TC21 titanium alloy powder for laser 3D printing and preparation and using methods

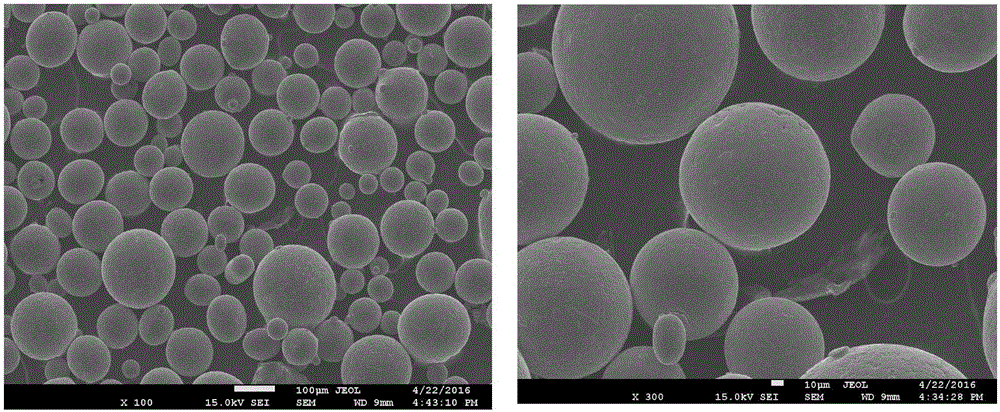

A 3D printing, TC21 technology, applied in the direction of metal processing equipment, additive manufacturing, transportation and packaging, etc., can solve the problems of high strength increase the difficulty of forming, titanium alloy is not easy to hot form, high equipment requirements, etc., to achieve low oxygen content, The effect of smooth surface, good fluidity and low defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] A TC21 titanium alloy powder for laser 3D printing, the composition is by mass percentage: Al: 5.8%, Sn: 1.9%, Zr: 1.8%, Mo: 2.5%, Cr: 1.2%, Nb: 1.9%, Fe: 0.005 %, C: 0.006%, N: 0.009%, H: 0.003%, O: 0.1%, and the balance is Ti.

[0090] The above-mentioned preparation method of TC21 titanium alloy powder for laser 3D printing specifically comprises the following steps:

[0091] Step 1, preprocessing:

[0092] (1) The raw material TC21 titanium alloy is made into a cylinder as an electrode titanium rod. The diameter of the bottom surface of the cylinder is 50mm and the length is 1000mm; then one end of the electrode titanium rod is processed into a 40-degree conical tip with a surface roughness of Ra12 .5. On the other end of the electrode titanium rod, process an annular slot with a width of 8mm and a depth of 4mm, 6mm away from the port of the titanium rod;

[0093] (2) Clean the electrode titanium rod and install it on the electrode control system in the vacuum ind...

Embodiment 2

[0138] A TC21 titanium alloy powder for laser 3D printing, the composition is by mass percentage: Al: 5.9%, Sn: 2.2%, Zr: 2.0%, Mo: 2.6%, Cr: 1.5%, Nb: 1.9%, Fe: 0.006 %, C: 0.006%, N: 0.002%, H: 0.003%, O: 0.08%, and the balance is Ti;

[0139] The above-mentioned preparation method of TC21 titanium alloy powder for laser 3D printing specifically comprises the following steps:

[0140] Step 1, preprocessing:

[0141] (1) The raw material TC21 titanium alloy is made into a cylinder as an electrode titanium rod. The diameter of the bottom surface of the cylinder is 50mm and the length is 1000mm; then one end of the electrode titanium rod is processed into a 40-degree conical tip with a surface roughness of Ra12 .5. On the other end of the electrode titanium rod, process an annular slot with a width of 8mm and a depth of 4mm, 6mm away from the port of the titanium rod;

[0142] (2) Clean the electrode titanium rod and install it on the electrode control system in the vacuum in...

Embodiment 3

[0189] A TC21 titanium alloy powder for laser 3D printing, the composition is by mass percentage: Al: 6.5%, Sn: 2.4%, Zr: 2.2%, Mo: 2.9%, Cr: 1.5%, Nb: 1.9%, Fe: 0.016 %, C: 0.011%, N: 0.005%, H: 0.006%, O: 0.09%, and the balance is Ti.

[0190] The above-mentioned preparation method of TC21 titanium alloy powder for laser 3D printing specifically comprises the following steps:

[0191] Step 1, preprocessing:

[0192] (1) The raw material TC21 titanium alloy is made into a cylinder as an electrode titanium rod. The diameter of the bottom surface of the cylinder is 50mm and the length is 1000mm; then one end of the electrode titanium rod is processed into a 40-degree conical tip with a surface roughness of Ra12 .5. On the other end of the electrode titanium rod, process an annular slot with a width of 8mm and a depth of 4mm, 6mm away from the port of the titanium rod;

[0193] (2) Clean the electrode titanium rod and install it on the electrode control system in the vacuum in...

PUM

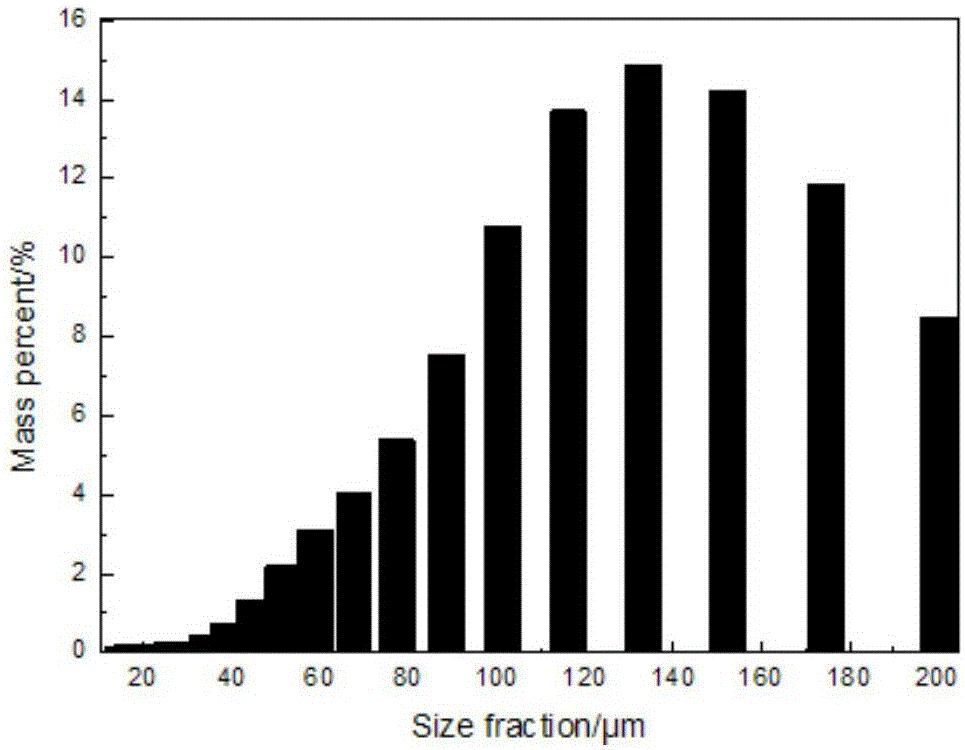

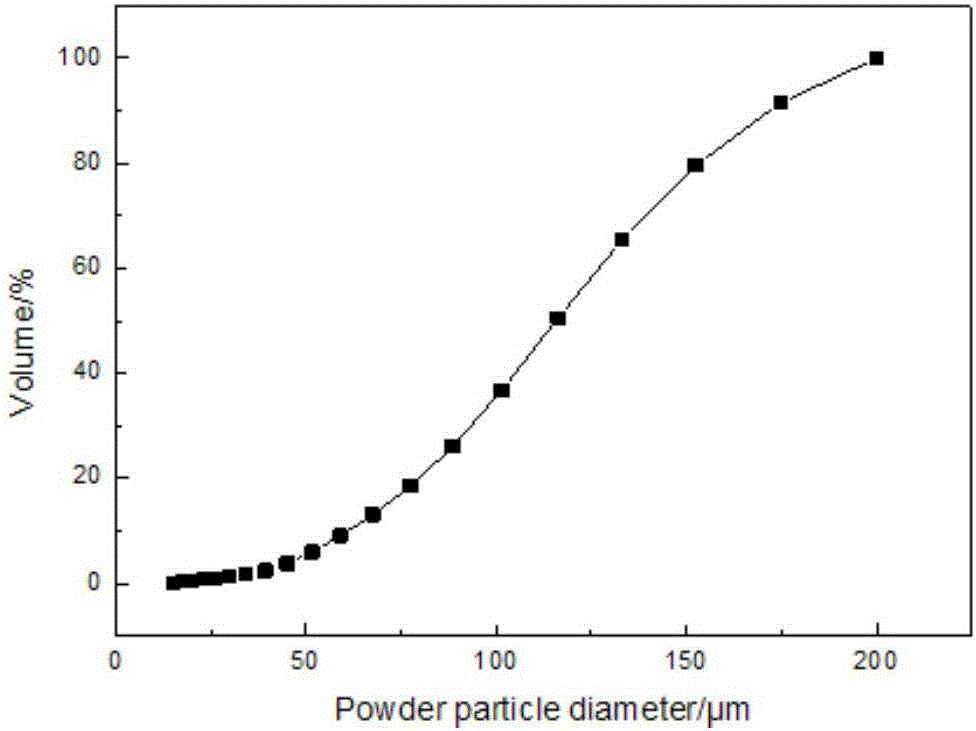

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com