Fuel oxidation adsorption desulfurization technology and device thereof

An adsorption desulfurization and oxidative desulfurization technology, which is applied in the petroleum industry, multi-stage series refining process treatment, hydrocarbon oil treatment, etc., can solve the problems of high liquid recovery loss, complicated separation process, and difficulty in demulsification and dehydration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

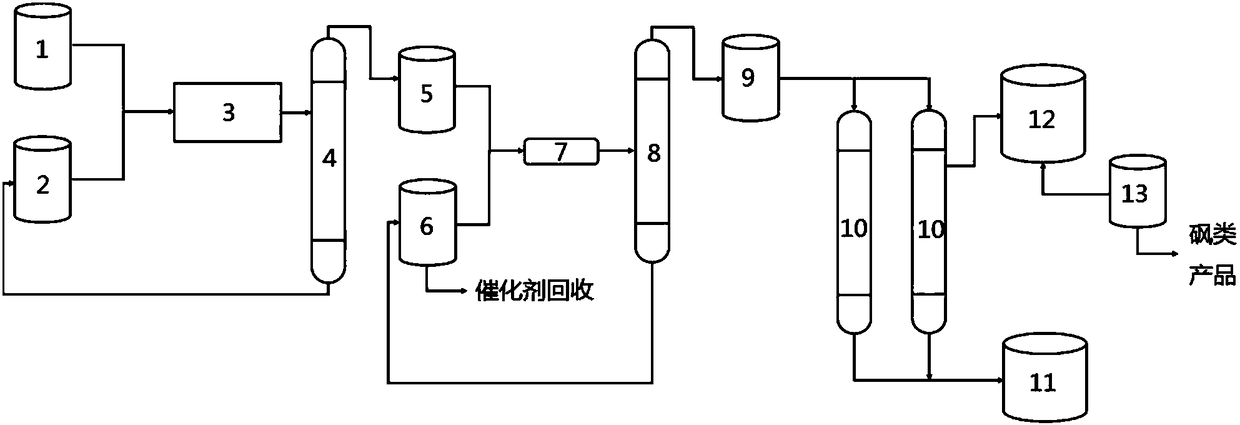

Method used

Image

Examples

Embodiment 1

[0034] The preparation of metal peroxide refers to literature W.Winter, C.Mark, V.Schurig, Inorganic Chemistry 1980,19,2045-2048.,

[0035] 1) MoO(O 2 ) 2 (molybdenum peroxide) preparation: take by weighing 50g MoO 3 and 150ml 30% H 2 o 2 Transfer the aqueous solution into a 500ml round bottom flask, stir overnight at 60°C, filter and separate, add N,N'-dimethylformamide (DMF) solvent to the collected filtrate, refrigerate and crystallize in the refrigerator for 2 days, and the precipitated crystals are pumped filtered and dried to obtain MoO(O 2 ) 2 • 2DMF (43.8g).

[0036] 2)WO(O 2 ) 2 (Tungsten peroxide) Preparation of hydrogen peroxide solution: Weigh tungstic acid (100g), dissolve in 500ml H 2 o 2 solution, stirred at room temperature for 24h, centrifuged, and the liquid product was collected as WO(O 2 ) 2 of hydrogen peroxide solution.

[0037] The preparation method of the catalyst refers to the literature S.E.Jacobson, R.Tang, F.Mares, Inorg Chem1978,17,30...

Embodiment 2

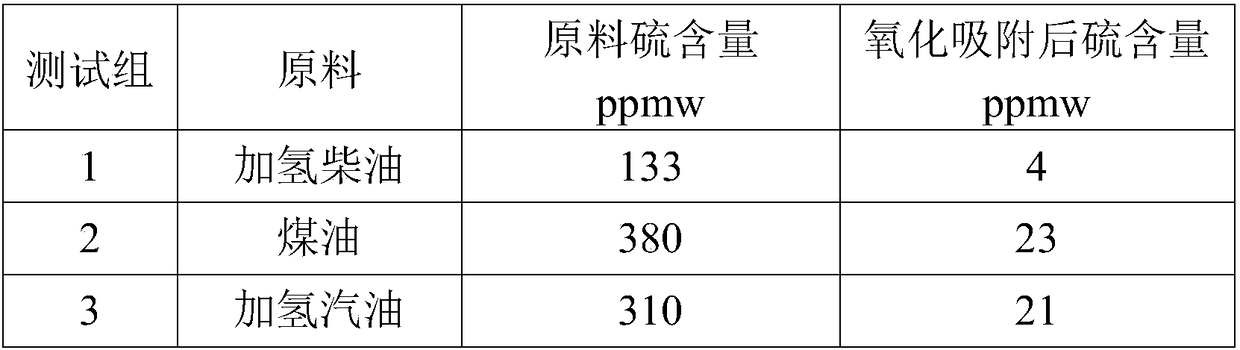

[0040] Set up test groups 1, 2, and 3, and take 1000ml of raw fuel oil hydrogen (diesel, kerosene or hydrogenated gasoline) and 1000ml of working fluid into the T-shaped microreactor respectively. The preparation method of described working liquid is: in embodiment 1, molybdenum-based catalyst MoO(O 2 ) 2 Me 2 The concentration of bpy is 2.5 mg / L, the oxidizing agent is ammonium persulfate, and the solvent is a methanol-water mixed solution with a volume percentage of methanol of 10%. The oxygen-sulfur molar ratio of the oxidant to the fuel oil is 12. The volume space velocity is 10h -1 , the reaction temperatures were 60, 40, and 30°C, and the reaction pressures were 0.2, 0.2, and 0.25 MPa. After separation, centrifugation, and desulfone adsorption through Y-type molecular sieves, the sulfur content analysis results before and after the reaction are shown in Table 1.

[0041] Table 1

[0042]

Embodiment 3

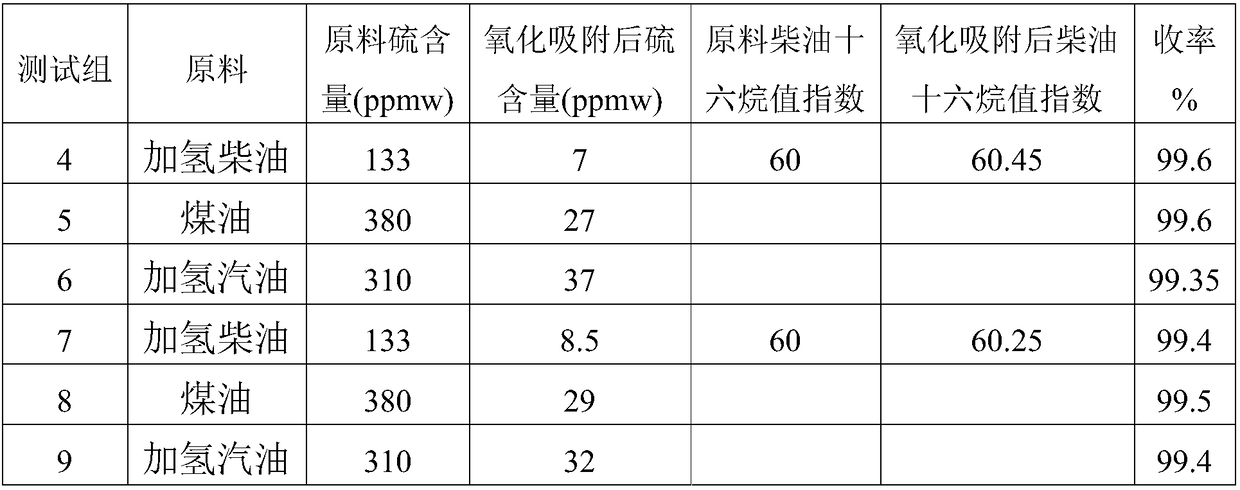

[0044] Set test group 4~9, take diesel oil, kerosene or hydrogenated gasoline respectively as raw material fuel oil (as table 2) and pump into straight pipe static mixer with working fluid mixing, the preparation method of described working fluid is: the tungsten in embodiment 1 The concentration of the base catalyst bipyridyl tungsten peroxide complex is 2.5 mg / L, the solvent is water, and the oxidant is hydrogen peroxide. The molar ratio of oxygen to sulfur is 20, and the volumetric space velocity is 4h -1 , the reaction temperatures were 60, 40, and 30°C, and the reaction pressures were 0.35, 0.35, and 0.4MPa.

[0045] The oil volume ratio in test groups 4 to 6 is 1:1, and the oil volume ratio in test groups 7 to 9 is 1:2. After separation, coalescer dehydration, and acidic alumina bed adsorption to remove sulfone, the sulfur content analysis results of fuel oil mixture samples before and after the reaction are shown in Table 2.

[0046] Table 2

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com