Patents

Literature

1602 results about "Laser printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser printing is an electrostatic digital printing process. It produces high-quality text and graphics (and moderate-quality photographs) by repeatedly passing a laser beam back and forth over a negatively charged cylinder called a "drum" to define a differentially charged image. The drum then selectively collects electrically charged powdered ink (toner), and transfers the image to paper, which is then heated in order to permanently fuse the text, imagery, or both, to the paper. As with digital photocopiers, laser printers employ a xerographic printing process. Laser printing differs from traditional xerography as implemented in analog photocopiers in that in the latter, the image is formed by reflecting light off an existing document onto the exposed drum.

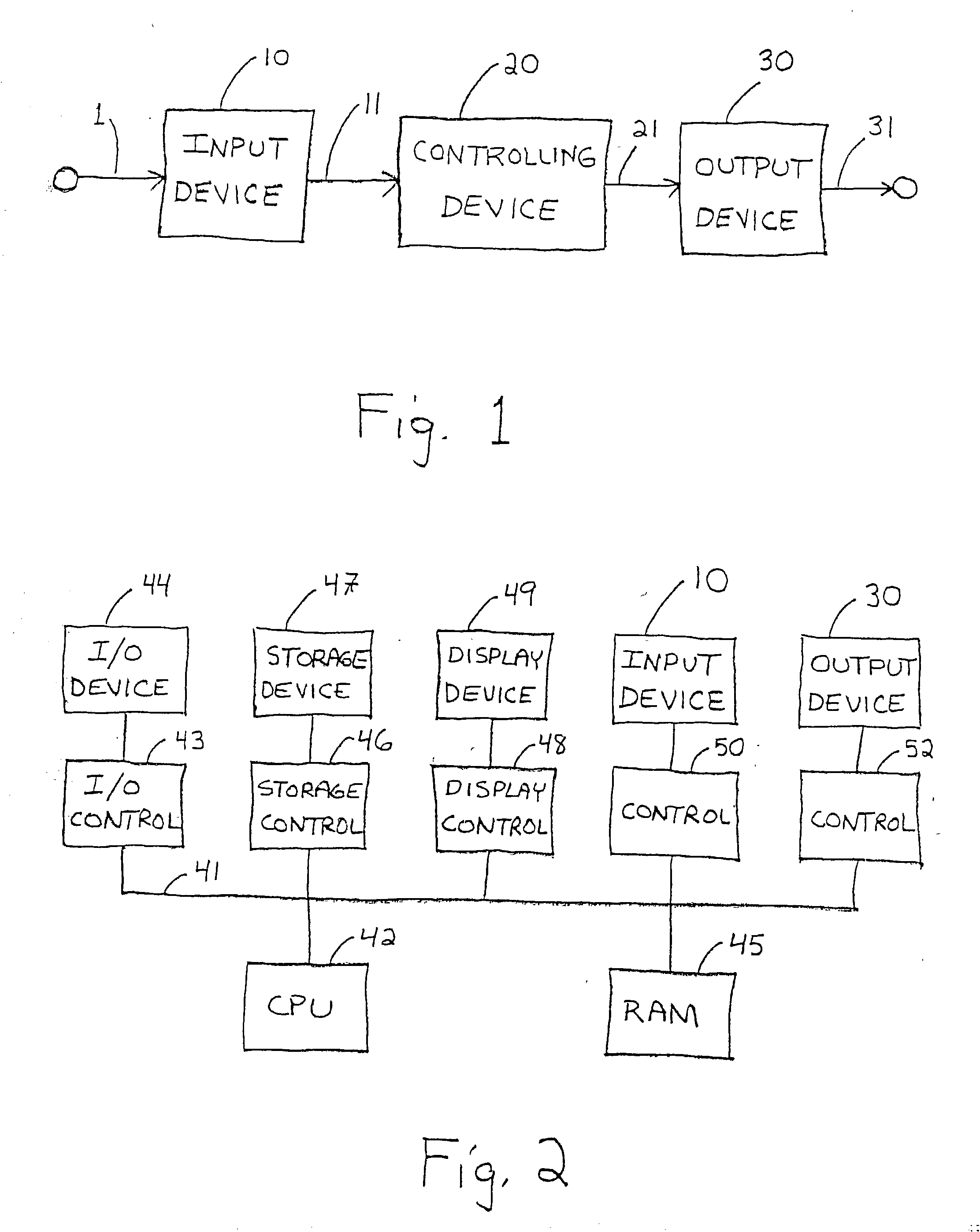

Apparatus, systems and methods for printing dimensionally accurate symbologies on laser printers configured with remote client computer devices

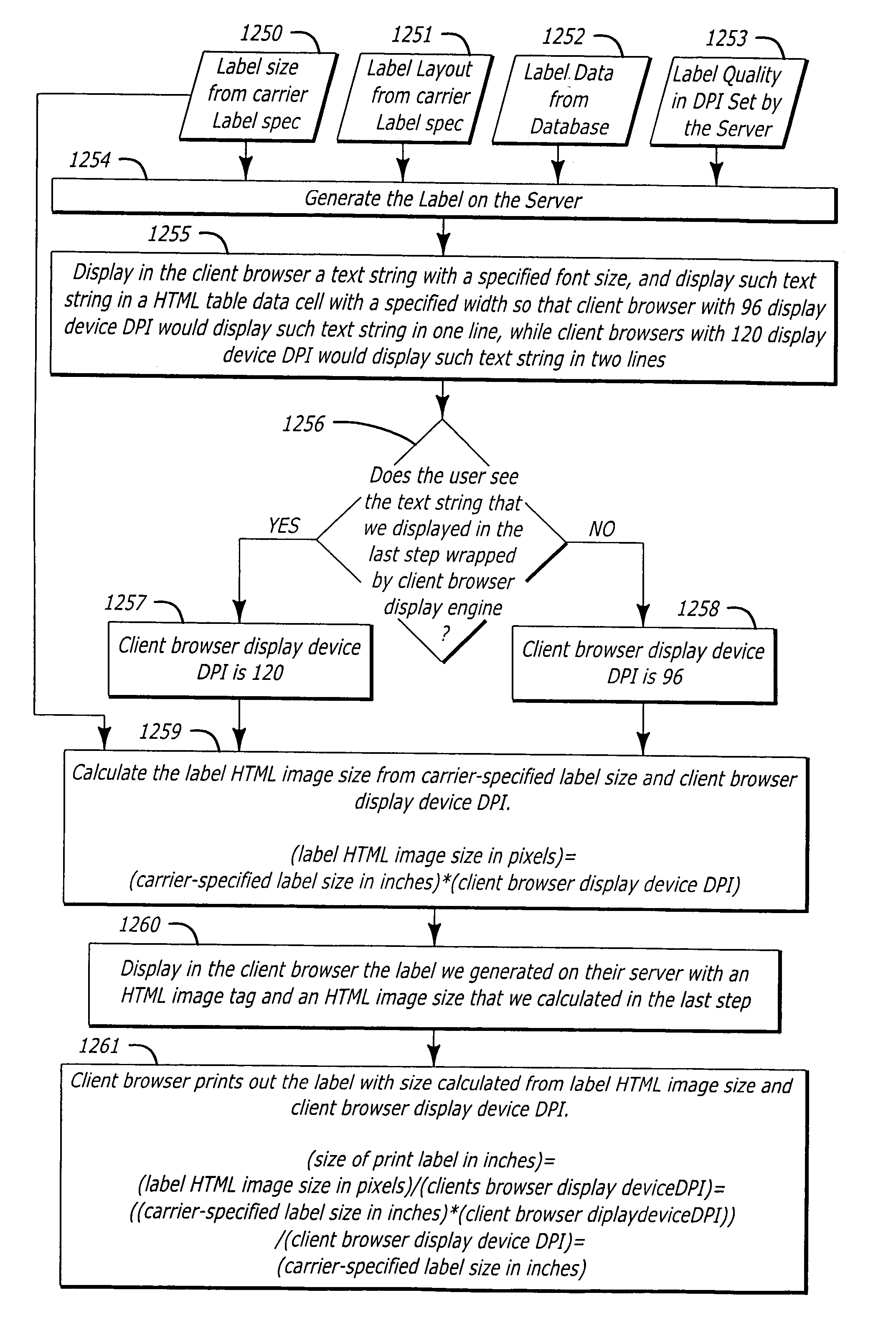

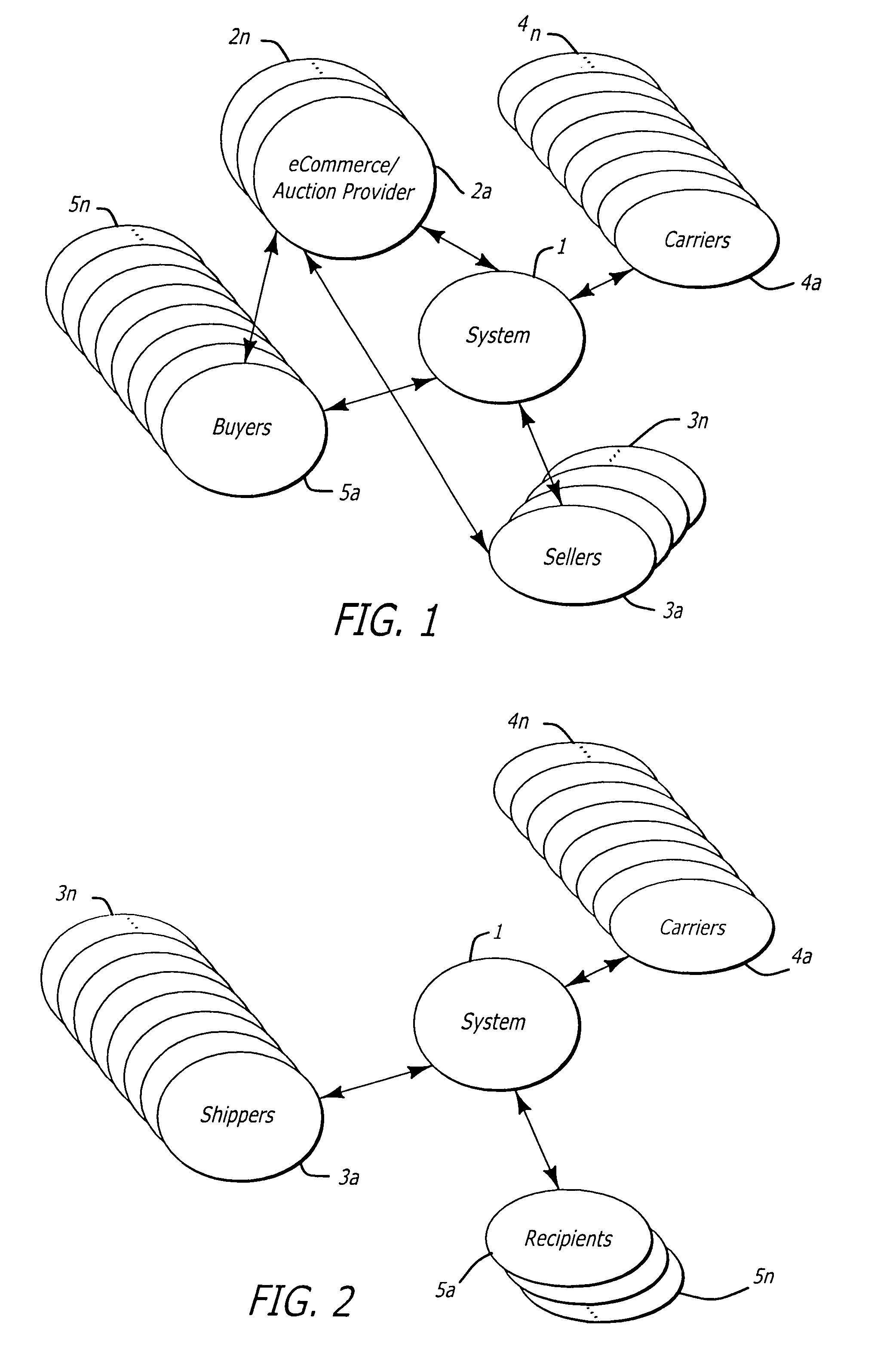

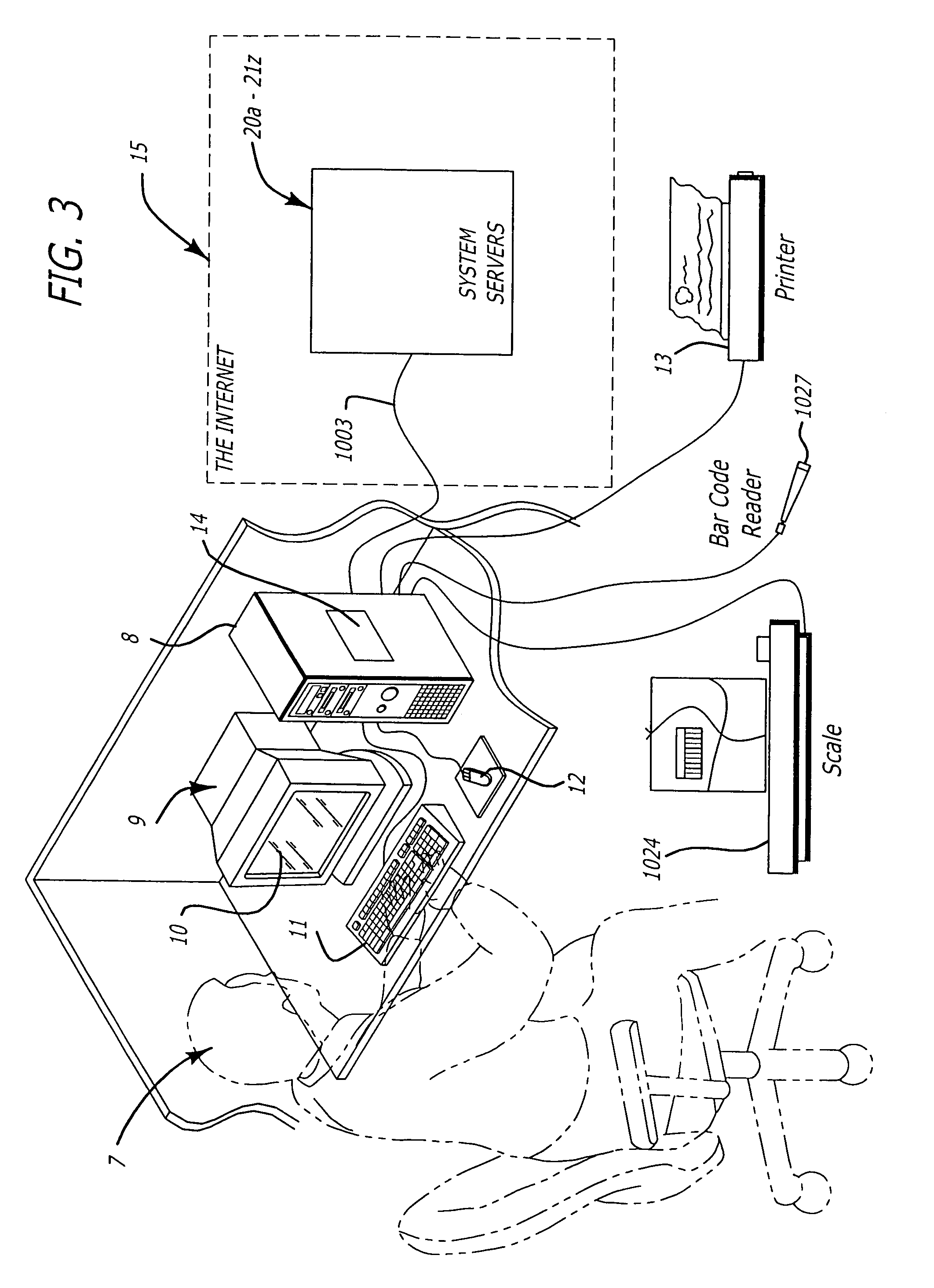

The present invention provides apparatus, systems and methods providing a printer interface in a global communications environment for a shipping management system resident on a server computer device remote from a user client computer device, that creates an image of a shipping label with dimensionally accurate symbologies, such as a bar code label, for display on a remote display device and for printing on a remote printing device, such as a laser printer, configured with the remote user client computer device. The present invention provides apparatus, systems and methods providing a printer interface that recognizes the graphic resolution for each printer, including laser printers, configured with each of a plurality of remote user client computer devices, wherein the printer interface communicates with each remote user client computer device over a global communications network. The present invention provides apparatus, systems and methods for creating a shipping label image bearing a dimensionally accurate symbology for display on a display device configured with the particular remote user client computer device for printing on the particular printer device.

Owner:ISHIP +1

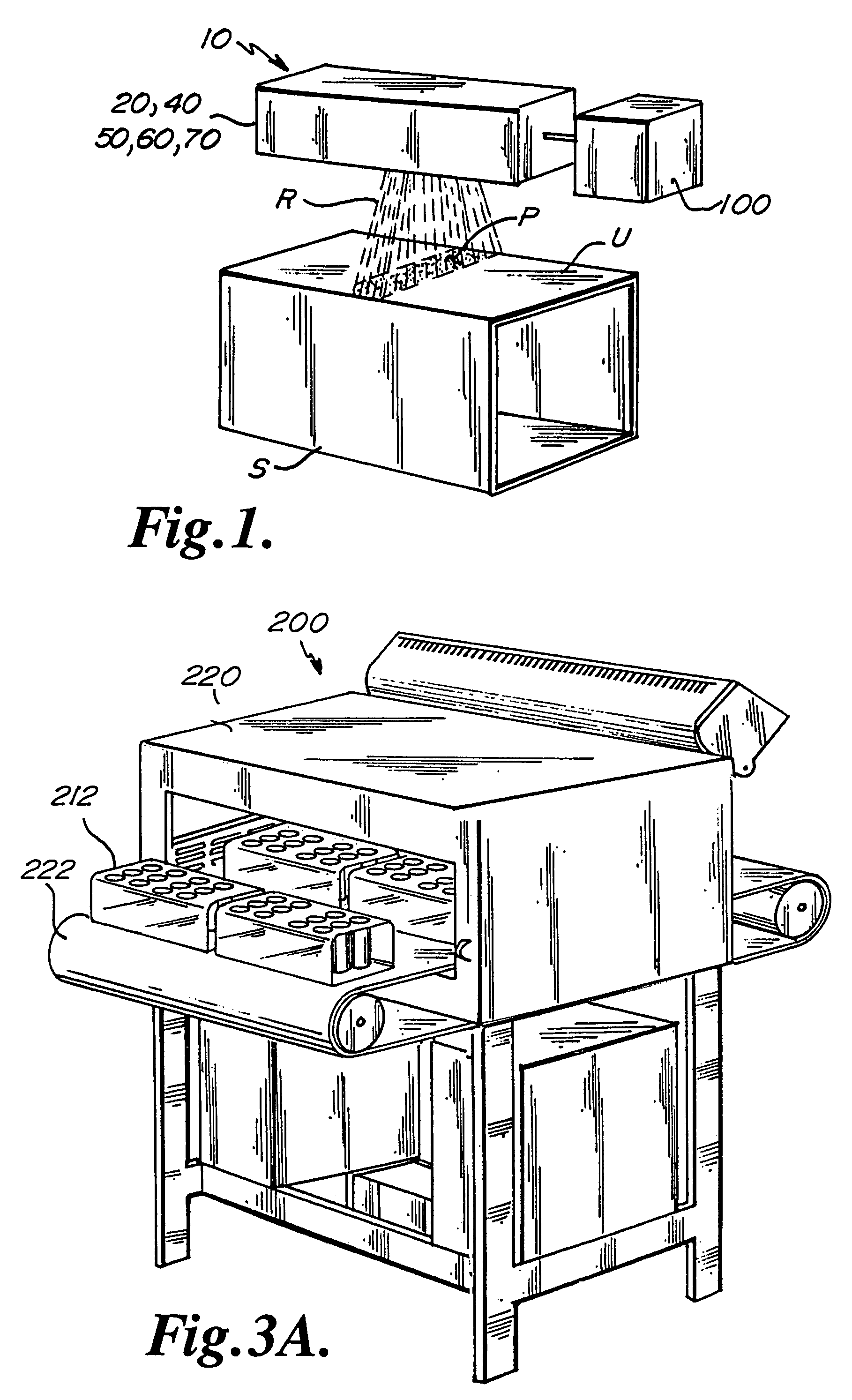

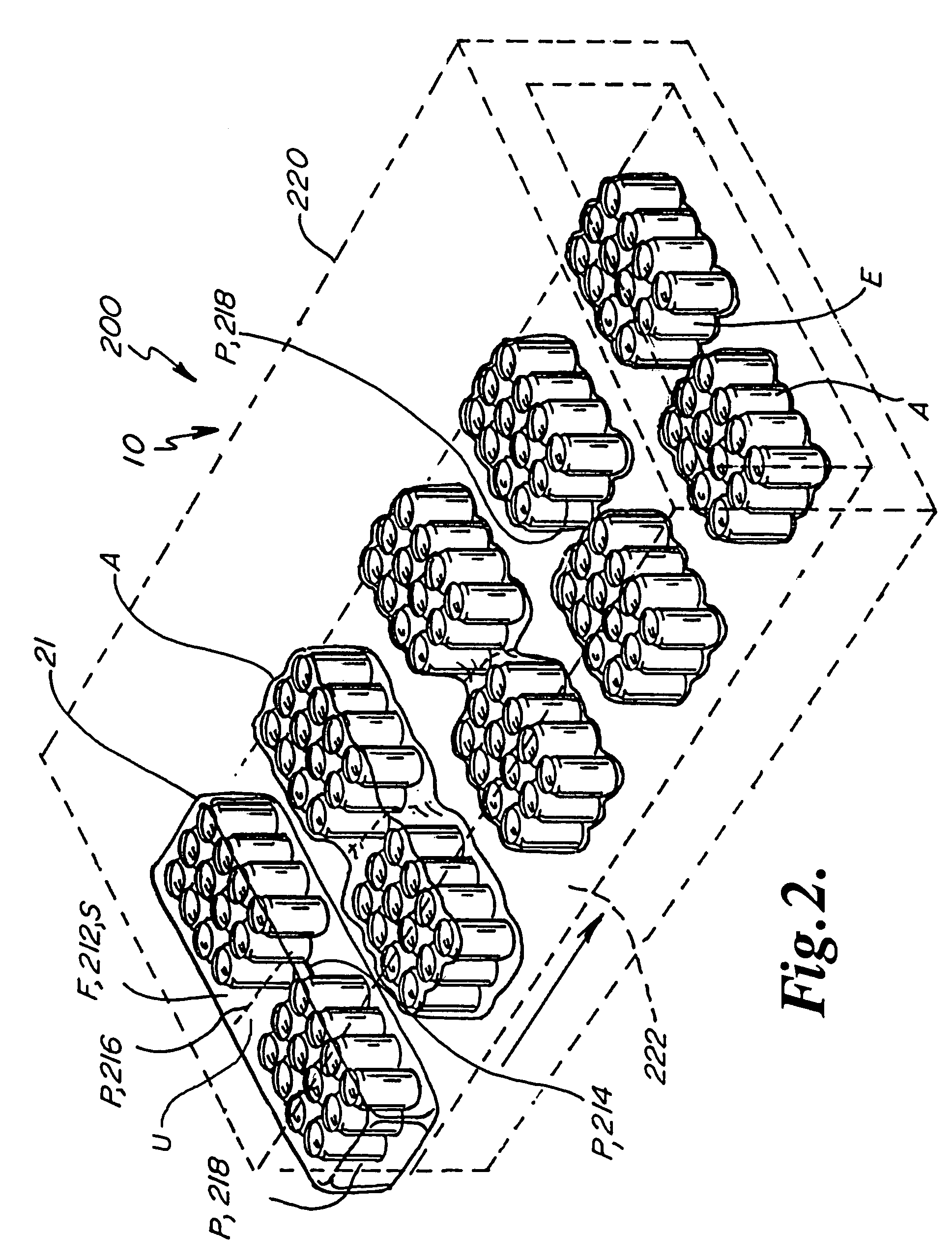

Laser Printing System

ActiveUS20160279707A1Improve homogeneityLess alignment workAdditive manufacturing apparatusElectrographic process apparatusLaser arrayLaser light

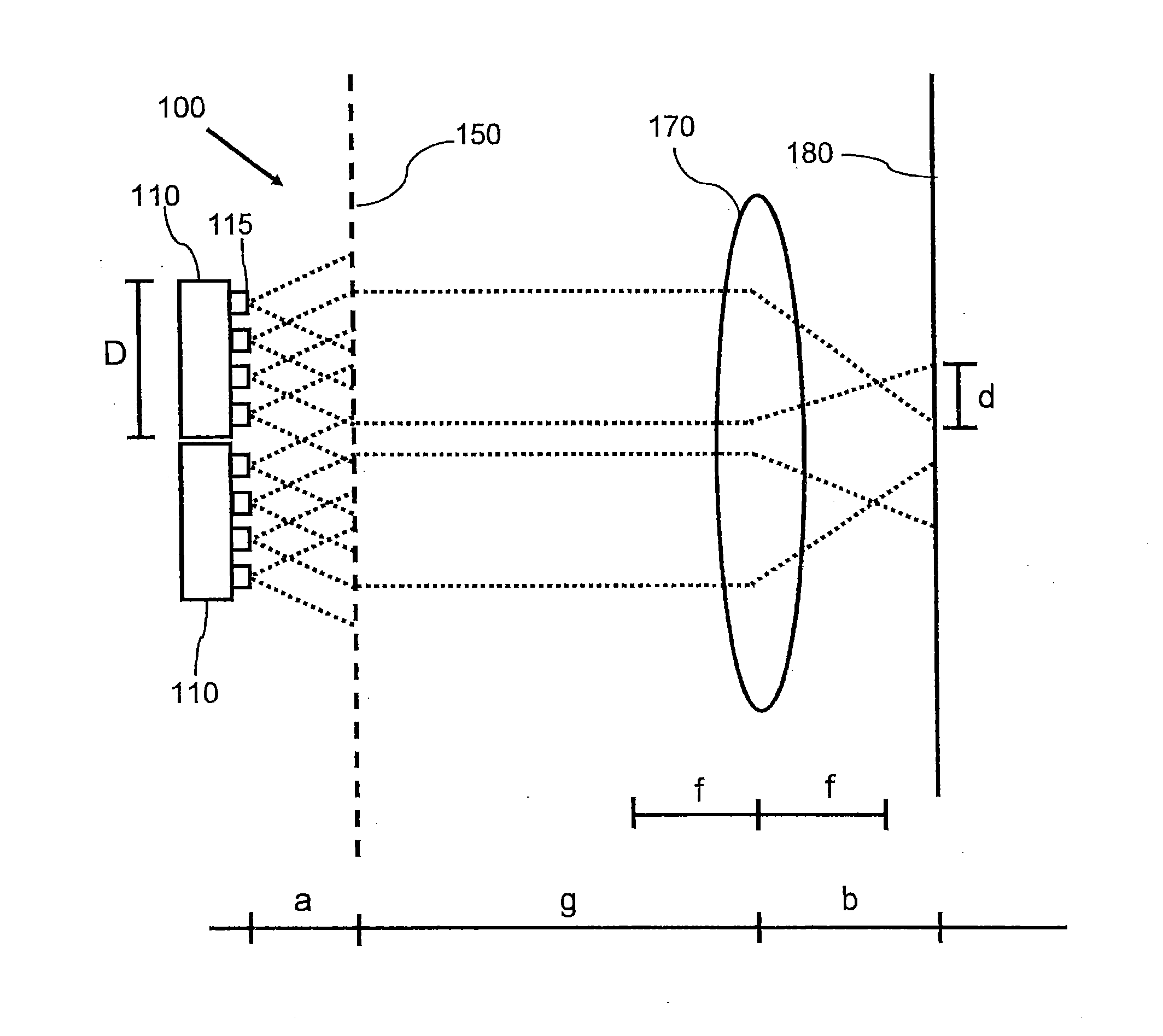

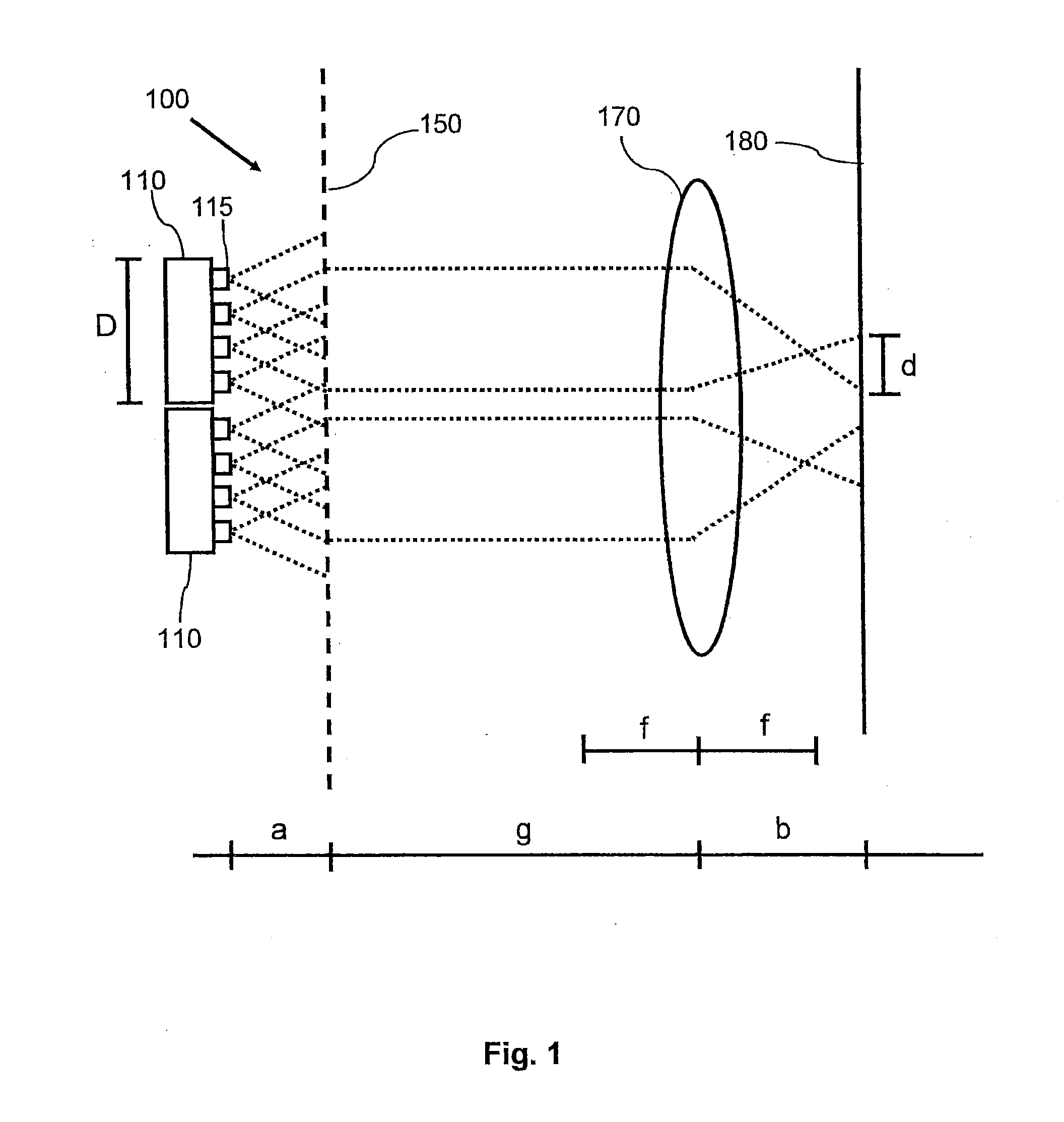

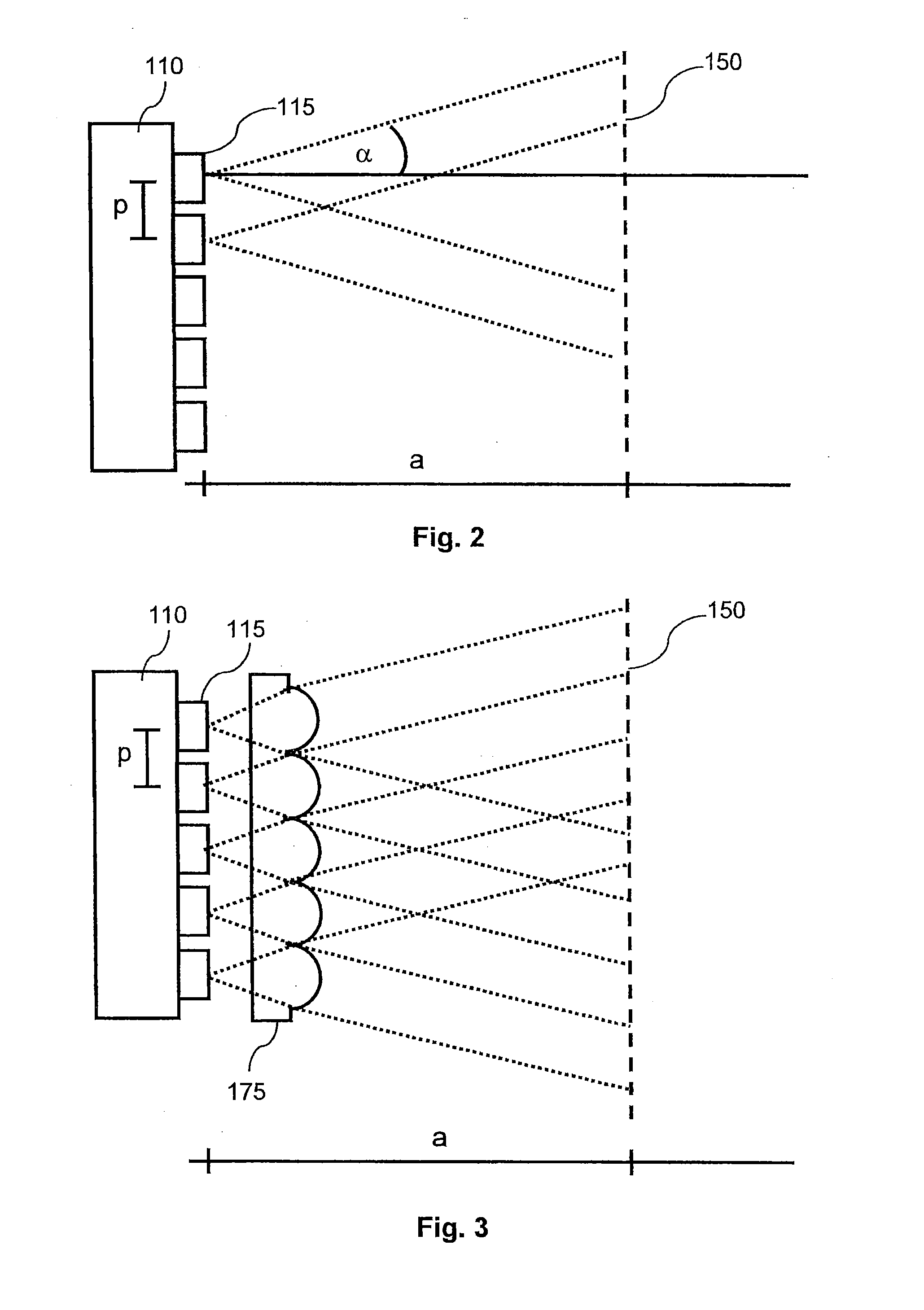

The invention describes a laser printing system (100) for illuminating an object moving relative to a laser module of the laser printing system (100) in a working plane (180), the laser module comprising at least two laser arrays of semiconductor lasers and at least one optical element, wherein the optical element is adapted to image laser light emitted by the laser arrays, such that laser light of semiconductor lasers of one laser array is imaged to one pixel in the working plane of the laser printing system, and wherein the laser printing system is a 3D printing system for additive manufacturing and wherein two, three, four or a multitude of laser modules (201, 202) are provided, which are arranged in columns (c1, c2) perpendicular to a direction of movement (250) of the object in the working plane (180), and wherein the columns are staggered with respect to each other such that a first laser module (201) of a first column of laser modules (c1) is adapted to illuminate a first area (y1) of the object and a second laser module (202) of a second column (c2) of laser modules is adapted to illuminate a second area (y2) of the object, wherein the first area (y1) is adjacent to the second area (y2) such that continuous illumination of the object is enabled.

Owner:EOS ELECTRO OPTICAL SYST

Materialized heart 3D model manufacturing method capable of achieving internal and external structures

ActiveCN104462650AClear and complete structureIncrease success rateSpecial data processing applications3D modellingDICOMMedical imaging data

The invention relates to a materialized heart 3D model manufacturing method capable of achieving internal and external structures. The method can overcome the defects in the prior art. The method includes the steps that (1) the heart part of a patient is scanned to obtain medical image data to form a DICOM file; (2) the DICOM file obtained in the step (1) is identified through Mimics software and stored to form a computer-identified .mcs file; (3) different data templates are extracted from the software; (4) the templates, with cavity structures or incomplete images or unclear boundaries, obtained in the step (3) are processed to be made clear and complete; (5) a needed template is formed by adding or deleting or separating or combining the templates; (6) a 3D image formed in the step (5) is processed to enable the exterior of the 3D image to be smooth and interior image templates to be complete to form an STL file; (7) data processed in the step (6) are input in a 3D laser printer, and accordingly a heart model is printed. According to the method, heart models with clear and complete structures can be obtained, and the success rate of heart operations can be greatly increased.

Owner:河南龙光三维生物工程有限公司

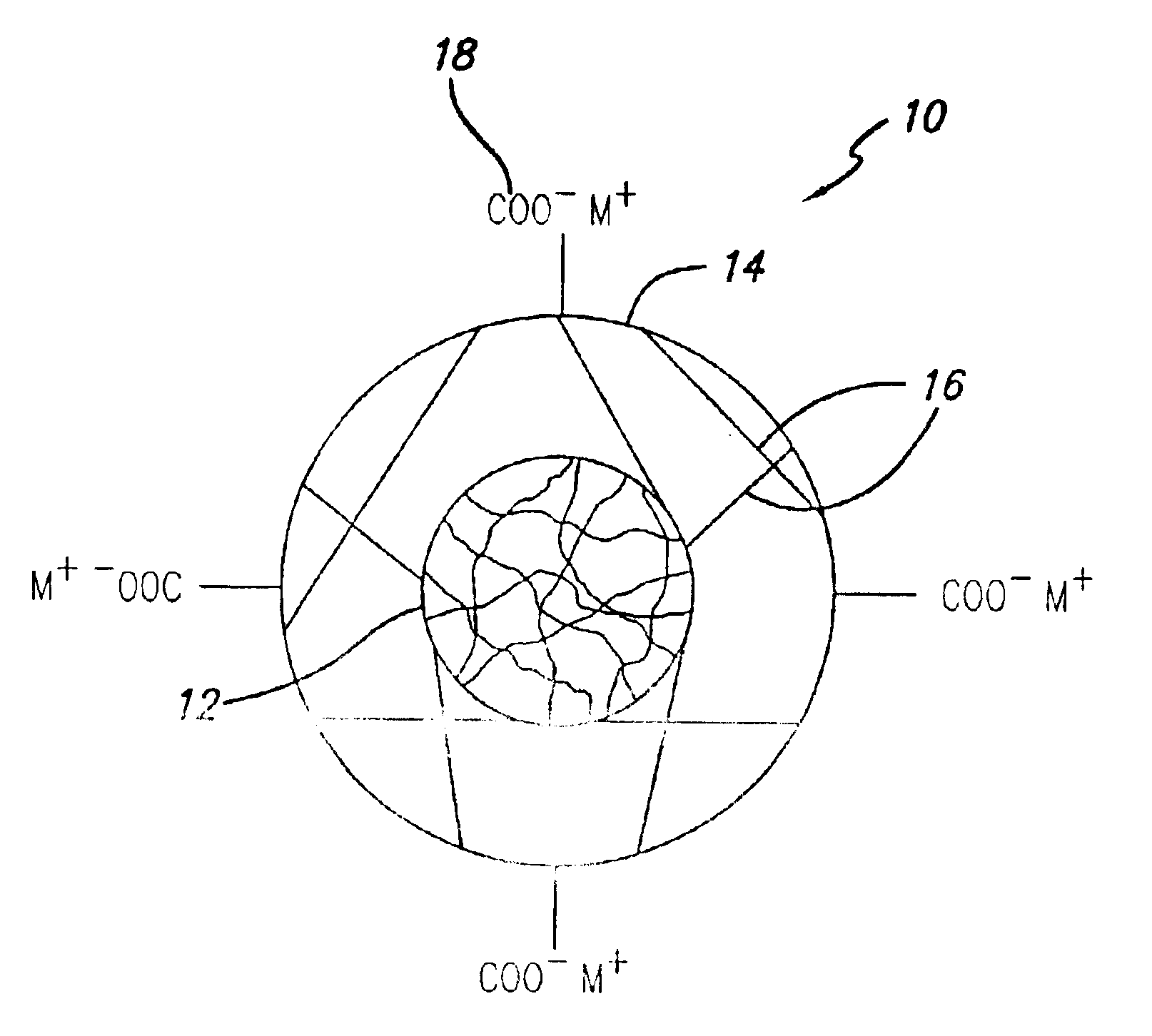

Specific core-shell polymer additive for ink-jet inks to improve durability

InactiveUS6858301B2Improve propertiesGood shear stabilityPhotosensitive materialsDuplicating/marking methodsHydrophilic monomerVitrification

Polymer particles are provided having (1) a core with a glass transition temperature within a range of −50° to +110° C. and (2) a shell surrounding the core. The core comprises at least one layer, with the layer(s) comprising at least one polymerized hydrophobic monomer and, optionally, a first cross-linker. The shell comprises a copolymerized mixture of least one hydrophobic monomer and at least one hydrophilic monomer and a second cross-linker for increasing thermal shear stability by forming cross-linkages. Use of these polymer particles in aqueous-based ink-jet inks provide laser print quality without any secondary treatment.

Owner:HEWLETT PACKARD DEV CO LP

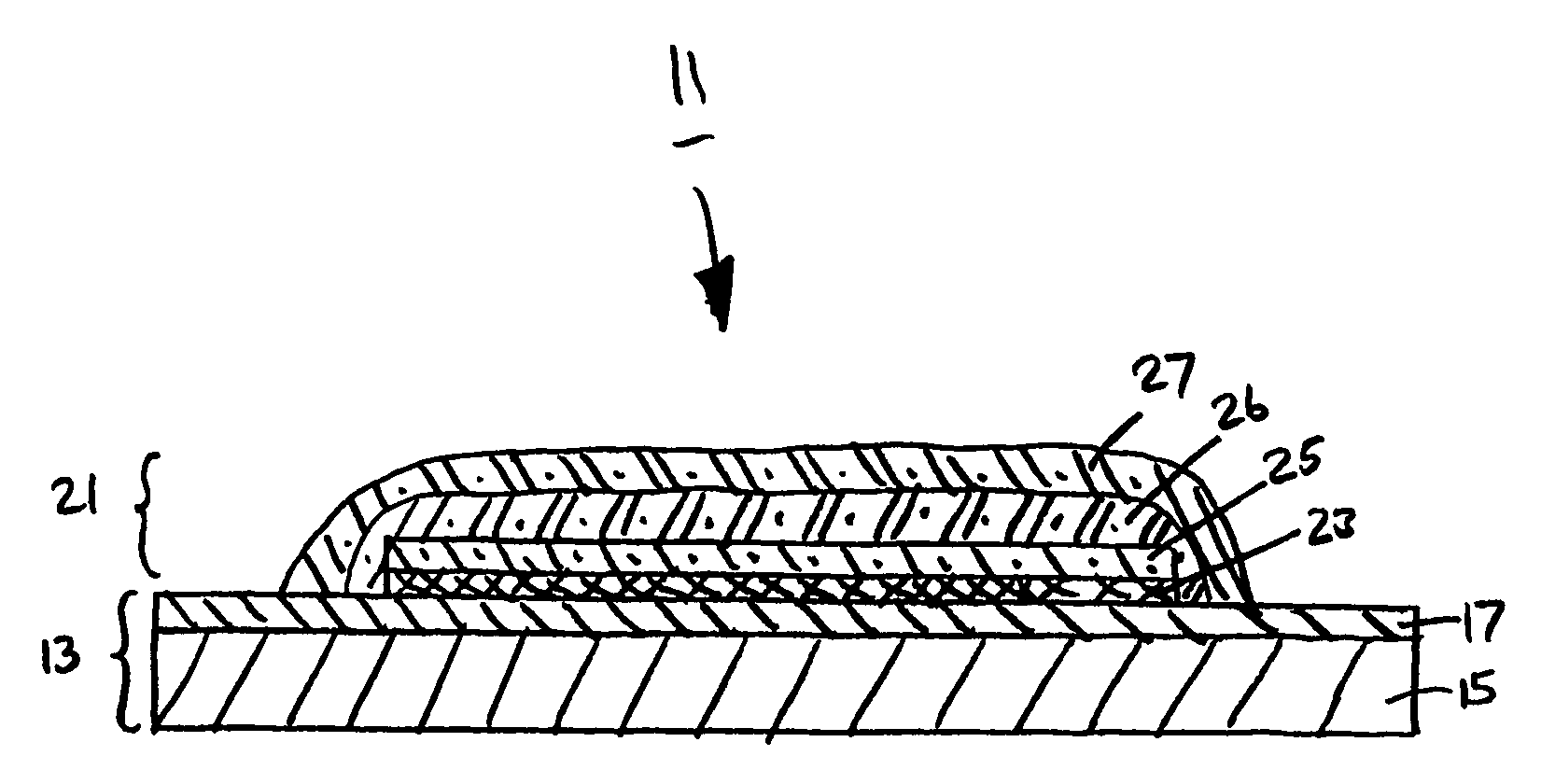

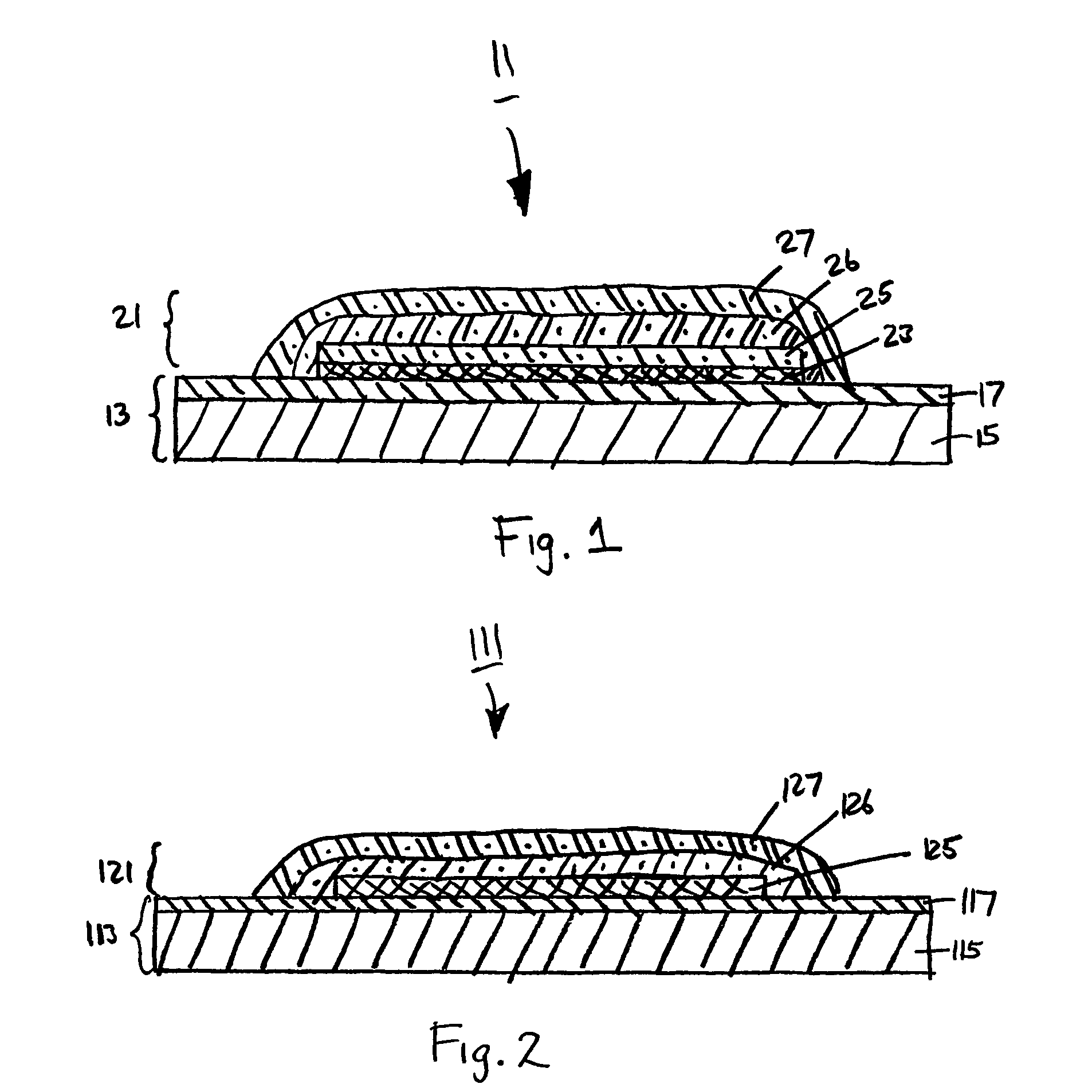

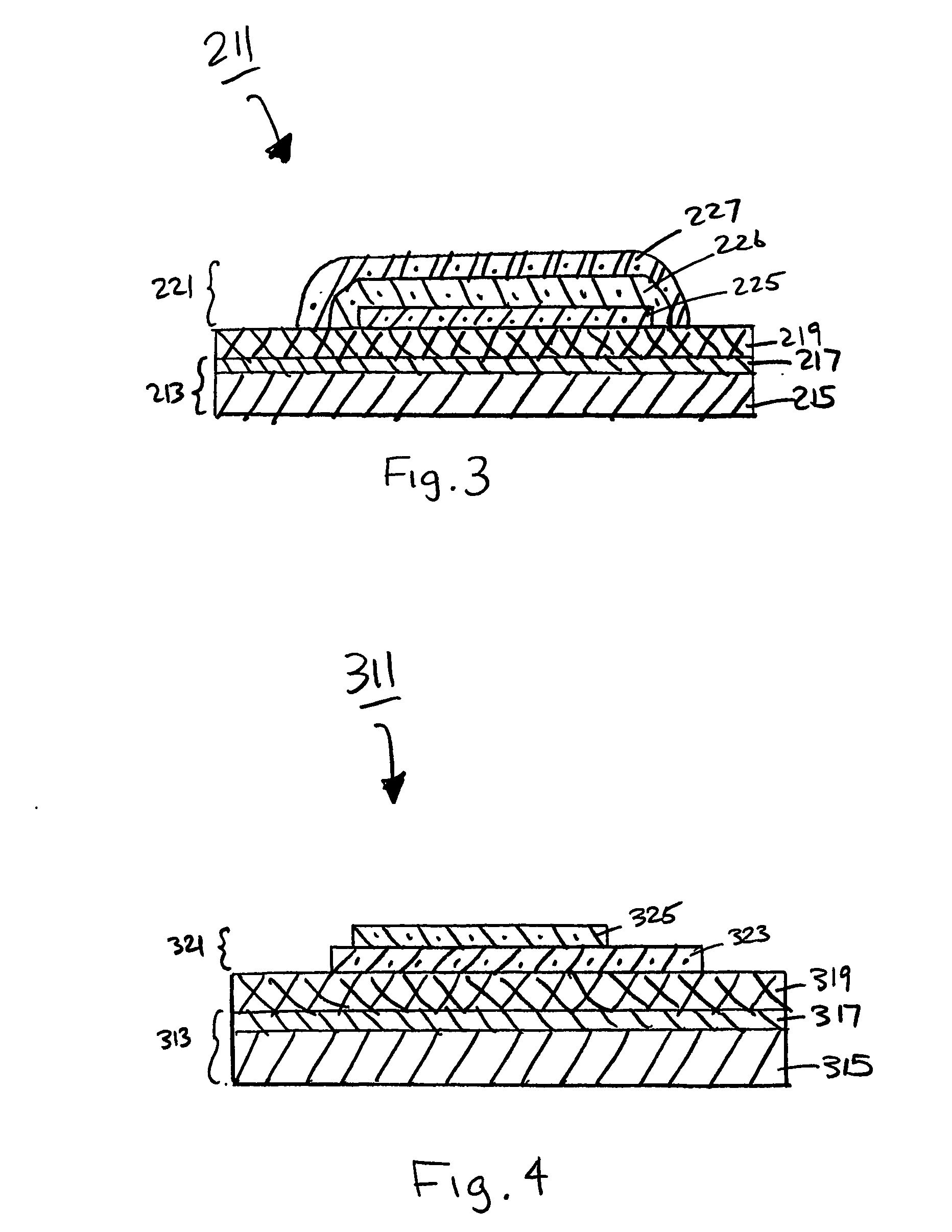

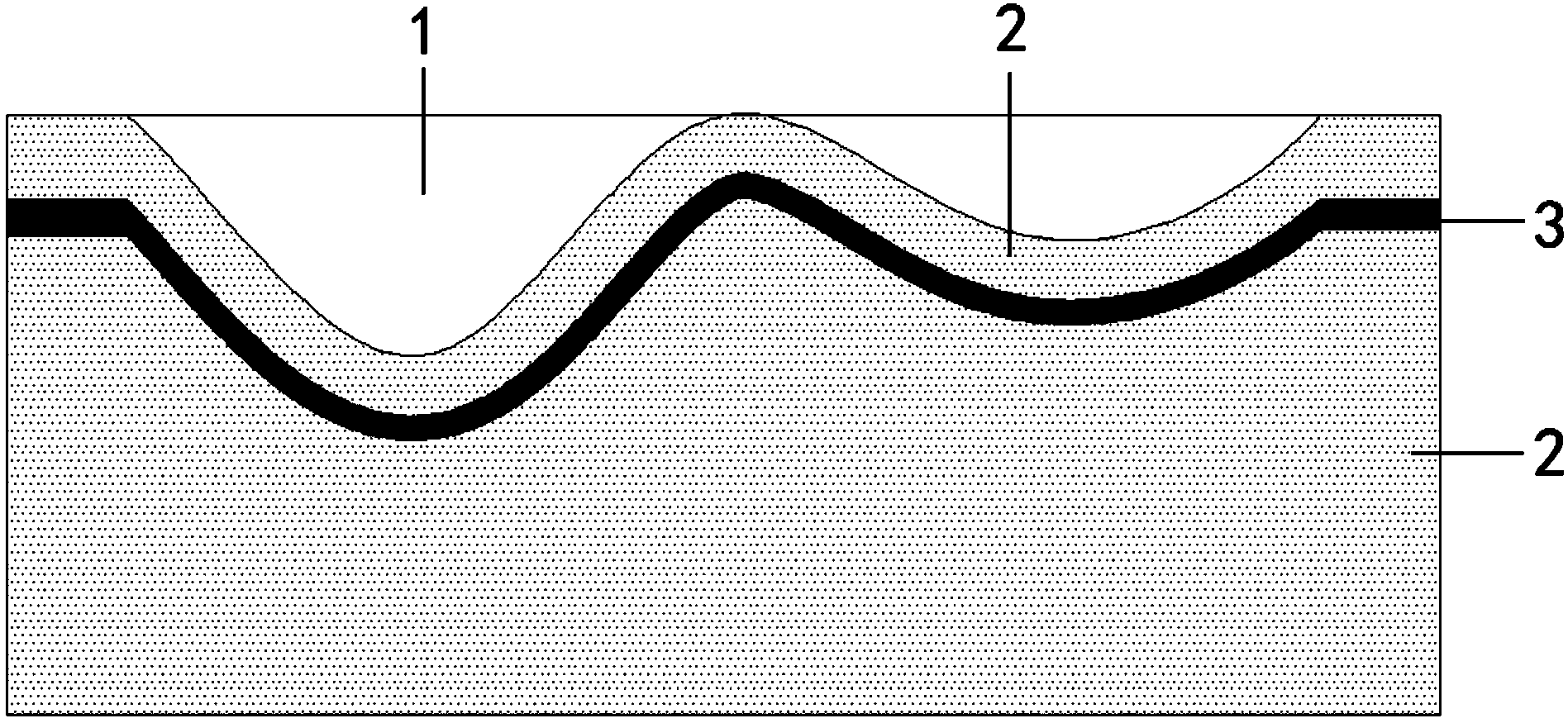

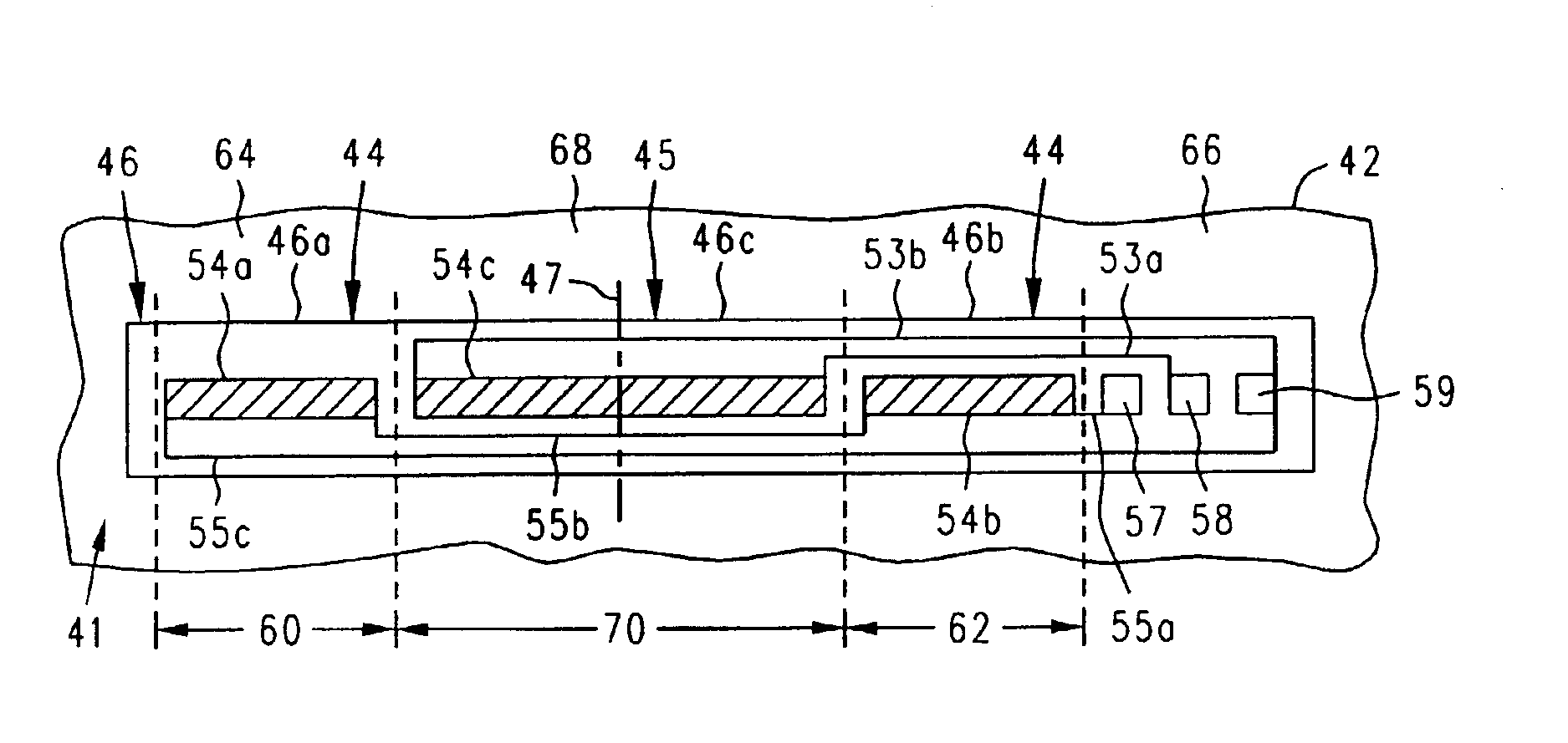

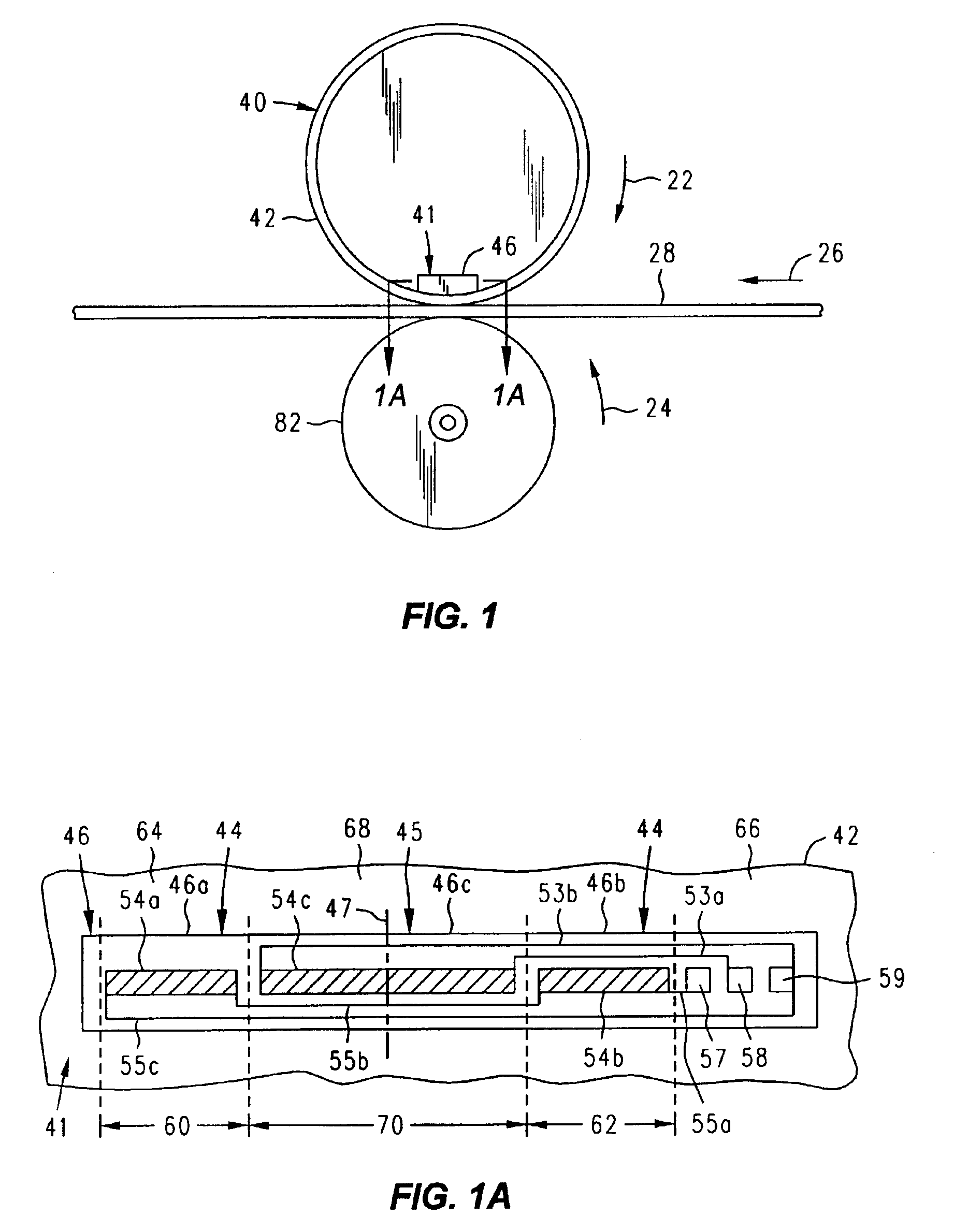

Method for labeling fabrics and heat-transfer label well-suited for use in said method cross-reference to related applications

A method for labeling fabrics, such as fabric garments, and a heat-transfer label (311) well-suited for use in said method. In one embodiment, the heat-transfer label (311) comprises (i) a support portion (313), the support portion (313) comprising a carrier (315) and a release layer (317); (ii) a wax layer (319), the wax layer overcoating the release layer (317); and (iii) a transfer portion (321), the transfer portion (321) comprising an adhesive layer (323) printed directly onto the wax layer (319) and an ink design layer (325) printed directly onto the adhesive layer (323). Each of the adhesive layer (323) and the ink design layer includes a non-cross-linked PVC resin. The ink design layer may be screen printed onto the adhesive layer (323) or may be printed onto the adhesive layer (323) using thermal transfer printing, ink jet printing or laser printing.

Owner:AVERY DENNISON CORP

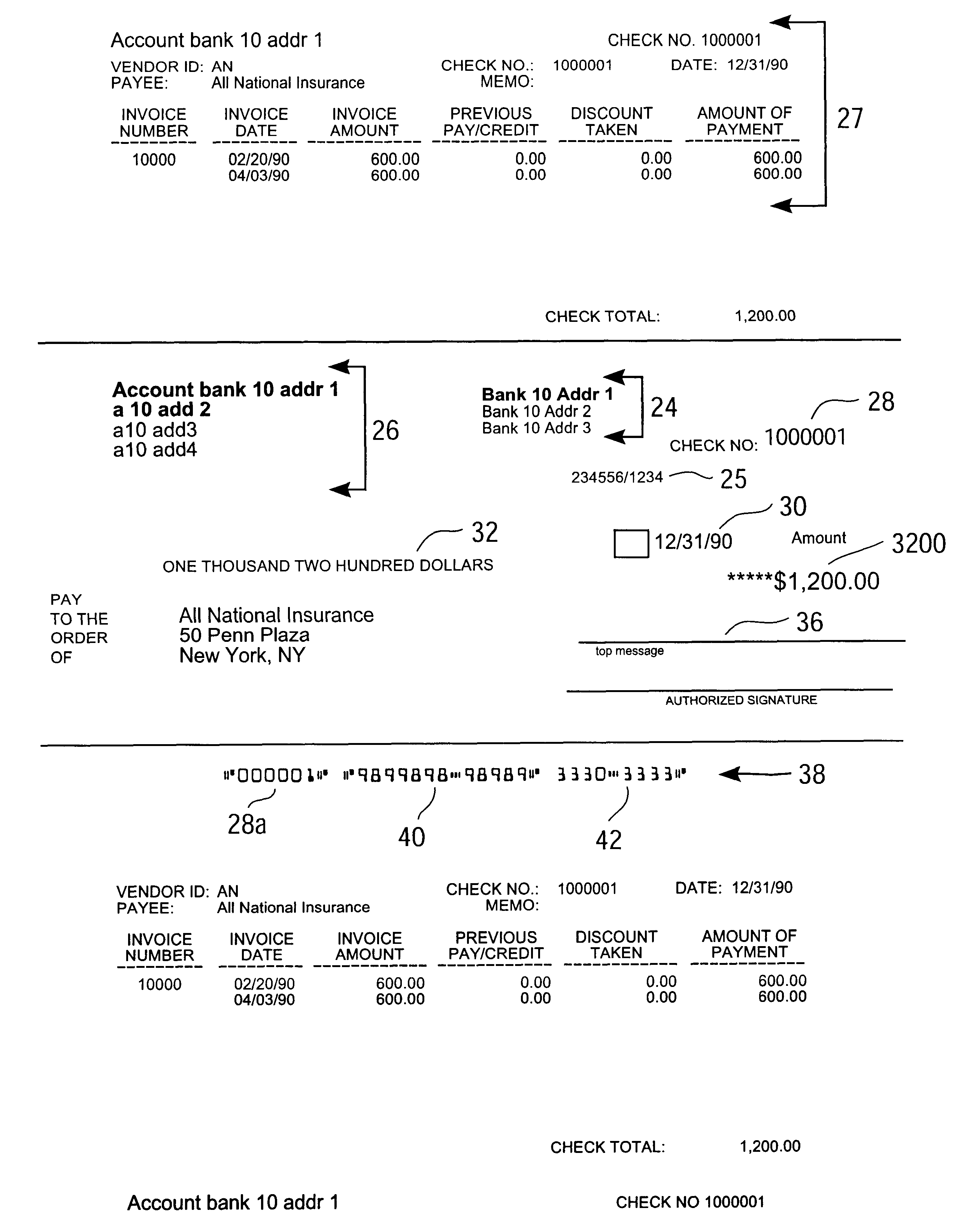

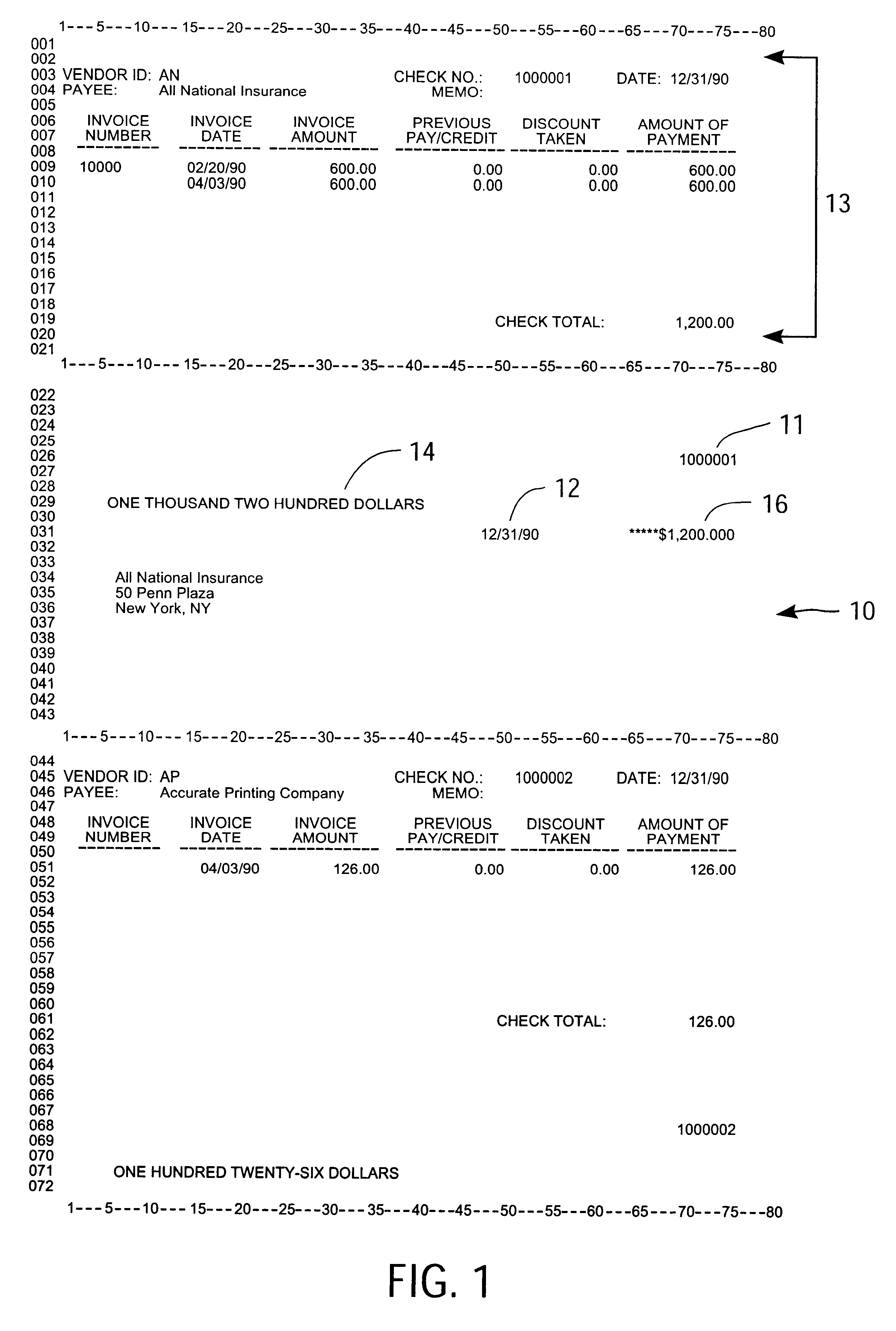

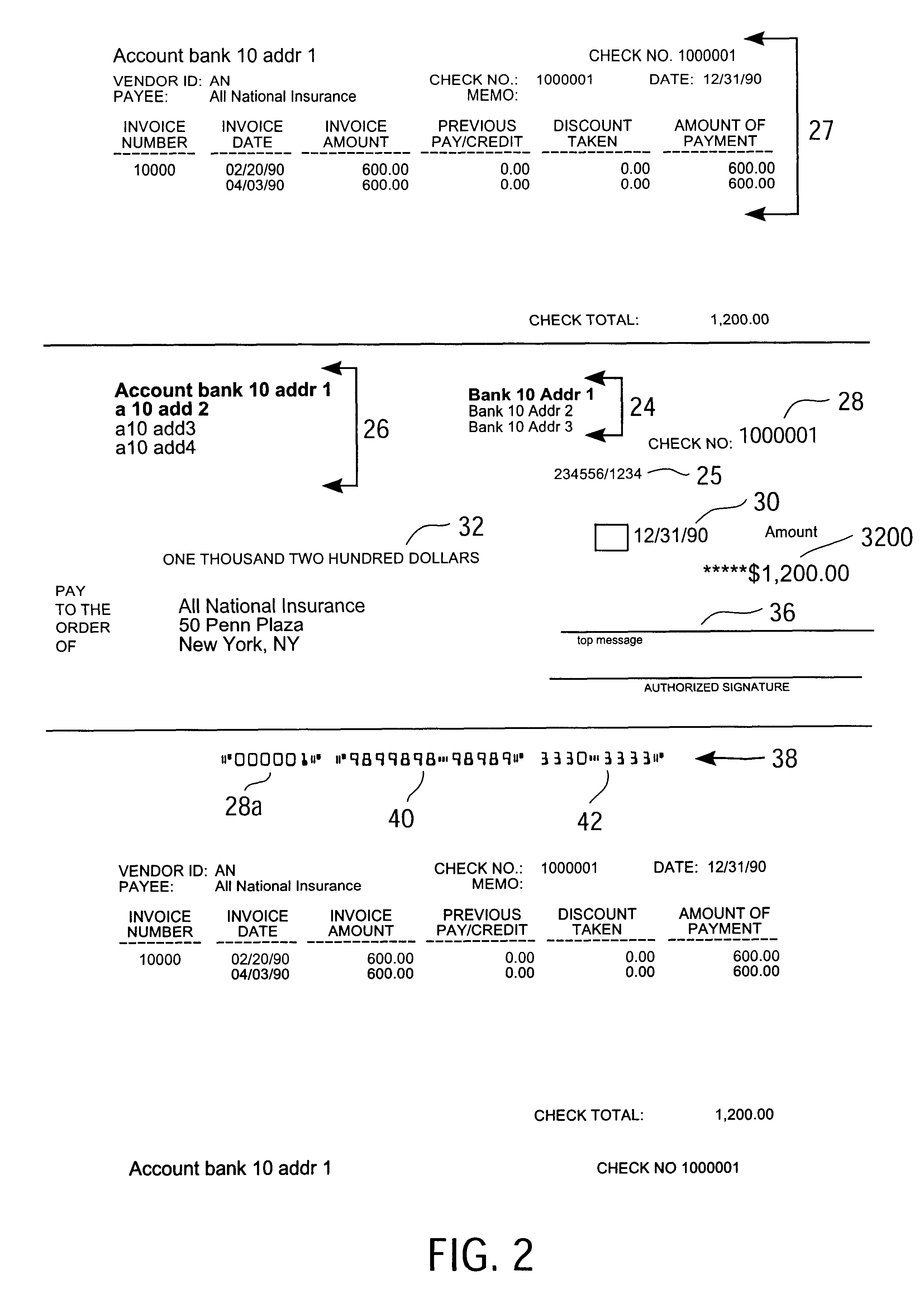

Method of printing complete MICR checks on blank sheets from host program data using laser printers

An improved method for accurately and correctly encoding and printing complete checks on blank paper sheets with data derived from a host check printing program which may employ partially preprinted check forms. The method includes forming, in computer memory, a matrix array representative of the information printed by the host program. Intercepting the print check data generated by the host program. Deciphering and reformatting such host check data with other check information stored in a control file. The control file information is keyed to a selected assigned series of check numbers stored in a control file and extracted based on the check number of the check being processed. Checks are printed on blank paper sheets using the host check data under the control of a separate program that includes printing MICR information with magnetic ink in MICR font.

Owner:SIMONOFF JEROME

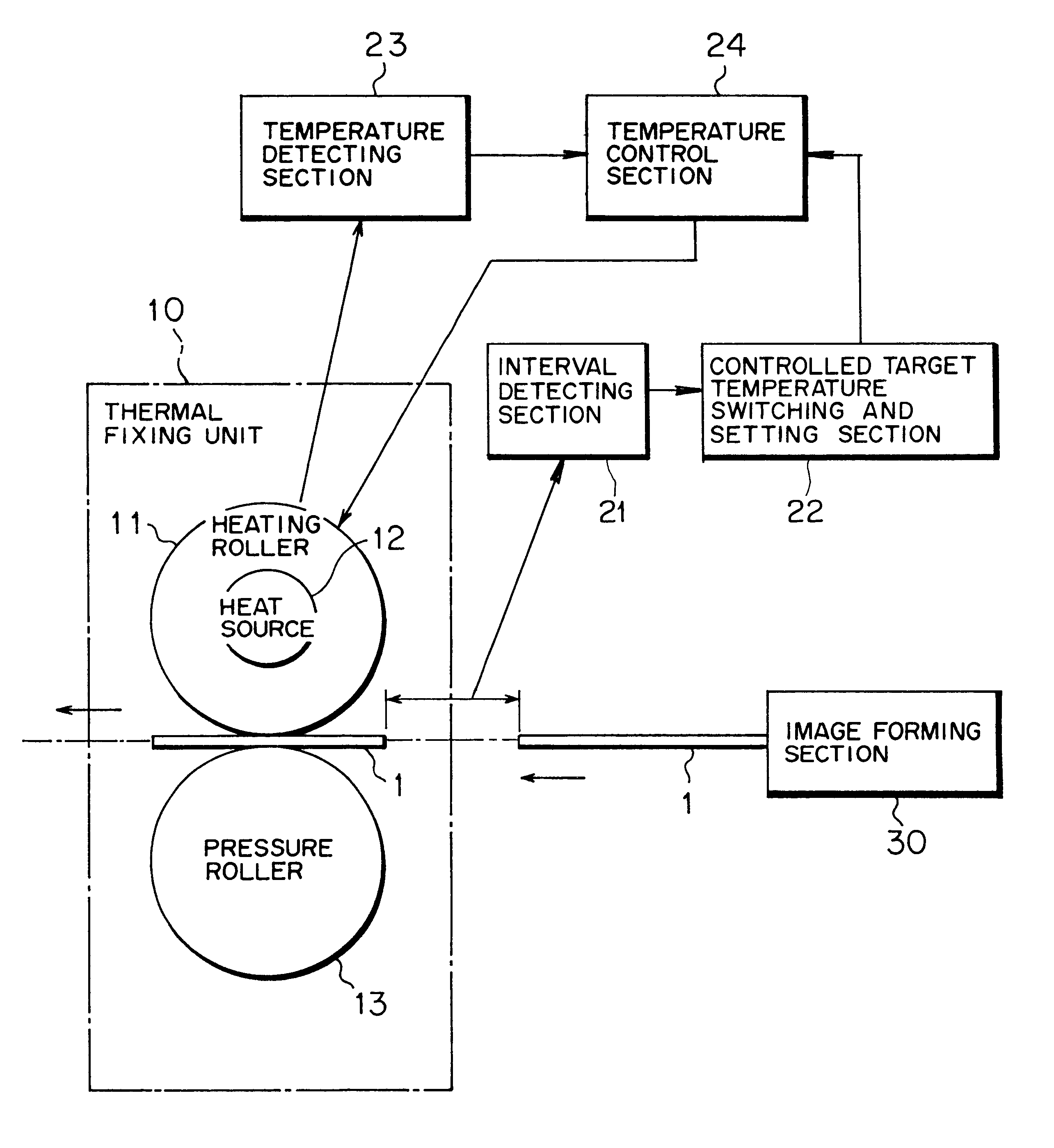

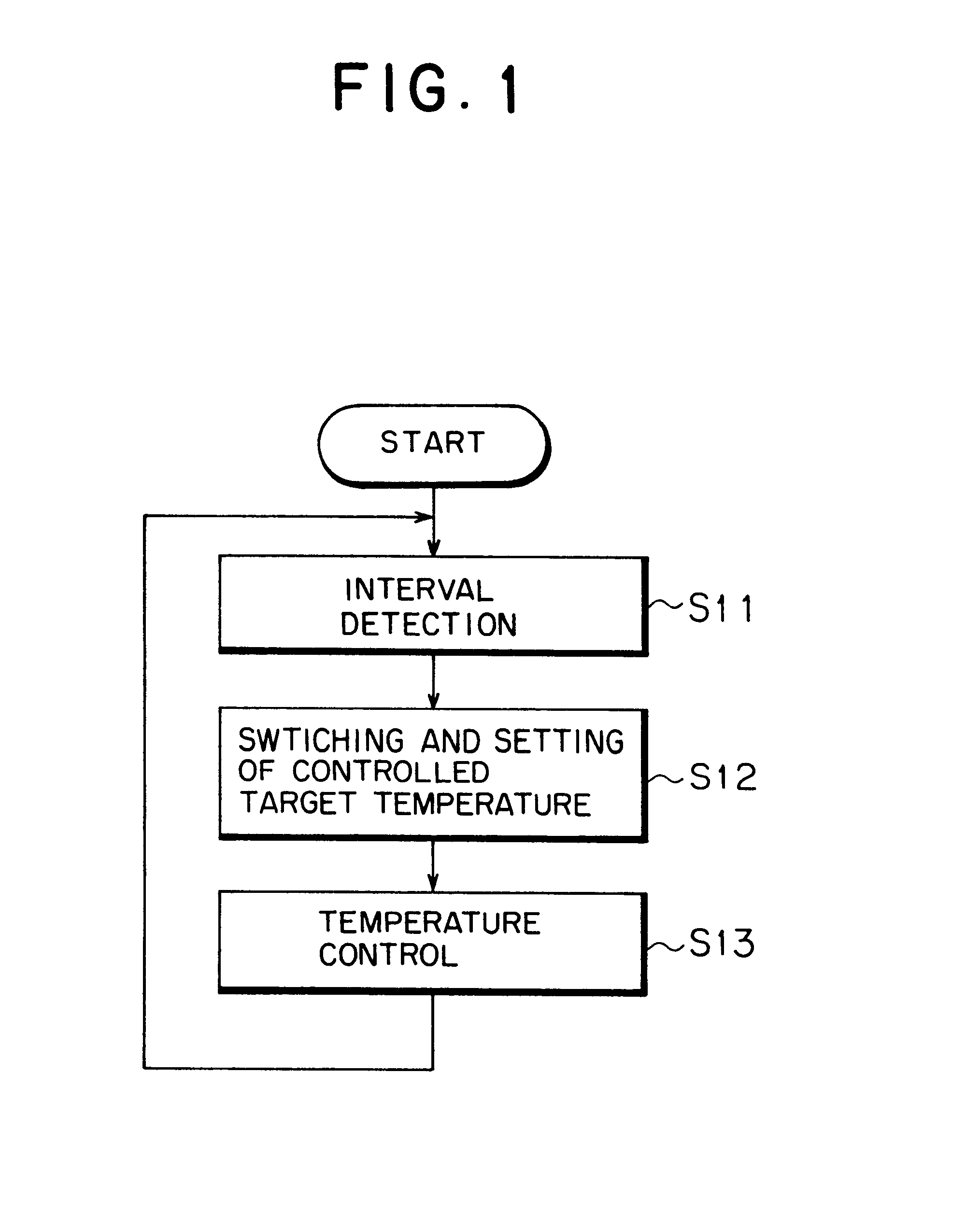

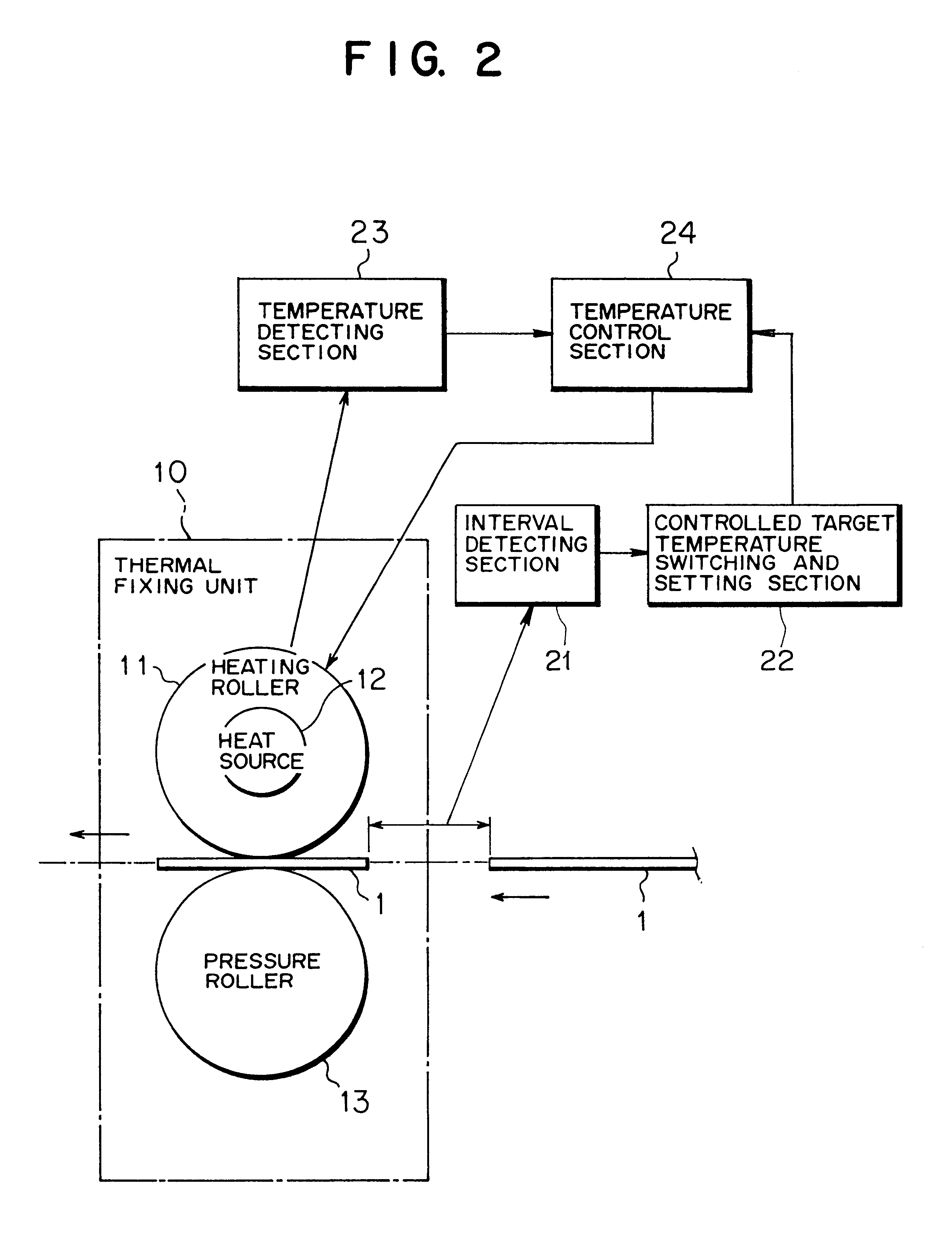

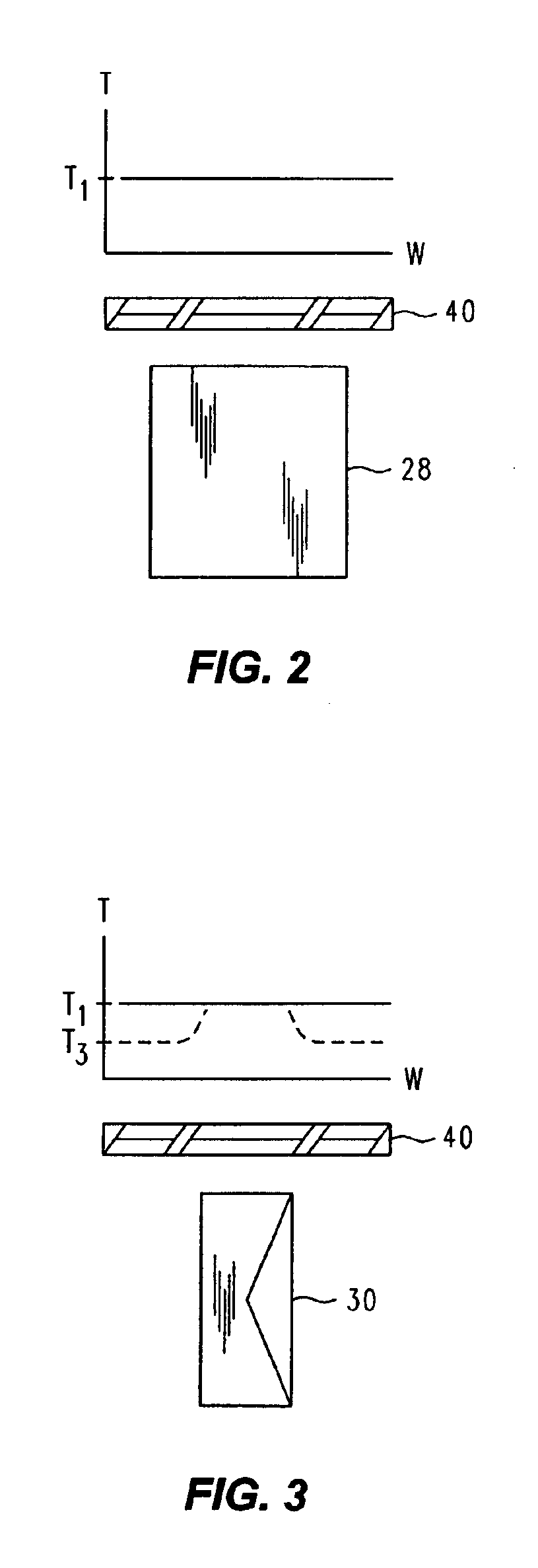

Temperature control method and system for thermal fixing unit, and image forming apparatus

InactiveUS6552304B1Easy to getImprove printing qualityOhmic-resistance heatingElectrographic process apparatusTemperature controlImage formation

Method and apparatus for controlling a temperature of a thermal fixing unit which is for the purpose of maintaining the balance between a fixing rate and the occurrence of wrinkles even if a distance between paper sheets greatly varies within a printer. When image formation is consecutively made onto a plurality of record mediums without stopping an operation of an image forming apparatus, an interval between the record mediums is detected, and a controlled target temperature for a thermal fixing unit is switched and set in accordance with the interval between the record mediums to control a heat source so that the temperature of the thermal fixing unit reaches the controlled target temperature. The image Corming apparatus may include an electrophotographic recording apparatus such as a copying machine, facsimile and laser printer using a toner.

Owner:FUJIFILM BUSINESS INNOVATION CORP

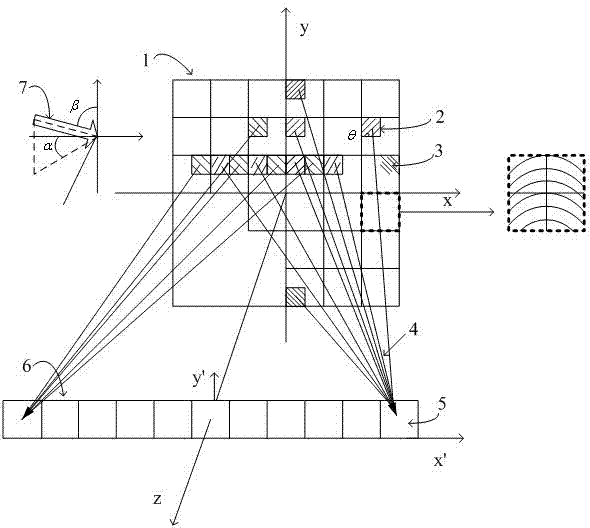

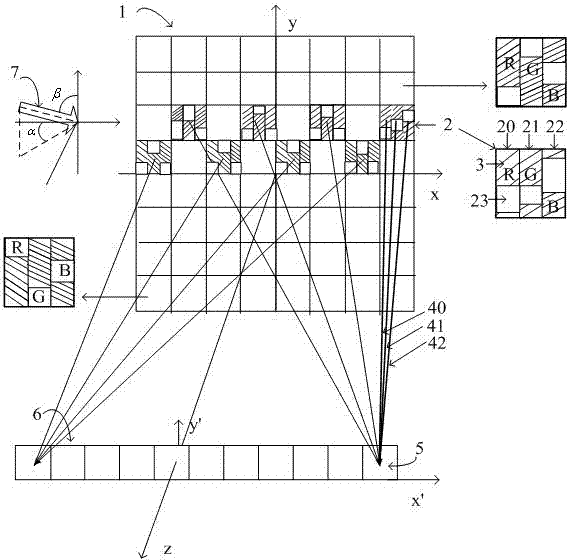

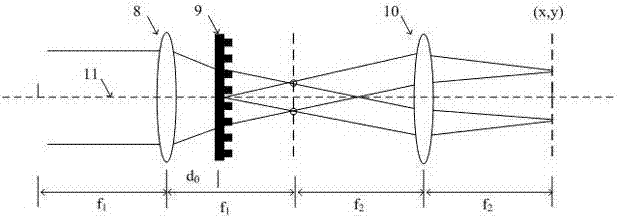

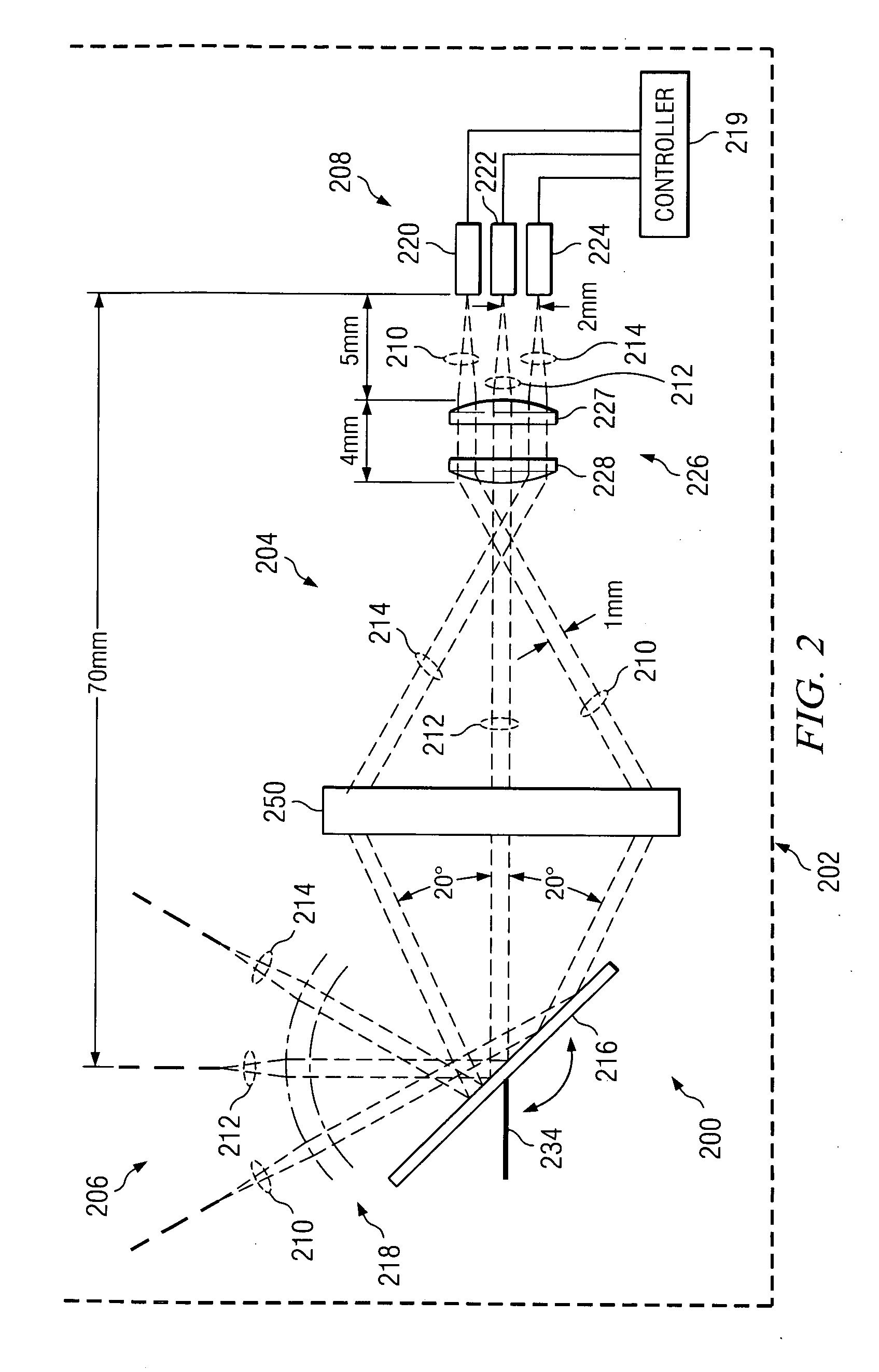

3D laser printing method and system

ActiveCN103246195ARealize continuously adjustableStrong three-dimensional senseDiffraction gratingsColor imageMicro nano

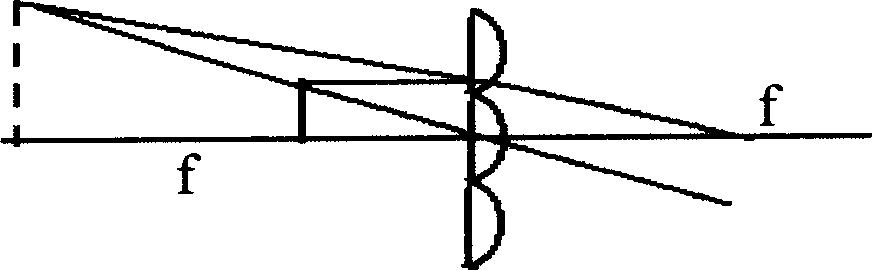

The invention discloses a 3D laser printing method and system. A four-parameter continuous modulation laser printout method is adopted to prepare a 3D image consisting of diffraction pixels arranged according to the position coordinates and provided with both a specific grating space frequency and an angle of orientation; the modulation method of parameters of grating stripes in the diffraction pixels is realized on the basis of a 4F imaging system and a diffraction grating; the 4F imaging system comprises a first Fourier transformation lens or lens group and a second Fourier transformation lens or lens group; the diffraction grating is placed between the first Fourier transformation lens or lens group and the second Fourier transformation lens or lens group; the distance between the diffraction grating and the first Fourier transformation lens or lens group is changed to realize continuous modulation of the space frequency of the grating stripes; and the diffraction grating is rotated to realize continuous modulation of the grating orientation angle of the grating stripes. The 3D laser printing method and system realize continuous adjustment of the space frequency and the orientation of the grating, and encodes on the basis of the four-parameter micro-nano structure with continuously changeable space frequency and orientation of the grating to form a 3D color image.

Owner:SVG TECH GRP CO LTD

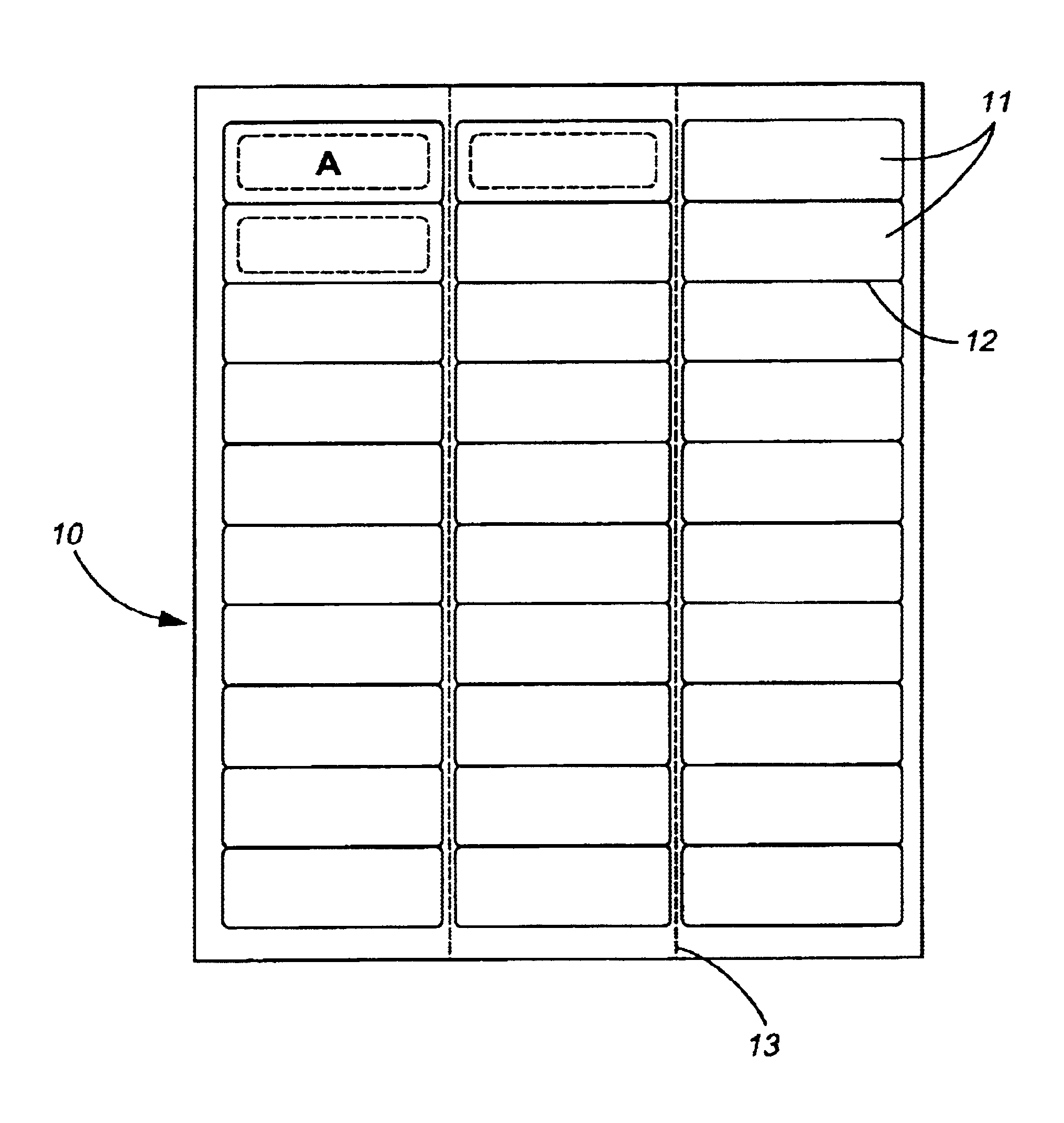

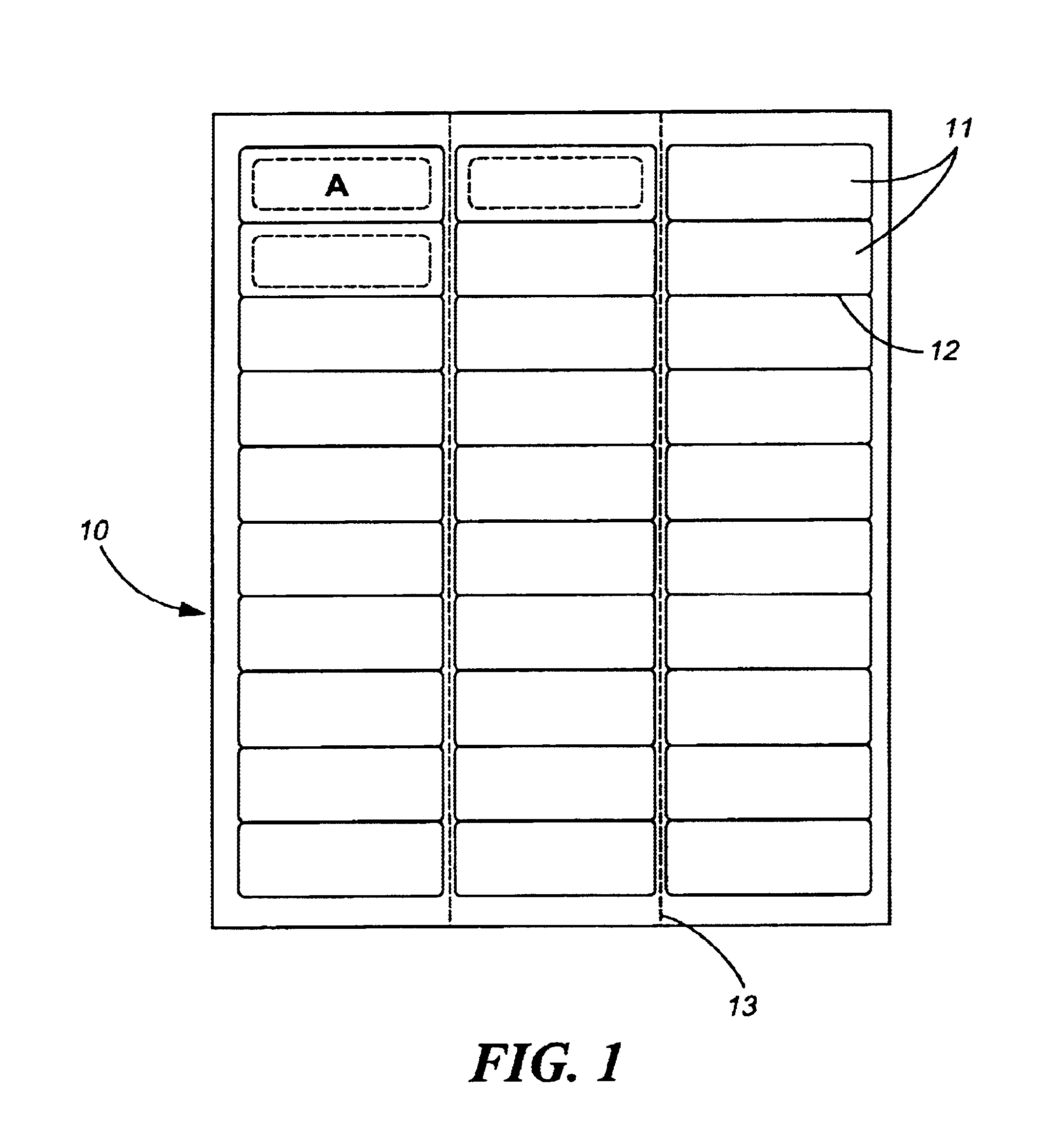

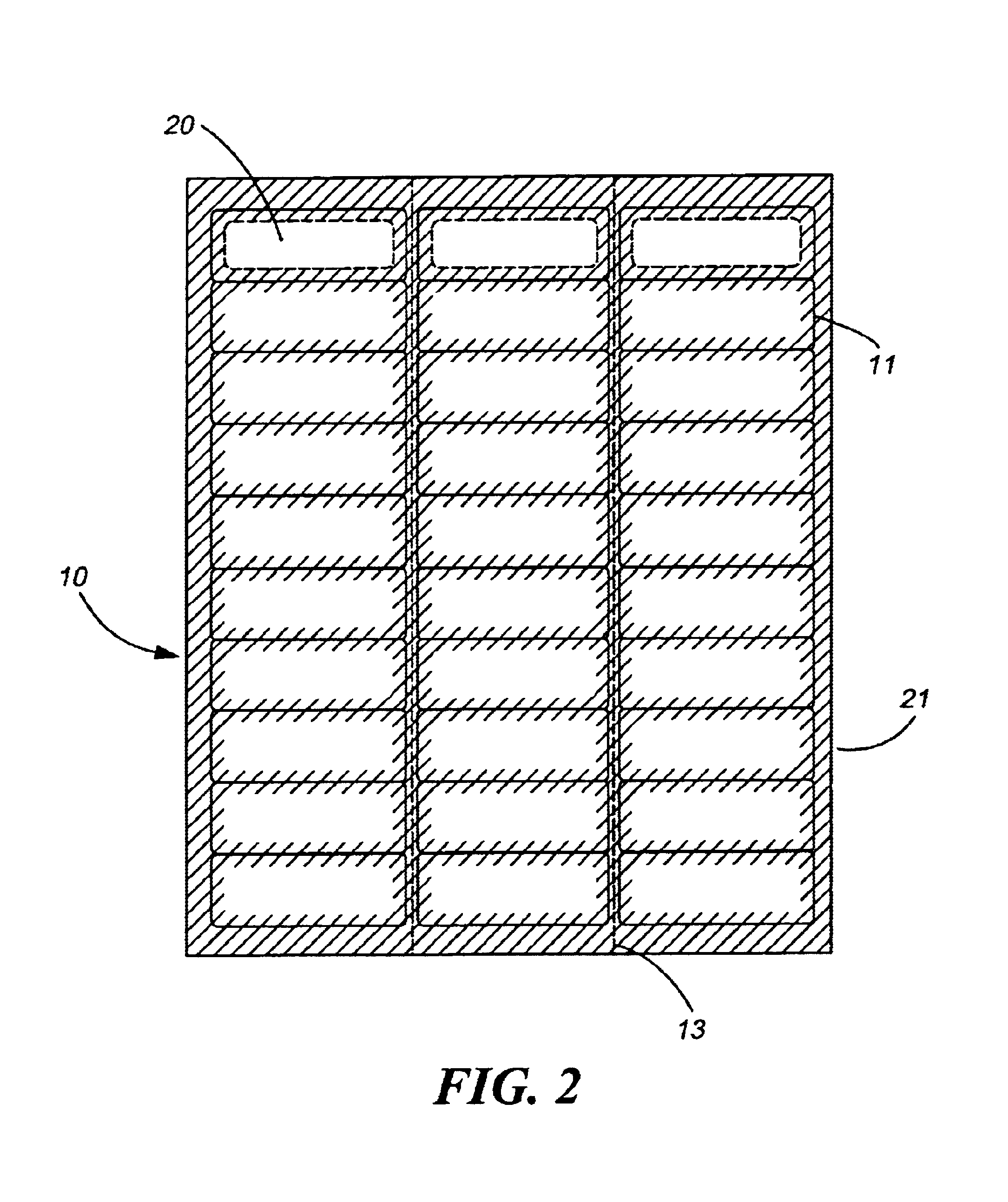

Label and disposition of adhesive and adhesive release

InactiveUS6905747B2Extensive adhesionStampsOther printing matterBiomedical engineeringComputer printing

Owner:LASER SUBSTRATES

Continuous microlens array amplifying displaying antifogery method

InactiveCN1552589AZoom in on the 3D effectShow 3D effectPhotomechanical apparatusLight effect designsGraphicsComputer science

A continuous microlens array magnifying display method for antiforge purpose is disclosed. The printing, laser printing, fine processing and microcarving are used to make the micrographics. The fine processing is used to make the microlens array with continuous surface. The diameter of each microlens is matched with that of each micrographics. After they are combined in different modes, a 3D magnifying display effect with single graphics-single color or multiple graphicses-multiple colors is obtained, which can be used for antiforge purpose.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

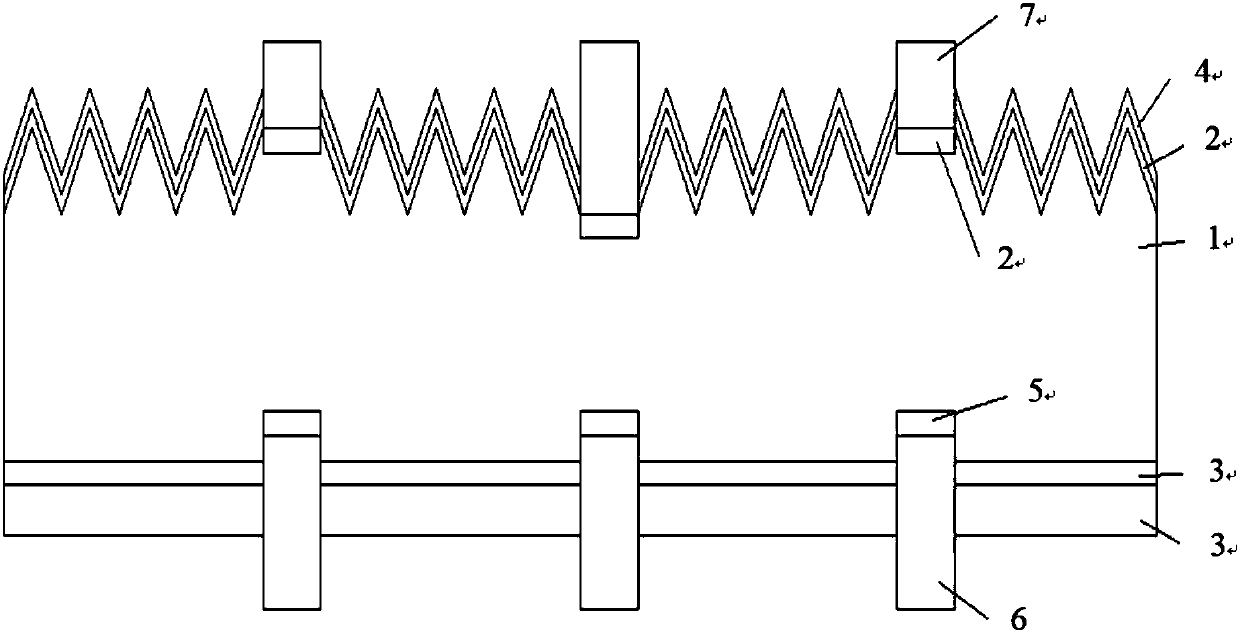

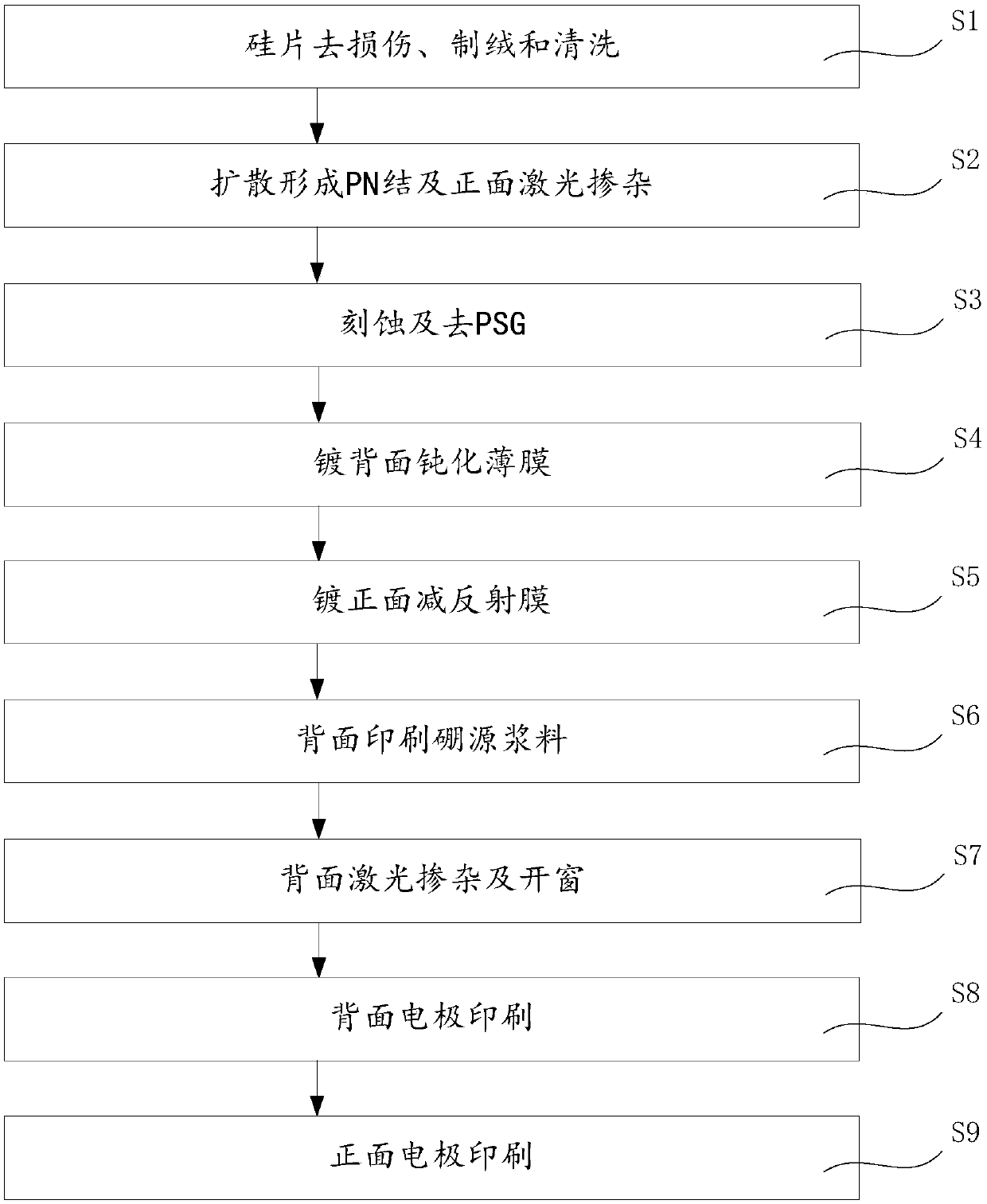

Fabrication method of double-side PERC crystalline silicon solar cell

InactiveCN107863419AImprove conversion efficiencyImplement backside metallizationFinal product manufactureSemiconductor/solid-state device manufacturingScreen printingSilicon solar cell

The invention discloses a fabrication method of a double-side PERC crystalline silicon solar cell. The fabrication method comprises the following steps of (1) removing damage of a silicon wafer, and performing texturing and cleaning; (2) performing diffusion to form a pn junction and performing front-surface laser doping; (3) etching and removing PSG; (4) plating a back-surface passivation thin film; (5) plating a front-surface anti-reflection film; (6) printing boron source paste on a back surface; (7) performing back-surface laser doping and windowing; (8) performing back-surface electrode printing; and (9) performing front-surface electrode printing. A laser doping technology is applied to a process of a selective emitter formed on a front surface and local boron doping on the back surface, only two processes of laser doping and boron source paste printing are added on the basis of a conventional PERC battery process, and the conversion efficiency of the double-side PERC cell is greatly improved; moreover, with the adoption of a secondary printing alignment laser printing MARK point mode, the back-surface metallization of the double-side PERC cell is achieved; and by the method,the problem of difficulty in alignment of a back-surface aluminum grid line to a laser windowing grid line of the silk-screen printed double-sided PERC cell is completely solved.

Owner:SPIC XIAN SOLAR POWER CO LTD

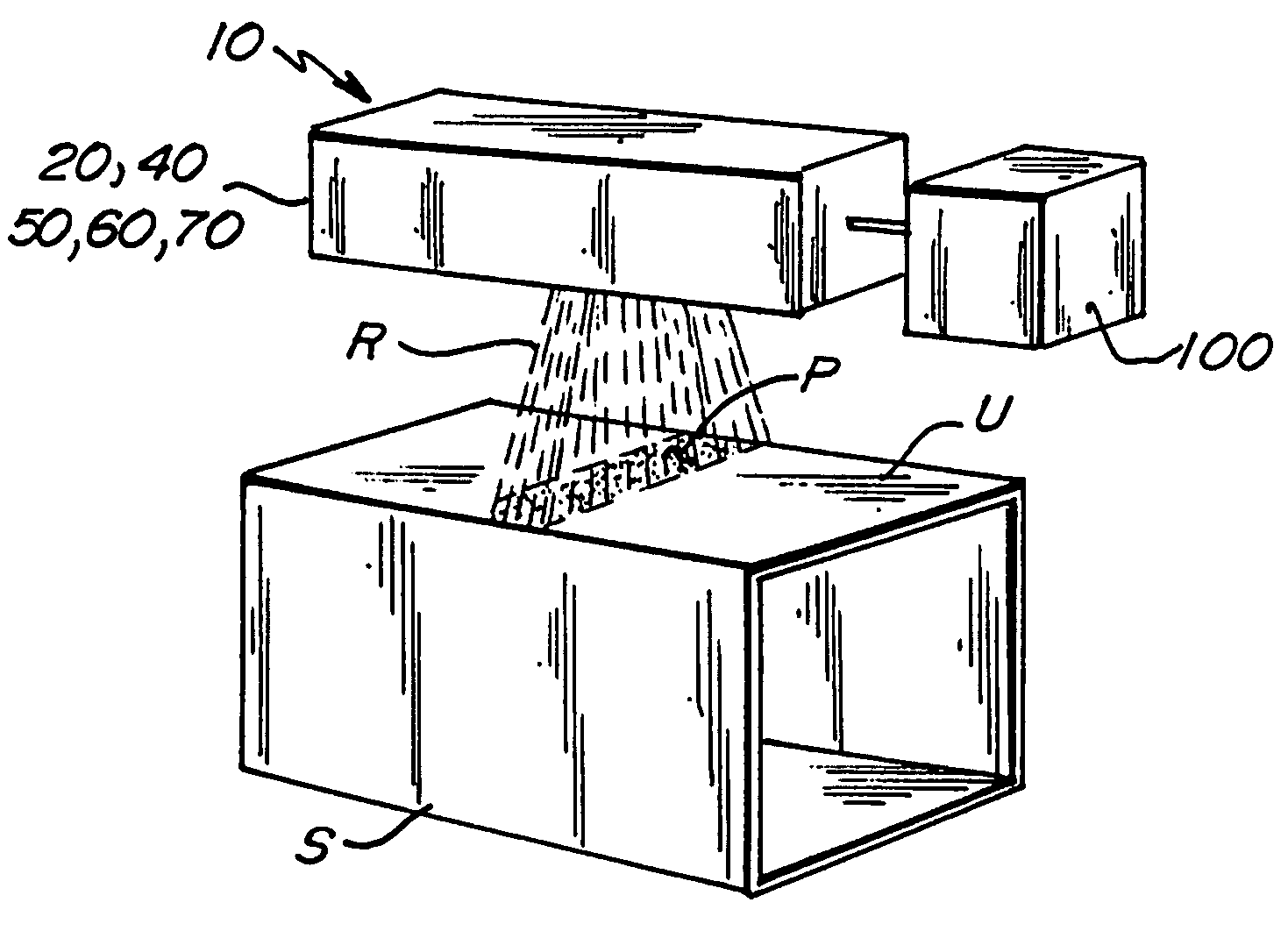

Apparatus and method for selective processing of materials with radiant energy

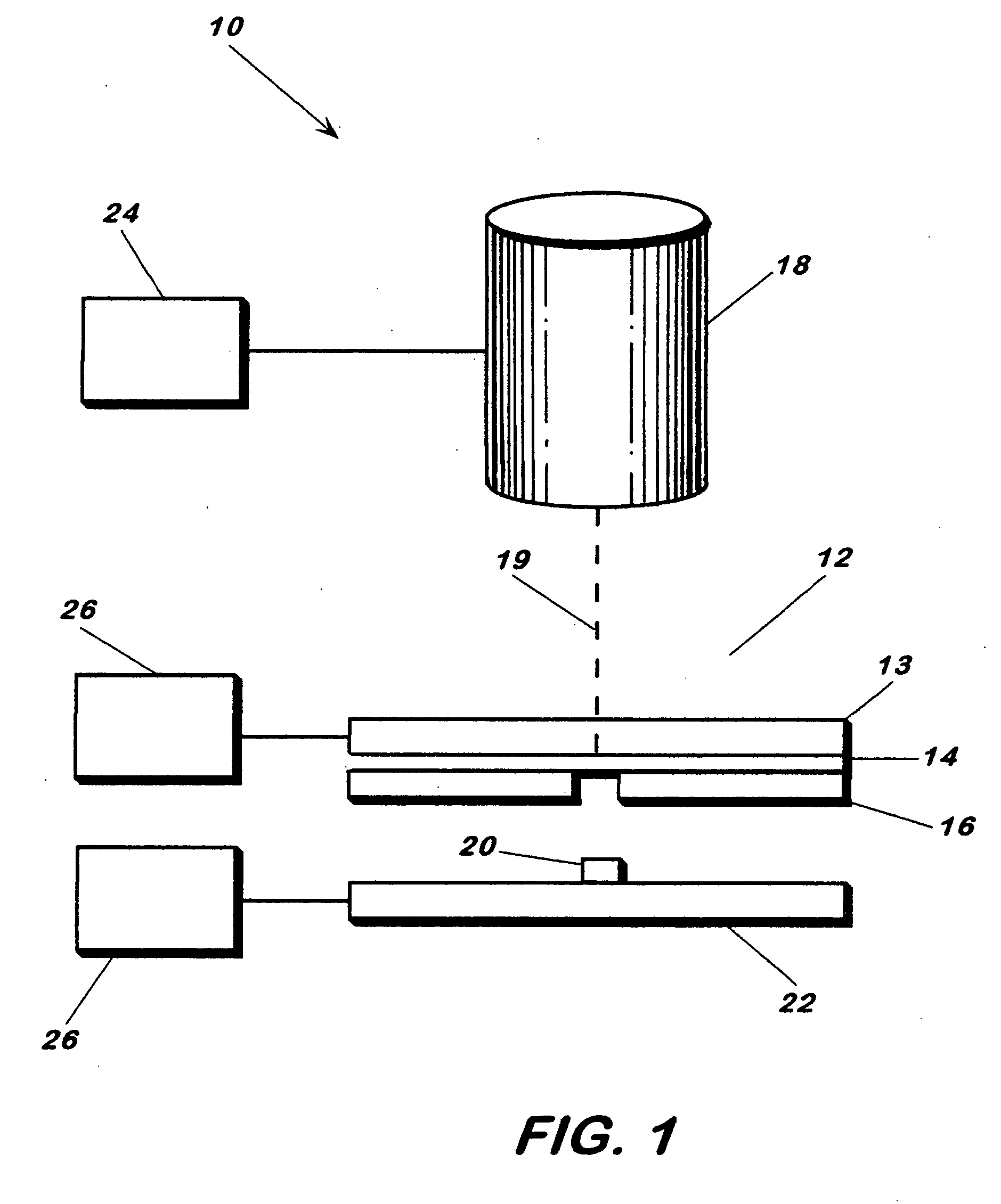

InactiveUS7823366B2Maximize contactReduce capacityWrappers shrinkageMechanical working/deformationControl systemDna testing

Apparatus selectively processes a substrate using radiant energy. The substrate can consist of any target material having a portion to be processed using the radiant energy and a larger portion to be unprocessed. The apparatus includes a source of radiant energy (preferably a quantum cascade laser) that has a customizable spectrum that can be configured to be specifically absorbed only by the portion to be processed, and a control system for targeting the radiant energy only at the portion to be processed. Specific examples of the use of the apparatus and method are in the technologies of heat-shrinking polyethylene film, fusing toner to paper in a laser printer, heating reaction vessels in DNA testing, and temperature profiling bottle pre-forms.

Owner:DOUGLAS MACHINE LIABILITY

PWM rendering for color/gray-scale text and graphics for laser printer

InactiveUS20030210409A1Improved edge renditionGood lookingDigitally marking record carriersDrawing from basic elementsGraphicsComputer vision

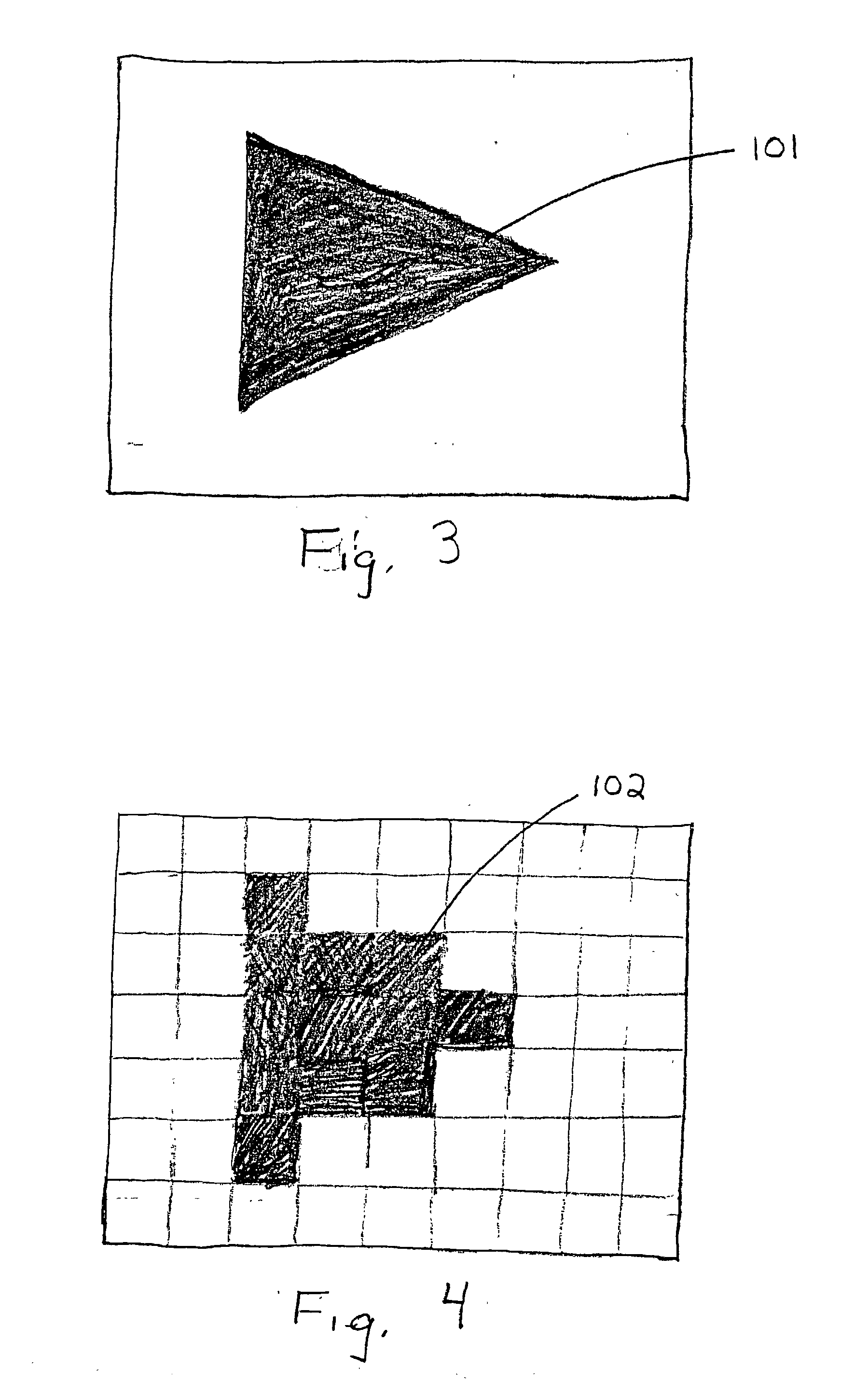

The appearance of edges in an image is improved through precise placement of subpixels within pixel cells that are located on or near edges in an image. Image data is examined to identify a "target pixel" near the edge of an object that represents the object and is adjacent to a "background pixel" that represents only background. The target pixel may represent both the object and its background or it may represent the object only. A "second pixel", adjacent to the target pixel and representing the object, is also identified. The second pixel may represent both the object and its background or it may represent the object only. The target pixel's location with respect to the second pixel is analyzed to determine the placement of a subpixel within the target pixel cell and the placement of a subpixel within the second pixel cell, such that the edge of the object is well-defined and the density of the object is preserved. A vertical smoothing process can additionally be performed to improve further the appearance of edges in the image. The technique is particularly advantageous for printing a halftoned object represented by pixels that are not saturated.

Owner:SEIKO EPSON CORP

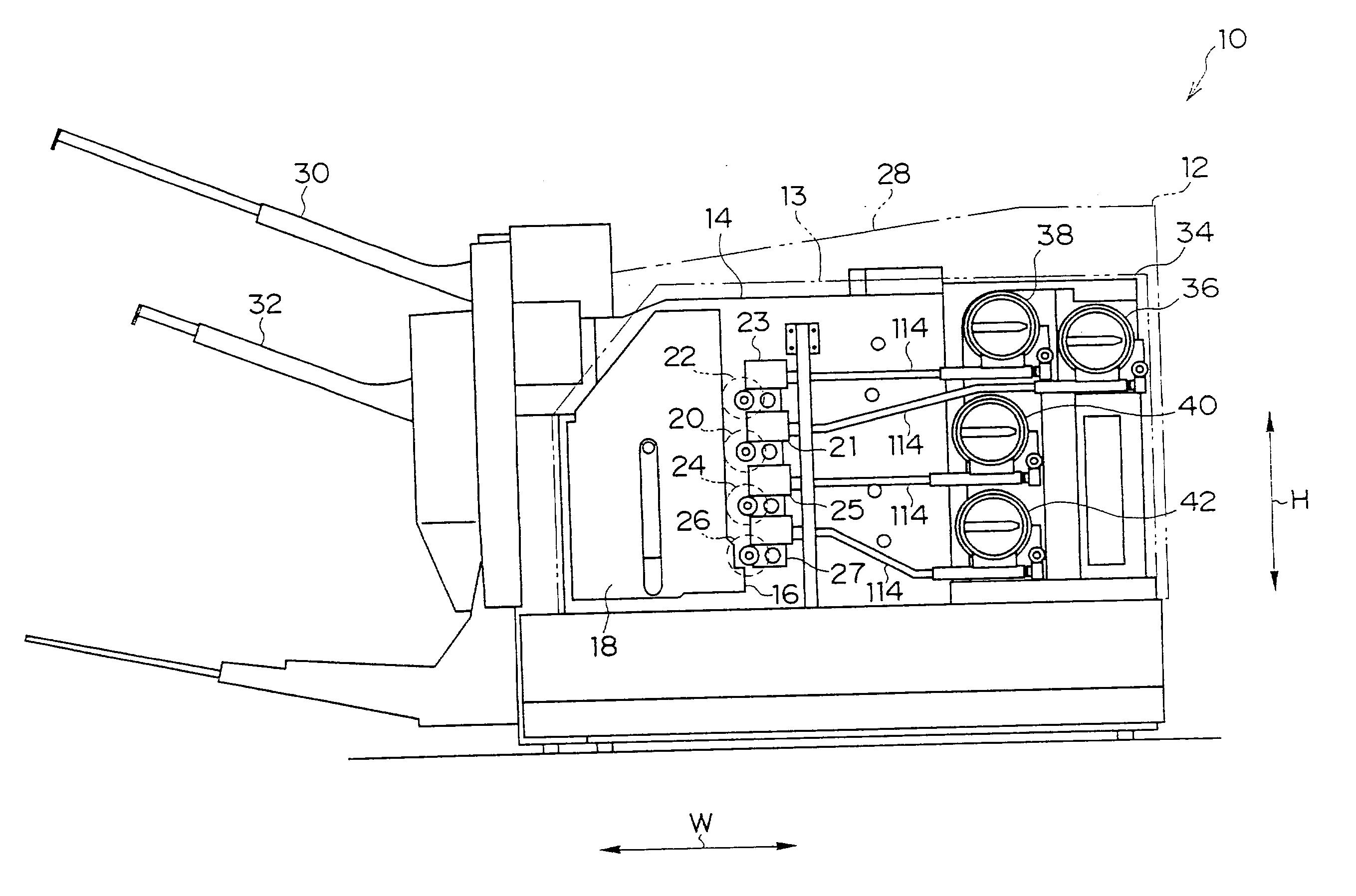

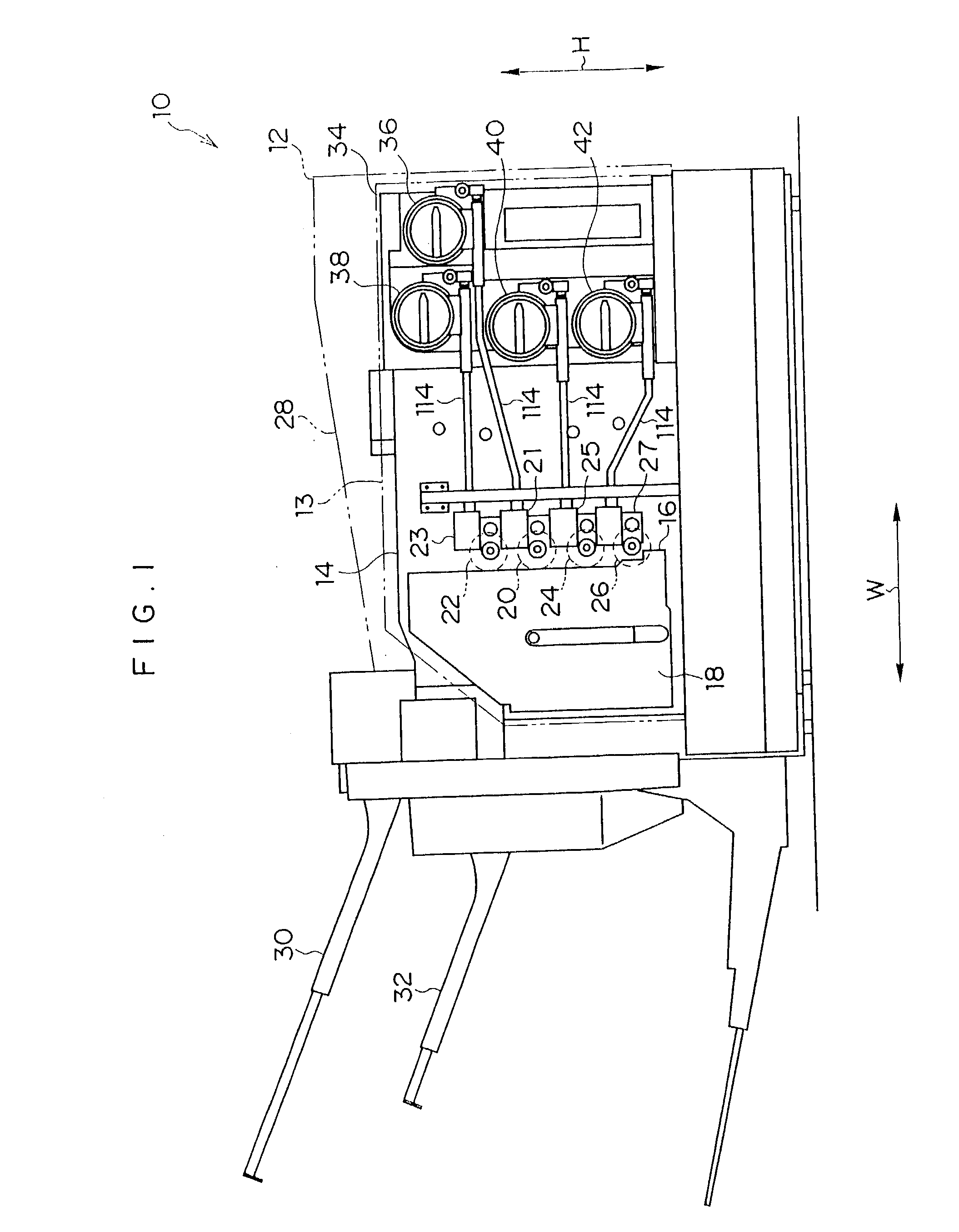

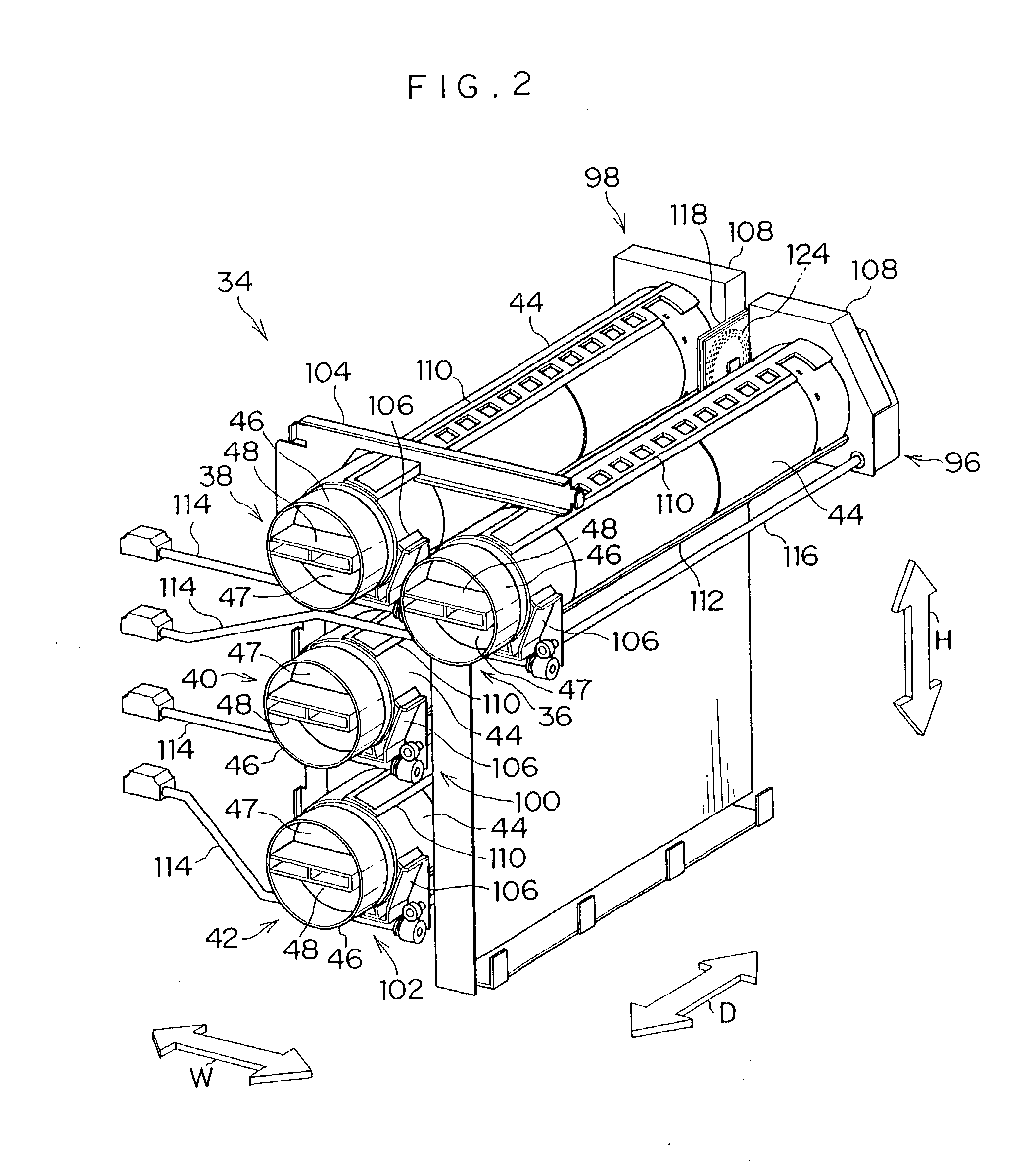

Wireless communication system and image forming device

InactiveUS20040203413A1Easy to adjustNear-field systems using receiversElectrographic process apparatusCommunications systemLaser

Tag attaching portions at cartridge parts which are loaded into different cartridge loading portions have common structures and configurations. A position of a wireless communication tag at the cartridge part is easily adjusted to a position suited for communication with a main body antenna. In a laser printer, accommodating chambers and accommodating portions are provided at plural regions of toner cartridges. The wireless communication tag is selectively inserted and fit into one of the accommodating chambers and accommodating portions, in accordance with a position of the cartridge loading portion in which the toner cartridge is loaded. In this way, in a state in which the toner cartridges are respectively loaded in the cartridge loading portions, the wireless communication tags are substantially parallel to and sufficiently close to the main body antennas of antenna units.

Owner:FUJIFILM BUSINESS INNOVATION CORP

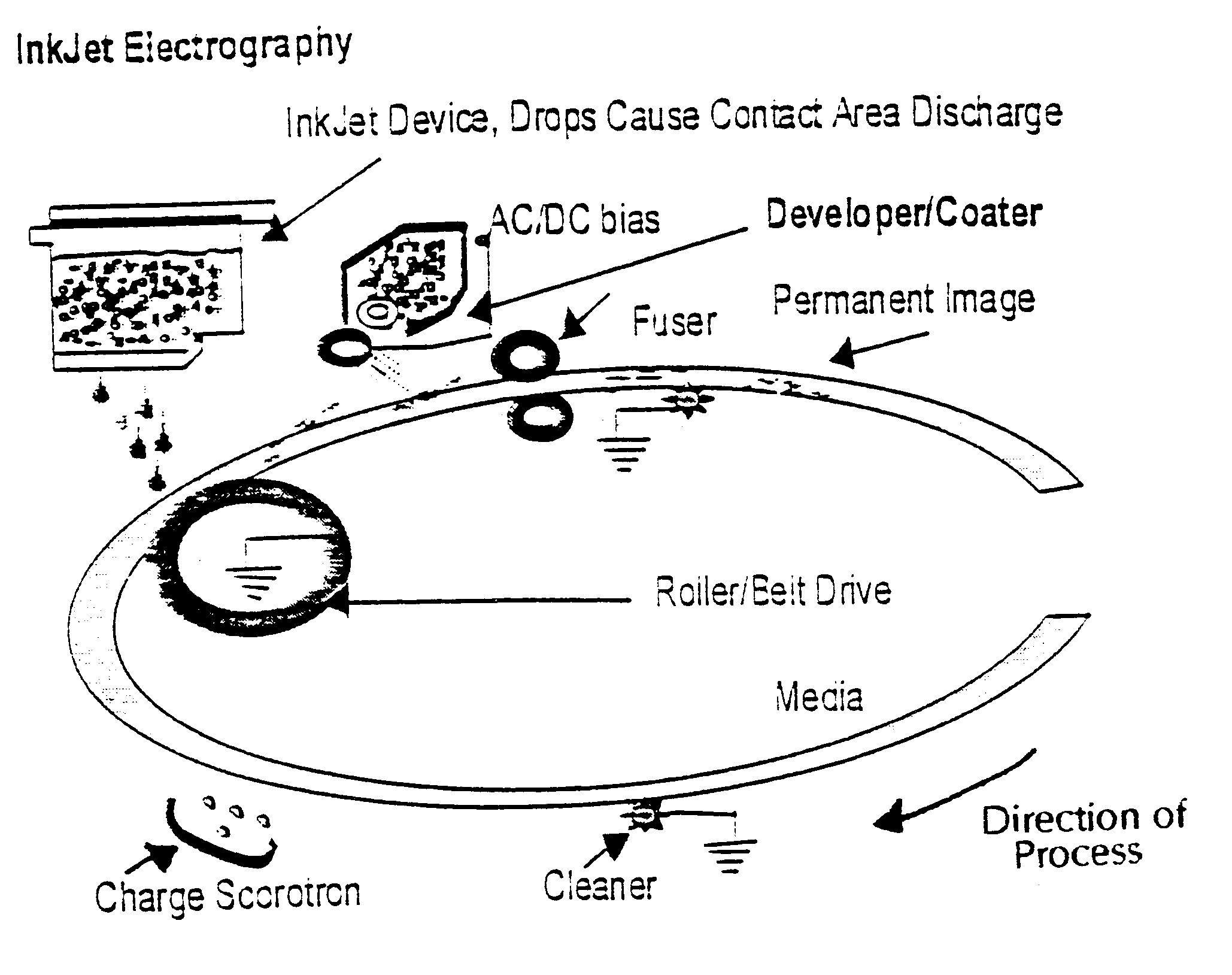

Energy activated electrographic printing process

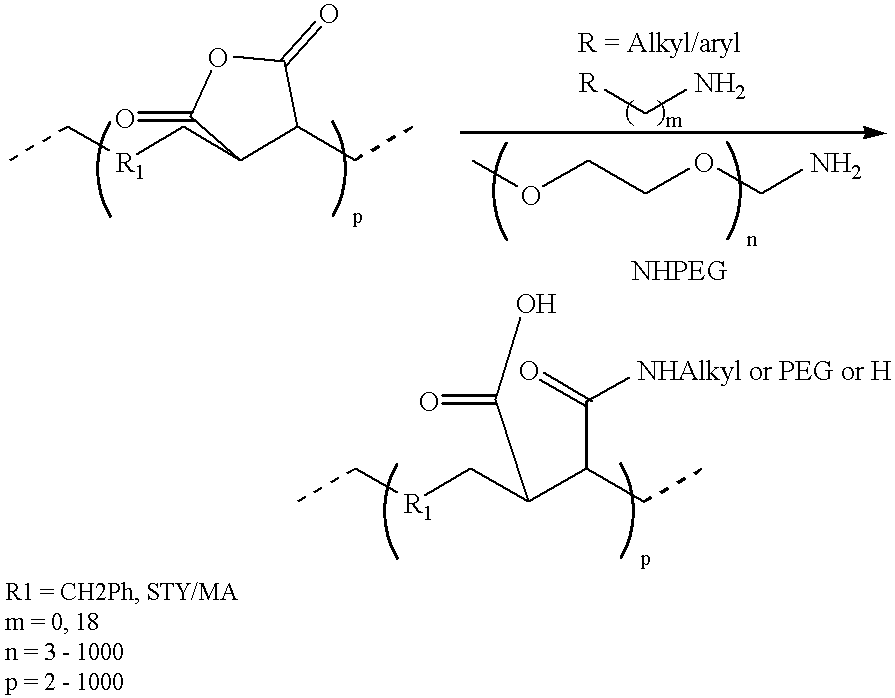

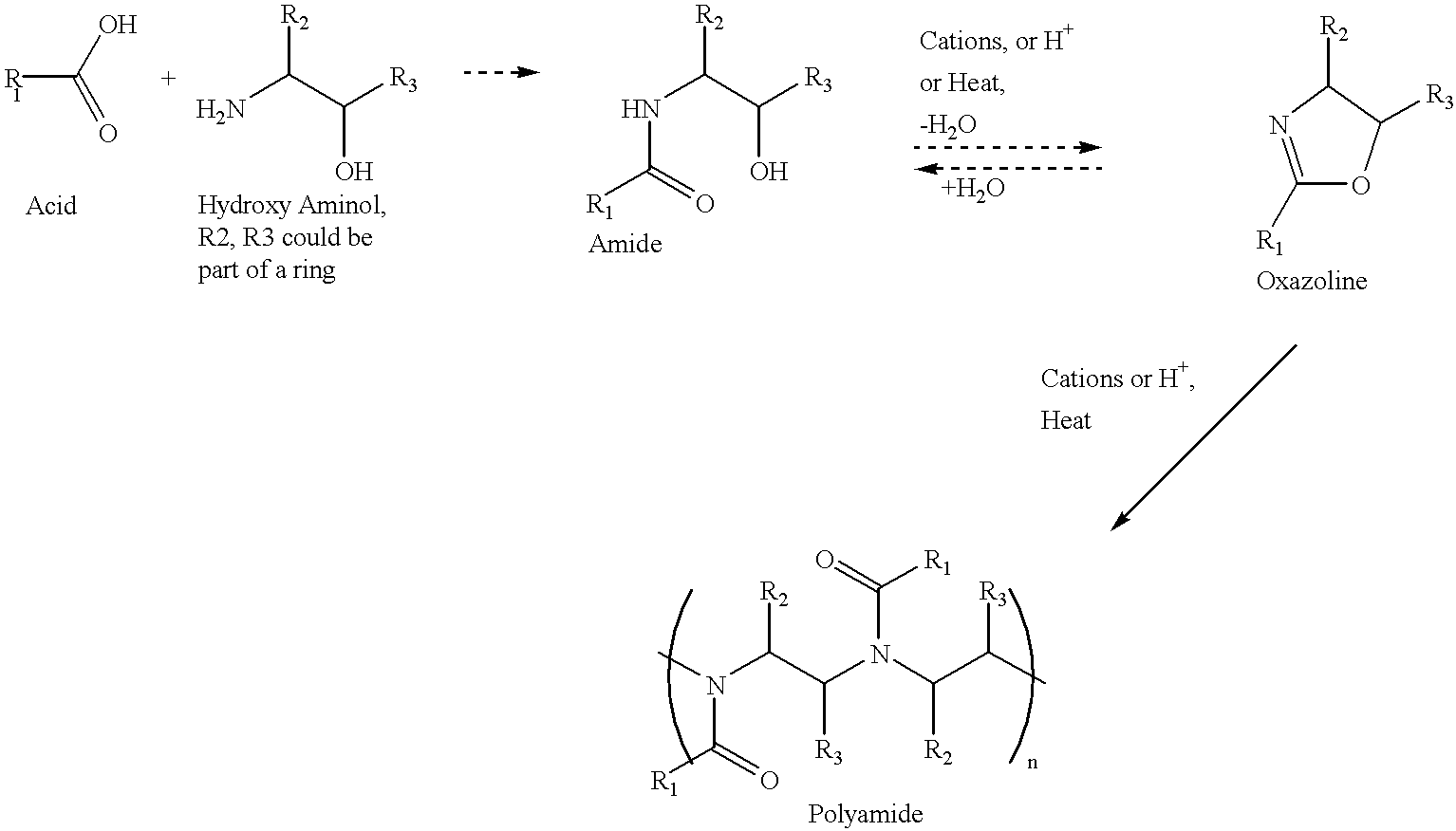

InactiveUS6849370B2Improve responseImprove permeabilityDevelopersElectrographic process apparatusCross-linkWax

A reactive toner that is energy-activated is printed by means of an electrographic device such as a laser printer. The reactive toner is printed onto a substrate. Toner components that cross-link and bond the printed toner permanently onto the substrate, or another substrate through a transfer process, are activated by the application of energy to react after printing. Reaction of the energy-activated components may be inhibited with blocking or protecting agents. The image is permanently bonded onto the substrate when the protection provided by the protecting agents is removed by the application of energy to the printed toner. The toner may comprise energy-activated components, colorants, color enhancing polymeric materials, binder resins, internal and external additives such as waxes and charge control agents. The energy-activated components have multiple functional groups that react with active hydrogen, components that contain active hydrogen, or components that are capable of conversion to active hydrogen containing groups.

Owner:WAGNER BARBARA +2

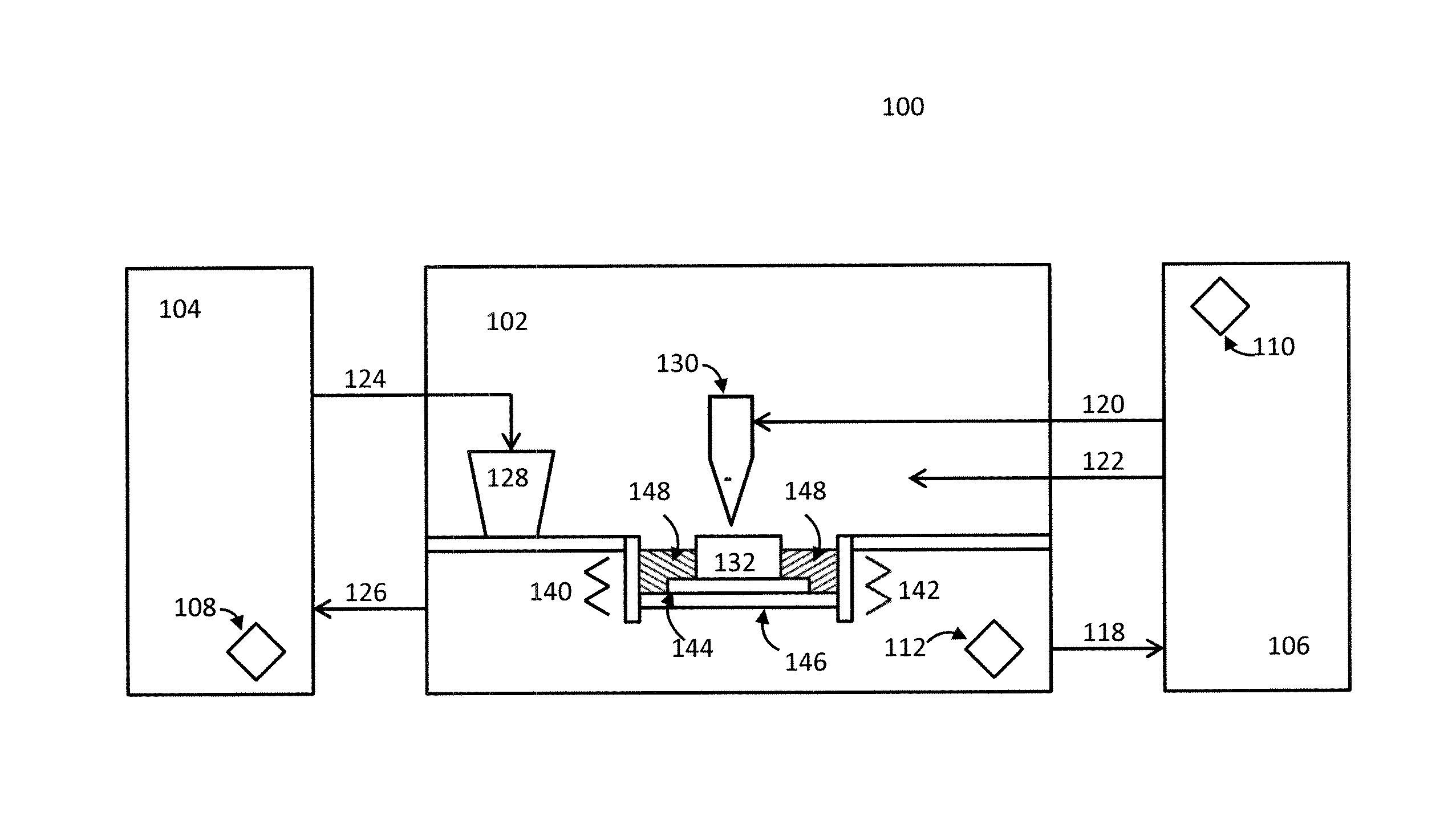

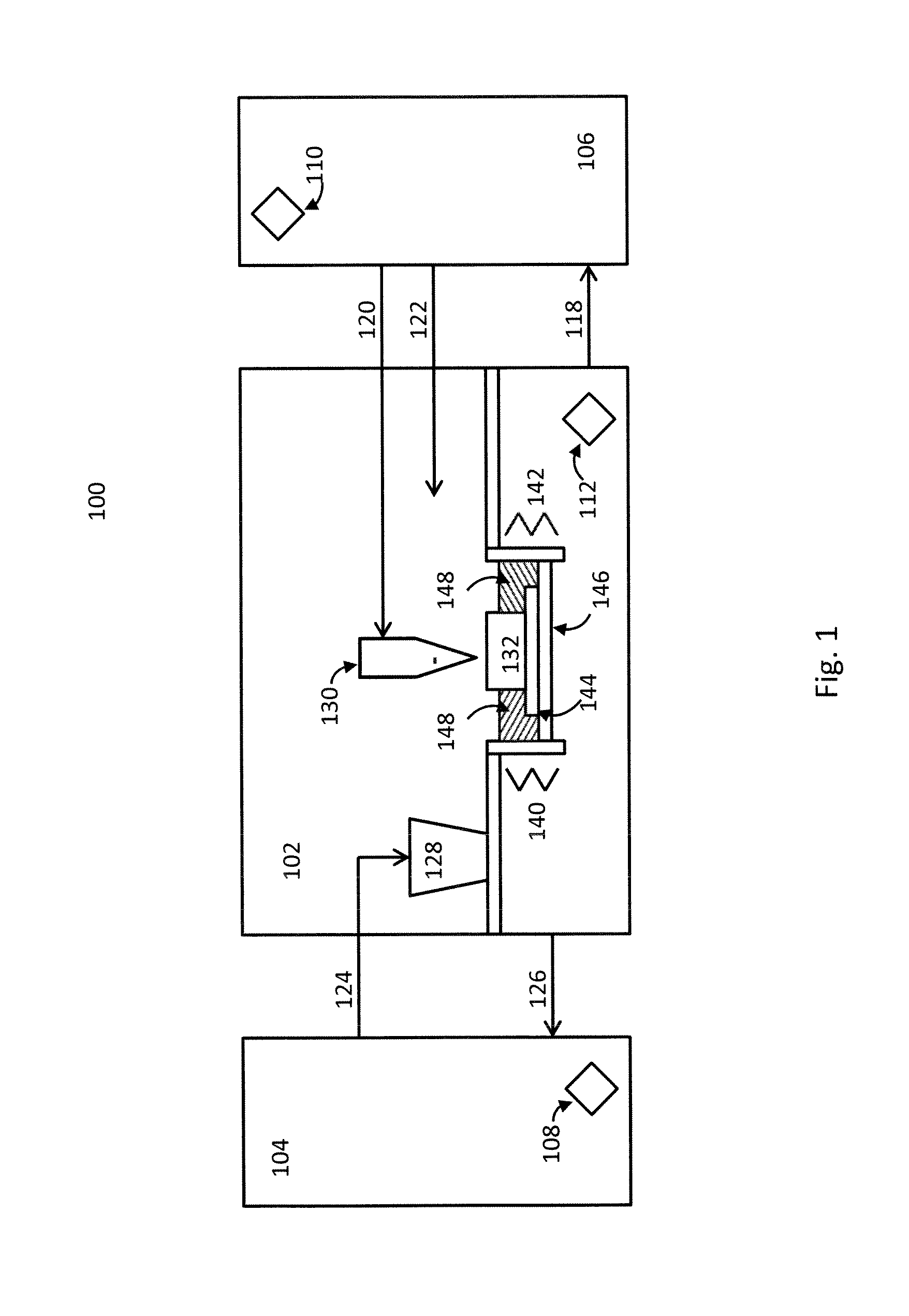

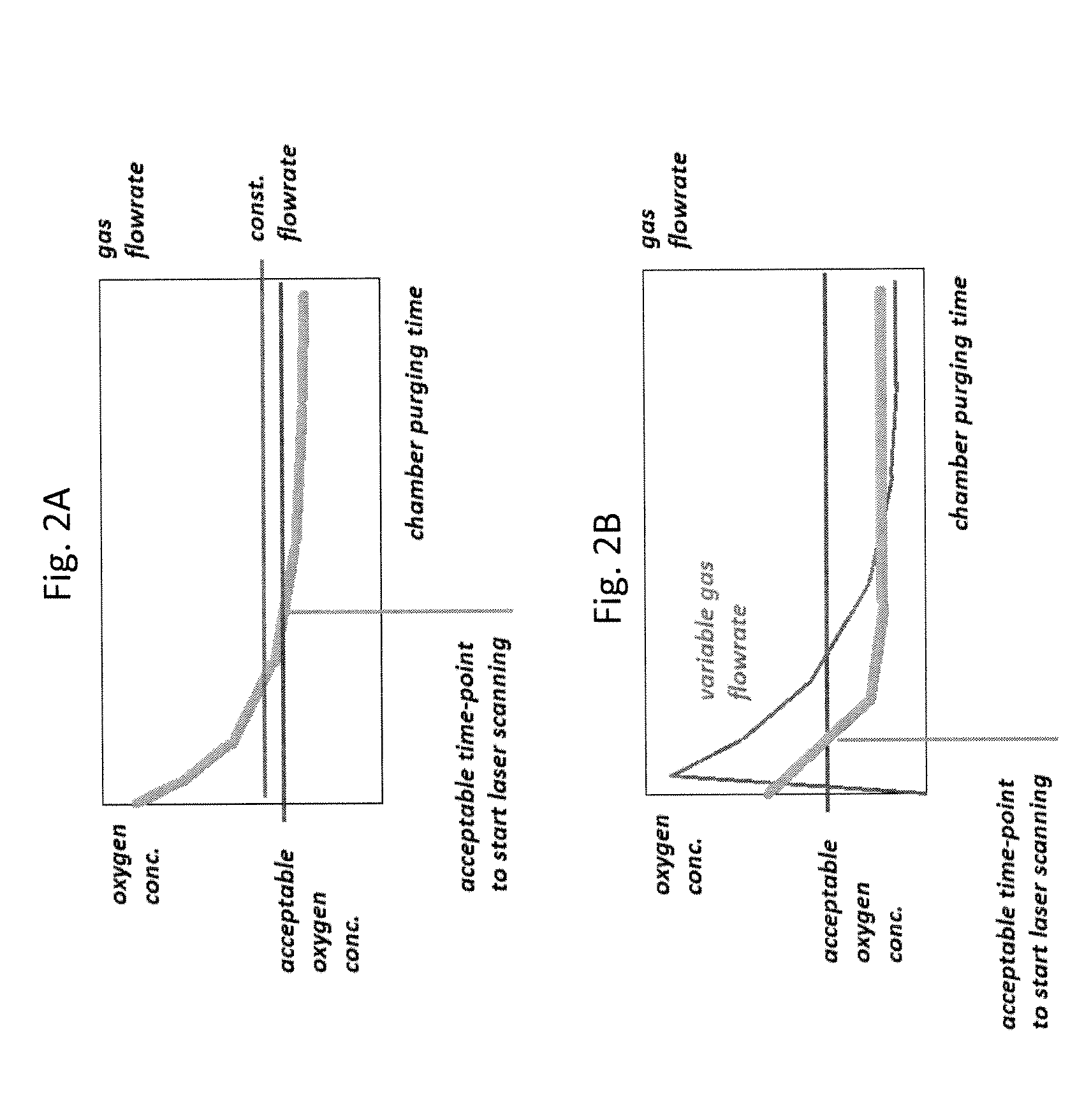

Gas Atmosphere Control In Laser Printing Using Metallic Powders

Methods and systems for controlling gas atmospheres in three-dimensional laser printing and weld overlay consolidation operations using metallic powders are provided. In one or more embodiments, such systems and methods comprise a printing chamber or laser weld overlay system, a gas supply system, a feed powder system, and one or more sensors employed to control the printing or welding operation. The methods and systems of the invention employ one or more inert gases having a purity greater than or equal to 99.995%

Owner:AIR PROD & CHEM INC

Energy activated electrographic printing process

InactiveUS6649317B2Excellent image definition and color vibrancy and wash fastnessMechanical recordingRecord information storageCross-linkWax

A reactive toner that is energy-activated is printed by means of an electrographic device such as a laser printer. The reactive toner is printed onto a substrate. Toner components that cross-link and bond the printed toner permanently onto the substrate, or another substrate through a transfer process, are activated by the application of energy to react after printing. Reaction of the energy-activated components may be inhibited with blocking or protecting agents. The image is permanently bonded onto the substrate when the protection provided by the protecting agents is removed by the application of energy to the printed toner. The toner may comprise energy-activated components, colorants, color enhancing polymeric materials, binder resins, internal and external additives such as waxes and charge control agents. The energy-activated components have multiple functional groups that react with active hydrogen, components that contain active hydrogen, or components that are capable of conversion to active hydrogen containing groups.

Owner:WAGNER BARBARA +2

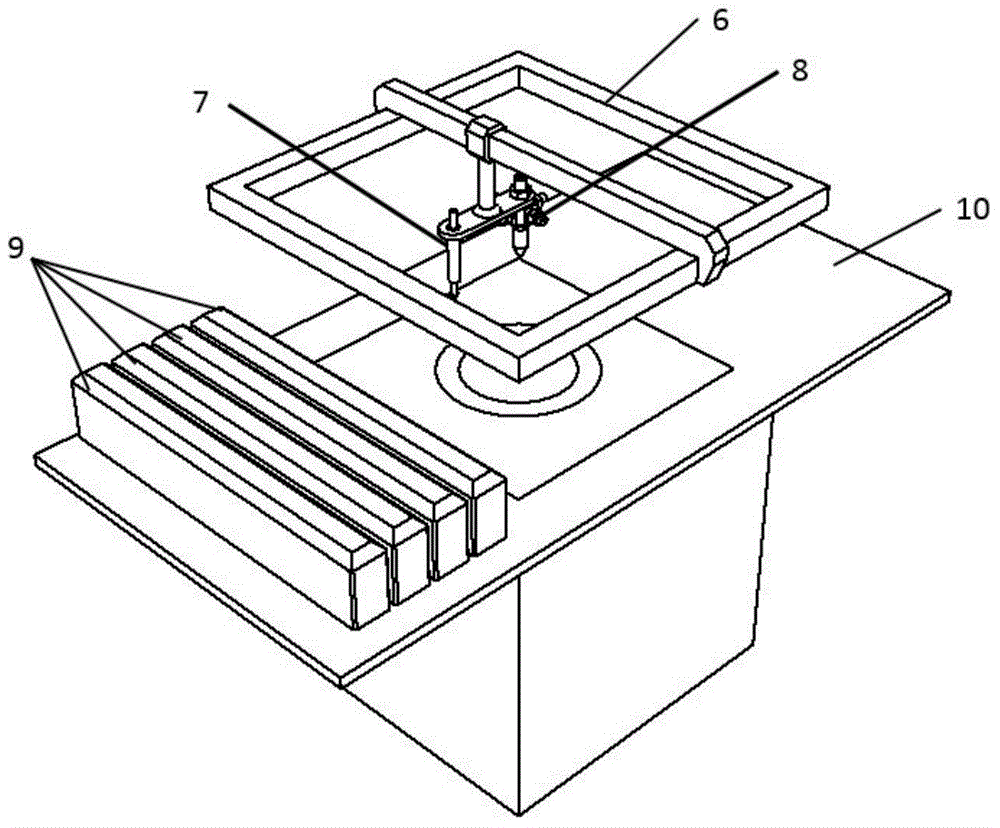

3D printing method of gradient material structure

InactiveCN104923787AFast preparationFast processingIncreasing energy efficiencyComputer control systemGradient material

The invention discloses a 3D printing method of a gradient material structure. Mixed printing of multiple materials can be achieved, and the structure having gradient gradually-changing mechanical property and physical property is processed. The device adopted in the 3D printing method mainly comprises a computer-control system, a powder spreading mechanism, a laser printing system and a printing worktable. When the 3D printing method is used for 3D printing, a gradient gradually-changing layer and a composite layer in a printing layer piece are needed to be further subdivided, and the material component information of layer pieces, selection information of the powder spreading device, powder spreading path information and printing path information are recorded. The information is utilized to control the powder spreading process and printing process in the printing forming process in real time. The 3D printing method is a novel method for quick processing and manufacture of functional gradient material structures and composite material structures and quick manufacture of complicated-shaped functional gradient material structures and composite material structures.

Owner:TONGJI UNIV

Material and method for preparing aluminum alloy structural member by using laser 3D (Three-Dimensional) printing technology

InactiveCN104759625AImprove performanceIncrease profitAdditive manufacturing apparatusComputer Aided DesignMaterial synthesis

The invention discloses a material and method for preparing an aluminum alloy structural member by using a laser 3D (Three-Dimensional) printing technology. Technologies such as a CAD (Computer Aided Design) three-dimensional entity model slicing technology, a digital programming technology and a laser quick forming technology and a material synthesis technology are combined integrally; under the condition that no any special mold or tool is used, multi-layer cladding accumulation is performed through quick melting and solidification of a laser beam on an aluminum alloy substrate by taking the powder of Al, Fe, Cu, Si, Ti, B, Mn, C and Ce according to the mass percentage of 80.0, 3.0, 2.0, 3.0, 4.0, 3.0, 1.5, 2.0 and 1.5 as a raw material; an aluminum alloy structural member with good comprehensive performance such as high performance, full compactness and high fatigue life is directly finished from a part digital model in one step. The method has the characteristics of low cost, short period and high material utilization rate, and is suitable for integrated quick forming manufacturing of large-sized and complex aluminum alloy structural members; the shapes and the sizes of the prepared parts are not limited, and the requirement on structural integration can be met.

Owner:GUILIN UNIV OF ELECTRONIC TECH

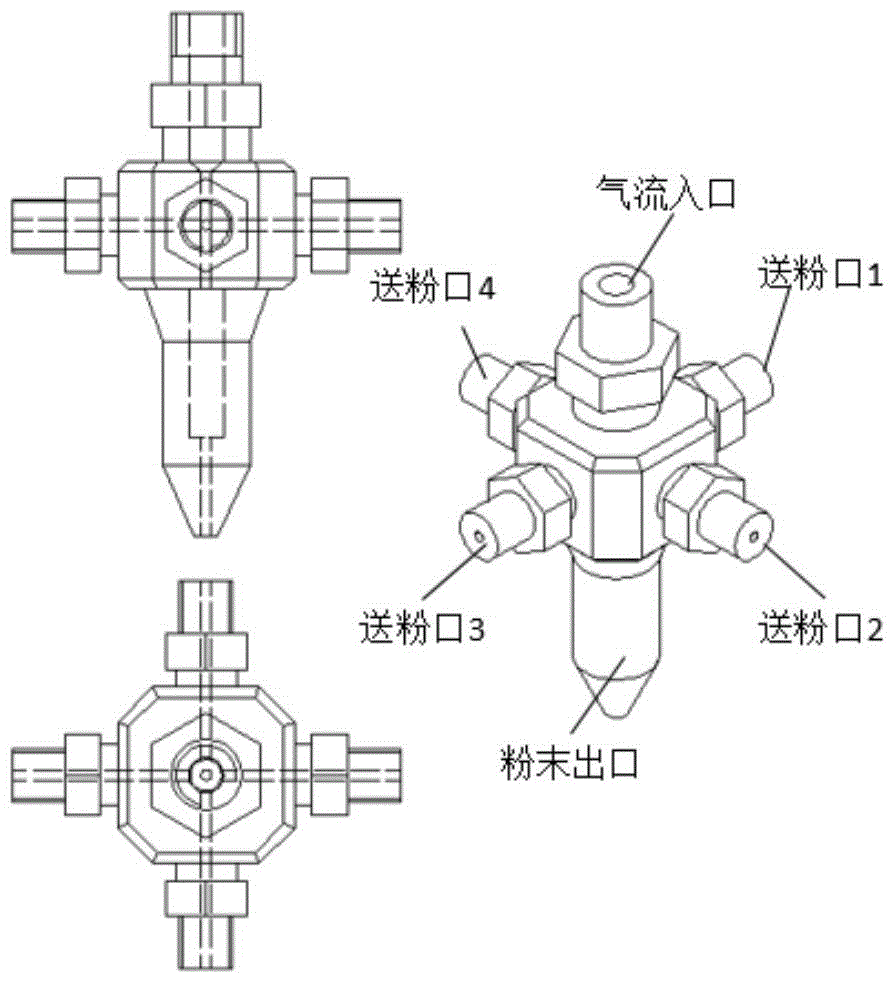

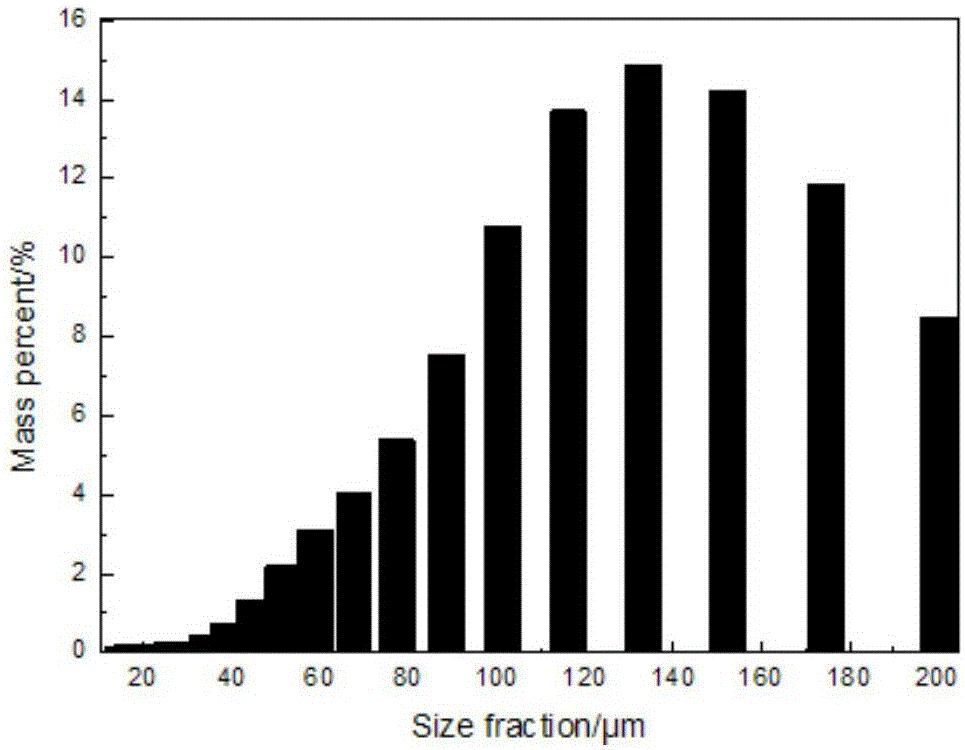

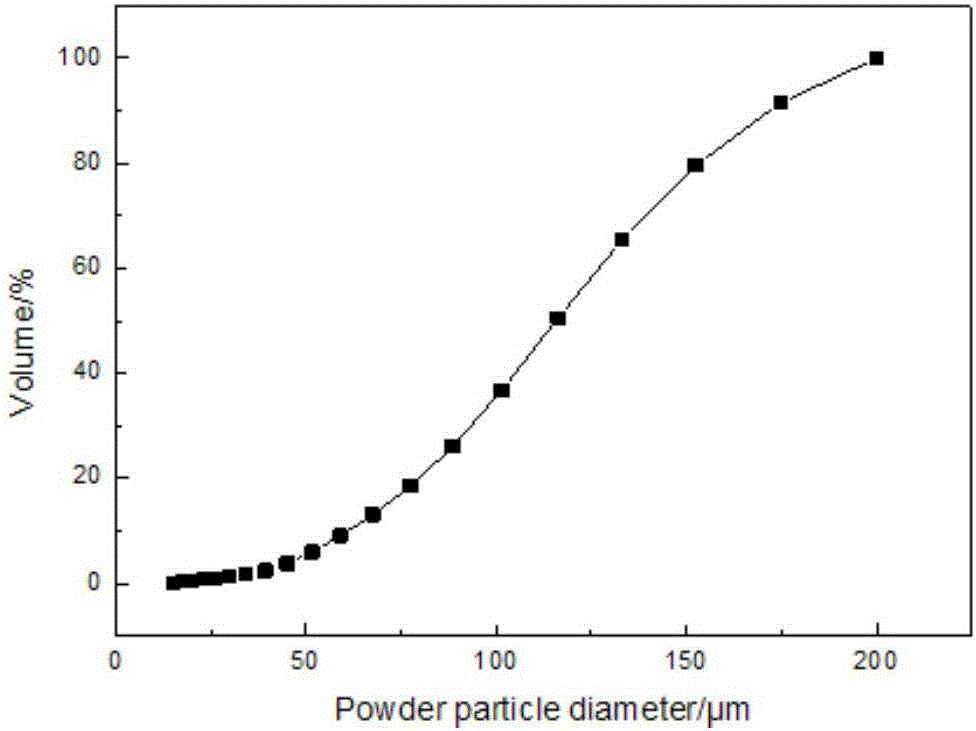

TC21 titanium alloy powder for laser 3D printing and preparation and using methods

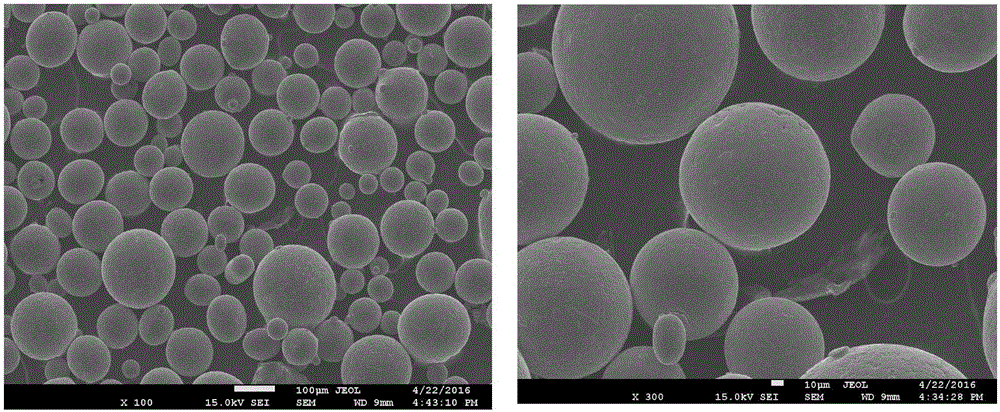

ActiveCN106435270AHigh sphericitySmooth surface and good fluidityAdditive manufacturing apparatusTransportation and packagingMicrometerSpray nozzle

The invention provides TC21 titanium alloy powder for laser 3D printing and preparation and using methods. The powder is prepared from, by mass, 5.5%-6.7% of Al, 1.7%-2.4% of Sn, 1.7%-2.4% of Zr, 2.4%-3.1% of Mo, 1.0%-1.8% of Cr, 1.8%-2.2% of Nb, 0.004%-0.18% of Fe, 0.004%-0.01% of C, 0.002%-0.009% of N, 0.003%-0.01% of H, 0.08%-0.1% of O and the balance Ti. The preparation method comprises the steps that TC21 titanium alloy is machined into an electrode and then rotates and goes down in a smelting chamber, gas acts on the conical tip of a titanium bar when the tip of the titanium bar is bright white, titanium alloy liquid drops are brought into an atomizing chamber through nozzles to be cooled into alloy powder, and the alloy powder is collected. The using method comprises the steps that after the alloy powder with the particle size ranging from 54 micrometers to 180 micrometers and a substrate are pretreated, the as-deposited TC21 titanium alloy with the good strength and toughness is printed by adopting a laser 3D printer, wherein the tensile strength is 1,100-1,150 Mpa, the yield strength is 1,010-1,030 Mpa, and the elongation rate is 7%-8%.

Owner:NORTHEASTERN UNIV

Permanent images produced by use of highly selective electrostatic transfer of dry clear toner to areas contacted by ink

The present invention relates to ink-jet inks in combination with a clear, dry toner to produce a permanent ink-jet image. In particular, this invention relates to an ink system that utilizes the addition of specific toner / developers, typically found in the laser printer field, with aqueous based in-jet inks. These dual systems produce a permanent image that is resistant to image degradation factors such as mechanical abrasion, light, water, and solvents such as the ones used in highlighter markers.

Owner:HEWLETT PACKARD DEV CO LP

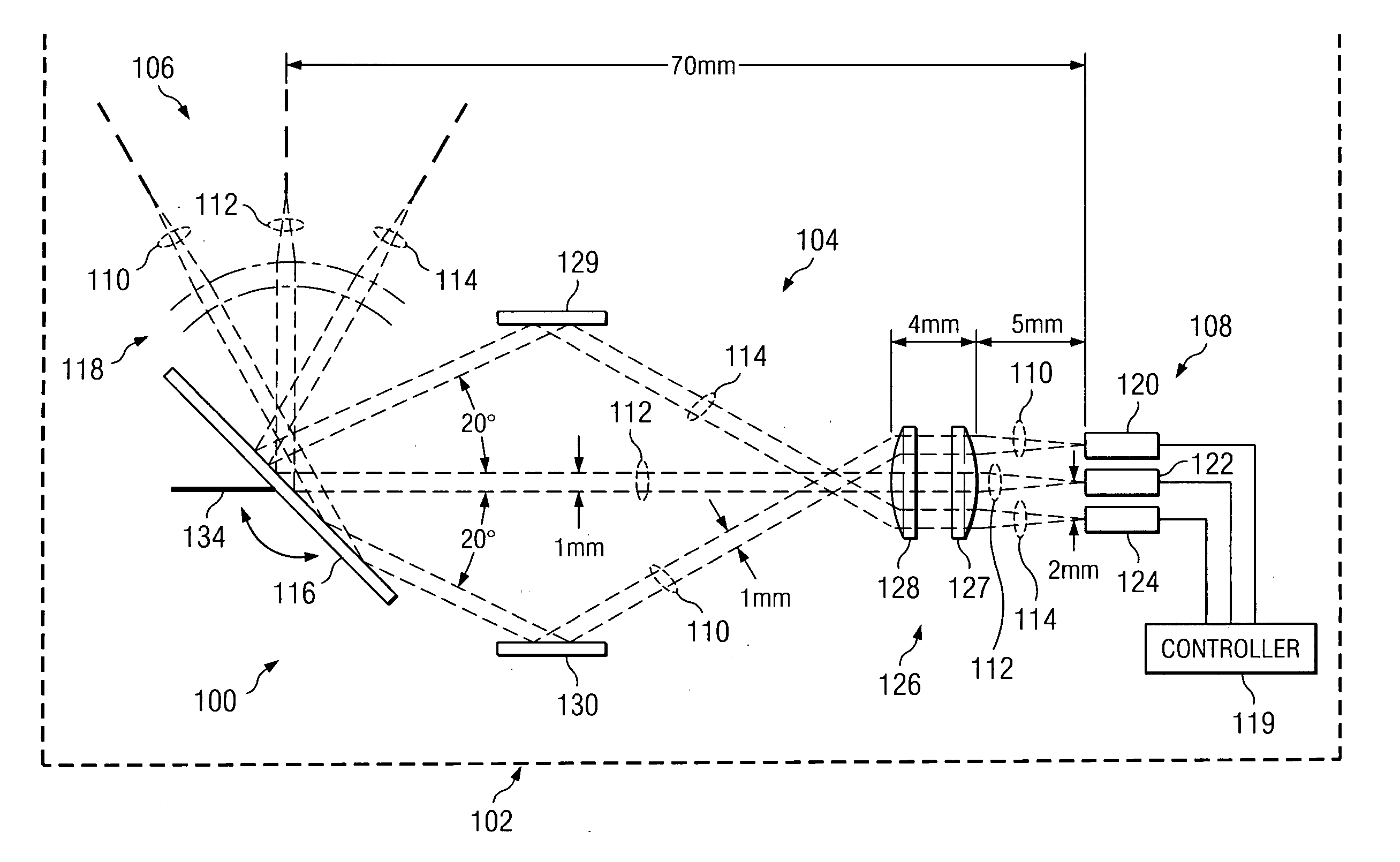

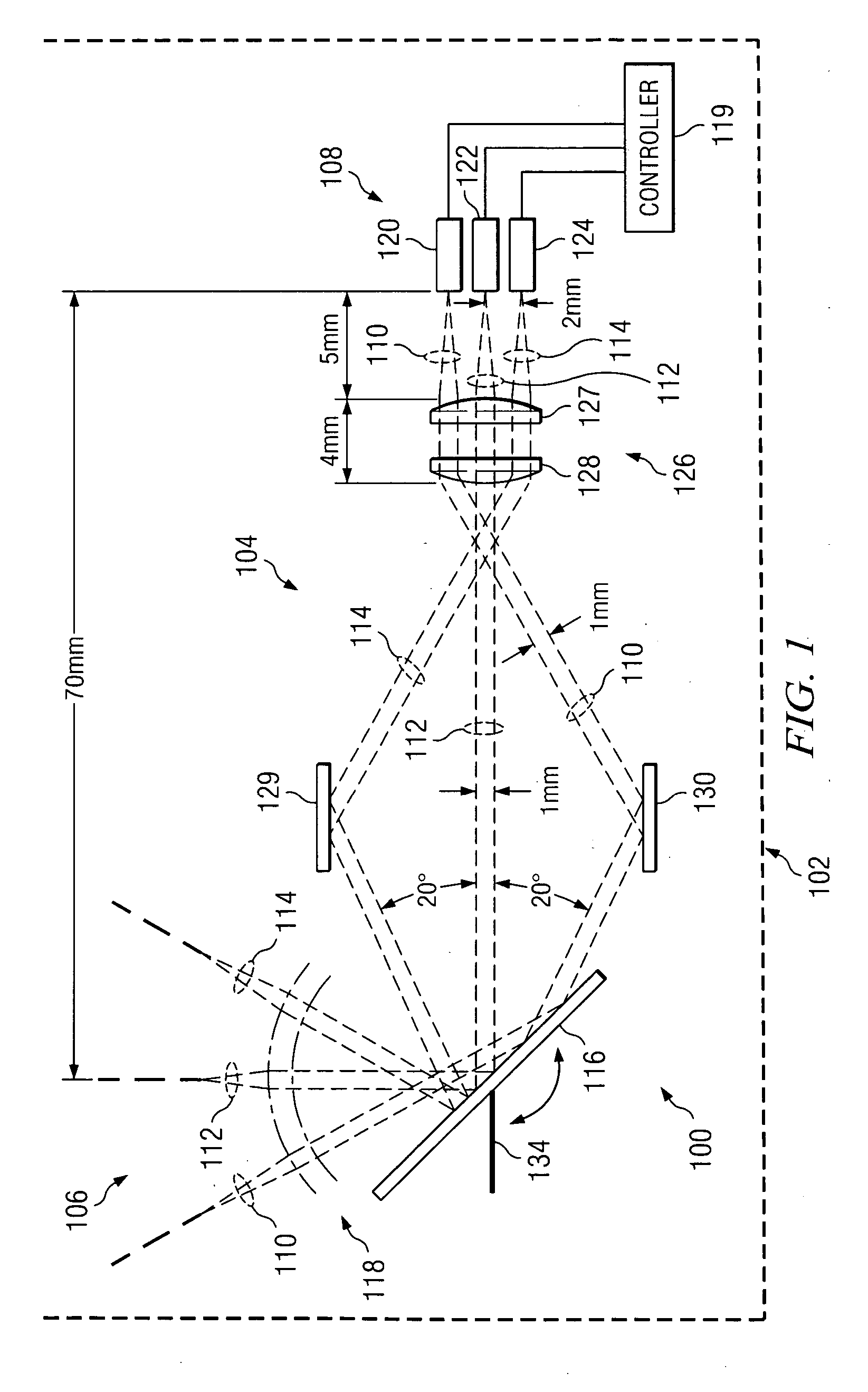

Optical system having extended angular scan range

System and method for scanning light across a light-receiving surface. A system for scanning light across a light-receiving surface to project a scanned line on the light-receiving surface has a light beam generator for generating a plurality of light beams. A scanning mechanism simultaneously scans each light beam of the plurality of light beams across the light-receiving surface to project a different portion of the scanned line on the light-receiving surface. The scanning system can be utilized in a compact laser printer capable of printing at a high rate, and in other scanning applications.

Owner:AVAGO TECH INT SALES PTE LTD

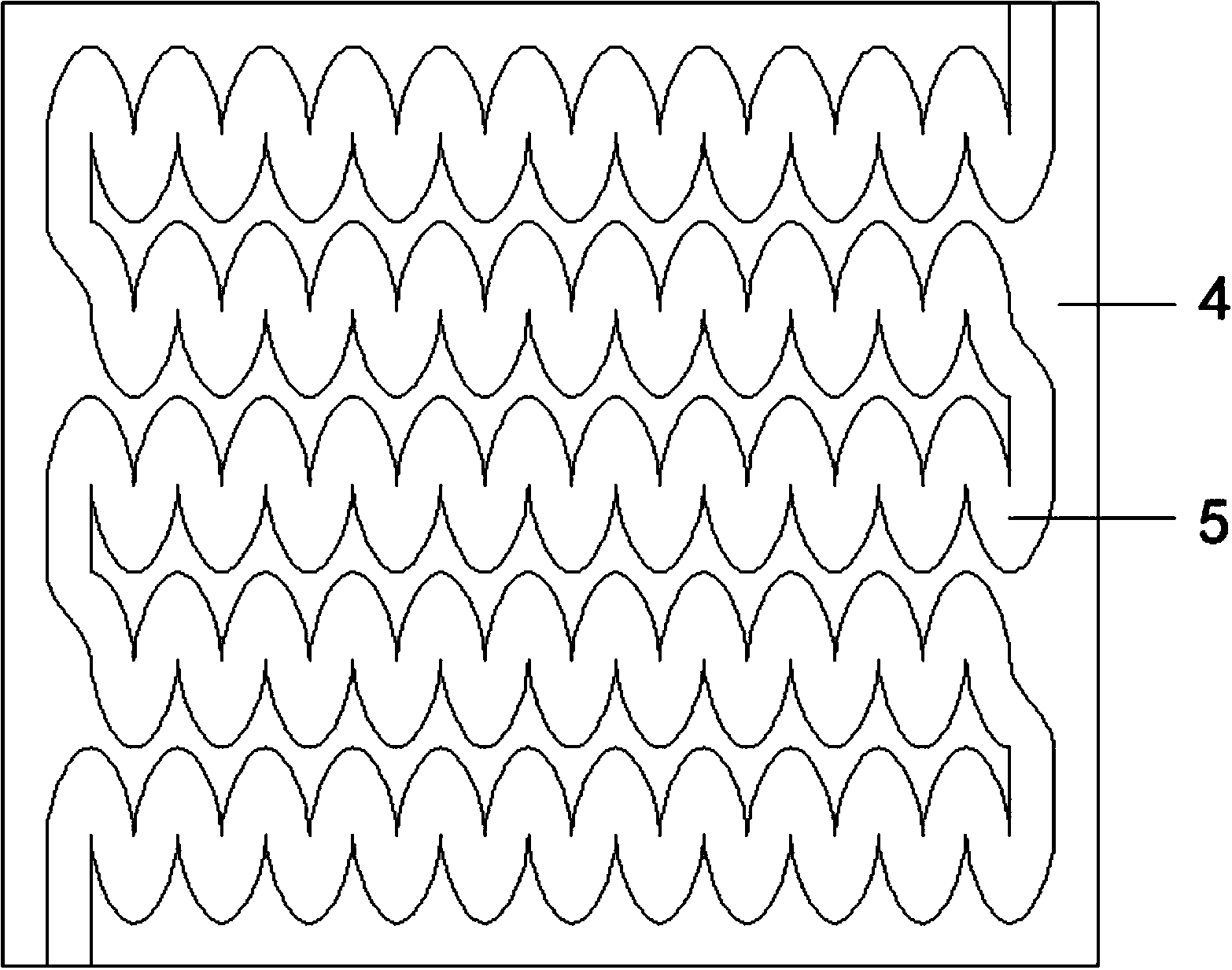

Maze conformal cooling method and structure of mold

The invention provides a maze conformal cooling method and structure of a mold, and aims to solve the problem that the conventional mold cooling method cannot meet efficient and uniform cooling requirement of a complex mold. Compared with three traditional mold cooling method including a straight hole flow channel, a built-in bent pipe flow channel and a common tubular shape follow-up flow channel, the maze conformal cooling method is high in cooling efficiency and good in cooling effect. According to the structure, a hollow layer nearly parallel to the inner surface of a cavity is arranged in the position, having certain thickness distance from the cavity, in the mold, a maze type partition wall is arranged in the hollow layer, and a cooling medium flows in a channel formed by partition wall gapes in a cooling layer. The maze conformal cooling method and the structure of the mold have the advantages that the cooling state of the cooling medium in the gaps of the maze type partition wall is turbulence, and the contact area between the cooling medium and the mold is increased, so that the cooing efficiency is high, the service life of the mold is long, an injection molding process period is shortened, and the injection molding manufacturing cost is reduced. A 3-dimensional laser printing technology is adopted to directly manufacture the mold with the layered maze flow channel conformal cooling structure, components in the mold are uniform, the molding process is simple, the mold manufacturing period is short, and the mold manufacturing cost is low.

Owner:HUAZHONG UNIV OF SCI & TECH

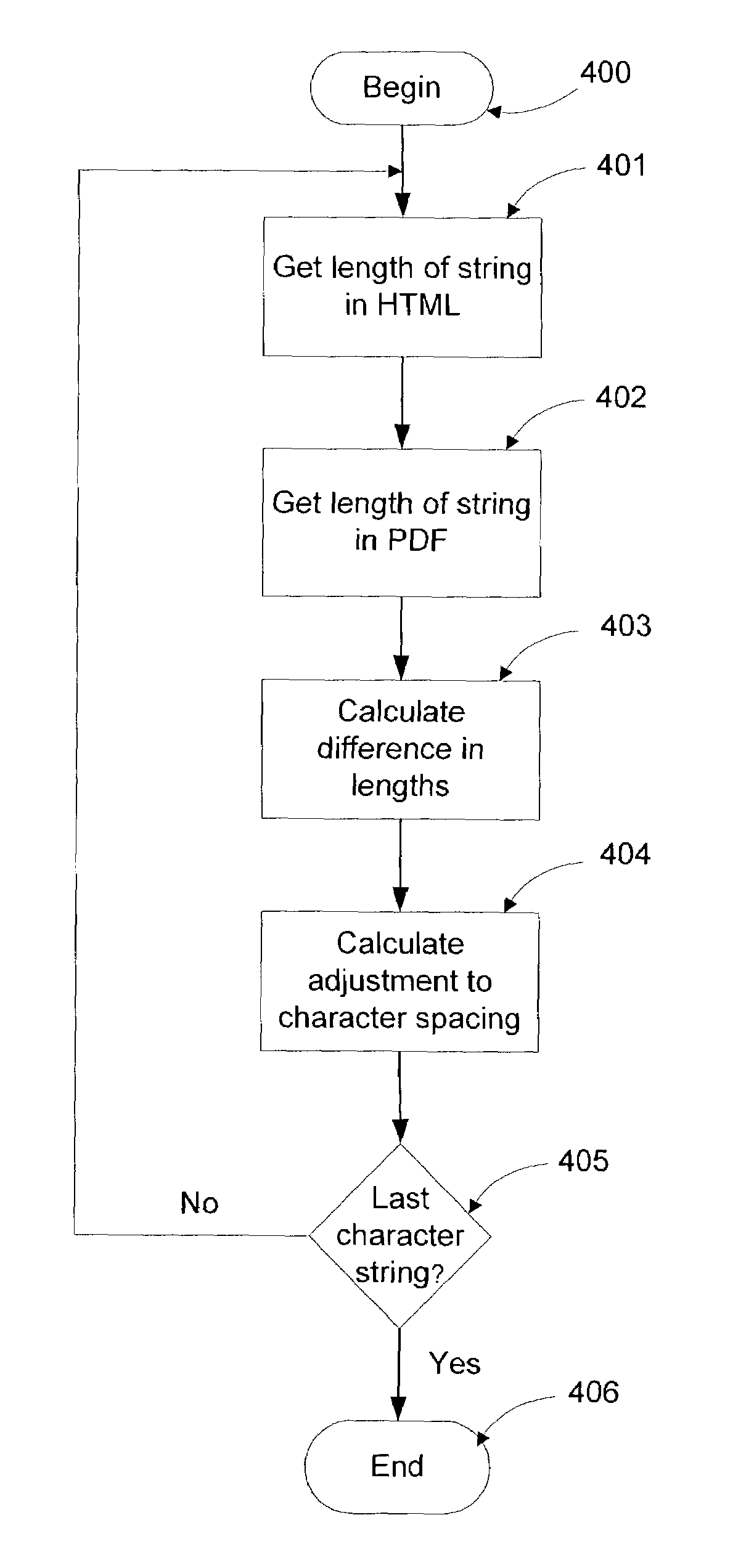

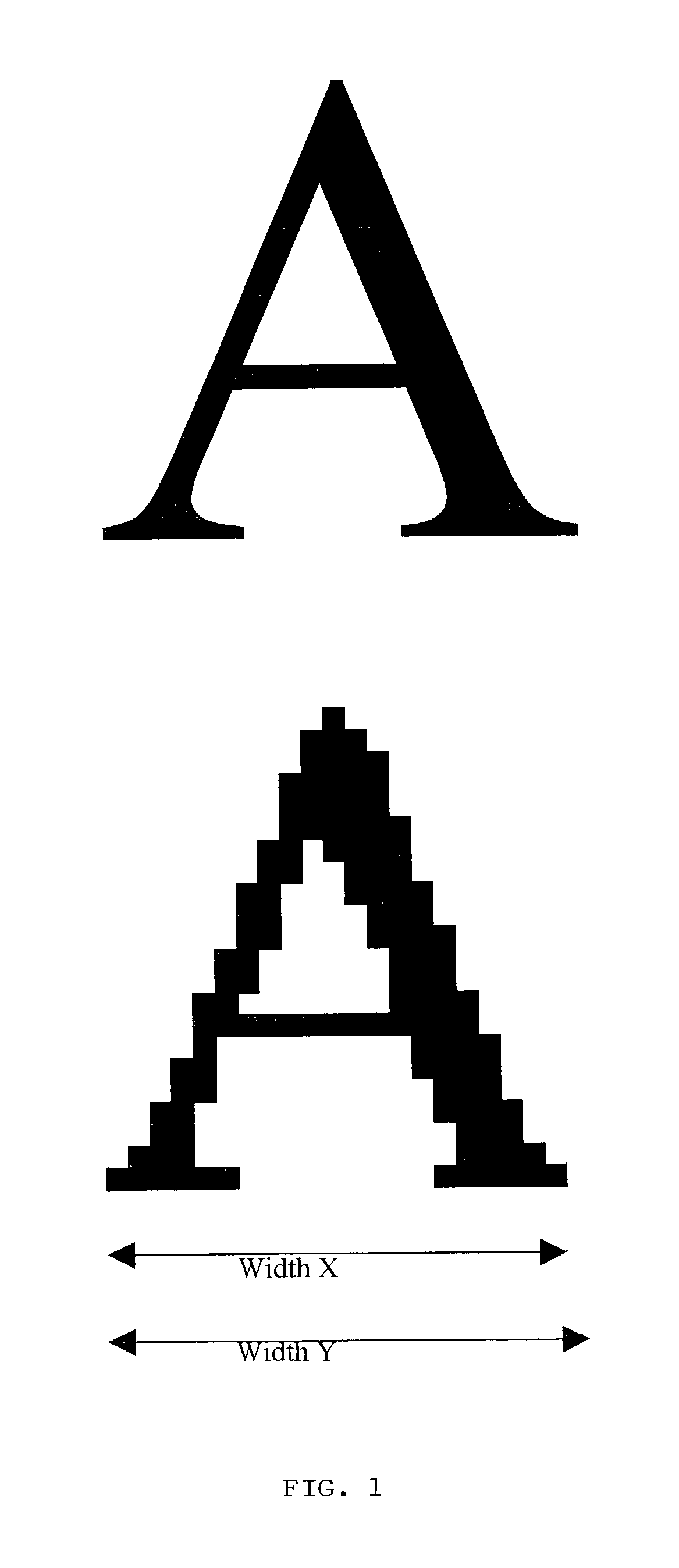

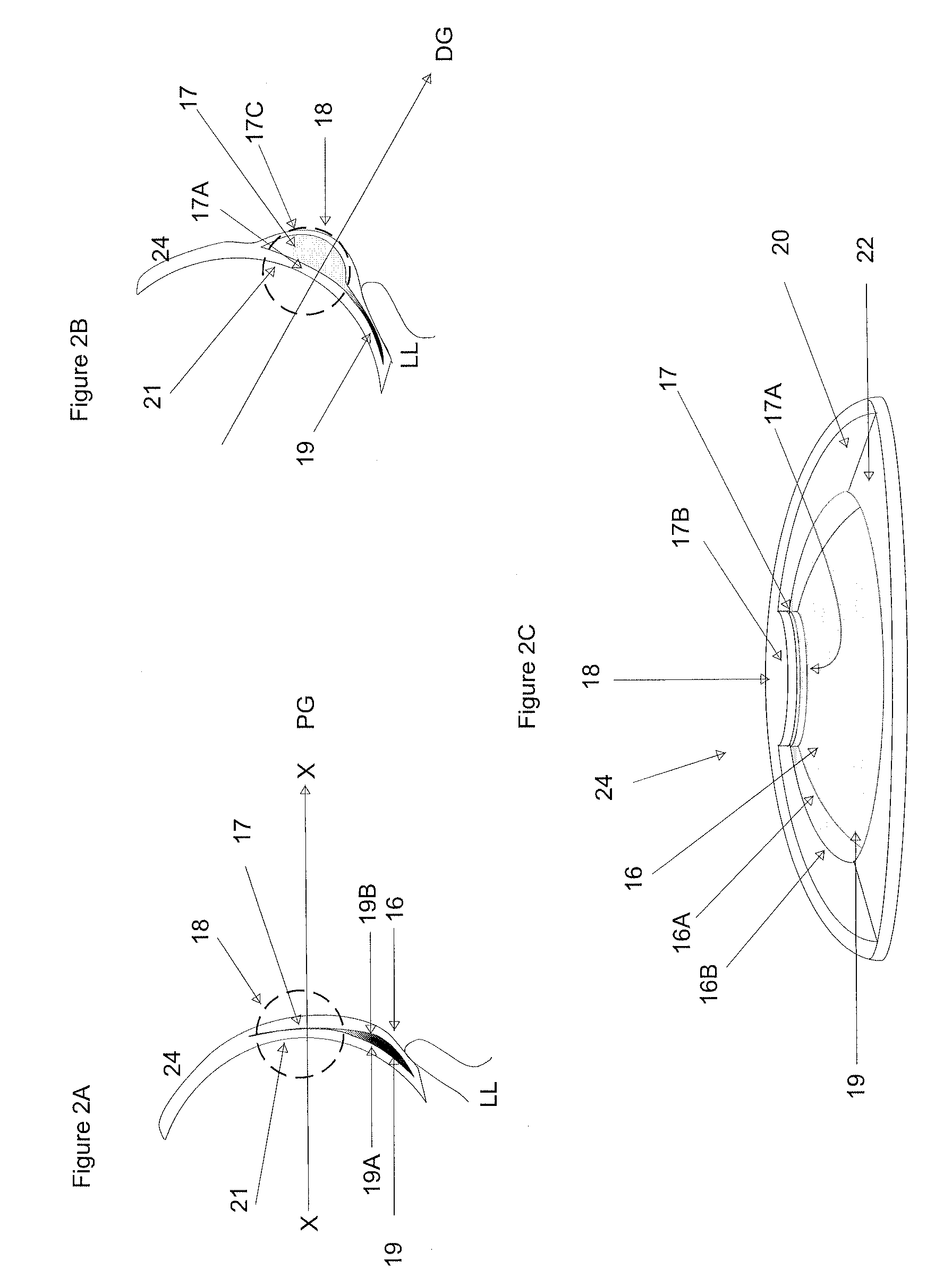

Low resolution-to-high resolution image correlation

ActiveUS6993209B1Character and pattern recognitionEditing/combining figures or textComputer monitorImage resolution

Systems and methods for facilitating a WYSIWYG relationship between character strings when rendered on a relatively low resolution device, such as a computer monitor, and the same character strings when rendered on a relatively high resolution device, such as a laser printer or commercial offset printing press, involve determining the difference in the widths of each character string when rendered in both the low resolution format and the high resolution format and inserting or deleting space as required between the individual characters in the character string such that the widths of the low resolution and high resolution strings are substantially equalized.

Owner:CIMPRESS SCHWEIZ

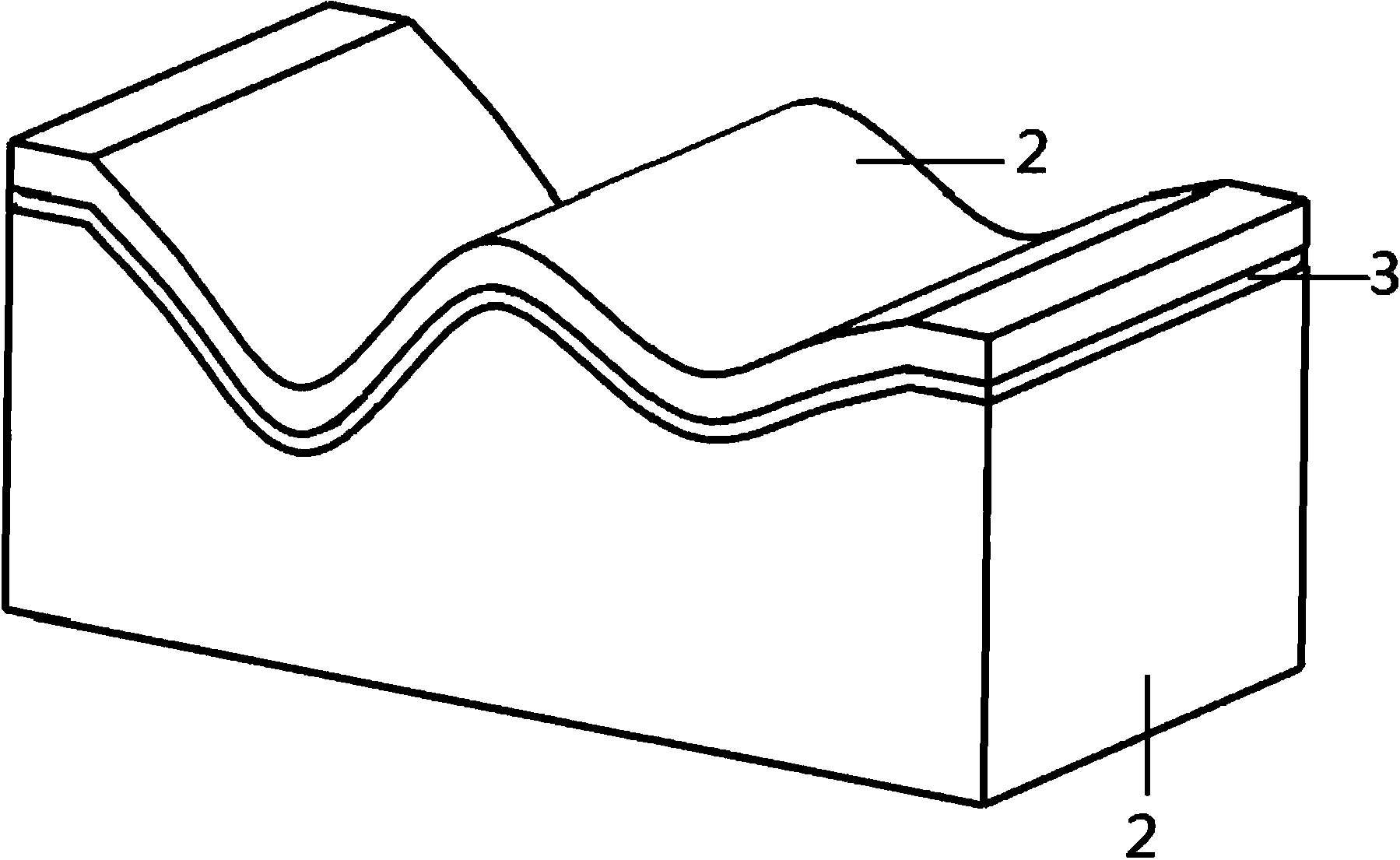

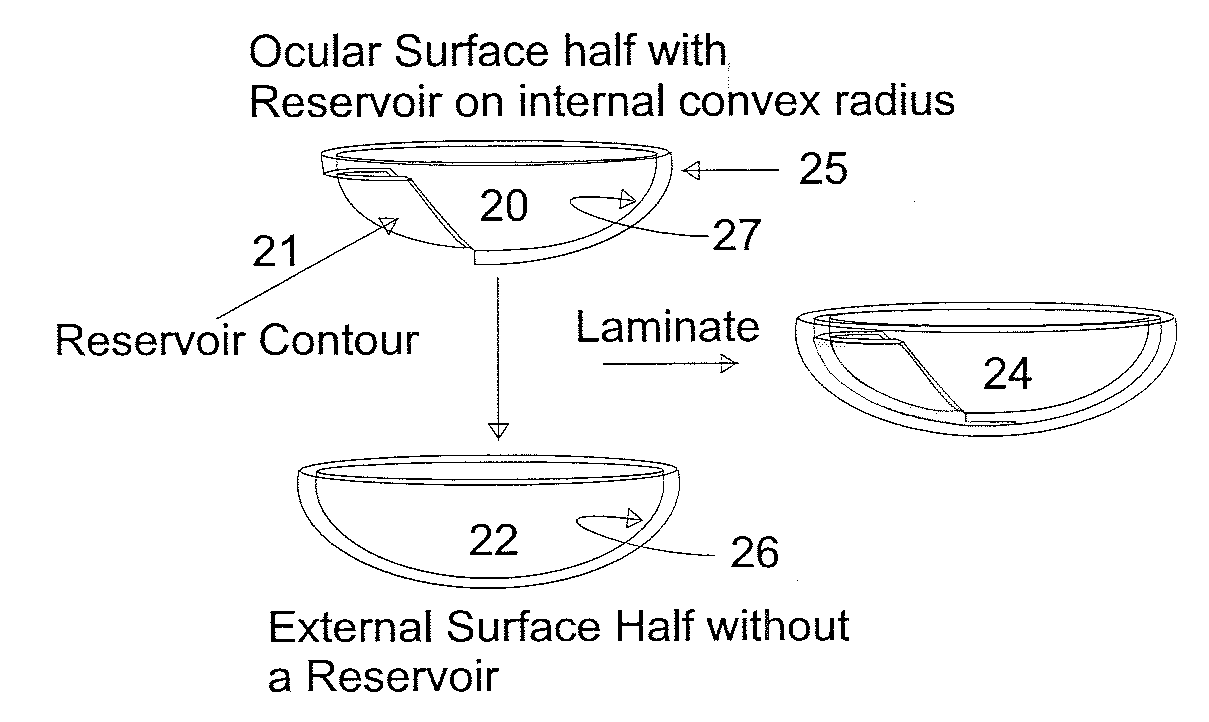

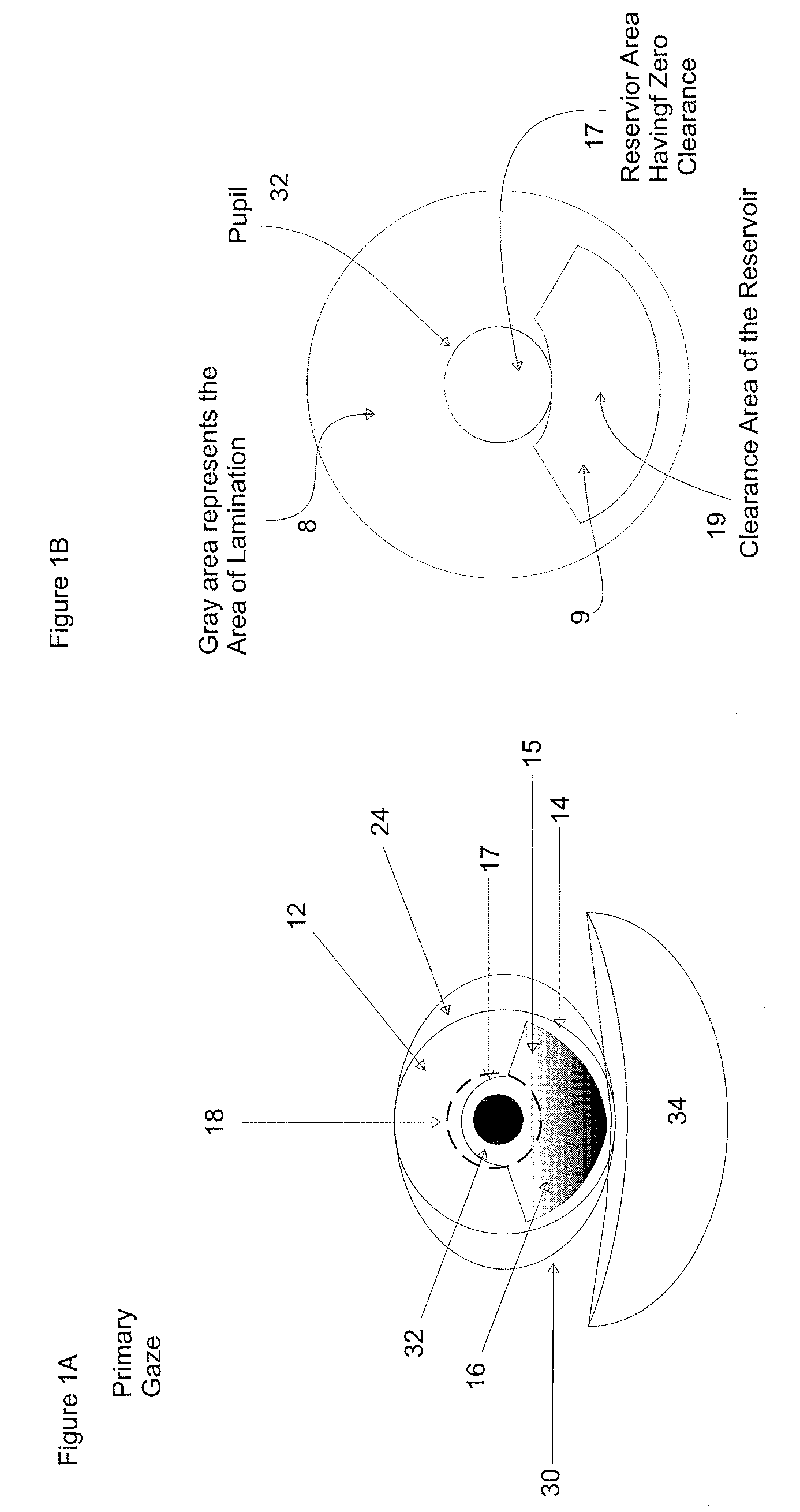

Manufacturing Techniques for the Production of Hydrodynamic Multifocal Contact Lenses

Several methods for making a contact lens with a reservoir are disclosed. The reservoir is filled with fluid and is shaped to change dynamically the optical characteristics of the lens. One method includes forming two shells with a depression therebetween, laminating the shells together, with the reservoir being filled with a fluid. Other methods include molding lens shells and laminating them together, or forming the lens with a unitary body using laser printing techniques.

Owner:IN TECH HLDG

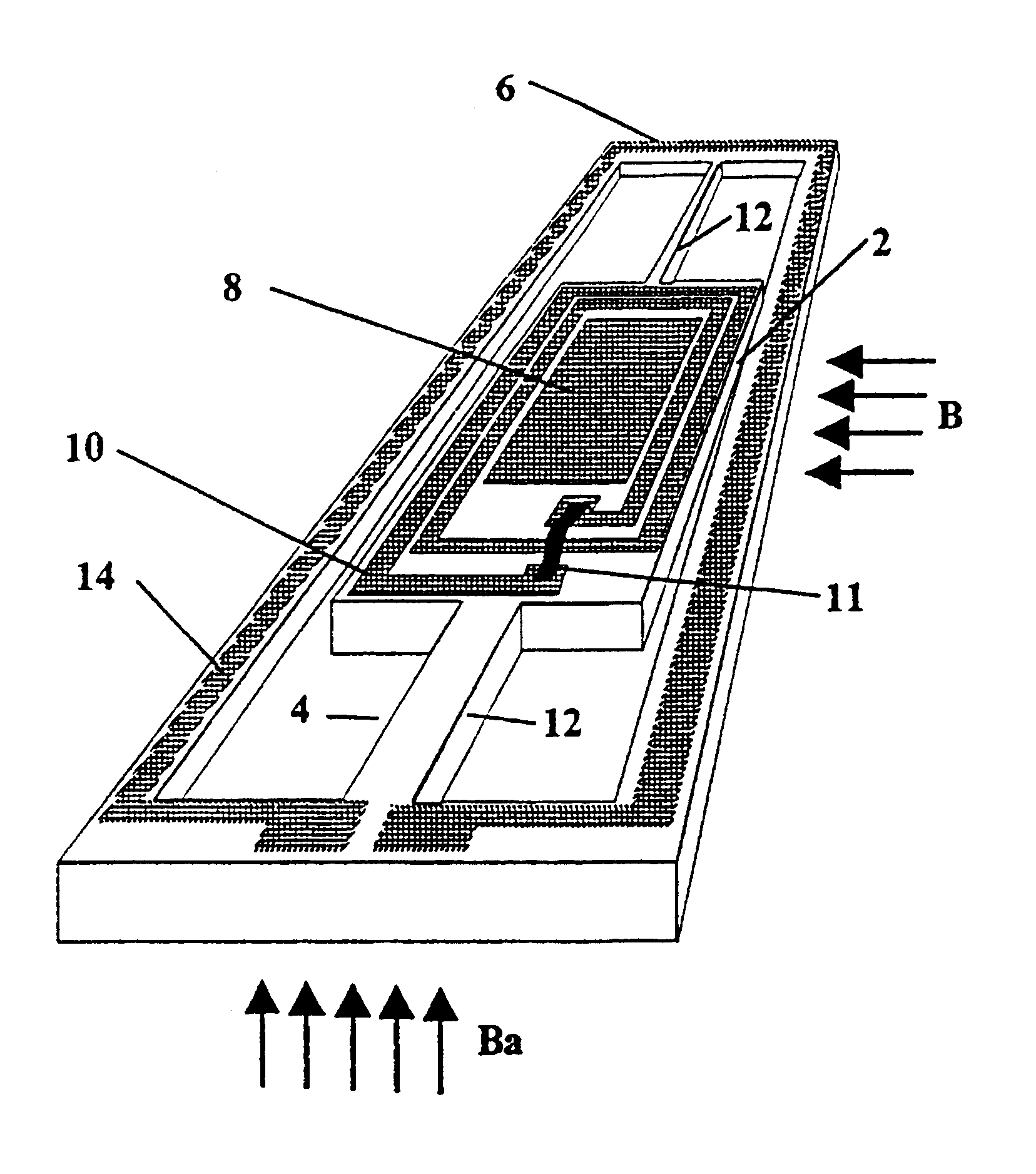

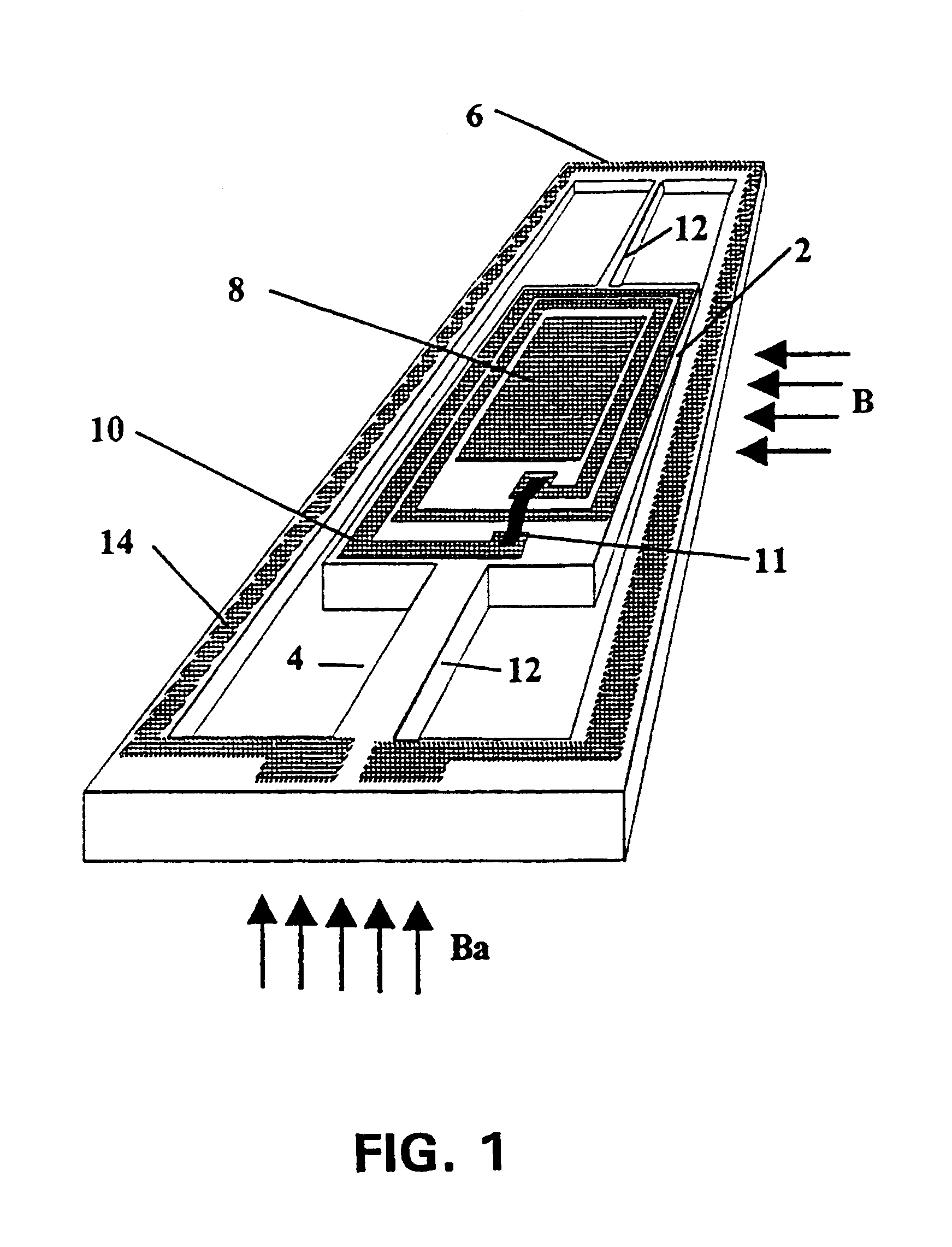

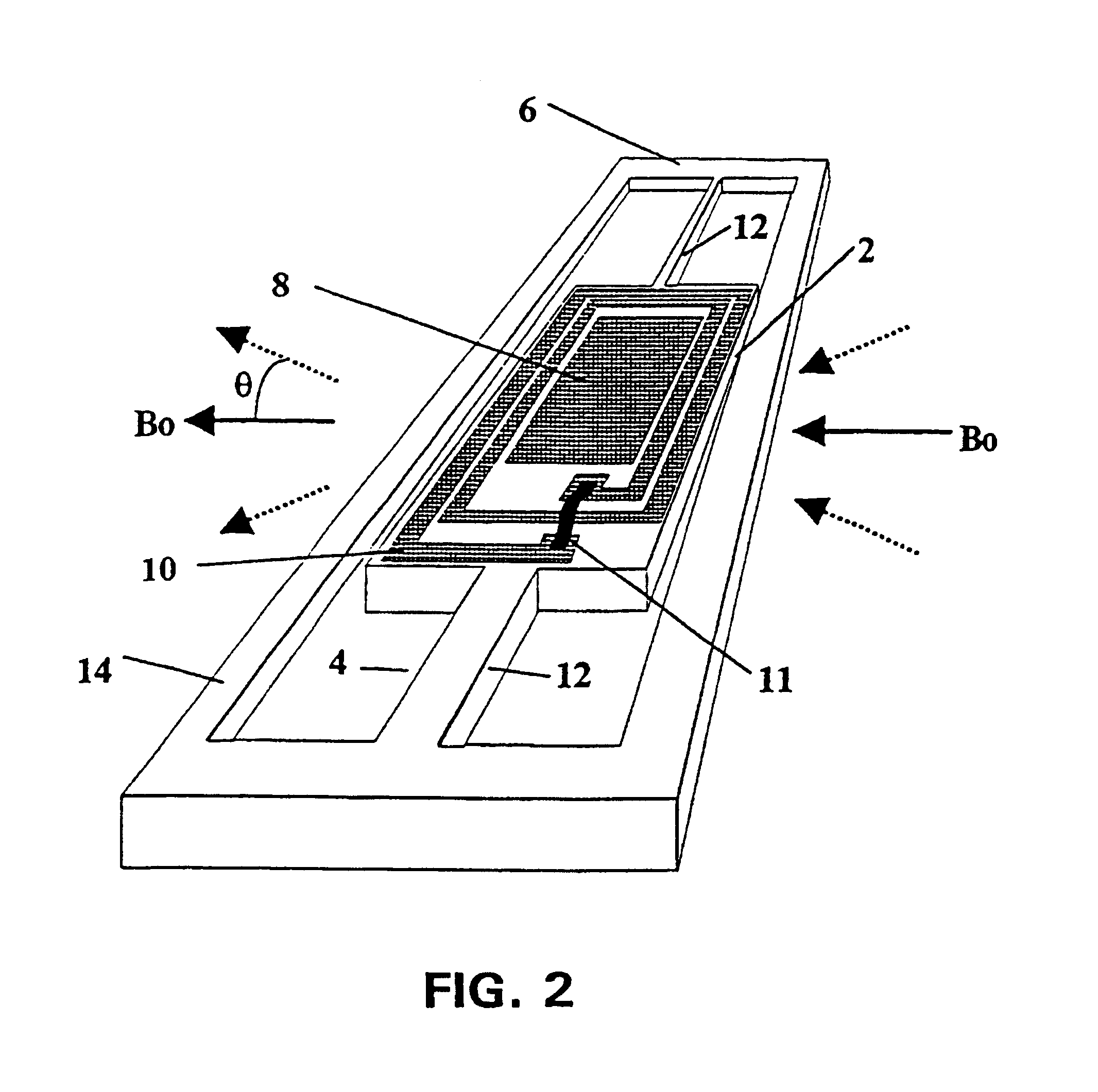

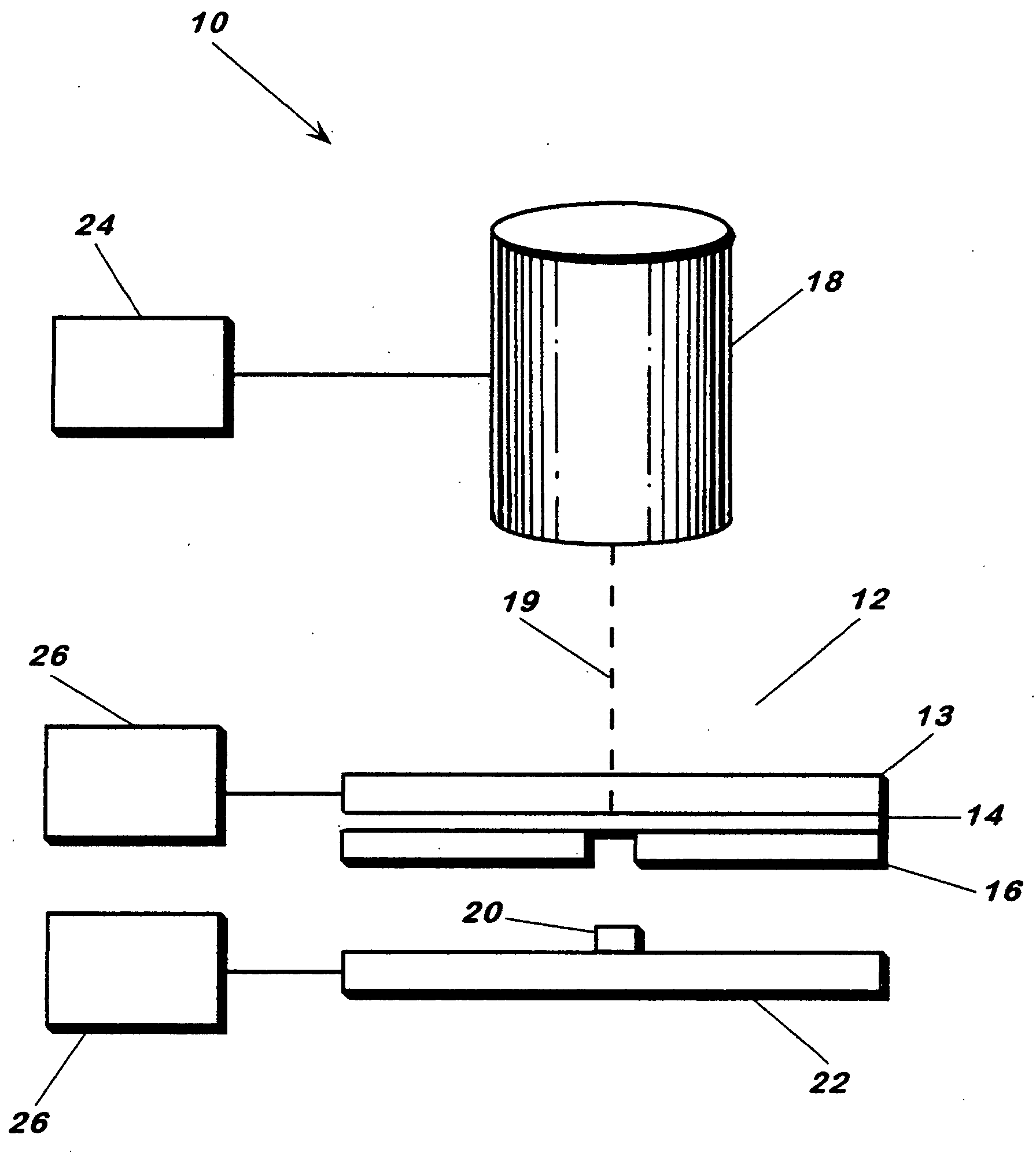

Induction microscanner

InactiveUS6285485B1Consumes less powerIncrease deflection angleDynamo-electric machinesOptical elementsControl electronicsPhysics

A micro-electromechanical scanner is disclosed for the efficient, controlled deflection of light beams. The device comprises a moving rotor, a suspension system, and a stator. The rotor comprises a closed-circuit coil and a mirror. The suspension system may be, for example, a set of torsion bars on which the rotor is mounted. The stator may be, for example, a rectangular frame holding the suspension system. When placed in a constant magnetic field and excited by an alternating magnet field, the rotor oscillates at the frequency of the alternating magnetic field, All else being equal, the highest deflection angles occur at the natural mechanical resonance frequency of the rotor-suspension combination. Compared to conventional devices, the novel device can be smaller, can be less expensive, can consume less power, and may exhibit higher deflection angles over a given time scale than other micromechanical devices operating on different actuation principles. The novel device may be used, for example, to replace the scanning devices currently used in laser printers, laser bar-code readers, and laser image projectors (e.g., large screen televisions). The control electronics may optionally be manufactured on the same device, eliminating the need for a separate controller and reducing costs.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

Biological laser printing via indirect photon-biomaterial interactions

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Weatherproof sheets for copying, printing and writing and methods related thereto

InactiveUS6863940B2Water-repelling agents additionSpecial ornamental structuresWater basedGeneral purpose

Weatherproof sheets, suitable for conventional printing, writing, photocopying, and laser printing, are prepared by impregnantly coating a cellulosic substrate on at least one side with a durable weatherproofing composition that is water-based. The composition that is used for general-purpose weatherproof sheets comprises a styrenic acrylic copolymer, a wax, a filler for blocking resistance, a filler for tooth, and a pigment. The preparation of all-purpose weatherproof sheets, usable in photocopiers and laser printers, is made possible by substantially omitting calcium carbonate and titanium dioxide from the composition. The weatherproof sheets resist falling apart, remain legible, and can be written upon when wet. They are also non-yellowing, biodegradable and recylclable. Also, disclosed are methods for making the weatherproof sheets, as well as weatherproof sheets made by those methods.

Owner:JL DARLING

Fuser and fusing roller useable in a printing process, laser printer, and method of printing

Owner:HEWLETT PACKARD DEV CO LP

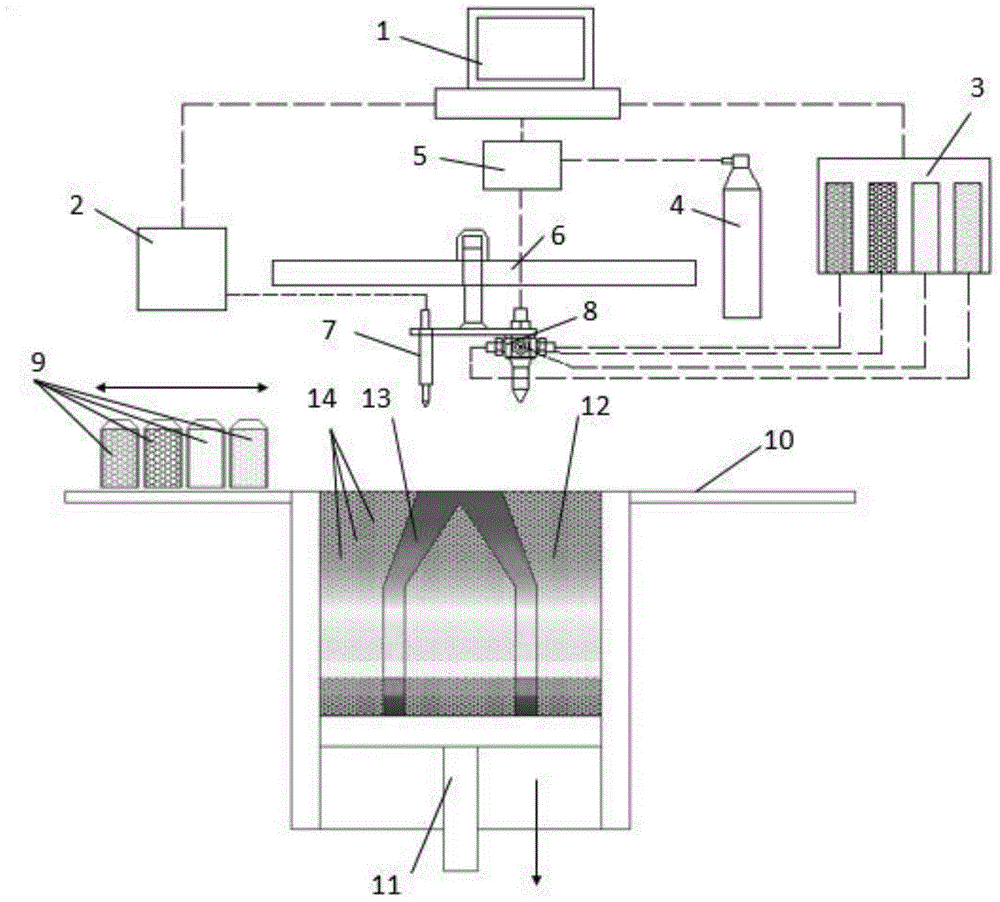

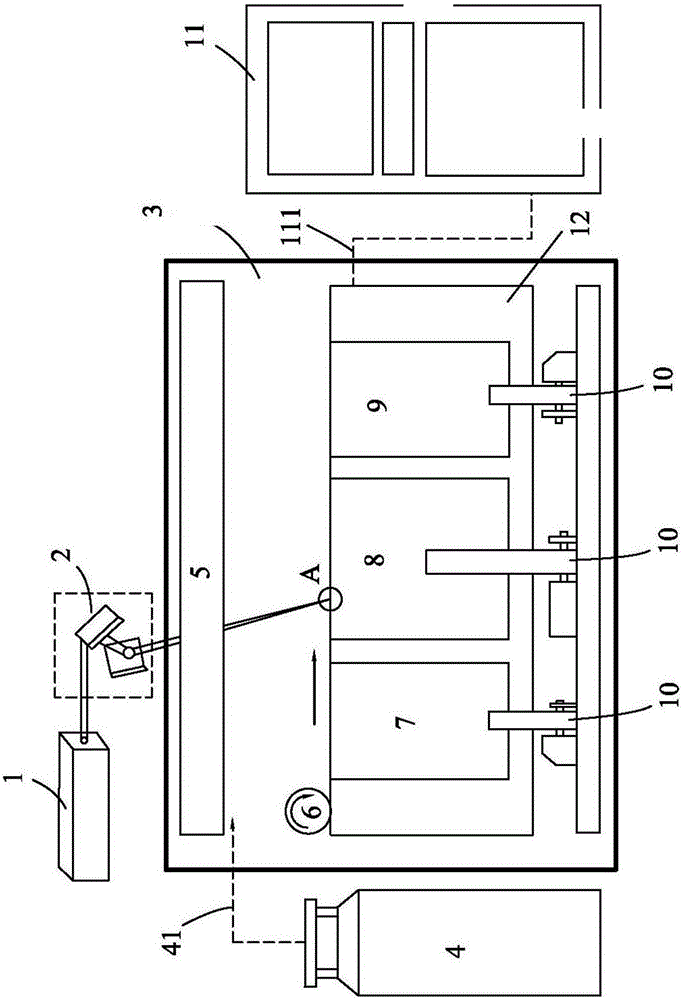

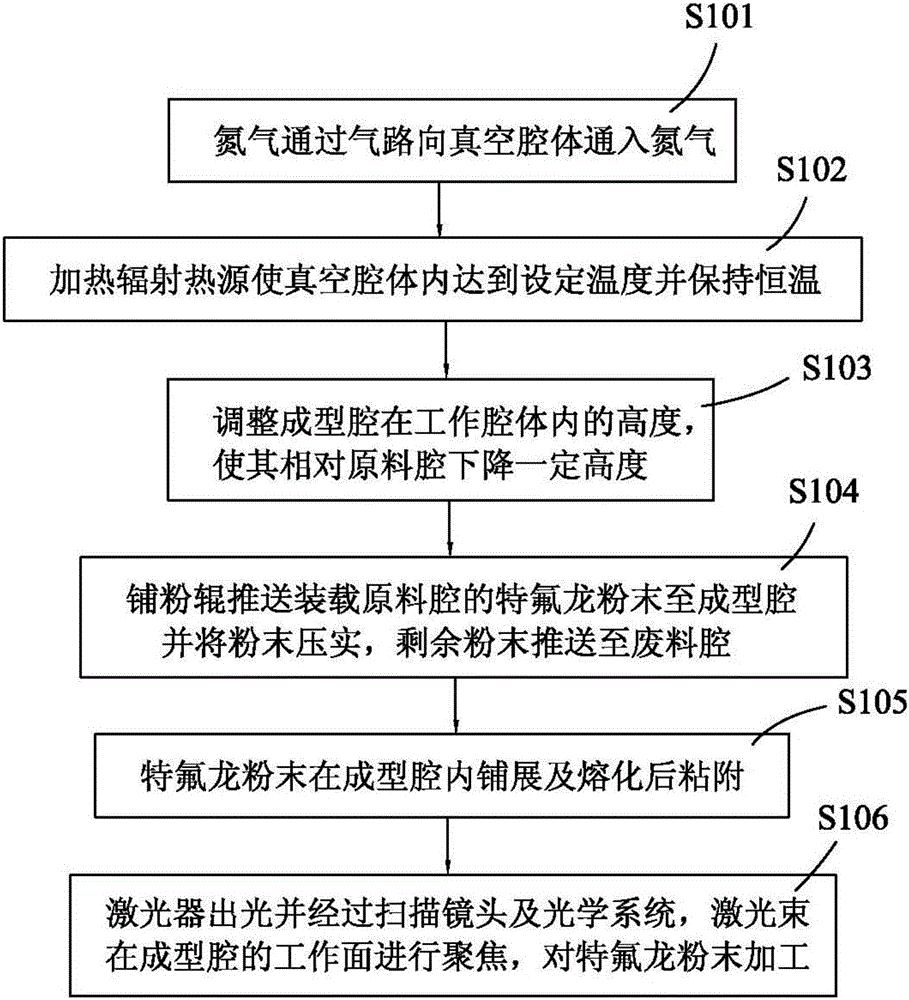

Laser 3D printing system and printing method thereof

InactiveCN105711104AEasy to processPersonalizeAdditive manufacturing apparatusGas cylinderEngineering

The present invention provides a laser 3D printing system and its printing method. The printing system includes: a laser, a scanning lens connected to the laser, an optical system, a vacuum cavity, a gas cylinder located outside the vacuum cavity, and a gas cylinder connected to the gas cylinder. And extend into the air pipe of the vacuum cavity, the working cavity and the radiant heat source positioned in the vacuum cavity, the powder spreading roller positioned on the working cavity, wherein the working cavity is provided with a raw material cavity, a molding cavity, and waste cavity. The present invention uses Teflon powder as consumables for 3D printing. By adopting laser selective sintering technology, the environment and process of molding are controlled at the same time. Efforts have been made to improve the detection and control of the already formed environment, and realize the rapid prototyping process that can use Teflon material series.

Owner:HANS LASER TECH IND GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com