Laser 3D printing system and printing method thereof

A 3D printing and laser technology, applied in the field of Teflon processing, can solve the problems of long production cycle, high customization cost, limited structure and material, etc., and achieve the goal of improving processing capacity, expanding applicable fields, and fast processing of special structures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

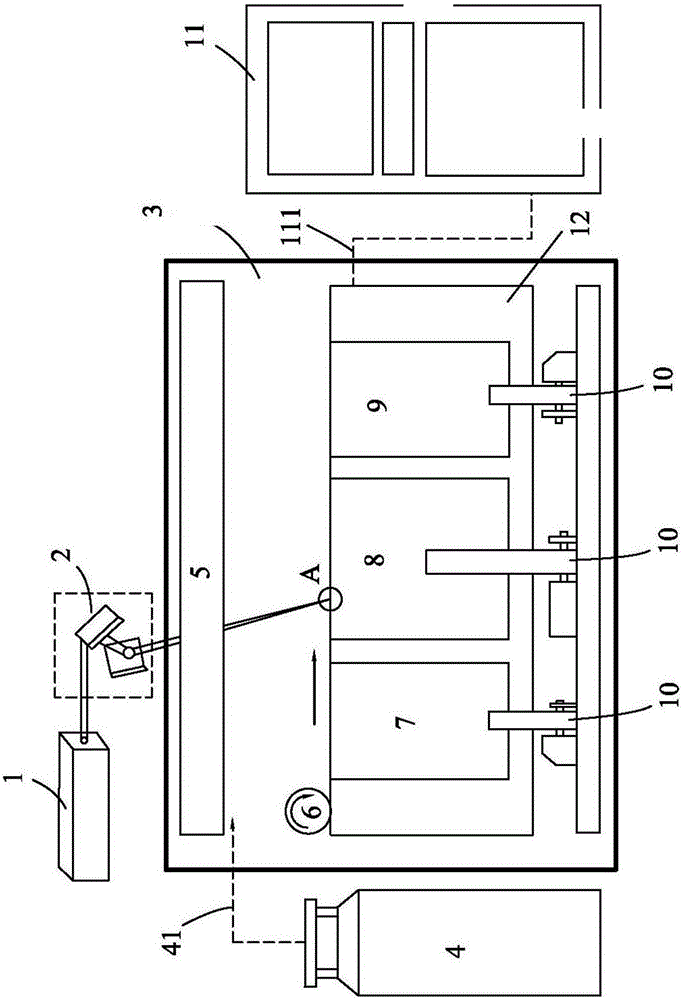

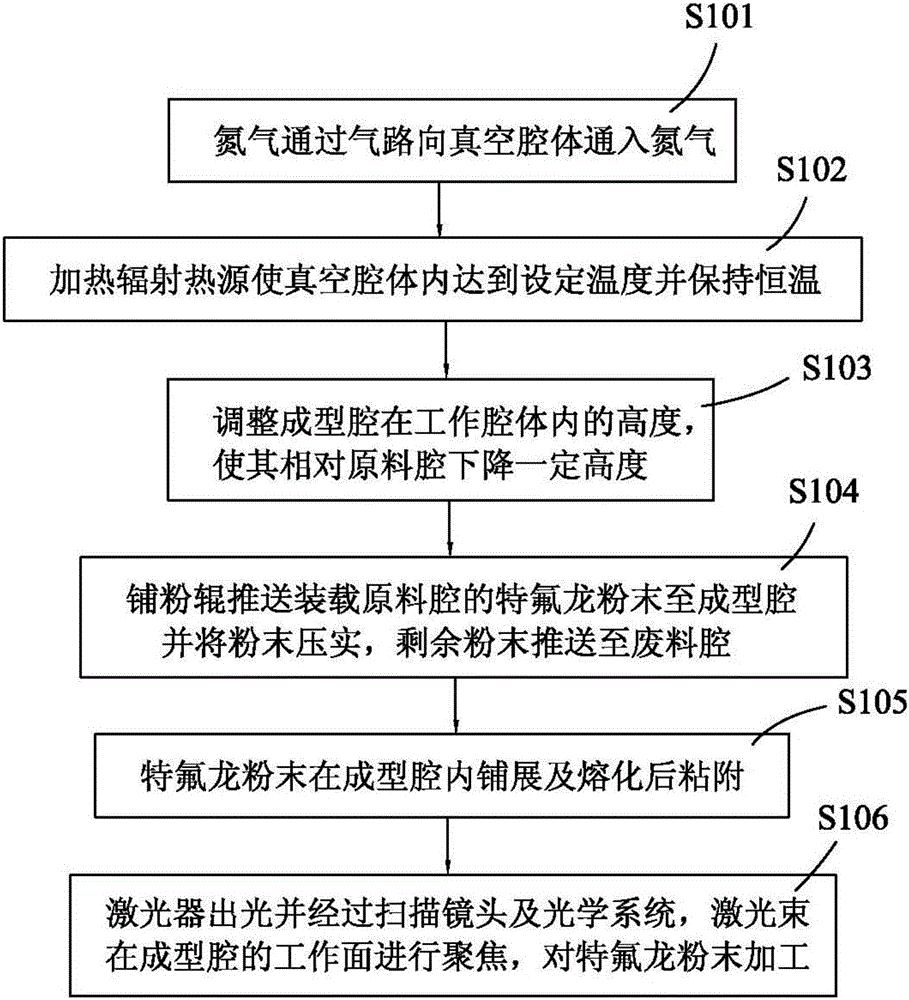

[0021] figure 1 It is a schematic diagram of a laser 3D printer system according to an embodiment of the present invention. The present invention adopts laser selective sintering technology, and laser selective sintering (Selected Laser Sintering, SLS) uses a CO2 laser to process powder materials (plastic powder, ceramic and binder mixed powder) , mixed powder of metal and binder, etc.) for selective sintering is a process method in which discrete points are piled up layer by layer into a three-dimensional entity.

[0022] The laser 3D printing system includes: a laser 1, a scanning lens connected to the laser 1 and an optical system 2, a vacuum chamber 3, a gas cylinder 4 outside the vacuum chamber 2 and a control system 11, which is connected to the gas cylinder 4 and The air pipe 41 extending into the vacuum cavity 3, the working cavity 12 and the radiant heat source 5 in the vacuum cavity 3, the powder spreading roller 6, the raw material cavity 7, the molding cavity 8, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com