Fabrication method of double-side PERC crystalline silicon solar cell

A technology of solar cells and crystalline silicon, applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., to achieve the effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

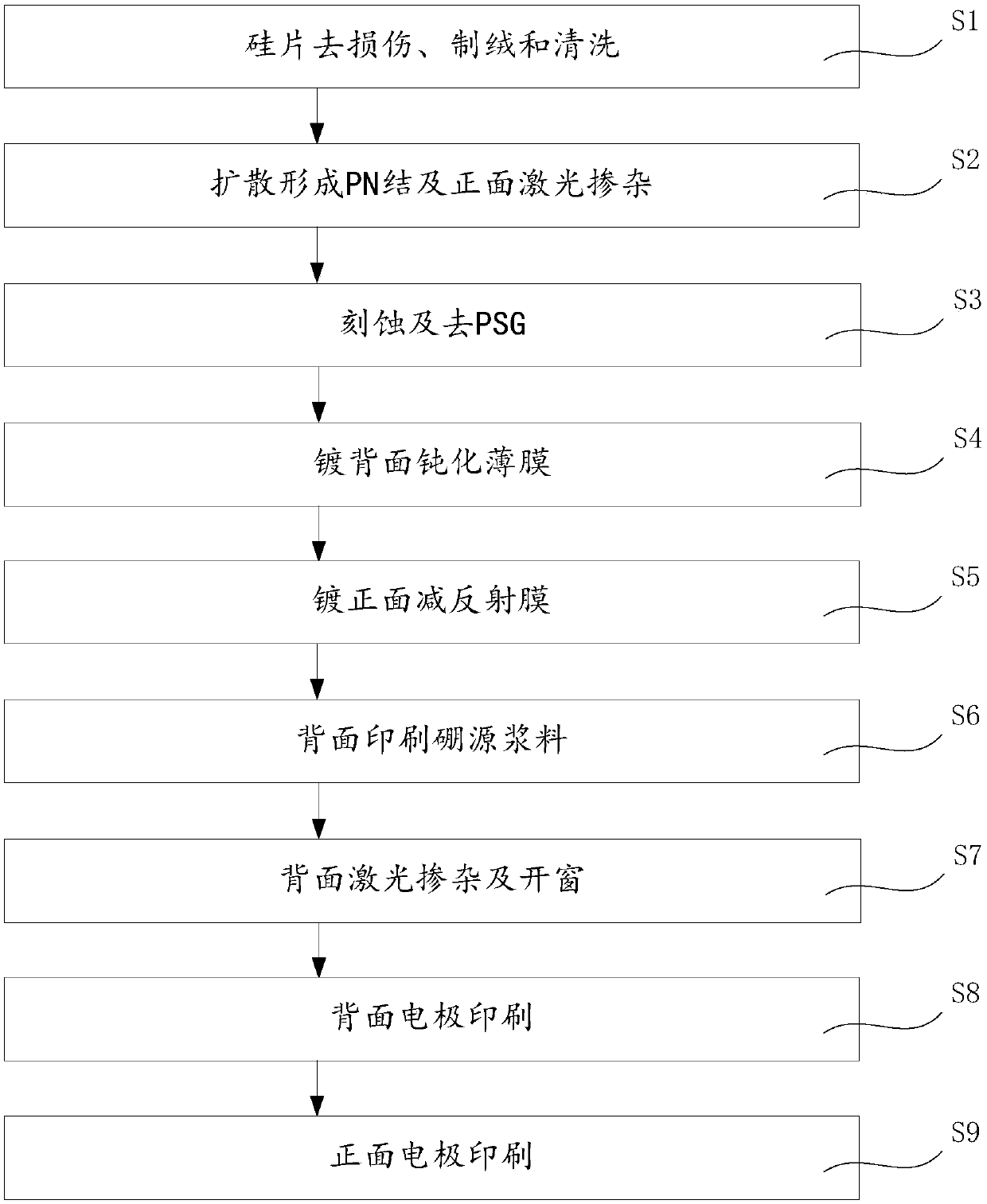

[0032] Such as figure 2 As shown, the preparation method of the double-sided PERC crystalline silicon solar cell provided by the embodiment of the present invention includes the following steps:

[0033] S1: Silicon wafer damage removal, texturing and cleaning: After removing the damaged layer of the silicon wafer, texture it in a lye and additive system at a temperature of 80-85°C to form a textured surface on the front and back of the silicon wafer, and then Cleaning in solution to remove surface impurities;

[0034] S2: Diffusion to form a PN junction and front-side laser doping: Perform high-temperature phosphorus diffusion on silicon wafers to form a PN junction. The diffusion temperature is 830-860°C, the diffusion time is 80-100 minutes, and the surface sheet resistance after diffusion is 130-160Ω / □ , use the laser to heat the front side of the silicon wafer, push the phosphorus atoms in the phosphosilicate glass into the PN junction, form the corresponding N++ layer,...

Embodiment 1

[0045] The manufacturing method of the double-sided PERC crystalline silicon solar cell provided in this embodiment includes the following steps:

[0046](1) Texturing: Select a P-type diamond wire-cut monocrystalline silicon wafer with a size of 156.75 mm×156.75 mm and a resistivity of 2.5 Ω cm as the base material, and put it into hydrogen oxide with a mass percentage concentration of 3% heated to 80°C. In a mixed solution of sodium and additives with a mass percentage concentration of 1.5%, the corrosion reaction takes 20 minutes, the thinning of the texture is 0.60g, and the size of the bottom of the pyramid of the texture is about 2.0mm. The additive is a conventional texture additive, and its main component is water. , IPA (isopropanol), NaOH, weak acid salt; after texturing, use HF / HCl mixed acid solution to clean the silicon wafers after texturing at room temperature, the volume percentage concentration of HF is 5%, and the volume percentage concentration of HCl is 5%. ...

Embodiment 2

[0058] The manufacturing method of the double-sided PERC crystalline silicon solar cell provided in this embodiment includes the following steps:

[0059] (1) Texturing: select 156.75mm * 156.75mm, the P-type diamond wire-cut monocrystalline silicon slice of resistivity 2Ω cm as the base material, put into the mass percentage concentration that is heated to 80 ℃ and be 3% sodium hydroxide, In an additive mixed solution with a mass percentage concentration of 1.5%, the corrosion reaction takes 18 minutes, the thinning of the textured surface is 0.55 g, and the bottom size of the pyramid of the textured surface is about 1.8 mm; after the textured surface, the mixed acid solution of HF / HCl is used to clean the textured textured surface at room temperature. For silicon wafers, the concentration of HF volume percentage is 4%, the volume percentage concentration of HCl is 4%, and the surface reflectance of silicon wafers after texturing is 10.5%;

[0060] (2) Diffusion: The method o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com