Maze conformal cooling method and structure of mold

A conformal cooling and mold cooling technology, applied in the field of mold manufacturing, can solve the problems of straight-hole runners that cannot be evenly approached, small mold contact area, uneven cooling effect, etc., to shorten the injection molding process cycle, uniform cooling effect, improve The effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

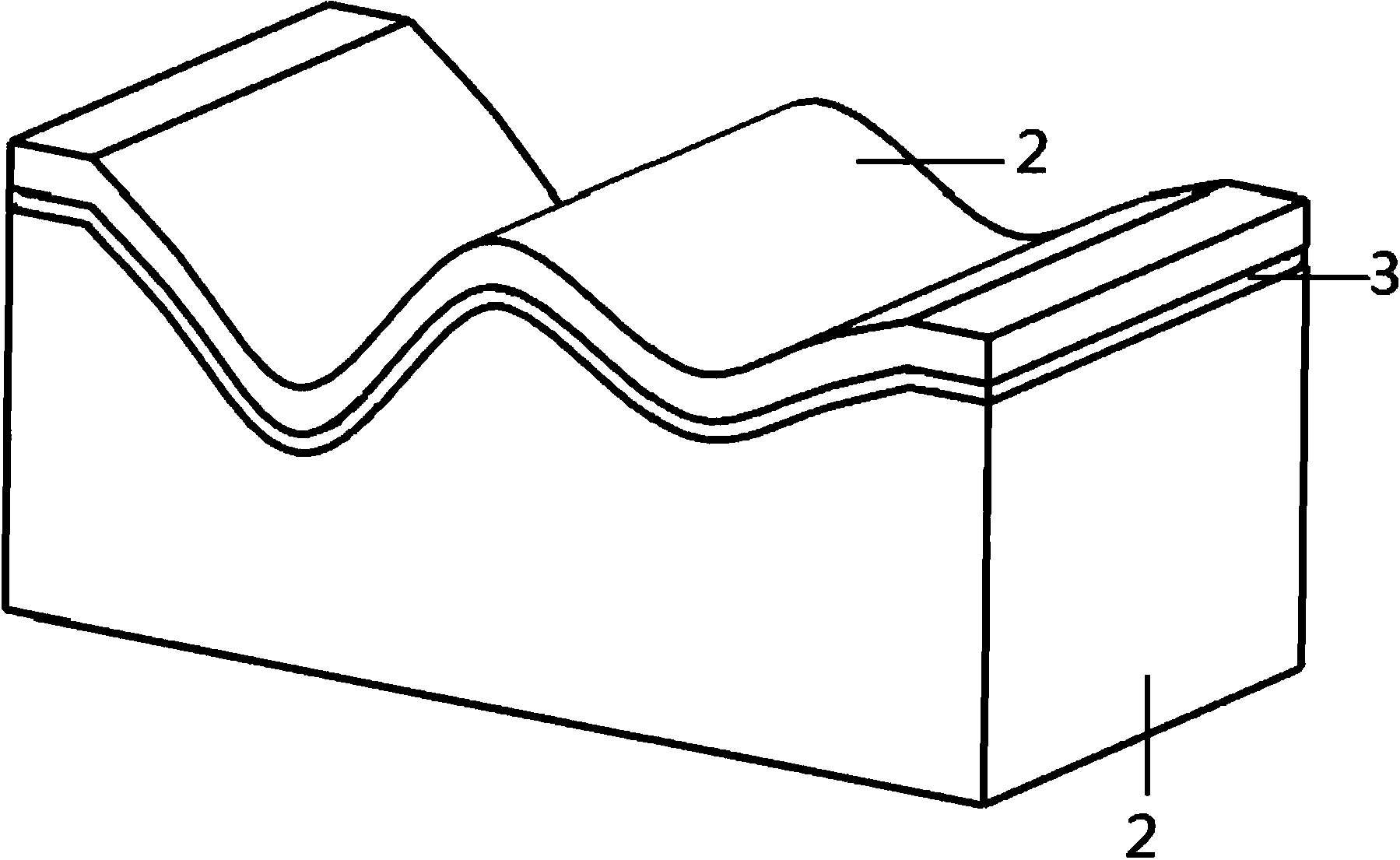

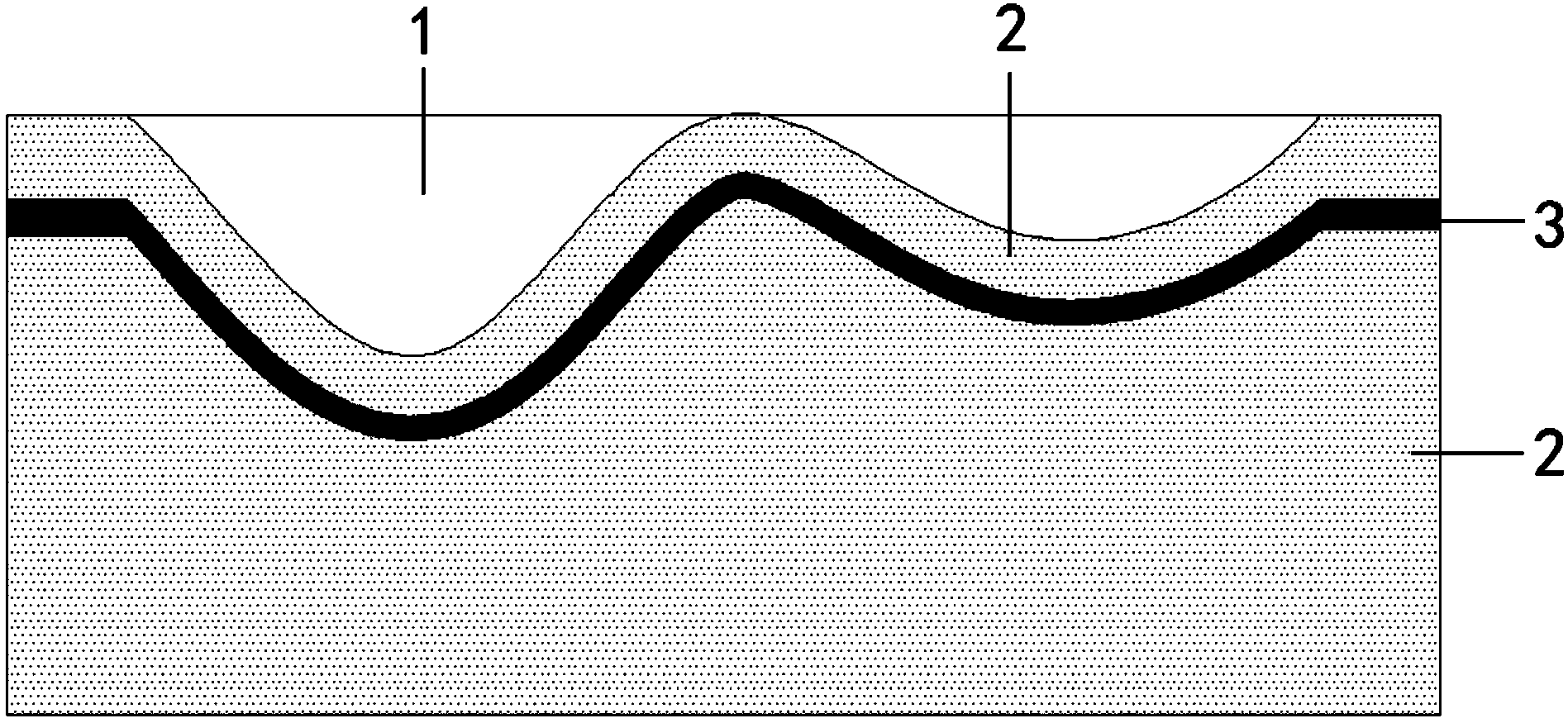

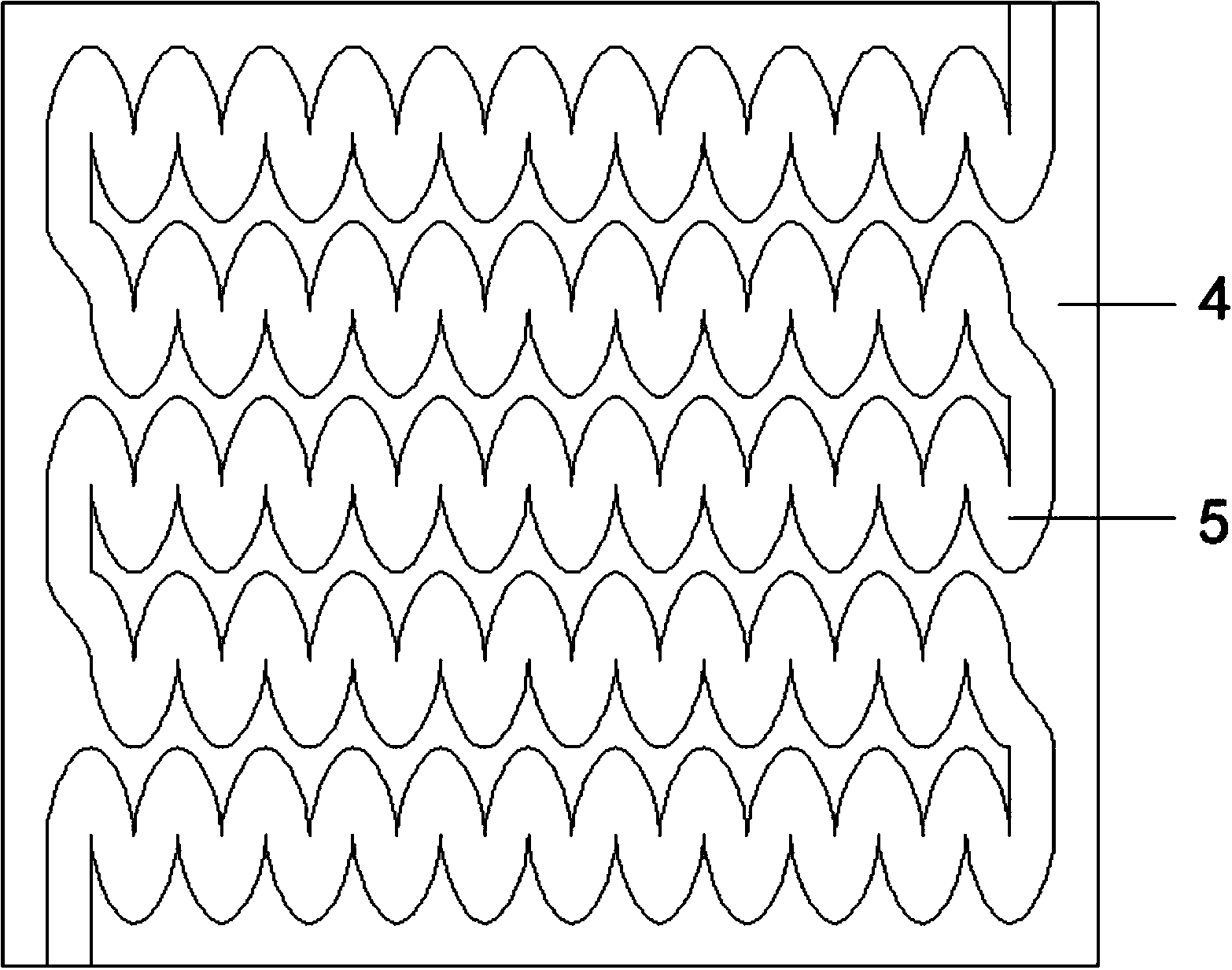

[0015] In the method provided by the invention, a cooling layer is set at a certain distance from the surface of the mold, and labyrinth flow channels are distributed in the cooling layer. Laminar cooling increases the contact area between the cooling medium and the mold, and at the same time, the cooling medium in the labyrinth flow channels will generate a strong In the turbulent flow state, the cooling efficiency is further increased compared with the tubular conformal cooling method.

[0016] The mold with the labyrinth conformal cooling layer provided by the invention has a hollow layer nearly parallel to the inner surface of the mold cavity inside the mold body. The position of the labyrinth cooling layer is set according to the change of the heat dissipation of the part: at the hot joint part with large wall thickness, the cooling layer is close to the cavity; at the part with small heat dissipation, the cooling layer is properly far away from the cavity. Realize contin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com