3D printing method of gradient material structure

A technology of 3D printing and gradient materials, which is applied in the direction of improving process efficiency and improving energy efficiency, so as to achieve the effect of fast processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

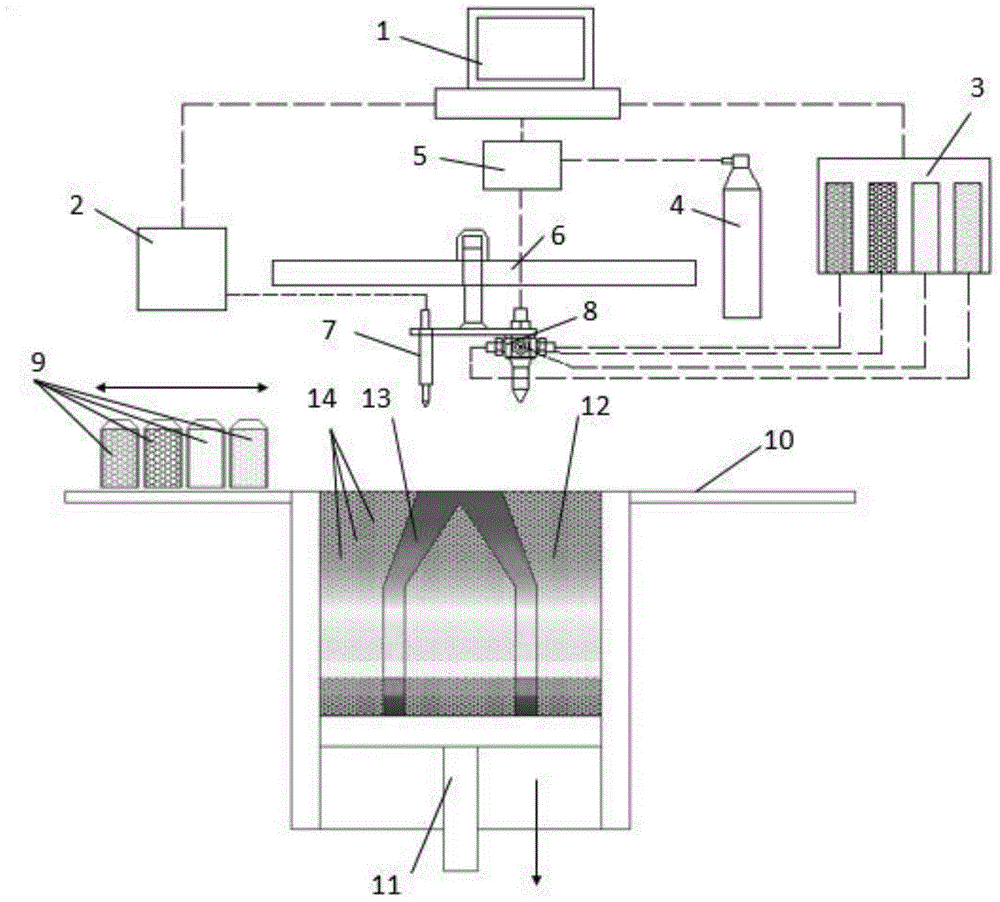

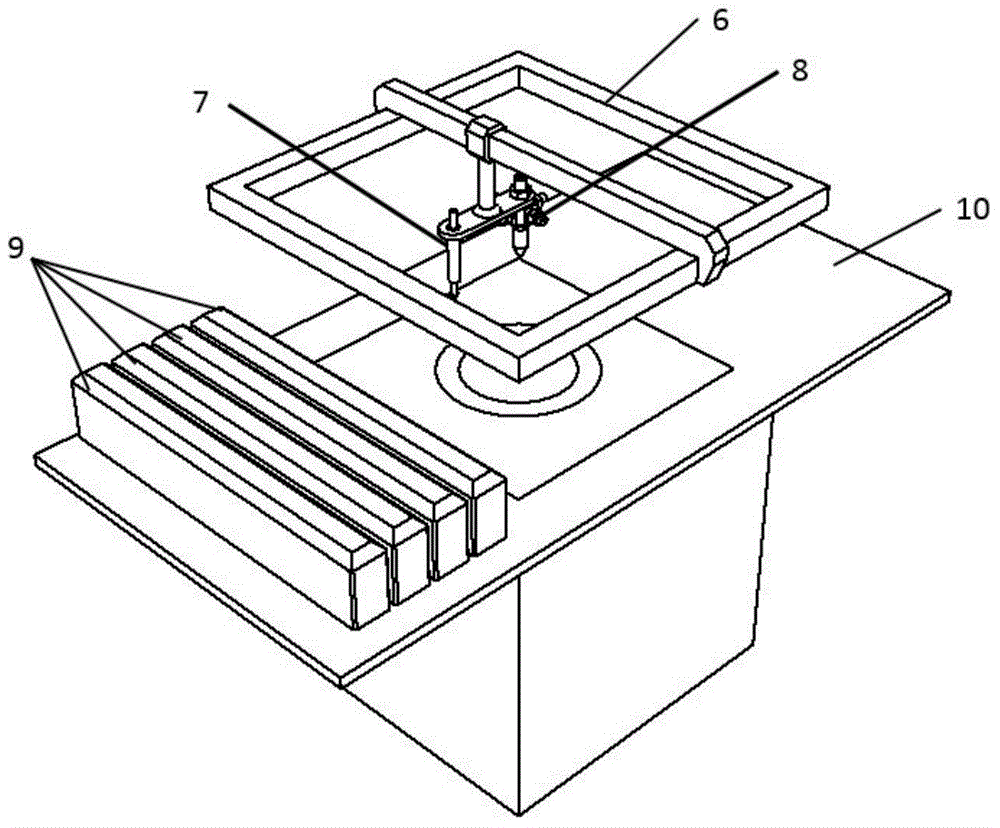

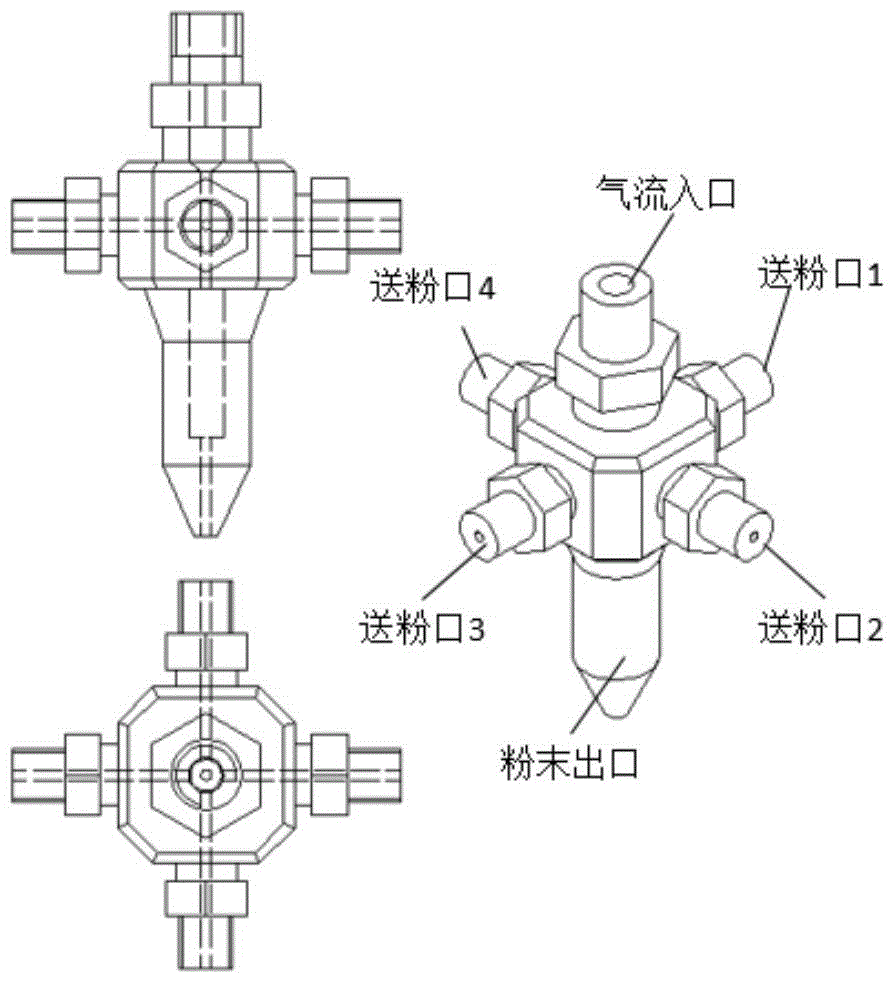

[0042] like figure 1 Shown is a schematic diagram of the principle of the 3D printing method of the gradient material structure of the present invention, where printing such as Figure 4 The gradient material structural member composed of four materials A, B, C, and D is shown as an example for illustration. Figure 4 Example printed components and layered schematic diagrams, this figure is only for illustration purposes, and is not intended to limit the present invention.

[0043] Figure 4 The structural part is a cylinder, which is divided into 10 layers, of which, 1, 2, 3, 4, 9, and 10 are single material layers; 5 is a longitudinal gradient material layer, gradually transitioning from material D to material C; 6 , 7 is the transverse gradient material layer, the material of the 6th layer gradually transitions from material B to material A from the inside to the outside, and the material of the 7th layer gradually transitions from material B to material C from left to ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com