Gaseous hydrocarbon steam conversion upper-section catalyst and preparation method thereof

A technology of catalysts and gaseous hydrocarbons, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, molecular sieve catalysts, etc., which can solve the problems of environmental hazards, low consumption of waste dosage, and high processing costs, so as to reduce preparation costs and relieve huge pressure , good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

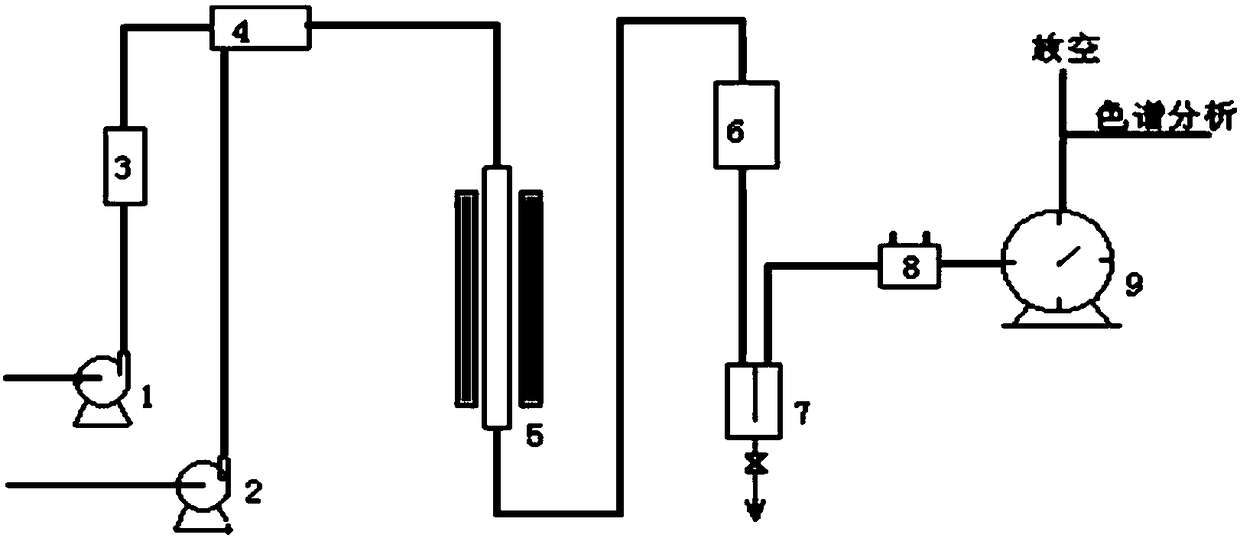

Image

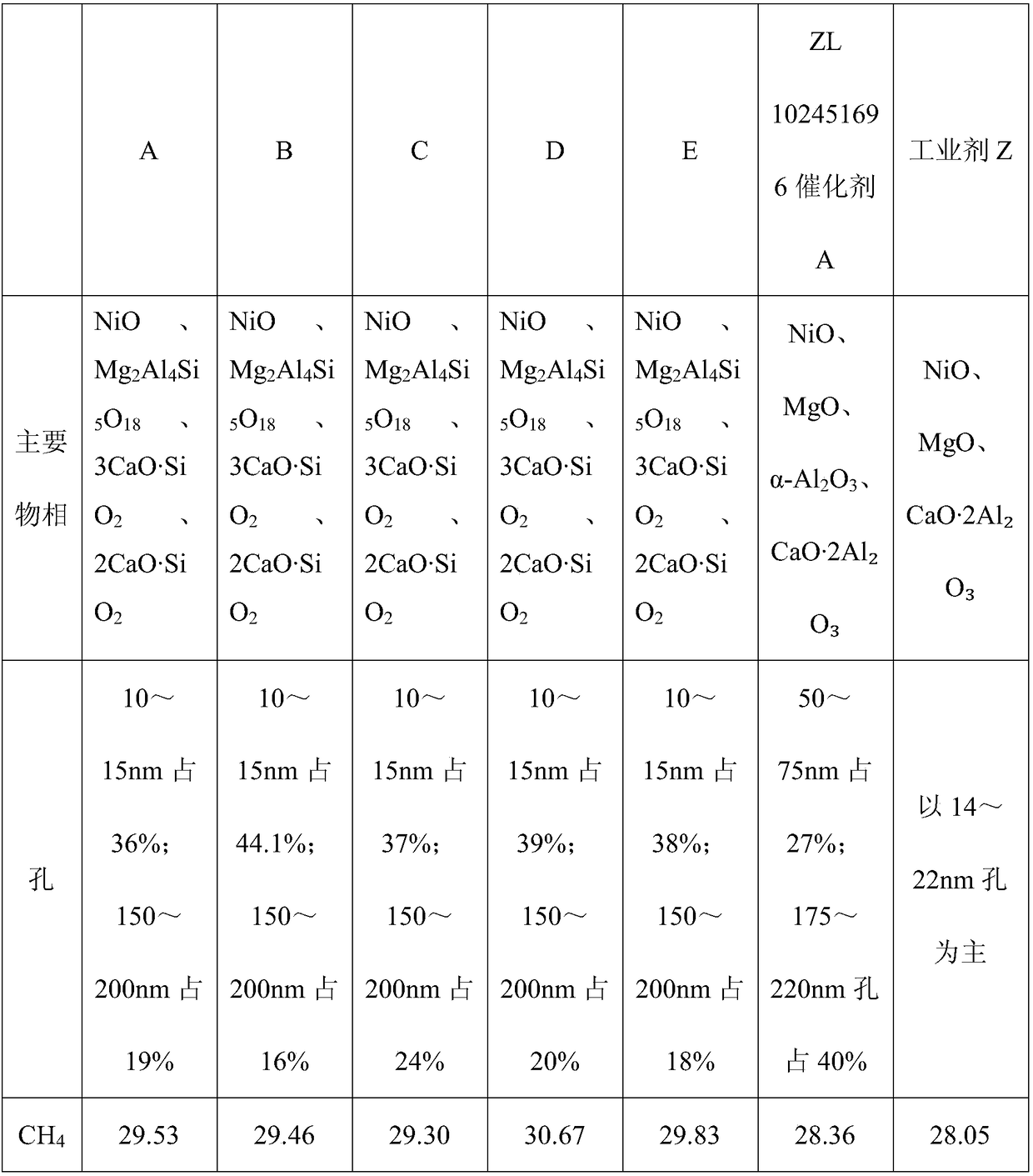

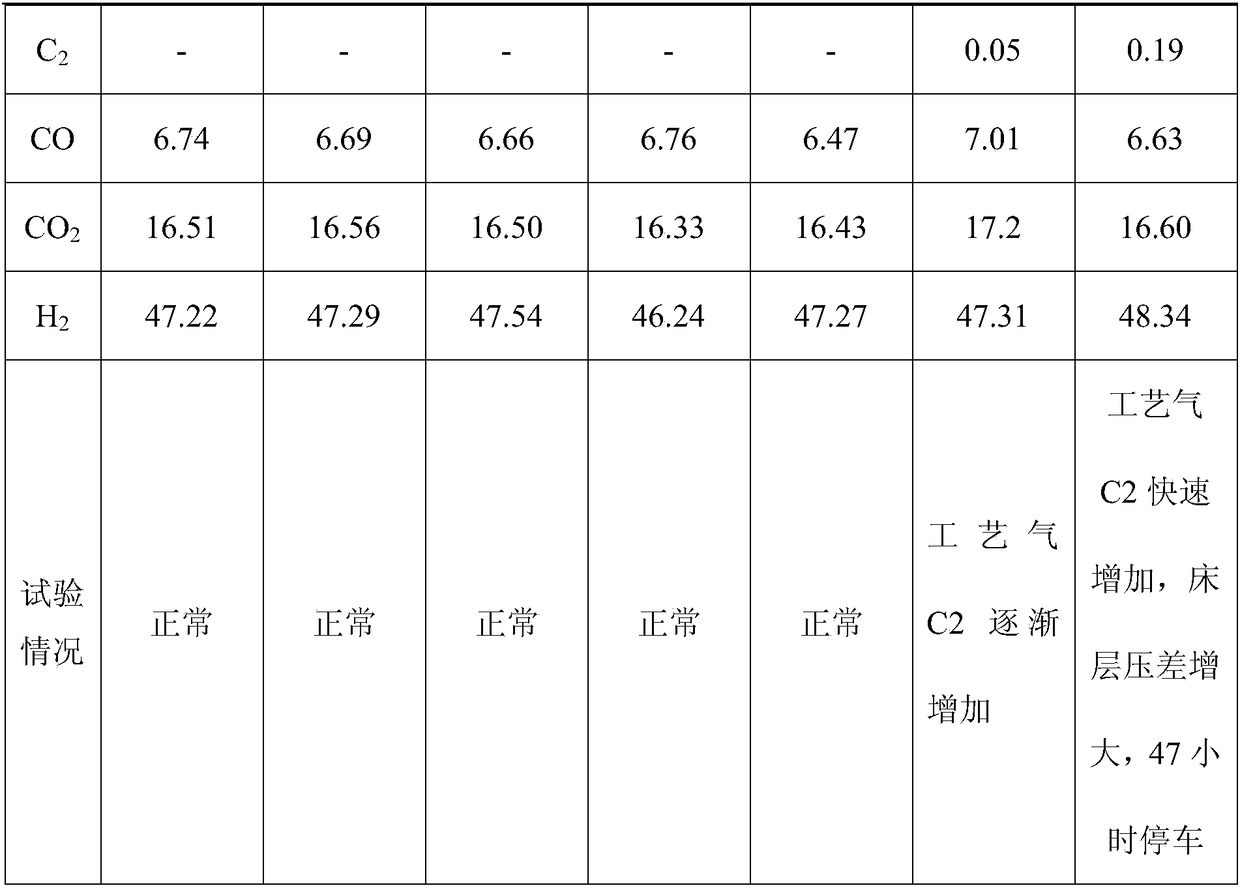

Examples

Embodiment 1

[0041] The waste FCC agent is calcined in an air atmosphere at a temperature of 700°C for 2 hours, and the waste agent after roasting is crushed through a 320-mesh sieve, which is called raw material I.

Embodiment 2

[0043] The spent FCC agent was calcined under air atmosphere, the calcining temperature was 500°C, and the calcining time was 10 h. The roasted waste agent is crushed through a 280-mesh sieve, which is called raw material II.

Embodiment 3

[0045] The spent FCC agent was calcined under air atmosphere, the calcining temperature was 600°C, and the calcining time was 4h. The roasted waste agent is crushed through a 320 mesh sieve, and is called raw material III.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com