Treatment method for removing nitrogen oxides by virtue of ozone function

A nitrogen oxide and treatment method technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as poor adaptability, difficult to handle by-products, increase production costs of enterprises, etc., to improve oxidation efficiency, good oxidation Response, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

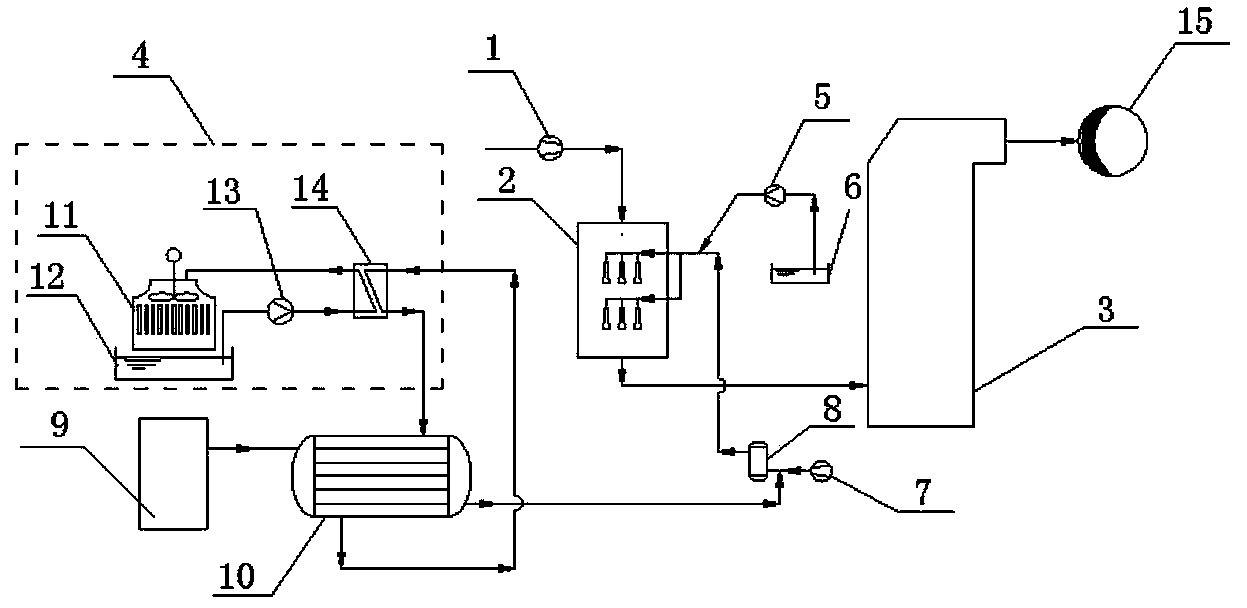

[0031] Such as figure 1 shown, as figure 1 As shown, a treatment device for removing nitrogen oxides by using ozone, including a booster fan 1, an ozone dosing distributor 2, an absorption tower 3, a cooling system 4, a water pump 5, a water tank 6, a dilution fan 7, and a gas source 9, mixer 8, ozone generator 10, one end of the ozone generator 10 is connected to the gas source 9, and the other end is connected to the end of the mixer 8 after being communicated with the dilution fan 7 through a pipeline, and the other end of the mixer 8 is connected to the The water pump 5 is connected to the ozone dosing distributor 2 after being communicated through the pipeline; the top of the ozone dosing distributor 2 is connected to the booster fan 1, and the bottom is connected to the absorption tower 3, and the cooling system 4 is bidirectionally connected to the ozone generator 10 , the lower end of the water pump 5 is provided with a water tank 6; the cooling system 4 includes a co...

Embodiment 2

[0038] The processing device of the present invention is applied to the actual desulfurization and denitrification integrated wet process system of 2x40T heating industrial boilers, and the inlet flue gas volume is 185,000 m 3, the temperature of the flue gas is 90-130 degrees, the flue gas passes through the boiler induced draft fan of the bag filter from the boiler, enters the ozone dosing distributor 2 in the flue, and uses the ozone generated by the ozone generator 10 to pass through the cooling system 4 and the dilution fan 7 is diluted and enters the mixer 8, and then enters the ozone dosing distributor 2 in the flue to generate an oxidation reaction with the flue gas, and the oxidized flue gas enters the absorption tower 3 for absorption reaction.

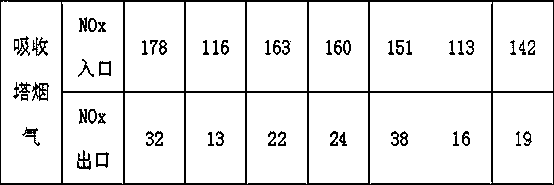

[0039] Inlet NOx content is 110~280mg / m 3 , the export content sampling results are as follows:

[0040]

[0041] Absorbent water is added to the absorption tower 3, and the flue gas is absorbed and washed by water and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com