A preparation method of high-temperature-resistant and wear-resistant brake pads

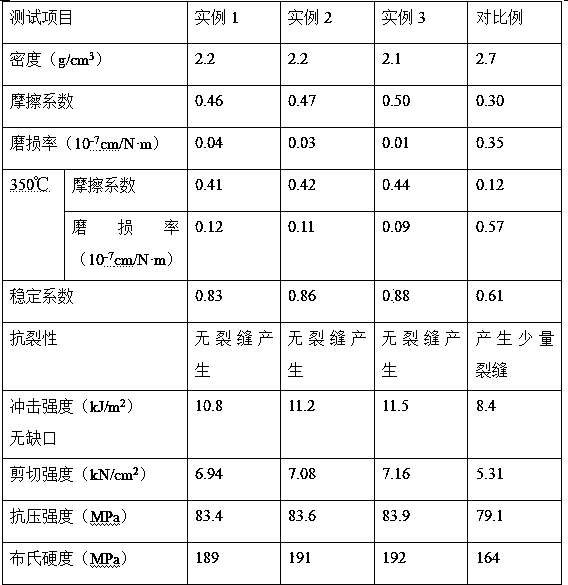

A wear-resistant, brake pad technology, used in chemical instruments and methods, friction linings, mechanical equipment, etc., can solve the problems of insufficient wear resistance and poor high temperature resistance of brake pads, and achieve impact resistance and mechanical strength. Effect of improvement, high temperature resistance and strength improvement, mechanical properties and wear resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]In terms of parts by weight, weigh 5-7 parts of titanium powder, 5.0-5.5 parts of carbon powder, 10-11 parts of aluminum powder and 12-13 parts of iron powder into a three-dimensional mixer and mix at a speed of 200-300r / min 5 to 6 hours to prepare the solid mixture, in parts by weight, put 3 to 5 parts of the solid mixture, 1 to 2 parts of urea granules and 10 to 11 parts of absolute ethanol in a three-dimensional mixer and mix for 5 to 6 hours to obtain the solid mixture. Liquid mixture; put the above solid-liquid mixture into a muffle furnace, heat up to 220-230°C and preheat for 60-70 minutes. The iron powder is mixed according to the mass ratio of 1:2 to prepare the ignition powder, and the ignition powder with a mass of 50-60% of the solid-liquid mixture is put into the muffle furnace, and the combustion reaction is 40-50 minutes. The metal composite product is obtained, and it is set aside; in parts by weight, 3 to 5 parts of graphite powder, 1.5 to 1.8 parts of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com