Preparation method of graphene-polyester nanometer composite fiber

A nanocomposite fiber and graphene technology, applied in fiber processing, fiber chemical characteristics, melt spinning, etc., can solve problems such as uneven fiber texture, different drawing time, and unstable spinning quality, and achieve high spinning quality High, uniform cooling effect, improve the effect of uniform cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

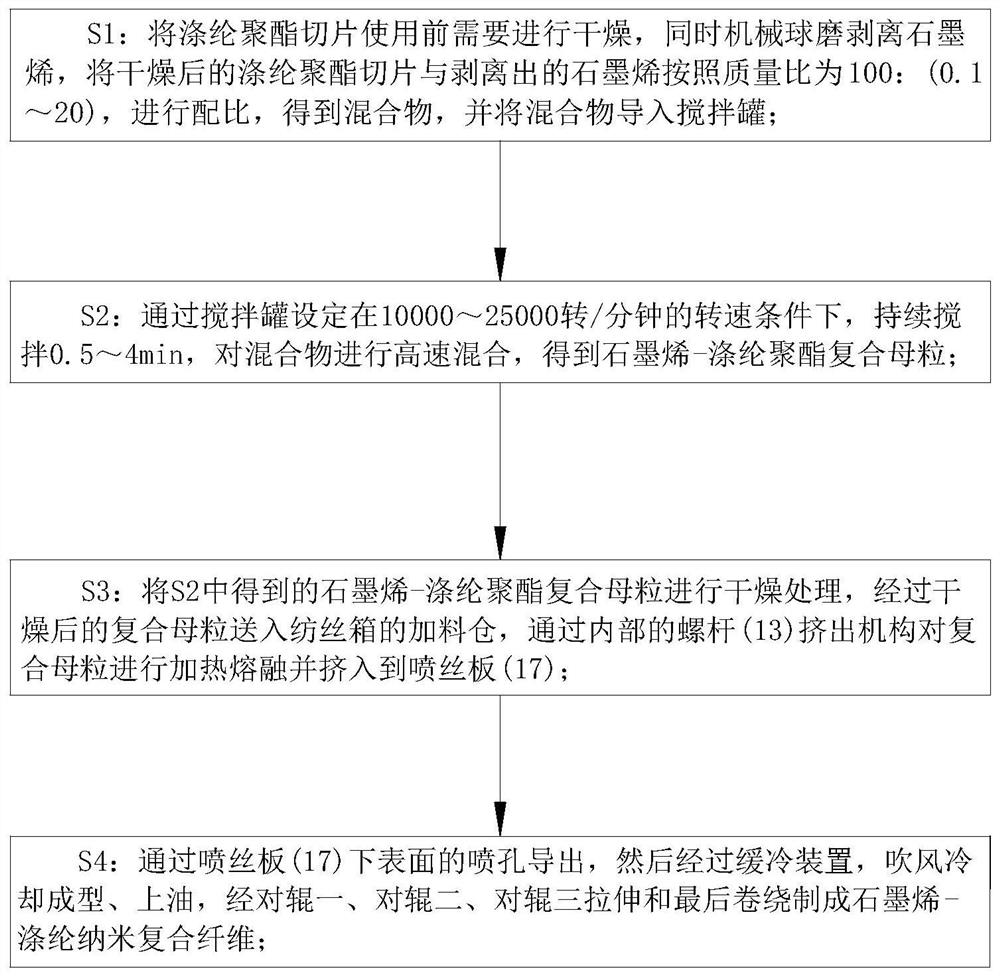

[0028] Such as Figure 1 to Figure 5 Shown, the preparation method of a kind of graphene-polyester nanocomposite fiber of the present invention, this preparation method comprises the following steps:

[0029] S1: The polyester polyester chips need to be dried before use, and at the same time, the graphene is peeled off by mechanical ball milling, and the dried polyester polyester chips and the peeled graphene are mixed according to the mass ratio of 100:0.1~20 to obtain a mixture , and introduce the mixture into the stirring tank; graphene, as a two-dimensional honeycomb crystal composed of carbon atoms, has unparalleled mechanical properties and functionalities such as electrical conductivity, thermal conductivity, antibacterial, and radiation resistance. It is currently the thinnest known , the material with the highest strength, so compared with the prior art, the breaking strength of the graphene-polyester nanocomposite fiber has been greatly improved;

[0030] S2: Set th...

Embodiment approach

[0034] As an embodiment of the present invention, the front and rear longitudinal sections of the air guide rod 3 are designed with a triangular structure; the opposite sides of the air guide rod 3 are designed with a tapered structure; The cross-section of the rod 3 is designed as a triangular structure. When the spinning fiber is pulled down and passes through the air guide rod 3, it can be pulled more smoothly, reducing the resistance effect of the air guide rod 3 on the downward pulling of the spinning fiber, and avoiding air guide The rod 3 causes a large area of broken filaments in the spinning fiber. At the same time, the end surface of the air guide rod 3 is designed as a tapered structure. fibers, causing breakage of the spun fibers.

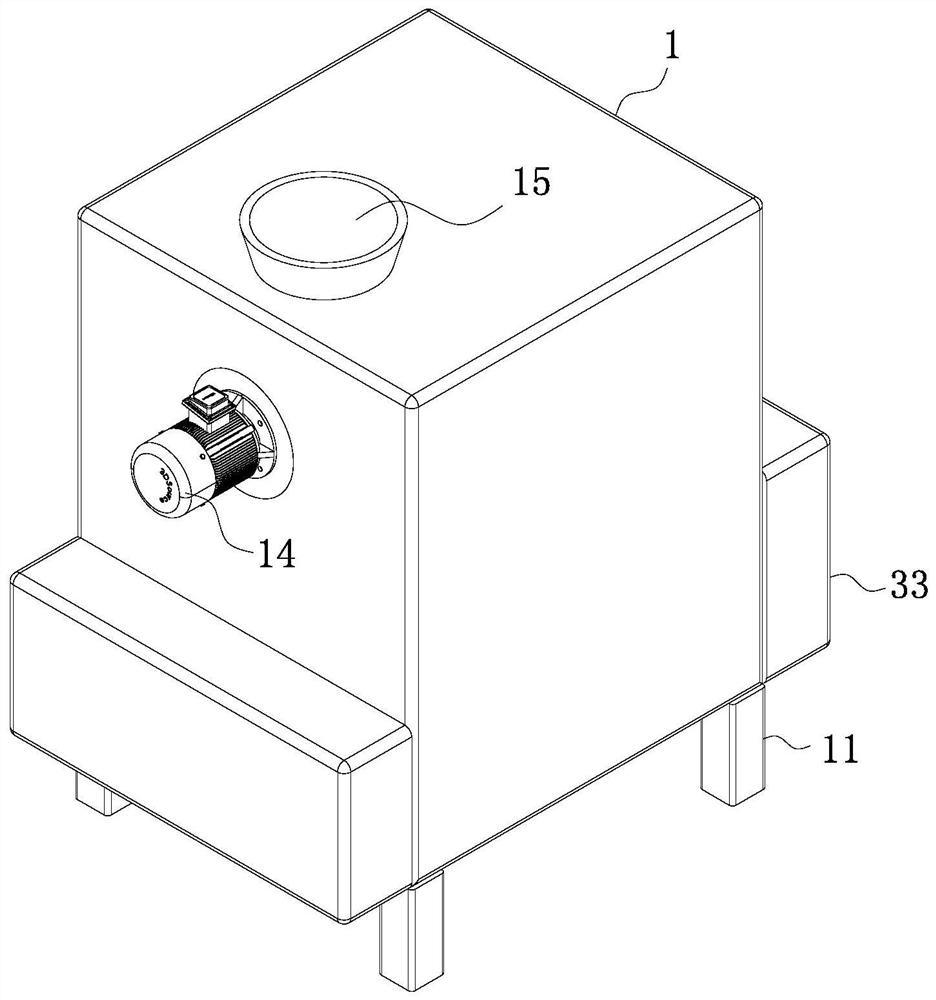

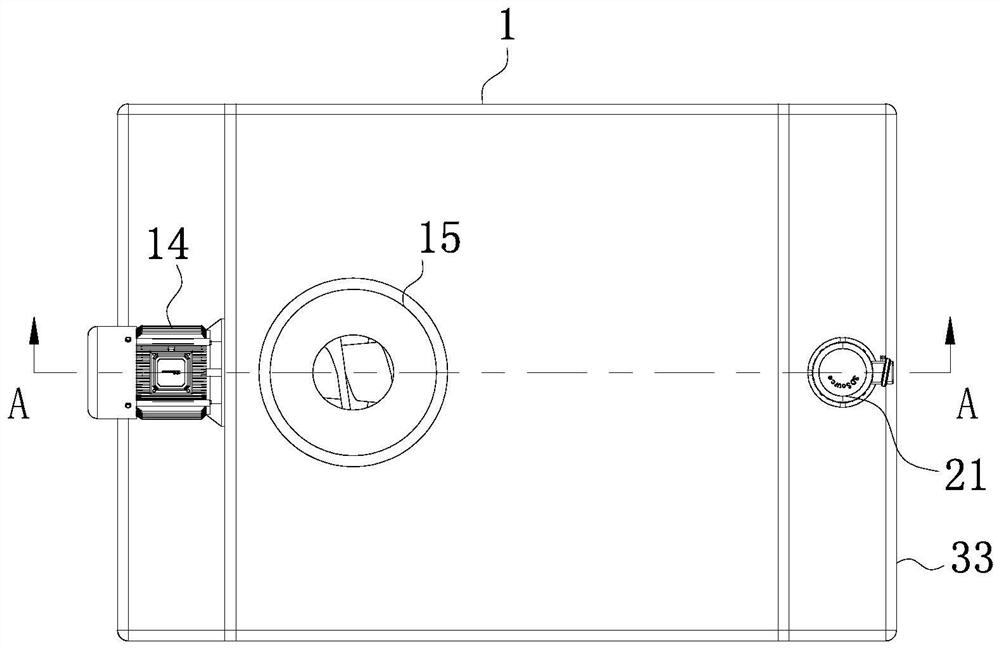

[0035] As an embodiment of the present invention, the left and right sides of the box body 1 are fixedly connected with fixing blocks 33 at the position of the cold plate 31; Both are provided with chute, and the cold plate 31 is all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com