Steam heating type fast heat-circulation injection mould

A technology of injection mold and thermal cycle, which is applied in the field of injection molding of material processing discipline, can solve problems such as inability to adapt, and achieve the effect of compact mold structure, high thermal response efficiency, uniform heating and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

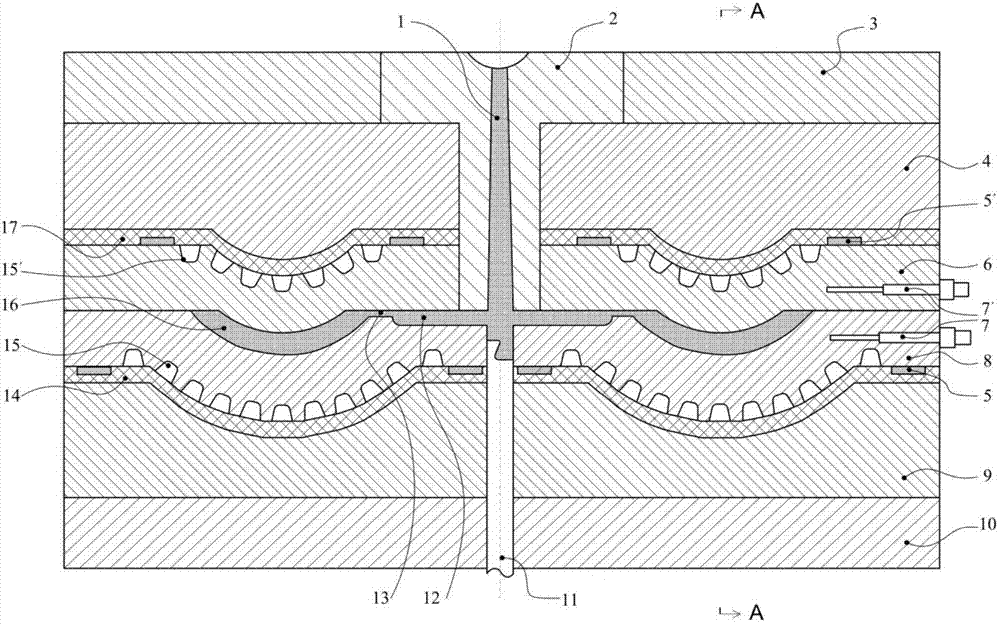

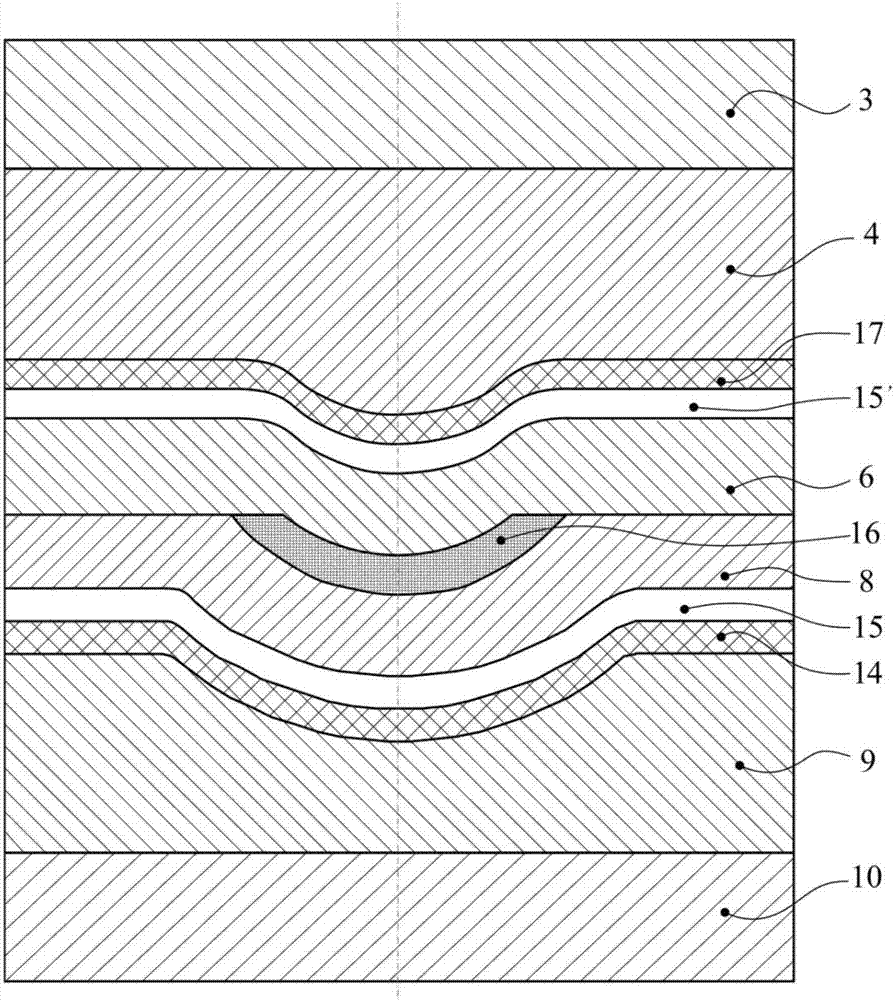

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

[0024] The cavity side of the steam-heated rapid thermal cycle injection mold includes a cavity plate 8, a cavity heat insulating plate 14, a cavity support plate 9, a fixing plate 10, a pull rod 11, and the like. The cavity heat insulating plate 14 is located between the cavity plate 8 and the cavity supporting plate 9; The surface of the cavity support plate 9 is a pair of mating surfaces; the first sealing gasket 5 is arranged between the cavity plate 8 and the cavity insulation plate 14; the back of the cavity plate 8 has a similar profile to its surface, and the cavity plate 8 A large number of conformal grooves are evenly distributed on the back of the cavity, and the distance between each groove and the surface of the cavity is uniform; the groove on the back of the cavity plate 8 and the surface of the cavity insulation plate 14 form a closed pipeline,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com