHydrocarbonsAlkenePetroleum

The invention relates to a method for increasing yields of low-carbon olefins and aromatics by coker gasoline steam cracking, which comprises the following steps: raw oil is subjected to ionic liquid solvent extraction to remove aromatics and olefins, thereby obtaining a hydrocarbon stream in which the aromatic content is lower than 2 wt% and the olefin content is lower than 5 wt%; the hydrocarbon stream enters a steam cracking procedure to be subjected to cracking and separation; the crude aromatic stream is sent into a cracked gasoline hydrogenation unit together with cracked gasoline, and the olefins are hydrogenated and sent into a hydrocracked gasoline aromatic extraction unit to separate the aromatic product; and the obtained stream containing rich saturated hydrocarbons is returned and introduced into the cracking procedure together with a petroleum hydrocarbon stream containing less aromatics to react and produce the low-carbon olefins. The method provides an effective utilization way for the coker gasoline raw material, widens the ethylene sources, recycles the non-aromatic components by using the original cracking hydrogasoline aromatic extraction system, and increases the yields of the low-carbon olefins and aromatics in the cracking process.

Owner:CHINA PETROLEUM & CHEM CORP +1

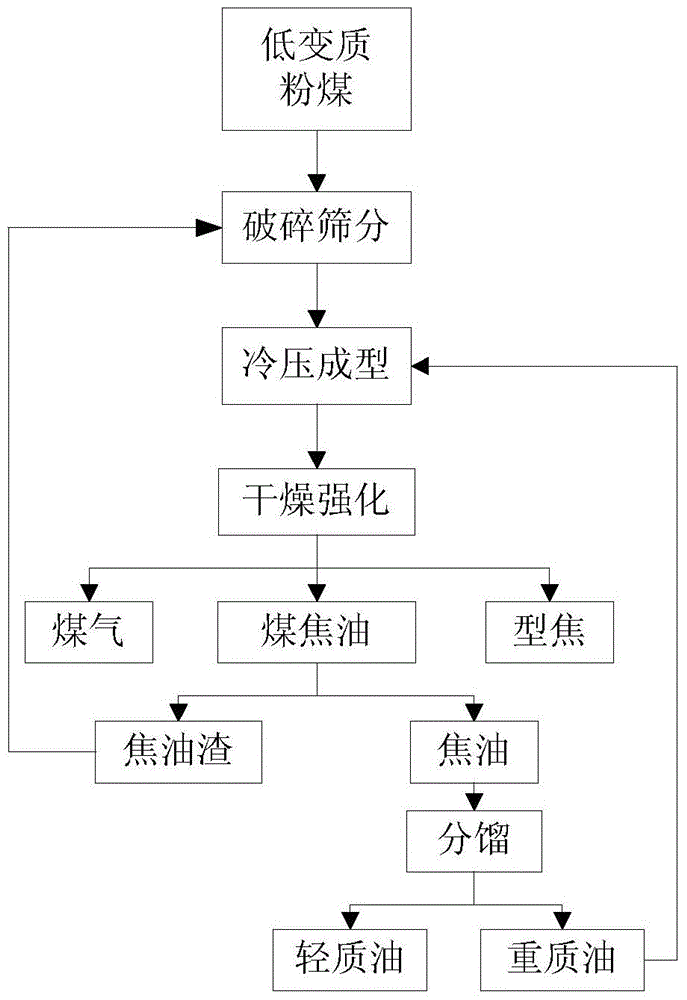

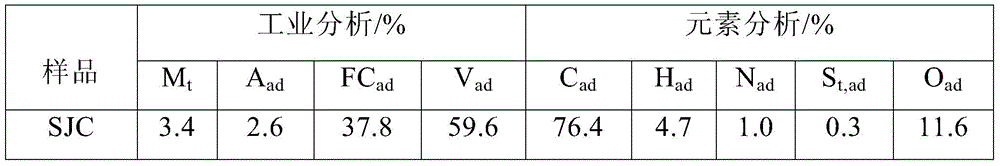

A method for preparing molded coke from low-modified pulverized coal, heavy oil, and tar residue

InactiveCN104650937BSolve the problem of comprehensive utilization of resourcesAchieve graded quality improvementSpecial form destructive distillationCoking carbonaceous materialsCokeFuel oil

The invention provides a method for preparing formed coke from low-metamorphic pulverized coal, heavy oil and tar residues as raw materials. The method comprises the following steps: firstly, grinding and sieving the low-metamorphic pulverized coal to obtain a raw material powder having a certain particle size, next, evenly mixing the low-metamorphic pulverized coal, the heavy oil and the tar residues together, performing pressure forming in a forming die, performing drying and strengthening treatment on the prepared briquette coal under a low temperature condition, and putting the treated briquette coal into a destructive distillation device for pyrolysis, thereby obtaining the formed coke, coal tar and gas, wherein the gas can be taken as a fuel gas or a chemical raw material gas; and the liquid oil is treated by fractionation to obtain a heavy oil and a light oil, the light oil is treated by hydrogenation for producing a fuel oil, and the heavy oil and the tar residues can be recycled to the briquette coal preparation process. The method is mainly applied to the medium-low temperature pyrolysis and upgrading and grading of the low-metamorphic pulverized coal, and is capable of recycling the tar and the hydrogen-enriched gas in the pulverized coal to the utmost extent while obtaining the formed coke product; and in short, the method has the characteristics of simple process, high production efficiency, high pyrolysis speed, good forked coke strength, good formed coke strength and high light oil yield.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

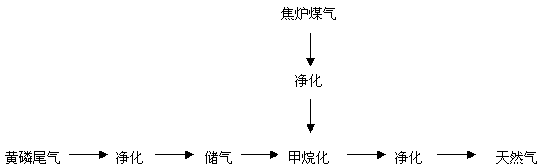

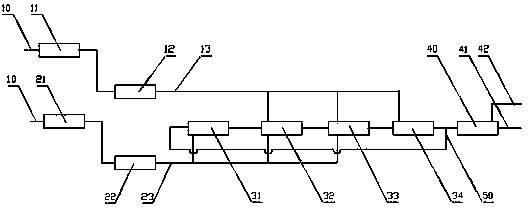

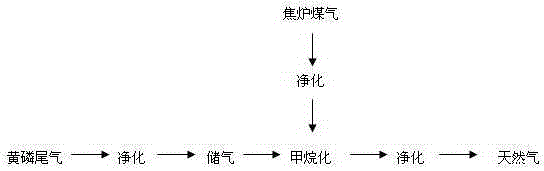

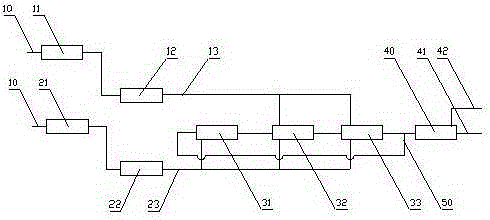

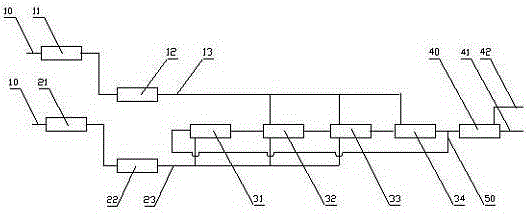

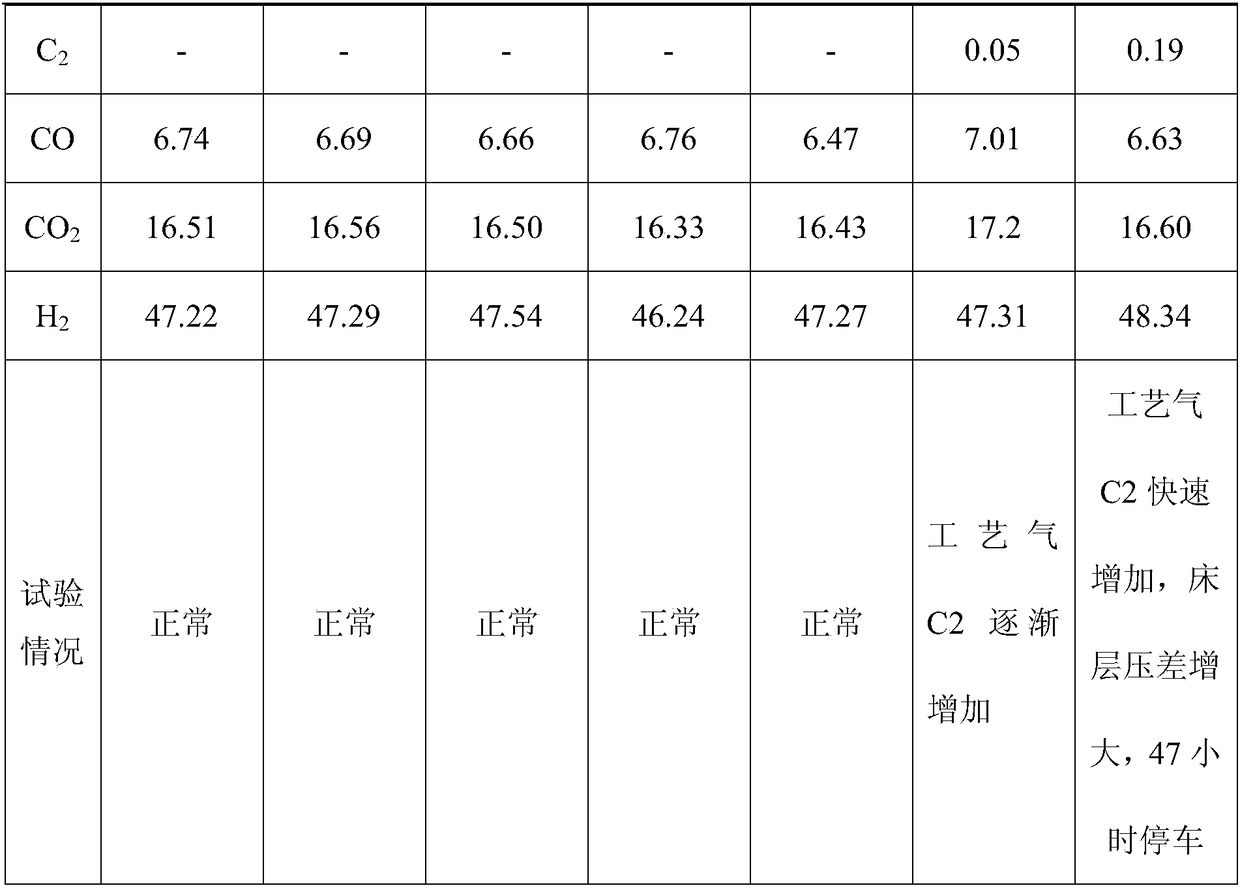

Method for preparing natural gas from yellow phosphorus tail gas and production device using method

The invention relates to a method for preparing natural gas from yellow phosphorus tail gas and a production device using the method. The method comprises the following step: by using yellow phosphorus tail gas and coke oven gas as raw gases, carrying out methanation reaction in a methanation device by using hydrogen in the raw gases and carbon monoxide and carbon dioxide in the raw gases, wherein the ratio of the yellow phosphorus tail gas to the coke oven gas is controlled to control the ratio of the hydrogen to the carbon monoxide and carbon dioxide in the reaction system, so that the contents of the hydrogen, carbon monoxide and carbon dioxide in the gas after reaction respectively conform to the requirements for natural gas, and the volume ratio of the yellow phosphorus tail gas to the coke oven gas is 1:(9-12). The production device comprises the methanation device, a raw gas purification device before the methanation device, and a natural gas purification device after the methanation device, wherein the methanation device is a three-stage or four-stage methanation facility. The method has the advantages of reasonable technological design and low cost, recycles the yellow phosphorus tail gas, avoids waste of resources and environmental pollution, and enhances the economic benefit.

Owner:北京中凯环能高科技有限公司

Sargassum fusiforme tabletted candy and preparation method thereof

The invention relates to a sargassum fusiforme tabletted candy and a preparation method thereof. The tabletted candy comprises the following components in parts by weight: 20-40 parts of a sargassum fusiforme extract, 25-45 parts of an agaric lotus leaf extract, 10-15 parts of microcrystalline cellulose, 15-25 parts of maltodextrin, 1-3 parts of magnesium stearate and 1-3 parts of a coating agent.The method has the beneficial effects that (1) the sargassum fusiforme is subjected to deodorization and arsenic removal treatment, so that the flavor is improved, and the food safety is improved; (2) the sargassum fusiforme extraction efficiency is high, the effective substance content of the extract is high, and the blood fat reducing effect is remarkable; and (3) a formula is reasonable in design, and the sargassum fusiforme extract and the agaric lotus leaf extract are proportioned, so that the tabletted candy has a remarkable blood fat reducing effect and is suitable for people with hyperlipidemia risk; (4) the selected dosage form is beneficial to retention of functional substances, the product is convenient to carry and eat, and is an effective utilization way for sargassum fusiforme; and (5) the preparation method is simple and clear and has practical operability.

Owner:GUANGDONG YUEWEI EDIBLE FUNGI TECH +1

Autoclaved brick adopting germanium-extracted lignite tailings as main raw material and preparation method of autoclaved brick

InactiveCN103964799AEffective way to useSolve potential safety hazards, environmental pollution and other issuesSolid waste managementBrickFly ash

The invention discloses an autoclaved brick adopting germanium-extracted lignite tailings as a main raw material and a preparation method of the autoclaved brick. The autoclaved brick comprises the following constituents: pre-treated germanium-extracted lignite tailings, fly ash, slaked lime, water and an additive. The preparation method comprises the following steps: mixing the pre-treated germanium-extracted lignite tailings, the fly ash and the slaked lime; adding water and the additive; continuing to stir till the mixture is uniform; pressing the mixture for forming; standing; conducing autoclaved curing under the condition of 1.05-1.25 Mpa; naturally cooling to obtain the autoclaved brick adopting the germanium-extracted lignite tailings as the main raw material. The autoclaved brick and the preparation method thereof have the benefits that the energy consumption of the process is small, the utilization rate of the tailings is higher, and the product performance is better.

Owner:LINCANG TEACHERS COLLEGE

Non-sintered ceramic aggregate with stone coal vanadium extraction tailings as main raw material and preparation method thereof

InactiveCN102617097BEffective way to useExpand sourceSolid waste managementThermal insulationExpanded clay aggregate

The invention relates to a non-sintered ceramic aggregate with stone coal vanadium extraction tailings as a main raw material and a preparation method thereof. The non-sintered ceramic aggregate comprises the following raw material components in percentage by weight: 45-60 percent of stone coal vanadium extraction tailings, 10-30 percent of fly ash, 7-15 percent of solid alkali exciter, 5-10 percent of cement, 5-10 percent of quick lime, 2-5 percent of gypsum and 5-15 percent of water. The preparation method comprises the following steps of: according to the raw materials and the contents thereof, uniformly mixing the stone coal vanadium extraction tailings and the solid alkali exciter and grinding to be below 0.074 mm to prepare a prefabricated material; adding the fly ash, the cement, the quick lime, the gypsum and the water into the prefabricated material and uniformly stirring to prepare a mixture; aging the mixture for 1-3 hours; pelletizing; aging for 3-7 days; holding in an autoclave; and autoclaving under the condition of 0.8-1.2 MPa for 6-10 hours. The non-sintered ceramic aggregate has the advantages of environmental friendliness, simple process, low energy consumption and high utilization rate of tailings; and a prepared non-sintered ceramic aggregate product has high strength and good thermal insulation performance.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing refined ferrosilicon by utilizing silicon slag

The invention provides a method for preparing refined ferrosilicon by utilizing silicon slag. The method comprises the following steps of identifying and separating slag and ferrosilicon in the silicon slag by utilizing a photoelectric detection technology, melting the ferrosilicon at 1550-1650 DEG C to obtain ferrosilicon melt, and adding a synthetic flux into the ferrosilicon melt; and the synthetic flux comprises quartz sand, lime, dolomite and calcite. According to the method, the ferrosilicon and the slag in the silicon slag can be separated thoroughly, and the purity of the selected ferrosilicon is high; remelting refining on the separated ferrosilicon and a specific synthetic flux is carried out, and the produced refined ferrosilicon completely meets the standards and requirements of customers.

Owner:内蒙古鄂尔多斯电力冶金集团股份有限公司 +1

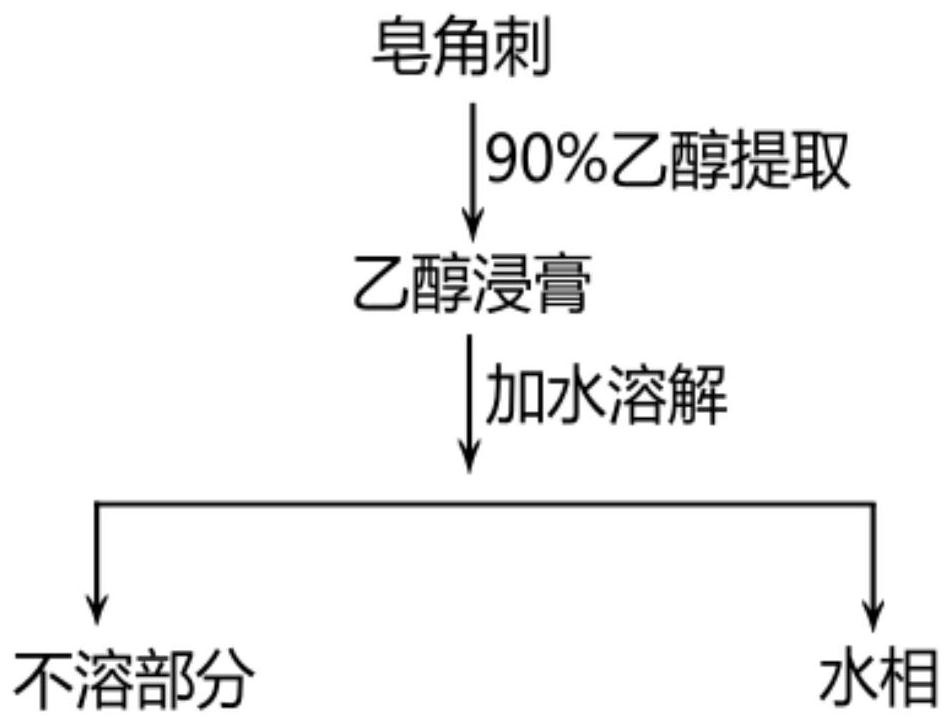

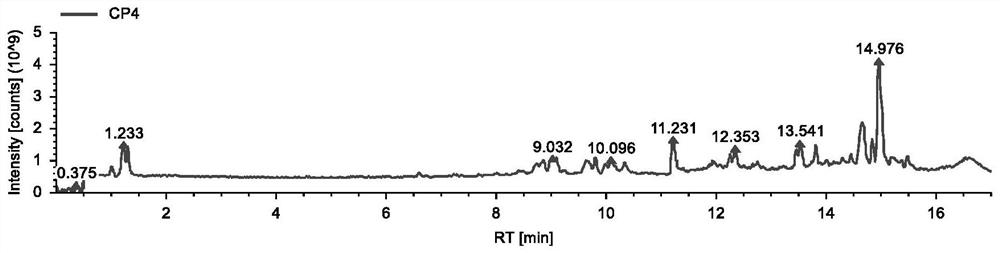

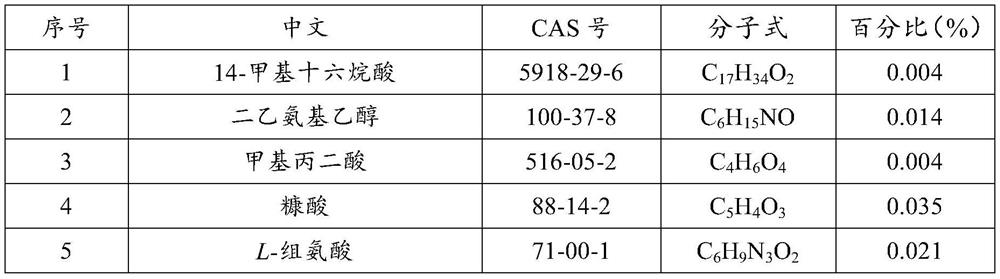

Spina gleditsiae-based bacteriostatic and antiallergic shampoo and preparation method thereof

InactiveCN111888292ARealize comprehensive utilizationEffective way to useCosmetic preparationsHair cosmeticsBiotechnologyAllergic anti

The invention proposes a spina gleditsiae-based bacteriostatic and antiallergic shampoo. In parts by weight, the shampoo is prepared from 20-40 parts of spina gleditsiae water extract, 1-2 parts of ammonium laureth sulfate (70%), 5-10 parts of fructus gleditsiae water extract, 2-4 parts of glycerin, 5-10 parts of honey and 30-60 parts of deionized water. The shampoo of the invention maintains theoriginal ecological fragrance of plants and bacteriostatic activity of the plants, has good bactericidal and bacteriostatic properties, and meanwhile, has the effects of nourishing and protecting hairand promoting hair growth.

Owner:成都天河农业旅游发展有限公司

Biosolid-sludge mixed ceram site

ActiveCN101585672BImprove protectionEfficient use ofSolid waste disposalSludgeToxic industrial waste

The present invention discloses biosolid-sludge mixed ceram site, belonging to the technical field of light materials. The biosolid-sludge mixed ceram site is prepared using raw materials as follows: biosolid of 10-30 parts by weight, and sludge of 70-90 parts by weight, wherein the biosolid is dehydrated mud and the sludge is river sludge and / or piling sludge. Accordingly, the mixed ceram site makes effective use of urban mud, and changes industrial waste solid into valuable; further, this utility model is wide in raw material source and is relatively low in cost.

Owner:ZHEJIANG FANGYUAN BUILDING MATERIALS TECH

Water-retaining thickening and strengthening additive for cement mortar and cement mortar containing additive

The invention discloses a water-retaining, thickening and reinforcing additive for cement mortar and cement mortar containing the additive, wherein the additive is corn straw cellulose or / and modified corn straw cellulose. The water-retaining, thickening and reinforcing additive for cement mortar and the cement mortar containing the additive, disclosed by the invention, have the beneficial effects that the water-retaining, thickening and reinforcing additive for cement mortar is a green environment-friendly product which is free from toxicity, peculiar smell, pollution and corrosivity; if the water-retaining, thickening and reinforcing additive for cement mortar, disclosed by the invention, is doped into cement mortar, the water-retaining property of mortar can be effectively improved; the water-retaining property of freshly mixed mortar is more than 90% and meets standard requirements; simultaneously, the intensity of mortar is obviously increased; the use amount of cement is effectively reduced; the intensity of mortar is increased by above 25%; the 14d tensile adhesive intensity is increased by above 13%; the cost of the water-retaining and thickening material is reduced by above 16%; a utilization way of the industrial by-product, namely cellulose, separated from corn straws, is effectively provided; furthermore, the utilization value is higher. The cost of the water-retaining, thickening and reinforcing additive for cement mortar, disclosed by the invention, is 4000-8000 yuan / ton, and the water-retaining, thickening and reinforcing additive for cement mortar, disclosed by the invention, is wide in source of used raw materials, proper in cost, convenient to use, high in operability and beneficial to popularization.

Owner:SHANDONG HUASEN CONCRETE

Autoclaved bricks with lignite germanium tailings as main raw material and preparation method thereof

The invention discloses an autoclaved brick with lignite germanium extraction tailings as the main raw material and a preparation method thereof. The raw material components of the autoclaved brick are pretreated lignite germanium extraction tailings, fly ash, slaked lime, water, and additives ; After dry mixing the pretreated lignite germanium tailings, fly ash and slaked lime, adding water and additives and continuing to stir evenly, the resulting mixture is pressed into shape, rested, and then autoclaved under the condition of 1.05Mpa~1.25Mpa. , the process of natural cooling to prepare the autoclaved brick with lignite extracting germanium tailings as the main raw material; the process of the invention has low energy consumption, high tailings utilization rate and good product performance.

Owner:LINCANG TEACHERS COLLEGE

Water-resistant light gypsum mortar

The invention relates to the field of building materials, in particular to water-resistant light gypsum mortar, which is prepared from the following raw materials in parts by mass: 40-50 parts of building gypsum powder, 40-50 parts of mineral powder, 50-80 parts of furnace slag, 5-10 parts of cement, 1-3 parts of early strength agent, 0.1-0.3 part of water-retaining agent, 0.1-0.3 part of retarder, 0.1-0.3 part of thixotropic agent and 0.3-0.5 part of organic soil. According to the water-resistant light gypsum mortar, slag is used for replacing traditional light aggregate such as vitrified micro bubbles and perlite, the physical property that the slag is high in mechanical strength is fully utilized, and the mechanical strength of the light gypsum mortar is improved; besides, the slag is a porous alkaline substance, is light in volume weight, has certain activity and can be subjected to a gelatinization reaction with the building gypsum powder in an alkaline environment, meanwhile, gypsum, the slag and cement can be subjected to a gelatinization reaction, and the mechanical strength of the light gypsum mortar is further improved.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD +1

Method for preparing natural gas from yellow phosphorus tail gas and production device using the method

InactiveCN104031705BEffective way to useTake advantage ofGaseous fuelsMethanationEnvironmental engineering

The invention relates to a method for preparing natural gas from yellow phosphorus tail gas and a production device using the method. The method comprises the following step: by using yellow phosphorus tail gas and coke oven gas as raw gases, carrying out methanation reaction in a methanation device by using hydrogen in the raw gases and carbon monoxide and carbon dioxide in the raw gases, wherein the ratio of the yellow phosphorus tail gas to the coke oven gas is controlled to control the ratio of the hydrogen to the carbon monoxide and carbon dioxide in the reaction system, so that the contents of the hydrogen, carbon monoxide and carbon dioxide in the gas after reaction respectively conform to the requirements for natural gas, and the volume ratio of the yellow phosphorus tail gas to the coke oven gas is 1:(9-12). The production device comprises the methanation device, a raw gas purification device before the methanation device, and a natural gas purification device after the methanation device, wherein the methanation device is a three-stage or four-stage methanation facility. The method has the advantages of reasonable technological design and low cost, recycles the yellow phosphorus tail gas, avoids waste of resources and environmental pollution, and enhances the economic benefit.

Owner:北京中凯环能高科技有限公司

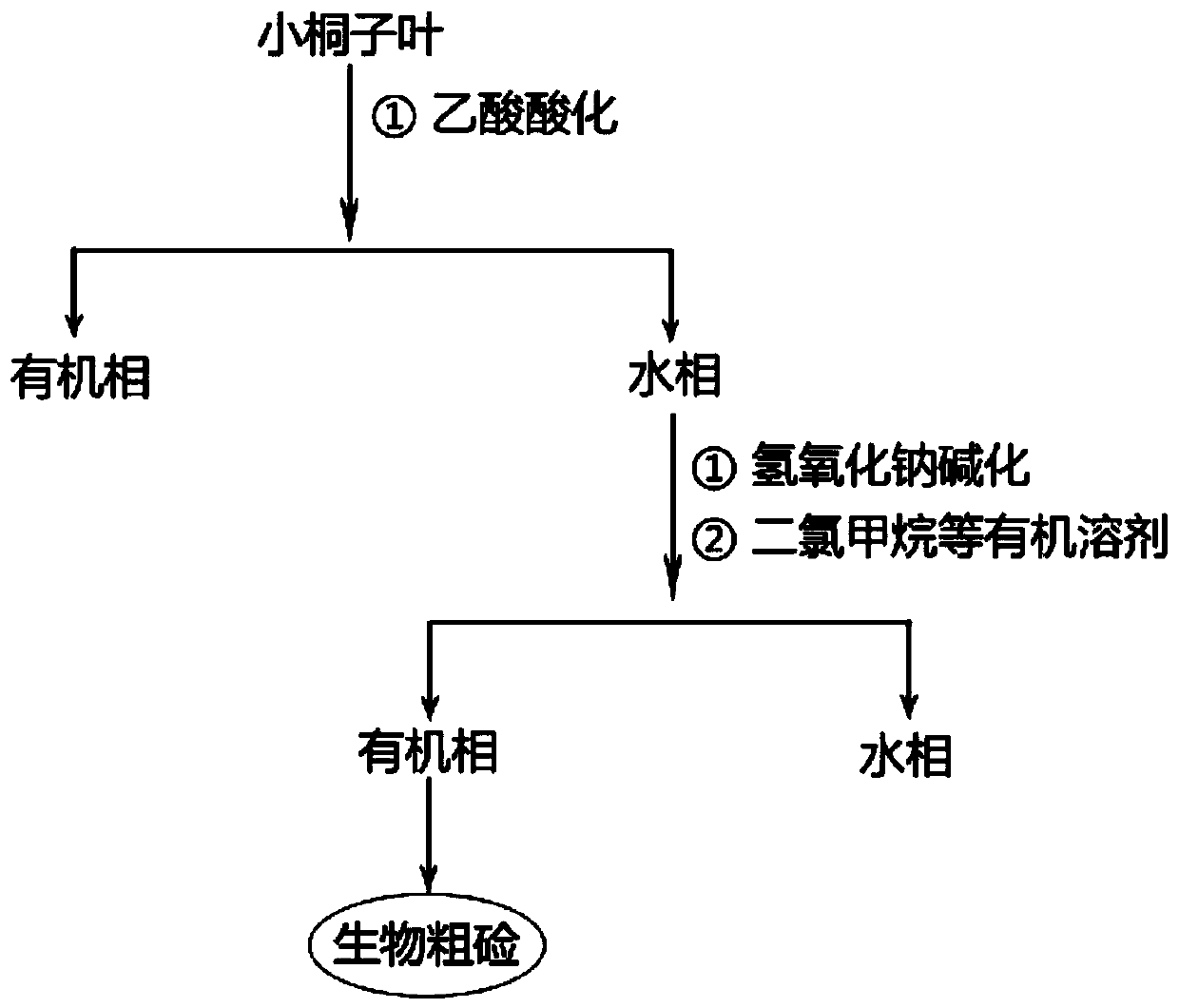

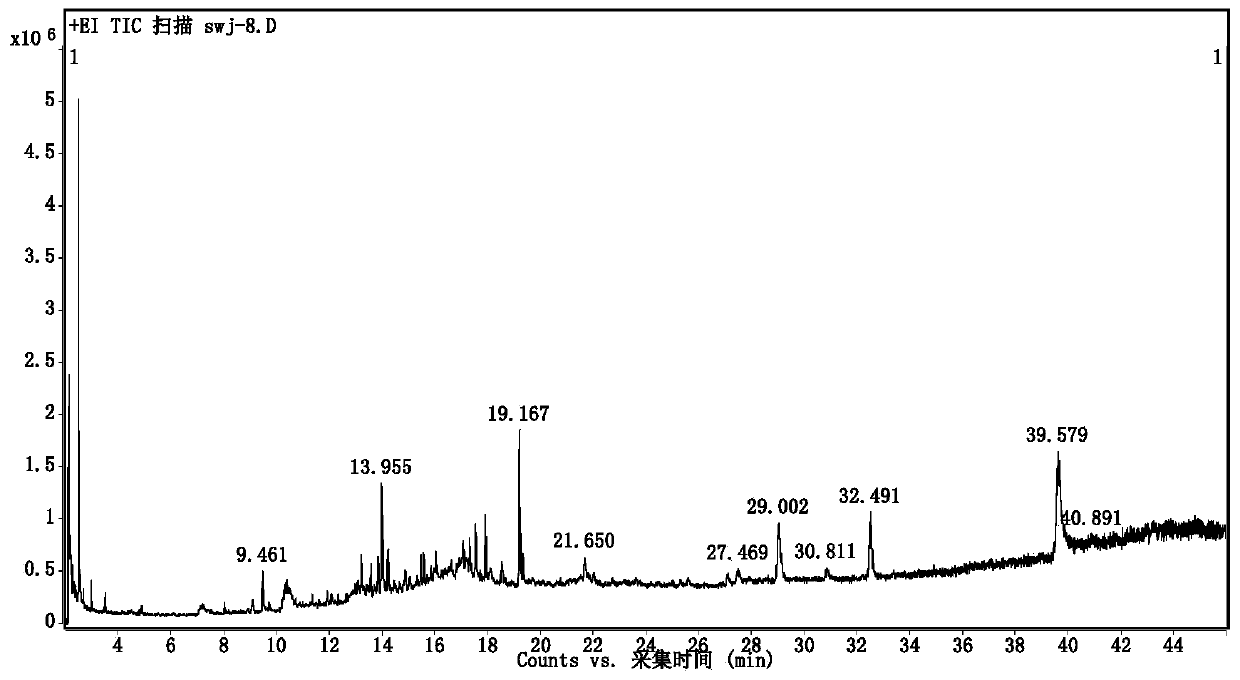

Extraction process of biological crude alkali from leaves of jatropha curcas

InactiveCN110755878AFully develop and utilizeEasy accessLiquid solutions solvent extractionEnergy based chemical/physical/physico-chemical processesOrganosolvJatropha curcas

The invention provides an extraction process of biological crude alkali from leaves of jatropha curcas, and belongs to the technical field of biotechnology. The extraction process comprises the following steps that a, hoarded leaves of the jatropha curcas are naturally air-dried or dried by a dryer, and is smashed by adopting a pulverizer, the size is less than or equal to 5 mm after sieving, andstorage is conducted at room temperature; b, 1.0-5.0 kg of the sieved leaves of the jatropha curcas is dispersed into 10-50 L of an ethanol / water mixed solution for extraction, and ultrasonic treatment is conducted while stirring; c, residues are removed by filtration, after ethanol of an obtained yellow solution is removed by rotary evaporation, 1-5 L of an acetic acid aqueous solution or a hydrochloric acid aqueous solution is added for immersing for 0.5-1.0 h; and filtering is conducted to obtain yellow water phase; d, the above steps are repeatedly conducted for 2-4 times; e, an alkalineaqueous solution such as sodium hydroxide is added into water phase obtained in the step d, and the pH value is adjusted to about 10.0; and f, the combined mixed solution in the step e is filtered orsubjected to suction filtration by a vacuum pump, and then is extracted for 3 times with a water-insoluble organic solvent with equal volume and low boiling point, and the combined organic phase is dried, filtered and rotary-evaporated to obtain the biological crude alkali.

Owner:凉山德农生物能源股份有限公司

A method for increasing production of low-carbon olefins and aromatics by steam cracking of coker gasoline

ActiveCN103664479BExpand sourceEffective way to useHydrocarbon purification/separationHydrocarbonsPetroleumIonic liquid

The invention relates to a method for increasing yields of low-carbon olefins and aromatics by coker gasoline steam cracking, which comprises the following steps: raw oil is subjected to ionic liquid solvent extraction to remove aromatics and olefins, thereby obtaining a hydrocarbon stream in which the aromatic content is lower than 2 wt% and the olefin content is lower than 5 wt%; the hydrocarbon stream enters a steam cracking procedure to be subjected to cracking and separation; the crude aromatic stream is sent into a cracked gasoline hydrogenation unit together with cracked gasoline, and the olefins are hydrogenated and sent into a hydrocracked gasoline aromatic extraction unit to separate the aromatic product; and the obtained stream containing rich saturated hydrocarbons is returned and introduced into the cracking procedure together with a petroleum hydrocarbon stream containing less aromatics to react and produce the low-carbon olefins. The method provides an effective utilization way for the coker gasoline raw material, widens the ethylene sources, recycles the non-aromatic components by using the original cracking hydrogasoline aromatic extraction system, and increases the yields of the low-carbon olefins and aromatics in the cracking process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Konilite wet ball milling-paint integrated preparation method

The invention discloses a konilite wet ball milling-paint integrated preparation method. The konilite used as the main raw material is firstly subjected to wet ball milling to obtain the konilite ultrafine slurry, and other powder slurries are added in the paint preparation link to obtain the konilite-base paint; the coated film is bright and fine; and the method solves the problem of paint pollution caused by wearing iron powder since the konilite with high hardness can easily wear and damage the sand mill in the paint sanding link.

Owner:GUIZHOU LIANHE NEW BUILDING MATERIAL

Phosphogypsum granular soil and preparation method thereof

InactiveCN110950622AGood water and fertilizer retention functionHigh water retentionCalcareous fertilisersGrowth substratesBound waterSoil science

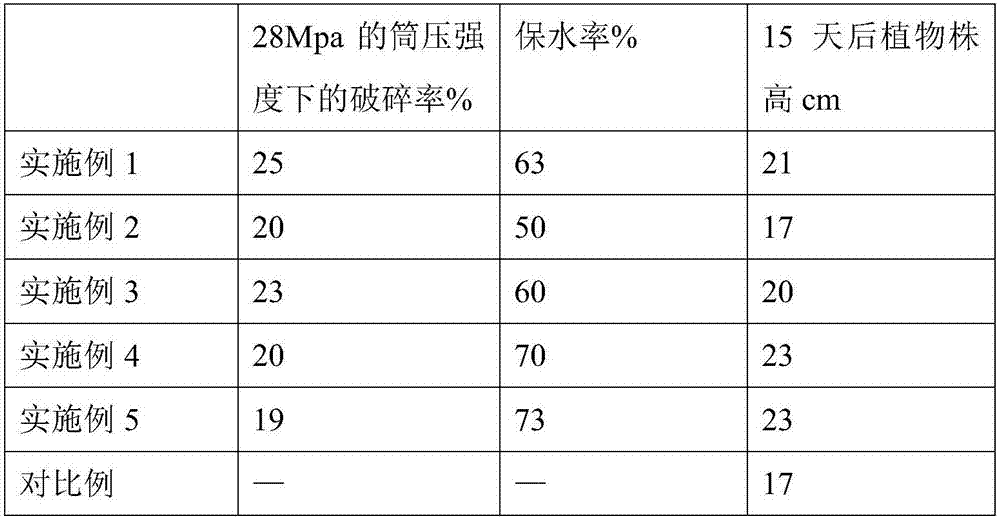

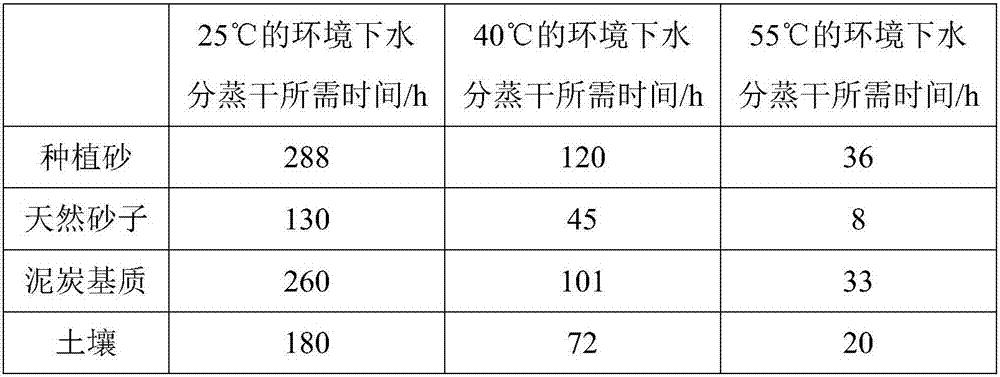

The invention relates to the field of granular soil, particularly to phosphogypsum granular soil and a preparation method thereof. Based on the problem of waste of resources due to phosphogypsum stacking, the invention provides phosphogypsum granular soil and a preparation method thereof so as to achieve the efficient reuse of phosphogypsum and prepare granular soil with good water and fertilizerretention effects. According to the invention, by using phosphogypsum as a main raw material, in a process for changing dihydrate gypsum in the phosphogypsum into insoluble anhydrous gypsum, a large amount of free water and bound water are lost to form a large number of pores formed in granular soil, and expanded perlite is added, is a white granular material with a honeycomb-like structure inside, and has low stacking density and strong water retention function, so that the granular soil has good water and fertilizer retention functions, and has the water retention rate of 65-85%; the granular soil has high strength under the dual action of silica sol bonding and phosphogypsum self-solidification, and the breakage rate under 28 MPa is smaller than 25%; and the granular soil prepared by the method can well meet the growth requirements of plants.

Owner:GUANGDONG TSINGDA TONGKE ENVIRONMENTAL PROTECTION TECH CO LTD

Non-fired ceramsite with lignite germanium extraction tailings as main raw material and preparation method thereof

InactiveCN103896543BEffective way to useAvoid damageSolid waste managementPre treatmentEnergy consumption

The invention discloses an unfired ceramsite by using lignite extracted germanium tailings as a main raw material and a preparation method of the unfired ceramsite. The raw material components of the unfired ceramsite comprise pretreated lignite extracted germanium tailings, cement, unslaked lime, water and additive. The method comprises the following steps: drily mixing the pretreated lignite extracted germanium tailings, cement and unslaked lime, adding water and additive to uniformly stir, ageing the mixture and pelletizing, standing, steaming and pressing curing at 0.75-1.05Mpa to prepare the unfired ceramsite by using lignite extracted germanium tailings as the main raw material in the natural cooling process. The energy consumption is small, the utilization rate of the tailing is high, and the product property is good.

Owner:LINCANG TEACHERS COLLEGE

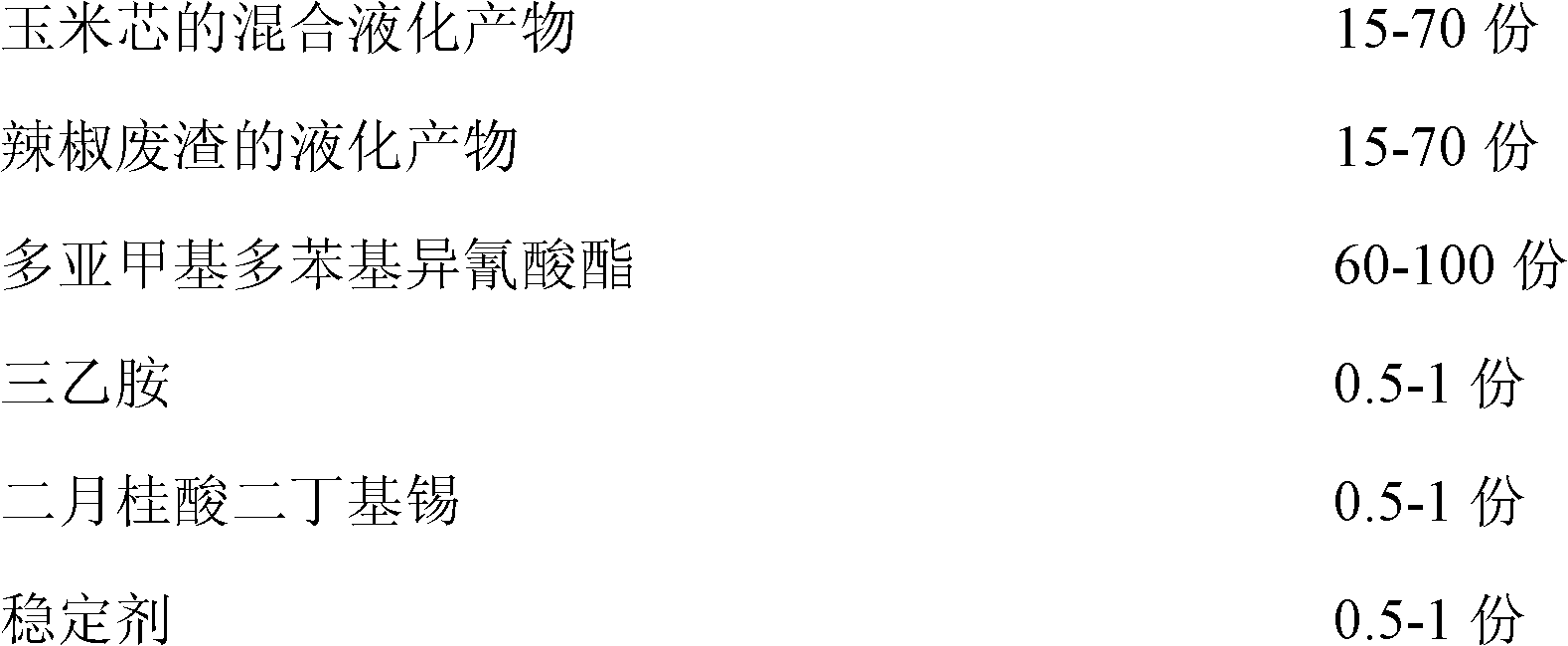

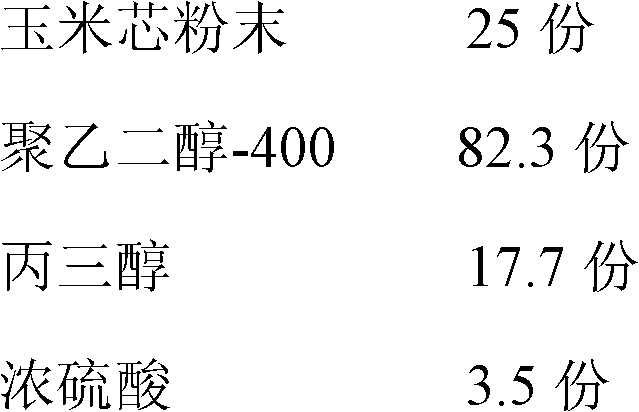

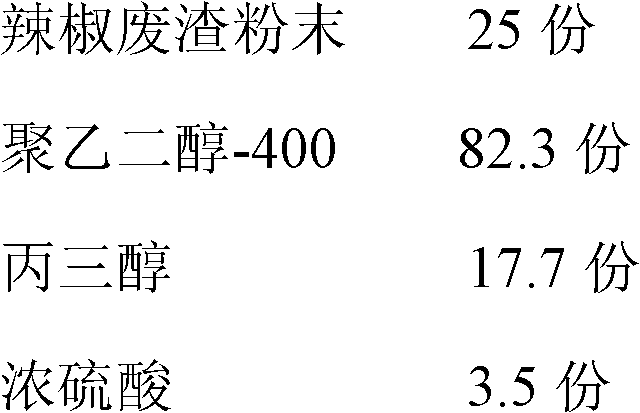

Method for synthesizing degradable polyurethane by using corncob and industrial capsicum waste residue

Owner:CHINA AGRI UNIV

A method for increasing production of low-carbon olefins and aromatics by steam cracking of coker gasoline

ActiveCN103666550BExpand sourceEffective way to useOrganic chemistryHydrocarbon oils refiningGasolineSolvent

Owner:CHINA PETROLEUM & CHEM CORP +1

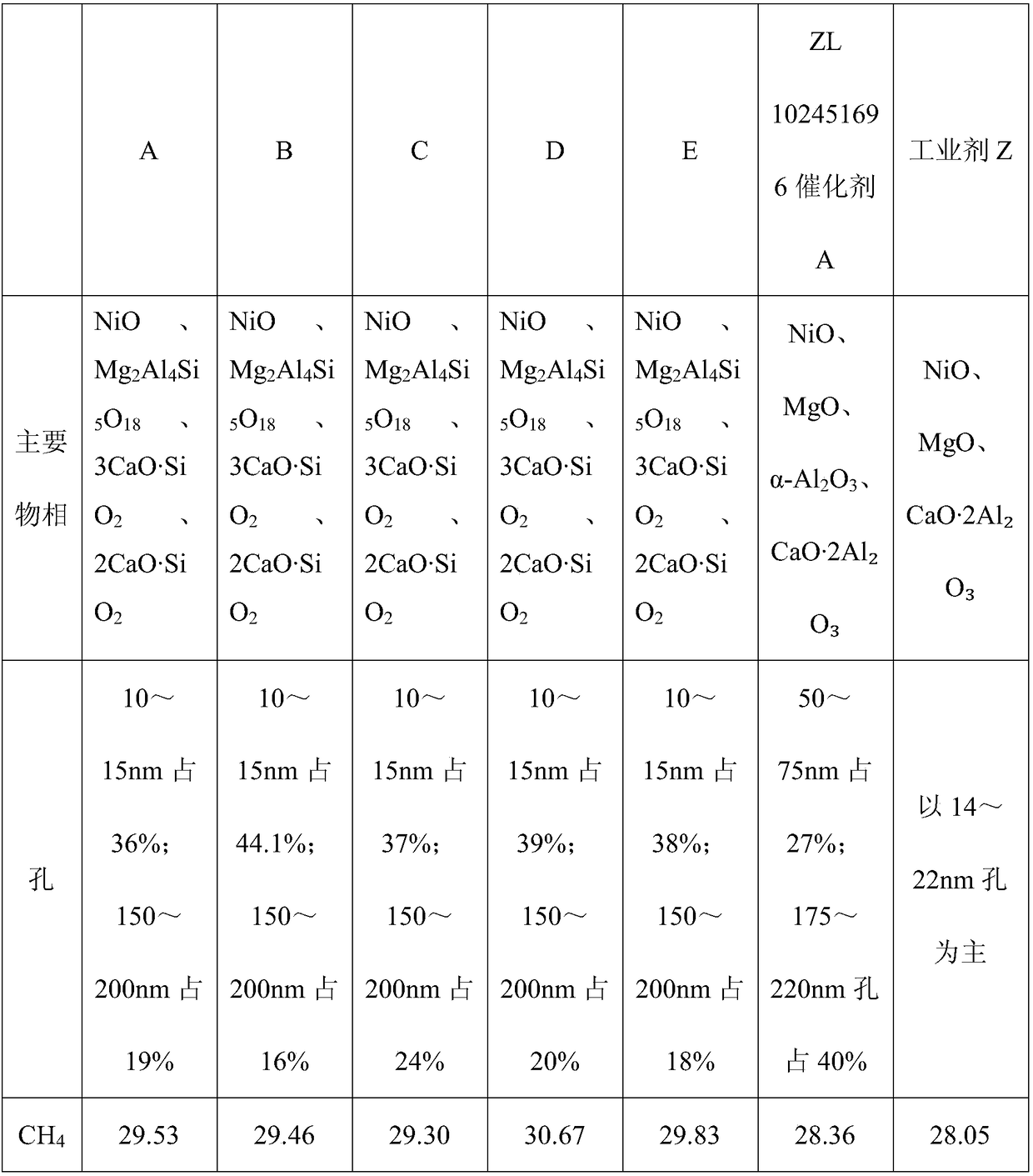

Gaseous hydrocarbon steam conversion upper-section catalyst and preparation method thereof

ActiveCN109382136AMicrostructural stabilityRelieve great pressureHydrogenMolecular sieve catalystsAir atmosphereCarbon resistance

The invention belongs to the technical field of hydrocarbon-based steam conversion, and particularly relates to a gaseous hydrocarbon steam conversion upper-section catalyst and a preparation method thereof. According to the catalyst, nickel and rare earth are used as active components; the NiO content in the catalyst is 5-25 wt%, and the rare earth metal oxide content is 0.3-15 wt%; the active components nickel and rare earth are loaded on the carrier by using a co-impregnation method; and the carrier preparation method comprises: (1) FCC catalyst waste agent treatment, wherein a FCC catalystwaste agent is calcined in an air atmosphere, and crushing and screening are performed to obtain powder, and (2) carrier preparation, wherein the powder, magnesium oxide, an anti-carbon auxiliary agent, a pore-forming agent, a lubricant and a binder are mixed, ball milling, kneading, granulation and extrusion molding are performed to obtain a raw ring, and curing, drying and roasting are performed to obtain the carrier. According to the present invention, the catalyst has advantages of good carbon resistance, good mechanical strength and good conversion activity, and is used for preparing hydrogen or carbonyl synthesis gas by combining with the lower-section catalyst; and the preparation method has characteristics of simple process and low cost.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com